Page 1

33cc

GA S/PE T ROL

Evolution® Gas Engines

Page 2

EN

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole

discretion of Horizon Hobby, Inc. For up-to-date product literature, visit horizonhobby.com

and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product literature to indicate various levels

of potential harm when operating this product:

NOTICE: Procedures, which if not properly followed, create a possibility of physical property

damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical

property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property

damage, collateral damage, serious injury or death OR create a high probability of

superficial injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features

of the product before operating. Failure to operate the product correctly can result

in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product and NOT a toy. It must be operated with caution and

common sense and requires some basic mechanical ability. Failure to operate this Product

in a safe and responsible manner could result in injury or damage to the product or other

property. This product is not intended for use by children without direct adult supervision.

Do not use with incompatible components or alter this product in any way outside of the

instructions provided by Horizon Hobby, Inc. This manual contains instructions for safety,

operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid

damage or serious injury.

CAUTION: This product can become extremely hot when in use, which could lead

to burns.

Age Recommendation: Not for children under 14 years. This is not a toy.

Safety Warnings

Model engines produce a substantial amount of power, which can create unsafe situations if not

used correctly. Always use common sense and observe all safety precautions when operating,

handling or performing any procedure involving your engine. Failure to follow safety precautions

could result in serious injury and property damage.

• Always ensure spectators, especially children, are at least 30 feet away when running

the engine.

• Always ensure that the propeller is securely attached to the engine shaft and all retaining

fasteners are tightened properly before EACH flight. Use of blue threadlock to tighten nuts

is advisable.

• Always keep small parts out of the reach of children as they can be choking hazards.

• Always secure the airplane before powering the engine.

• Always keep your face and body away from the path of the propeller blades when starting

or running your engine.

• Always stand behind the propeller when making carburetor adjustments.

• Always wear safety glasses or goggles when starting and running your engine.

2

Page 3

• Always keep your fuel in a safe place away from sparks, heat or anything that can ignite.

• Always ensure the aircraft is secure and will not move once the engine is started.

• Always rebind your transmitter to your receiver(s) after setup and before rst ight.

• Always ensure the throttle failsafe is set to low throttle in your transmitter.

• Always perform a range check prior to ight.

• Always cut off the fuel supply (pinch or disconnect the fuel line to the carburetor) or use

the throttle linkage to shut off the air in order to stop the engine.

• Never use hands, ngers, or any other body part to stop the propeller.

• Never throw any object into a propeller to stop it.

• Never run the engine in the vicinity of loose small objects, such as gravel or sand, to avoid

the propeller uncontrollably throwing such materials.

• Never wear loose clothing or a loose neckstrap when operating your model engine as these

items could become entangled in the propeller.

• Never have loose objects such as screwdrivers, pencils, etc. in your pockets when operating

your model engine. These could fall into the propeller.

• Never allow fuel to come into contact with eyes or mouth. Gasoline and other fuels used

in model engines are poisonous.

• Always ensure gasoline and fuel are stored in a clearly marked container away from

the reach of children.

Precautionary Guidelines

• Always mount the engine securely on a bench mount or high-quality engine mount.

• Always use the correct size and pitch of propeller for your engine. Refer to the Propeller Chart

in this manual.

• Always conrm proper balance of your propeller prior to installation of the engine. Failure

to do so could result in damage to the engine and/or airframe.

• Always utilize an electric starter to start your engine.

• Always discard any propeller that is nicked, scratched, cracked or damaged in any way.

• Always run your model engine in a well-ventilated area. Model engines can produce possibly

harmful carbon monoxide fumes.

• Always store your fuel safely in a sealed, water-resistant container.

• Always store fuel in a cool, dry location. Do not allow fuel containers to come in direct

contact with concrete, as the fuel may absorb moisture.

• Always responsibly discard fuel if there is condensation and/or water inside the fuel

container.

• Never return unused fuel from the fuel tank back into the fuel container.

• Never attempt to repair or modify a propeller beyond its intended use.

• Never handle model engines, mufers and/or tuned pipes until they have had time to cool.

They can become extremely hot when in use.

EN

3

Page 4

EN

Introduction

Congratulations on your purchase of one of the exciting new engines in the Evolution® gas

engine series. All of the Evolution brand gas engines have been painstakingly designed and

tested to ensure a hassle-free experience without giving away anything in expected performance

or durability and are backed by a 2-year limited warranty. This manual, when read and followed,

will guide you through the simple steps to your success. Welcome to the Evolution family.

33cc Gas Engine Design

Starting with our already proven glow engines enjoyed by thousands around the world, we

endeavored to take that excitement and experience into the realm of gasoline fuel to provide

you with a complete package; great performance and low cost of operation.

Step 1 Start with a ‘clean sheet of paper’. This is a completely new engine designed as a

powerhouse for your 20–30cc aerobatic and scale airframes. We kept ease of use

and reliability at the forefront of the design process to ensure an excellent operating

experience.

Step 2 Utilize a known and proven Walbro carburetor system that will be reliable and provide

hassle-free use by the owners, and add the appropriate throttle and choke levers that

simplify the engine control and installation.

Step 3 Design the proper muffler system with appropriate volume and muffler orientation that

allows a great looking installation while providing appropriate noise reduction.

Step 4 Design operating accessories that enhance the “new to gas (petrol)” user experience.

• Because the amount of fuel consumed is one third that of a comparable sized

glow engine, the construction and reliability of the fuel delivery system to the

carburetor becomes three times as critical. Microscopic pieces of dirt that used

to safely pass through the larger fuel passages of a glow carburetor will wreak

havoc on a gasoline system. By using a quality inline lter like our Inline Filter

(EVOA105) we can take care of the dirt problem. One of these is included with

your engine.

• The same holds true for air bubbles from the tank or any small leak in the fuel

tubing; what would pass harmlessly through a glow carburetor simply is not tolerated in a gasoline system because the air bubbles are effectively three times

the size they used to be. We have developed and sourced an excellent felt filter

clunk that, when used in the tank, stops all the air bubbles from moving into the

fuel delivery tubes. This felt clunk is critical to successful and reliable operation.

One of these is included with your engine.

• We found that high mufer temperatures would destroy normal Tygon

(the go-to choice for gasoline engines) within minutes. We found that Neoprene

tubing would withstand the temperatures but it tended to degrade quickly in

use. We sourced the proper sized uoroelastomer tubing (FKM tubing), which

withstands not only the high temperatures, but its durability is much greater

than that of either Tygon or Neoprene. The added bonus is that it fits and holds

well to the fuel fittings without any need for additional wire or tie-wrap keepers.

We have included a supply of this tubing with your engine.

®

tubing

4

Page 5

EN

Included Content

ENGINE

• Mufer (EVOG33601)

• Mufer Screws & Gasket (EVOG33100A)

• Spark Plug (EVOG33350)

• Evolution/Spektrum™ Telemetry RPM

Adapter Cable (EVOA107)

• Large Gas-FKM Fuel Tubing (EVOA109)

• Large In-line Fuel Filter (EVOA111)

• Large In-tank Felt Filter/Clunk (EVOA112)

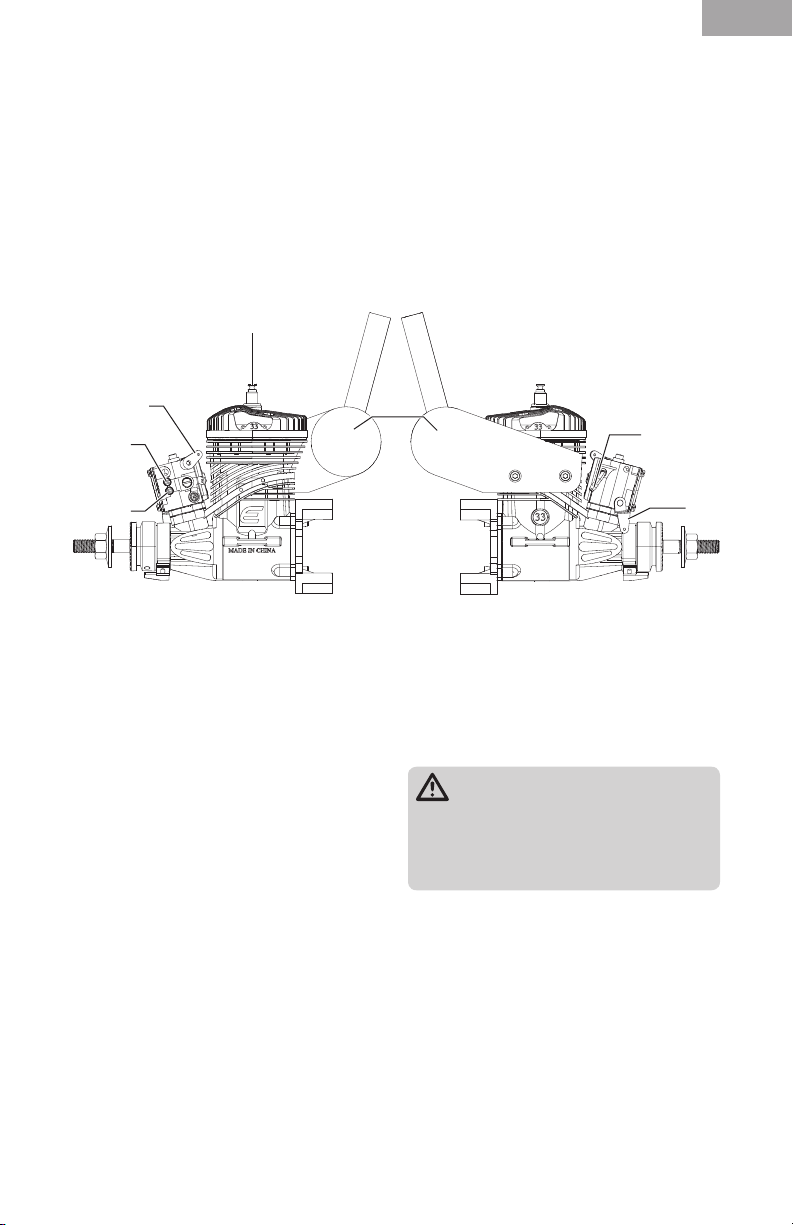

Spark Plug

Choke Arm

High-Speed

Needle

Low-Speed

Needle

Installing the Engine

Rail-mount Installation

1. Remove the 4 screws which attach the

rear-mount.

2. Remove the rear-mount and replace the 4

screws with the shorter M3 screws included

with this engine.

3. Secure the engine mount on the airplane

firewall. Tighten the engine mount screws

in the firewall.

4. Install the engine on the engine mount

according to the airplane manufacturer’s

instructions.

OPTIONAL ITEMS

• Tachometer (HAN156)

• Propeller 17 x 8 (APC17080) for break-in;

18 x 8 (APC18080) for normal ight

• Optical Electronic Ignition Kill Switch

(EVOA100)

• Evolution Synthetic 2-Cycle Oil, (EVOX1001Q)

• Ultra Fuel Pump (HAN155)

Muffler

Fuel Nipple

Throttle

Arm

Rear-mount Installation

1. Secure the engine to the airplane firewall

using either M5 or 10-32 bolts. Use spacers

or standoffs as needed to set the correct

firewall-propeller distance according to the

airplane manufacturer’s instructions.

WARNING: Tighten all engine

mounting screws before each flight. If

you do not tighten the engine

mounting screws, the screws may

vibrate loose and cause the engine to

separate from the fuselage.

5

Page 6

EN

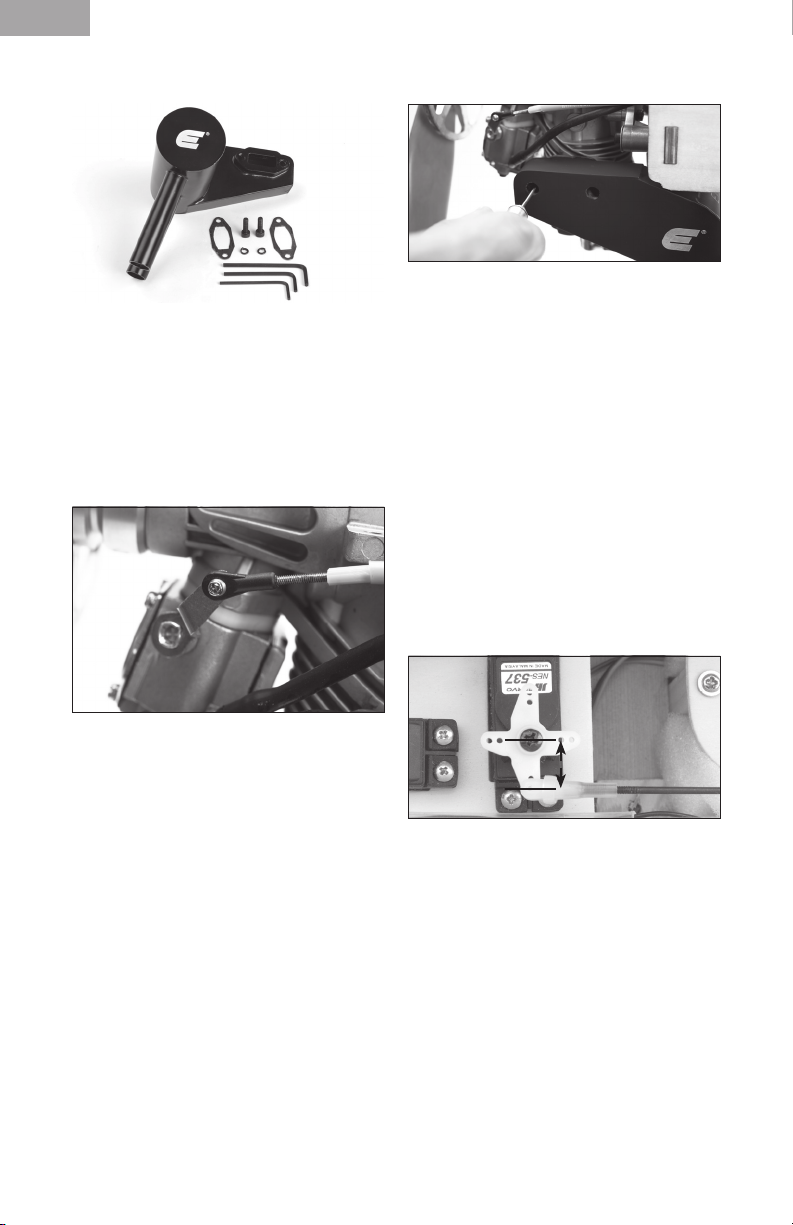

Installing the Muffler

The muffler mounting accessory package

includes mounting screws (2), lock washers

(2), muffler gaskets (2) and L- wrenches (2).

We suggest using high-temperature RTV as a

locking agent on the muffler screws to keep

them tight.

Connecting the Throttle Linkage

1. Put a lock washer on each of the muffler

screws. Push the muffler screws through

the muffler.

2. Place the muffler gasket over the muffler

mounting screws.

3. Align the mufer gasket with the exhaust

opening and the muffler mounting screws.

4. Tighten the muffler screws.

4. Adjust the throttle arm so the arm is 90

degrees to the throttle pushrod.

5. With the throttle servo centered, install a

servo arm with a hole at least 15mm (5/8

in) from the center of the arm.

6. Use a clevis to attach the throttle linkage to

the servo arm.

1. Use a secure method to attach the

throttle linkage to the throttle arm on the

carburetor.

2. Power on the transmitter and receiver.

3. Move the throttle stick to the middle stick

position.

Adjusting the Throttle Opening

1. Lower the throttle and center the throttle

trim.

2. Adjust the length of the throttle linkage

until the throttle is open 1mm.

3. Move the throttle stick up to conrm the

throttle opens. If the throttle does not

open, reverse the throttle channel in your

transmitter.

4. Move the throttle stick and throttle trim

down to confirm the throttle closes.

6

15mm

5. If you reversed the throttle channel in your

transmitter and you are using a 2.4GHz

radio system, you must re-bind your radio

system to set the correct failsafe position.

You may need to adjust the endpoints on your

radio to achieve full throttle motion. Using

a longer servo arm will help obtain the best

throttle geometry.

Page 7

Attaching the Fuel Lines

Fuel Line

1. Connect medium diameter large diameter

FKM fuel tubing to the carburetor and the

fuel tank supply line.

2. Connect large diameter FKM fuel line to the

vent line. Run this fuel line either around

the back of the tank or make a loop on top

of the tank to create an “anti-syphoning”

loop. Take the other end of the fuel line

and route it outside the airplane fuselage.

RECOMMENDED PROPELLERS

17 x 6–20 x 8 (18 x 8 has tested to be the

best performer with this engine, although

the performance is very good throughout the

recommended range)

Attaching the Propeller and Spinner

3. Cover the propeller with a cloth and use an

4. Install the spinner cone. Make sure the

5. Tighten the spinner screw(s) to secure the

EN

adjustable wrench to tighten the prop nut.

spinner cone is not touching the propeller.

Trim the propeller opening if necessary.

spinner cone.

1. Remove the prop nut and prop washer from

the crankshaft.

2. Install the spinner backplate, followed by

the propeller, prop washer and prop nut.

7

Page 8

EN

Connecting the Electronic Ignition

The Evolution Electronic Ignition Assembly is designed and engineered specifically for the

small block engine series. It is smaller and lighter so it fits into tighter spaces of the airplanes

the engines are designed to power. The battery voltage required is between 4.8V (4-cell Ni-MH

pack) and 8.4V (2S Li-Po battery) and no voltage regulators are needed with any of these

batteries. We recommend a 2S Li-Fe battery (such as the Team Orion® Avionics Li-Fe Receiver

Pack 1300mAh 6.6V (ORI60503)) and we have done extensive testing with these packs. The

maximum amp draw at full throttle is 450mAh, and our more typical average has been between

250–300mAh.

The assembly consists of:

• Ignition module with battery connector, ignition sensor connector, tachometer readout

connector and spark plug connector

• Ignition sensor (already attached to your engine)

• Sensor magnet (already installed in the prop drive hub of your engine)

Mounting Your Electronic Ignition

• You can mount the unit in any orientation

and place that is convenient for your

installation. The module is sized to conveniently fit into the tank compartment of

most glow powered airplanes alongside or

underneath the recommended fuel tanks.

You can also mount it to the firewall or

under the engine firewall extension if your

airplane is so equipped. Keep in mind that

it should be mounted away from the heat of

the muffler.

• Secure the ignition module to your chosen

location with foam padding to provide

vibration isolation. We typically mount it

conveniently with tie wraps after wrapping

the ignition in lightweight 1/4-inch foam

rubber.

• You may need to route both the spark plug

connector wire and the ignition sensor wire

through the firewall, so be sure to plan

ahead and provide adequately sized holes

that will allow you to pull either the ignition

sensor connector or the spark plug cap

connector through the holes for later

ignition removal.

• Mount a good quality radio receiver type

switch between the ignition unit and the

battery. Mount this switch in a convenient

place on the outer fuselage close to the

front of the airplane to make it easy to turn

the ignition on and off. Being able to easily

shut off the ignition is an important safety

consideration.

• Connect the ignition sensor wire to the

ignition module. The sensor wire will only

fit into one of the connectors so you cannot

connect it wrong.

• Connect the ON/OFF switch to the battery

connector lead of the ignition module. This

connector is the red connector.

• For added security and controllability, add

an additional radio-operated kill switch

(such as the Optical Ignition Kill Switch

EVOA100) between the ignition battery con-

nector lead and the ON/OFF switch.

• If desired, you can connect either the

separately available tachometer readout or

the included Evolution/Spektrum Telemetry

Adapter Cable (EVOA107) to the tachometer

readout connector. Plug the other end of

the adapter cable into the Spektrum

telemetry module’s rpm input port.

• Connect the spark plug connector to the

spark plug. This spark plug connector

utilizes a locking snap ring to ensure a

solid connection. Push it straight onto the

spark plug to secure.

Make sure you charge your ignition battery.

You are now ready to operate your electronic

ignition with the engine.

8

Page 9

Fuel

This engine requires a mix of 20:1 gas to oil

lubricant ratio for break-in and a mix of 32:1

gas/oil ratio for normal operation in order to

last a long time.

The needle bearing at the bottom end of the

conrod depends upon this lube ratio to operate properly.

Do not go higher than a 20:1 gas/oil ratio

for the first gallon of fuel. After this you may

decrease the oil content to a 32:1 gas/oil ratio

if desired. Do not go higher than a 32:1 gas/

oil ratio or the warranty on your engine will be

voided.

Fuel Delivery System

It is very important to properly construct

your fuel supply system to avoid operating

problems. Our experience has shown that

many seemingly engine related operating

problems are in fact fuel delivery problems,

not engine related problems.

Fuel Filtering - Because of the incredibly small

amount of fuel that is being used by this

engine, filtration of the fuel is mandatory in

three different spots in the system:

1. Between the fuel jug and the airplane fuel

tank.

2. Within the fuel tank itself (with a ltered

clunk EVOA112).

3. Between the fuel tank and carburetor (with

an in-line fuel lter EVOA111).

Both of these lters (2 and 3) are included in

the engine package.

Tank Choice and Construction – Choose a

tank between 12–18 oz (360–540 mL). These

tanks will yield 12 minutes (for the smaller

tank) to 18 minutes (for the larger tank) of full

throttle flying time.

• Ensure you use a tank stopper made for

use with gasoline and/or smoke oil.

To properly mix the fuel, for a mix of 20:1 gas

to oil, add 6.75 oz of good quality 2-stroke

oil to one gallon (or 53 mL of oil to one liter)

of 87–93 octane fuel. (EVOX1001Q Evolution

2-stroke oil is recommended) We prefer to

add the oil first to our fuel container and to

add the gasoline second. This helps to ensure

a good mixture of the oil with the fuel at the

outset.

We have tested our own Evolution 2-stroke oil,

Valvoline, Shell, RedLine and Husqvarna oils.

Other quality 2-stroke oils should work as

well. Do not use Amsoil synthetic oil in

any form.

• We suggest a three-line tank system; one

for the line to the carburetor with the clunk

attached internally, one for the vent line

from the tank, and one dedicated to fueling/defueling the tank. We try to avoid the

T-fittings and other inline valves because

they can be a possible source of air/fuel

leaks.

Gasoline-resistant

Rubber Cap

Fuel Tank

Filtered Weight

Vent Tube

Fueling Tube

Gasoline-resistant Tube

Carb Nipple

Fuel Filter

Gasoline-resistant Tube

• Ensure you use the provided FPM tubing in

all the plumbing of the tank, externally and

internally.

• Ensure you use the included felt lter clunk

inside the fuel tank.

• Ensure you use the included inline lter

between the tank and the carburetor.

• Ensure there is a good seal system for

the dedicated fueling/defueling line. We

highly recommend the HAN116 Fuel Filler

Assembly for its sleek look and ease of use

when installed on your airplane.

EN

9

Page 10

EN

Engine Break-in

Your new engine needs to be broken-in to ensure a long life of all the components. This engine

features a piston ring design, which requires a specific break-in procedure to ensure a tight seal

between the piston ring and liner. For this to be accomplished, this process requires repeated

heating and cooling cycles, and must be done at a needle setting that is slightly rich of peak to

ensure the ring expands and contracts. The ring needs to “grow” into the liner for it to develop a

good seal.

Breaking in the piston ring and liner by running it too rich does not provide the necessary parts

growth to accomplish the needed piston ring and liner fitting. However, using too lean of a

setting will cause the ring to become damaged by overheating. Please follow the steps below to

ensure a successful experience.

Important considerations during break-in

• Perform the break-in process with the

engine mounted on your airplane. There is

no need to bench-run the engine prior to

mounting it on your airplane.

• Use the suggested break-in prop to begin

your break-in process. This provides a light

load and high rpm that, when matched

with the heat of the engine, will break in

the engine properly.

• Use the proper recommended fuel with a

20:1 gas to oil ratio for the rst gallon of

operation.

The proper break-in flight procedure is to fly

the airplane at full throttle through a series

of gure eight maneuvers (i.e. Cuban Eight).

These maneuvers in particular benefit the engine because, when climbing, the additional

load on the engine will increase the temperature and, when diving, the lighter load and

higher rpm will decrease the temperature,

thus providing the heating/cooling cycles

required for the break-in process.

Break-in process

• Firsttankoffuel: Set the high-speed

needle valve at 1.5 turns out and use the

suggested break-in prop. Run the engine

on the ground for its first tank of fuel and

DO NOT go above half throttle. Cycle the

throttle between idle and half throttle every

minute.

• Second tank of fuel: Tune the needle valve

to be slightly rich of the peak RPM at full

throttle without a drop in RPM. Do not run

at full throttle on the ground for more than

30 seconds at a time. Tune the low speed

needle valve for a smooth transition from

idle to mid-range, go back to full throttle

to confirm the main needle valve setting

and then fly. During this flight, be sure to

be conscientous of extended periods of

heating the engine. Be sure to mix-in some

cool-down dives and lower-throttle flying.

• Third tank of fuel: Fly the engine at a high

throttle while performing the recommended

figure eight maneuvers. This will help the

piston ring and cylinder liner to expand and

contract; helping the breaking-in process.

Tune the needle valve to be slightly rich of

the peak RPM as necessary.

10

• Fourth tank of fuel: Select one of the rec-

ommended propellers for normal operation

and mount it on your engine. Tune the main

needle valve to be slightly rich of the peak

RPM and the low speed needle valve for a

smooth transition from idle to full throttle

and continue to break-in the engine in

flight.

Do not worry about an engine setting being

slightly rich during this process. When set

correctly, the engine will occasionally sound

as if it is misring (which it is). During the

climbing maneuvers this should go away and

might return during the diving maneuvers. If

it does not go away during the climbs, land

the airplane and lean the high-speed needle

by 1/16 of a turn, then take off and y again.

Enjoy the break-in process—you are doing a

lot of flying.

Fly the airplane through the first gallon of fuel,

then you can change the fuel mixture to 32:1

for continued operation.

Page 11

Telemetry

Telemetry is a huge asset to help you tune

your engine. The ignition module is even

capable of communicating with Spektrum

telemetry systems directly so you won’t have

to add an additional RPM sensor. You will

need to connect the Evolution Ignition

Telemetry Adapter (EVOA107) between the

RPM port on the ignition unit and the RPM

port on your Spektrum telemetry module in

order to utilize this feature. Telemetry systems

other than Spektrum may require a dedicated

RPM sensor.

We recommend using the Spektrum DSMX Full

Range Aircraft Telemetry Module (SPM9548)

in conjunction with the included adapter. This

system allows you to see real-time RPM and

temperature readings from the engine.

The temperature sensor should be wrapped

around the base of the spark plug on the

cylinder head. Using telemetry gives you an

accurate representation of actual temperature

and rpm figures during use, and warnings

can be set to go off if your engine is getting

too hot.

The temperature range should be 190–240°F

(87–115°C) on average. Set your maximum

temperature warning to go off if the engine

exceeds 300°F (150°C). If your engine is continually near this peak temperature or higher,

immediately decrease throttle to bring the

temperature down. If this continues to occur,

land the airplane and add additional baffling

to your cowl. It is not good for the engine to

run at temperatures this high and could cause

damage if not attended to.

Starting and Operating the 33GX Engine

Baseline needle valve settings can be found

in the ”Engine Tuning” section. With the 33GX

it is very important to allow the temperature

to stabilize above 140°F (60°C) before making any adjustments; adjusting prior to the

engine warming up will lead you to inaccurate

settings. As the engine warms up you will

notice the rpms naturally rising.

If you do not have a temp gun or have sensors

installed on your engine, allow the engine to

run at half throttle for at least 45 seconds before attempting to set the high-speed needle.

If you have accurately set the low-speed

needle as described you should not need to

adjust it.

Priming

1. Make sure your ignition is off.

2. Open the throttle fully and, close the choke

valve. Flip the propeller 6 times.

3. Close the carburetor completely with your

throttle stick and then open it two detents

from closed. This will allow the engine to

start at a low throttle setting.

Because each fuel system and installation

is slightly different, you may find the need

to modify the above procedure for your

individual setup. The above procedure should

work for most installations.

EN

11

Page 12

EN

Starting and Running the Engine

Until the engine is broken in, use an electric

starter to start the engine. Once it is fully

broken in it can be started by hand, but it is

easier and safer to start the engine with an

electric starter.

1. Turn on the ignition.

2. Close the choke valve.

3. If Using an Electric Starter

a. Rotate the propeller in a backwards

direction against compression.

b. Push the start firmly against the nose

cone and engage. The engine should fire

relatively quickly, within 1-2 seconds.

c. Turn off the choke and engage the starter

as before until the engine starts.

If Using a Starting Stick or Flipping by Hand

a. Rotate the propeller counter-clockwise

until against compression.

b. Flip the propeller through compression

until it fires.

Engine Tuning

The break-in settings for the carburetor

needles are:

• High-speed needle: 1.5 turns open

• Low-speed needle: 1.5 turns open

Use a tachometer (HAN111, HAN156, or

telemetry) to tune the engine based on RPM.

To lean the high- or low-end fuel mixture, turn

the high- or low-speed needle clockwise. To

enrich the high- or low-end fuel mixture, turn

the high- or low-speed needle counterclockwise. It is best to make all the carb adjustments with the engine turned off.

WARNING: Always adjust the

carburetor from behind the

propeller. Keep all loose items

away from the propeller at all times.

Never reach over or around the

propeller.

c. Turn off the choke.

d. Flip the engine through compression as

before until it starts.

4. Let the engine run at mid-throttle for 45

seconds to stabilize the temperatures.

a. If the engine doesn’t start quickly, disen-

gage the starter. Continuously running

the starter can flood the engine.

b. Check to make that fuel is moving

through the carburetor system.

c. If the engine appears not to have any

fuel, repeat the priming procedure

above.

d. Repeat 1–4 of Starting and Running the

Engine.

1. Start the engine.

2. Move the throttle stick up until the engine

is running at approximately 2,000 rpm.

3. Move the throttle stick up to full (open)

throttle. If the engine runs rough, the fuel

mixture is too rich. If the engine stops running, it is too lean.

4. With the engine shut down, either enrich

or lean (as indicated by the test in Step 3)

the high-speed needle screw by 1/16th of a

turn and restart the engine. Turn the high-

speed needle clockwise 1/16 turn to lean

the high-end fuel mixture.

5. Repeat Steps 3–4 until the engine is

running reliably at full (open) throttle.

12

Page 13

High-Speed Needle Tuning

Once the engine is running reliably at full

(open) throttle:

1. Turn the high-speed needle clockwise 1/16

of a turn at a time.

2. Wait 2–3 seconds for the engine to

respond.

a. If there is an increase in RPM: Turn the

high-speed needle clockwise an

additional 1/16 turn and wait for the

engine to respond to the tuning change.

If there is no increase in RPM after the

change, turn the high-speed needle back

to its previous position.

b. If there is a decrease in RPM: Turn the

high-speed needle counterclockwise 1/8

of a turn and wait for the engine RPM to

stabilize.

3. Repeat Step 2 until you determine the

maximum RPM with the fuel and propeller

you selected.

4. Enrich the high-end fuel mixture by turning

the high-speed needle counterclockwise

until the RPM is 200–300 RPM below maximum. This will allow the engine to achieve

proper fuel mixture during flight.

Low -Speed Needle Adjustment

The low-speed needle adjustment controls the fuel/air mixture at idle and the quality of the

transition between idle and wide open throttle.

Low -Speed Needle Tuning

1. Adjust the high-speed needle for the current conditions.

2. Allow the engine to idle for 10–15 seconds.

Rapidly advance the throttle from idle to

full open. If the engine transitions with

no hesitation, the low-speed needle is

adjusted perfectly. If the engine slowly

responds to throttle change and gradually

reaches peak RPM, the low-end fuel mixture is too rich. Turn the low-speed needle

clockwise 1/16 turn to lean out the low-end

fuel mixture and test again.

If the engine stops running, the low-end

fuel mixture is too lean. Enrich the low-end

fuel mixture by turning the low-speed

needle counterclockwise 1/16 turn and

test again.

3. When the low-speed needle adjustment

is correct, check the high-speed needle

setting again.

4. When you are satisfied with the needle

settings, you should not need to adjust the

mixture needles again.

The best indication that your engine is tuned

properly is the color of the spark plug when

you remove it from the cylinder. A nice, dry,

tan color is an indicator that the fuel mixture

is correct and burning well. Wet plugs or

carbon deposits generally indicate that the

engine is running too rich. If the spark plug

has a white or gray appearance, you are running your engine too lean.

EN

13

Page 14

EN

33GX Evolution Engines Specications

Disp Bore (mm) Stroke (mm) Weight (oz) Cylinder Propeller

33cc 37.5 29.5 48.8 Ringed 18 x 8 @ 8300 rpm

F

H

A

B

70mm

C D

E = height* F = length G= crankshaft thread size H = muffler bolt spacing

Weight (oz)

Dimensions

(mm)

* Height is from engine C/L to top of cylinder head.

Troubleshooting Guide

If the Engine Does Not Start

• Check and use a new spark plug if needed.

• Check fuel lines.

• Check for proper mechanical function by turning

the engine over.

• Check that the carburetor is correctly installed.

• Check that the vent line is attached and free

from any bends or blockages.

If the engine runs erratic

• Check for fuel systems problems. Are there any

holes in the fuel lines (inluding the clunk line

inside the fuel tank) or other possible sources

of air leaks, such as a loose fuel filter?

• Ensure the spark system is working

properly and the ignition battery is charged.

Mechanical Faults

If the engine cannot be turned over easily:

• The most likely cause is the engine is ooded

and by turning the engine over you are trying to

compress the fuel, not air.

1. Remove the spark plug.

2. Cover the cylinder head with a cloth or paper

14

Engine Only Muffler Ignition Total

38.8 5.8 3.6 48.8

A B C D E* F G H

50 60 31 73.3 104 121 3/8–24 36.5

towel and turn the propeller over to expel all

the excess fuel.

3. Replace the spark plug and try starting again.

• A possible cause is the piston in the cylinder is

seized: loosen and unscrew the cylinder head

bolts.

1. Carefully remove the cylinder liner.

2. Visually examine the piston and cylinder

to find the possible cause of the engine’s

mechanical problem.

Mechanical repairs must ALWAYS be completed by

an authorized Horizon Hobby service center.

Maintenance

After each flying session:

1. Fully drain the fuel from the tank.

2. Start the engine and run it until the fuel is

completely run out of the engine.

3. Try starting the engine three more times or until

it will no longer fire. This gets all the fuel out of

the engine.

If you need additional help or have any questions,

please call Horizon’s Support Team. Horizon has

trained technicians who are qualified to answer

your engine questions.

G

54mm

Page 15

Exploded View

EN

23 22 2024

29

19

2

8

17

16 14

15

31

1

3

4/29

5

6

7

9

13

27

25

32

26/29

12

11

18

28

102128/29/30

15

Page 16

EN

Parts List

# Description Part

1 Engine Crankcase

Screw Set (10)

2 Spark Plug (CM6) EVOG33350

3 Cylinder Head EVOG33103

4 Cylinder Head Gasket (2) EVOG33112

5 Cylinder EVOG33202

6 Piston Ring EVOG33236

7 Piston Set EVOG33214R

8 Piston Pin & Retainer EVOG33213

9 Connecting Rod EVOG33204

10 Prop Washer & Nut EVO108228

11 Drive Hub EVOG33219

12 Front Bearing EVO180109

13 Crankcase EVOG33101

14 Rear Bearing EVOG33110

15 Key EVO400218

16 Crankshaft EVOG33210

17 Back Cover Set EVOG33102

18 Wraparound In-Cowl

Muffler Assembly

19 Rear Engine Mount EVOG33147

EVOG3346408

EVOG33601

# Description Part

20 Complete Ignition

System

21 Ignition Sensor &

Mount Bracket

22 In Line Fuel Filter EVOA105

23 In Tank Fuel Filter/Clunk EVOA106

24 Medium Gas-FPM Fuel

Tubing

25 Carburetor Assembly EVOG33801

26 Carburetor Mount

Gasket Set

27 Carburetor Insulator EVOG33803

28 Muffler Mounting

Screw Set

29 Gasket Set EVOG33416

30 Mufer Gasket Set (2) EVOG33609

31 Carb Mount Bolt Set EVOG33119

32 Throttle & Choke Arm EVOGG33864

NS Carburetor Rebuild Kit EVOG33108A

NS Carburetor Gasket Set EVOG33109A

NS High-Speed/Low-

Speed Needle Set

EVOG33300

EVOG33310A

EVOA102

EVOG33804

EVOG33100A

EVOG33829

2-YEAR LIMITED WARRANTY

What this Warranty Covers - Horizon Hobby, Inc.,

(Horizon) warrants to the original purchaser that

the product purchased (the “Product”) will be free

from defects in materials and workmanship for a

period of 2 years from the date of purchase.

What is Not Covered - This warranty is not trans-

ferable and does not cover (i) cosmetic damage, (ii) damage due to acts of God, accident,

misuse, abuse, negligence, commercial use,

or due to improper use, installation, operation

or maintenance, (iii) modication of or to any

part of the Product, (iv) attempted service by

anyone other than a Horizon Hobby authorized

service center, (v) Product not purchased from

an authorized Horizon dealer, or (vi) Product not

compliant with applicable technical regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE,

HORIZON MAKES NO OTHER WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND

16

ALL IMPLIED WARRANTIES, INCLUDING, WITHOUT

LIMITATION, THE IMPLIED WARRANTIES OF NONINFRINGEMENT, MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET

THE REQUIREMENTS OF THE PURCHASER’S IN-

TENDED USE.

Purchaser’s Remedy - Horizon’s sole obligation

and purchaser’s sole and exclusive remedy shall

be that Horizon will, at its option, either (i) service,

or (ii) replace, any Product determined by Horizon

to be defective. Horizon reserves the right to in-

spect any and all Product(s) involved in a warranty

claim. Service or replacement decisions are at

the sole discretion of Horizon. Proof of purchase

is required for all warranty claims. SERVICE OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY.

Page 17

EN

Limitation of Liability - HORIZON SHALL NOT BE

LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY,

REGARDLESS OF WHETHER SUCH CLAIM IS BASED

IN CONTRACT, WARRANTY, TORT, NEGLIGENCE,

STRICT LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES. Further, in

no event shall the liability of Horizon exceed the

individual price of the Product on which liability

is asserted. As Horizon has no control over use,

setup, final assembly, modification or misuse, no

liability shall be assumed nor accepted for any re-

sulting damage or injury. By the act of use, setup

or assembly, the user accepts all resulting liability.

If you as the purchaser or user are not prepared to

accept the liability associated with the use of the

Product, purchaser is advised to return the Product immediately in new and unused condition to

the place of purchase.

Law - These terms are governed by Illinois law

(without regard to conict of law principals). This

warranty gives you specific legal rights, and you

may also have other rights which vary from state

to state. Horizon reserves the right to change or

modify this warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services - Your local

hobby store and/or place of purchase cannot provide warranty support or service. Once assembly,

setup or use of the Product has been started, you

must contact your local distributor or Horizon directly. This will enable Horizon to better answer

your questions and service you in the event that

you may need any assistance. For questions or

assistance, please visit our website at www.horizonhobby.com, submit a Product Support Inquiry,

or call the toll free telephone number referenced

in the Warranty and Service Contact Information

section to speak with a Product Support representative.

Inspection or Services - If this Product needs to

be inspected or serviced and is compliant in the

country you live and use the Product in, please

use the Horizon Online Service Request submission process found on our website or call Horizon

to obtain a Return Merchandise Authorization

(RMA) number. Pack the Product securely using

a shipping carton. Please note that original boxes

may be included, but are not designed to withstand the rigors of shipping without additional

protection. Ship via a carrier that provides tracking and insurance for lost or damaged parcels, as

Horizon is not responsible for merchandise until

it arrives and is accepted at our facility. An Online

Service Request is available at http://www.horizonhobby.com/content/_service-center_renderservice-center. If you do not have internet access,

please contact Horizon Product Support to obtain

a RMA number along with instructions for submitting your product for service. When calling Horizon, you will be asked to provide your complete

name, street address, email address and phone

number where you can be reached during business hours. When sending product into Horizon,

please include your RMA number, a list of the

included items, and a brief summary of the problem. A copy of your original sales receipt must be

included for warranty consideration. Be sure your

name, address, and RMA number are clearly written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If

you have any issue with a LiPo battery, please

contact the appropriate Horizon Product Support

office.

Warranty Requirements - For Warranty consideration, you must include your original sales receipt

verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product

will be serviced or replaced free of charge. Service

or replacement decisions are at the sole discretion

of Horizon.

Non-Warranty Service - Should your service not

be covered by warranty, service will be completed

and payment will be required without notification

or estimate of the expense unless the expense

exceeds 50% of the retail purchase cost. By sub-

mitting the item for service you are agreeing to

payment of the service without notification. Service estimates are available upon request. You

must include this request with your item submitted for service. Non-warranty service estimates

will be billed a minimum of ½ hour of labor. In addition you will be billed for return freight. Horizon

accepts money orders and cashier’s checks, as

well as Visa, MasterCard, American Express, and

Discover cards. By submitting any item to Horizon

for service, you are agreeing to Horizon’s Terms

and Conditions found on our website http://www.

horizonhobby.com/content/_service-center_render-service-center.

ATTENTION: Horizon service is limited to Product

compliant in the country of use and ownership.

If received, a non-compliant Product will not be

serviced. Further, the sender will be responsible

for arranging return shipment of the un-serviced

Product, through a carrier of the sender’s choice

and at the sender’s expense. Horizon will hold

non-compliant Product for a period of 60 days

from notification, after which it will be discarded.

17

Page 18

EN

WARRANTY AND SERVICE CONTACT INFORMATION

Country of

Purchase

United States of

America

United Kingdom

Germany

France

China

COMPLIANCE INFORMATION FOR

THE EUROPEAN UNION

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH2013032705

Product(s): EVO 33cc Gas Engine

Item Number(s): EVOE33GX

The object of declaration described above is in

conformity with the requirements of the

specifications listed below, following the provi-

sions of the European EMC Directive 2004/108/

EC:

EN55022:2010 + AC:2011

EN55024:2010

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

March 27, 2013

18

Horizon Hobby Contact Information Address

Horizon Service

Center

(Repairs and

Repair Requests)

Horizon Product

Support

(Product Technical

Assistance)

Sales

Service/Parts/

Sales:

Horizon Hobby

Limited

Horizon Tech-

nischer Service

Sales: Horizon

Hobby GmbH

Service/Parts/

Sales:

Horizon Hobby

SAS

Service/Parts/

Sales:

Horizon Hobby –

China

Steven A. Hall

Executive Vice President and Chief Operating Ofcer

International Operations and Risk Management

Horizon Hobby, Inc.

servicecenter.horizonhobby.

com/RequestForm/

www.quickbase.com/db/

bghj7ey8c?a=GenNewRecord

888-959-2305

sales@horizonhobby.com

888-959-2305

sales@horizonhobby.co.uk Units 1–4 , Ployters Rd,

+44 (0) 1279 641 097

service@horizonhobby.de

+49 (0) 4121 2655 100

infofrance@horizonhobby.com

+33 (0) 1 60 18 34 90

info@horizonhobby.com.cn

+86 (021) 5180 9868

Instructions for disposal of WEEE by

users in the European Union

This product must not be disposed of

with other waste. Instead, it is the user’s responsibility to dispose of their waste equipment by

handing it over to a designated collections point

for the recycling of waste electrical and electronic equipment. The separate collection and

recycling of your waste equipment at the time of

disposal will help to conserve natural resources

and ensure that it is recycled in a manner that

protects human health and the environment.

For more information about where you can drop

off your waste equipment for recycling, please

contact your local city office, your household

waste disposal service or where you purchased

the product.

4105 Fieldstone Rd

Champaign, Illinois,

61822 USA

Staple Tye

Harlow, Essex, CM18 7NS,

United Kingdom

Christian-Junge-Straße 1

25337 Elmshorn, Germany

11 Rue Georges Charpak

77127 Lieusaint, France

Room 506, No. 97 Chang-

shou Rd.

Shanghai, China 200060

Page 19

2013 Horizon Hobby, Inc.

©

Evolution and the Horizon Hobby logo are registered trademarks of Horizon Hobby, Inc.

The Spektrum trademark is used with permission of Bachmann Industries, Inc.

All other trademarks, service marks and logos are the property of their respective owners.

®

Tygon

is a registered trademark of Saint-Gobain Performance Plastics Corporation.

33286 Created 03/2013

Loading...

Loading...