Page 1

Evolution Propeller Drill Guide

6

7

8

This Propeller Drill Guide is used to help drill accurate holes for the propeller screws so the propeller can

®

be mounted securely and safely to the engine. It is specifically designed for use on the Evolution

gasoline engines, the EVO45GX/GX2, 58GX/GX2 and 116GX/GX2.

line of

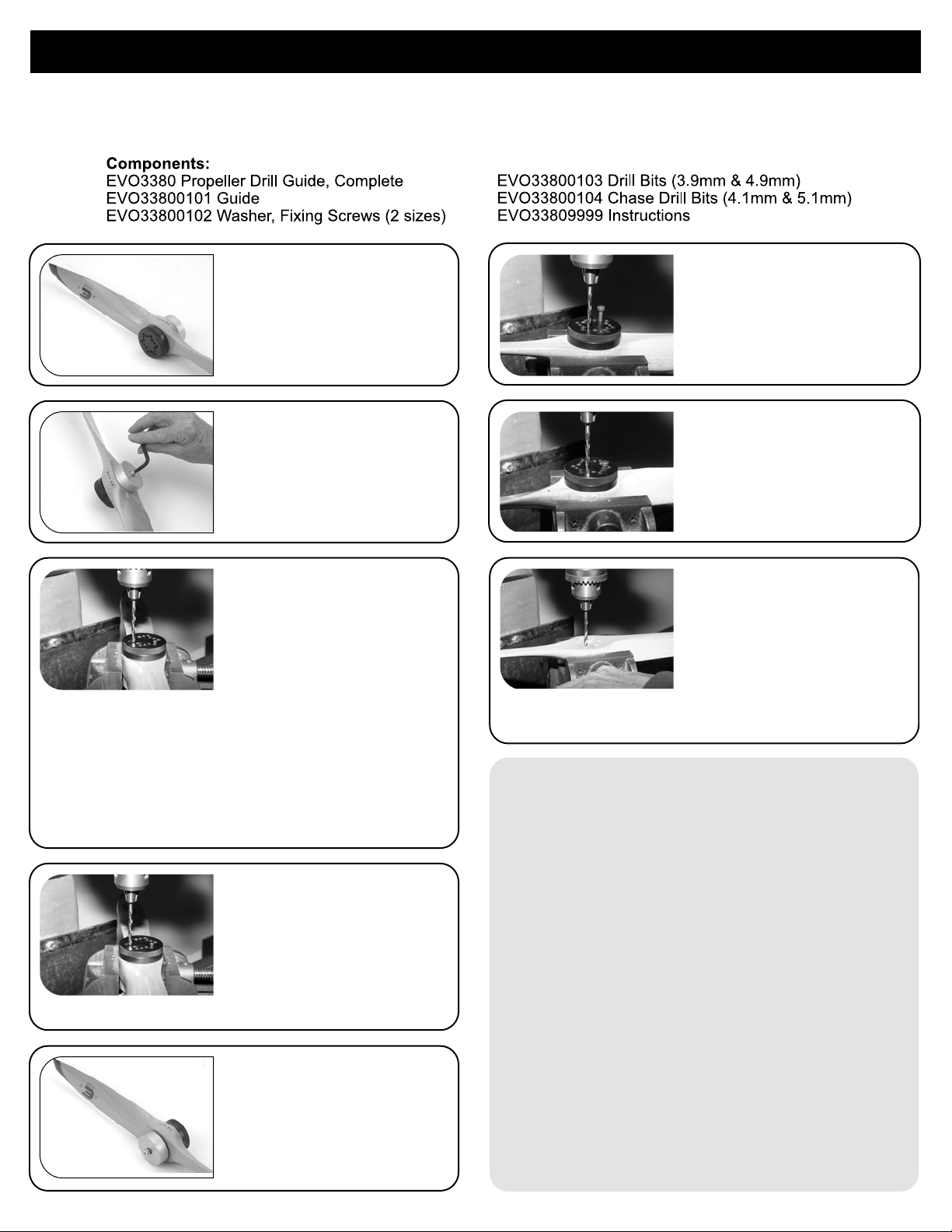

Place the guide on the front

side of the propeller, so it is

centered with the central

fixing screw in the propeller

1

center hole (diameter 10mm).

Screw it together firmly.

Screw down the washer with

one of the enclosed fixing

screws (choose the one of

the proper length).

2

Use of a drill press is recom mended. Once the propeller

blade is fixed in position,

drill the first hole in full depth.

Use the 3.9mm bit for the

3

58GX/GX2 propeller screws

and the 4.9mm bit for the 45GX/GX2 propeller screws.

A chase drill bit will be used to finish boring out the

holes once the initial holes are all drilled. The 4.9mm

bit is also for use on the 116GX/GX2. Pin the jig in

place by placing one of the propeller bolts into the first

full depth hole. This will ensure that the jig does not

rotate during the drilling of the remaining holes.

Pin the full depth hole using

a propeller bolt and then

screw the guide firmly

together and proceed to

6

6

7

Remove the drill guide and

replace bit with a chase bit

to finish boring out the holes.

The 4.1mm chase bit is used

to drill out the 3.9 holes and

8

the 5.1mm chase bit is used

to drill out the 4.9 holes to the proper diameter for the

propeller bolts.

OPTION: In case one has to use a hand

drill (not recommended), repeat the above

bore the other half of the

propeller bolt holes.

Bore the other holes from

the other side to full depth.

Drill all the other holes into

depth about one half of the

propeller thickness. The use

of two bolts to pin in place

will help ensure the rest of

4

the holes line up when you

go to step 6.

Unscrew the drill guide

assembly, and reposition the

guide portion of the jig to the

opposite side of the propeller

5

2

(Do not tighten the drill guide

center bolt until the next step.)

procedure, but mount the drill guide on the

back side of the propeller. Use the drill

guide with a bolt fastener as an arrestor

pin and drill the holes from the back side

of the propeller first.

IMPORTANT: Each bolt should be in place

and tight, to prevent the propeller from

bending or breaking the bolts.

Loading...

Loading...