Page 1

Original Instructions

Originalbetriebsanleitung

Notice Originale

Instrucciones Originales

Oryginalna Instrukcja

Instruções Originais

Instrucțiuni Iniţiale

Оригинальные Инструкции

Orijinal Talimatlar

026-0001,

026-0002,

026-0003

027-0001,

027-0002,

027-0003

GB2438285

Original written in UK English Date Published: 01 / 06 / 2018

027-0001C, 027-0002C,

027-0003C, 027-0004,

027-0006, 027-0010

027-0001A, 027-0002A,

027-0003A, 027-0004A,

027-0006A

Page 2

www.evolutionpowertools.com

TABLE OF CONTENTS

INTRODUCTION

Warranty Page 3

Specifications Page 4

Items Supplied Page 4

Vibration Page 4

Labels And Symbols Page 6

Intended Use Of This Power Tool Page 7

Prohibited Use Of This Power Tool Page 7

SAFETY PRECAUTIONS

Electrical Safety Page 7

Outdoor Use Page 7

General Power Tool Safety

Instructions

Health Advice Page 9

Safety Instructions For All Saws Page 9

Additional Safety Instructions For

Circular Saws

GETTING STARTED

Unpacking Page 11

Machine Overview Page 12

Preparation Page 21

Installing/Removing A Blade Page 21

Parallel Edge Guide Page 22

Cutting Depth Adjustment Page 22

Cutting Angle Adjustment Page 22

Operating Advice

(Pre Operation Checks)

PPE Page 23

The On/Off Trigger Switch Page 23

Cutting Tracks Page 24

Page 7

Page 11

Page 22

MAINTENANCE &

ADJUSTMENTS

Checking & Replacing Carbon

Brushes

General Maintenance & Cleaning Page 29

Environmental Protection Page 29

DECLARATION OF

CONFORMITY

Page 28

Page 29

Page 30

ADDITIONAL ADVICE

Debris Collection Port Page 26

Led Light Page 26

Specialised Adjustments Page 27

General Cutting Advice Page 27

Cut Material Ejection Port Page 28

2

Page 3

www.evolutionpowertools.com

DE

EN

FR

ES

(1.2) INTRODUCTION

IMPORTANT

Please read these operating and safety instructions

carefully and completely.

For your own safety, if you are uncertain about any

aspect of using this equipment please access the relevant

Technical Helpline, the number of which can be found on

the Evolution Power Tools website. We operate several

Helplines throughout our worldwide organization, but

Technical help is also available from your supplier.

(1.3) CONTACT:

Web: www.evolutionpowertools.com

UK/EU/AUS: customer.services@evolutionpowertools.com

USA: evolutioninfo@evolutionpowertools.com

(1.4) WARRANTY

Congratulations on your purchase of an Evolution Power

Tools Machine. Please complete your product registration

‘online’ as explained in the registration leaflet included

with this machine. This will enable you to validate your

machine’s warranty period via Evolutions website by

entering your details and thus ensure prompt service if

ever needed.

We sincerely thank you for selecting

a product from Evolution Power Tools.

3

Page 4

www.evolutionpowertools.com

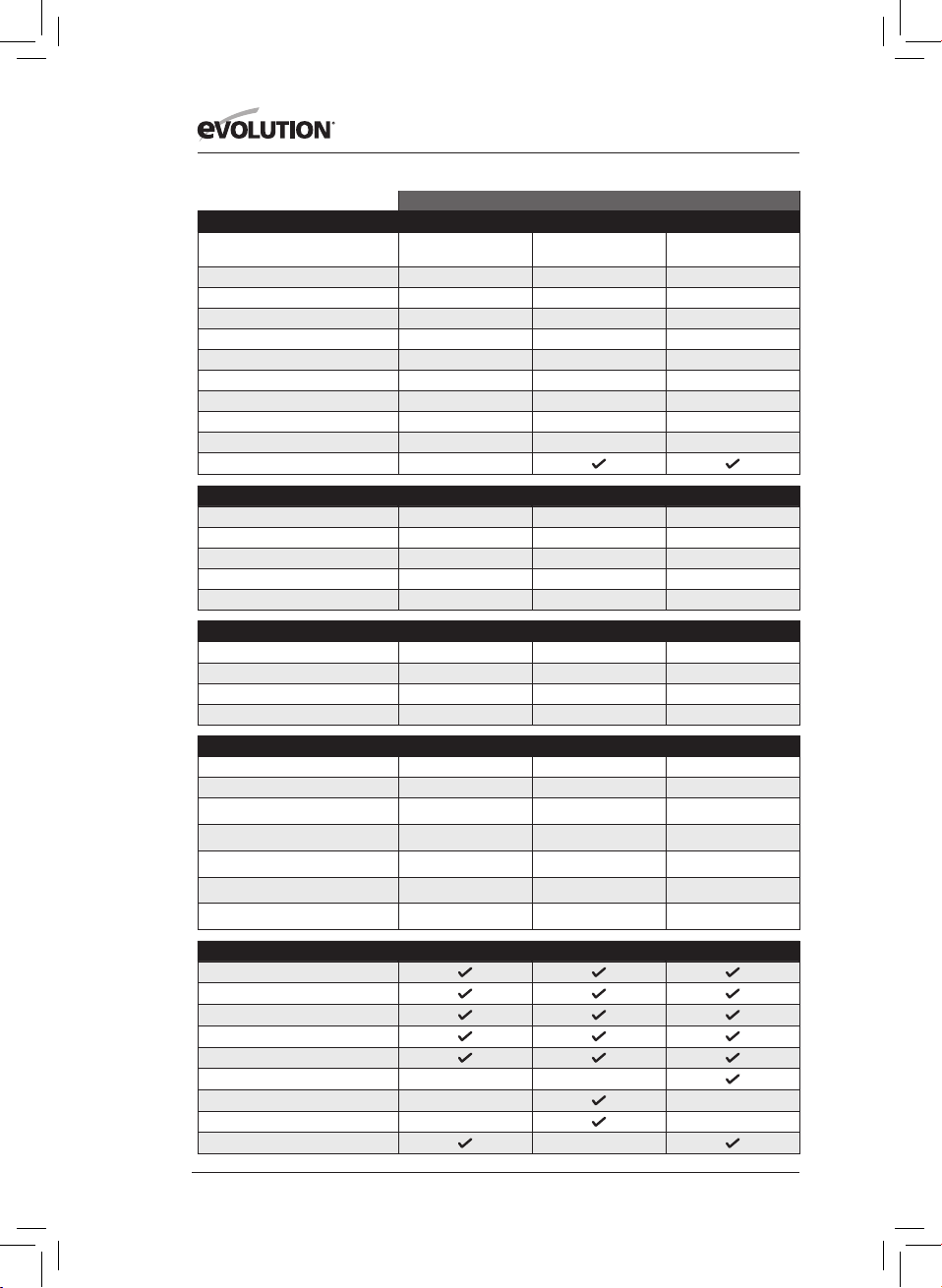

SPECIFICATIONS

USA

MACHINE SPECIFICATIONS R185CCS R185CCSX R185CCSX+

Model No:

0270004 0270004C 0270004A

Motor EU (220-240V ~ 50 Hz)

Motor UK (110V ~ 50 Hz)

Motor USA (120V ~ 60 Hz) 15A 15A 15A

No-Load Speed (220-240v)

No-Load Speed (110v & 120v) 3700 min

-1

/ rpm 3700 min

-1

/ rpm 3700 min

-1

/ rpm

Weight 10.8 lb 11.2 lb 11.2 lb

Max. Blade Bevel Angle (Degrees) 60˚ 45˚ 45˚

Power Cable Length 13 ft 13 ft 13 ft

Circular Saw Base Type Cast Aluminum Cast Aluminum Cast Aluminum

Cutting Track Compatible

CUTTING CAPACITIES R185CCS R185CCSX R185CCSX+

Mild Steel Plate (Max. Thickness) 1/4” 1/4” 1/4”

Mild Steel Box Section (Max. Wall) 1/4” 1/4” 1/4”

Max. Cutting Thickness (0°) 2-1/2” 2-1/2” (2-5/16” w/Track) 2-1/2” (2-5/16” w/Track)

Max. Cutting Thickness (45°) 1-9/16” 1-13/16” (1-5/8” w/Track) 1-13/16” (1-5/8” w/Track)

Max. Cutting Thickness (60°) 1”

BLADE SPECIFICATIONS R185CCS R185CCSX R185CCSX+

Blade Diameter Ø 7-1/4” Ø 7-1/4” Ø 7-1/4”

Number of Teeth 16 16 16

Bore Diameter 25/32” 25/32” 25/32”

Kerf 1.7mm 1.7mm 1.7mm

NOISE & VIBRATION DATA R185CCS R185CCSX R185CCSX+

Sound Pressure Level L

Sound Power Level L

Vibration - Main Handle (Sawing Wood)

Vibration - Auxiliary Handle (Sawing Wood)

Vibration - Main Handle (Sawing Metal)

Vibration - Auxiliary Handle (Sawing Metal)

pa

wa

Uncertainty K

94,3dB(A) K=3 dB(A) 94,3dB(A) K=3 dB(A) 94,3dB(A) K=3 dB(A)

105,3dB(A) K=3 dB(A) 105,3dB(A) K=3 dB(A) 105,3dB(A) K=3 dB(A)

A

= 3,347m/s

h,w

A

= 3,119m/s

h,w

a

= 3,572m/s

h,M

a

= 3,241m/s

h,M

1,5m/s

2

a

= 3,347m/s

2

2

2

2

h,w

a

= 3,119m/s

h,w

a

= 3,572m/s

h,M

a

= 3,241m/s

h,M

1,5m/s

2

a

= 3,347m/s

2

2

2

2

h,w

a

= 3,119m/s

h,w

a

= 3,572m/s

h,M

a

= 3,241m/s

h,M

1,5m/s

2

2

2

2

2

ITEMS SUPPLIED R185CCS R185CCSX R185CCSX+

Multi-Material TCT Blade

Hex Key (Blade Change)

Parallel Edge Guide

Dust Port Adapter

Dust Hose Connector

Carry Case

Cutting Track - 340mm (13-3/8”) x3

Connector Bar & Screws (x4)

LED Light

4

Page 5

www.evolutionpowertools.com

DE

EN

FR

ES

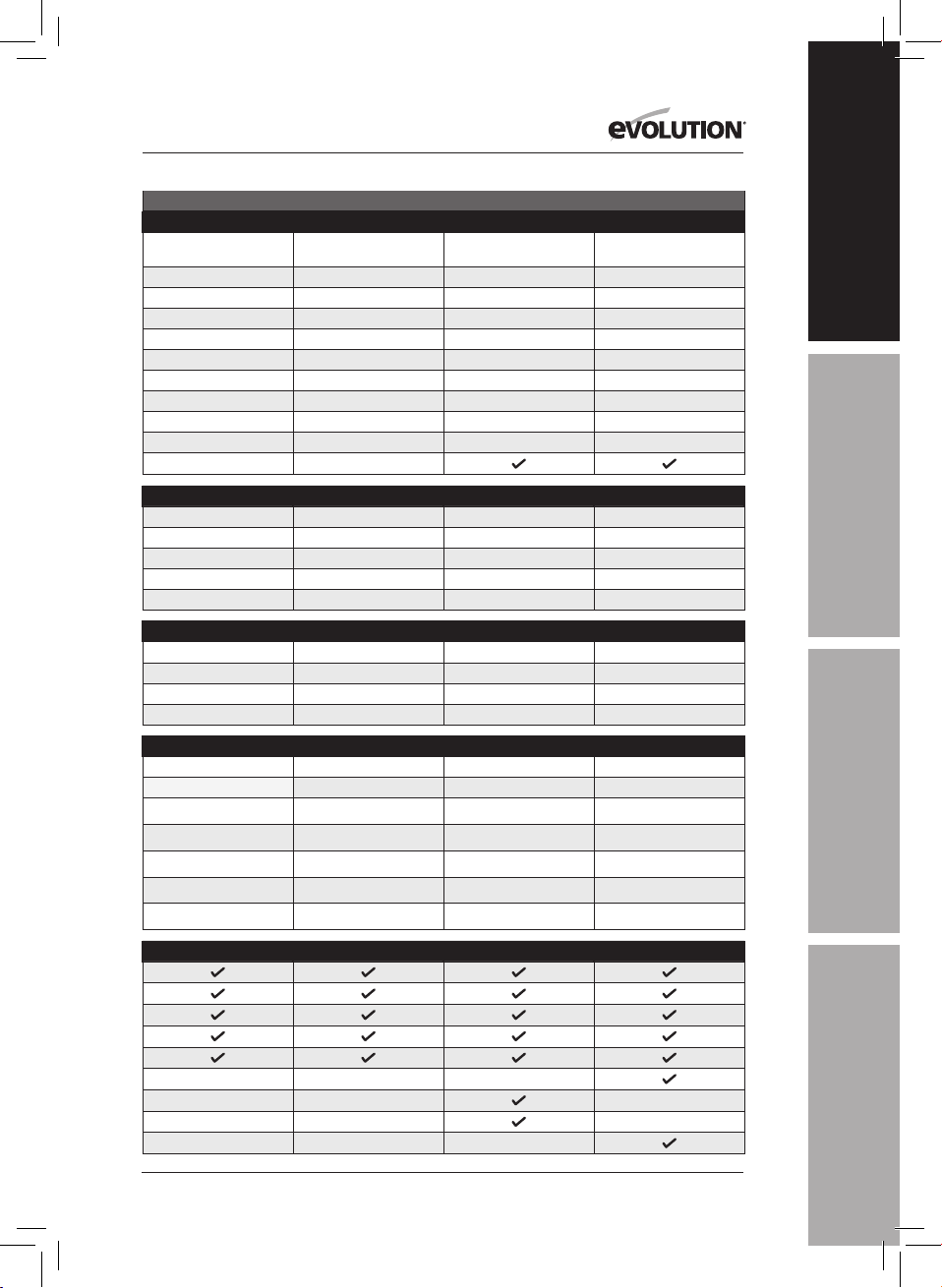

R165CCSL R185CCS R185CCSX R185CCSX+

0260001 / 0260002 /

0260003

1200W 1600W 1600W 1600W

1200W 1600W 1600W 1600W

UK / EU / AUS

0270001C /

0270002C / 0270003C

0270001 /

0270002 / 0270003

0270001A /

0270002A / 0270003A

-1

3700 min

/ rpm 3900 min

-1

3700 min

/ rpm 3700 min

-1

/ rpm 3900 min

-1

/ rpm 3700 min

-1

/ rpm 3900 min

-1

/ rpm 3700 min

-1

-1

/ rpm

/ rpm

4.3 kg 4.9 kg 5.1 kg 5.1 kg

45˚ 60˚ 45˚ 45˚

3m 3m 3m 4m

Pressed Steel Cast Aluminium Cast Aluminium Cast Aluminium

R165CCSL R185CCS R185CCSX R185CCSX+

3mm 6mm 3mm 6mm

3mm 6mm 3mm 6mm

53mm 64mm 64mm (59mm w/Track) 64mm (59mm w/Track)

34mm 40mm 47mm (42mm w/Track) 47mm (42mm w/Track)

24mm

R165CCSL R185CCS R185CCSX R185CCSX+

Ø 165mm Ø 185mm Ø 185mm Ø 185mm

14 20 16 20

20mm 20mm 20mm 20mm

1.7mm 1.7mm 1.7mm 1.7mm

R165CCSL R185CCS R185CCSX R185CCSX+

92,4dB(A) K:3dB(A) 94,3dB(A) K=3 dB(A) 94,3dB(A) K=3 dB(A) 94,3dB(A) K=3 dB(A)

103,4dB(A) K:3dB(A) 105,3dB(A) K=3 dB(A) 105,3dB(A) K=3 dB(A) 105,3dB(A) K=3 dB(A)

a

= 2,747m/s2 a

h,w

a

= 2,619m/s

h,w

a

= 2,302m/s

h,M

a

= 2,239m/s

h,M

1,5m/s

2

2

2

2

= 3,347m/s

h,w

a

= 3,119m/s

h,w

a

= 3,572m/s

h,M

a

= 3,241m/s

h,M

1,5m/s

2

2

2

2

2

a

h,w

a

h,w

a

h,M

a

h,M

= 3,347m/s

= 3,119m/s

= 3,572m/s

= 3,241m/s

2

1,5m/s

2

2

2

2

a

= 3,347m/s

h,w

a

= 3,119m/s

h,w

a

= 3,572m/s

h,M

a

= 3,241m/s

h,M

1,5m/s

2

2

2

2

2

R165CCSL R185CCS R185CCSX R185CCSX+

5

Page 6

www.evolutionpowertools.com

VIBRATION

(1.5) Note: The vibration measurement

was made under standard conditions in

accordance with: EN 62841-1: 2015,

EN 62841-2-5: 2014

Warning: Wear hearing protection!

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

(1.6) WARNING: When using this machine

the operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as

well as producing general numbness.

Prolonged or regular users of this machine

should monitor the condition of their hands

and fingers closely. If any of the symptoms

become evident, seek immediate

medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

EN 62841-1 and EN 62841-2-5

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the effects of vibration:

Handling

• Handle the machine with care,

allowing the machine to do the work.

• Avoid using excessive physical effort on any

of the machines controls.

• Consider your security and stability, and the

orientation of the machine during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used.

The need to identify safety measures

and to protect the operator are based on

an estimation of exposure in the actual

conditions of use (taking account of all parts

of the operating cycle, such as the times the

tool is switched off, when it is running idle,

in addition to trigger time).

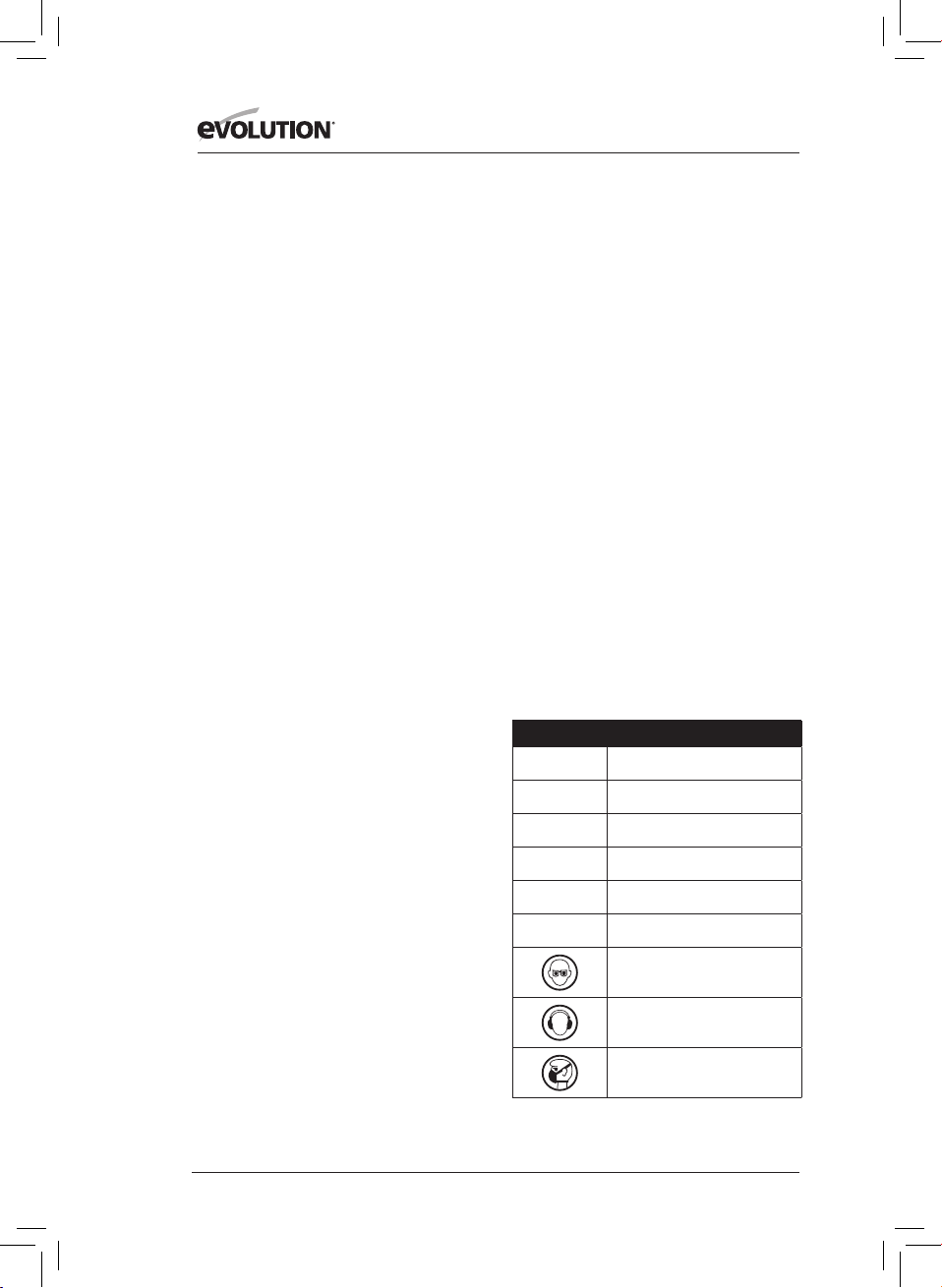

(1.7 ) LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

(1.8)

Symbol Description

V

A

Hz

Min-1 / RPM

~

n

o

Volts

Amperes

Hertz

Speed

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Wear Dust Protection

6

Page 7

www.evolutionpowertools.com

DE

EN

FR

ES

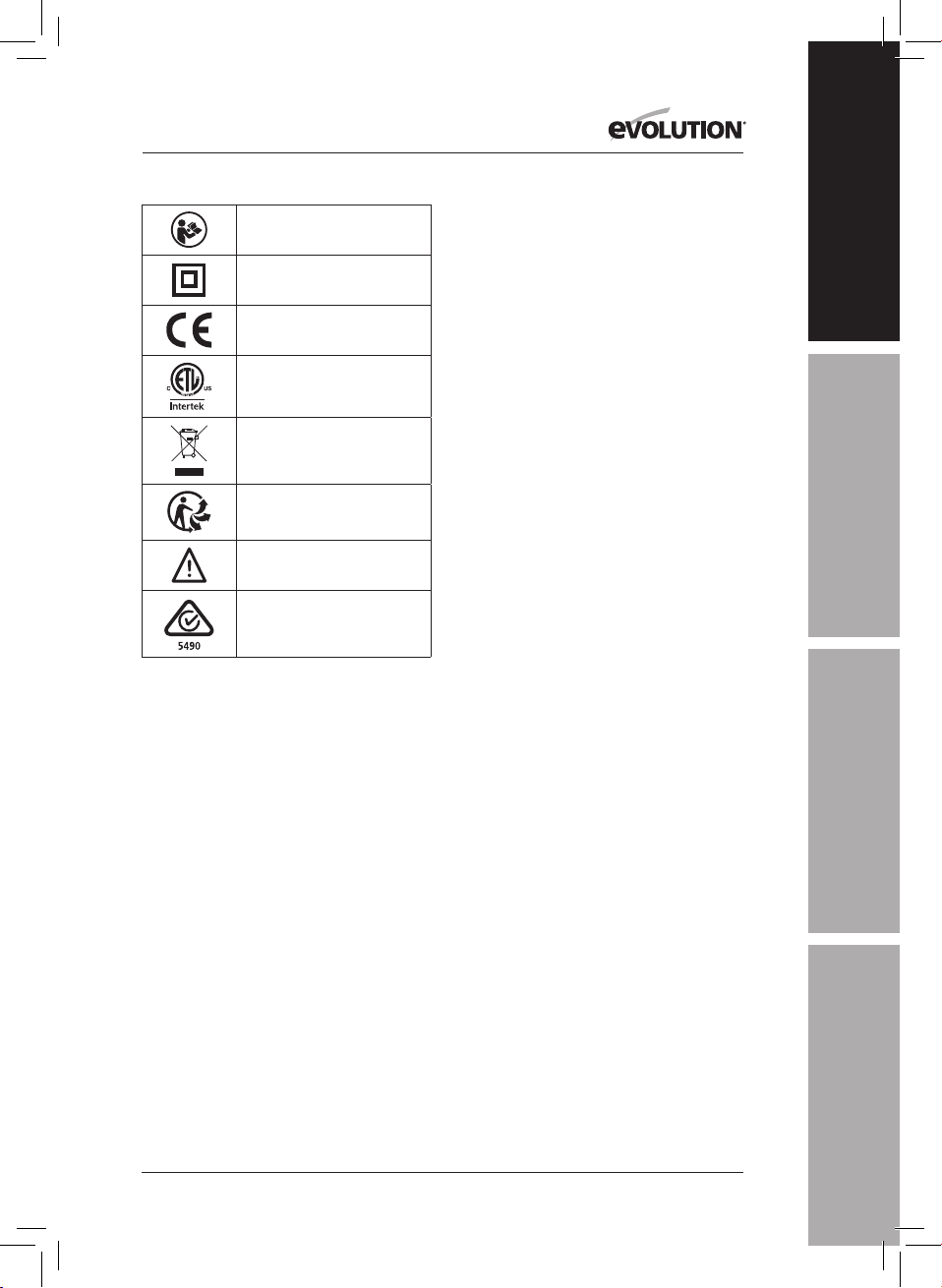

Read Instructions

Double Insulated

CE Certification

ETL Certification

Waste Electrical &

Electronic Equipment

Triman - Waste Collection

& Recycling

Warning

(RCM) Regulatory Compliance Mark

for electrical and electronic equipment.

Australian/New Zealand Standard

(1.9)

INTENDED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Circular Saw and has been designed to be

used with special Evolution blades. Only use

accessories designed for use in this machine

and/or those recommended specifically

by Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Mild Steel, Aluminium, Wood

Note: Cutting galvanised steel may reduce

blade life.

(1.10) PROHIBITED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Circular Saw and must only be used as such.

It must not be modified in any way, or used to

power any other equipment or drive any other

accessories other than those mentioned in this

Instruction Manual.

(1.11) WARNING: This machine is not intended

for use by persons (including children) with

reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning the safe

use of the machine by a person responsible

for their safety and who is competent

in its safe use.

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

(1.12) ELECTRICAL SAFETY

This machine is fitted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturers or its service agent.

(1.13) OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturers instructions should be

followed when using an extension cable.

(2.1) GENERAL SAFETY

INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in EN 62841-1: 2015).

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for

future reference. The term “power tool” in

7

Page 8

www.evolutionpowertools.com

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

(2.2) 1) General Power Tool

Safety Warnings [Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gasses or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating power tool. Distractions can cause

you to lose control.

(2.3) 2) General Power Tool Safety Warnings

[Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of

electric shock.

Note: The product is intended for use

only in premises having a service current

capacity≥100A per phase, supplied from a

distribution network having a nominal voltage

of 230V. If required, contact the electricity

company to ensure that the mains current

carrying capacity at the connection point

to the public power grid is adequate for

connecting the product.

(2.4) 3) General Power Tool Safety Warnings

[Personal Safety].

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising the

power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

from blade bolt before turning the power

tool on. A wrench or key left attached to a

rotating part of a power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving par ts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

h) Do not let familiarity gained from

frequent use of tools allow you to become

complacent and ignore tool safety

principles. A careless action can cause severe

injury within a fraction of a second.

8

Page 9

www.evolutionpowertools.com

DE

EN

FR

ES

(2.5) 4) General Power Tool Safety Warnings

[Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the power tool from the

power source from the power tool before

making any adjustments, changing

accessories, or storing power tools. Such

preventative safety measures reduce the risk

of starting the power

tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

h) Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow

for safe handling and control of the tool in

unexpected situations.

(2.6) 5) General Power Tool

Safety Warnings [Service]

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

(2.7) HEALTH ADVICE

WARNING: When using this machine,

dust particles may be produced. In some

instances, depending on the materials you

are working with, this dust can be particularly

harmful. If you suspect that paint on the

surface of material you wish to cut contains

lead, seek professional advice. Lead based

paints should only be removed by

a professional and you should not

attempt to remove it yourself.

Once the dust has been deposited on

surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

You are advised to consider the risks

associated with the materials you are working

with and to reduce the risk of exposure.

As some materials can produce dust that may

be hazardous to your health, we recommend

the use of an approved face mask with

replaceable filters when using this machine.

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment, such

as dust masks that are specially designed to

filter microscopic particles.

(2.8) WARNING: the operation of any power

tool can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where necessary.

SAFETY INSTRUCTIONS FOR ALL SAWS

[Cutting procedures]

a) DANGER: Keep hands away from cutting

area and the blade. Keep your second

hand on auxiliary handle, or motor

housing. If both hands are holding the saw,

they cannot be cut by the blade.

9

Page 10

www.evolutionpowertools.com

b) Do not reach underneath the workpiece.

The guard cannot protect you from the blade

below the workpiece.

c) Adjust the cutting depth to the thickness of

the workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

d) Never hold the workpiece in your hands

or across your leg while cutting. Secure

the workpiece to a stable platform. It is

important to support the work properly to

minimise body exposure, blade binding, or

loss of control.

e) Hold the power tool by insulated

gripping surfaces, when performing an

operation where the cutting tool may

contact hidden wiring or its own cord.

Contact with a “live” wire will also make

exposed metal parts of the power tool ‘live’

and could give the operator an electric shock.

f) When ripping, always use a rip fence

or straight edge guide. This improves the

accuracy of cut and reduces the chance of

blade binding.

g) Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the mounting

hardware of the saw will run off-centre,

causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw, for

optimum performance and safety of operation.

(3.2) [Kickback causes and

related warnings]

Kickback is a sudden reaction to a pinched,

jammed or misaligned saw blade, causing

an uncontrolled saw to lift up and out of the

workpiece toward the operator;

When the blade is pinched or jammed tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator;

(3.3)

Kickback is the result of saw misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below.

a) Maintain a firm grip with both hands on

the saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line

with the blade. Kickback could cause the

saw to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

b) When blade is binding, or when

interrupting a cut for any reason, release

the trigger and hold the saw motionless

in the material until the blade comes to a

complete stop. Never attempt to remove the

saw from the work or pull the saw backward

while the blade is in motion or kickback may

occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece,

centre the saw blade in the kerf so that the saw

teeth are not engaged into the material. If a saw

blade binds, it may walk up or kickback from the

workpiece as the saw is restarted.

d) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade

binding and kickback.

e) Blade depth and bevel adjusting locking

levers must be tight and secure before making

a cut. If the blade adjustment shifts while cutting

it may cause binding and kickback.

f) Blade depth and bevel adjusting locking

levers must be tight and secure before

making the cut. If blade adjustment shifts

while cutting, it may cause binding and

kickback.

g) Use extra caution when sawing into

existing walls or other blind areas. The

protruding blade may cut objects that can

cause kickback.

If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward the operator.

LOWER GUARD FUNCTION

a) Check the lower guard for proper closing

before each use. Do not operate the saw if

the lower guard does not move freely and

close instantly. Never clamp or tie the lower

guard into the open position. If the saw is

10

Page 11

www.evolutionpowertools.com

DE

EN

FR

ES

accidentally dropped, the lower guard may be

bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does

not touch the blade or any other part, in all

angles and depths of cut.

b) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use. Lower guard may operate

sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

c) The lower guard may be retracted

manually only for special cuts such as

“plunge cuts” and “compound cuts”.

Raise the lower guard by the retracting

handle and as soon as the blade enters the

material, the lower guard must be released.

For all other sawing, the lower guard should

operate automatically.

d) Always observe that the lower guard is

covering the blade before placing the saw

down on bench or floor. An unprotected,

coasting blade will cause the saw to walk

backwards, cutting whatever is in its path. Be

aware of the time it takes for the blade to stop

after switch is released.

ADDITIONAL SAFETY

INSTRUCTIONS

FOR CIRCULAR SAWS

a) Do not use High Speed Steel (HSS)

saw blades.

b) Inspect the machine and the blade

before each use. Do not use deformed,

cracked, worn or otherwise damaged blades.

c) Never use the saw without the original

guard protection system. Do not lock

the moving guard in the open position.

Ensure that the guard operates freely

without jamming.

d) Only use blades that comply with the

characteristics specified in this manual.

Before using accessories, always compare

the maximum allowed RPM of the

accessory with the RPM of the machine.

e) Do not use any abrasive wheels.

f) Use only blade diameter(s) in accordance

with the markings.

(3.4) WARNING: If any parts are missing, do

not operate your machine until the missing

parts are replaced. Failure to follow this rule

could result in serious personal injury.

(4.1) GETTING STARTED - UNPACKING

Caution: This packaging contains sharp objects.

Take care when unpacking. Remove the machine,

together with the accessories supplied from the

packaging. Check carefully to ensure that the

machine is in good condition and account for all

the accessories listed in this manual. Also make

sure that all the accessories are complete.

If any parts are found to be missing,

the machine and its accessories should be

returned together in their original packaging to

the retailer.

Do not throw the packaging away; keep it safe

throughout the warranty period. Dispose of the

packaging in an environmentally responsible

manner. Recycle if possible.

Do not let children play with empty plastic bags

due to the risk of suffocation.

(4.3) Evolution Instruction Manuals

Evolution Power Tools provides each product

with an Instruction Manual.

Each dedicated manual is carefully constructed

and designed to provide easily accessible and

useful information regarding the safe use, care

and maintenance of the product. Referencing

the information contained within the manual

will allow the operator to fully and safely

exploit the potential of the machine.

Evolutions policy of continual product

development may mean that, very

occasionally, the contents of a manual may not

completely reflect the latest improvements or

upgrades that have been incorporated into a

particular product. Upgrades/improvements

to the specification of a product could come

about as a consequence of technological

advances or changes to the legislative

framework of the receiving country, etc.

If you are at all unsure about any aspect of

the use, care or maintenance of an Evolution

product, contact the relevant Evolution

helpline where up to date information and

extra advice will be available.

11

Page 12

www.evolutionpowertools.com

USA

18

1

2

16

17

15

19

14

3

4

5

6

7

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 5/16” HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE ON/OFF SWITCH

12. UPPER BLADE GUARD

13

20

12

11

10

9

8

13. PRECISION ENGINEERED SOLE PLATE

14. BEVEL ADJUSTMENT THUMB LEVER

15. PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. LED LIGHT

18. DUST PORT CONNECTOR

19. 25/32” INNER BLADE FLANGE

20. 5/8” INNER BLADE FLANGE

12

Page 13

www.evolutionpowertools.com

DE

EN

FR

ES

USA

18

1

16

17

21

19

2

3

14

13

4

20

12

5

6

7

11

10

15

22

23 24 25

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 5/16” HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LEVER

10. DEPTH SCALE

11. REAR HANDLE ON/OFF SWITCH

12. UPPER BLADE GUARD

13. PRECISION ENGINEERED TRACK

COMPATIBLE SOLE PLATE

14. THUMB LEVER

15. REAR PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. LED LIGHT

13

9

8

18. DUST PORT CONNECTOR

19. 25/32” INNER BLADE FLANGE

20. 5/8” INNER BLADE FLANGE

21. TRACK ADJUST TURN BUTTONS

22. REAR BEVEL THUMB SCREW

23. 3x 13-3/8” TRACK

24. 4x TRACK CONNECTOR BARS

25. 1/8” HEX KEY (TRACK)

Page 14

www.evolutionpowertools.com

USA

18

1

2

16

17

21

19

14

3

4

5

6

7

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 8MM HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE ON/OFF SWITCH

12. UPPER BLADE GUARD

13

20

12

11

10

15

22

9

8

13. PRECISION ENGINEERED TR ACK

COMPATIBLE SOLE PLATE

14. THUMB LEVER

15. REAR PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. LED LIGHT

18. DUST PORT CONNECTOR

19. 25/32” INNER BLADE FLANGE

20. 5/8” INNER BLADE FLANGE

21. TRACK ADJUST TURN BUTTONS

22. REAR BEVEL THUMB SCREW

14

Page 15

www.evolutionpowertools.com

DE

EN

FR

ES

UK / EU / AUS

1

16

15

2

3

4

14

13

12

5

11

10

6

7

9

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 8MM HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE INCORPORATING

SAFETY START ON/OFF SWITCH

8

12. UPPER BLADE GUARD

13. PRECISION ENGINEERED SOLE PLATE

14. THUMB LEVER

15. PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

15

Page 16

www.evolutionpowertools.com

UK / EU

17

1

16

15

2

3

4

5

6

7

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 8MM HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE INCORPORATING

SAFETY START ON/OFF SWITCH

14

13

12

11

10

9

8

12. UPPER BLADE GUARD

13. PRECISION ENGINEERED SOLE PLATE

14. THUMB LEVER

15. PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. DUST PORT CONNECTOR

16

Page 17

www.evolutionpowertools.com

DE

EN

FR

ES

UK / EU

1

16

17

18

2

14

3

20

13

4

21

5

6

7

8

12

11

10

22

15

9

19

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 8MM HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE INCORPORATING

SAFETY START ON/OFF SWITCH

12. UPPER BLADE GUARD

13. PRECISION ENGINEERED TR ACK

COMPATIBLE SOLE PLATE

14. THUMB LEVER

15. REAR PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. DUST PORT CONNECTOR

18. TRACK ADJUST TURN BUTTONS

19. REAR BEVEL THUMB SCREW

20. 3x 340mm TR ACK

21. 4x TRACK CONNECTOR BARS

22. 3mm HEX KEY

17

Page 18

www.evolutionpowertools.com

UK / EU

17

1

16

18

2

3

4

5

6

7

1. CUT MATERIAL EJECTION PORT

2. THUMB LEVER

3. MULTI-MATERIAL TCT BLADE

4. LOWER BLADE GUARD

5. PARALLEL EDGE GUIDE

6. ERGONOMIC FRONT HANDLE

7. CARBON BRUSHES

8. 8MM HEX KEY (BLADE CHANGE)

9. DEPTH ADJUSTMENT LOCKING LEVER

10. DEPTH SCALE

11. REAR HANDLE INCORPORATING

SAFETY START ON/OFF SWITCH

14

13

12

11

10

15

19

9

8

12. UPPER BLADE GUARD

13. PRECISION ENGINEERED TR ACK

COMPATIBLE SOLE PLATE

14. THUMB LEVER

15. REAR PROTRACTOR SCALE

16. ARBOR LOCK BUTTON

17. DUST PORT CONNECTOR

18. TRACK ADJUST TURN BUTTONS

19. REAR BEVEL THUMB SCREW

18

Page 19

www.evolutionpowertools.com

DE

EN

FR

ES

Fig. 1

Fig. 4

Fig. 7a Fig. 7b Fig. 7c

Fig. 3Fig. 2

Fig. 6Fig. 5

Fig. 8

Fig. 9

19

Fig. 10

Page 20

www.evolutionpowertools.com

Fig. 11

Fig. 14

Fig. 17

Fig. 12

Fig. 15

Fig. 18

Fig. 13

Fig. 16

Fig. 19

1 -2mm

Fig. 21Fig. 20

Fig. 22

20

Page 21

www.evolutionpowertools.com

DE

EN

FR

ES

EU Dust Port Connector

US Dust Port Connector

Fig. 24Fig. 23

Fig. 25

Fig. 27Fig. 26

Fig. 29

Fig. 30

Fig. 32 Fig. 33

21

Fig. 28

Fig. 31

Fig. 34

Page 22

www.evolutionpowertools.com

(10) PREPARATION

WARNING: Always disconnect the machine

from the power source before making any

adjustments.

Note: These machines are equipped with an

approved power cord and plug for the intended

country of use. Do not alter or modify the power

cord.

(10.1) INSTALLING /

REMOVING A BLADE

WARNING: Use only genuine Evolution blades

(or those approved by Evolution Power Tools),

which are designed for use in these machines.

Ensure that the maximum speed of the blade is

compatible with the machine. Only perform this

operation with the machine disconnected from

the power supply.

Note: It is recommended that the operator

considers wearing protective gloves when

handling the blade during installation or when

changing the machines blade.

• Locate the supplied Blade Change Hex Key

which is housed in the onboard storage facility

(similarly position on all machines). (Fig. 1)

• Place saw on a level, secure surface.

Note: All machines can, with care, be balanced on

the flat end of the motor housing casing, (Fig. 2)

making access to the blade and blade fixings very

convenient.

• Locate the machines arbor lock button (which

is similarly positioned on all machines). Lock

the machines arbor by operating the arbor

lock button. (Fig. 3).

Note: Slowly rotating the blade by hand, whilst

gently pressing the arbor lock button will aid

arbor lock engagement.

• Using the Hex Key, loosen and remove the

arbor socket headed screw, associated fixings,

and outer blade drive flange. (Fig. 4)

Note: The socket headed arbor screw is equipped

with a standard screw thread.

Turn the screw clockwise to tighten. Turn the

screw counter clockwise to loosen.

• Safely store the outer blade flange and

associated fixings.

• Rotate the lower blade guard up into the

upper blade guard using the manual thumb

lever. (Fig. 5)

• Carefully remove the blade (if fitted) from

the machine.

• Thoroughly clean inner and outer blade

drive flanges.

Note: The inner blade flange can be left in

place if desired, but it should be checked and

thoroughly cleaned. If it is removed from the

machine it must be replaced back in the same

orientation as it was before removal.

• Thoroughly clean the blade around the bore

area (both surfaces) where the blade flanges

will touch and clamp the blade.

• Install the (new) blade.

• Ensure that the direction of rotation arrows

printed on the blade, match the direction

of rotation arrows found on the machines

upper and lower blade guards. (Fig. 6)

• Reinstall the outer drive flange, the

socket headed arbor screw, and its

associated fixings.

Note: The outer drive flange has a specially

machined bore which incorporates two

opposed ‘flats.’ (Fig. 7a) These ‘flats’ engage

with two complimentary ‘flats’ machined into

the machines arbor shaft.

• Re-engage the arbor lock and tighten the

arbor socket headed screw securely using

the Hex Key.

• Release the arbor lock button

• Return the Hex Key to its dedicated storage

position.

• Check that the arbor lock has fully released

by manually rotating the blade.

• Check the operation of the lower

blade guard.

Note: For North American market only, a dual

side arbor flange is included, to allow 1” bore

blades (Fig. 7b) and 5/8” bore blades (Fig. 7c).

22

Page 23

www.evolutionpowertools.com

DE

EN

FR

ES

(11) PARALLEL EDGE GUIDE

A Parallel Edge Guide (Fig. 8) which can be

particularly helpful when rip cutting, is supplied

with all CCS machines. The guide can be fitted

to the front of the sole plate.

The guides arm should be inserted through the

rectangular slots positioned at either side (front)

of the pressed steel sole plate, and slid under

the centrally located adjustment locking screw.

(Fig. 9)

Note: The Parallel Edge Guide can be fitted on

either side of the sole plate.

WARNING: Only fit and adjust the Guide with

the machine disconnected from the power

supply.

Note: The arm of the Parallel Edge Guide

must pass through all of the rectangular slots

provided in the sole plate.

WARNING: It is potentially dangerous to install,

and try to use the Edge Guide with the arm

passing through only one (1) of the machined

rectangular sole plate slots.

Adjust the edge guide so that it is at the

required distance from the blade and tighten

the adjusting screw. Check that the edge guide

is parallel to the saw blade.

(12) CUTTING DEPTH ADJUSTMENT

Note: All CCS machines share the same general

depth adjustment fixtures/fittings and employ

the same basic technique for setting the blade

depth.

• Loosen the Depth Adjustment Locking

Mechanism by pulling the operating lever

upwards. (Fig. 10)

• Adjust/re-position the sole plate to give the

required cutting depth (the amount by which

the blade protrudes through the sole plate).

Note: A depth scale can be found on the depth

adjustment quadrant, with a corresponding

index mark incorporated into the adjacent area

of the machines upper blade guard. (Fig. 11)

Using these features can aid rapid setting.

Note: Although the depth scale and index mark

are very useful, enabling rapid depth setting,

using them should always be regarded as a

guide to the setting achieved.

If a very precise depth of cut is required, then

the blade setting should be checked with an

engineers precision ruler (not supplied) or

similar and adjusted accordingly.

• In most cases the cutting depth should be set

at the thickness of the material to be cut plus

the depth of half of a saw tooth (tip of the

tooth to the tooth root). (Fig.12)

• Tighten the Depth Adjustment Locking

Mechanism by pushing the operating

lever downwards to securely to lock in the

machine in the required position.

(13) CUTTING ANGLE

(BEVEL) ADJUSTMENT

All CCSL & CCSX machines have the facility to

tilt the blade through (up to) 45˚ and all CCS

machines have the facility to tilt the blade

through (up to) 60˚ to the left hand side.

Bevel cuts are therefore possible.

Note: The blade is at the vertical position when

the protractor scale reads 0˚.

Note: A protractor scale (0˚- 45˚ or 0˚- 60˚) is

incorporated on the Bevel Locking quadrant

found at the front of the soleplate. Using this

will aid rapid bevel angle setting but should be

regarded as a guide only.

If a very precise bevel angle is required, then

the blade setting should be checked using a

vernier angle gauge (not supplied) and adjusted

accordingly.

• Loosen the Bevel Locking Mechanism found

at the front of the machine, by pulling the

lever upwards. (Fig. 13)

• Tilt the blade to the required angle as

indicated on the quadrant protractor scale.

(Fig. 14)

• Tighten the Bevel Locking Mechanism

securely when the desired bevel angle

has been achieved by pushing the lever

downwards.

(14) OPERATING ADVICE

(PRE OPERATION CHECKS)

Note: As all operating environments will be

unique and diverse, Evolution Power Tools offers

23

Page 24

www.evolutionpowertools.com

the following general advice on safe operational

procedures and practices for the consideration

of the operator.

This advice cannot be exhaustive as Evolution

has no influence on the type of workshops or

working environments in which these machines

may be used.

We recommend that the operator seeks advice

from a competent authority or the workshop

supervisor if they are at unsure of any aspect of

using these machines.

It is important that routine safety checks are

carried out (at each time of usage) before the

operator uses the machine.

WARNING: These pre-use safety checks should

be carried out with the machine disconnected

from the mains power supply.

• Check that all safety guards are operating

correctly, and that all adjustment handles/

screws are securely tightened.

• Check that the blade is secure and installed

correctly. Also check that it is the correct

blade for the material being cut.

• Check the integrity of the power cord.

• Whenever possible clamp the workpiece to a

rigid support structure such as a workbench,

saw horse or similar.

• The operator should always be aware of the

position and routing of the power cable.

(15) PPE

• The operator should wear all relevant PPE

(Personal Protection Equipment) necessary

for the task ahead.

This could include safety glasses,,full face

mask, dust masks, safety shoes etc.

Note: All CCS series machines are equipped

with a cutting line debris blower. This directs

air from a motor driven fan towards the area to

the front of the blade, thus keeping the cutting

line relatively debris free. This feature will aid the

operator sight and follow the progress of the

saw blade along the cut, keeping any markingout lines visible.

Some materials can be particularly harmful, and the

operator should always wear a dust mask which is

suitable for the material being worked with.

Professional help and advice should be sought if

the operator is at all unsure about the potential

toxicity of the material to be cut.

WARNING: These machines must never be

used to cut Asbestos or any material that

contains, or is suspected to contain, Asbestos.

Consult/inform the relevant authorities,

and seek additional guidance if Asbestos

contamination is suspected.

(16) ON/OFF TRIGGER SWITCH

Note: All machines destined for the European

and Australian market are equipped with a

‘safety start’ trigger switch to enhance operator

safety. (Fig.15)

To start the motor:

• Push in the safety lock button on the side of

the handle with your thumb.

• Depress the trigger switch.

To stop the motor:

• Release the trigger switch.

WARNING: The motor should never be started

with the saw blade in direct contact with any

surface of the workpiece.

Note: Machines destined for the North

American market are fitted with an ON/OFF

Trigger switch which does not incorporate a

‘safety start’ trigger switch.

WARNING: If the saw is ‘live’ (LED Light ‘ON’),

avoid unintentionally starting the motor when

picking up the machine from a workbench or

similar. Accidentally depressing the ON/OFF

Trigger switch (positioned in the main handle)

when picking up the machine from rest will

cause the motor to start.

WARNING: Any and all dust created is

potentially prejudicial to health.

24

Page 25

www.evolutionpowertools.com

DE

EN

FR

ES

CUTTING TRACKS

Evolution CCSX series machines (refer

to the Specification Page for applicable

models) have been engineered and

featured in such a way as to make them

Cutting Track compatible.

Note: Any circular saw that is capable of being

used with a Cutting Track will have a channel

along the under surface of the sole plate

Evolution machines so equipped can be

attached to, and used with most Cutting Tracks

(Guides) currently available.

Note: Consult the documentation supplied

with the track by the track manufacturer. The

supplied documentation will normally give

the assembly instructions for the track, as well

as information regarding the safe working

practices that need to be employed when

using such equipment.

Cutting Tracks can be employed where:

• The use of a chop or circular saw could

present Health and Safety (H&S) or other

practical workplace issues. For example

when working on a construction site

where very close and accurate control may

be necessary, (working on a roof or on a

scaffolding platform, etc.) using a cutting

track may provide the user with some extra

(and safe) operational possibilities.

• Accurate cuts across or along large

workpieces are required. For example on

frames, doors, large boards or wall panels,

etc, a cutting track/guide could eliminate the

need to use a circular saw in ‘free hand’ mode.

Note: Evolution’s cutting track compatible

machines have two (2) cams which project into

the sole plate channel (one at each end).

‘Turn-buttons’

rotate these cams.

Adjusting these cams will reduce slightly the

effective width of the sole plate channel.

This could be necessary to accommodate any

slight variation of rail width that can occur

during the manufacture of the track extrusion.

(Fig. 17) allow the operator to

(Fig. 16)

Track rail widths produced by different track

manufacturers may also vary slightly.

Note: The operator should adjust these cams so

that when the machine is placed correctly on

a track it can be moved forwards or backwards

easily and smoothly but without any lateral

movement (wobble) being detectable.

EVOLUTION CUTTING TRACKS

Some Evolution machines (depending upon

the model and market destination) are

supplied with a Cutting Track.

Note: Evolution Cutting Tracks are available as a

customer purchase option. Contact your supplier

or Evolution Power Tools for further details.

THE TRACK

The Evolution Track system consists of two (2) or

three (3) precision extruded alloy sections.

(Fig. 18) These sections must be joined together

using the joining bars supplied.

To Join The Sections Together (Fig. 19):

• Slide the bars into the ‘T’ slots found on the

under surface of the extrusions.

• Ensure that an equal length (approximately)

of the bars is inserted into both of the

sections to be joined together.

• Tighten the socket headed grub-screws to

secure the sections together.

Note: It is important to leave a small gap

between joined sections of between 1 to 2mm.

This will ensure that when a circular saw is

placed upon and used with an Evolution Cross

Cutting Track it will slide smoothly along the

entire track length.

(Fig. 19)

SAW TO TRACK COMMISSIONING

Note: The following guidelines refer to

Evolution circular saws and the Evolution

Cutting Track. Consult the information

supplied by the saw and/or the cutting track

manufacturers if a non-Evolution circular saw

or cutting track is to be used.

25

Page 26

www.evolutionpowertools.com

Before the first use of the Evolution Cutting

Track the cut line sealing strip

to match the saw and blade.

To match saw to track:

• Fully assemble the Cutting Track.

• Refer to the section entitled ‘Track

Positioning and Clamping’. Clamp the track

to an appropriate piece of spare or scrap

material.

• Set the saw blade to a depth suitable for the

scrap workpiece selected.

• Ensure that no obstructions are present

beneath the path of the blade.

• Refer to the section ‘Track Positioning and

Clamping’. Place the circular saw correctly

on the track.

• Start the motor and allow it to reach full

speed.

• Smoothly and slowly push the circular saw

along the full length of the track until the

blade has cut through the entire length of

the sealing strip.

Note: This process will match a specific saw to

a specific track.

If a different saw is used on such a prepared

track, the cut line seal may not provide the

same level of protection as the dedicated saw

to track configuration.

Note: The linear seal should be regarded as a

consumable item. Over time it will wear and abrade

and will therefore need replacement. It may also

need replacement if a different circular saw or saw

blade (one with a different kerf width) from the

original dedicated configuration is to be used.

(Fig. 21) needs

THE LINEAR SEAL

As a consumable item the Linear Seal should

be checked at regular intervals for damage or

abrasion caused by ‘wear and tear’. Replace the

seal if any damage or significant wear is apparent.

Replacement seals are available. Consult

your supplier or contact Evolution using the

appropriate helpline.

The replacement self adhesive Linear Seal

supplied is a direct substitution to the fitted

original. Simply pull the old seal gently from

the track and replace with the new seal.

Note: If a new seal is fitted, the Saw to Track

matching process must be repeated.

EVOLUTION TRACK CLAMPS

The Evolution Speed Clamp (Fig. 22) is

purpose designed to work with the Evolution

Cutting Track.

Note: Extra clamps can be purchased from

Evolution Power Tools or your local supplier.

Evolution clamps fit into and can slide along

the ‘T’ slots found on the under surface of the

alloy extrusions.

This enables the operator to locate the clamps

(one is required at each end of the track) in

positions which afford the maximum security,

and rigidity of the Cutting Track to the

workpiece.

(Fig. 23)

TRACK POSITIONING & CLAMPING

Note: The following guidelines are given as

advice. Evolution has no influence over the

working environments or conditions in which

this equipment is used.

WARNING: If this equipment is to be used on a

construction site, the operator should consult

the relevant person who has responsibility for

Health and Safety for further ‘on site’ specific

safety requirements or instructions.

• Mark out clearly the workpiece and

particularly the ‘line of cut’ along which the

saw blade is required to travel.

• Assemble the Cutting Track with as many

sections as required to span the workpiece

including an allowance for the overhang

needed.

• Using Evolution Speed Clamps (the

preferred option) or suitable ‘G’ clamps

26

Page 27

www.evolutionpowertools.com

DE

EN

FR

ES

position the Track on the workpiece and

secure by tightening the clamps.

• Ensure that the edge of the linear seal runs

exactly along the marked out cutting line.

WARNING: The Cutting Track must overhang

the worpiece at the ‘lead in’ edge.

The lower blade guard will need to be

retracted manually and pivot upwards into the

upper blade guard as the circular saw is placed

on the track.

WARNING: In this position the blade is

exposed.

DO NOT press the trigger until the

following safety checks have been carried out.

(Fig. 24)

PERFORMING A CUT

Performing a cut using a cutting track is very

similar to ordinary cutting with a circular saw.

All of the safety procedures and protocols that

apply to the use of a circular saw will also apply

when such a saw is used in conjunction with a

cross cutting track.

The following guidelines, though not

comprehensive offer some general advice:

• Carry out a safety check to ensure that the

Cutting Track is securely fastened to the

workpiece, and that the workpiece itself is

secure and cannot move during a cut.

• Check to ensure that there are no

obstructions under the workpiece that

could inhibit or impede the progress of the

saw blade or be damaged by the saw blade.

• Ensure that the mains cable is routed in such

a way that it does not pose a trip (or any

other form) hazard. Check particularly that

the mains cable cannot come into contact

with the spinning blade of the saw.

• The operator should ensure that when they

are pushing the saw along the track they can

maintain a sure footing, good balance and

complete control at all times throughout the

cut. Particular caution should be exercised as

the saw blade exits the workpiece.

WARNING: Particularly if working at height

(other circumstances may also apply) ensure

that any cut material cannot fall away and

possibly injure a bystander. The operator may

have to consider some way of containing or

catching such cut material. Consult the person

responsible for site safety for specific guidance.

Note: The operator should consider

performing a practice run with the saw

disconnected from the mains supply to

confirm that the cutting procedure will be

completely safe throughout.

When the cut has been completed the

operator should release the ON/OFF Trigger

Switch and allow the motor to stop and the

blade to become stationary.

As the saw is lifted from the Cutting Track

and workpiece the lower blade guard will

automatically deploy covering the blade

completely.

DUST / DEBRIS COLLECTION

An adaptor nozzle (Fig. 25) can be fitted to all

CCS machines. Fitting the nozzle allows the

machine to be connected to a dust/debris

collection device.

Note: The exact design of the nozzle supplied

will vary depending upon type of model and

the market destination of the machine.

The supplied nozzle will accept a wide variety

of debris/dust collection devices currently

available. The nozzle should be fitted to the

Cut Material Ejection Port.

Note:

A workshop dust/debris extraction

machine can be attached to the adaptor

nozzle if required. Follow the manufacturers

instructions if such a machine is fitted and

ensure that it is capable of handling the

ejected cut material.

(Fig. 26)

LED LIGHT

Some of these machines (depending upon the

model and market destination) are equipped

with an automatic LED Light.

27

Page 28

www.evolutionpowertools.com

Note: If you are unsure of which features

are provided on your machine, consult the

Specification Page provided in this manual.

The LED Light is positioned to the left hand

(LH) side of the blade.

(Fig. 27)

The beam from the LED will light up the left

hand side of the blade and also illuminate any

marking out lines present on the workpiece.

This should help the operator predict the path

of the blade through the workpiece and thus

aid efficiency, accuracy and safety.

Note: Operation of the LED Light is automatic.

As soon as the machine is connected to the

mains supply the LED will activate. This gives

the operator a clear visual indication that the

machine has been successfully connected to

the mains electrical supply, and is therefore

powered (is ‘live’) and ready for cutting

operations to commence.

Note: There are no user serviceable parts

incorporated within the LED Light assembly and

the beam direction is factory set. The protective

lens cover should be kept clear of dust etc.

(see Maintenance) to ensure the maximum

brightness of the projected beam is maintained.

WARNING: Only clean the lens cover with the

machine disconnected from the mains power

supply and the blade completely stationary.

INTEGRAL CUTTING AIDS

All Evolution circular saws are equipped with

various cutting aids or guides designed help

the operator achieve quick accurate cuts safely.

Note: Not all of the following features will

appear on every machine.

0˚ and 45˚ Line of Cut Guides (Fig. 28)

Located on the front edge of the machines sole

plate are two (2) small notches, which on some

machines are identified with an angular number.

These notches indicate the position of the blade

as it exits the workpiece when the bevel tilt angle

is set at 0˚ (blade vertical) or at an angle of 45˚.

Front of Blade Guide (Fig. 29)

Evolution machines compatible with

Note:

Evolutions Cutting Track have a notch located on

the right hand edge (RH) of the sole plate casting.

This notch indicates the position of the front

edge of the blade when the blade is set at

maximum cutting depth. This feature can be

used when placing and positioning the saw on

a Cutting Track.

WARNING: It is important that the lower blade

guard or blade do not touch any surface of the

workpiece during the initial positioning of the

saw on the Cutting Track.

Ruler Guides (Fig. 30)

Ruler guides are present on some Evolution

circular saws. They are positioned along the

front and/or side edges of the sole plate.

These guides can give a useful approximate

position or prediction of the saw blade in the

workpiece.

SPECIALISED ADJUSTMENTS

Your Evolution machine has many precision

engineered components and settings, most of

which are factory set and adjusted to ensure

consistent long term accuracy.

Maintenance and adjustment to these

components or settings will probably never be

needed. If maintenance or adjustment (after

considerable usage) is thought to be necessary

Evolution recommend that you contact the

technical helpline for further advice and

guidance.

Note: Certain adjustments procedures are

only possible with access to certain specialised

knowledge and/or equipment.

(17) GENERAL CUTTING ADVICE

WARNING: The operator must always be

aware of the position and routing of the power

cable. The cable must be routed in such a way

that there is no possibility of the blade coming

into contact with the mains cable.

28

Page 29

www.evolutionpowertools.com

DE

EN

FR

ES

The cable should not pose a trip (or any

other type) of hazard to the operator or any

bystanders.

• Do not force the machine.

• Allow the speed of the saw blade do the

work. Cutting performance will not be

improved by applying excessive pressure to

the machine and blade life will be reduced.

• When using the parallel edge guide, ensure

that it is parallel with the blade. The blade

and/or motor could become damaged if

the machine is used with an incorrectly

adjusted parallel edge guide.

• Place front edge of sole plate squarely on

the workpiece. Before starting the motor

ensure that the blade is not in contact with

the workpiece.

• When starting a cut, taking care to

introduce the blade to the material slowly,

so as not to damage blade teeth.

Note: Two (2) line of cut guides are provided

at the front of the sole plate of the CCSL

machine (for 0˚ and 45˚ bevel angles only).

• Use both hands to move the saw forwards

through the work piece.

• Apply smooth, constant pressure to move

the saw forwards through the workpiece.

Note: All CCS series machines have an

automatic lower blade guard which has a

specially shaped leading front edge. This

feature ensures that the blade guard retracts

smoothly and eortlessly as the machines

blade enters the workpiece. As the blade exits

the workpiece the lower blade guard will

automatically return to its normal position

covering the blade completely.

Note: On some occasions e.g. making a

plunge cut into a oor or wall etc. it may be

advantageous to retract the lower blade

guard manually.

A thumb operated lever is provided on

the lower blade guard. With care, a skilled

operator can retract the blade guard

manually, either partially or fully, allowing

plunge cuts to be made.

WARNING: If retracting the blade guard

manually great care must be taken to ensure

that the operators hand or ngers do not

touch any part of the machines blade.

When a cut has been completed:

• Release the ON/OFF Trigger switch.

• Allow the blade to come to a

complete stop.

• Remove the machine from the workpiece

allowing the lower blade guard to return to

its normal position covering the blade.

WARNING: If the motor should stop or stall

whilst a cut is being attempted release the

trigger switch immediately. Disconnect the

machine from the power supply and remove

the machine from the workpiece. Investigate

the cause of the problem and rectify if possible.

Only attempt to restar t the motor when you

are absolutely sure that it is safe to do so.

CUT MATERIAL EJECTION PORT

WARNING: Do not use the dust bag and dust

port adaptor when cutting metallic materials

including wood with nails.

(18) MAINTENANCE & ADJUSTMENTS

The 0˚ (blade vertical) position can be adjusted.

WARNING: The machine must be

disconnected from the mains power supply

when attempting this procedure.

To check 0˚

• Set the blade to the 0˚ position with the

• Check the blade against the sole plate

Note: The lower blade guard should be rotated

(manually) up into the upper blade guard. This

will help accurate positioning of the engineers

square and thus aid the checking process.

If adjustment is required:

position:

tilting mechanism against its stop.

using an engineers precision square (not

supplied). Take care to avoid the TCT tips of

the teeth. The blade should be at exactly 90˚

to sole plate.

29

Page 30

www.evolutionpowertools.com

R165CCSL & 185CCS

Turn the adjustment screw (Fig. 31) clockwise

or counter clockwise using a 4mm Hex Key

(not supplied) until the blade is at exactly 90˚

to the sole plate.

R185CCSX & 185CCSX+

Turn the adjustment screws (Fig. 32) clockwise

or counter clockwise using a 3mm Hex Key

(not supplied) until the blade is at exactly 90˚

to the sole plate.

To check 45˚ position (R185CCSX & 185CCSX+ ):

• Set the blade to the 45˚ position with the

tilting mechanism against its stop.

• Check the blade against the sole plate

using an engineers precision square (not

supplied). Take care to avoid the TCT tips of

the teeth. The blade should be at exactly 45˚

to sole plate.

Turn the adjustment screws (Fig. 33) clockwise

or counter clockwise using a 3mm Hex Key

(not supplied) until the blade is at exactly 45˚

to the sole plate.

(19) CHECKING AND REPLACING

THE CARBON BRUSHES

WARNING: Disconnect the machine from the

power supply before attempting to check or

replace the Carbon Brushes.

Note: Replace both carbon brushes if either

has less than 6mm length of carbon remaining,

or if the spring or wire is damaged or burned.

To remove the brushes:

• Unscrew the plastic caps found at the back

of the motor housing. (Fig. 34) Be careful as

the caps are spring-loaded.

• Withdraw the brushes with their springs.

• If replacement is necessary renew the

brushes and replace the caps.

• Run machines motor without load for

approximately 5 minutes. This will help the

new brushes to ‘bed-in’ and ensure that the

motor runs efficiently.

• Some sparking may be visible until the

brushes bed in fully.

(20) GENERAL MAINTENANCE

& CLEANING

Note: All maintenance must be carried

out with the machine switched off and

disconnected from the power supply.

• Check that all safety features and guards are

operating correctly on a regular basis. Only

use this machine if all guards/safety features

are fully operational.

• All motor bearings in these machines are

lubricated for life. No further lubrication is

required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

Remove any dust or other contaminants from

the lens cover of the LED module.

WARNING: Do not attempt to clean by

inserting pointed objects through openings

in the machines casings etc. The machines air

vents should be cleaned using compressed

dry air.

Note: The operator should employ all

necessary PPE when using compressed dry air

as a cleaning medium.

(21) ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

Note: Used but serviceable brushes can be

replaced, but only as long as they are returned

to the same position, and

inserted the same way round as they were

before being removed from the machine.

30

Page 31

www.evolutionpowertools.com

DE

EN

FR

ES

EC DECLARATION OF CONFORMITY

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2014/30/EU. Electromagnetic Compatibility Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive.

2012/19/EU. The Waste Electrical and Electronic Equipment (WEEE) Directive.

And is in conformity with the applicable requirements of the following documents:

EN 62841-1: 2015 • EN 62841-2-5: 2014 • EN 55014-1: 2017 • EN 55014-2: 2015

EN 61000-3-2: 2014 • EN 61000-3-3: 2013 (110V models) • EN 61000-3-11: 2000 (220-240V

models) • IEC 62321-1.0: 2008

Product Details

Description: R165CCSL 165mm (6-1/2”) Circular Saw

Model No: 0260001 / 0260002 / 0260003

Description: R185CCS 185mm (7-1/4”) Circular Saw

Model No: 0270001C / 0270002C /

Description: R185CCSX 185mm (7-1/4”) Circular Saw

Model No: 0270001 / 0270002 / 0270003

Description: R185CCSX+ 185mm (7-1/4”) Circular Saw

Model No: 0270001A / 0270002A /

Brand Name: EVOLUTION POWER TOOLS LIMITED

Voltages: 110V / 220-240V ~ 50Hz

Input: R165CCSL - 1200W

R185CCS, R185CCSX & R185CCSX+ - 1600W

0270003C

0270003A

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Barry Bloomer

Supply Chain & Procurement Director

Date: 01/06/18

31

Page 32

AUS

Total Tools (Importing) Pty Ltd

20 Thackray Road

Port Melbourne

Vic 3207

EU

Evolution Power Tools SAS

61 Avenue Lafontaine

33560, Carbon-Blanc

Bordeaux

T: 03 9261 1900

UK

Evolution Power Tools Ltd

Venture One, Longacre Close

Holbrook Industrial Estate

Sheffield, S20 3FR

T: +44 (0)114 251 1022

T: +33 (0)5 57 30 61 89

USA

Evolution Power Tools LLC

8363 Research Drive

Davenport, IA

52806

T: 866-EVO-TOOL

EPT QR CODE

027-9201.1 - V3

Loading...

Loading...