Page 1

DISCONTINUED

®

IQ plus

800/810

Digital Weight Indicators

Version 3.1

Installation Manual

42100

Page 2

DISCONTINUED

Page 3

DISCONTINUED

Contents

About this Manual.................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Optional Features ............................................................................................................................... 2

1.2 Front Panel Keys and Annunciators.................................................................................................... 3

2.0 Installation................................................................................................................................... 6

2.1 Power Connections ............................................................................................................................ 6

2.2 Board Connections............................................................................................................................. 6

2.3 Board Diagrams ................................................................................................................................. 8

2.4 Load Cell Wiring ................................................................................................................................. 8

2.5 Serial Communications Wiring ............................................................................................................ 9

2.6 Digital I/O Wiring................................................................................................................................. 9

2.7 Wall- and Panel-Mounting................................................................................................................. 10

2.7.1 IQ plus 810 Panel Mount Kit..................................................................................................................... 10

2.7.2 IQ plus 810 Wall Mount Kit....................................................................................................................... 11

2.7.3 IQ plus 810 SS and HE Model Wall Mounting........................................................................................... 11

2.7.4 IQ plus 800 Panel Mount Kit..................................................................................................................... 12

2.8 Battery Replacement ........................................................................................................................ 12

3.0 Configuration.............................................................................................................................. 13

3.1 Configuration Methods ..................................................................................................................... 13

3.1.1 Revolution Configuration .......................................................................................................................... 13

3.1.2 EDP Command Configuration .................................................................................................................. 14

3.1.3 Front Panel Configuration......................................................................................................................... 14

3.2 Menu Structures and Parameter Descriptions................................................................................... 15

3.2.1 Configuration Menu.................................................................................................................................. 15

3.2.2 Set Analog Menu...................................................................................................................................... 19

3.2.3 Format Menu............................................................................................................................................ 20

3.2.4 Setpoints Menu........................................................................................................................................ 23

3.2.5 Serial Menu.............................................................................................................................................. 30

3.2.6 Print Format Menu ................................................................................................................................... 33

3.2.7 Digital Input Menu .................................................................................................................................... 34

3.2.8 Analog Output Menu................................................................................................................................ 35

3.2.9 Bar Graph Menu ...................................................................................................................................... 36

3.2.10 Calibration Menu..................................................................................................................................... 37

3.2.11 Version Menu.......................................................................................................................................... 37

4.0 Calibration.................................................................................................................................. 38

4.1 Front Panel Calibration...................................................................................................................... 38

4.2 EDP Command Calibration............................................................................................................... 40

4.3 Revolution

4.4 Adjusting Final Calibration................................................................................................................. 40

5.0 Operating Modes........................................................................................................................ 41

5.1 Setup Mode ..................................................................................................................................... 41

5.2 Normal Mode ................................................................................................................................... 41

5.2.1 Push-Button Tares................................................................................................................................... 41

5.2.2 Keyed Tares............................................................................................................................................. 41

™

Calibration.................................................................................................................... 40

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.rlws.com or obtained by

Copyright © 2002 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

calling 715-234-9171 and asking for the training department.

Specifications subject to change without notice.

Version 3.1, November 2002

Page 4

ii

DISCONTINUED

5.3 Truck Modes.................................................................................................................................... 41

5.3.1 Using the Truck Modes ............................................................................................................................ 42

5.3.2 Single-Transaction Tare Weights and IDs ................................................................................................. 43

5.3.3 Multiple Scales......................................................................................................................................... 43

5.4 Individual Scale Setup....................................................................................................................... 43

5.5 Using the TOTAL Channel ................................................................................................................ 43

6.0 EDP Commands.......................................................................................................................... 45

6.1 The EDP Command Set ................................................................................................................... 45

6.1.1 Key Press Commands.............................................................................................................................. 45

6.1.2 Reporting Commands.............................................................................................................................. 46

6.1.3 Special Function Commands.................................................................................................................... 46

6.1.4 Parameter Setting Commands ................................................................................................................. 46

6.1.5 Transmit Weight Data Commands............................................................................................................ 50

6.1.6 Batching Control Commands................................................................................................................... 50

6.2 Saving and Transferring Data............................................................................................................ 52

6.2.1 Printing Configuration and Setpoint Data.................................................................................................. 52

6.2.2 Saving Indicator Data to a Personal Computer ......................................................................................... 52

6.2.3 Downloading Configuration Data from PC to Indicator.............................................................................. 53

6.2.4 Transferring Configuration Data from One Indicator to Another................................................................. 53

7.0 Print Formatting......................................................................................................................... 54

7.1 Customizing Print Formats................................................................................................................ 54

7.1.1 Using the EDP Port .................................................................................................................................. 54

7.1.2 Using the Front Panel............................................................................................................................... 55

7.1.3 Using Revolution...................................................................................................................................... 55

7.2 Ticket Formats.................................................................................................................................. 56

7.2.1 Gross/Net Demand Ticket Format............................................................................................................ 56

7.2.2 Truck Weigh-in and Weigh-out Tickets..................................................................................................... 57

7.2.3 Setpoint Push Print Ticket ........................................................................................................................ 57

7.3 Extended Print Format Commands................................................................................................... 58

7.4 Resetting ID, Consecutive Number, and Accumulator Values for Print Commands........................... 58

8.0 Setpoints and Batch Processing................................................................................................ 59

8.1 Using Continuous Setpoints ............................................................................................................. 61

8.2 Using Batch Setpoints...................................................................................................................... 61

8.3 Front Panel Preact Value Access...................................................................................................... 62

8.4 Setpoint Names................................................................................................................................ 62

8.4.1 Defining Setpoint Names.......................................................................................................................... 63

8.4.2 Assigning Names to Setpoints.................................................................................................................. 63

9.0 Optional and Advanced Features............................................................................................... 64

9.1 Accumulate Function ........................................................................................................................ 64

9.1.1 Front Panel Access .................................................................................................................................. 64

9.1.2 Setpoint Access....................................................................................................................................... 65

9.2 Rate of Change Function.................................................................................................................. 65

9.3 Peak Hold Function.......................................................................................................................... 66

9.4 Passwords ....................................................................................................................................... 67

9.5 Supervisor Setup Switch................................................................................................................... 67

9.6 Batching Switch ............................................................................................................................... 68

9.7 Bar Graph......................................................................................................................................... 69

9.8 Expanded Serial Communications.................................................................................................... 71

9.8.1 Duplex 20 mA Current Loop..................................................................................................................... 71

9.8.2 RS-485 Communications......................................................................................................................... 71

9.9 IQ plus 810 Expansion Board........................................................................................................... 71

9.10 Remote Keyboard........................................................................................................................... 73

9.11 Analog Output................................................................................................................................. 73

9.12 Multiple Scale Inputs....................................................................................................................... 76

9.13 2- and 4-Channel Relay Boards (IQ plus 800).................................................................................. 76

IQ plus 800/810 Installation Manual

Page 5

DISCONTINUED

9.13.1 2-Channel Relay Board............................................................................................................................ 77

9.13.2 4-Channel Relay Board............................................................................................................................ 77

9.14 Setpoint Digital Output Expander.................................................................................................... 78

9.15 IQ plus 810 4- and 16-Channel Relay Racks................................................................................... 79

9.16 Jetpak™ High Speed Option.......................................................................................................... 82

9.17 Allen-Bradley Remote I/O Interface ................................................................................................. 83

9.18 Profibus Indicator Interface ............................................................................................................. 83

9.19 Dual Range Option ......................................................................................................................... 83

10.0 Appendix.................................................................................................................................... 84

10.1 Error Messages............................................................................................................................... 84

10.2 ASCII Character Chart .................................................................................................................... 85

10.3 Data Formats.................................................................................................................................. 87

10.3.1 Continuous Output Serial Data Format..................................................................................................... 87

10.3.2 Demand Output Serial Data Format......................................................................................................... 87

10.3.3 RS-485 Data Formats.............................................................................................................................. 87

10.4 Conversion Factors for Secondary Units......................................................................................... 88

10.5 Filtering........................................................................................................................................... 89

10.5.1 Analog Filtering........................................................................................................................................ 89

10.5.2 Digital Filtering ......................................................................................................................................... 89

10.6 Software Revision History ............................................................................................................... 90

10.7 Specifications ................................................................................................................................. 91

IQ plus 800/810 Limited Warranty......................................................................................................... 93

iii

Page 6

iv

DISCONTINUED

IQ plus 800/810 Installation Manual

Page 7

About this Manual

DISCONTINUED

This manual is intended for use by service technicians

responsible for installing and servicing the IQ plus

800/810 digital weight indicators. This manual applies

to Version 3.1 software for the IQ plus 800/810

indicators. See Section 10.6 on page 90 for a summary

of software changes included in Version 3.1.

This manual is organized so that you can learn about

the basic installation and standard operations first,

then find more detailed information about specific

optional features in later sections.

The configuration menu charts include parameter

choices for both the standard and optional features.

When configuring the IQ plus 800 or 810, you can

ignore the settings for parameters dealing with options

not installed on your indicator; settings chosen for

non-installed options are ignored.

Warning

Most procedures described in this

manual require work inside the indicator

enclosure. These procedures are to be

performed by qualified service

personnel only.

Authorized distributors and their

employees can view or download this

manual from the Rice Lake Weighing

Systems distributor site at

www.rlws.com

®

more information.

.

Warning

The digital output of continuous setpoints using the

TRIP parameter with INBAND or OUTBAND specified

is reversed in this release. Existing setpoints using

these values must be redefined for use with Version

3.1.

When the indicator is placed in setup mode:

•Analog outputs are set off (0 VDC or 0 mA)

•Batching stops automatically

When the indicator is returned to operating mode, the

interrupted batch must be manually restarted.

The BATSTRT digital input no longer requires an

active BATRUN digital input to start and run a

batch sequence. If no digital input is assigned to

BATRUN, batching proceeds as if BATRUN were

always on. See Section 3.2.7 on page 34 for

If you are upgrading to Version 3.1 or are

familiar with prior releases of the IQ plus

800/810 software, please note the

following changes before using the

software:

1.0 Introduction

For basic weighing applications, the IQ plus 800 and

IQ plus 810 have more useful standard features than

any other digital indicator currently available. For

more complex weighing applications, the IQ plus 800/

810 series indicators are expandable, programmable,

process controllers with an impressive array of

options.

The economical IQ plus 800 indicator is available in a

compact stainless steel enclosure. It carries all the

features of the standard IQ plus 800/810 indicators,

but its compact enclosure size will not accept all the

expansion options of the larger 810 enclosures.

The IQ plus 810 is available in desktop, stainless steel

batching (SS), and hostile environment batching (HE)

models. The 800 and all 810 models are

NTEP-certified for Class III and Class IIIL at 10,000

divisions. The 800 stainless steel, 810 SS and HE

models are certified for NEMA 4X washdown

applications.

Introduction

1

Page 8

2

DISCONTINUED

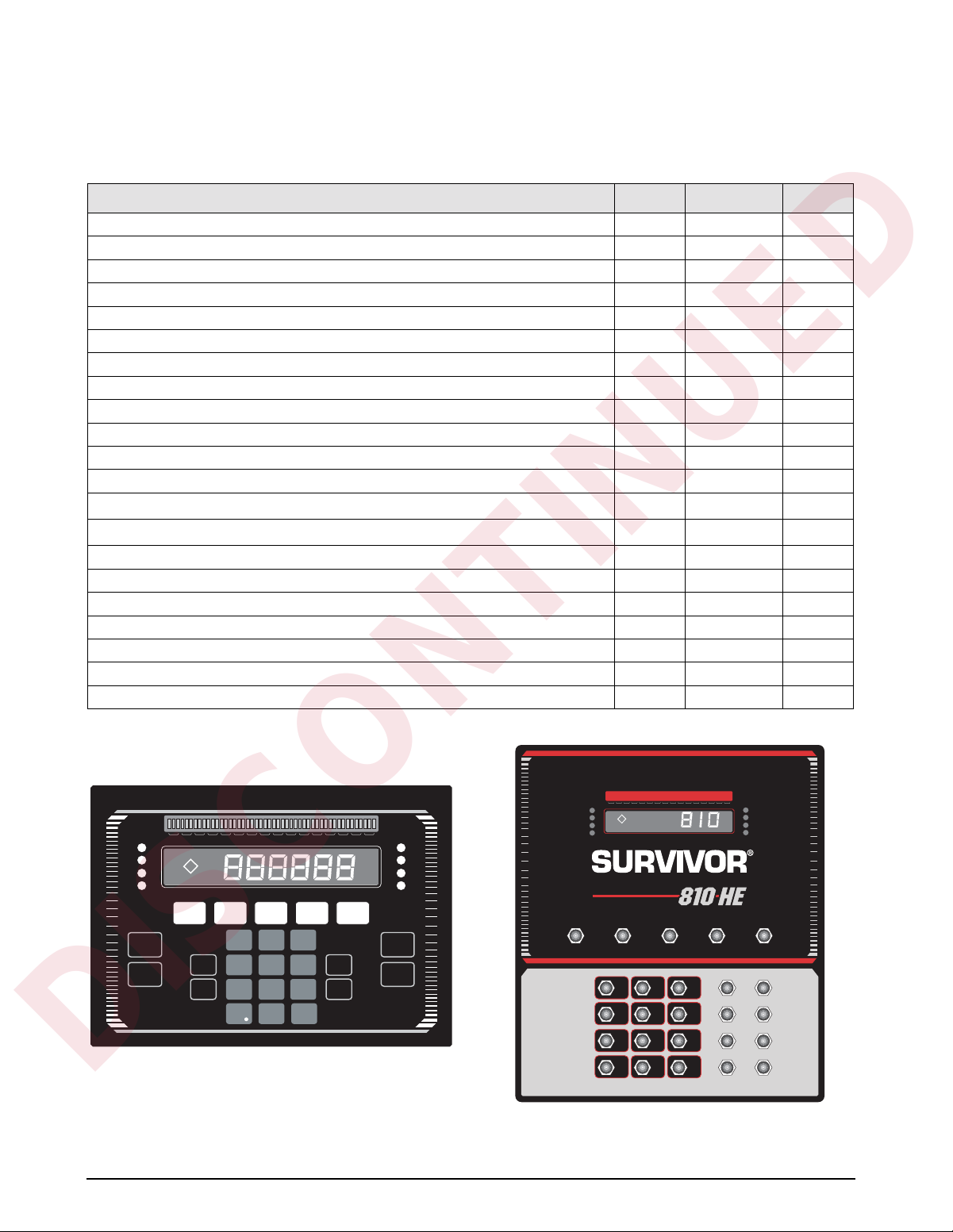

1.1 Optional Features

Table 1-1 lists some of the optional features available for the IQ plus 800/810 indicators, including references to

pages in this manual for more information. See page 10 for information about wall- and panel-mounting options.

Option

Option PN Model See Page

Rate of Change Function 19359 All 65

Peak Hold Function 19360 All 66

Passwords 30547 All 67

Supervisor Setup Switch 19375 All 67

Batching Switch 19369 All 68

Bar Graph 19363 All 69

Duplex 20 mA Current Loop 19374 All 71

RS-485 Communications 19372 All 71

Dual Channel Load Cell Expansion Board for 800/810 desktop model 40386 800/810 71

Dual-Channel Load Cell Expansion Board for wall mount models) 67595 810 HE/SS 71

Remote Keyboard Input Expansion Board 40385 800/810 73

Analog Output 19357 All 73

2-Channel Relay Rack (Internal) 30549

4-Channel Relay Rack (Internal) 36080

800

800

77

77

Setpoint Digital Output Expansion Board 19362 All 78

4-Channel Relay Rack (External) 19365 All 79

16-Channel Relay Rack (External) 19373 All 79

Jetpak™ High Speed Option various All 82

Allen Bradley Remote I/O Interface (External) 35888 All 83

Profibus Interface (External) 49974 All 83

Dual Range Option 61138 All 83

Table 1-1. IQ plus 800/810 Optional Features

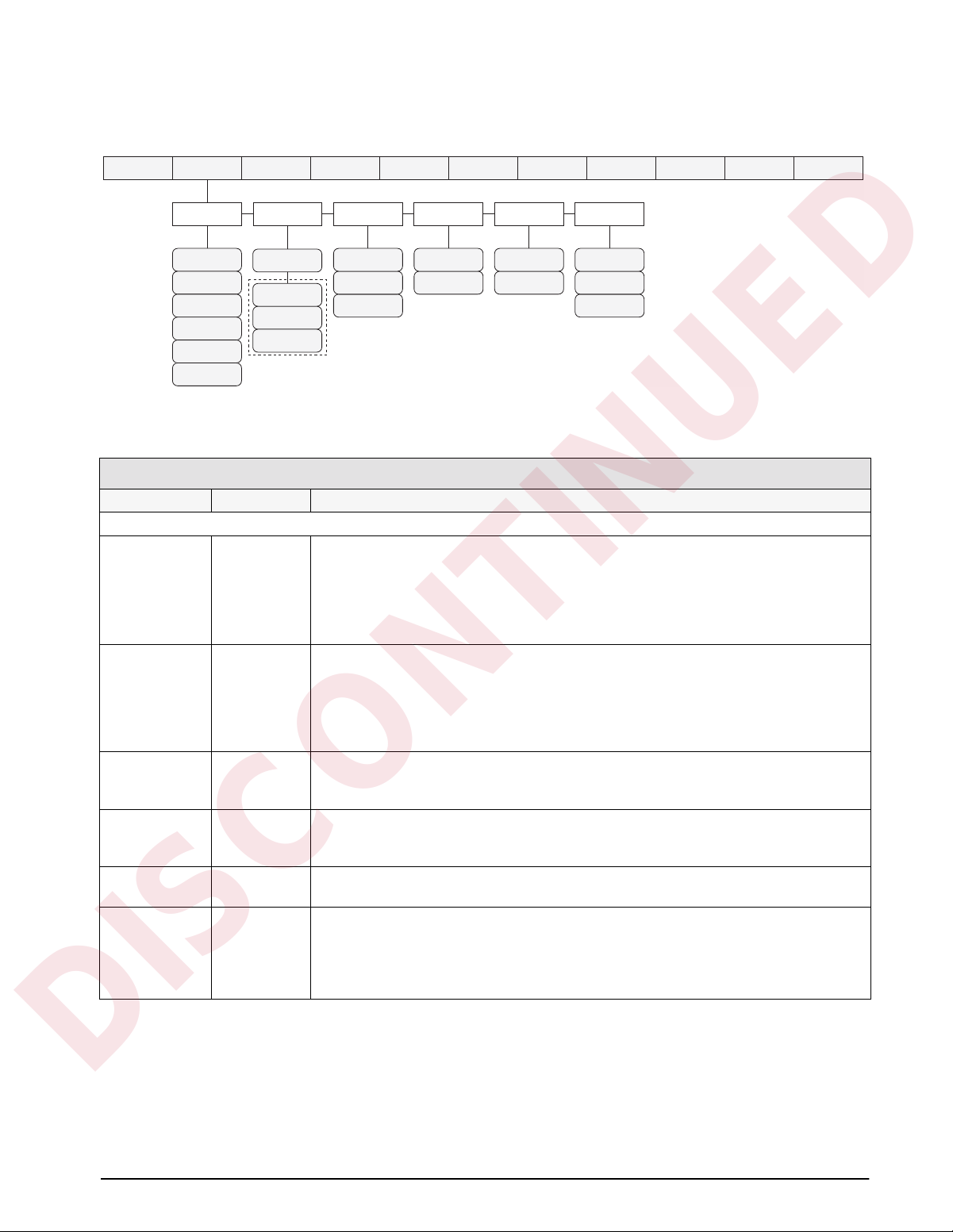

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Lb

Kg

ROC

Accum

ZERO PRINTUNITSTAREG/N

DISP

TARE

TIME/

DATE

ACCUM

DISP

ROC

123

DISP

456

789

0

ENTER

SCALE

NEW

I.D.

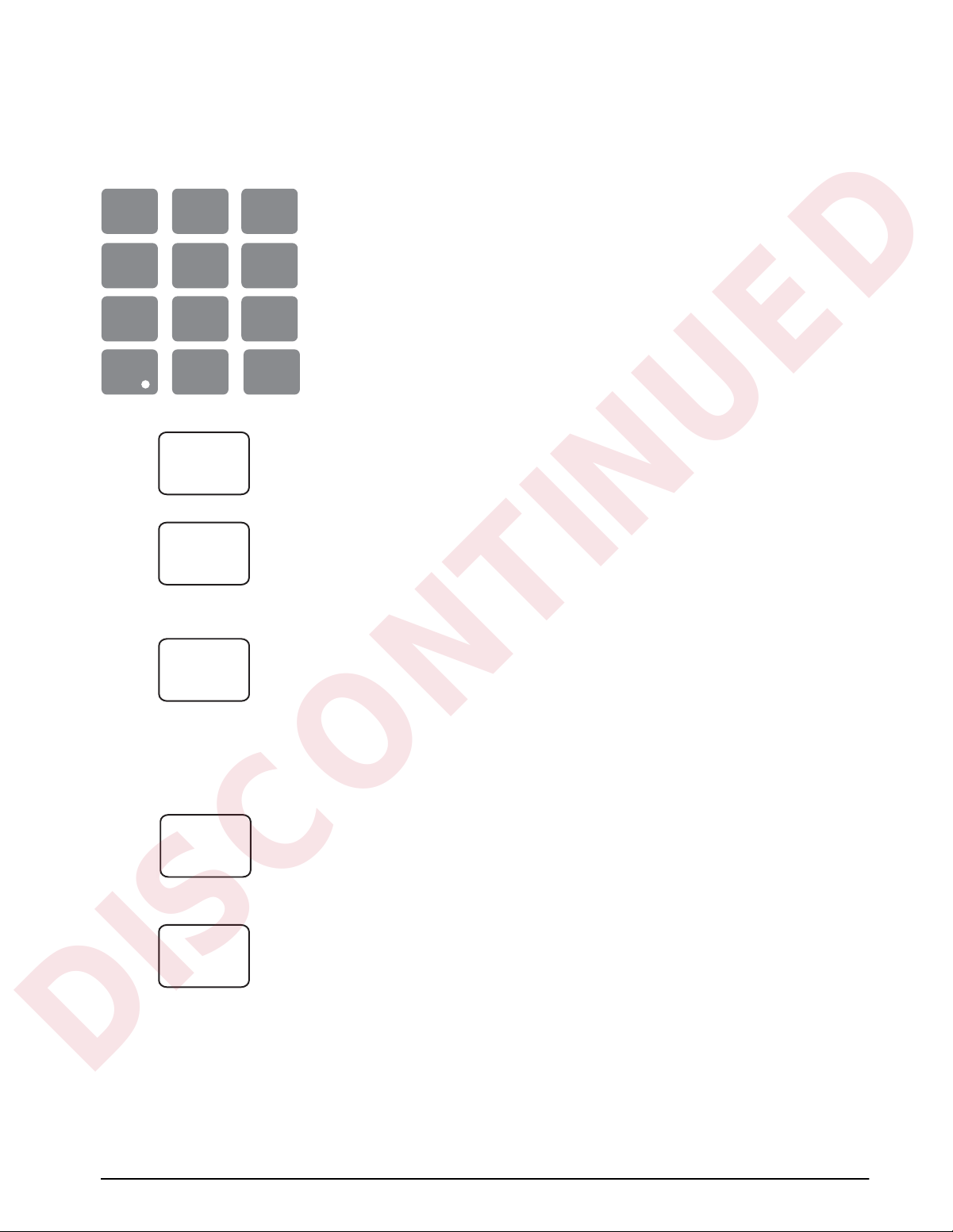

Figure 1-1. IQ plus 800/810 Front Panel

Lb

Kg

ROC

Scale 1

Scale 2

Scale 3

Scale 4

SET

POINT

CLEAR

#

ACCUM

ZERO GROSS/NET TARE UNITS PRINT

123

456

789

•

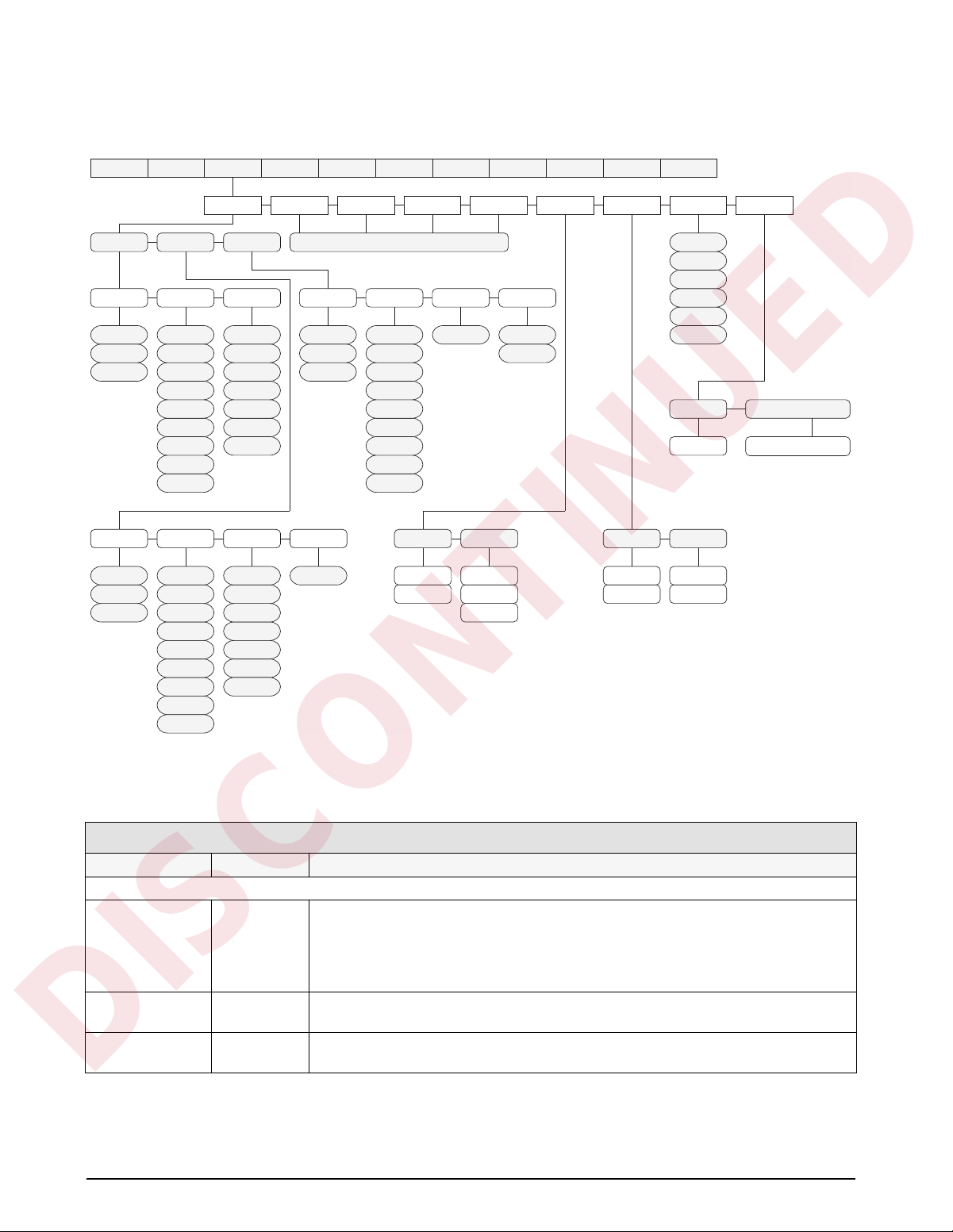

10 11 12 13 14 15 163 4 5 6 7 8 91 2

ENTER

0

SCALE 1

SCALE 2

SCALE 3

SCALE 4

NEW I.D.DISP ACCUM

SCALE #DISP R.O.C.

SET POINTDISP TARE

CLEARTIME/DATE

Figure 1-2. IQ plus 810 HE Front Panel

IQ plus 800/810 Installation Manual

Page 9

DISCONTINUED

1.2 Front Panel Keys and Annunciators

The following section describes the front panel keys, annunciators, and display functions of the IQ plus 800/810

indicators.

Numeric keypad

123

456

789

0

ZERO

ENTER

The numeric keypad is used to enter numeric values, such as tare weights and ID

numbers. Normally, you key a number, and then press

key. Each digit appears on the display screen as entered. If you key a number and

don’t press

reverts to the previous mode and the number is ignored.

If you make a mistake entering a number, press

Continue pressing

If you key a number and press

and the display returns to normal mode.

ZERO

Resets the scale gross weight to zero. The

scale is in motion or when the displayed weight value is outside of the

configured zero range.

ENTER

and/or a function key within several seconds, the display

CLEAR

to erase the remaining digits as necessary.

G/N

before pressing

ZERO

ENTER

CLEAR

ENTER

key cannot be used when the

and/or a function

to erase a single digit.

, the number is erased

G/N

TARE

UNITS

PRINT

G/N

Toggles between Gross and Net display modes. In Net mode, the display shows

NET

net weight and the

gross weight and the

Also, you can use

TARE

Captures the current gross weight as a tare value and switches to net mode. The

gross weight must be positive and the scale at standstill to perform a tare

operation.

Tare values can also be entered using the numeric keypad, then pressing

or by sending commands to the EDP port

The

T

and rhombus appear on the display when a tare is in the system. The

and rhombus indicates a manually entered (keyed) tare.

UNITS

Toggles the display between the primary and secondary units. Although the

standard label shows pounds and kilograms, other units can be defined in the

configuration menus. See the description of the LED annunciators on page 5 for

more information.

PRINT

In normal mode and with the scale at standstill, pressing the

data to the serial port. See Section 7.0 on page 54 for information about creating

custom print formats.

annunciator lights. In Gross mode, the display shows

G

annunciator lights.

G/N

to revert to normal weighing mode if in another mode.

PRINT

TARE

pT

key sends

,

Introduction

3

Page 10

DISP

DISCONTINUED

TARE

TIME/

DA TE

DISP

ACCUM

4

DISP TARE

In the normal weighing mode,

CLEAR

T

annunciator.

CLEAR

ENTER

, the display prompts

any, and lights the

In the truck in/out mode, key in a truck ID number and press

NO ID

appears on the display. If the ID is found, press

value. If you press

truck ID.

In the Truck In/Out mode, press

TIME/DATE

Press once to display the date, press again to display the time.

You can enter new values for the date and time while they appear in the display by typing the

new value and pressing

DISP ACCUM

Displays the current weight from the accumulator register and sequentially lights the

accumulator annunciators. Press repeatedly to scroll through all five accumulators or enter an

accumulator number (0–4) and press

If you press

register.

DISP TARE

, the display prompts

DISP TARE

. Use the 24-hour format to enter time values.

displays the current weight in the tare register, if

DISP TARE

ENTER

CLR ID?

repeatedly to scroll through the stored IDs.

DISP ACCUM

CLR AC?.

.

Press

; press

CLEAR

to display the stored weight

CLEAR

again to clear the accumulate

. If the ID is not found,

again to clear the stored

DISP

ROC

NEW

I.D.

SCALE

#

DISP ROC

Displays the rate of change for weight data on the current scale channel. The ROC value is

expressed as the change in weight during a specific period of time, such as lb/min or Kg/hour.

The

DISP ROC

annunciator lights when the rate of change feature is active.

NEW ID

In the truck in/out mode,

the numeric keys and press

to enter the new ID number, save the tare, and print a weigh-in ticket, all in one step. Also, you

can use

See Section 5.3 on page 41 for information about using the truck modes.

SCALE #

Selects an individual scale channel or total channel for display.

The scale number LED annunciator lights to show which scale weight is displayed. If sources

are totaled, more than one LED is lit. The

channel is enabled and selected.

NEW ID to enter an ID number not associated with the truck program or weight storage.

key functions only if the rate of change feature is installed; the ROC

NEW ID

lets you enter a new truck ID number. Key in a number with

NEW ID to save. When a truck is on the scale, you can use NEW ID

SCALE # key functions only if more than one input

IQ plus 800/810 Installation Manual

Page 11

SET

DISCONTINUED

POINT

CLEAR

SETPOINT

Press to show defined setpoint values. When you first press this key, the display shows

two seconds, then switches to show the setpoint value. Each time you press

next defined setpoint is shown.

You can change the setpoint value by keying in a number and pressing

setpoint, press

NOTE: In Version 3.1, you can reactivate setpoints that have been turned off at the front panel.

Press the

setpoint back on.

If you make an error when keying in a value, press

to normal mode, press

You can use the

normal mode. See Section 8.3 on page 62 for more information using the

access preact values.

See Section 8.4 on page 62 for more information about naming setpoints.

CLEAR

Erases digits entered from the keyboard or clears special function values.

• In the

• In the

to display the prompt CLR ACn (where n is the accumulator number, 0–4). Press CLEAR a

second time to clear the accumulator.

• In the

the prompt CLR TR?. Press CLEAR a second time to clear the tare register.

• In the

values.

CLEAR. The message OFF appears on the display for disabled setpoints.

SETPOINT key to show the OFF status for the setpoint, then press ENTER to turn the

CLEAR to erase individual digits. To return

G/N or wait for the display to switch back.

SETPOINT key to view or change preact v alues from the front panel during the

SETPOINT function, CLEAR disables setpoints or erases individual digits.

DISP ACCUM function, with the current accumulator value displayed, press CLEAR

DISP TARE function with the current tare value displayed, press CLEAR to display

DISP TARE function (truck in/out mode), CLEAR erases truck IDs, as well as tare

SETPOINT, the

ENTER. To turn off a

SETPOINT key to

SP 1 for

Lb

Kg

ROC

Accum

Scale 1

Scale 2

Scale 3

Scale 4

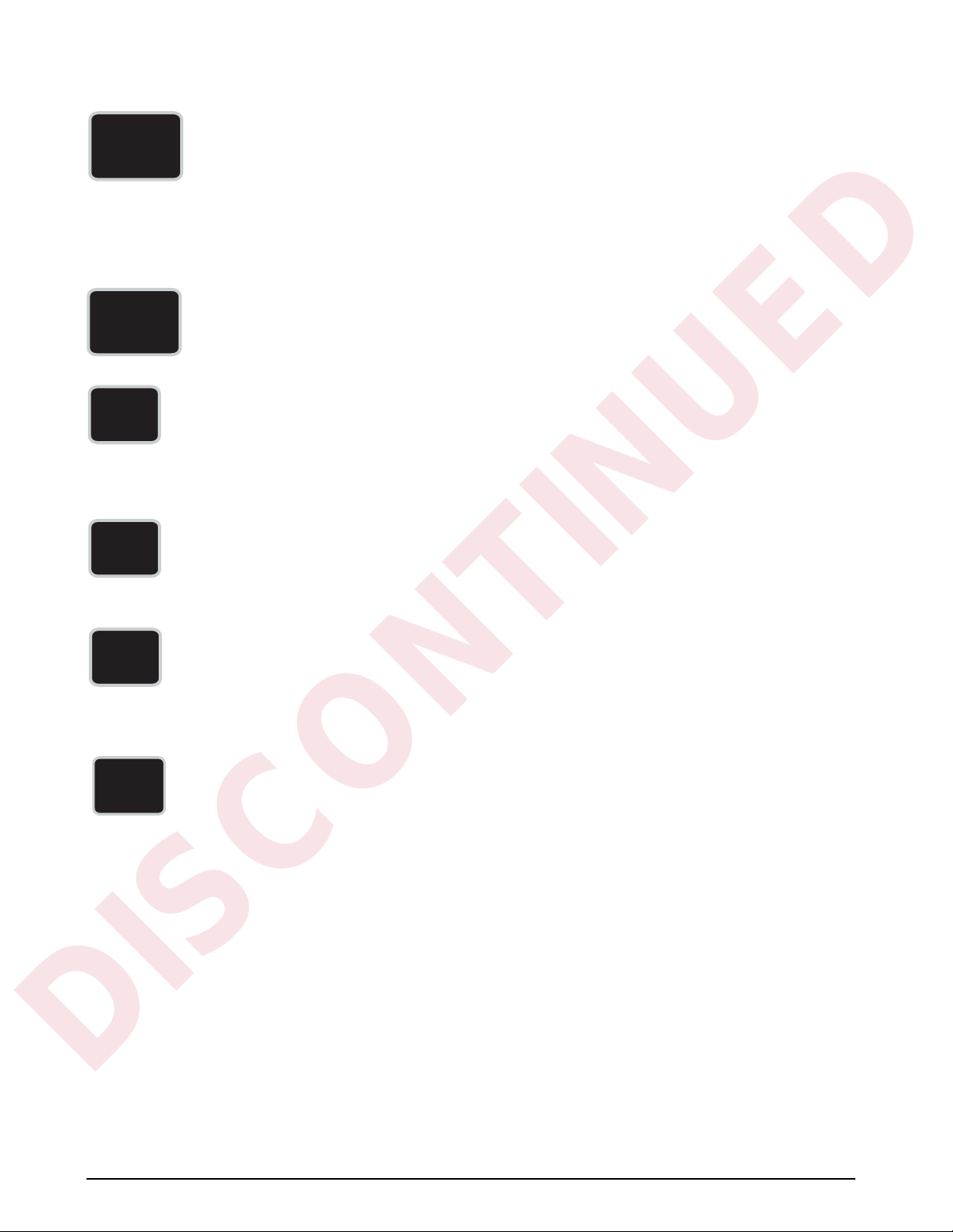

LED Annunciators

The LED annunciators provide status information about the indicator.

The LEDs on the left side of the display indicate the display units and whether the value

displayed is a rate of change or accumulator value. The Lb and Kg (Units) LEDs function as

follows:

• If the displayed weight is in pounds, the Lb LED is lit; if kilograms, the Kg LED is lit.

• If the primary unit of weight is pounds, the Kg LED is lit for secondary units—or, if the

primary unit is kilograms, the Lb LED is lit for secondary units, unless the secondary unit

of weight is the same as the primary unit.

• If neither primary nor secondary units are pounds or kilograms, the Lb LED is used as a

primary units annunciator and the Kg LED is used as the secondary units annunciator.

See the descriptions of the

The scale channel LEDs on the right side of the display indicate which scale weight is

displayed. See the description of the

UNITS, DISP ROC, and DISP ACCUM keys for more information.

SCALE # key for more information.

Introduction 5

Page 12

2.0 Installation

DISCONTINUED

2.1 Power Connections

The IQ plus 800/810 can operate from either a 115

VAC or 230 VAC 3-wire power supply line at 50 or 60

Hz. It is further recommended that the 800/810 be

connected to an AC power supply that is on a separate

branch or feeder from other AC equipment that causes

step-load changes and/or other AC line disturbances.

The transformer on the power supply/display board is

pre-wired at the factory for 115 VAC operation. If the

installation requires 230 VAC operation, move the

transformer connector from J5 to J9 on the power

supply/display board. Also, be sure to install the

correct fuse. See Section 10.7 on page 91 for

specifications

SERIAL COMM WIRING

J7-1

J7-2

PINS 1–6:

J7-3

PRINTER PORT

J7-4

CONNECTORS

J7-5

J7-6

J7-7

PINS 7–12:

J7-8

EDP PORT

J7-9

CONNECTORS

J7-10

J7-11

J7-12

MAIN

BOARD

DISPLAY

BOARD

TO J10

2.2 Board Connections

The main CPU board is connected to the power

supply/display board by two ribbon cables. The power

ribbon cable connects between J1 on both boards; the

data ribbon cable connects between J2 on both boards.

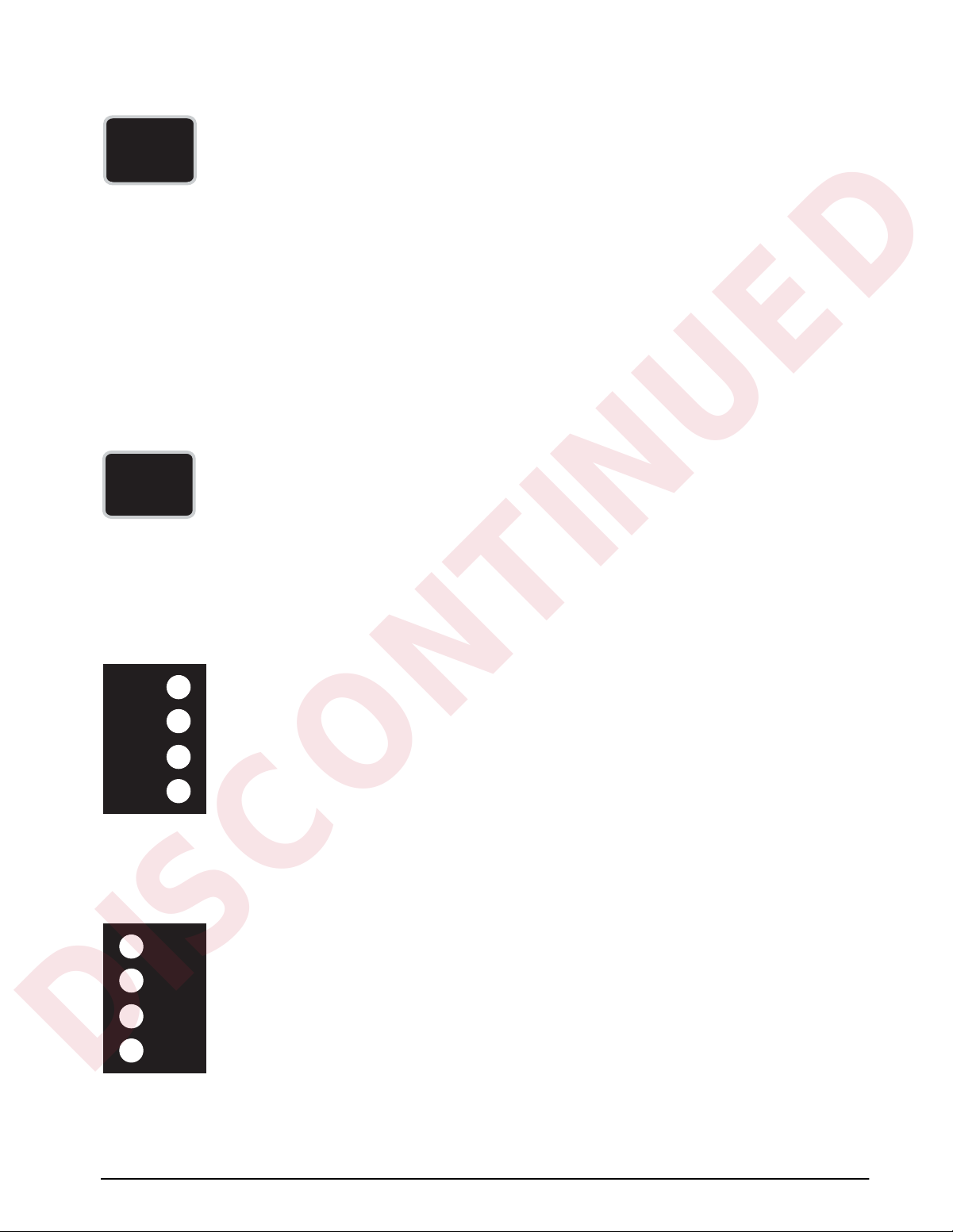

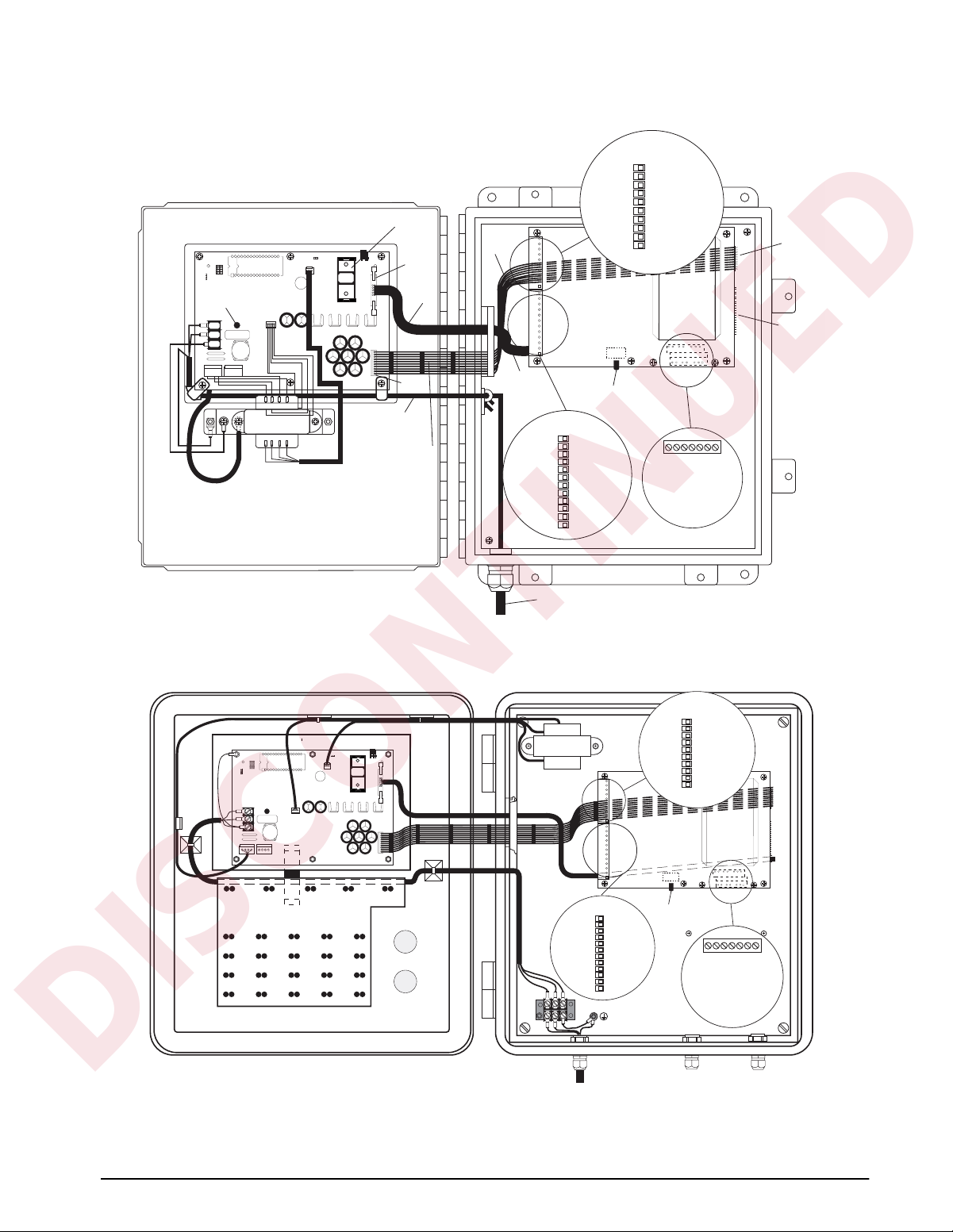

Figures 2-1 through 2-3 show board locations and

cabling for the IQ plus 810, HE, and SS models.

Board locations and cabling for the IQ plus 800 are

essentially the same as for the IQ plus 810.

SETUP

SWITCH

TO J7

J7

TO J4

J4

DIGITAL I/O

DIGITAL I/O WIRING

J4-1 DIG OUT 1

J4-2 DIG OUT 2

J4-3 DIG OUT 3

J4-4 DIG OUT 4

J4-5 DIG IN 3

J4-6 DIG IN 2

J4-7 DIG IN 1

J4-8 GND

J4-9 GND

J4-10 +5 VDC

SERIAL

COMMUNICATIONS

LOAD CELL

GROUND

AC POWER

Figure 2-1. IQ plus 810 Wiring, Side View

SERIAL COMMUNICATIONS

CABLE TO J7

GROUND

LOAD CELL

CABLE TO J10

J10

J10-1 +Sig

J10-2 –Sig

J10-3 +Sense

J10-4 –Sense

J10-5 Shield

J10-6 +Exc

J10-7 –Exc

DIGITAL I/O

CABLE TO J4

SETUP SWITCH

7 6 5 4 3 2 1

Load Cell Wiring

J10

AC POWER

J7

Figure 2-2. IQ plus 810 Wiring, Top View

6 IQ plus 800/810 Installation Manual

Page 13

Power Supply Display Board

DISCONTINUED

Display Driver

Fuse

DIGITAL I/O WIRING

J4-10

+5 VDC

J4-9

GND

J4-8

GND

J4-7

DIG IN 1

J4-6

DIG IN 2

J4-5

DIG IN 3

J4-4

Battery

REMOVE JUMPER

J6

J11 BEFORE

INSTALLING

BATTERY

J2

Data

Cable

Power

Ribbon

Cable

CPU Board A/D Module

J4-3

J4-2

J4-1

DIG OUT 4

DIG OUT 3

DIG OUT 2

DIG OUT 1

J1

J2

AC Power

Cable

Transformer

Power Supply Display Board

Display

Driver

Fuse

J4

Keyboard

AC Power Cable

Power Ribbon Cable

Figure 2-3. IQ plus 810 SS Wiring

REMOVE JUMPER

J6

J11 BEFORE

INSTALLING

BATTERY

Battery

J2

J1

J1

Data

Ribbon

Cable

Power Ribbon

Cable

AC Power

Cable

Pre-drilled holes for

Batching Switch Option

Data

Ribbon

Cable

Power

Ribbon

Cable

SERIAL COMM.

J7-12

J7-11

7-12

J7-10

EDP

J7-9

PORT

J7-8

J7-7

J7-6

1-6

J7-5

PRINTER

J7-4

PORT

J7-3

J7-2

J7-1

AC Power In

Transformer

SERIAL COMM.

J7-12

J7-11

J7-10

J7-9

J7-8

J7-7

J7-6

J7-5

J7-4

J7-3

J7-2

J7-1

Setup Switch

J4

J7

7-12

EDP

PORT

1-6

PRINTER

PORT

1234567

LOAD CELL WIRING

+Sig

1

–Sig

2

+Sense

3

–Sense

4

Shield

5

+Exc

6

–Exc

7

DIGITAL I/O WIRING

J4-10

J4-9

J4-8

J4-7

J4-6

J4-5

J4-4

J4-3

J4-2

J4-1

CPU Board

Setup Switch

+5 VDC

GND

GND

DIG IN 1

DIG IN 2

DIG IN 3

DIG OUT 4

DIG OUT 3

DIG OUT 2

DIG OUT 1

A/D Module

1234567

LOAD CELL WIRING

+Sig

1

–Sig

2

+Sense

3

–Sense

4

Shield

5

+Exc

6

–Exc

7

J1

J2

AC Power In

Figure 2-4. IQ plus 810 HE Wiring

Installation 7

Page 14

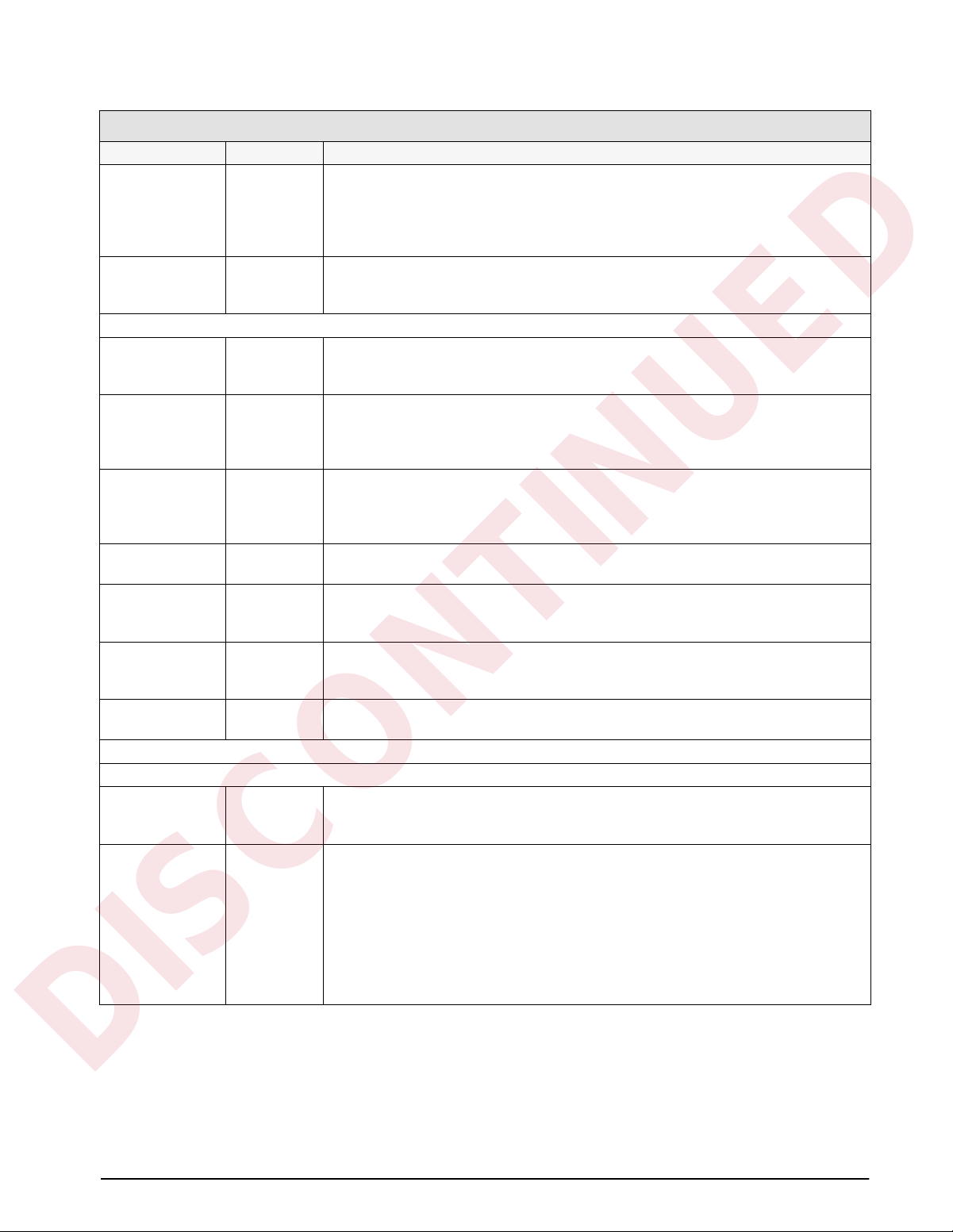

2.3 Board Diagrams

DISCONTINUED

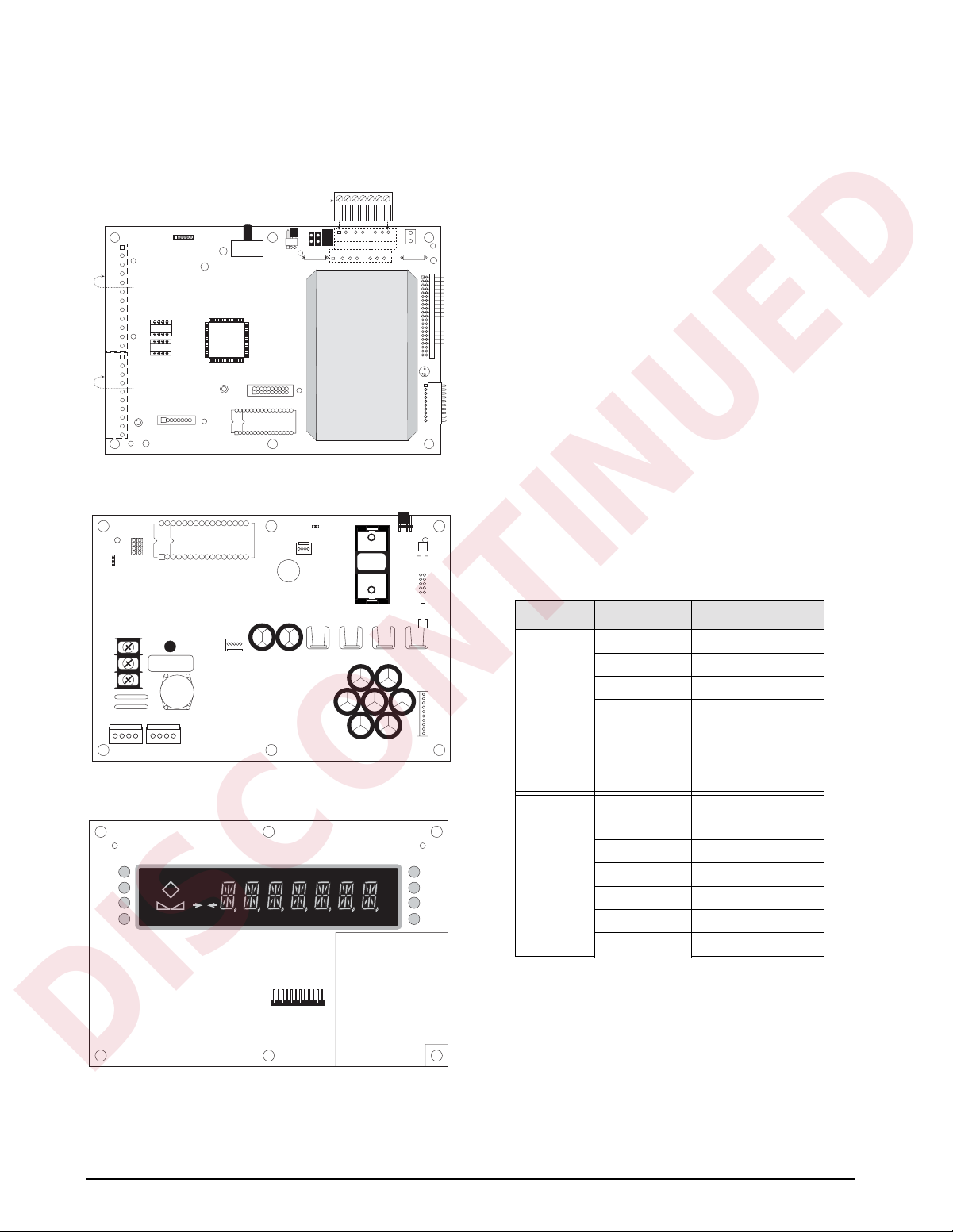

Figures 2-5 through 2-7 show major component

locations on the IQ plus 800/810 circuit boards.

JP1

JP3

J6

1234567

JP2

(1st Load Cell Term)

(2nd Load Cell Term)

A/D Converter

B1

REMOVE JUMPER

J11 BEFORE

INSTALLING

BATTERY

J2

J1

J11

J2

Load Cell Connector

J10

(Terminal Screws on Back)

J9

(Factory Use Only)

(J7) Serial Communications

U22

U24

(J4) Digital I/O Wiring

J5

SW1

J8

J6

EPROM

Figure 2-5. CPU Board, Component Side

J3

J8

EEPROM

2.4 Load Cell Wiring

Wire the analog input cable from the load cell or

junction box to the removable connector and plug into

the CPU board at J10 near the A/D module. If your

indicator was purchased after June 1, 1996, the A/D

module is surface mounted to the CPU board.

Note that earlier indicators (with A/D modules

mounted on standoffs) have J10 pin assignments in

reversed order from those shown in Table 2-1.

For a single-channel A/D module, use the upper

plug-in connector for the load cell. If a dual-channel

A/D module is being used, plug the second load cell

cable into the lower connector at J10.

If using 4-wire load cell cable, leave jumpers JP1 and

JP2 on (these jumpers connect pins 3 and 6, 4 and 7, at

terminal J10). For a 6-wire installation using sense

leads, remove the jumpers.

For dual-channel A/D modules, there are jumper pins

on the board near J10. The sense jumpers are labeled

JP1–JP2 for channel one, and JP3–JP4 for channel

two. Leave the jumpers installed for a 4-wire cable,

remove them for a 6-wire installation.

Table 2-1 shows the J10 pin assignments for load cell

connections.

L

(AC HOT)

N

(AC NEUTRAL)

G

(AC GROUND)

F1 (FUSE)

C32

C34

J9J5

J7

C33

T2

U8U7U6U5

J1

Figure 2-6. Power Supply/Display Board, Component Side

DS6

DS7

DS8

DS9

NET

P

T

BG–

0

J4

DS5

DS4

DS3

DS2

Channel J10 Pin Signal

11+SIGNAL

2 –SIGNAL

3 +SENSE

4 –SENSE

5 SHIELD

6 +EXCITATION

7 –EXCITATION

21+SIGNAL

2 –SIGNAL

3 +SENSE

4 –SENSE

5 SHIELD

6 +EXCITATION

7 –EXCITATION

Table 2-1. J10 Pin Assignments (Load Cells)

Figure 2-7. Power Supply/Display Board, Display Side

8 IQ plus 800/810 Installation Manual

Page 15

2.5 Serial Communications Wiring

DISCONTINUED

Terminal block J7 on the CPU board connects both the

EDP (Electronic Data Processing) port and the printer

port. See Section 3.2.5 on page 30 for information

about configuring the serial ports.

The EDP port supports full-duplex RS-232 or simplex

20 mA current loop communication, with half-duplex

RS-485 and full-duplex 20 mA current loop as

optional features. The printer port can support full

duplex RS-232 and simplex 20 mA transmissions.

(Pin 3 is used as an RS-232 receive in some custom

software versions only.) See Section 9.8 on page 71

for information about serial communications options.

Table 2-2 shows the J7 pin assignments for serial

communications connections.

20mA

Port J7 Pin RS-232

Printer 1

2

3

4 –20mA OUT

5 TxD

6 GND +20mA OUT

EDP 7 +20mA IN 485-A

8

9 RxD

10 –20mA OUT

11 TxD

12 GND +20mA OUT

Table 2-2. J7 Pin Assignments (Serial Communications)

RS-485 Wiring

Biasing resistors R38 and R39 can be used to assure

that the RS-485 loop remains in a

idle. If the indicator is installed at the end of the

RS-485 cable, install a 100Ω termination resistor

across the inputs.

The IQ plus 800/810 RS-485 option requires

installation of a single chip (U24) to provide 2-wire,

half-duplex communications. RS-485

SPACE states are generated or detected when the

following conditions exist:

•

MARK state if 485-A (pin J7-7) is > 200 mV

lower than 485-B (J7-8)

•

SPACE state if 485-A (pin J7-7) is > 200 mV

higher than 485-B (J7-8)

Equipment using the 4-wire RS-485 implementation

can be incorporated into a network of IQ plus 800/810

indicators by tying the transmit (A) and receive (A)

RxD

Current Loop

–20mA IN 485-B

MARK state when

RS-485

R38/GND

R39/+5V

MARK and

pins together, and tying the transmit (B) and receive

(B) pins together.

2.6 Digital I/O Wiring

The standard unit allows three digital inputs and four

digital outputs. Wire any active digital inputs and

outputs to connector J4 on the CPU board. Table 2-3

shows the digital I/O assignments for the J4

connector.

J4 Pin Signal

1 DIG OUT 1

2 DIG OUT 2

3 DIG OUT 3

4 DIG OUT 4

5 DIG IN 3

6 DIG IN 2

7 DIG IN 1

8 GND

9 GND

10 +5 VDC

Table 2-3. J4 Pin Assignments (Digital I/O)

Typically, digital outputs control relays which operate

other equipment. Each output is a normally-open

collector circuit, capable of sinking 250 mA when on

and withstanding +40 VDC when off. All logic levels

are active (on) when a low voltage signal (0 VDC) is

present. The output circuits also include 5V pull-up

resistors to send a 5V TTL or 5V CMOS logic signal

when the outputs are closed (on). Use the SETPNTS

menu to configure the digital outputs.

You can wire as many as three external switches to the

digital inputs. These inputs can be set to duplicate

keyboard functions. When used with the batching

switch, PN 19369, the inputs can be set up to start,

run, pause, and stop batch sequences. As with the

outputs, the inputs are active (on) with low voltage (0

VDC) and can be driven by TTL or 5V logic without

additional hardware. Use the DIG IN menu to

configure the digital inputs (see Section 3.2.7 on

page 34).

NOTE: Indicators manufactured prior to September 1,

1996 do not provide a 5 VDC power supply at J4, pin

10. Two methods may be used to provide 5 VDC

power to this pin:

• Solder an insulated jumper wire from J1, pin

4 to J4, pin 10.

• Use an external power supply to energize J4,

pin 10. PN 16418 is recommended.

Indicators made after September 1, 1996 have 5 VDC

built into J4, pin 10.

Installation 9

Page 16

2.7 Wall- and Panel-Mounting

DISCONTINUED

The following sections describe wall- and

panel-mounting procedures for the IQ plus 800/810

indicators.

2.7.1 IQ plus 810 Panel Mount Kit

The panel mounting kit for the IQ plus 810 desktop

model contains five screws with washers to replace the

original screws holding the body to the faceplate.

1. Create a template using the drawing in

Figure 2-8 to mark the hole cutout in the

panel.

10

9-7/16

5

9/16

15/32

To J10

To J7

Load Cell

Cable

7-29/64

1/8 R (8) OPTIONAL

7/32 DIA THRU (5)

2-5/8

Figure 2-8. IQ plus 810 Panel Cutout

4

9-1/4

2. Disconnect power to the indicator.

3. Remove the back of the indicator by

unscrewing the six machine bolts holding the

back to the faceplate.

4. Temporarily remove any cable connections

from the indicator terminals. Remove the

ground cable from the cast lug on the rear of

the indicator case.

5. Using a template made from the drawing

shown in Figure 2-8, transfer the cutout to the

panel. Cut out the panel and drill the holes to

size. Hold the faceplate against the panel and

secure with the five machine screws and

washers provided.

6. Attach the ground wire that was connected to

the lug on the indicator body to one of the five

screws (see Figure 2-9).

7. Reattach cables to indicator terminals. Power

up and test the indicator.

6-1/2

5/8

To J4

Ground

Figure 2-9. IQ plus 810 Panel Mount Wiring

Communications

Cable

AC Power Cable

10 IQ plus 800/810 Installation Manual

Page 17

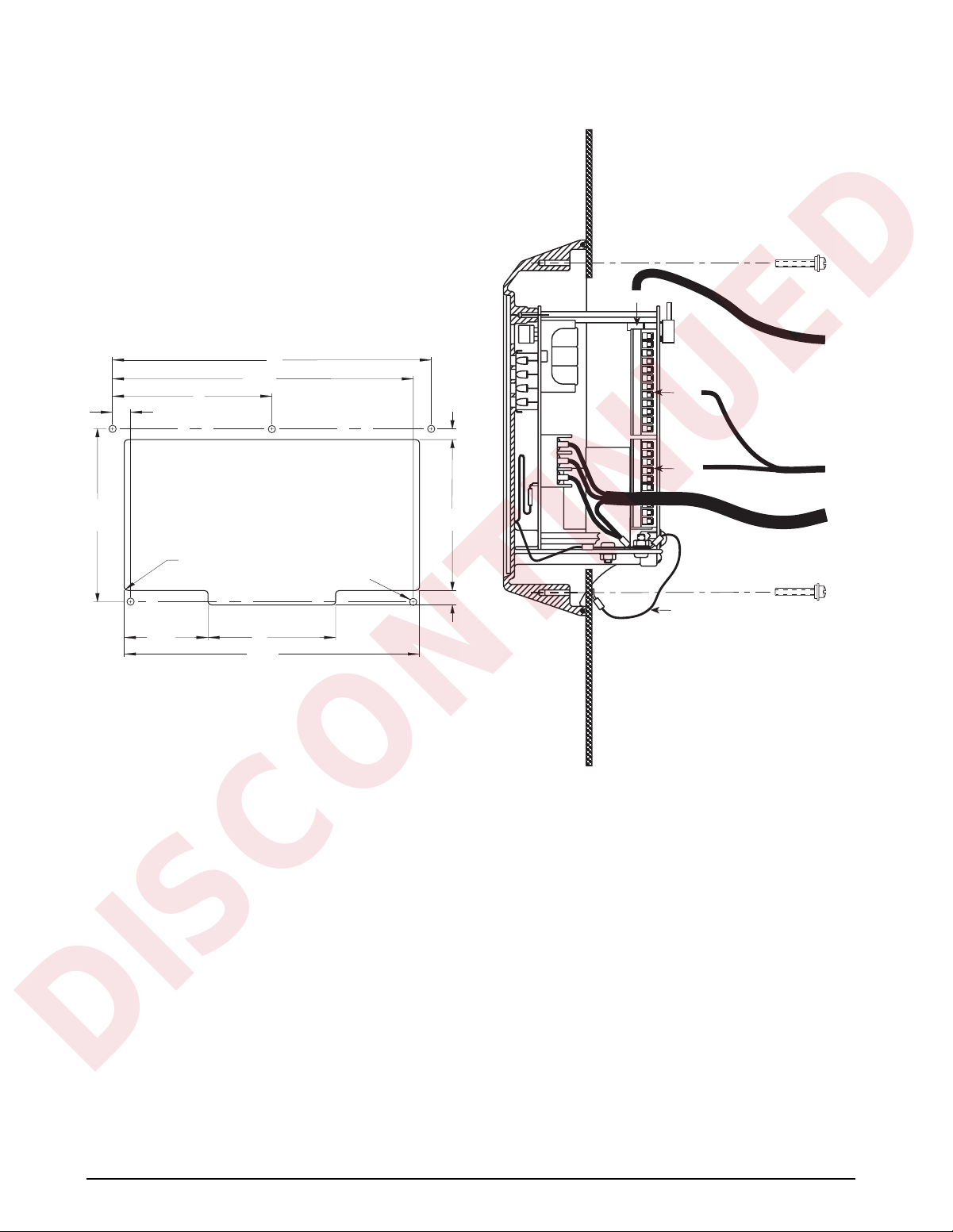

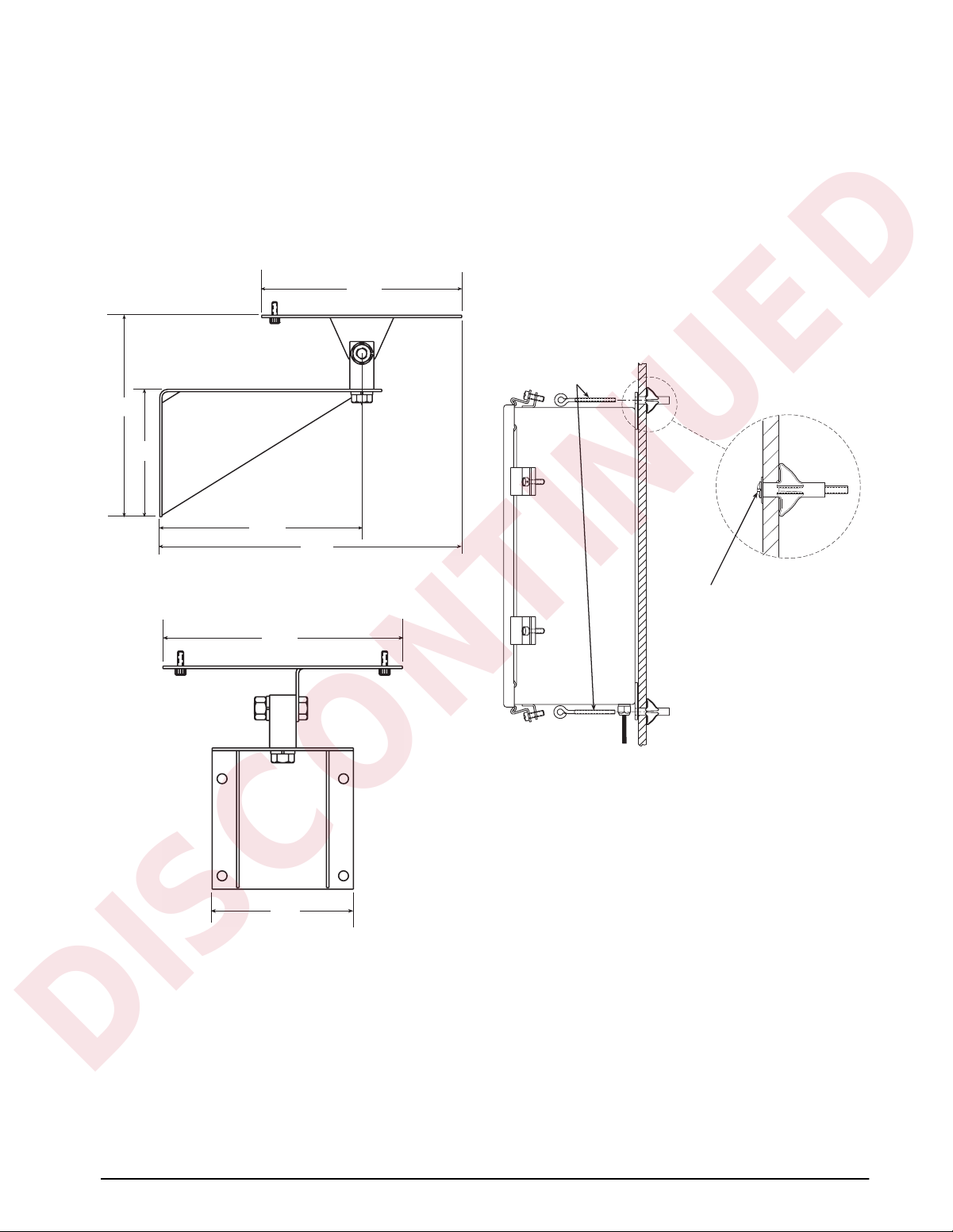

2.7.2 IQ plus 810 Wall Mount Kit

Remove installation screw after

threaded wall anchor is spread

Threaded eyebolts

hold indicator case

to wall anchor

DISCONTINUED

A wall mount kit is available for mounting the IQ plus

810 against vertical surfaces. The indicator mounting

plate both swivels and tilts for adjusting the viewing

angle. The indicator case is secured to the mounting

plate with two machine screws turned into threaded

holes in the bottom of the indicator body. Overall

dimensions are shown in Figures 2-10 and 2-11.

6.28

6.32

4.0

6.34

9.48

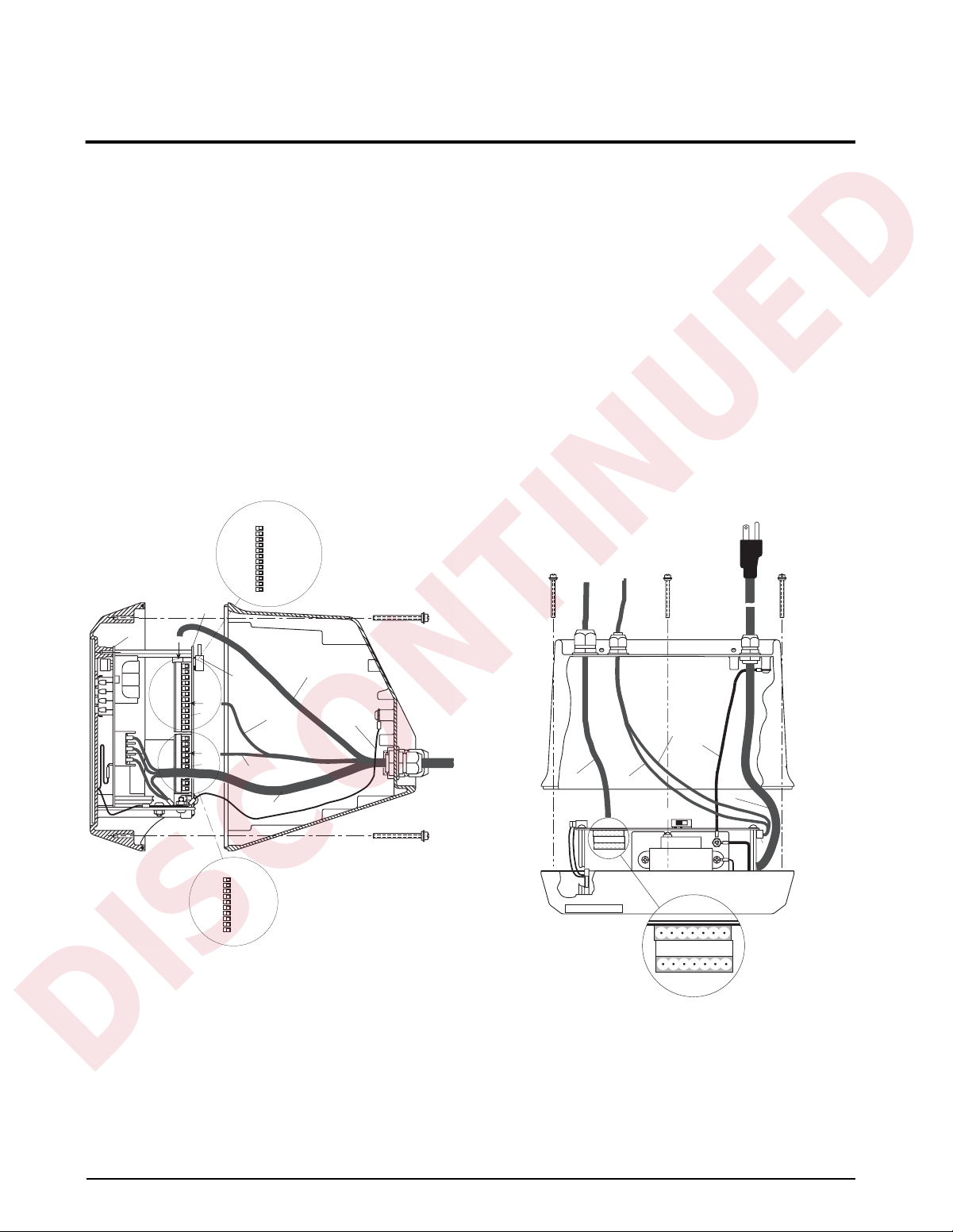

2.7.3 IQ plus 810 SS and HE Model Wall Mounting

If you are permanently mounting an SS or HE model

to a wall, Underwriters Laboratories (UL) requires

that you run the AC power cord in conduit and connect

it to the case with a conduit hub according to standard

construction practices. For portable units, the standard

power cord is sufficient.

Figure 2-12 shows a typical method for mounting the

indicator which maintains its portability. Use the

installation screws to secure four #10 wall anchors.

Then remove the installation screws and attach the

indicator with four threaded eye bolts.

Figure 2-10. IQ plus 810 Wall Mount (Side View)

6.78

Figure 2-12. Wall Mounting for HE and SS Models

4.0

Figure 2-11. IQ plus 810 Wall Mount (Front View)

Installation 11

Page 18

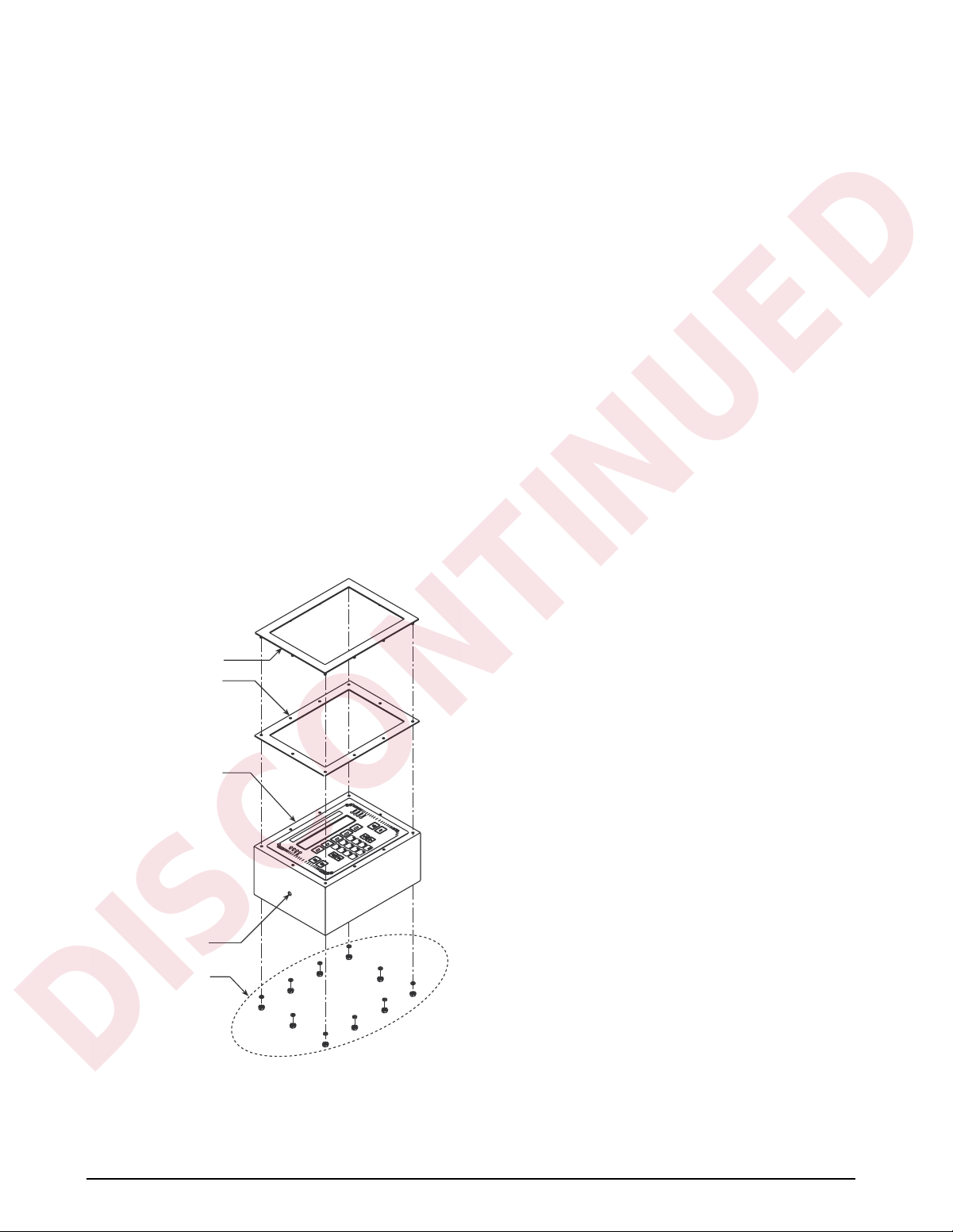

2.7.4 IQ plus 800 Panel Mount Kit

DISCONTINUED

Use the following procedure when panel mounting IQ

plus 800 indicators manufactured after September

1997. These indicators use the same cutout

dimensions as that for the older IQ plus 800 models;

the panel mount kit includes a larger bezel and gasket

for secure mounting.

1. Make a 9 13/16 W x 7 5/16 H inch cutout in

the panel.

2. Remove the tilt stand from the indicator

enclosure.

3. Remove the 14 screws and washers that hold

the backplate to the enclosure body. Note the

location of the larger fillister head screw

above the setup switch access screw.

4. Slowly pull the backplate away from the

enclosure. Disconnect the ribbon cable

extension from the front panel membrane

overlay tail before attempting to completely

remove the backplate and boards from the

enclosure.

5. Remove the 10 nuts and washers that secure

the bezel to the front of the enclosure (see

Figure 2-13).

Bezel

Gasket

6. Remove the standard bezel and gasket from

the front of the indicator and replace with the

larger bezel and gasket from the panel mount

kit. Replace the washers and nuts to secure

the new front bezel.

7. Feed the power, load cell, and

communications cables through the cord grips

on the backplate. Make cable connections as

required.

8. Reassemble the indicator enclosure to the

backplate and boards. Move the indicator

halves together until the ribbon cable

extension can be reconnected to the front

panel membrane overlay tail. Reconnect the

ribbon cable extension then slide the

backplate and boards fully into the enclosure.

9. Place the indicator face-down on the antistatic

mat. Align the holes in the backplate with

those in the enclosure, then reassemble the

washers and screws remov ed in step 3. Use an

alternating pattern when tightening the screws

to prevent distorting the backplate gasket.

10. Feed indicator cables through the panel cutout

from front to rear. Insert the indicator into the

panel from the front and hold in place.

11. From the rear of the panel, use the 1/4-20 x

3/8 pan-head screws and lock washers

provided to attach the panel mount brackets to

the sides of the indicator as shown in Figure

1.

12. Thread the four 10-32 x 1 3/4-inch

round-head machine screws into the panel

mount brackets and tighten until the indicator

is held securely against the panel.

Enclosure

Scale 1

Scale 2

Scale 3

Scale 4

SET

POINT

PRINT

CLEAR

UNITS

NEW

I.D.

3

TARE

SCALE

#

6

2

9

G/N

5

Lb

1

8

ENTER

Kg

ROC

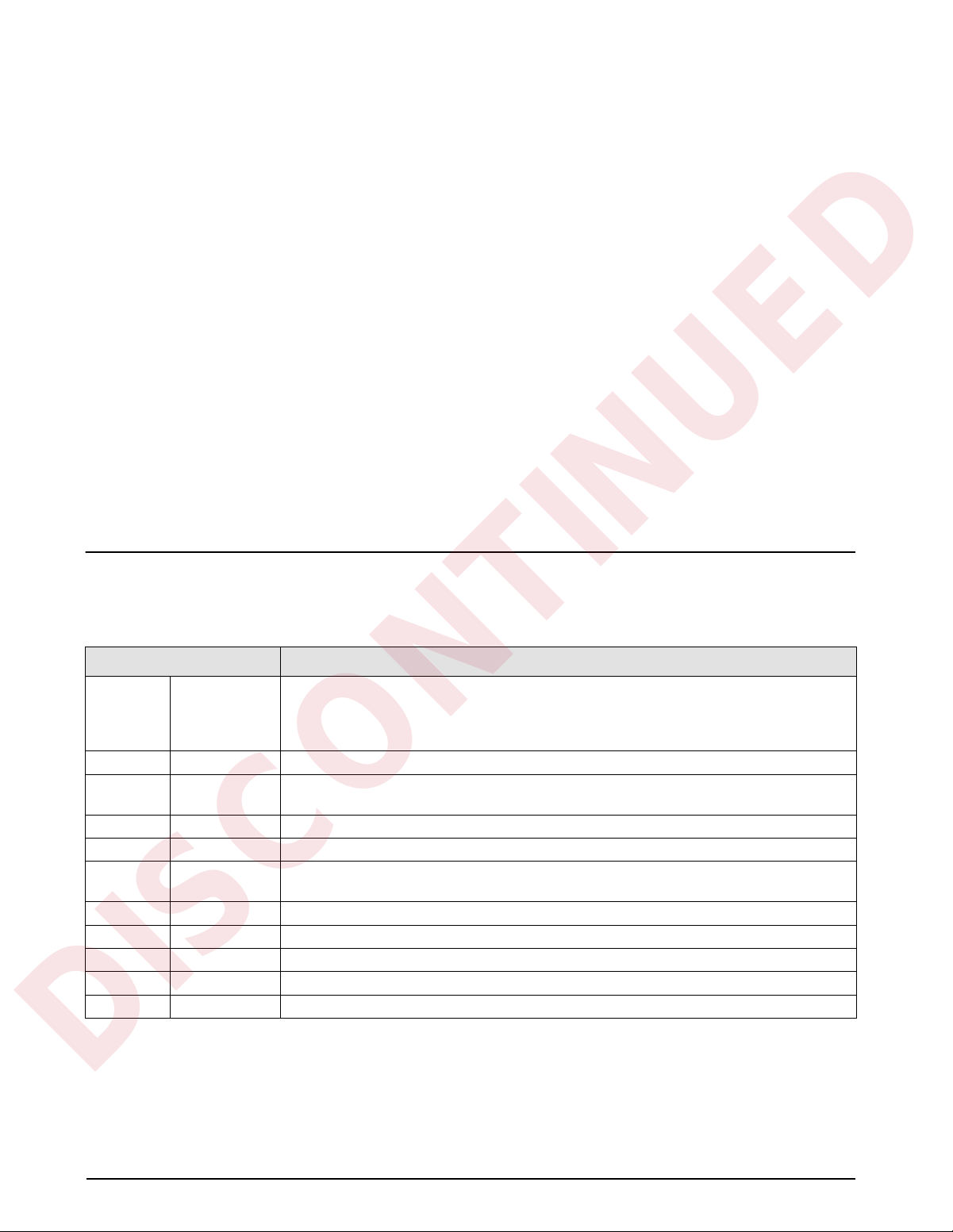

Accum

4

ZERO

0

7

DISP

.

ACCUM

DISP

ROC

DISP

TARE

TIME/

DATE

2.8 Battery Replacement

The 3.0V lithium battery on the power supply/display

board maintains the real-time clock and protects data

stored in the system RAM when the indicator is not

connected to AC power.

System RAM data includes time and date, print

formats, truck ID storage, and setpoint configuration.

This information is lost if the battery loses power and

the indicator is disconnected from AC power. To

Mounting hole for

panel mount bracket

Retaining nuts & washers

for front bezel (10 each)

prevent loss of data, do the following:

• Periodically check the battery voltage and

replace when the voltage drops. The battery

should last a minimum of one year.

• Use the Revolution

™

configuration utility or

EDP commands (see Section 6.2 on page 52)

to store a copy of the indicator configuration

on a PC before attempting battery

replacement. If any data is lost, the indicator

Figure 2-13. IQ plus 800 Bezel and Gasket Replacement

(for indicators manufactured after September 1997)

12 IQ plus 800/810 Installation Manual

configuration can be restored from the PC.

Page 19

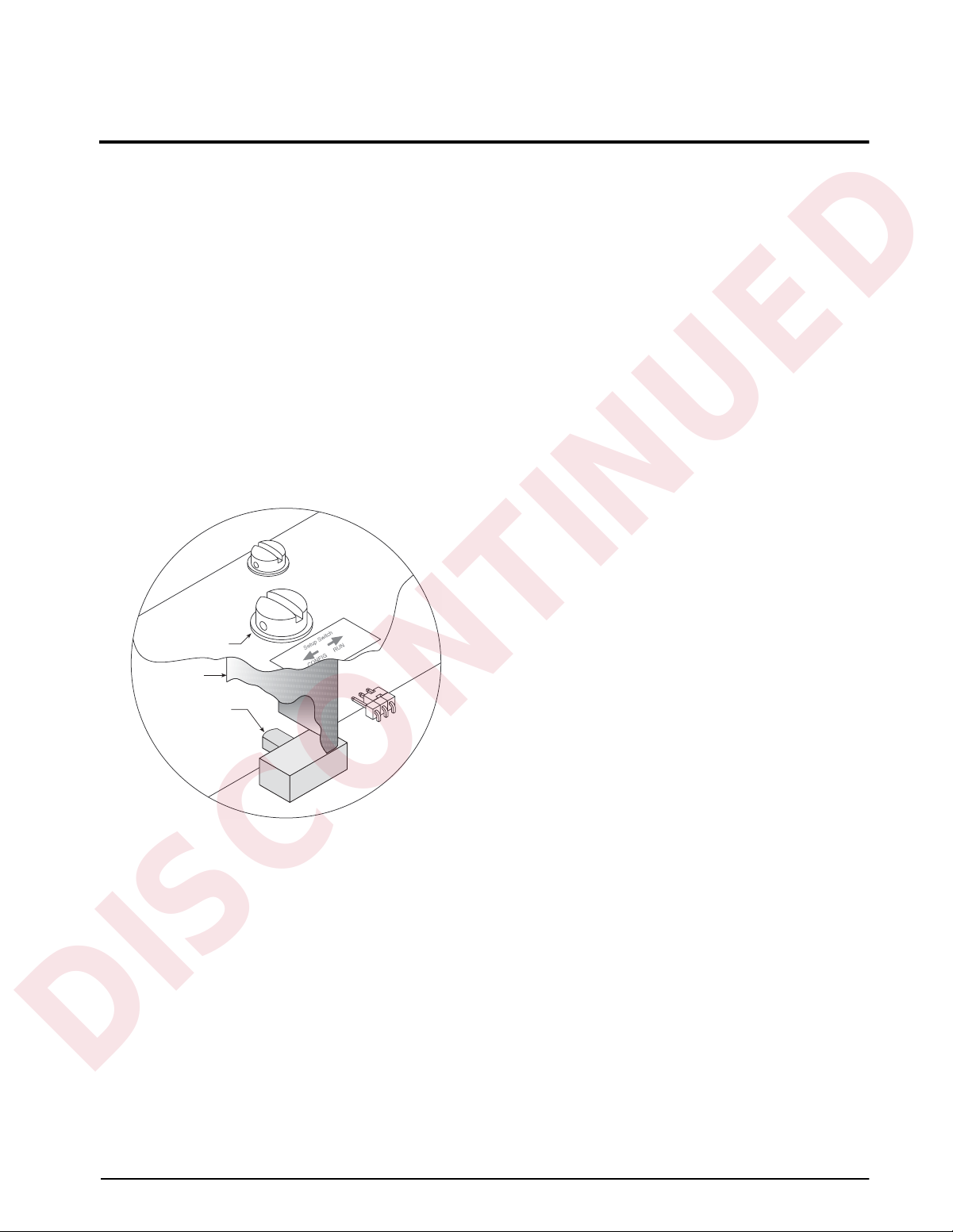

3.0 Configuration

DISCONTINUED

To configure the IQ plus 800/810 indicators, the

indicator must be placed in setup mode. The setup

switch is located on the top edge of the

vertically-mounted CPU board, near the middle of the

board. Moving the two-position setup switch toggles

between setup or normal mode. Access to the setup

switch depends on the type of indicator.

NOTE: Entering setup mode erases any pushbutton zero

values.

IQ plus 800

The setup switch is accessed by removing a screw on

the enclosure backplate. Switch position is changed

by inserting the screwdriver into the access hole and

moving the switch left (CONFIGURE) or right

(RUN), as indicated by the label immediately below

the access hole. Figure 3-1 shows a cutaway view of

the setup switch access screw and the setup

switch.

ACCESS SCREW

GUARD PLATE

SETUP SWITCH

Figure 3-1. IQ plus 800 Setup Switch Access

NOTE: For IQ plus 800 enclosures manufactured prior to

September 1997, the setup switch is accessed by

removing four screws that secure the setup switch cover

to the top of the enclosure.

IQ plus 810

The setup switch (SW1) is accessed by separating the

enclosure halves. See Figure 2-5 on page 8 for switch

location.

When the indicator is placed in setup mode, the word

CONFIG is shown on the display. The CONFIG menu

is the first of the main menus used to configure the

indicator. Detailed descriptions of these menus are

given in Section 3.2. When configuration is complete,

move the setup switch to the run position and replace

the setup switch access screw or reassemble the

enclosure, as required.

3.1 Configuration Methods

The IQ plus 800/810 indicators can be configured by

using the front panel keys to navigate through a series

of configuration menus or by sending commands or

configuration data to the EDP port. Configuration

using the menus is described in Section 3.1.3.

Configuration using the EDP port can be

accomplished using either the EDP command set

described in Section 6.0 or the Revolution

configuration utility.

3.1.1 Revolution Configuration

The Revolution configuration utility provides the

preferred method for configuring the IQ plus 800/810

indicators. Revolution runs on a personal computer to

set configuration parameters for the indicator. When

Revolution configuration is complete, configuration

data is downloaded to the indicator.

Revolution supports both uploading and downloading

of indicator configuration data. This capability allows

configuration data to be retrieved from one indicator,

edited, then downloaded to another.

To use Revolution, do the following:

1. Install Revolution on an IBM-compatible

personal computer running Windows

Windows 95. Minimum system requirements

are 4MB of extended memory and at least

5MB of available hard disk space.

2. With both indicator and PC powered off,

connect the PC serial port to the RS-232 pins

on the indicator EDP port.

3. Power up the PC and the indicator. Use the

setup switch to place the indicator in setup

mode.

4. Start the Revolution program.

Figure 3-2 on page 14 shows an example of one of the

Revolution configuration displays.

®

3.11 or

™

Windows® is a registered trademark of Microsoft Corporation

Configuration 13

Page 20

DISCONTINUED

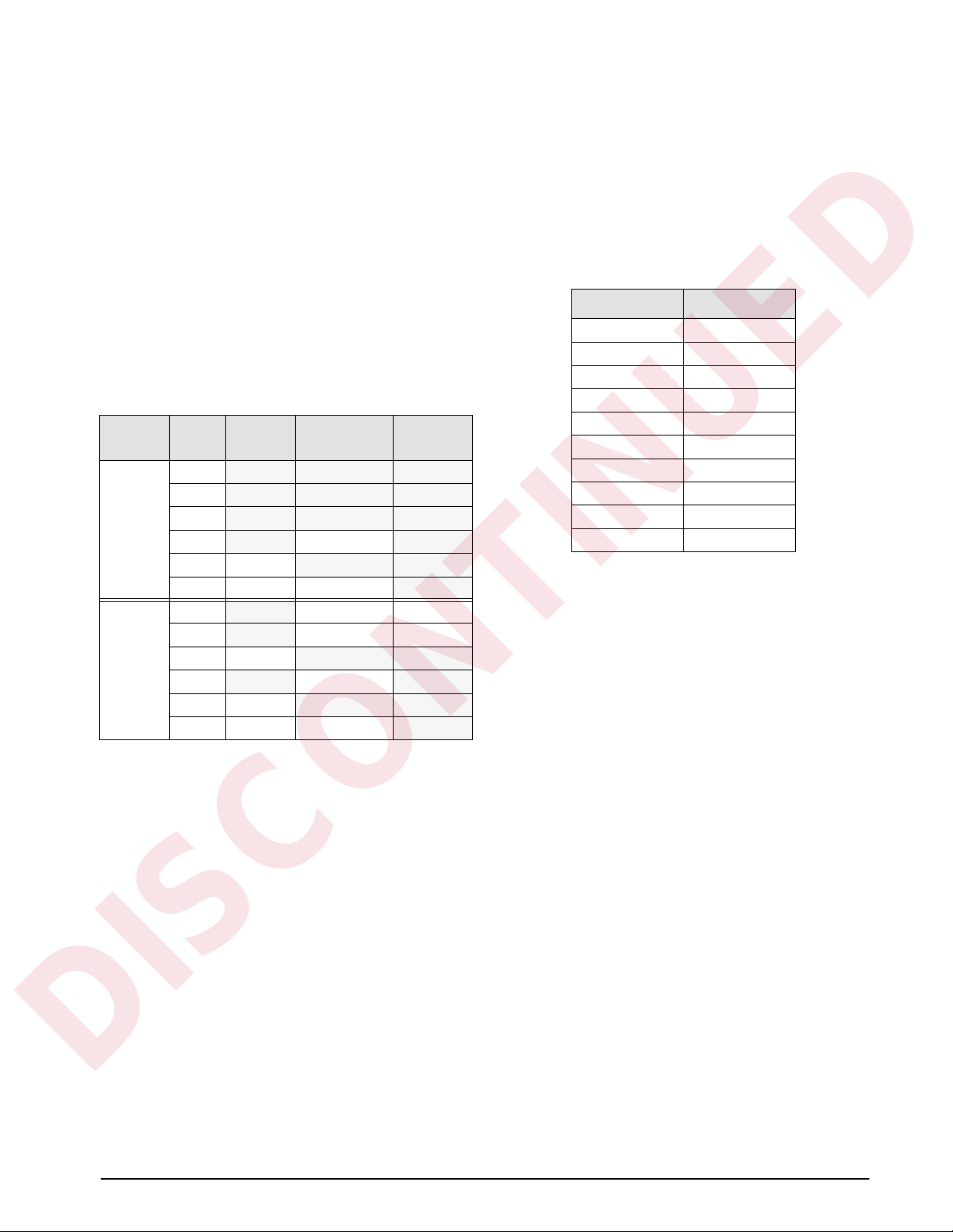

Figure 3-2. Sample Revolution Configuration Display

3.1.3 Front Panel Configuration

The IQ plus 800/810 indicators can be configured using a series of menus accessed through the indicator front

panel when the indicator is in setup mode. Table 3-1 provides a summary of the configuration functions provided

by each of these menus.

Revolution provides online help for each of its

configuration displays. Parameter descriptions

provided in this manual for front panel configuration

can also be used when configuring the indicator using

Revolution: the interface is different, but the

parameters set are the same.

3.1.2 EDP Command Configuration

The EDP command set can be used to configure the

IQ plus 800/810 indicators using either a personal

computer, terminal, or remote keyboard. Like

Revolution, EDP command configuration sends

commands to the indicator EDP port; unlike

Revolution, EDP commands can be sent using any

external device capable of sending ASCII characters

over a serial connection.

EDP commands duplicate the functions available

using the indicator front panel and provide some

functions not otherwise available. EDP commands can

be used to simulate pressing front panel keys, to

configure the indicator, or to dump lists of parameter

settings. See Section 6.0 for more information about

using the EDP command set.

Menu Menu Function

CONFIG Configuration Configure input channels and select general indicator functions. CONFIG menu is used to set

grads, zero tracking, zero range, motion band, overload, and digital filtering for each scale

channel, select truck modes and power-up mode, set consecutive number initial value, set

tare function, define passwords, and enable optional features.

SET ALG Set Analog Select input channels, TOTALS channel configuration, resolution, and analog filtering.

FORMAT Format Set display format (units, decimal point position, display divisions) for primary, secondary, and

rate-of-change weight displays, time and date information, and define setpoint names.

SETPNTS Setpoints Configure setpoints. See Section 8.0 for more information about setpoint configuration.

SERIAL Serial Configure EDP, printer, and auxiliary communications ports.

P FORMT Print Format Set print format used for demand, truck, and setpoint push-print tickets. See Section 7.0 for

more information about print formatting.

DIG IN Digital Input Assign digital input functions.

ALG OUT Analog Output Configure analog output modules. Used only if analog output option is installed.

BAR GRF Bar Graph Configure bar graph function. Used only if bar graph option is installed.

CALIBRT Calibrate Calibrate input channels. See Section 4.0 for calibration information.

VERSION Version Displays installed software version number.

Table 3-1. IQ plus 800/810 Menu Summary

Four front panel keys are used as directional keys to navigate through the menus in setup mode (see Figure 3-3).

The

SETPOINT and CLEAR keys scroll left and right (horizontally) on the same level; DISP TARE and TIME/

DATE move up and down (vertically) to different menu levels.

14 IQ plus 800/810 Installation Manual

Page 21

To select a parameter, press SETPOINT or CLEAR

DISCONTINUED

until the desired menu group appears on the display,

DISP

TARE

SET

POINT

then press

level. When moving down through the menus, the

default setting appears first on the display . To change a

default, scroll left or right through the various options

TIME/

DA TE

CLEAR

for that level. When the desired option appears on the

display , press

move back up one level. For parameters requiring a

numerical entry, key in the number, press

scroll up to lock in the number.

Figure 3-3. Menu Navigation Keys

3.2 Menu Structures and Parameter Descriptions

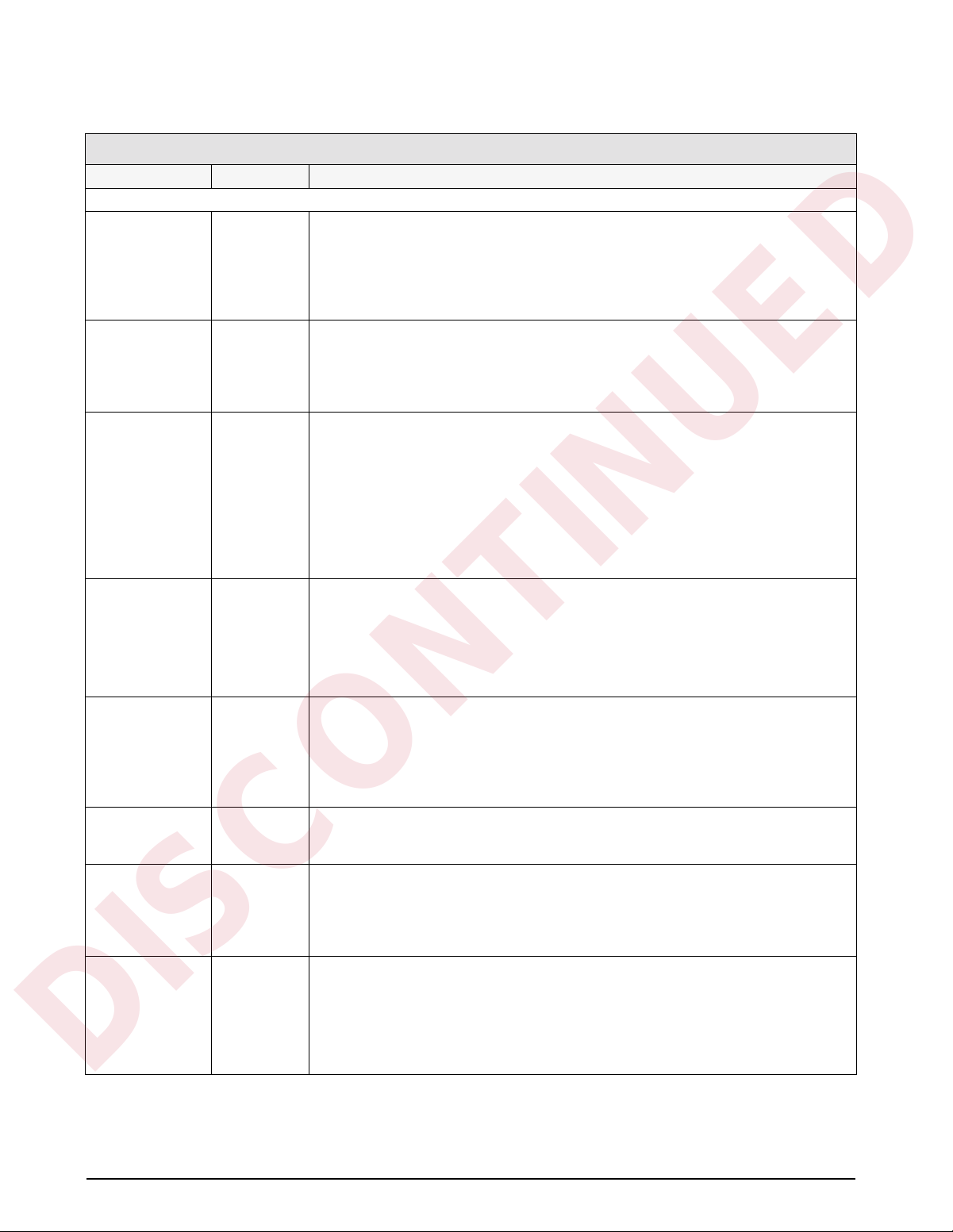

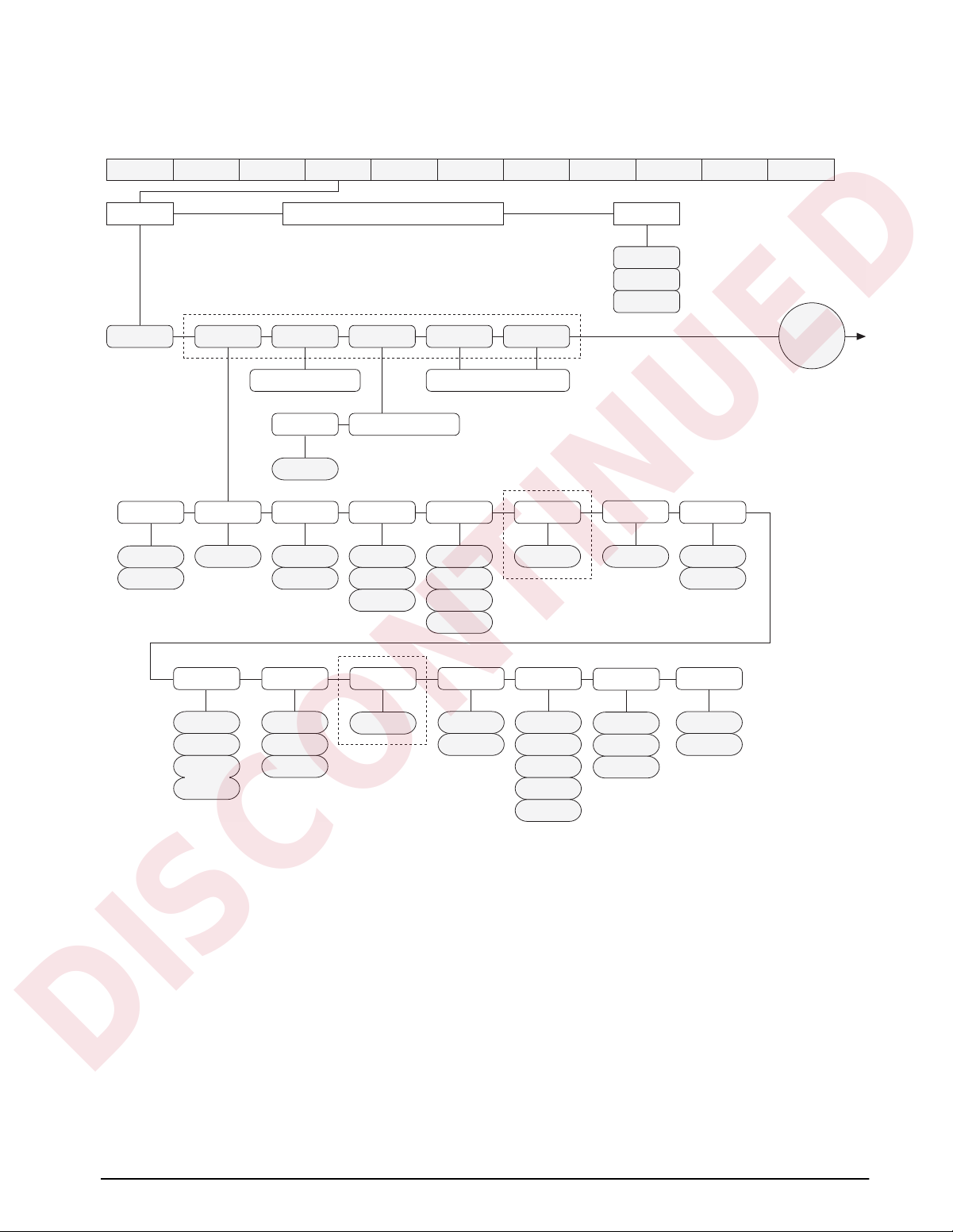

The following sections provide graphic

representations of the IQ plus 800/810 menu

structures (Figures 3-4 through 3-15). In the actual

menu structure, the settings you choose under each

parameter are arranged horizontally. To save page

space, menu choices are shown in vertical columns.

The factory default setting appears at the top of each

column. Settings shown surrounded by a dotted-line

box only appear under the special circumstances

explained under each box.

Most menu diagrams are accompanied by one or more

tables that describe all parameters and parameter

values associated with that menu option. Default

parameter values are shown in bold type.

TIME/DATE to move down to the desired

DISP TARE to lock in your selection and

ENTER, and

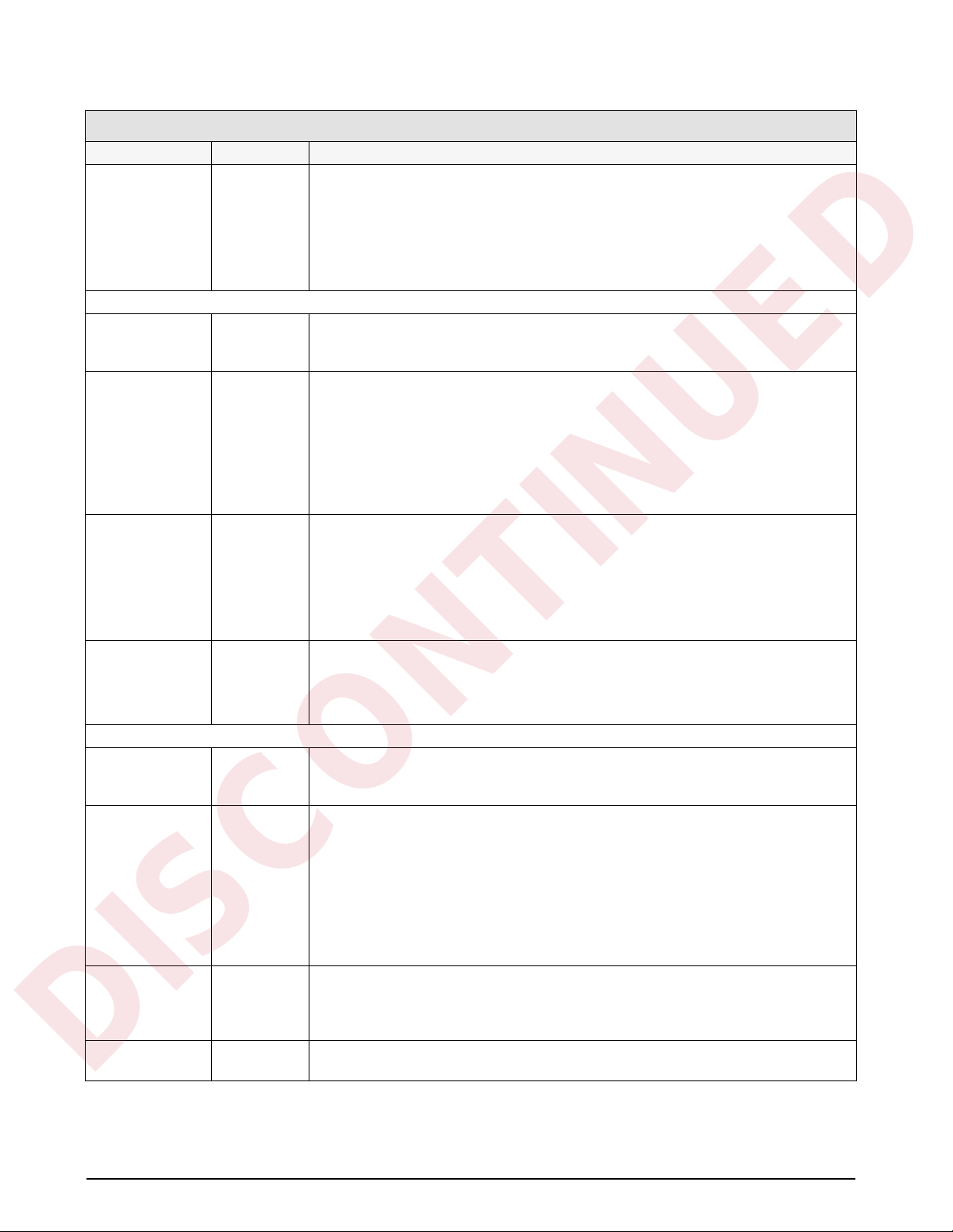

3.2.1 Configuration Menu

CONFIG SET ALG

SCALE 1 SCALE 2

same as SCALE 1

ZTRKBNDGRADS

number

OFF

0.5 D

1 D

3 D

1.9%

100%

XXXXXXX CALIBRT XXXXXXXVERSIONXXXXXXXBAR GRFALG OUTDIG INXXXXXXXSERIAL P FORMTSETPNTSFORMATXXXXXXX

1 D

2 D

3 D

5 D

PWRUPMD

GO

DELAY

OVRLOAD

FS + 2%

FS + 1D

FS + 9D

FS

OFF

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

DIGFLTR

4

8

16

32

64

128

4 RT

8 RT

16 RT

32 RT

OFF BOTH

NORMAL

BI-DIR

AUTO

if PK HOLD is

ON

ACCUM

64 RT

128 RT

SCALE 4SCALE 3

MOTBANDZRANGE

10 D

20 D

OFF

TARE FNPK HOLDTARE200

NO TARE

PB TARE

KEYED

ON

1

2

ROC

LGLMODE

LEGAL

INDUST

access code number

OFF/ON

if OFF

number

PASSWRDPEAK

SP PWDCFG PWD

passwordpassword

if ON

3.13 and later only

FEATUREPASSWRDCONSNUM

OFF

A/B

DEFAULT

RESET

Software versions

Figure 3-4. Configuration Menu

Configuration 15

Page 22

CONFIG Menu

DISCONTINUED

Parameter Choices Description

Level 2 submenus

SCALE 1–4 GRADS

ZTRKBND

ZRANGE

MOTBAND

OVRLOAD

DIGFLTR

PWRUPMD GO

DELAY

TARE200 OFF

MODE 1

MODE 2

MODE 3

MODE 4

MODE 5

MODE 6

PK HOLD OFF

NORMAL

BI-DIR

AUTO

TARE FN BOTH

NO TARE

PB TARE

KEYED

LGLMODE LEGAL

INDUST

CONSNUM 0

number

PASSWRD OFF

CFG PWD

SP PWD

Specifies the analog input channel being configured. See level 3 submenus for

configuration choices.

Power up mode. In GO mode, the scale goes into operation immediately after a brief

power up display test. In DELAY mode, the scale performs a power up display test, then

warms up (WARM UP and standstill symbol displayed). Indicator becomes operational

when no motion is detected for 30 seconds. DELAY mode is used where local regulations

require a warm-up period.

200 ID/Tare Truck In/Truck Out mode. Specifies one of six truck modes. If selected, the

indicator shifts from normal weighing mode to the selected truck mode. See Section 5.3

on page 41 for more information about truck modes.

MODE 1: Auto clear ID, keyed tares, value swapping

MODE 2: Auto clear ID, no keyed tares, value swapping

MODE 3: Stored ID, keyed tares, value swapping

MODE 4: Stored ID, no keyed tares, value swapping

MODE 5: Stored ID, keyed tares, no value swapping

MODE 6: Stored ID, no keyed tares, no value swapping

Peak hold function. Optional feature used to hold display of the highest net weight

achieved during a weighing cycle.

If the peak hold function is enabled, PK HOLD is set on for all channels. The TOTAL

channel peak value is independent of the individual channels; it does not represent the

sum of the channel peak values. See Section 10 for more information about the peak hold

function.

Tare function. Enables or disables push-button and keyed tares. Possible values are:

BOTH: Both push-button and keyed tares are enabled

NO TARE: No tare allowed (gross mode only)

PB TARE: Push-button tares enabled

KEYED: Keyed tares enabled

Legal/industrial mode. Controls whether scale switches to gross or net display when a

tare of zero is entered in gross mode. If LEGAL is selected, scale r eturns to gross mode; if

INDUST is selected, scale switches to net display.

Consecutive numbering. Specifies starting value for sequential numbering used to count

batch sequences or serialize ticket numbers. The consecutive number can be printed on

any print ticket; value is incremented after it is printed. If consecutive number is not

printed, it is effectively disabled. The CONSECNUM EDP command allows you to view or

change consecutive numbers.

Password. Optional feature supports two passwords: one for configuration menus in

setup mode (CFG PWD), one for setpoint configuration using supervisor switch and

SETPOINT key (SP PWD). Passwords can be entered only if feature is enabled (see

FEATURE parameter).

Enter up to seven digits for each password. See Section 9.4 on page 67 for more

information.

Table 3-2. Configuration Menu Parameters

16 IQ plus 800/810 Installation Manual

Page 23

CONFIG Menu

DISCONTINUED

Parameter Choices Description

FEATURE ACCUM

ROC

PEAK

PASSWRD

A/B

DEFAULT RESET Press the down (TIME/DATE) key to reset configuration parameters to default values. This

Level 3 submenus

GRADS number Graduations. Specifies the number of full scale graduations. The value entered should be

ZTRKBND OFF

0.5 D

1 D

3 D

ZRANGE 1.9%

100%

MOTBAND 1D

2 D

3 D

5 D

10 D

20 D

OFF

OVRLOAD FS + 2%

FS + 1D

FS + 9D

FS

Allows you to verify current feature status or to activate a feature. See the Level 3

parameter descriptions on page 18 for information about activating these features.

parameter is available only with software versions 3.13 and later.

NOTE: Indicator must be reconfigured and load cells recalibrated after performing this

function.

consistent with legal requirements and environmental limits on system resolution. Enter a

value with the numeric keypad; exit upward to save the new value.

To calculate GRADS, use the formula, GRADS = Capacity / Display Divisions.

Display divisions for primary and secondary units are specified on the FORMAT menu.

Zero track band. Automatically zeroes the scale when within the range specified, as long

as the input is within the ZRANGE and scale is at standstill. Selections are ± display

divisions. Maximum legal value varies depending on local regulations.

Zero range. Selects the range within which the scale can be zeroed. The 1.9% selection is

± 1.9% around the calibrated zero point, for a total range of 3.8%. Indicator must be in

standstill and in gross weight display mode to zero the scale. Use 1.9% for legal-for-trade

applications

When the ZERO key is pressed while displaying the total channel, the amount on each

individual channel is zeroed off, if possible. If the ZERO is not possible on all channels,

then the ZERO is denied.

Motion band. Sets the level, in display divisions, at which scale motion is detected by

comparing the current display with the previous display. If motion is not detected for 1

second or more, the standstill symbol lights, enabling the scale to process a PRINT

command. Maximum legal value varies depending on local regulations.

If OFF is selected, ZTRKBAND must also be set to OFF. TOTAL channel is considered at

standstill when all individual channels are out of motion.

Overload. Determines the point at which the display blanks and an out-of-range error

message is displayed. Maximum legal value varies depending on local regulations.

When any individual channel is overloaded, the total channel display is also blanked.

Table 3-2. Configuration Menu Parameters (Continued)

Configuration 17

Page 24

CONFIG Menu

DISCONTINUED

Parameter Choices Description

DIGFLT 4

ACCUM

ROC

PEAK

PASSWRD

A/B

8

16

32

64

128

4 RT

8 RT

16 RT

32 RT

64 RT

128 RT

1

2

OFF

ON

Digital filtering. Selects the digital filtering rate used to reduce the effects of mechanical

vibration from the immediate area of the indicator.

Choices indicate the number of A/D conversions per update that are averaged to obtain

the displayed reading. A higher number gives a more accurate display by minimizing the

effect of a few noisy readings, but slows down the settling rate of the indicator.

RATTLETRAP

filtering repeating vibrations caused by mechanical noise from nearby machines but may

increase settling times over standard digital filter selections.

See Section 10.5 on page 89 for more information on digital filtering.

ACCUM is a standard feature and can simply be turned ON or OFF. Use the following

procedure to activate the ROC, PEAK, PASSWRD, and A/B features:

1. From the selected feature (ROC, PEAK, PASSWRD, or A/B), press TIME/DATE to

move down and show the feature status. If OFF, press TIME/DATE again to display a

unique number generated by the indicator. This number is used to calculate the

access code for the feature.

2. Record the generated number, then use the number in the following equation to

calculate the feature access code:

(generated_number

where feature_type is:

For example, if the number generated for the ROC feature is 5000, the access code

would be:

(5000 x 5) + 14 = 25000 + 14 = 25014

3. Use the numeric keypad to enter the calculated access code, then press ENTER. The

display should return to show the changed feature status value (ON).

®

selections (shown with “RT” after the number) are most effective at

x 5) + feature_type

14 for ROC

21 for PEAK

28 for PASSWRD

35 for A/B

The CLEARALLFEATURES EDP command can be used to turn off all active features.

See Section 9.0 for more information about using these features.

Table 3-2. Configuration Menu Parameters (Continued)

18 IQ plus 800/810 Installation Manual

Page 25

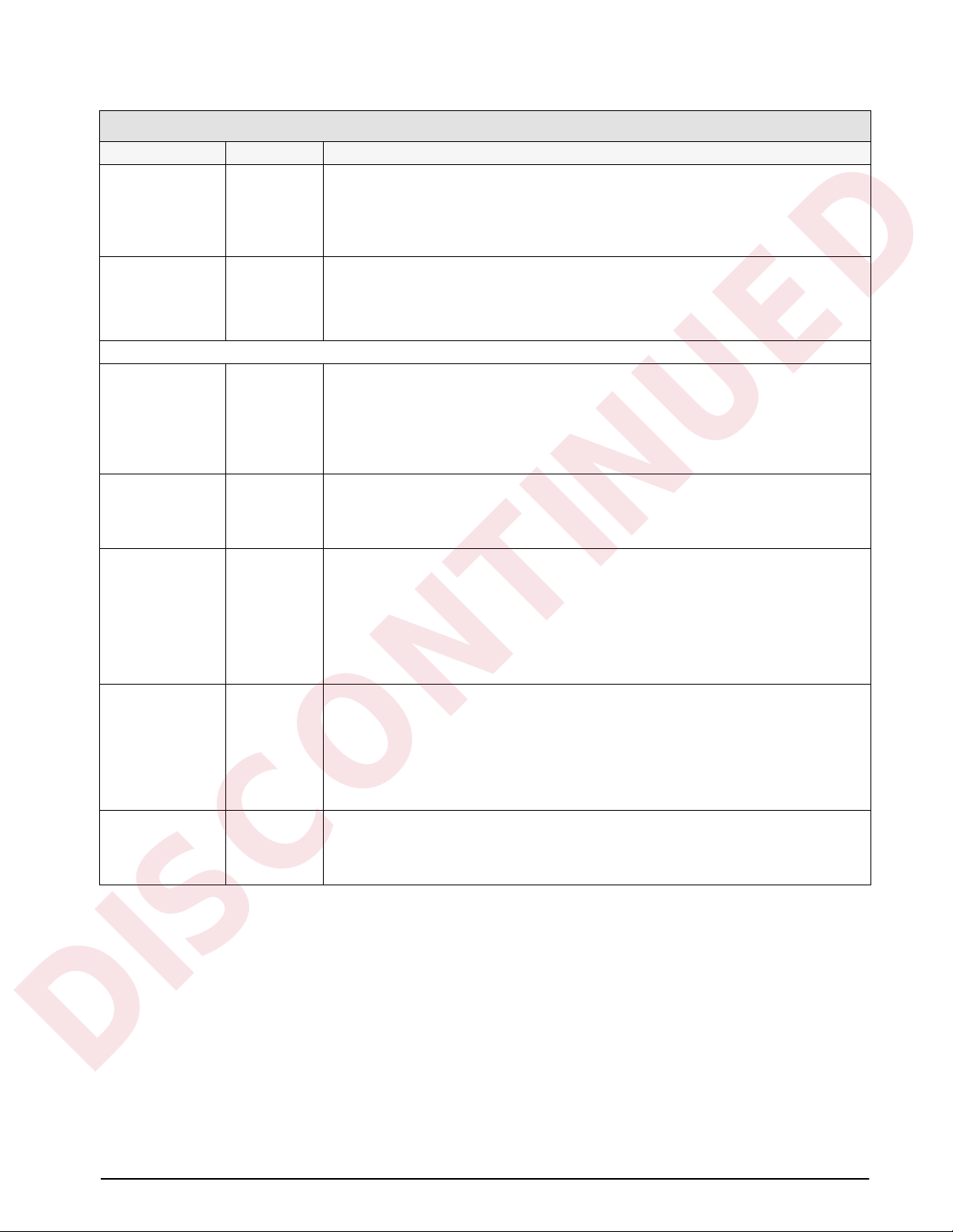

3.2.2 Set Analog Menu

DISCONTINUED

CONFIG SET ALG

1 2

1 3

1 3 4

1 2 3 4

1 FAST

OFF

ENABLE

T ONLY

OFF

Available if multiple

channels are selected

OFF

P1>CH3

P>CH3+4

STANDRD

HIGH

60 HZ

50 HZ

Figure 3-5. Set Analog Menu

SET ALG Menu

Parameter Choices Description

Level 2 submenus

CHANS 1

1 2

1 3

1 3 4

1 2 3 4

1 FAST

TOTALS OFF

ENABLE

T ONLY

PULS IN OFF

P1>CH3

P>CH3+4

RESOLUT STANDRD

HIGH

FREQ 60 HZ

50 HZ

ALGFLTR 8 HZ

OFF

2 HZ

Channels. Selects the channels used for analog input to the indicator. The standard unit has

one channel; up to four channels can be specified. If the Jetpak option is installed, channel

1 can be selected as a high-speed channel (1 FAST) with an update rate of 100/second.

TOTALS channel configuration. Possible values are:

OFF: TOTALS channel disabled. This is the default value for all channel configurations.

ENABLE: TOTALS channel enabled. Indicator displays TOTALS with other configured

channels.

T ONLY: Indicator displays only the TOTALS channel

Pulse input. This option is not available at this time.

Resolution. Selects between standard (360 000 grads a t 120V, 60 Hz, 20 updates/sec) and

high resolution (740 000 grads at 120V, 60 Hz, 10 updates/sec). Internal resolution is

increased by 20% with 50 Hz AC power supply.

Frequency. Sets the A/D converter to match AC power supply.

Analog filter. Selects the range used for filtering mechanical and electrical noise. 8 Hz value

has a medium filtering effect; 2 Hz has the greatest effect. Normally, the minimum filter value

that allows a stable display should be selected. If digital filtering is also used, select either 2

Hz or 8 Hz for this parameter. See Section 10.5 on page 89 for more information about

analog filtering.

XXXXXXX CALIBRT XXXXXXXVERSIONXXXXXXXBAR GRFALG OUTDIG INXXXXXXXSERIAL P FORMTSETPNTSFORMATXXXXXXX

ALGFLTRFREQRESOLUTPULS INCHANS TOTALS

8 HZ1

OFF

2 HZ

Table 3-3. Set Analog Menu Parameters

Configuration 19

Page 26

3.2.3 Format Menu

DISCONTINUED

CONFIG SET ALG

PRIMARY SECNDRY RATECHG

DSP DIV UNITSDEC PNT

1

2

5

DSP DIV MULTUNITSDEC PNT

5

1

2

8888888

888888.8

88888.88

8888.888

888.8888

88.88888

8.888888

8888800

8888880

888888.8

88888.88

8888.888

888.8888

8.888888

8888800

8888880

8888888

LB

KG

OZ

TN

GR

G

NONE

KG

OZ

TN

GR

G88.88888

NONE

LB

same as SCALE 1

DSP DIV TIMEMULTDEC PNT

1

2

5

number

8888888

888888.8

88888.88

8888.888

888.8888

88.88888

8.888888

8888800

8888880

SCALE 4SCALE 3SCALE 2SCALE 1

DATEFMT DATESEP

MMDDYY

DDMMYY

TOTAL

SLASH

DASH

SEMI

XXXXXXX CALIBRT XXXXXXXVERSIONXXXXXXXBAR GRFALG OUTDIG INXXXXXXXSERIAL P FORMTSETPNTSFORMATXXXXXXX

SECnumber

MIN

TIMEDATE

LB

KG

OZ

TN

GR

G

NAME 0

name

TIMEFMT TIMESEP

12 HOUR

COLON

COMMA24 HOUR

SPNAMEUNITS

NAME 1 thru NAME 9

same as NAME 0

Figure 3-6. Format Menu

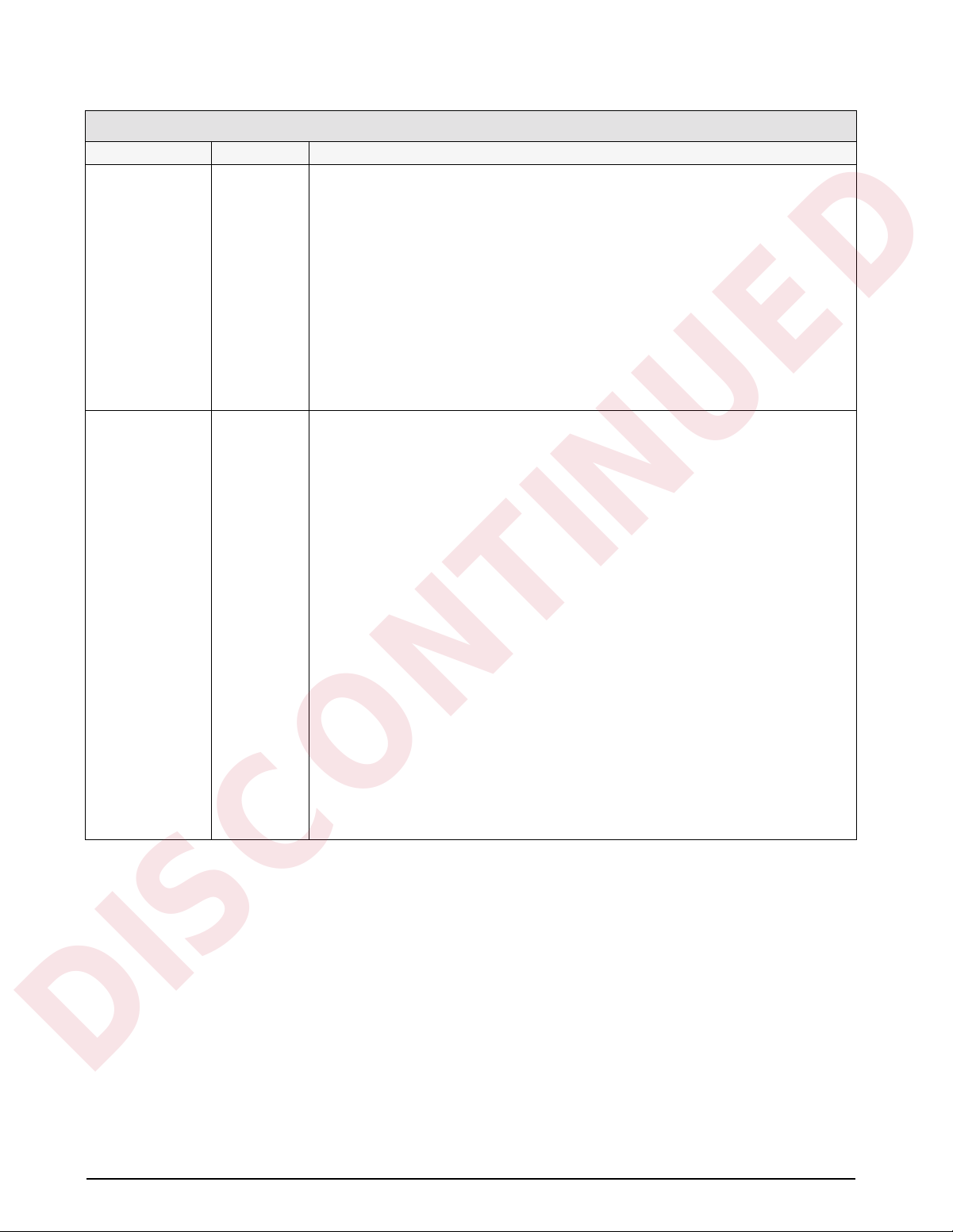

FORMAT Menu

Parameter Choices Description

Level 2 submenus

SCALE 1

SCALE 2

SCALE 3

PRIMARY

SECNDRY

RATECHG

Selects the format for an analog input channel., including primary, secondary, and rate of

change units used to display weight data for each channel.

SCALE 4

TOTAL

DATE DATEFMT

Allows selection of date format and separator character.

DATESEP

TIME TIMEFMT

Allows selection of time format and separator character.

TIMESEP

Table 3-4. Format Menu Parameters

20 IQ plus 800/810 Installation Manual

Page 27

FORMAT Menu

DISCONTINUED

Parameter Choices Description

UNITS unit ID Allows customization of default units identifiers for displayed and printed weights. Default

values (LB=pound; KG=kilogram; OZ=ounce; TN=ton; GR=gram; G=grain) can be

modified using the procedure described for the P FORMT menu. Customized identifiers

are listed in the UNITS subparameter values for primary, secondary, and ROC

parameters.

SPNAME SPNAME0 –

SPNAME9

Level 3 submenus

PRIMARY DSP DIV

DEC PNT

UNITS

SECNDRY DSP DIV

DEC PNT

UNITS

MULT

RATECHG DSP DIV

DEC PNT

MULT

TIME

DATEFMT MMDDYY

DDMMYY

DATESEP SLASH

DASH

SEMI

TIMEFMT 12 HOUR

24 HOUR

TIMESEP COLON

COMMA

Level 4 submenus

Primary Units

DSP DIV 1

2

5

DEC PNT 8888888

888888.8

88888.88

8888.888

888.8888

88.88888

8.888888

8888800

8888880

Allows specification of setpoint names. Use the procedure described under the P FORMT

menu to assign names for SPNAME0 through SPNAME9. Names specified on this

parameter are assigned to setpoints using the NAME parameter on the SETPNTS menu.

Allows selection of display divisions, decimal point location, and units for the primary

units.

Allows selection of display divisions, decimal point location, units, and multiplier for

secondary units.

Allows selection of display divisions, decimal point location, multiplier, and time for the

rate of change (ROC) function. See Section 9.2 on page 65 for more information about

the ROC function.

Date format. Specifies the format in which the date is printed and displayed, either month/

day/year, or day/month/year.

Date separator. Specifies the separator character between the day, month, and year

when the date is printed. The display always uses a period (.) as the date separator.

Time format. Specifies the format in which the time is displayed and printed, either in

12-hour or 24-hour format. The actual setting of time is done through the front panel