Page 1

EVOLUTION SC

INK JET PRINTERS

INSTALLATION AND OPERATION MANUAL

digital design inc.

67 Sand Park Road

Cedar Grove, NJ 07009

(973)

www.evolutioninkjet.com

This manual is for use in operating and maintaining the EVOLUTION 1 Ink Jet

Printer. This includes various optional features, which may not be included in

your basic model printer. For basic start-up instructions, please refer to PART 1

Installation Procedures.

All rights reserved. No part of this document may be reproduced, stored on a

retrieval system, or transmitted in any form, or by any means electronic,

mechanical, photocopying, recording or otherwise, without the prior permission of

Digital Design Inc.

Digital Design Inc. has a policy of continual product improvement. The Company

therefore reserves the right to modify the information contained in this manual

without prior notice.

857-9500

Trend Marking Systems

PO Box 1311

Castle Hill, NSW, 1765, AUSTRALIA

(+61) 02-96299535

www.trendmarking.com.au

ALL PRINT CARTRIDGES SUPPLIED BY DIGITAL DESIGN INC.

ARE FACTORY TESTED AND PROFILED TO PRODUCE AN

OPTIMUM AND CONSISTANT CODE. USING OTHER THAN

AUTHORIZED

RESULTS.

EACH FLASH DATA CARD IS PROFILED EXPLICITELY FOR ITS’

INTENDED

USE IN OTHER THAN THE ORIGINAL PRINTER FOR WHICH IT

WAS PURCHASED. KEEP ALL UPGRADE CARDS IN A SECURE

PLACE.

EVOLUTION

PROGRAMMING CAPABILITIES. OPTIONAL SOFTWARE MAY

BE ADDED TO A BASIC UNIT AND IS COVERED IN THIS

MANUAL.

i

CARTRIDGES WILL CAUSE UNDESIRABLE

PRINTER, AND IS SECURITY LOCKED PROHIBITING

1 IS A BASIC MODEL WITH NO VARIABLE FIELD

EVOLUTION 1

SYSTEM MANUAL Issue 1.4 16 May 2006

Page 2

INSTALLATION AND OPERATION MANUAL

TABLE OF CONTENTS

PART 1 INSTALLATION PROCEDURES 1-1

PART 2 OPERATION PROCEDURES 2-1

PART 3 MAINTENANCE PROCEDURES 3-1

PART 4 TROUBLESHOOTING AND REPAIRS 4-1

PART 5 PARTS LIST AND OPTIONS

PART 6 COMMUNICATIONS PROTOCOL 6-1

PART 7 JUMPER SETTINGS 7-1

PART 8 SPECIFICATIONS 8-1

PART 9 MSDS 9-1

AMENDMENT RECORD

Amendment Date

All Pages at First Issue 1.0

Second Issue 1.1

Third Issue 1.2

Fourth Issue 1.3

Fifth Issue 1.4

1 Dec 2004

18 Mar 2005

5 April 2005

8 June 2005

16 May 2006

5-1

Page 3

PART 1: INSTALLATION PROCEDURES

CONTENTS

INSTALLING THE SYSTEM 1-2

Mounting on production line 1-2

Ground Strap Installation 1-3

Input Power Connection and Modification 1-3

Installing the Print CARTRIDGE 1-4

CONNECTING THE CONTROLLER TO THE CARRIAGE 1-5

CONFIGURING THE PRINTING SYSTEM 1-6

System Reset 1-6

MULTIPLE PRINT HEADS 1-7

EVOLUTION 1 QUICK START

Changing Language Prompts 1-8

Enabling Print Mode 1-8

Head Select Mode 1-8

Entering a Message 1-9

Saving a Message 1-10

Loading a Message 1-11

EVOLUTION 1 SYSTEM QUICK SETUP

1-8

1-12

1 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 4

INSTALLING THE EVOLUTION 1 PRINTING SYSTEM

Caution should be taken while installing the EVOLUTION 1 printing system on your

equipment. Digital Design Inc. has taken every precaution to ensure a safe and

accurate instruction set to guide the installer through the installation process.

Follow the operational guidelines in the installation procedures.

VERIFY THAT YOUR EQUIPMENT IS IN PROPER OPERATING

CONDITION.

LOCATE A CONVENIENT POSITION ON YOUR EQUIPMENT.

EVOLUTION 1 REQUIRES 4-1/2" OF SPACE ON THE PRODUCTION

LINE.

FOLLOW THE INSTALLATION PROCEDURES.

READ CAREFULLY ALL INSTALLATION PROCEDURES BEFORE

PROCEEDING.

INSTALL THE PRINTING SYSTEM ON YOUR EQUIPMENT.

THERE IS NO EXTRA HARDWARE REQUIRED OTHER THEN

THAT SUPPLIED IN THE INSTALLATION KIT.

MOUNTING ON PRODUCTION LINE

Locate the supplied mounting template

and affix in a convenient location on the

production line. Spot and drill both

mounting holes for a 5/16” bolt. NOTE:

the user may also thread the side of the

conveyer using a 5/16” tap.

Fasten the mounting bracket to the

conveyer using the supplied mounting

hardware and ensuring that the supplied

ground strap is located securely beneath

either of the two mounting bolts, and that

conductivity to earth ground is less than 1 ohm. This ensures a proper path for

static discharge, should the need arise.

2 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 5

GROUNDING STRAP INSTALLATION

INSTALL STRAP

UNDER 5/16”

SCREW. E

CONDUCTIVITY TO

EARTH GROUND IS

LESS THAN 1 OHM

NSURE

INPUT POWER CONNECTION AND MODIFICATION

Insert the power plug to the available power source. The supplied power supply

will is universal and will auto detect 100/240 VAC 50-60hZ.

No other adjustments are necessary.

3 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 6

INSTALLING THE PRINT CARTRIDGE

Remove the protective film from the face of the print head and retain the film.

This protective film may be re-applied to store partially used cartridges. If it is

necessary to remove the print head and store for a long period of time, it is best

to re-apply the plastic film, and place the cartridge in a closeable plastic bag.

Rotate the Print Head Release mechanism to the rear of the print head so that it

is free for insertion of the print cartridge. Push the print cartridge in and down to

insert it into the print carriage. Gently lift the locking arm and press forward

against the print cartridge. A snap will be felt as the locking mechanism presses

the cartridge into the correct position.

NOTE: EACH PRINT CARTRIDGE HAS BEEN PROFILED

AT THE FACTORY. THIS PROCEDURE DETERMINES

THE OPTIMAL OPERATING CHARACTERISTECS FOR

EACH INDIVIDUAL CARTRIDGE. USING ANY OTHER

PRINT CARTRIDGE WILL HAVE UNDESIRABLE

RESULTS.

NOTE: WHEN A NEW CARTRIDGE IS INSTALLED,

BOTH THE RED AND GREEN LIGHT WILL FLASH

TWICE INDICATING A CORRECT INSTALLATION.

THE USER MUST REMEMBER TO RESET THE INK

LEVEL UNDER THE F4 FUNCTION KEY.

4 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 7

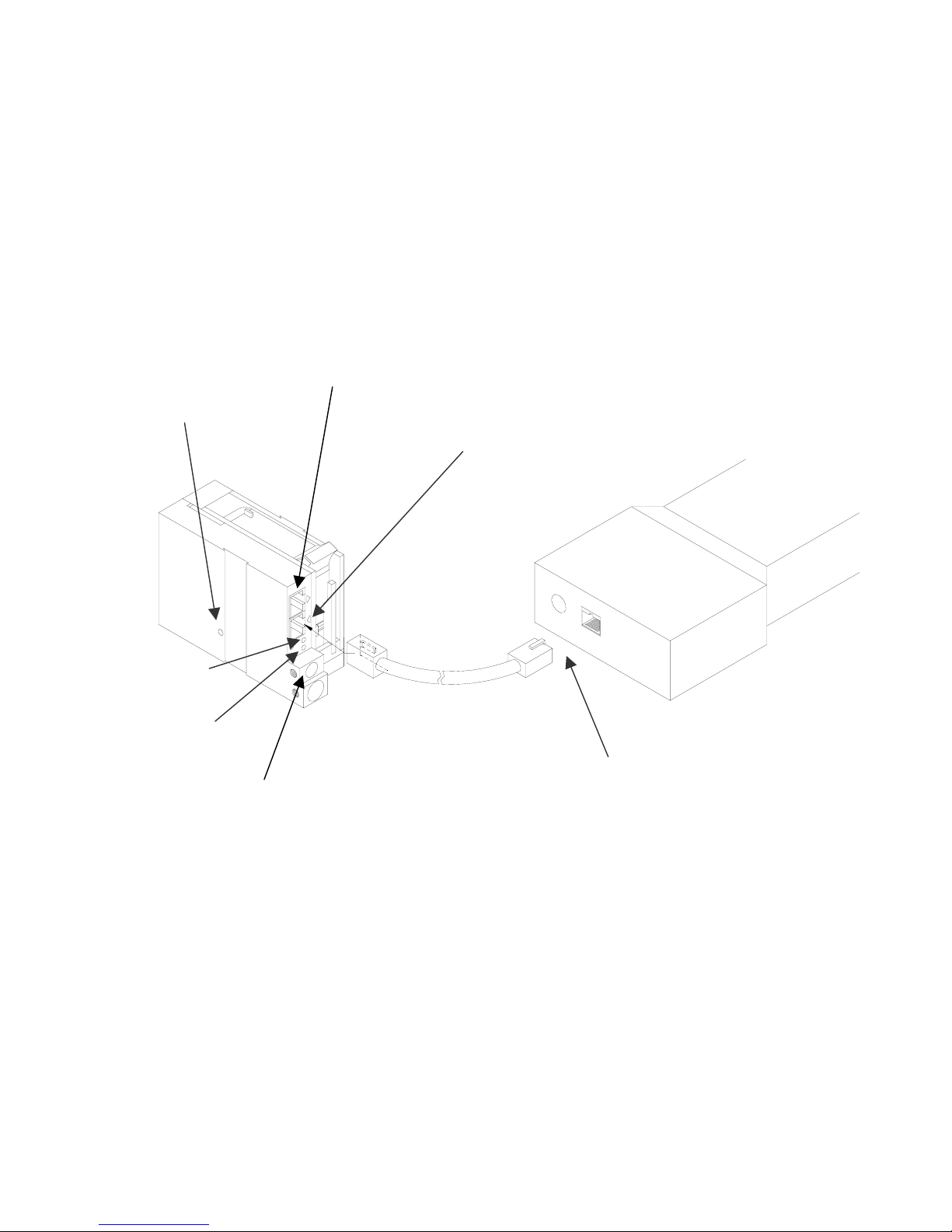

CONNECTING THE CONTROLLER TO THE CARRIAGE

Connect the Controller to the print carriage using the supplied 3 FT (.9 mm)

interconnect cable C21008-3 supplied with the Printing System. The cable is a

standard RJ50 (10 conductor). Longer cables are available as required.

Connect either end of the cable to the Carriage Assembly and securely lock in

place. NOTE: THE CONNECTOR MUST BE PLUGGED INTO THE INPUT RJ50

CONNECTOR LOCATED ADJACENT TO THE LED’S AND MARKED WITH

AN ARROW POINTING TO THE CONNECTOR. A click will be heard when the

connector is in the appropriate position. Connect the free end to the Controller

Assembly and ensure connector is securely seated.

PRINT CARRIAGE RJ50

RESET

SWITCH

ACCESS

HOLE

OUTPUT CONNECTOR

PRINT CARRIAGE RJ50

INPUT CONNECTOR

GREEN

CYCLE LED

RED PRINT

ENABLE LED

CONTROLLER RJ50

POWER INPUT

+12VDC @1.5A

CONNECTOR

CAUTION:

NOTE ORIENTATION OF THE CONNECTORS. DO NOT FORCE

CONNECTORS INTO POSITION SECURELY LATCH (CLICK) INTO

POSITION.

CONTROLLER MUST PLUG INTO THE PRINT CARRIAGE RJ50 INPUT

CONNECTOR FOR PROPER OPERATION. THE PRINT CARRIAGE RJ50

OUTPUT CONNECTOR IS USED EITHER FOR CONNECTION TO THE NEXT

PRINTER ON A NETWORK OR FOR EXTERNAL PRODUCT OR EXTERNAL

ENCODER INPUT.

THE POWER INPUT CONNECTOR MUST BE SECURELY INSERTED INTO

THE PRINT CARRIAGE. UPON PROPER INSERTION BOTH THE RED AND

GREEN LED’S WILL FLASH INDICATING PROPER CONNECTION.

5 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 8

CONFIGURING THE PRINTER

To verify the current operating software press the STOP PRINT

key.

Press the V key

CONTROLLER 7.08

PRINTER 2.08J

PRINTER SN XXXXXX

EXIT ANY KEY

The first line indicates the version of the controller software

The second line numerics indicate printer software version and the letter is the

firmware version of the printer. The ‘+’ (s) following indicate options installed:

+ _ _ _ = Option 1

_ _ + _ = Option 1.5

+ _ + _ = Option 1 and Option 1.5

+++ _ = Option 2

++++ = Option 3

The third line indicates the serial number of the printer

SYSTEM RESET

There are two types of resets available in the Evolution printing system. The first

type of reset is a SOFT RESET.

ERASE STORED

MESSAGES

YES OR NO Y/N

RESET PRINT HEAD

YES OR NO Y/N

ALL HEADS

WILL BE RESET

CONTINUE = X KEY

ANY OTHER EXITS

Depressing the R key while applying power to the

unit will display the reset command mode

CAUTION: A response of Y will delete all stored

messages.

The next screen to appear prompts the user to

determine if a print head is to be restored to its

default value.

CAUTION: ALL PRINT HEADS CONNECTED

TO THE CONTROLLER WILL BE RESET TO

FACTORY DEFAULT CONDITIONS. THIS

INCLUDES RESETING EACH UNIT ADDRESS

TO 1. TO PREVENT THIS REMOVE ALL

INTERCONNECTED PRINT HEADS EXCEPT

FOR THE UNIT TO BE RESET FROM THE

DATA LINK.

6 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 9

The second reset is a hard reset. Disconnect the power cable. Insert a standard

paper clip into the hole on the female dovetail side of the cabinet, and while

holding the paper clip in place (a light click will be felt) re-apply the power

connector.

This operation will reset the print carriage assembly to the factory default settings

and clear any current message.

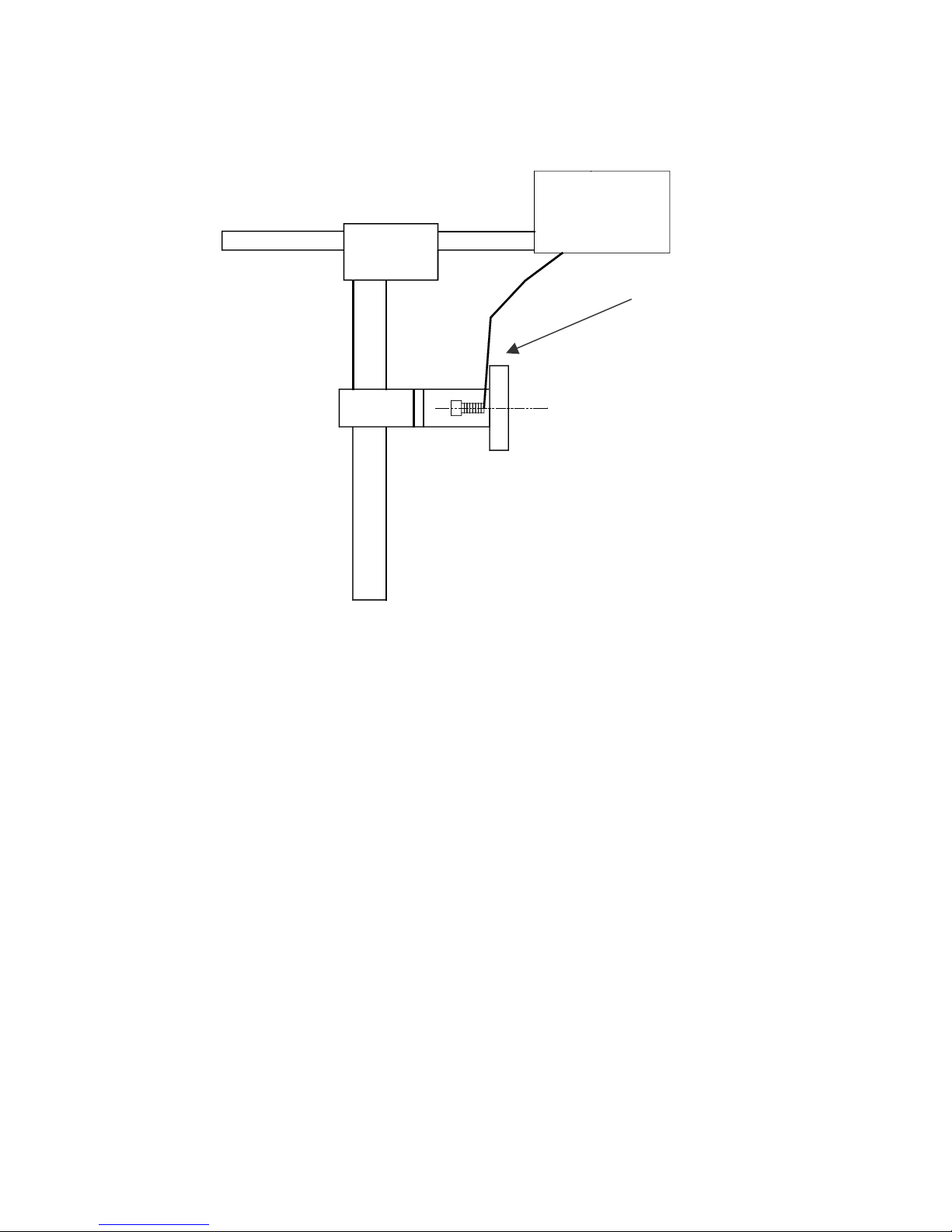

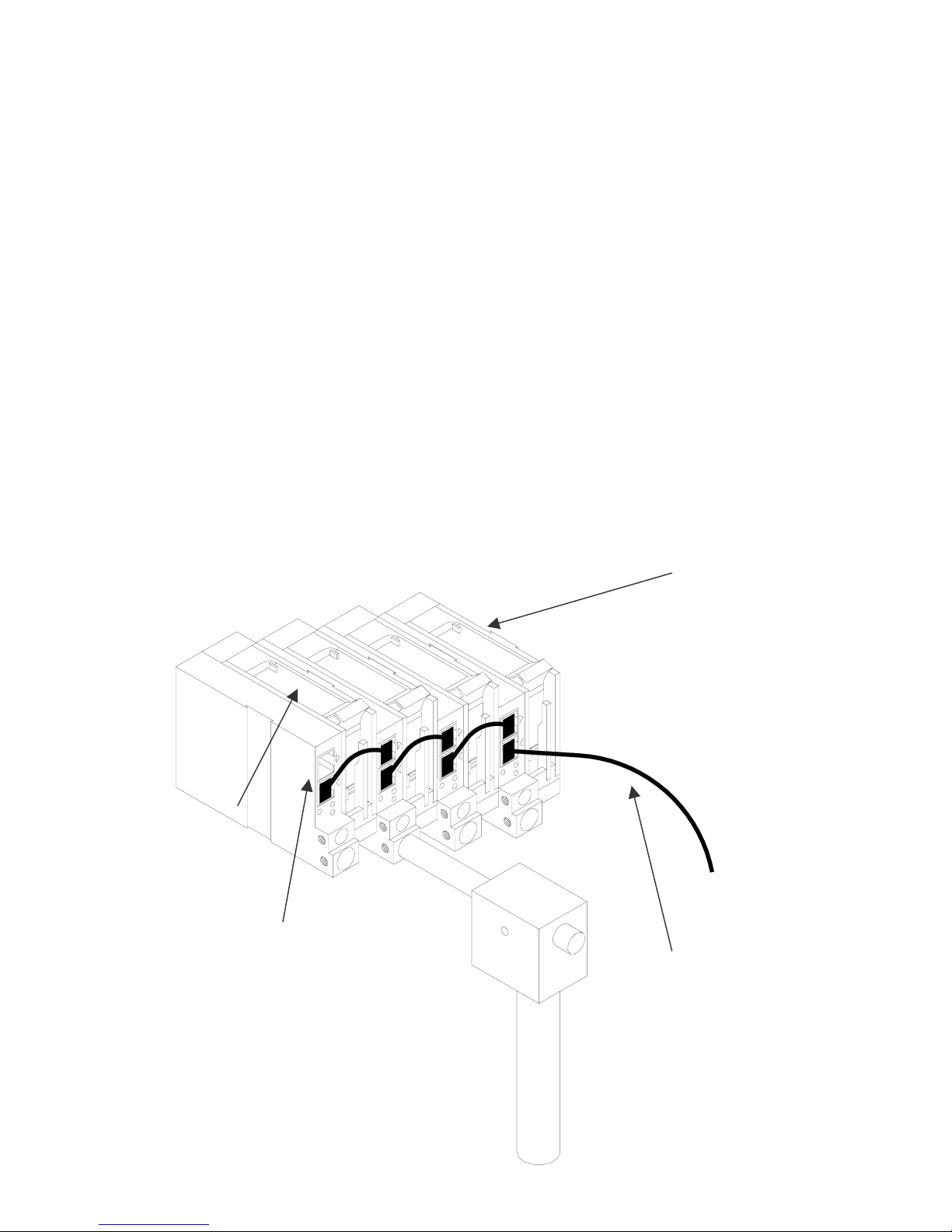

MULTIPLE PRINT HEADS

EVOLUTION 1 printing systems have the ability to reside on a network. The

network may contain from 1 to 32 print carriages connected via RJ50 cables.

These cables are available in varying lengths depending on the application.

Each mounting bracket can support up to 4 print carriages and would typically

interconnect with a 6” RJ50 data cable.

NOTE: Please address each unit individually as per page 2-17 prior to daisy

chaining the printers. Special care must be taken to connect the output of the

first print carriage to the input of the next print carriage.

When connecting multiple print carriages place no more than 2 stations on a side

of the mounting bracket as shown.

PRINT CARRIAGE

ADDRESS 4

PRINT CARRIAGE

LOCKING SET

SCREW

PRINT CARRIAGE

ADDRESS 1

TO

CONTROLLER

OR COMPUTER

DATA LINK

7 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 10

EVOLUTION 1 QUICK START

Connect the printer carriage to the appropriate

STOPPED

HD 1- - >SPEED=120

EVOLUTION 1

power source.

Connect the controller to the carriage assembly.

The controller derives power from the carriage.

On startup the LCD will display as pictured.

CHANGING LANGUAGE PROMPTS

< - - SELECT - - >

ENGLISH

Press the F4 key

LANGUAGE. Use the

desired language and press the

language.

ENABLING PRINT MODE

PRINTING

HD 1- - >SPEED=120

EVOLUTION 1

Press the GREEN PRINT key to start printing

HEAD SELECT MODE

STOPPED

HD 1- - >SPEED=120

The hand held controller can program up to 32 print

carriages on an RS485 data link. The factory default

sets each print carriage to ADDRESS 1. Selection

of another print head other than ADDRESS 1, press

EVOLUTION 1

and select for

keys to select the

to select the

< - - SELECT - - >

WHICH HEAD = 1

NO RESPONSE

ANY KEY TO EXIT

8 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

the

alternate print carriage number and press the

key. The print carriage whose address was selected

will respond with the current message and

appropriate parameters.

As an added convenience using the

scan to find the next available head connected to

the environment

Accessing an address not associated with any print

carriage will result in a no response message.

key. Use the keys to select the

will auto

Page 11

ENTERING A MESSAGE

STOPPED

HD 1- - >SPEED=120

EVOLUTION 1

MESSAGE ENTRY

FONT 1 LINE

EVOLUTION 1

MESSAGE ENTRY

FONT 1 LINE

MESSAGE ENTRY

FONT 1 LINE

EXP 12/10/04

PRINTING

HD 1- - >SPEED=120

EXP 12/10/04

Press the GREEN PRINT key

The LCD display will change from PRINTING to

STOPPED.

Press the GREEN EDIT key

Press the BLUE F3 key

message

Press the BLUE FONT key to select

the desired font size and enter the text EXP

12/10/04

Press the ENTER key

EDIT mode

Press the GREEN print enable key to enter

the print mode

to end the MESSAGE

to delete the entire

9 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 12

STORING A MESSAGE (OPTION PACK 1, 1.5, 2 OR 3)

STOPPED

HD 1- - >SPEED=120

EXP 12/10/04

MESSAGE # 1

PLEASE WAIT

MESSAGE # 1

MESSAGE STORED

EXP 12/10/04

STOPPED

HD 1- - >SPEED=120

EXP 12/10/04

Press the GREEN STOP PRINT KEY

Note: In option pack 1 there is a

maximum of 50 messages stored.

Option pack 1.5 increases message

storage to 99 messages.

Press the RED MESSAGE STORE key

The LCD display will display the message storage

screen

Use the

location

Press the RED MESSAGE STORE KEY

second time and the current message appears in

the selected location and is stored.

Press the ENTER key

command prompt.

or to select the desired storage

a

to return to the

10 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 13

LOADING A MESSAGE ((OPTION PACK 1, 1.5, 2 OR 3)

STOPPED

HD 1- - >SPEED=120

EVOLUTION 1

MESSAGE # 1

PLEASE WAIT

MESSAGE # 1

EXP 12/10/04

STOPPED

HD 1- - >SPEED=120

EXP 12/10/04

Press the GREEN STOP PRINT KEY

Note: In option pack 1 there is a

maximum of 50 messages stored.

Option pack 1.5 increases message

storage to 99 messages.

Press the RED MESSAGE STORE key

use the or keys to select the desired

message

and press the ENTER

key

and

PRINTING

HD 1- - >SPEED=120

EXP 12/10/04

Press the GREEN print enable key

the print mode

to enter

11 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 14

EVOLUTION 1 QUICK SETUP

Install a new cartridge. Press the following keys in order:

REMAINING INK

100 %

C NEW CARTRIDGE

OTHER KEY EXIT

Each time a new print cartridge is installed the system automatically profiles the

correct operating parameters for the new cartridge. These parameters set the

required voltage and on time to produce consistent results without user

intervention..

NOTE: USING OTHER THAN AUTHORIZED CARTRIDGES MAY CAUSE

UNDESIRABLE RESULTS.

Press the GREEN print enable key

To set the LINE SPEED, press to put the system in the Printing mode. Set

character width by

To set the PRINT DELAY press: to put the system in the Printing mode. Set

print delay by

To reset the ink level detector press

to enter the print mode

. NOTE: Each increment or decrement changes the delay by the pre-defined

amount.

You may continue to experiment with line speed and print delay until the desired

code registration on the product is achieved.

12 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 15

PART 2: OPERATION PROCEDURES

CONTENTS

OVERVIEW 2-2

Controller and LCD 2-2

Keypad Key Descriptions 2-3

Turning on the Print Station for the First Time 2-4

Checking System and Font information 2-4

Changing System Time and Date (OPTION PACK 2) 2-5

PROGRAMMING 2-6

Definitions and Modes of Operation 2-6

Menu Structure 2-7

F1 Menu 2-8

Character Spacing 2-8

External Encoder 2-8

Date Offset (OPTION PACK 3) 2-8

F2 Menu 2-9

Direction 2-9

Print Inverse 2-9

Product Detect 2-9

Auto Repeat (OPTION PACK 1 OR 2) 2-10

F3 Menu 2-11

Product Counter (OPTION PACK 3) 2-11

Shift Code (OPTION PACK 3) 2-12

Format Date (OPTION PACK 2) 2-13

Format Time (OPTION PACK 2) 2-14

F4 Menu 2-15

Change Language 2-15

Ink Supply 2-15

Set Unit Address 2-16

Load Card Fonts-Logos-Optional Software 2-17

SETTING UP LINE SPEED AND PRINT DELAY 2-20

Setting Line Speed 2-20

Setting Print Delay 2-21

INPUT, EDIT AND DELETE MESSAGES 2-22

Editing Messages 2-22

PASSWORD PROTECTION (OPTION PACK 1 OR 2) 2-24

MESSAGE STORAGE (OPTION PACK 1, 1.5 OR 2) 2-25

Storing a Message 2-25

Recalling A Stored Message 2-25

1 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 16

OVERVIEW

CONTROLLER AND LCD

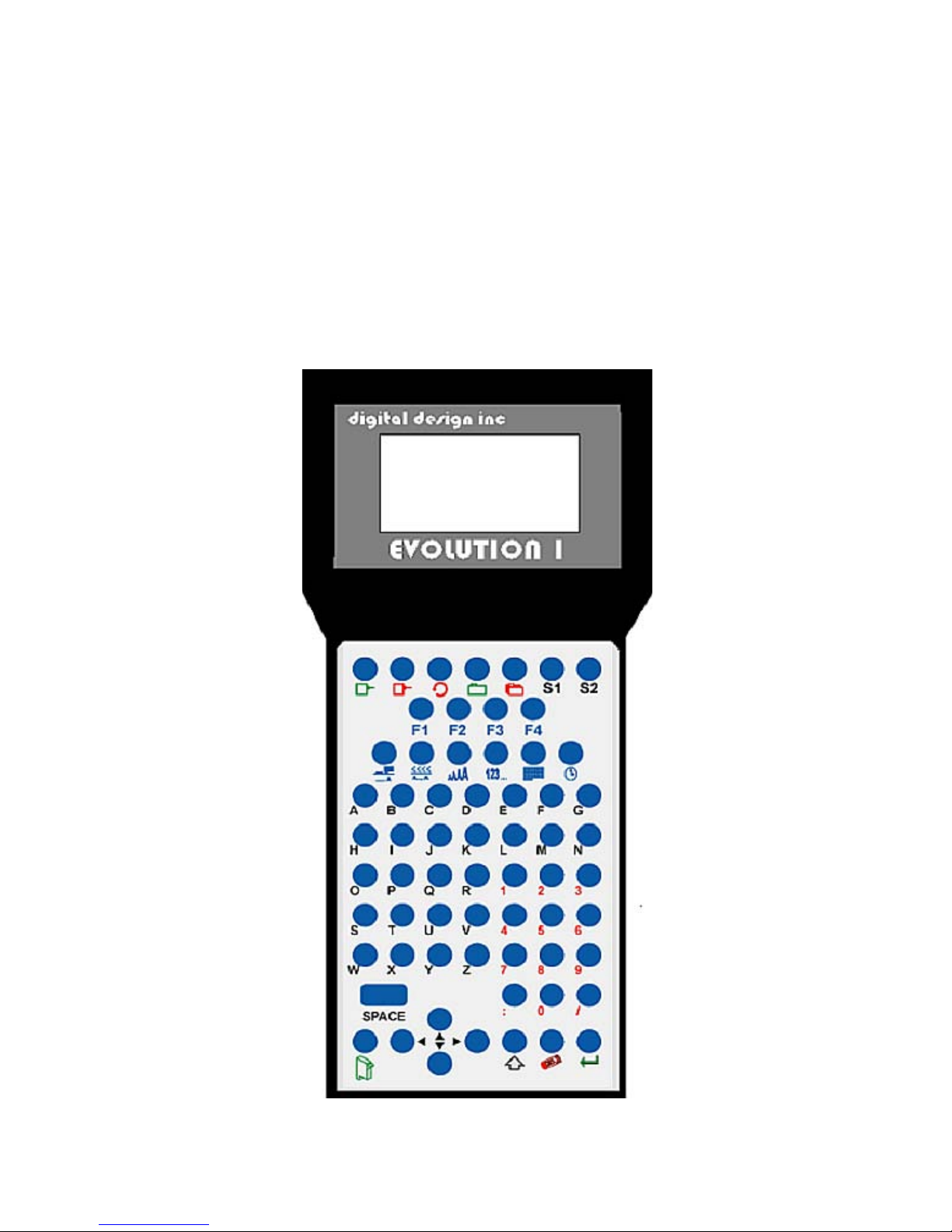

The keypad on the print station, pictured here, contains 64 keys. The LCD will

display various messages to assist in programming on the upper half of the

display. The lower half of the display will show up to two lines of the entered

print message.

The 4 keys on the top row are the function keys F1 through F4. They each

consist of submenus for modifying various printer functions. Their specific

menus are detailed later in this section.

.

STOPPED

HD 1 - ->SPEED= 120

EVOLUTION 1

2 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 17

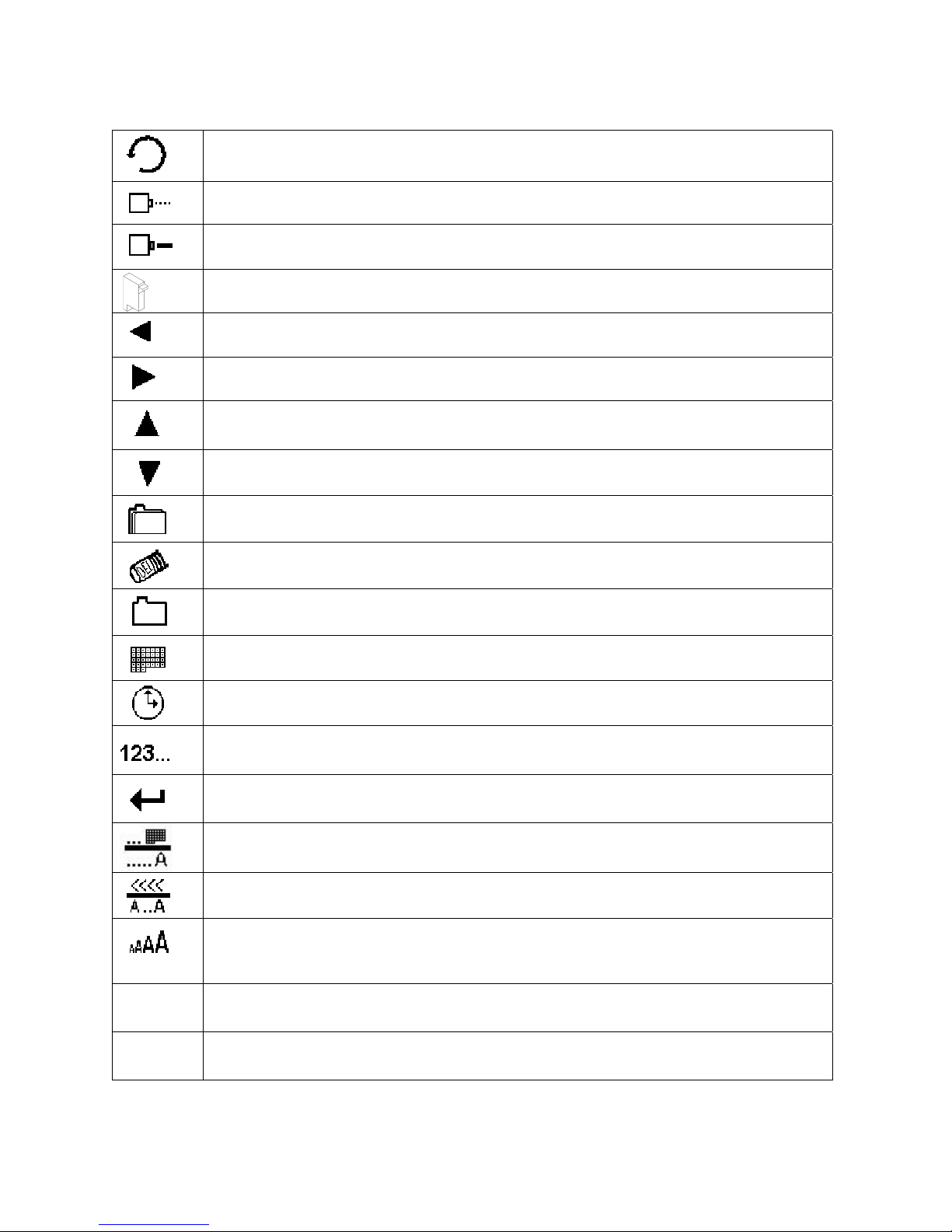

KEYPAD KEY DESCRIPTIONS

This is the manual cycle key. When in the Stopped mode, pressing this

key causes the printer to print one code

.

This is the Print key. Use it to place the unit in the Print mode

This is the Purge key. Use it to purge ink for maintenance purposes. The

unit must be in the Command mode to use this key.

This is the Head Select key. Use it to select the address of the head to be

S1

communicated with.

Use this arrow to decrease values, and use it to move the cursor in the

message line while editing the message.

Use this arrow to increase values and use it to move the cursor in the

message line while editing the message.

Use this arrow to move the cursor between the message lines while in

Edit mode and building a message.

Use this arrow to move the cursor between the message lines while in

Edit mode and building a message.

This key is the Message Storage key. Use it to store and to recall

individual codes.

This is the Delete key. Use it to backspace to delete a character when

mistyped as well as to exit from certain menus.

This is the Message Entry key. Use this key to enter the Message Entry

mode, to input a code or to edit a code.

This is the Date key. Use this key to enter the Date in Message Entry

Mode. (OPTION PACK 2). Change Date in STOPPED mode.

This is the Time key. Use this key to enter the Time in Message Entry

Mode. (OPTION PACK 2). Change Time in STOPPED mode.

This is the Sequence Number key. Use this key to enter the Sequence

Number in Message Entry Mode. (OPTION PACK 2)

This is the Enter or Return key. When pressed, the unit will accept input

and exit certain menus.

This key selects the Print Delay in COMMAND mode and Offset Date in

EDIT mode (OPTION PACK 3)

This key selects the Line Speed in COMMAND mode and the shift code in

the EDIT mode (OPTION PACK 3)

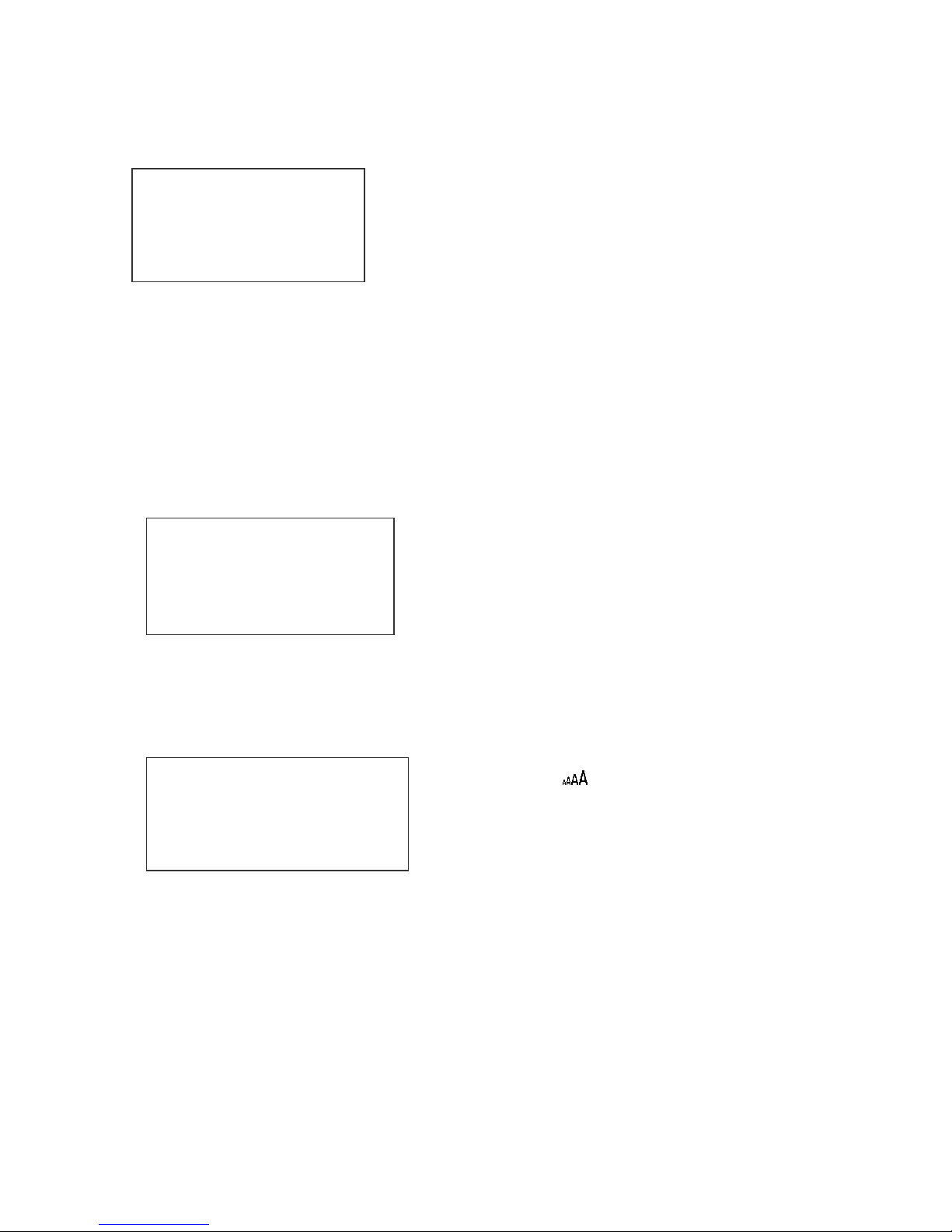

This key selects the Font size in the EDIT mode.

In the COMMAND mode pressing this key displays the current fonts

loaded in the print head.

Pressing this key while in the Message Entry mode accesses special

characters

S2

3 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

This key is reserved for special customer Logos

Page 18

TURNING ON THE PRINT STATION FOR THE FIRST TIME

To turn the print station on insert the power jack into

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

information regarding the system:

The Top line indicates the operating mode of the unit: “STOPPED” when in

Command mode, “ PRINTING” when in Print mode, and “MESSAGE ENTRY

when in message entry.

The 2

product and the programmed SPEED.

The lower half two lines of the display shows the message entered for printing.

This may represent one or two lines of code.

nd

line shows the print head currently selected, the direction of travel for the

the DC power connector.

There is no on/off switch.

The first time the print station is turned on, as

received from the factory, the LCD will look like the

illustration on the left. Each line gives important

CHECKING SYSTEM INFORMATION

CONTROLLER 7.08

PRINTER 2.08J +++

PRINTER SN284955

ANY KEY TO EXIT

pack 1, the second + indicates option pack 1.5 and the last + indicates option

pack 2.

Verify system information by pressing the V key

on the hand held controller keyboard. The LCD

screen will display the software, firmware, serial

number and options enabled. Enabled options

are indicated on the second line as a series of +

characters where the first + indicates option

CHECKING LOADED FONTS

ACTIVE FONTS

2 LINE fontname

1 LINE fontname

ANY KEY TO EXIT

Press the FONT key in the COMMAND

mode to check what fonts are currently loaded

in the print head.

4 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 19

CHANGING SYSTEM DATE (OPTION PACK 2 INSTALLED)

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

PRESENT SETTING

ANY CHANGES Y/N

01/04/00

ENTER MONTH-

PRESENT SETTING

ANY CHANGES Y/N

04/23/05

When the unit is in the STOPPED mode

pressing the DATE key allows the user to

change the system date. If there are no

changes press the N key to return to the

STOPPED mode.

Press the Y key to change the date.

The system will prompt the user first for the

Month (enter 2 digits), then the Day (2 digits)

and finally the year (2 digits).

After the data is entered the system displays

the currently entered date and pressing the N

key returns the user to the STOPPED mode,

or press Y to the correct the date.

CHANGING SYSTEM TIME (OPTION PACK 2 INSTALLED)

Select the N key if the time is correct and

PRESENT SETTING

ANY CHANGES Y/N

23:05

PRESENT SETTING

ANY CHANGES Y/N

23:05

ENTER HOURS -

PRESENT SETTING

return to the STOPPED mode.

Press the Y key to change to the correct time.

Enter the correct hours (2 digits) followed by

the correct minutes (2 digits). The screen

displays the corrected time. Press the Y key to

make further changes or N key to return to the

STOPPED mode.

Notice the time is in 24-hour format.

ANY CHANGES Y/N

13:50

5 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 20

PROGRAMMING

DEFINITIONS

There are two parts to programming the EVOLUTION 1 ink jet printer,

• Setting the operations parameters, (character width, delay, etc.) and

• Building the message.

MODES OF OPERATION

The system operates is 3 basic modes. They are: Print Mode, Command Mode,

and Message Entry Mode.

In Print Mode the majority of the keys on the keypad are disabled to avoid

inadvertent changes. When in Print Mode the Top line of the LCD will display

PRINTING.

The Command Mode is used to change the functions of the printer. When in the

Command Mode the display will show STOPPED on the top line.

The Message Entry Mode is used to create or modify printable codes, when in

this mode the top line of the display will show MESSAGE ENTRY.

PRINT MODE AND STOPPED “COMMAND” MODE

PRINTING

HD1- - >SPEED=120

EVOLUTION 1

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

Mode. To enter Command mode, press

When in the Print mode the screen will look like

the screen on the left. When PRINTING is seen

on the LCD, the unit will print as product passes in

front of the carriage assembly. To enter Print

mode, press

When in the Command Mode the screen looks like

the illustration at left. When STOPPED the printer

will not print when product is moved past the

carriage assembly.

In Command mode, access can be made to the

menus under the function keys, F1 through F4

icon control keys plus access to Message Entry

.

.

6 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 21

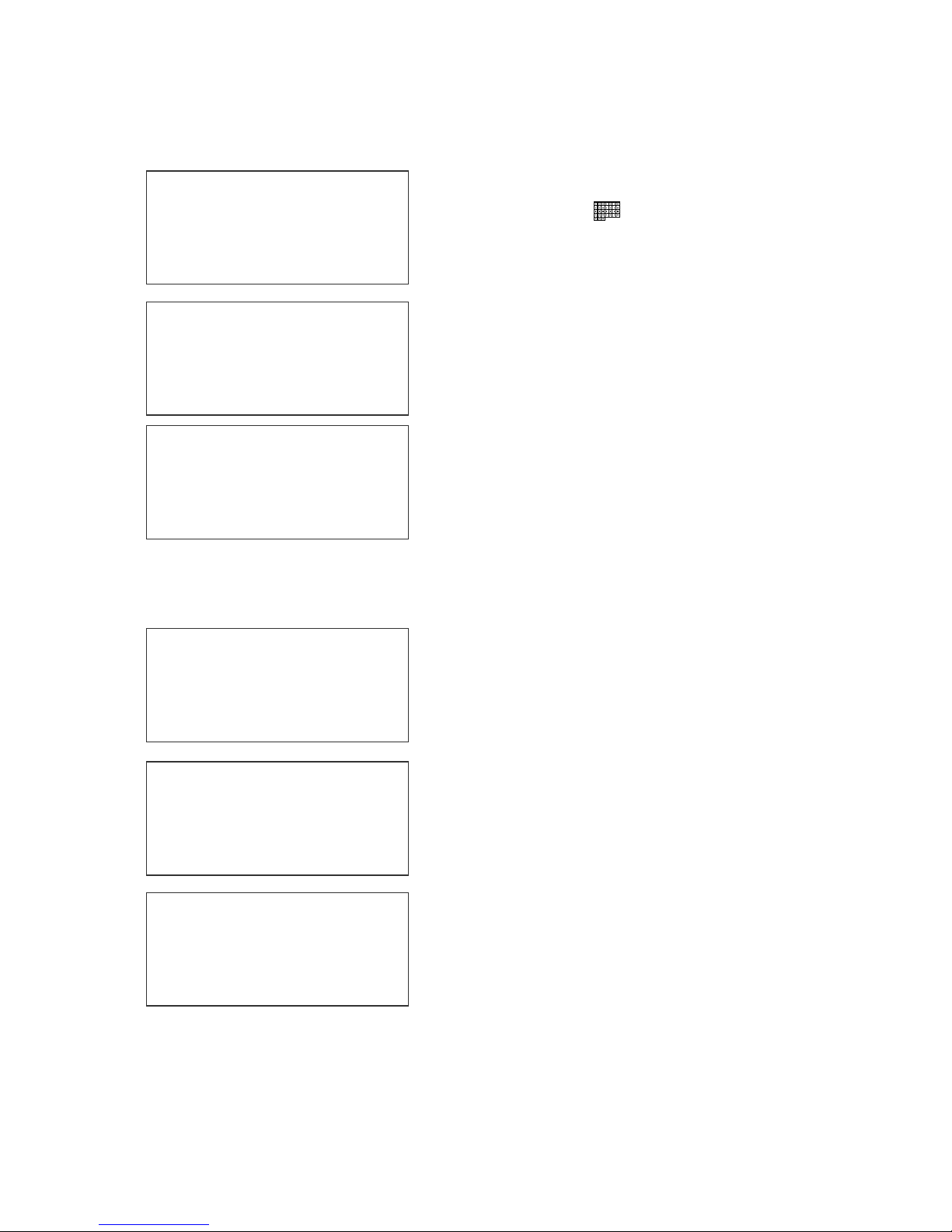

MENU STRUCTURE

In the Command mode, access is allowed to the menu structure for basic

parameters. The menus reside within the function keys, F1 through F4. In order

to select one of the parameters, press the number key that corresponds to the

desired parameter.

The F1 key, when pressed, brings up the menu as shown below.

1=CHAR. SPACING

2=EXT. ENCODER

3=DATE OFFSET

The F2 key, when pressed, brings up the menu as shown below.

1=DIRECTION

2=PRINT INVERSE

3=PRODUCT DETECT

4=AUTO REPEAT

The F3 key, when pressed, brings up the menu as shown below.

NOT AVAILABLE

ANY KEY TO EXIT

1= PRODOCT COUNT

2= SHIFT CODE

3=DATE FORMAT

4=TIME FORMAT

The F4 key, when pressed, brings up the menu as shown below.

#3 VALID IN OPTION PACK 3 ONLY

SCREEN WITHOUT OPTION PACK 2 OR 3

INSTALLED

#1 VALID IN OPTION PACK 3 ONLY

#2 VALID IN OPTION PACK 3 ONLY

#3 VALID IN OPTION PACK 2 OR 3

#4 VALID IN OPTION PACK 2 OR 3

1=LANGUAGE

2=INK SUPPLY

3=SET UNIT I.D.

4=LOAD CARD

7 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 22

F1 MENU

1=CHAR. SPACING

2=EXT. ENCODER

3=DATE OFFSET

reserved for future system expansion.

Place the unit in the Command mode and press

. The screen shown to the left is produced.

Press the correct number to make changes to that

parameter. Those selections designated as NOT

AVAILABLE will not respond to selection. They are

1 = CHARACTER SPACING:

< - - SELECT - - >

# OF SPACES- 1

This parameter controls the amount of space

between characters in the code. Spacing can be

varied from 1 to 25 columns. Use this control to

make printed codes more legible when code is

change the value. Press

compressed. Press the

once the desired value is displayed.

then press or to

2 = EXT. ENCODER:

ENCODER

1=INTERNAL

2=EXTERNAL

line. The printer can be set to produce a perfect aspect ratio character (300 dpi

vertical and horizontal) or compressed by setting the print head line speed faster

than the actual line speed, or expanded by changing the internal speed slower

than the actual line speed.

In the event there is an acceleration or deceleration to the production line, or

there is a requirement to guarantee accurate aspect ratio, such in the case of

barcodes, an external encoder is necessary. Press

encoder. While external encoder is selected the LINE SPEED key will adjust

the expansion and compression of the printed message. NOTE: WHEN

PRODUCING BARCODES IT IS NECESSARY TO PRODUCE A PERFECT

ASPECT RATIO CHARACTER.

Press to select internal time base. This

parameter controls the source of the time base used

for printing. Each vertical column printed requires a

signal necessary to produce a character

representative of the line speed of the production

to select external

3 = DATE OFFSET: (OPTION PACK 3 ONLY)

This selection is only available with option pack 3

DATE OFFSET

USE KEYS 0->9

# OF DAYS = 100

installed. This allows the user to preset the number of

days used in the date offset calculation to a maximum

of 999 days. The format of the date offset can be

different than a normal date and may be set with the

F3 #3 option DATE FORMAT.

8 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 23

F2 MENU

Place the unit in the Command mode and press

1=DIRECTION

2=PRINT INVERSE

3=PRODUCT DETECT

4=AUTO REPEAT

produced. Press the correct number to make

changes to that parameter

NOTE: OPTION 4 ONLY APPEARS IF OPTION

PACK 1 IS INSTALLED

. The screen shown to the left is

1 - DIRECTION:

The arrow shown on the LCD’s third line screen

< - - SELECT - - >

LINE DIRECTION

< - - - -

should agree with the direction of product travel.

Press

for the unit to accept the change.

or to change direction. Press

2 - PRINT INVERSE:

CODE ORIENTATION

1 = NORMAL PRINT

This parameter allows the code to print right side

up or upside down. Pressing

the following screen. Press for normal print

will produce

2 = UPSIDE DOWN

on the imprint.

or

by pressing . Look for the change of direction

for upside down codes. Save the choice

3 – PRODUCT DETECT:

PRODUCT DETECT

1 = INTERNAL

2 = EXTERNAL

a portion of the product not directly in front of the print head then an external

product detect sensor must be used. This setting also allows the EVOLUTION 1 to

be controlled from other sources, like a PLC. When external product detect is

selected the user must also change the jumper option within the print head. Refer

to the OPTION SELECT section for proper use.

This menu selection allows the user to select the

source of the product detect feature. Press

to use the internal product detect sensor located

at the front of the print carriage just below the

print cartridge. If it becomes necessary to sense

9 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 24

4 - AUTO REPEAT: (OPTION PACK 1, 2 OR 3)

< - - SELECT - - >

REPEAT TIME= 0

time delay adds or subtracts a distance equivalent to the pre-defined setting.

Save your choice by pressing

This option enables the unit to continuously print

repeated codes at specified time intervals along

the entire length of the product. A time of 0

disables the Auto Repeat option. Use

or

to change the repeat time. Each number in the

.

10 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 25

F3 MENU

This menu is reserved for system expansion.

NOT AVAILABLE

ANY KEY TO EXIT

WITH OPTION PACKS INSTALLED

1 – PRODUCT COUNT: (OPTION PACK 3 ONLY)

1= PRODUCT COUNT

2= SHIFT CODE

3=DATE FORMAT

4=TIME FORMAT

Press F3 to change the product count feature.

Each of the following screens prompts the user

to enter the desired format.

NOTE: this is not a printable field.

PRODUCT COUNT

CHANGES Y / N OR C

08:00 - - > 16:00

COUNT = 000000

Enter Y to change the product count start and

end times or N to abort. If the counter is to be

cleared enter the letter C

PRODUCT COUNT

START TIME

08:00 - - > 16:00

ENTER HOURS-

Selecting Y prompts the user to enter the

desired hours-starting time.

NOTE: all times are entered in military time

PRODUCT COUNT

START TIME

08:00 - - > 16:00

ENTER MINUTES-

The next screen prompts for the start time

minutes.

PRODUCT COUNT

END TIME

08:00 - - > 16:00

ENTER HOURS-

PRODUCT COUNT

START TIME

08:00 - - > 16:00

Next the user enters the ending hours time.

NOTE: all times are in military time.

Finally, the ending time minutes are entered.

The product count feature is a non-printable

value and may only be accessed via this menu

function. It will accumulate product counts each

day until the value is cleared using the C key at

the start of the menu option.

ENTER MINUTES-

11 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 26

2 – SHIFT CODE: (OPTION PACK 3 ONLY)

1= PRODUCT COUNT

2= SHIFT CODE

3=DATE FORMAT

4=TIME FORMAT

ADJUST SHIFTS

< - - SELECT - - >

SHIFT 1 07:00 A

ANY CHANGES Y/N

The shift code option allows the user to enter 6

different shift times per day. Use the arrow keys

to select a shift and enter a Y to change a shifts

start time.

ADJUST SHIFTS

SHIFT 1

START TIME

ENTER HOURS -

Enter the shift starting hours.

Note: all times are in military format

ADJUST SHIFTS

SHIFT 1

START TIME

ENTER MINUTES -

The next screen prompts for the shift starting

minutes.

ADJUST SHIFTS

SHIFT 1

PRINT CODE -

Finally, enter the desired code required to

represent a shift. This may be any

alpha/numeric field. This field will automatically

increment with each shift change.

NOTE: TO DISABLE A SHIFT ENTER A SPACE CHARACTER IN

THE PRINT CODE FIELD. THE SHIFT TIMES WILL BE

DISPLAYED AS --:-- FOR ALL DISABLED SHIFT TIMES.

12 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 27

3 – DATE FORMAT: (OPTION PACK 2 OR 3)

Press F3 to change the date formatting. Each of

1= NOT AVAILABLE

2= NOT AVAILABLE

3=DATE FORMAT

4=TIME FORMAT

CHANGE FORMAT

1=CALENDAR DATE

2=OFFSET DATE

MONTH FORMAT

1=NUMERIC

2=LETTERS

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

dm/dd/dy

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

jjj

DATE FORMAT

D=DAY M=MONTH

Y=YEAR J=JULIAN

jjjyy

return to the STOPPED mode.

MONTH FORMAT

1=NUMERIC

2=LETTERS

the following screens prompts the user to enter

the desired format for printing.

When option pack 3 is installed the user has the

option of selecting a different date format for the

normal printed calendar date and the printed

date offset. Select 1 or 2 to alter the appropriate

date field.

Selecting the standard numeric format will

prompt the user to enter the format of the date in

standard number format.

The default as shipped from the factory is

dm/dd/dy, and may be modified as required.

If the offset format was selected the word DATE

is replaced with the word OFFSET.

To change the format press the delete key and

the last line on the display will be erased. The

entire format will be erased and must be reentered.

Press either of the designator keys (ie M for

month) and the display will display the correct

code for the item selected. As an example enter

the Julian date and year. Press the J key

followed by the Y key. The code entered will

print the Julian date followed by the 2-digit year.

Notice no delimiters were selected, but may

have been entered by selecting the appropriate

key on the keyboard. Press the Enter key to

Alpha characters may have bee selected by

pressing option 2.

13 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 28

Delete the current formatting by pressing the

DATE FORMAT

D=DAY M=MONTH

Y=YEAR

jjjyy

DATE FORMAT

D=DAY M=MONTH

Y=YEAR

ddmmmyy

Delete key.

NOTE: DELIMITER CHARACTERS

LIKE A / CODE MAY BE ENTERED TO

SEPARATE FIELDS

Enter the desired Date Format and notice when

the M (month) is selected the display shows

mmm. Select the appropriate key on the

keyboard by entering in the desired code. Press

the Enter key to return to the STOPPED mode.

4 – TIME FORMAT: (OPTION PACK 2 OR 3)

Change the Time Format by selecting option 4.

1= NOT AVAILABLE

2= NOT AVAILABLE

3=DATE FORMAT

4=TIME FORMAT

TIME FORMAT

H=HOURS

M=MINUTES

hh:mm

TIME FORMAT

H=HOURS

M=MINUTES

hh

NOTE: Delimiter characters like a :

code may be entered to separate fields

The factory default for time formatting is hh:mm

and may be changed as required. Press the

Delete key and the last line on the display is

erased.

Enter the desired format by pressing the H and or

M keys, and select delimiters as required. Select

H if only hours are required.

Press the Enter key to return to the STOPPED

mode.

14 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 29

F4 MENU

1 = LANGUAGE

2 = INK SUPPLY

3 = SET UNIT I.D.

4 = LOAD CARD

Place the unit in the Command mode and press

. The screen shown at left is produced.

Press the number that corresponds to the

parameter you wish to change.

1 - LANGUAGE:

Press and the screen will change like the

< - - SELECT - - >

ENGLISH

mode. Whenever language is chosen, all prompts and commands shown on the

screen will be in that language.

one on the left. The default language is English;

the other choice is Spanish. Scroll through the

choices using either or . Once the

desired language is shown on the screen, press

. This will return the unit to the Command

2 - INK SUPPLY:

The second line of the display shows the

REMAINING INK

100

C

NEW CARTRIDGE

ANY KEY TO EXIT

When a C is entered the system automatically profiles the operating conditions

for the new cartridge.

Each cartridge is tested and profiled at the factory eliminating the burden of

personalizing each cartridge by the user. There are a number of tasks associated

with print cartridge profiling, as each print cartridge differs from another. The

correct drive voltage, pulse width timing and pre-fire pulse warming must be

calculated for optimum operation.

percentage of ink remaining in the print

cartridge.

Each time a new cartridge is installed the user

must reset the system ink gauge by pressing the

C key.

NOTE: USING NON-AUTHORIZED CARTRIDGES MAY

PRODUCE UNDESIRABLE RESULTS

15 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 30

3 – SET UNIT I.D.:

< - - SELECT - - >

SET HEAD # = 1

when adding multiple print carriages to affix a label indicating the unique

ADDRESS number of the individual carriage. To program a carriage it must be

connected directly to the hand held controller, with no other carriages connected.

Each print carriage can contain a unique address

to distinguish multiple carriages when controlled

by a single hand held controller or computer data

link using an RS485 data link. The default for each

new print carriage module is ADDRESS 1.

Addresses can range from 1 to 32. It is advisable

16 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 31

4 – LOAD CARD:

LOADING FONTS (MENU SELECT 1)

EXECUTE LOADER

1=LOAD FONTS

2=LOAD LOGOS

3=LOAD OPTIONS

LOAD FONT

1= LOAD DEFAULTS

2= LOAD ALTERNATE

LOAD RESULTS

PLEASE WAIT

MEMORY ERROR

NO FLASH CARD

ANY KEY TO EXIT

LOAD RESULTS

2 LINE fontname

1 LINE fontname

ANY KEY TO EXIT

LOAD RESULTS

2 AF fontname

The user can replace the existing FONT, add up

to six logos, or load optional software from a Data

Flash card, which is plugged into the top of the

print carriage. Select 1 to load a different font to

replace the current system font.

The screen to the left will appear and after a few

seconds a result will be displayed to indicate

NOTHING LOADED or the name of the newly

loaded font, logos or software upgrades.

To load or replace the current LOGOS in the

system press the

FONTS the screen at the left will appear indicating

the load results.

This screen will be displayed if the data flash card

is either not present or cannot be read.

CHECK THAT THE DATA FLASH CARD IS

PROPERLY INSTALLED

A successful load will display the current font

names loaded into the print head. This screen will

be displayed when the default fonts are loaded.

When loading alternate fonts the AF will replace

LINE for the alternate font or fonts loaded.

1 AF fontname

ANY KEY TO EXIT

key. Similar to loading

17 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 32

LOADING LOGOS (MENU SELECT 2)

EXECUTE LOADER

1=LOAD FONTS

2=LOAD LOGOS

3=LOAD OPTIONS

EXECUTE LOADER

PLEASE WAIT

MEMORY ERROR

NO FLASH CARD

ANY KEY TO EXIT

LOAD RESULTS

2 LINE 1 2 3

1 LINE 1 2 3

ANY KEY TO EXIT

LOADING OPTIONS (menu select 3)

EXECUTE LOADER

1=LOAD FONTS

2=LOAD LOGOS

3=LOAD OPTIONS

NOTE: when optional software is loaded into the system the Data Flash

Card is encoded with the serial number of the unit and is valid only for the

unit in which the software was loaded.

CONTROLLER 7.08

PRINTER 2.08I ++++

PRINTER SN284955

ANY KEY TO EXIT

1, the second + indicates option pack 1.5 the third is option pack 2 and the last +

indicates option pack 3.

The user can replace the existing FONT, add up

to six logos, or load optional software from a Data

Flash card, which is plugged into the top of the

print carriage. Select

print head.

This screen will be displayed if the data flash card

is either not present or cannot be read.

CHECK THAT THE DATA FLASH CARD IS

PROPERLY INSTALLED

Displaying the number of logos as indicated in the

pictorial indicates successful loading.

The display indicates the number of logos loaded

for the 1 line or 2 line mode.

Optional software may be added via Data Flash

Card to the basic unit to add features.

Verify system information by pressing the V key

on the hand held controller keyboard. The LCD

screen will display the software, firmware, serial

number and options enabled. Enabled options are

indicated on the second line as a series of +

characters where the first + indicates option pack

to load logos into the

18 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 33

NOTE: THE FIGURE BELOW SHOWS THE CORRECT

ORIENTATION FOR INSERTING THE DATA FLASH CARD.

INSERT THE DATA FLASH CARD INTO THE

SLOT PROVIDED AT THE TOP OF THE PRINT

CARRIAGE AS SHOWN. NOTE THE

ORIENTATION OF THE LABEL ON THE CARD.

PRESS THE CARD COMPLETELY INTO THE

SLOT. THE CARD SHOULD BE REMOVED

AFTER USE AND STORED IN A SAFE PLACE.

ONCE LOADED (FONTS & OPTIONS) THE CA

IS SECURITY LOCKED WITH THE SERIAL

NUMBER OF THE PRINTER CARRIAGE AND

WILL NOT OPERATE IN ANOTHER PRINT

CARRIAGE.

RD

NOTE:

There are two fonts loaded into the EVOLUTION printer at

any one time. Loading a new font will overwrite the existing font

or fonts. Print starts at the bottom nozzle of the print head (dot

150 for line 2) and at the middle of the print head (dot 75 line 1).

The printer is shipped with a 1/2” font (FONT1 for a single line of

print) and a 7/32” font (FONT0 for two lines of print). The 1/2”

font may be replaced with other than a 1/2” tall character.

Alternate fonts that are loaded replace the existing fonts.

Inserting a data flash card containing alternate fonts and cycling

the power will temporarily use the alternate fonts on the data

flash card until the card is removed and either the power is

cycled or the print station is set to the STOPPED mode. This

eliminates the need to load the alternate font using the LOAD

CARD option.

19 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 34

SETTING PRINT DELAY AND LINE SPEED

LINE SPEED – This setting adjusts the width of the printer message on the

product. This setting should be adjusted to produce the desired print on the

product. Line speed can be increased or decreased to stretch or compress the

message to fit the desired print area.

PRINT DELAY – This setting adjusts the location of the printed message on the

product.

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

Access to these parameters is possible when the

unit is in either the STOPPED or PRINTING mode

as shown to the left.

Pressing the delay key allows the user

to determine the amount of print delay. Each

PRINTING

HD1- - >SPEED=120

EVOLUTION 1

count at a normal aspect ratio is

approximately 0.060”. This will vary

according the amount of compression or

expansion used.

SETTING LINE SPEED

Normally, the system will be set to use the internal

< - - SELECT - - >

LINE SPEED = 100

this parameter. Once pressed, a new screen appears, as shown to

the left. Changes can now be made by using

character width is 1 to 200. Once the desired number is chosen, press

save your entry.

< - - SELECT - - >

ENCODER DIV = 4

time base for line speed control. The default value is

100, which creates a normal width character on a

line moving at 100 ft per min. The print can be

narrowed by increasing the number and widened by

decreasing the number. Pressing accesses

or . The range of values for

to

If external encoder is enabled and the unit is in the

PRINTING mode the user has the option of

adjusting the compression ratio of the printer

message. Changes may be made by using

. Once the desired number is chosen, press

to save your entry.

or

20 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 35

SETTING PRINT DELAY

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

is either in the PRINTING or STOPPED mode

PRINTING

HD1- - >SPEED=120

EVOLUTION 1

< - - SELECT - - >

PRINT DELAY= 100

PERFECT ASPECT RATIO CHARACTER. WHEN PRINTING A COMPRESSED

OR EXPANDED CHARACTER THE ACTUAL DIMENSIONAL NUMBER WILL

BE DIFFERENT BUT CAN BE ESTIMATED BASED ON THE 18 COLUMNS

PER COUNT.

NOTE: Setting the line speed first, then adjusting the print delay may prove

to be the best starting point

Print delay is used to position a message on the

product at a location other than at the leading edge.

Access this parameter by pressing

keypad.

NOTE: This parameter may be set when the unit

To change the value use either

range of values for this parameter is 1 to 255. Each

increment represents 18 columns, approximately

.060” (1.5mm). Therefore, a delay of 255 would

approximate 15.3” (388mm). Once a number is

chosen, press

DIMENSION INDICATED IS WHILE PRINTING A

to save the entry. NOTE: THE

on the

or . The

21 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 36

INPUT, EDIT OR DELETE MESSAGES

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

MESSAGE ENTRY

FONT 1 LINE

EVOLUTION 1

MESSAGE ENTRY

FONT 1 LINE

MESSAGE ENTRY

FONT 1 LINE

EXP 12/01/2004

MESSAGE ENTRY

FONT 2 LINE

BEST BY

EXP 12/01/2004

STOPPED

HD1- - >SPEED=120

BEST BY

To input, delete or edit a message, the unit must be

in the STOPPED Mode. If the LCD reads

PRINTING, press

similar to the one shown at the left.

Enter the Message Entry mode by pressing

The top portion of the screen will change as shown

on the left.

The user has two options to edit or change a

message. If a new message is to be entered press

the

For example, to produce a single line of 1 LINE.

Press until the 1/2 “ font size is shown, and

enter EXP 12/01/2004.

The message shown to the left would be an

example if the 1 LINE font were used.

To place two lines use the to select 2 LINE

size. Press the

Press the

will be entered on. Enter BEST BY. The pictorial at

the left shows two lines of 2 LINE character size. To

enter and print only 1 line of 2 LINE select the line

and enter data to that line only.

Once the message line(s) is complete, save the

change by pressing

key to delete the entire existing message.

EXP 12/01/2004

. The screen should be

.

to delete the entire message.

to select which line the data

.

22 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 37

MESSAGE ENTRY

FONT 1 LINE

EXP 12/01/2004

MESSAGE ENTRY

FONT 1 LINE

EXP 12/0

MESSAGE ENTRY

FONT 1 LINE

EXP 12/05/2005

MESSAGE ENTRY

FONT 1 LINE

EXP 12/15/2004

< - - SELECT - - >

!#

$&( )*+=¢ŇẾỖ

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

The second option is to replace characters by using

the key or moving the cursor over a character to

be replaced. When the MESSAGE ENTRY mode is

entered the cursor is placed at the end of the line.

Pressing the key will delete the last character on

the line. Successive

last character on a line.

At the left the characters 4 0 0 2 / 1 were deleted.

Enter the correct data, in this case 5/2005.

The alternative approach if just a few characters are

to change is to use the

over the characters to be changed and retype the

correct characters. In this example the 01 was

changed to 15.

Symbols are inserted by pressing

Message Entry mode, position the cursor where a

symbol is needed and press . The screen will

show a line of symbols as presented on the left.

Position the cursor by pressing

special character to be inserted and press

Continue to build the message or press

to the Command mode.

’s will continue to delete the

or to place the cursor

. When in

or on the

.

to return

23 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 38

PASSWORD PROTECTION (OPTION PACK 1 OR 2)

The EVOLUTION 1 contains a password function

PASSWORD XXXXX

password (which is 12345). Enter the 12345.

ENABLE PASSWORD

YES OR NO Y/N

PASSWORD XXXXX

password.

If the new password is misplaced or forgotten, reset the unit.

designed to limit access to the edit menu and

prevent unauthorized changing of message lines.

To activate this function, switch the unit off, then

press and hold

The display changes and requests the default

The screen to the left appears and prompts the

operator or ENABLE PASSWORD

A response of N maintains the current

password and disables password protection.

If the response Y is selected the screen at the left

appears to prompt the user to enter a new

password. Enter the new 5 character password

any combination of letters and numbers may be

used. Once this has been completed, the unit will

not allow message editing without the entry of the

while switching the unit on.

24 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 39

MESSAGE STORAGE (OPTION PACK 1, 1.5 OR 2)

STORING A MESSAGE

All EVOLUTION 1 printers are able to store up to 50

MESSAGE # 1

MESSAGE # 1

PLEASE WAIT

MESSAGE # 1

MESSAGE STORED

EVOLUTION 1

NOTE: Message storage should be used after the product has been coded

satisfactorily. When a message is stored all operating parameters of the

printed code are saved. Once recalled, codes will be printed the same as

they had been before.

Option pack 1 enables the user to store up to 50 messages in the hand held

controller. With option pack 1.5 or 2 the controller is capable of storing up

to 99 messages.

system wide programmed messages and their

associated parameters. Follow these steps to store

a message. Create the message and press

Press

message location number.

Press

into that numeric location for recall at a later time.

Use the same procedure to overwrite an existing

stored message as well.

The LCD display will indicate that the message is

stored.

Press

. Using or , scroll to the desired

a second time. This places the message

to exit.

.

RECALLING A STORED MESSAGE

MESSAGE # 1

EVOLUTION 1

STOPPED

HD1- - >SPEED=120

Place the unit in “Stopped” mode and press .

Use the or to scroll through the stored

messages. Find the desired message and press

. That message is now displayed on the screen

ready for printing.

EVOLUTION 1

25 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 40

PART 3: MAINTENANCE PROCEDURES

CONTENTS

PERIODS OF SHUT-DOWN 3-2

Short Periods of Shutdown 3-2

Long Periods of Shutdown 3-3

PRINT CARTRIDGE MAINTENANCE 3-4

PRINT CARRIAGE MAINTENANCE 3-5

EXPLODED VIEW OF PRINT CARRIAGE 3-5

1 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 41

PERIODS OF SHUTDOWN

SHORT PERIODS OF SHUT-DOWN

When the printer has been shut down overnight, the system might require a

purge to clear out dust particles that have settled on the nozzle area during nonuse. This is only necessary if there are missing dots in the printed code on

product.

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

PURGING

HD1- - >SPEED=120

EVOLUTION 1

STOPPED

HD1- - >SPEED=120

EVOLUTION 1

PRINTING

HD1- - >SPEED=120

EVOLUTION 1

To purge be sure that the unit is in the STOPPED

Mode by pressing green

changes to STOPPED as shown to left.

Place a piece of lint free wipe (or absorbant paper)

in front of the print head and press the red

Allow the unit to purge for several seconds. There is

an automatic shut down after 1,000 printed columns

to ensure that the print head will not be damaged. If

ink residue has solidified on the nozzle area a small

drop of water may be applied to the lint free wipe.

When purging is complete the LCD will be returned

to the STOPPED mode.

Press the green

PRINTING, as shown at the left. The unit is ready

to begin coding.

and the screen changes to

key. The screen

.

2 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 42

LONG PERIODS OF SHUT-DOWN

When the printer is to be shut down for extended periods, or the ink cartridge

needs to be changed to insert a different color cartridge, the ink cartridge should

be removed.

Clean the print head nozzle area with a soft, lint free wipes and insure there is no

ink residue remaining on the nozzle area. Re-apply the sealing tape. The print

cartridge may be stored in a sealable plastic bag.

CAUTION: USE THE ORIGINAL SEALING TAPE SUPPLIED WITH

THE EVOLUTION 1 INK CARTRIDGE. DO NOT USE ANY OTHER

MATERIAL OR ANY ADHESIVE BACKED PRODUCT, AS THIS

WILL DAMAGE THE NOZZLE AREA.

3 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 43

PRINT CARTRIDGE MAINTENANCE

It is necessary to maintain the EVOLUTION 1 print cartridge free from accumulated

dust and debris. Periodically the cartridge should be removed and cleaned. This

is totally dependent on the operating environment and the average printable life

of the ink cartridge. In extremely dusty environments, this maintenance

procedure may be required regularly.

To clean the cartridge, carefully clean the face of the cartridge with a soft, lint

free wipe. Use caution in wiping the NOZZLE area so as not to scratch the face.

Always wipe in the ARRAY PLATE vertically as indicated.

Clean the CONTACT area in a similar fashion.

DIRECTION OF WIPING

4 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

NOZZLES

CONTACT AREA

Page 44

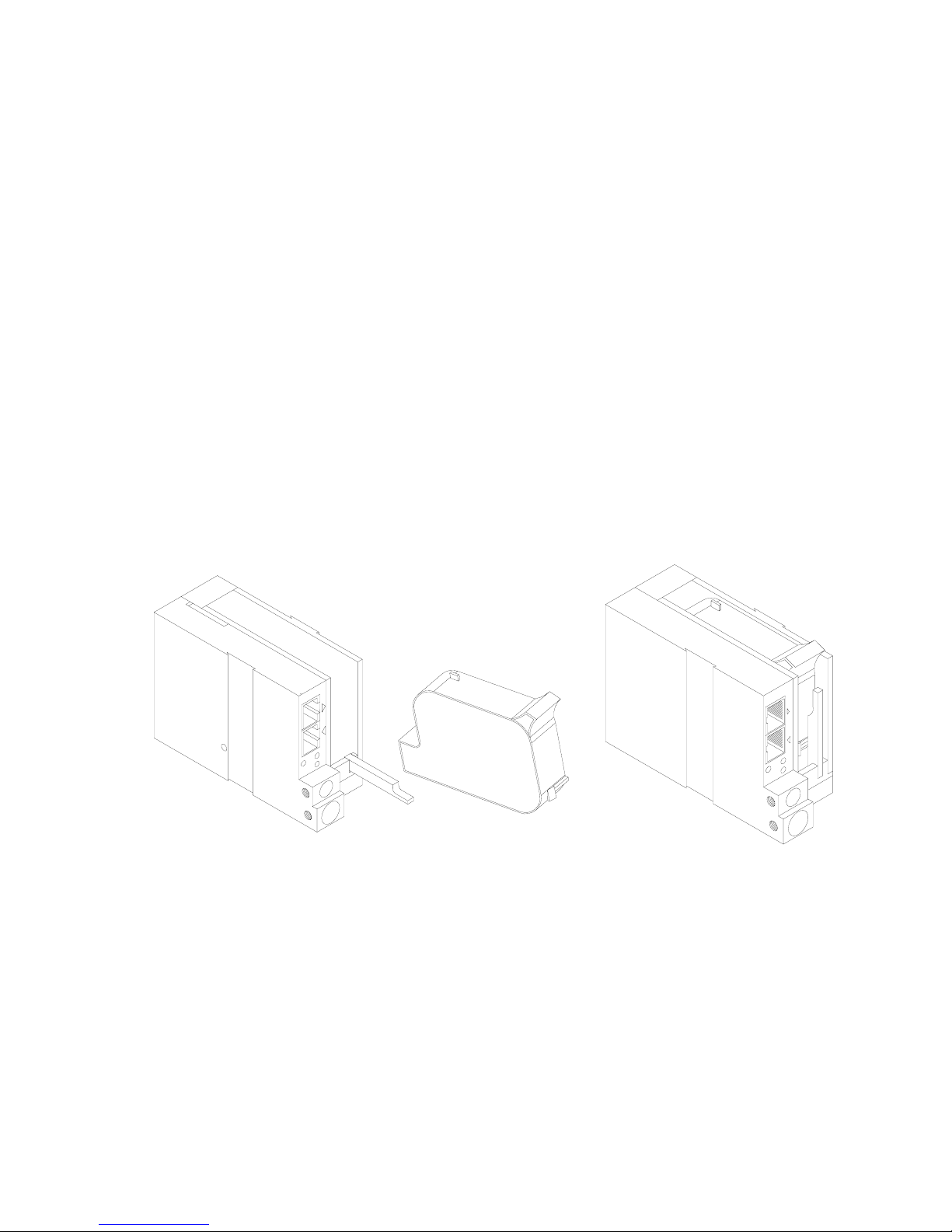

PRINT CARRIAGE MAINTENANCE

It is necessary to maintain the print head carriage free from accumulated dust

and debris. Periodically the print head carriage should be inspected and cleaned.

This is totally dependent on the operating environment. In extremely dusty

environments, this maintenance procedure may be required occasionally but on

average every week should be sufficient.

Remove the print cartridge and carefully inspect the print carriage C21001 for

dust and debris.

Re-insert the print cartridge and place the unit into the PRINTING mode by

pressing

.

EXPLODED VIEW OF THE C21002 PRINT CARRIAGE

5 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 45

PART 4: TROUBLESHOOTING AND REPAIRS

CONTENTS

FAULTS 4-2

LCD remains blank 4-2

Unit does not print, although LCD shows information 4-2

Low ink indicator on with full ink cartridge 4-2

Unit does not purge 4-2

Missing one or more dots from code. 4-2

Unit loses data while printing 4-2

1 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 46

FAULTS

This chart was created to assist the user in troubleshooting the unit. Find the

problem in the first column; apply the remedy(s) suggested in the third column.

Condition Probable Cause Remedy

LCD remains blank. No power.

Ensure the controller is securely

connected to the correct port on

the print carriage assembly

Unit does not print, although

LCD shows information.

Unit in “COMMAND”

No message in unit Input your message (see pages

2-18).

Press

.

mode.

No ink. Replace ink cartridge; reset ink

volume parameter (press

and follow the sequence.

Low ink indicator on with full

ink cartridge.

Did not reset ink volume

parameter.

Press . Continue key

entry following menu prompts.

Unit does not purge. Out of ink. Replace with full ink cartridge.

Reset ink volume parameter

Unit in “PRINTING” mode

(press

Press Stop Print.

).

Ink cartridge clogged Clean Ink Cartridge Nozzle area

with lint free wipe

Missing one or more dots

from code.

No ink. Clean or Replace cartridge and

purge system (press ).

Long down-time. Follow daily start-up procedure if

your line experienced a long

down time.

Unit loses data while printing Static electricity Eliminate source of static.

Attach ground strap between

print head and low impedance

earth ground.

High levels of radio

frequency.

Move unit to an alternate

location or attach ground strap

as above.

Spikes in electrical line. Use AC line filter

2 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 47

PART 5: PARTS LIST AND OPTIONS

Part No. Description

C21001-1

SPARE PARTS

EVOLUTION 1 Controller Cabinet

C21001-2

C21001-3

C30238

C21002

C21002-7

C21002-8

C21005

C21000-2

96280-01 Floor stand

C21003 Top Coding Mounting Bracket

C21006 External Product Detect

C21007 External Encoder

C21012 Optional Junction Box

EV1-SW1 Option Pack 1 Password, Message Store, Auto Repeat

EV1-SW1.5 Option Pack 1.5 Expanded Message Length

EVOLUTION 1 Controller LCD Assembly

EVOLUTION 1 Controller PCB Assembly

EVOLUTION 1 Controller Keypad

EVOLUTION 1 Print Head Carriage Assembly

EVOLUTION 1 Print Head Carriage CPU Assembly

EVOLUTION 1 Print Head Carriage POGO Assembly

EVOLUTION 1 Mounting Bracket Assembly

EVOLUTION 1 Power supply

OPTIONS

EV1-SW2 Option Pack 2 (Option Pack 1 & 1.5) & Time, Date, Sequential Number

EV1-SW3 Option Pack 3 (Option Pack 2) & Date Offset, Shift Code, Product Count

EV1-FONT Alternate Font (Specify when ordering)

EV1-LOGO Logo Option (Specify when ordering)

C21008-1

C21008-3

C21008-10

C21008-25

C21008-50

C21008-100

CABLES

EVOLUTION 1 RJ50 Cable 6 INCH

EVOLUTION 1 RJ50 Cable 3 Feet

EVOLUTION 1 RJ50 Cable 10 Feet

EVOLUTION 1 RJ50 Cable 25 Feet

EVOLUTION 1 RJ50 Cable 50 Feet

EVOLUTION 1 RJ50 Cable 100 Feet

EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006 1

Page 48

INKS

4500BK6 6 Pack of Black Ink Cartridges

4500RD6 6 Pack of Red Ink Cartridges

4500GR6 6 Pack of Green Ink Cartridges

4500BL6 6 Pack of Blue Ink Cartridges

4500YW6 6 Pack of Yellow Ink Cartridges

4500CY6 6 Pack of Cyan Ink Cartridges

4500UV6 6 Pack of Ultra Violet Ink Cartridges

4600BK6 6 Pack of Black Ink Cartridges (SEMI-POROUS)

EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006 2

Page 49

PART 6: COMMUNICATIONS PROTOCOL

CONTENTS

DESCRIPTION 6-2

Data Word Definitions 6-2

Baud Rate 6-2

Definitions 6-2

Cabling 6-2

Hardware Interface 6-2

Physical Connections for RS485 6-2

Protocol Format 6-3

SOFTWARE PROTOCOL 6-4

ERROR CODES 6-4

LIST OF COMMANDS 6-5

1 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 50

DESCRIPTION

This communication protocol is Version 1.4 and was released NOV 2005 and is

used with all EVOLUTION products. The communications option converses with

a host computer via an RS485 data link.

NOTE: EACH REQUEST OR COMMAND SENT TO A PRINT STATION

RECEIVES A RESPONSE FROM THAT PRINT STATION. COMMUNICATIONS

SOFTWARE MUST WAIT FOR A RESPONSE TO DETERMINE IF THE PRINT

STATION WAS READY TO ACCEPT THE COMMAND, AND THE DATA WAS

VALID AND PROCESSED. NO RESPONSE COULD INDICATE THE DATA

WAS LOST. IF AN ERROR WAS DETECTED IN PROCESSING A NAK WITH

AN ERROR CODE IS RETURNED.

DATA WORD DEFINITION

Full Duplex - 7 Data Bits - 1 Even Parity Bit - 1 Start Bit - 1 Stop Bit

BAUD RATE

115,200 Bits per second

DEFINITIONS

Q=QUERY TO HEAD

R=RESPONSE FROM HEAD

D=DATA UPDATE TO HEAD

X=ACK FROM HEAD

‘!’=ASCII CHARACTER OR CHARACTERS

0x21 HEX DATA EQUIVELENT

ADDRESS= TWO ASCII REPRESENTATIONS OF HEX CHARACTERS

CABLING FOR EVLINK ENVIRONMENT

C20552 RS232C to RS485 converter module

C20551 Cable from PC to RS485 converter module

C21008-xxxx Cable (define length) from EVOLUTION units to RS485 data link

C21009 Termination plug for RS485 data link

HARDWARE INTERFACE

When connecting multiple print carriages via an RS485 link, input and output

connectors are provided on the print station, which allows the cabling to be daisy

chained. NOTE: It is important to remember to set each of the print stations to a

unique address.

PHYSICAL CONNECTIONS RS485 PRINT CARRIAGE

Pin # 4 = Receive +

Pin # 5 = Receive Pin # 6 = Transmit +

Pin # 7 = Transmit Pin # 9 = Ground

2 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 51

Note: At the end of the data link a termination plug is installed to balance the

RS485 data link.

This termination plug connects pin 4 to pin 5 and pin 6 to pin 7. This adds a 120ohm termination resistor across the data lines.

PROTOCOL FORMAT:

Host request for information;

ESC|Command|SOH|EOT (Single End Host to 1 printer)

Or

ESC|STX|Address|Command|SOH|EOT (Multiple printers)

Host sending new information;

ESC|Command|Data|EOT (Single End Host to 1 printer)

Or

ESC|STX|Address|Command|Data|EOT (Multiple printers)

Evolution Printable Character Set

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

0 1 2 3 4 5 6 7 8 9

Special Symbols:

ASCII Character

Space (0x20) Space

! (0x21) Hour Glass

# (0x23) #

$ (0x24) $

& (0x26) &

( (0x28) (

) (0x29) )

* (0x2a) *

+ (0x2b) +

- (0x2d) . (0x2e) Period

= (0x3d) =

: (0x3a) :

/ (0x2f) /

" (0x22) Cents

% (0x25) Solid block

; (0x3b) Ň

? (0x3f) Ě

@ (0x40) Ó

{ (0x7b} Logo 1

| (0x7c) Logo 2

} (0x7d} Logo 3

NOTE: ALL OTHER CHARACTERS ARE ILLEGAL AND MUST NOT BE SENT

TO THE PRINT HEAD.

Hexadecimal Prints As

3 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 52

SOFTWARE PROTOCOL

In the following pages, all references to characters or digits pertain to the

standard ASCII character set. The | (bar) character is used as a field separator

and it is not part of the transferred data. When data is shown in hexadecimal, it

will consist of the hex number followed by an H, for example (1BH). All packets to

and from a print station begin with an ESC (1BH) and terminate with an EOT

(04H).

There are two types of commands:

The first sends information to the print station and the second requests

information from the print station.

To distinguish the two types of commands, a SOH (HEX 01) is placed after the

command byte in a request command string. The following illustrates this

concept:

To download data to print station

ESC/GROUP ADDRESS/UNITADDRESS/COMMAND/DATA/EOT

To request data from the Print Station

ESC/GROUP ADDRESS/UNITADDRESS/COMMAND/SOH/EOT

NOTE: EACH REQUEST OR COMMAND SENT TO A PRINT STATION

RECEIVES A RESPONSE FROM THAT PRINT STATION. COMMUNICATIONS

SOFTWARE MUST WAIT FOR A RESPONSE TO DETERMINE IF THE PRINT

STATION WAS READY TO ACCEPT THE COMMAND, AND THE DATA WAS

VALID AND PROCESSED. NO RESPONSE COULD INDICATE THE DATA

WAS LOST. IF AN ERROR WAS DETECTED IN PROCESSING A NAK WITH

AN ERROR CODE IS RETURNED.

ERROR CODES

Commands to a print station, if completed successfully, return a single byte

response of an ASCII ACK (06H). If the command was not successful, a twobyte response of an ASCII NAK (15H) is returned, followed by an error code.

Below is a list of the returned error codes.

NAK 1 = Transmission Error

NAK 2 = Illegal Command Byte

NAK 3 = Trying to print while in command mode

NAK 4 = Trying to read a write only register

NAK 5 = Trying to write a read only register

NAK 6 = Print station buffer full must print before next download to clear

buffer.

NAK 7 = Print station busy with user interaction through local keyboard (i.e. in

edit mode).

NAK 8 = Print station busy.

4 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 53

COMMANDS:

'!' 0x21 Software Version (read only)

Q. ESC|STX|Address|`!`|SOH|EOT

R. ESC|STX|Address|`PRINTERxxxxxyyyy`|CR|EOT

Where:

PRINTER= ASCII word PRINTER

xxxxx = Software and Firmware versions

(e.g. 2.02H indicates version 2.02 with Firmware version H)

yyyy = Optional Software loaded

Where:

The first y indicates option pack 1

The second y indicates option pack 2

The third y indicates option pack 1.5

The last y indicates option pack 3

The presence of an option pack is indicated by the character

+ (&h2B)

The absence of an option pack is indicated by an ASCII

SPACE (&h20)

'\' 0x5c Unit Serial Number

Q. ESC|STX|Address|`\`|SOH|EOT

R. ESC|STX|Address|`\`|`serial number`|CR|EOT

'B' 0x42 Set Unit Address (Write Only)

D. ESC|STX|Address|`B`|`xy`|EOT

X. ESC|STX|Address|`B`|ACK|EOT

Where: xy = 8 bit unit address

i.e. x = 31 & y = 35 yields unit address 15

'#' 0x23 Printer Configuration (read only)

Q. ESC|STX|Address|`#`|SOH|EOT

R. ESC|STX|Address|`#`|`xy`|EOT

Where: Byte x Bits 3,2,1,0

Bit 3 = if 1 Cartridge Not Valid

Bit 2 = Not Used

Bits 1,0 = System Type

11 = Evolution 1

10 = Evolution 2

01 = Evolution 3

00 = Evolution 4

Where: Byte y Bits 3,2,1,0

0000 = no options available

0001 = option1 enabled

0010 = option2 enabled

0100 = option3 enabled

5 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 54

'r' 0x52 Remaining Ink (0 to 99%)

Q. ESC|STX|Address|`r` |SOH|EOT

R. ESC|STX|Address|`r`|`ab`|EOT

Where ‘ab’ is a percentage

ESC|STX|Address|’r’|0|0|EOT Resets the ink level

'1' 0x31 Auto Repeat Inter-print delay (0 - 255) – OP1/2/3

Q. ESC|STX|Address|`1`|SOH|EOT

R. ESC|STX|Address|`1`|`ab`|EOT

D. ESC|STX|Address|`1`|`ab`|EOT

X. ESC|STX|Address|`1`|ACK|EOT

0 = Auto Repeat Disabled and each count provides a delay equal to 18

columns of print.

'8' 0x38 Control Flags

Q. ESC|STX|Address|`8`|SOH|EOT

R. ESC|STX|Address|`8`|`xy`|EOT

Where x bits 7,6,5,4,

y bits 3,2,1,0

Bit 0 1 = Enable print mode

Bit 1 1 = Direction forward

Bit 2 1 = External Product Detect

Bit 3 1 = External Encoder

Bit 4 1 = Head busy purging

Bit 5 1 = Head busy manual cycle

Bit 6 1 = Print image inverted

Bit 7 1 = Head busy printing message

D. ESC|STX|Address|`8`|`xy`|EOT

X. ESC|STX|Address|`8`|ACK|EOT

Bit 0 1 = Enable print mode

Bit 1 1 = Direction forward

Bit 2 1 = External Product Detect

Bit 3 1 = External Encoder

Bit 4 Don't Care

Bit 5 Don't Care

Bit 6 1 = Print image inverted

Bit 7 Don't Care

'&' 0x26 Line Speed (RANGE 10-200)

Q. ESC|STX|Address|`&`|SOH|EOT

R. ESC|STX|Address|`&`|`xy`|EOT

D. ESC|STX|Address|`&`|`xy`|EOT

X. ESC|STX|Address|`&`|ACK|EOT

6 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 55

'd' 0x64 Encoder Divider (Range 0-7)

Q. ESC|STX|Address|`d`|SOH|EOT

R. ESC|STX|Address|`d`|`ab`|EOT

D. ESC|STX|Address|`d`|`ab`|EOT

X. ESC|STX|Address|`d`|ACK|EOT

'’' 0x27 Product Delay (RANGE 1-255)

Q. ESC|STX|Address|`0x27`|SOH|EOT

R. ESC|STX|Address|`0x27`|`xy`|EOT

D. ESC|STX|Address|`0x27`|`xy'|EOT

X. ESC|STX|Address|`0x27`|ACK|EOT

')' 0x29 Inter-Character spaces (RANGE 1-25)

Q. ESC|STX|Address|`)`|SOH|EOT

R. ESC|STX|Address|`)`|`xy`|EOT

D. ESC|STX|Address|`)`|`xy'|EOT

X. ESC|STX|Address|`)`|ACK|EOT

‘j’ Reset Print Head (Write only)

D. ESC|STX|Address|`j`| 96 |CR|EOT

X. ESC|STX|Address|`j`|ACK|EOT

‘G’ 0x47 Errors

Q. ESC|STX|Address|`G`|SOH||EOT

R. ESC|STX|Address|`G`|'xy'|EOT

Where:

Byte x Bits 3,2,1,0

Bit 3 = UART Overrun Error

Bit 2 = Communication Overrun Error

Bit 1 = UART Framing Error

Bit 0 = UART Parity Error

Where:

Byte y Bits 3,2,1,0

Bit 3 = Font checksum error loading from card to chip

Bit 2 = Font 1 checksum error in Ram

Bit 1 = Font 0 checksum error in Ram

Bit 0 = Real Time Clock Memory error

D. ESC|STX|Address|`G`|'xy'|EOT

same bit positions as above

use only as a mask to clear error bits.

i.e. X = 0001 and y = 0100 clears real time clock memory

error and communications overrun error.

X. ESC|STX|Address|`G`|ACK|EOT

7 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 56

SPECIAL FIELD OBJECTS

Message Objects define special characteristics about the messages

contained in line 1 or line 2. These may define for example font size, sequence

number, date code, etc. There may be up to 15 Objects (special fields) for each

line in a message with the limitation that there can only be 1 sequence number

imbedded in a message.

'P' 0x50 Message Objects

Q. ESC|STX|Address|`P`|SOH|aabbEOT

R. ESC|STX|Address|`P`|'aabbccddeeffgggghhhh' |EOT

Where: aa = objects for which line 0 or 1

bb = number of objects transmitted. (Max 15)

Each object as defined by bb: (repeat the following for each

object)

cc = Position within message string

dd = Number of characters in object

ee = Attribute of the object

Where: ee= 00 Normal Alpha/Numeric character

ee= 01 Time Hours

ee= 02 Time Minutes

ee= 03 Time Seconds

ee= 04 Date Month

ee= 05 Date Day

ee= 06 Date Year

ee= 07 Date Julian

ee= 08 Sequence Number (only 1 per

message)

ee= 09 Barcode

ee= 0A Shift Code

ee= 0B Expiration Date Month

ee= 0C Alpha Date Code

ee= 0D Expiration Date Year

ee= 0E Expiration Date Julian

ee= 0F Expiration Date Day

ff = font of object

Where: ff= 00 for 2 Line Font

ff= 01 for 1 Line Font

gggg = starting column of object in printed image (reserved

hhhh = starting row of object in printed image

D. ESC|STX|Address|`P`|'aabbccddeeffgggghhhh’ |EOT

X. ESC|STX|Address|`P`|ACK|EOT

8 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 57

'$' 0x24 Line 1 Message (max 24 characters)

Q. ESC|STX|Address|`$`|SOH|EOT

R. ESC|STX|Address|`$`|`message`|CR|EOT

D. ESC|STX|Address|`$`|`message`|CR|EOT

X. ESC|STX|Address|`$`|ACK|EOT

'%' 0x25 Line 2 Message (max 24 characters)

Q. ESC|STX|Address|`%`|SOH|EOT

R. ESC|STX|Address|`%`|`message`|CR|EOT

D. ESC|STX|Address|`%`|`message`|CR|EOT

X. ESC|STX|Address|`%`|ACK|EOT

':' 0x3A Logo1 Name (read only - max 9 characters)

Q. ESC|STX|Address|`:`|SOH|`xy`|EOT

R. ESC|STX|Address|`:`|`logo name`|CR|EOT

Where: x = don’t care

y = Bit 0 = 0 = Logo Name in Font 0

1 = Logo Name in Font 1

Bit 1 = 0 = Get Name from on board data flash chip

1 = Get Name fro Data Flash card

';' 0x3B Logo2 Name (read only - max 9 characters)

Q. ESC|STX|Address|`;`|SOH|xy|EOT

R. ESC|STX|Address|`;`|` logo name `|CR|EOT

Where: x = don’t care

y = Bit 0 = 0 = Logo Name in Font 0

1 = Logo Name in Font 1

Bit 1 = 0 = Get Name from on board data flash chip

1 = Get Name fro Data Flash card

'<' 0x3C Logo3 Name (read only - max 9 characters)

Q. ESC|STX|Address|`<`|SOH|`xy`|EOT

R. ESC|STX|Address|`<`|` logo name `|CR|EOT

Where: x = don’t care

y = Bit 0 = 0 = Logo Name in Font 0

1 = Logo Name in Font 1

Bit 1 = 0 = Get Name from on board data flash chip

1 = Get Name fro Data Flash card

9 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 58

'G' 0x47 Error Flags (read only)

Q. ESC|STX|Address|`G`|SOH|EOT

R. ESC|STX|Address|`G`|`xy'|EOT

Where Byte x Bits 3,2,1,0

Bit 3 = Not Used

Bit 2 = Font Load error

Bit 1 = Uart Parity Error

Bit 0 = clock chip memory read/write error

Where Byte y Bits 3,2,1,0

Bit 3 = Not Used

Bit 2 = Not Used

Bit 1 = Not Used

Bit 0 = Not Used

'R' 0x52 Head Status (read only)

Q. ESC|STX|Address|`R`|SOH|EOT

R. ESC|STX|Address|`R`|`xy'|EOT

Where: Byte x Bits 3,2,1,0

Bit 3 = Not Used

Bit 2 = Latched eye active

Bit 1 = Unfiltered eye active

Bit 0 = Product being printed

Where: Byte y Bits 3,2,1,0

Bit 3 = auto repeat print gap active

Bit 2 = Not Used

Bit 1 = Input buffer Line 2 full

Bit 0 = Input buffer Line 1 full

'Q' 0x51 Starting Sequence Number (max. 9 digits) – OP2/3

Q. ESC|STX|Address|`Q`|SOH|EOT

R. ESC|STX|Address|`Q`|`zzzzzzzzz'| CR | EOT

Where: zzzzzzzzz = starting sequence number.

D. ESC|STX|Address|`Q `|`zzzzzzzzz'| CR | EOT

X. ESC|STX|Address|`Q`|ACK|EOT

‘3’ 0X31 Days until Expiration (max 999) – OP3

Q. ESC|STX|Address|`3`|SOH|EOT

R. ESC|STX|Address|`3`|`aaaa`|EOT

Where: aaaa = number of days until expiration in BCD format

D. ESC|STX|Address|`3`|aaaa`|EOT

Where: aaaa = number of days until expiration in BCD format

X. ESC|STX|Address|`3`|ACK|EOT

10 EVOLUTION 1 SYSTEM MANUAL Issue 1.4 16 May 2006

Page 59

‘0’ 0x30 Shift Code – OP3

Q. ESC|STX|Address|`0`|SOH||EOT

R. ESC|STX|Address|`0`|`xxyyzz`|CR|EOT

Where: xx = shift start hours