Page 1

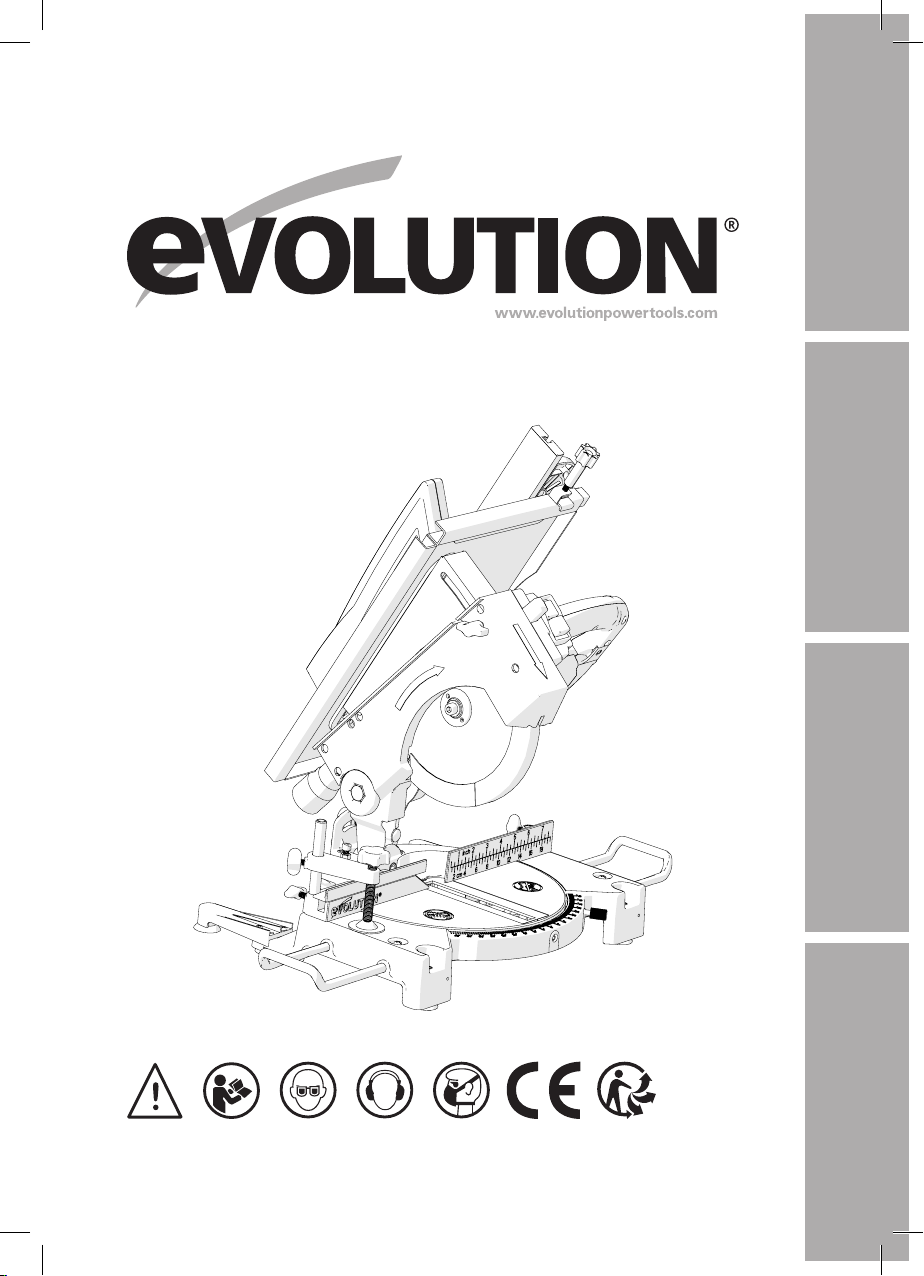

FURY6

EN

Original Instructions

DE

FR

TR

Date Published: 01 / 03 / 2016Written in UK English

Page 2

Page 3

ENGLISH

Original Instructions

EN

EN

DE

FR

TR

Page 4

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 2

Deutsch Seite 34

Français Page 68

Türk Sayfa 100

INTRODUCTION Page 5

Guarantee Page 5

Machine Specification Page 6

Vibration Page 7

Labels and Symbols Page 7

Intended use of this Power Tool Page 8

Prohibited use of this Power Tool Page 8

SAFETY PRECAUTIONS Page 9

Electrical Safety Page 9

Outdoor Use Page 9

General Power Tool Safety Instructions Page 11

Additional Safety Instructions Page 13

GETTING STARTED Page 14

Unpacking Page 14

Machine Overview Page 15

Service Parts Diagram Page 16

Assembly and Preparation Page 17

Operating Instructions Page 18

MAINTENANCE Page 29

Environmental Protection Page 29

DECLARATION OF CONFORMITY Page 31

4

Page 5

www.evolutionpowertools.com

(1.2) THIS INSTRUCTION MANUAL

WAS ORIGINALLY WRITTEN IN ENGLISH

(1.3) IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but Technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com

(1.4) Congratulations on your purchase

of an Evolution Power Tools Machine.

Please complete your product registration

‘online’ as explained in the A4 online

guarantee registration leaflet included with

this machine. You can also scan the QR code

found on the A4 leaflet with a Smart Phone.

This will enable you to validate your machine’s

guarantee period via Evolutions website by

entering your details and thus ensure prompt

service if ever needed. We sincerely thank

you for selecting a product from

Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE.

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

(1.5) Evolution Power Tools will, within

the guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the tool

being returned has been used beyond the

recommendations in the Instruction Manual or

if the machine has been damaged by accident,

neglect, or improper service.

This guarantee does not apply to machines

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective

shall be returned prepaid freight to

Evolution Power Tools.

Evolution Power Tools reserves the right to

optionally repair or replace it with the same

or equivalent item. There is no warranty –

written or verbal – for consumable accessories

such as (following list not exhaustive) blades,

cutters, drills, chisels or paddles etc. In no

event shall Evolution Power Tools be liable for

loss or damage resulting directly or indirectly

from the use of our merchandise or from any

other cause. Evolution Power Tools is not

liable for any costs incurred on such goods or

consequential damages. No officer, employee

or agent of Evolution Power Tools is authorized

to make oral representations of fitness or

to waive any of the foregoing terms of sale

and none shall be binding on Evolution

Power Tools.

Questions relating to this limited guarantee

should be directed to the company’s head

office, or call the appropriate Helpline number.

EN

DE

FR

TR

5

Page 6

www.evolutionpowertools.com

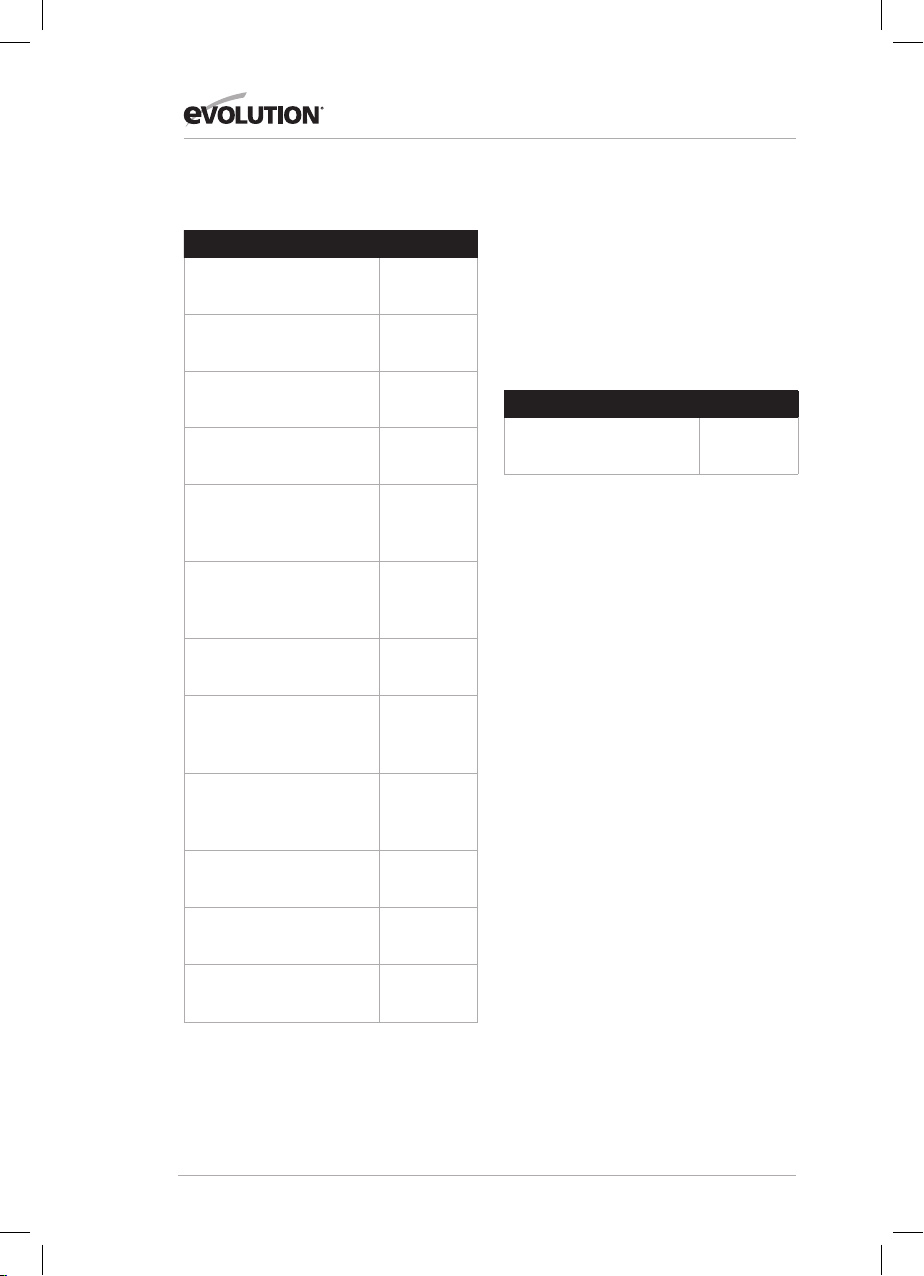

SPECIFICATIONS

MACHINE METRIC IMPERIAL

Motor (230-240V~ 50 Hz) 1200W 5A

Speed No Load 3500min

Weight 9.45kg 20lb

CUTTING CAPACITIES METRIC IMPERIAL

Mild Steel Plate - Max Thickness 3mm 1/8”

-1

3500rpm

MAXIMUM CUTTING CAPACITY ALUMINIUM, WOOD & PVC

MITRE SAW CONFIGURATION

MITRE BEVEL

MAX WIDTH

OF CUT

MAX DEPTH

OF CUT

90° 90° 115mm (4-1/2”) 55mm (2-1/8”)

45° 90° 65mm (2-1/2”) 55mm (2-1/8”)

45° 45° 40mm (1-9/16”) 25mm (15/16”)

MAXIMUM CUTTING CAPACITY TABLE SAW CONFIGURATION

CUTTING CAPACITIES METRIC IMPERIAL

Wood - Max Thickness 32mm 1-1/4”

BLADE DIMENSIONS METRIC IMPERIAL

Diameter 210mm 8-1/4”

Bore 25.4mm 1”

Number of Teeth 20 20

Kerf 1.7mm 1/16”

NOISE & VIBRATION DATA

Sound Pressure LPA 94.57dB(A) K=3dB(A)

Sound Power Level LWA 107.57dB(A) K=3dB(A)

Vibration Level 2.5m/s2 K=1.5m/s

2

(1.6) Note: The vibration measurement was made under standard conditions in accordance with:

BS EN 61029-1:2009+A11.

6

Page 7

www.evolutionpowertools.com

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

(1.7) VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm. It

is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as well

as producing general numbness. Prolonged

or regular users of this machine should

monitor the condition of their hands and

fingers closely. If any of the symptoms become

evident, seek immediate medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002.

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce the

effects of vibration:

Handling

• Handle the machine with care,

allowing the machine to do the work.

• Avoid using excessive physical effort

on any of the machines controls.

• Consider your security and stability,

and the orientation of the machine

during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used. The need

to identify safety measures and to protect

the operator are based on an estimation

of exposure in the actual conditions of use

(taking account of all parts of the operating

cycle, such as the times the tool is switched

off, when it is running idle, in addition

to trigger time).

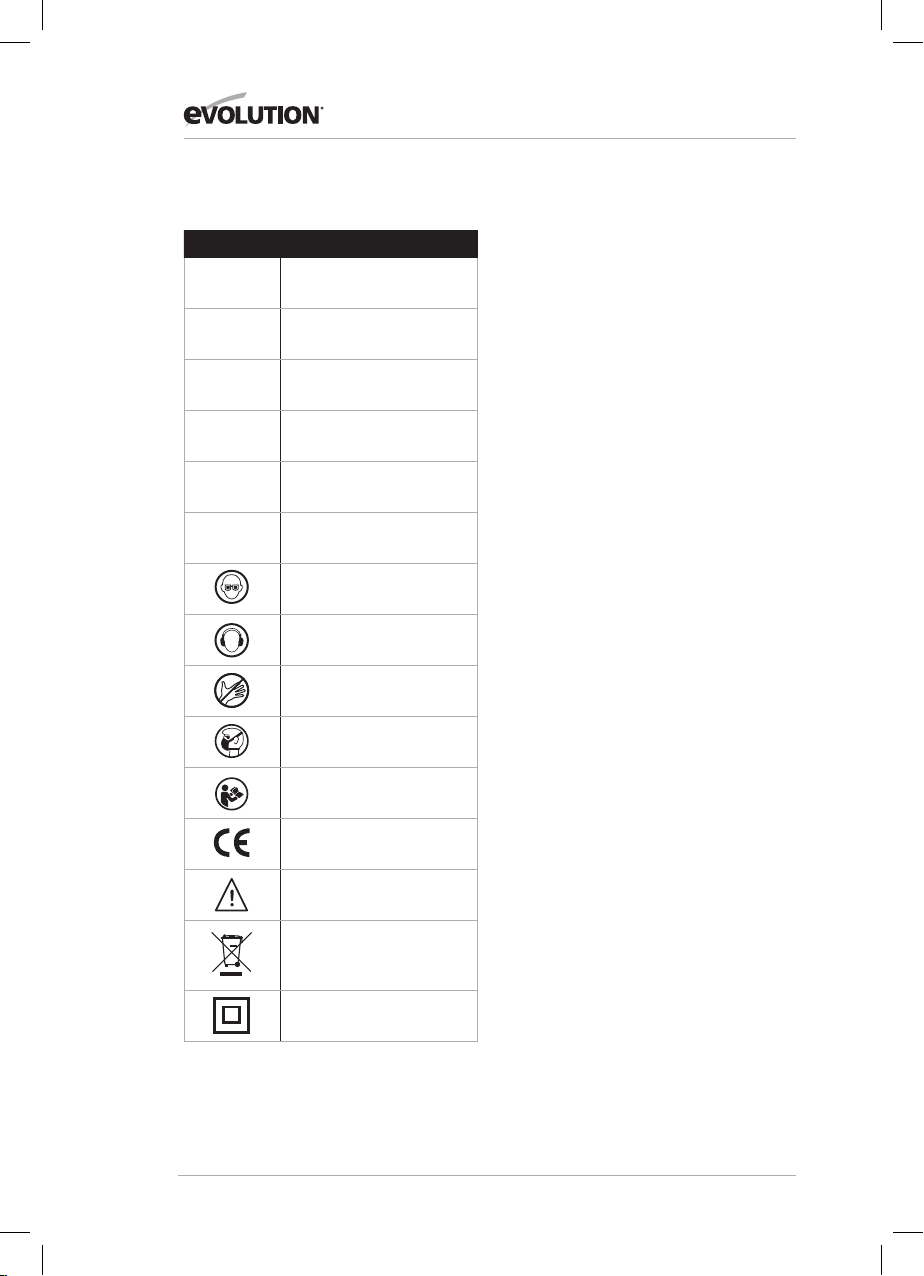

(1.8) LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

EN

DE

FR

TR

7

Page 8

www.evolutionpowertools.com

(1.9) LABELS & SYMBOLS

Symbol Description

V

A

Amperes

Hz

-1

Min

~

n

o

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Read Instructions

CE certification

Warning

Volts

Hertz

Speed

(1.10) INTENDED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Compound Mitre Saw and has been designed

to be used with special Evolution blades.

Only use accessories designed for use in

this machine and/or those recommended

specifically by Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Mild Steel

Aluminium

Wood

(1.11) PROHIBITED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Compound Mitre Saw and must only be used

as such. It must not be modified in any way,

or used to power any other equipment or

drive any other accessories other than those

mentioned in this Instruction Manual.

(1.13) WARNING: This machine is not

intended for use by persons (including

children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been

given supervision or instruction concerning

the safe use of the machine by a person

responsible for their safety and who

is competent in its safe use.

Waste electrical and

electronic equipment

Double Insulated

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

8

Page 9

www.evolutionpowertools.com

(1.14) ELECTRICAL SAFETY

This machine is fitted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturers or its service agent.

(1.15) OUTDOOR USE

WARNING: For your protection if this

tool is to be used outdoors it should not be

exposed to rain, or used in damp locations.

Do not place the tool on damp surfaces.

Use a clean, dry workbench if available.

For added protection use a residual current

device (R.C.D.) that will interrupt the supply

if the leakage current to earth exceeds 30mA

for 30ms. Always check the operation of the

residual current device (R.C.D.) before using

the machine.

If an extension cable is required it must

be a suitable type for use outdoors and

so labelled. The manufacturers instructions

should be followed when using an

extension cable.

(2.1) POWER TOOL GENERAL SAFETY

INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in BS EN 60745-1:2009 &

EN 61029-1:2009)

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for future

reference. The term “power tool” in the

warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

(2.2) 1) General Power Tool

Safety Warnings [Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gasses or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating power tool. Distractions

can cause you to lose control.

(2.3) 2) General Power Tool Safety

Warnings [Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce the risk of electric shock.

b) Avoid body contact with earthed

or grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat,

oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk

of electric shock.

EN

DE

FR

TR

9

Page 10

www.evolutionpowertools.com

(2.4) 3) General Power Tool Safety

Warnings [Personal Safety].

a) Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

the power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of a

power tool may result in personal injury .

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection can

reduce dust-related hazards.

(2.5) 4) General Power Tool Safety

Warnings [Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at a rate for which

it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools. Such preventative safety measures

reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

Instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

10

Page 11

www.evolutionpowertools.com

(2.6) 5) General Power Tool

Safety Warnings [Service]

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

(2.7) HEALTH ADVICE

WARNING: When using this machine, dust

particles may be produced. In some instances,

depending on the materials you are working

with, this dust can be particularly harmful.

If you suspect that paint on the surface of

material you wish to cut contains lead, seek

professional advice. Lead based paints should

only be removed by a professional and you

should not attempt to remove it yourself.

Once the dust has been deposited on surfaces,

hand to mouth contact can result in the

ingestion of lead.

Exposure to even low levels of lead can

cause irreversible brain and nervous system

damage. The young and unborn children are

particularly vulnerable. You are advised to

consider the risks associated with the materials

you are working with and to reduce the risk

of exposure. As some materials can produce

dust that may be hazardous to your health,

we recommend the use of an approved face

mask with replaceable filters when using

this machine.

(2.8) WARNING: the operation of any power

tool can result in foreign objects being thrown

towards your eyes, which could result in severe

eye damage. Before beginning power tool

operation, always wear safety goggles

or safety glasses with side shield or a full

face shield where necessary.

(3.5) ADDITIONAL SAFETY

INSTRUCTIONS - MITRE SAWS

The following specific safety instructions

for Mitre Saws are based on the requirements

of EN61029-2-9:2009.

BLADE SAFETY

WARNING: Rotating Circular Saw Blades are

extremely dangerous and can cause serious

injury and amputation. Always keep fingers

and hands at least 150mm away from the

blade at all times. Never attempt to retrieve

sawn material until the cutting head is in the

raised position, the guard is fully closed and

the saw blade has stopped rotating.

Only use saw blades that are recommended

by the manufacturer and as detailed in

this manual and that comply with the

requirements of EN 847-1.

Do Not use saw blades that are damaged or

deformed as they could shatter and cause

serious injury to the operator or bystanders.

EN

DE

FR

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment,

such as dust masks that are specially

designed to filter microscopic particles.

Do Not use saw blades that are manufactured

from high speed steel (HSS).

If the table insert becomes damaged or

worn it must be replaced with an identical

one available from the manufacturer

as detailed in this manual.

TR

11

Page 12

www.evolutionpowertools.com

(3.6) PERSONAL PROTECTIVE

EQUIPMENT (PPE)

Hearing protection should be worn in order

to reduce the risk of induced hearing loss.

Eye protection should be worn in order to

prevent the possibility of the loss of sight

from ejected chippings.

Respiratory protection is also advised as some

wood and wood type products especially MDF

(Medium Density Fibreboard) can produce

dust that can be hazardous to your health.

We recommend the use of an approved face

mask with replaceable filters when using

this machine in addition to using the dust

extraction facility.

Gloves should be worn when handling blades

or rough material. It is recommended that saw

blades should be carried in a holder wherever

practicable. It is not advisable to wear gloves

when operating the mitre saw.

(3.7) SAFE OPERATION

Always ensure that you have selected the

correct saw blade for the material being cut.

Do Not use this mitre saw to cut materials

other than those specified in this

Instruction Manual.

When transporting a mitre saw ensure that

the cutting head is locked in the 90 degree

down position (if a sliding mitre saw ensure

that the slide bars are locked). Lift the machine

by gripping the outer edges of the base with

both hands (if a sliding mitre saw, transport

using the handles provided). Under no

circumstances shall the machine be lifted

or transported using the retractable guard

or any part of its operating mechanism.

Before each use check the operation

of the retractable guard and its operating

mechanism ensuring that there is no damage,

and that all moving parts operate

smoothly and correctly.

Keep the work bench and floor area clear of all

debris including sawdust, chips and off-cuts.

Always check and ensure that the speed

marked on the saw blade is at least equal to

the no load speed marked on the mitre saw.

Under no circumstances shall a saw blade

be used that is marked with a speed that

is less than the no load speed marked

on the mitre saw.

Where it is necessary to use spacer or reducing

rings these must be suitable for the intended

purpose and only as recommended by the

manufacturer.

If the mitre saw is fitted with a laser it shall not

be replaced with a different type. If the laser

fails to operate it shall be repaired or replaced

by the manufacturer or his authorised agent.

The saw blade shall only be replaced as

detailed in this Instruction Manual.

Never attempt to retrieve off-cuts or any other

part of the work piece until the cutting head is

in the raised position, the guard is fully closed

and the saw blade has stopped rotating.

12

Page 13

www.evolutionpowertools.com

(3.8) PERFORM CUTS

CORRECTLY & SAFELY

Wherever practicable always secure the work

piece to the saw table using the work clamp

where provided.

Always ensure that before each cut the mitre

saw is mounted in a stable position.

If needed the mitre saw can be mounted

on a wooden base or work bench or attached

to a mitre saw stand as detailed in this

Instruction Manual.

Long work pieces should be supported on

the work supports provided or on appropriate

additional work supports.

(3.4) WARNING: If any parts are missing, do

not operate your machine until the missing

parts are replaced. Failure to follow this rule

could result in serious personal injury.

(3.9) ADDITIONAL SAFETY ADVICE

CARRYING YOUR TABLE MITRE SAW

Safety Advice

• Although compact, this saw is heavy.

To reduce the risk of back injury, get

competent help whenever you have to

lift the saw.

• To reduce the risk of back injury, hold

the tool close to your body when lifting.

Bending your knees so you can lift with

your legs, not your back. Lift by using

the handhold areas at each side of the

machines base.

• Never carry the Table Mitre Saw by the

power cord. Carrying the tool by the power

cord could cause damage to the insulation

or the wire connections resulting in electric

shock or fire.

• Before moving the saw tighten the

mitre and bevel locking screws to guard

against sudden unexpected movement.

• Lock the Cutting Head in its lowest position.

Ensure that the Cutting Head Locking Pin is

completely engaged in its socket.

WARNING: Do not use the blade guard

as a ‘lifting point’. The power cord must be

removed from the power supply before

attempting to move the machine.

• Lock the Cutting Head in the down position

using the Cutting Head locking pin.

• Loosen the Mitre Angle Locking Screw. Turn

the table to either of its maximum settings.

• Lock the table in position using the Locking

Screw.

• Use the two carry handle cut-outs

machined into either side of the machine

base, to transport the machine.

Place the saw on a secure stationary work

surface and check the saw over carefully.

Check particularly the operation of all the

machines safety features before attempting to

operate the machine.

(4.1) GETTING STARTED - UNPACKING

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good

condition and account for all the accessories

listed in this manual.

Also make sure that all the accessories are

complete. If any parts are found to be missing,

the machine and its accessories should be

returned together in their original packaging

to the retailer. Do not throw the packaging

away; keep it safe throughout the guarantee

period. Dispose of the packaging in an

environmentally responsible manner. Recycle

if possible. Do not let children play with empty

plastic bags due to the risk of suffocation.

EN

DE

FR

TR

13

Page 14

www.evolutionpowertools.com

(4.2) ITEMS SUPPLIED

Description Quantity

Instruction Manual 1

Hold Down Clamp 1

Push Stick 1

Pin Spanner (Blade Change) 1

Hex Key 6mm

(Blade Change)

Hex Key 5mm

(Riving Knife Adjustment)

Multi-Purpose Blade (Fitted)

Rip Fence/

Bevel Guide Assembly

4.3 ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com or

from your local retailer.

(4.4)

Description Part No

FURY Blade FURY210

1

1

1

1

Auxiliary Lower Blade Guard

(Fitted)

Dust Bag Adaptor Tube

Workpiece Supports

Rear Stabilising Arms

1

1

2

2

14

Page 15

www.evolutionpowertools.com

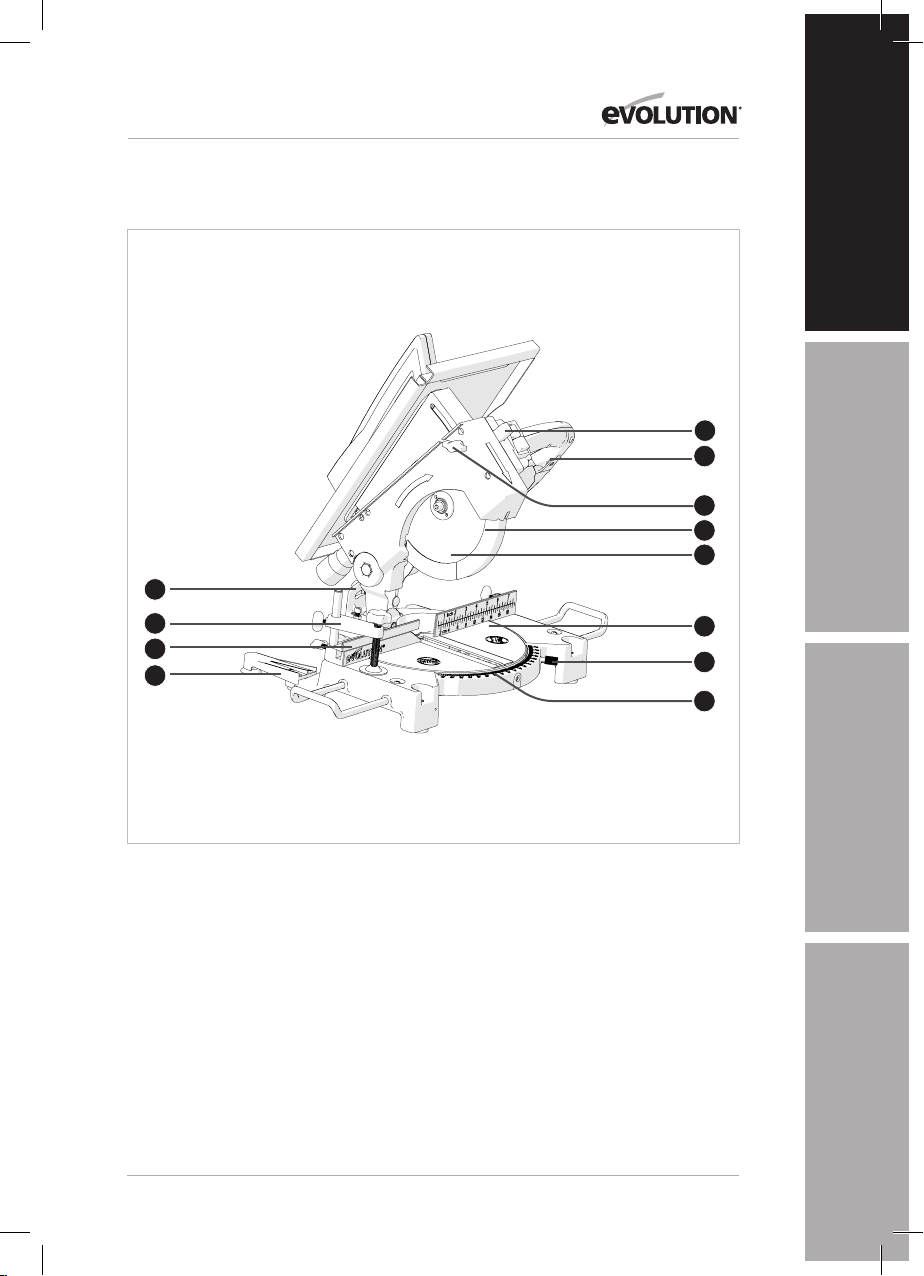

LH VIEW OF FURY 6 MITRE SAW CONFIGURATION

5

9

8

10

EN

11

1

12

3

4

2

6

7

DE

1. CUTTING HANDLE

2. ROTARY TABLE

3. RETRACTABLE LOWER BLADE GUARD

4. BLADE

5. BEVEL LOCKING LEVER

(Back of the machine)

6. MITRE ANGLE LOCKING SCREW

FR

7. MITRE ANGLE SCALE

8. FENCE

9. HOLD DOWN CLAMP

10. STABILISING ARMS

(X2 Back of machine)

11. CUTTING HEAD RELEASE LEVER

12. TABLE HEIGHT ADJUSTING SCREW

TR

15

Page 16

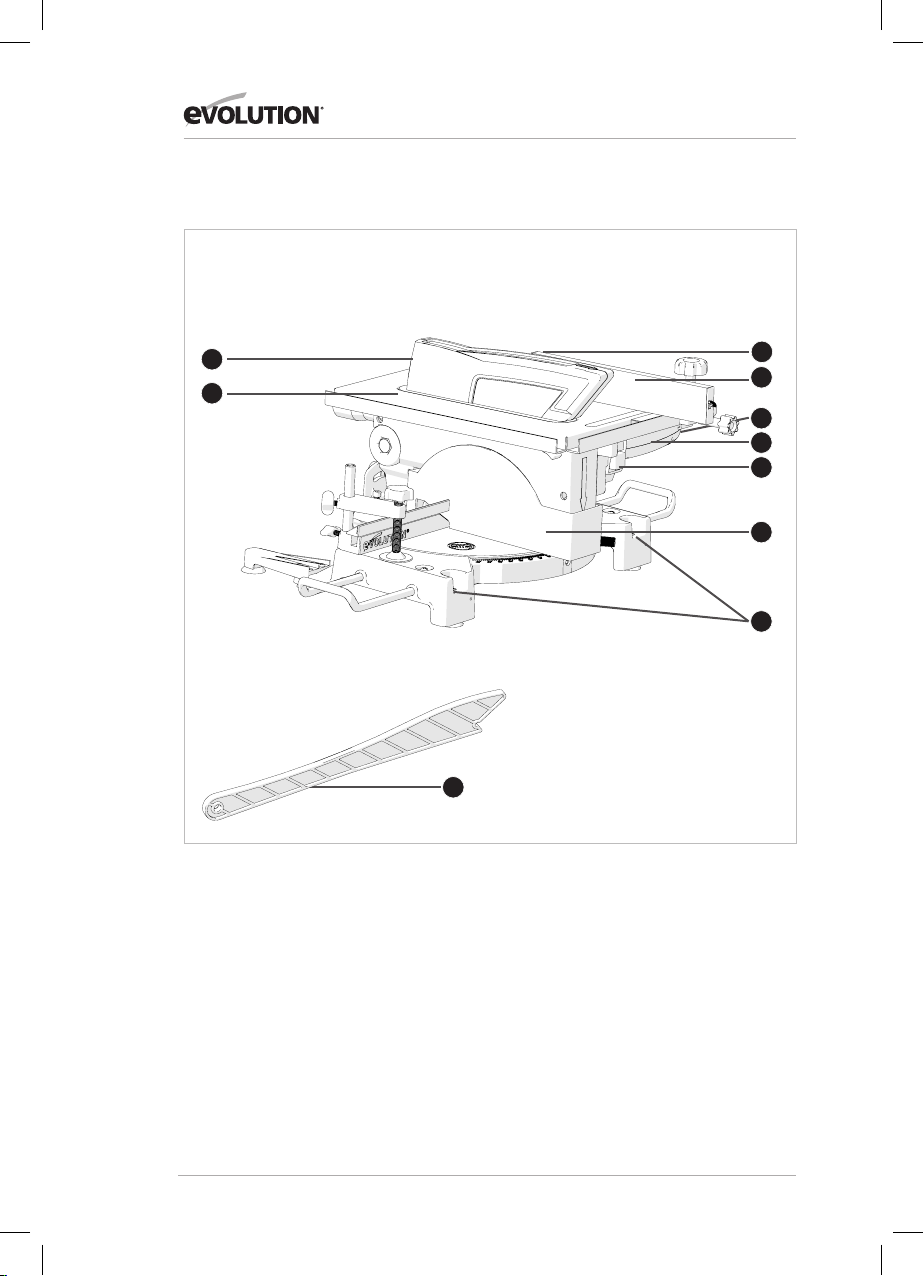

LH VIEW OF FURY 6 TABLE SAW CONFIGURATION

www.evolutionpowertools.com

6

4

8

1. ON/OFF TRIGGER SWITCH (Inside handle)

2. ON/OFF LATCHING SWITCHES

3. CUTTING HANDLE

4. TABLE TOP

5. AUXILIARY LOWER BLADE GUARD

6. UPPER BLADE GUARD

10

7

1

3

2

5

9

7. RIP FENCE

8. PUSH STICK

9. MOUNTING HOLE (2 at the front and

2 under the stabilising arms)

10. CUTTING HEAD LATCHING PIN

(Not shown in this view)

16

Page 17

www.evolutionpowertools.com

GETTING STARTED

WARNING: ALWAYS DISCONNECT THE SAW FROM THE POWER

SOURCE BEFORE MAKING ANY ADJUSTMENTS.

Refer to the “Service Parts Diagram”. Install a blade as detailed in

the “Installing or Removing the Blade” section.

Note: We recommend that the operator reads the ‘Important

Information’ sticker applied to the table of the Fury6. Practicing

and becoming familiar with the procedures outlined on

this sticker will make subsequent adjustments/assembly or

configuring fairly straightforward.

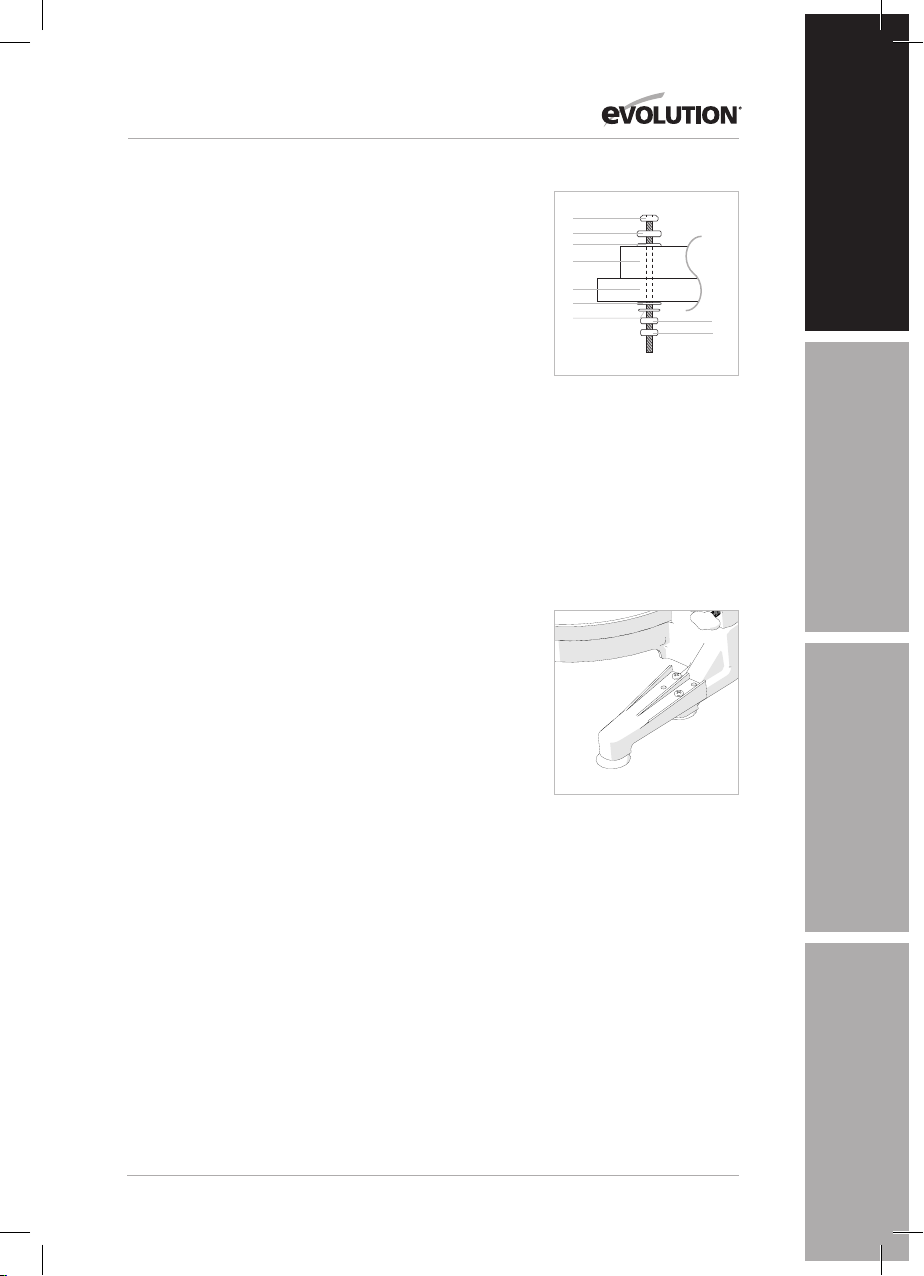

PERMANENTLY MOUNTING THE FURY6 TABLE/MITRE SAW

(Fig. 1)

WARNING: To reduce the risk of injury from unexpected saw

movement, place the saw in the desired location either on a

workbench or other recommended leg set. The base of the saw

has four holes to mount the mitre saw. If the saw is to be used in

one location, permanently fasten it to the workbench or leg set

using appropriate bolts with lock washers and nuts.

Note: When permanently mounting the Fury6 we recommend that

the four (4) rubber feet located underneath each of the mounting

holes are removed and stored safely for possible future use.

1. Tighten the mitre and bevel locks.

2. Position the saw so other people cannot stand behind it.

Thrown debris could injure people in its path.

3. Place the saw on a firm, level surface where there is plenty of

room for handling and properly supporting the workpiece.

4. Support the saw so that the table is level and the saw does

not rock.

5. Bolt or clamp the saw to its support.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Fig. 1

1) Hex headed bolt

2) Spring washer

3) Flat washer

4) Mitre saw base

5) Workbench

6) Flat washer

7) Spring washer

8) Hex nut

9) Lock nut

Fig. 2

EN

(8)

(9)

DE

FR

For Portable Use (Fig. 2)

Note: The Fury6 is designed to be a highly portable machine.

For portable use the Fury6 must be fitted with

the two (2) rear Stabilising Arms.

17

TR

Page 18

www.evolutionpowertools.com

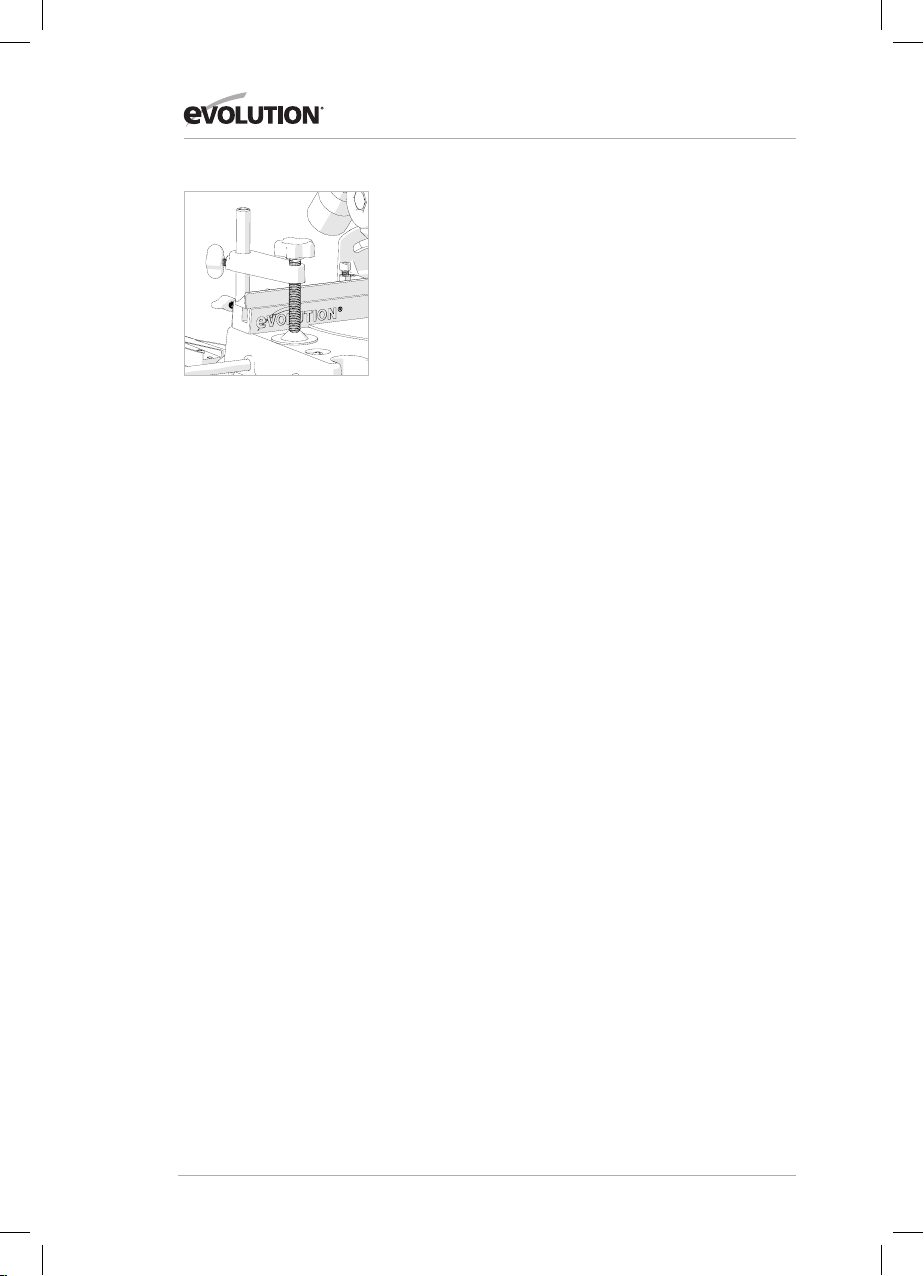

To fit the Stabilising Arms:

• Remove the cross head machine screws from the two (2) rear

mounting positions.

• Attach the Stabilising Arms with the machine screws, two per

arm and tighten securely.

Note: The Stabilising Arms are fitted with rubber feet. The base

of the Fury6 is also fitted with four (4) identical rubber feet

positioned underneath the mounting holes in the base.

Fig. 3a

Fig. 3b

(Dust bag, not supplied)

Fig. 4

When used as a portable machine the six (6) rubber feet provide

the security and stability necessary for safe operation.

Note: When the machine is re-positioned the operator should

ensure that none of the rubber feet become detached from the

machine. The rubber feet can, in some circumstances, stick to

some surfaces due to vacuum suction.

If any of the rubber feet become detached or damaged they

must be replaced.

DUST BAG

A Dust Bag (not supplied) can be fitted to the extraction port at

the rear of the machine. (Fig. 3a & 3b)

• Push the adaptor tube into the extraction port at the rear of

the machine.

• Slide the Dust Bag onto the adaptor tube ensuring that the

spring clip grips the tube holding the Dust Bag securely in place.

Note: For operational efficiency empty the Dust Bag when it

becomes 2/3 full. Dispose of the contents of the Dust Bag in an

environmentally responsible way. It may be necessary to wear a

dust mask when emptying the Dust Bag

WARNING: DO NOT USE A DUST BAG WHEN CUTTING STEEL.

Fig. 5

18

Page 19

www.evolutionpowertools.com

TO CONFIGURE THE FURY6

FOR USE AS A MITRE SAW

WARNING: Only carry out this procedure with the machine

disconnected from the power source.

Caution: The Fury6 has many built in safety features and

safety interlocks. It is important that the following instructions,

and those found on the label attached to the machine table

are read, understood and acted upon. Failure to carry out the

configuration procedure could result in damage to the machine

and/or injury to the operator.

• Loosen the table height adjustment screw. (Fig.4)

• Raise the table top to its upmost position and tighten the

height adjustment screw. (Fig. 5)

• Slightly push down on the Cutting Head Handle.

• Pull out the Cutting Head Latching Pin and allow the Cutting

Head to rise to its upmost position. (Fig. 6)

• Remove the Auxiliary Lower Blade Guard and store safely for

future use.

The Fury6 is now ready to use as a Mitre Saw. (Fig. 7)

WORKPIECE SUPPORTS (Fig. 8)

Workpiece supports can be fitted to both sides of the machine

base if required.

EN

Fig. 6

DE

Fig. 7

• Loosen the relevant Workpiece Retaining Screw located in a

socket at the top front of the machine base.

• Insert the Workpiece Support into the holes machined in the

base.

Note: The Workpiece Support should be pushed ‘fully home’

into the machine base.

Correct installation will require approximately 65mm of the

Workpiece Support to slide into the machine base.

• Fasten the Workpiece Support into the base by tightening

the Retaining Screw.

Workpiece Supports can be very useful in providing extra

support for long workpieces when using the Fury6 in Mitre Saw

configuration.

19

FR

Fig. 8

TR

Page 20

Fig. 9

www.evolutionpowertools.com

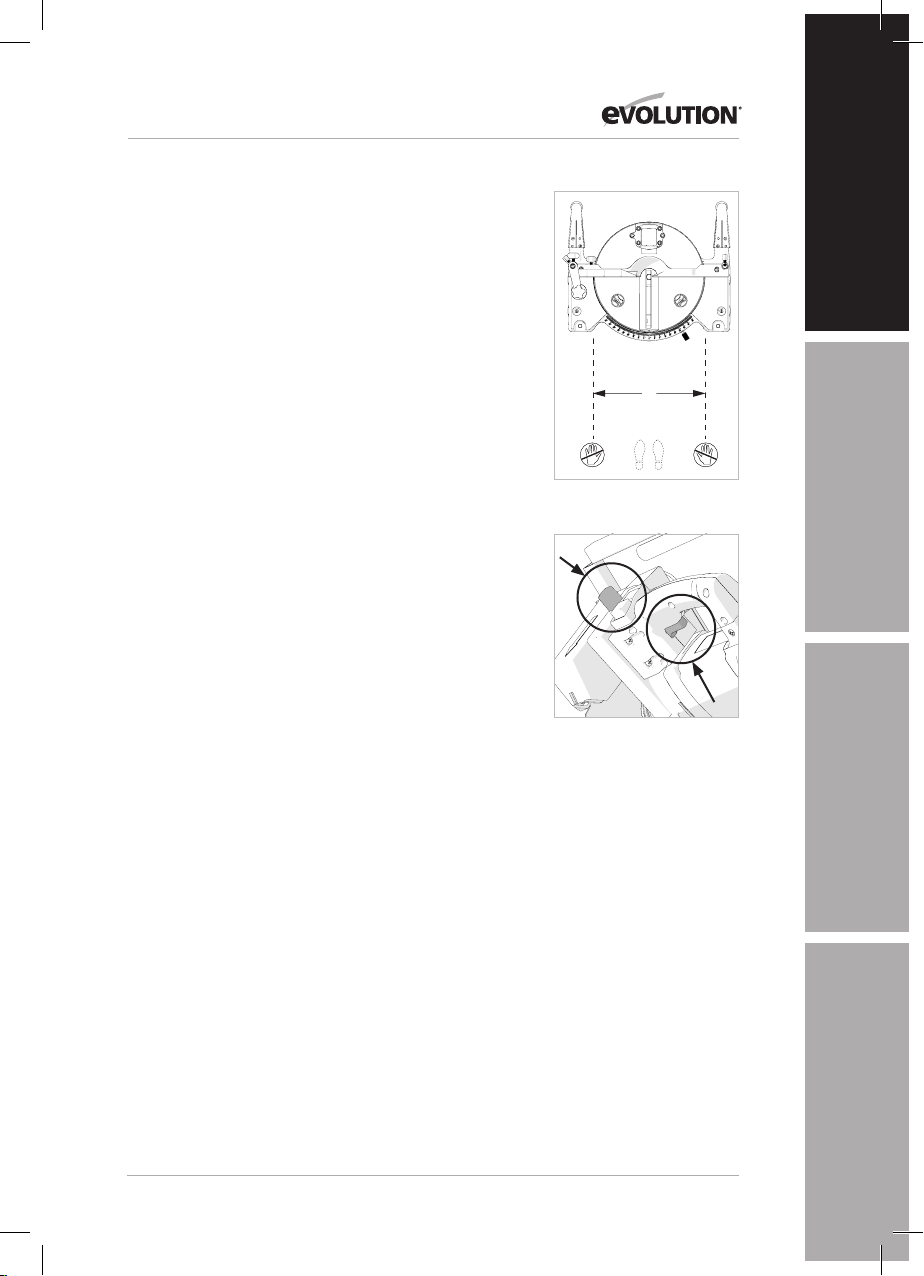

HOLD DOWN CLAMP (Fig. 9)

A Hold Down clamp is supplied with the Fury6.

Two sockets (one on either side) are incorporated into the rear

of the machines fence.

• Fit the pillar of the clamp into the socket that best suits the

cutting application, ensuring that it is pushed fully down.

• Tighten the fence thumbscrew to lock the pillar of the Hold

Down Clamp into the fence socket.

• Put the workpiece onto the rotary table and against the fence.

• Adjust the Hold Down Clamp so that it securely holds the

workpiece to the rotary table.

• Before attempting any cutting check to ensure that the

clamp does not interfere with the blade path as the Cutting

Head is lowered.

OPERATING INSTRUCTIONS

MITRE SAW CONFIGURATION

WARNING: It is important that the operator is adequately trained

in the use, adjustment and operation of the machine, and has

read the Instruction Manual before commencing operations.

Note: We recommend that when the Fury6 is being used as a

Mitre Saw, the complete Fence Assembly is removed from the

machine as stored safely for future use.

1. Releasing the Cutting Head

Note: When configured in Mitre Saw mode the Cutting Head will

be automatically locked in its upper position with the Retractable

Lower Blade Guard completely covering the blade teeth.

To release the Cutting Head press and hold the Cutting Head

Release Lever.

Gently press down on the Cutting Head Handle to lower the

Cutting Head. The operation of the Retractable Lower Blade

Guard is automatic.

Note: We recommend that when the machine is not in use the

Cutting Head is locked in its down position, with the Auxiliary

Lower Blade Guard correctly installed and the Cutting Head

Latching Pin fully engaged in its socket.

20

Page 21

www.evolutionpowertools.com

2. Preparing to make a cut

• Avoid awkward operations and hand positions where a sudden

slip could cause fingers or hands to move into the blade.

• Cut only one workpiece at a time.

• Clear everything except the workpiece and related support

devices away from the blade before commencing operations.

• Fasten the workpiece using clamp(s) to hold the workpiece

securely to the table and fence.

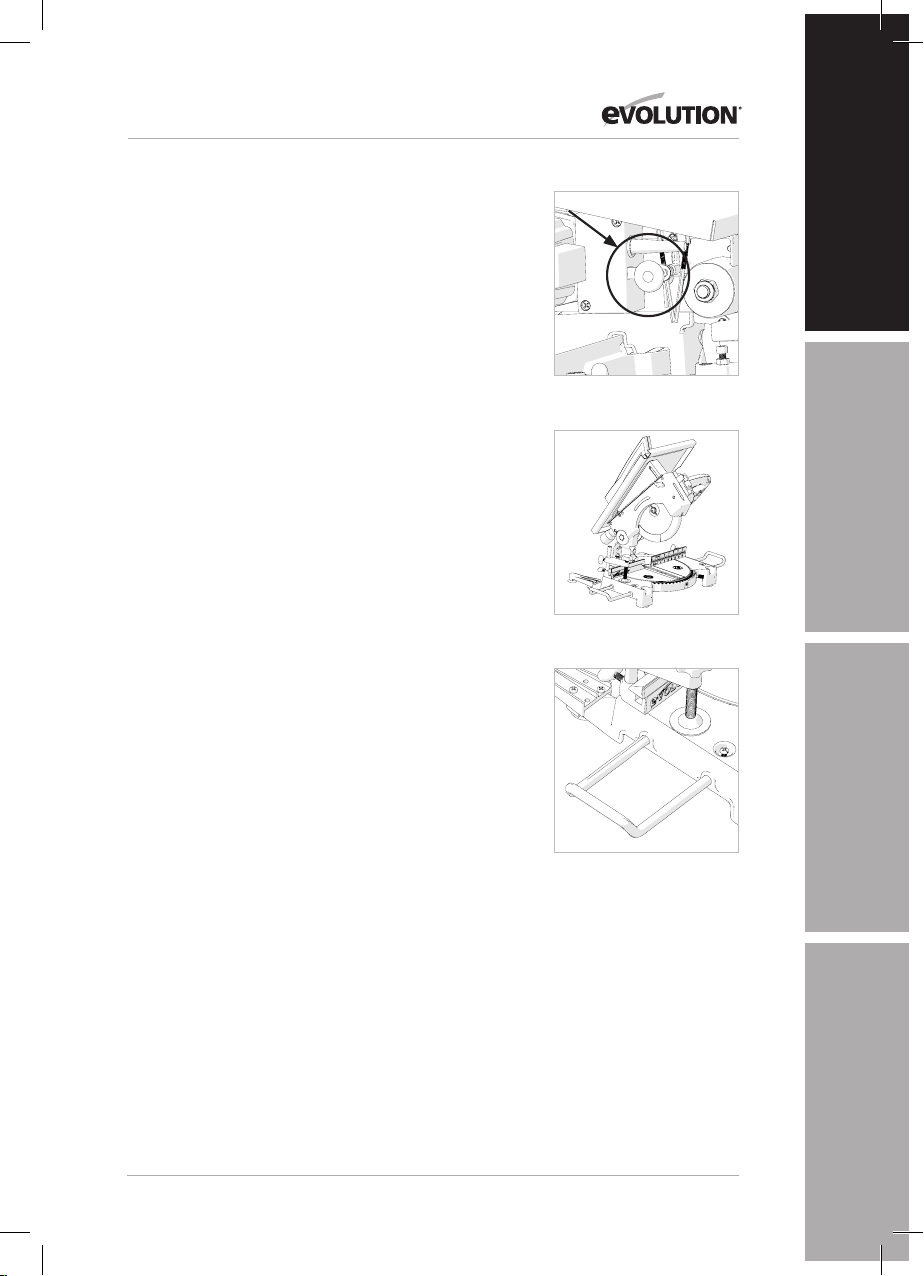

3. Body and Hand position (Fig. 10)

• Never place hands within the ‘no hands zone’ (at least

150mm away from the blade). Pictograms on the machines

rotary table are provided as an aid to safe working practices.

Keep hands away from the path of the blade.

• Hold the workpiece firmly to the fence to prevent any

movement. Use a Hold Down Clamp if possible but check

that it is positioned that it does not interfere with the path of

the blade or other moving machine parts.

• Before attempting a cut, make a ‘dry run’ with the power off

so that you can see the path of the blade.

• Keep hands in position until the ON/OFF trigger has been

released and the blade has completely stopped.

4. The Mitre Saw On/Off Trigger Switch Operation (Fig. 11a)

The On/Off Switch is a non-latching trigger type switch which is

ergonomically located on the inside of the Cutting Head Handle.

Operate the switch to turn on the machines motor. Release the

switch to turn off the machines motor.

280 mm

Fig. 10

B

Fig. 11a + 11b

EN

No-Hands ZoneNo-Hands Zone

DE

A

FR

Note: The Cutting Head cannot be lowered until the Cutting

Head Release Lever is operated. (Fig. 11b) The Blade will

remain covered by the retractable guard until the Cutting Head

is released. Operation of the Retractable Guard is automatic.

5. Chop Cutting

The Cutting Head is gently pushed down to cut through the

workpiece.

• Place the workpiece on the Rotary Table and against the fence

in the desired position. Secure with clamp(s) as appropriate.

• Grasp the Cutting Handle.

• Turn on the motor using the trigger switch and allow the

blade to reach full operating speed.

21

TR

Page 22

Fig. 12

www.evolutionpowertools.com

• Press and hold the Cutting Head Release Lever to release the

Cutting Head.

• Gently lower the Cutting Head to its lowest position,

cutting through the workpiece.

• After the cut is completed, turn off the motor by releasing

the trigger switch. Allow the blade to come to a complete

stop. Allow the Cutting Head to rise to its upper position.

• Only remove your hands or the workpiece from the machine

when the Cutting Head is in its upper position with the blade

teeth completely covered by the Retractable Blade Guard.

6. Mitre Cutting

Any angle from 45˚ left to 45˚ right is available, and a protractor

scale can be found to the front of the Rotary Table.

Positive stops are provided for every 5˚ of angular movement.

Note: The rotary table must always be locked into position with

the Mitre Angle Locking Screw even if a positive stop is selected.

To select a Mitre Angle:

• Loosen the Mitre Angle Locking Screw. (Fig.12) This is found

at the front RH side of the table near the 30˚ index mark.

• Turn the Rotary Table to the required angle. To aid setting,

an index mark is machined into the table just in front of the

table insert.

• Tighten the Mitre Angle Locking Screw securely when the

desired angle has been selected.

A Mitre Cut can now be made using the same techniques as

previously described in Chop Cutting.

22

Page 23

www.evolutionpowertools.com

7. Bevel Cutting

The Cutting Head can be set at any angle up to 45˚ to the Left

Hand side only.

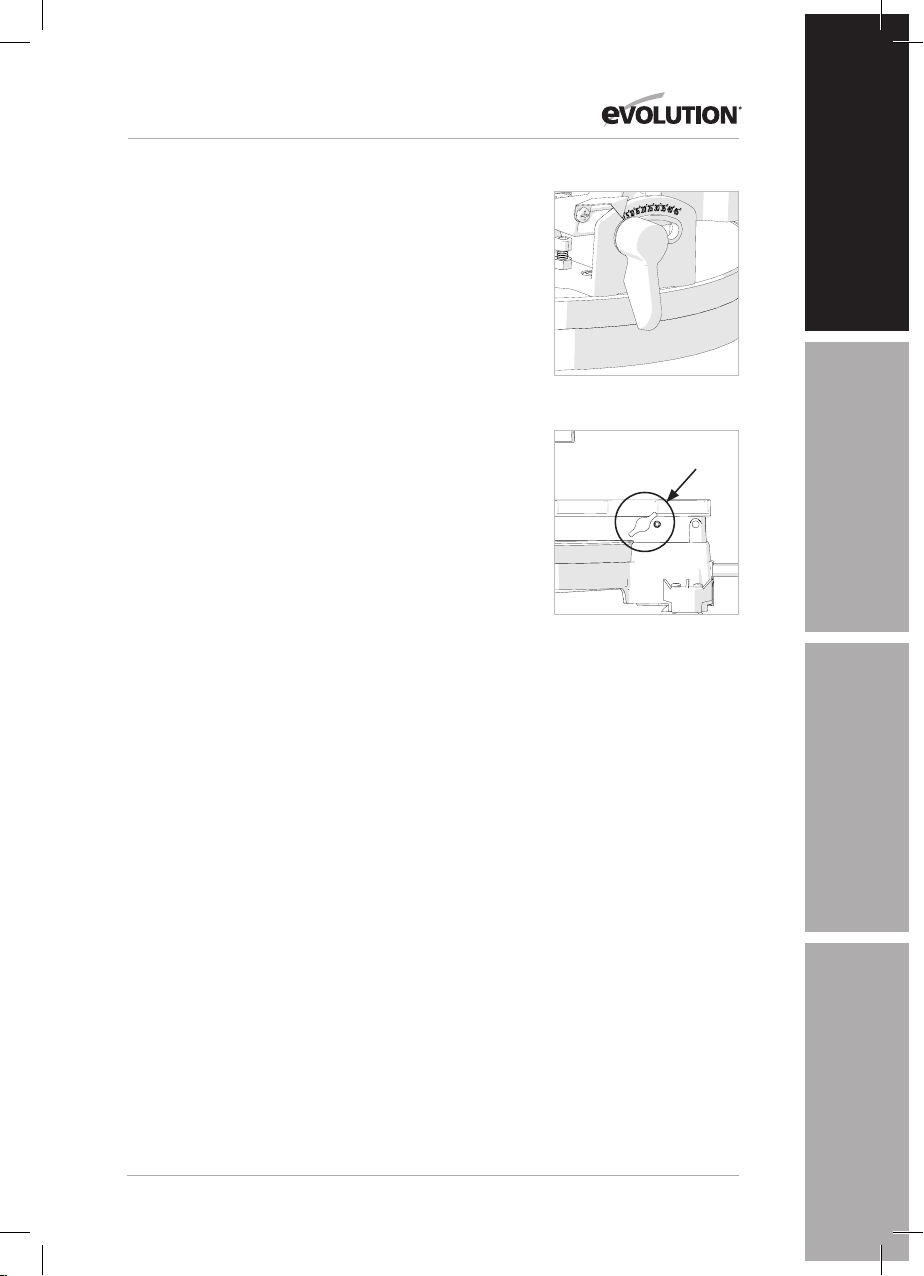

The Bevel Locking Lever is found at the rear of the machine.

A protractor guide and pointer are incorporated into the bevel

mechanism to aid setting. (Fig.13)

To set a Bevel Angle:

• Loosen the Bevel Lock Handle

• Tilt the Cutting Head to the desired angle. Use the protractor

guide to aid with setting.

• Ensure that the Bevel Lock Handle is securely tightened

when the desired angle has been achieved.

A Bevel Cut can now be made using the same techniques as

previously outlined.

Note: Always make a ‘dry run’ with the machine switched ‘off’

so that the path of the blade can be checked. Some Bevel

and Compound Cuts may require the Hold Down Clamp to

be positioned to the RH side of the Cutting Head. This may be

necessary to avoid interference with the blade and other parts

of the machine as the Cutting Head is lowered.

8. Fence Adjustment

Note: The left hand side of the fence is provided with additional

adjustments. The upper portion of the fence can slide to the left

to provide clearance for the blade. This may be necessary when

acute bevel angles are selected.

EN

Fig. 13

DE

Fig. 14

FR

To adjust the fence:

• Loosen the thumbscrew. (Fig 14)

• Slide the upper portion of the fence to the required position

and tighten the thumbscrew.

• Lower the Cutting Head to check the path of the blade. Ensure

there is no interference with any other parts of the machine.

9. Compound Cutting

A Compound Cut is a combination of a Mitre Cut and Bevel Cut.

• Set the Mitre Angle required as previously described.

• Set the Bevel Angle as previously described.

• Ensure the tightness of all adjustment/locking screws, and

conduct a ‘dry run’ to check the path of the blade.

• Make the cut as previously described.

23

TR

Page 24

www.evolutionpowertools.com

10. Cutting Bowed Material (Fig 15)

Before cutting any workpiece, check to see if it is bowed. If it is

bowed the workpiece must be positioned and cut as shown.

Do not position the workpiece incorrectly or cut the workpiece

without the support of the fence.

11. Clearing Jammed Material

Fig. 15

Fig. 16

Fig. 17

• Turn mitre saw “OFF” and allow the blade to come to a

complete halt.

• If possible allow the Cutting Head to rise to its upper position.

• Unplug the Mitre Saw from the mains supply.

• Carefully remove any jammed material from the machine.

TO CONFIGURE THE FURY6

FOR USE AS A TABLE SAW

WARNING: Do not cut metal or metallic materials when the

machine is configured as a Table Saw.

WARNING: Only carry out this procedure with the machine

disconnected from the power supply.

Caution: The Fury6 has many built in safety features and

safety interlocks. It is important that the following instructions,

and those found on the label attached to the machine table

are read, understood and acted upon. Failure to carry out the

configuration procedure could result in damage to the machine

and/or injury to the operator.

• Ensure that the Rotary Table is set at 0˚ Mitre angle and the

Cutting Head is set at 0˚ Bevel angle.

• Position the Auxiliary Lower Blade Guard on the Rotary Table

over the table insert and straddling the Fence. (Fig. 16)

• Lower the Cutting Head to the fully down position, ‘capturing’

the Lower Auxiliary Blade Guard. Push the Cutting Head

Latching Pin into its socket. (Fig. 17)

• Loosen the Table Height Adjustment Screw (Fig.18) and

lower the table to its lowest position.

• Tighten the Height Adjustment Screw.

Fig. 18

The Fury6 is now ready to use as a Table Saw.

24

Page 25

www.evolutionpowertools.com

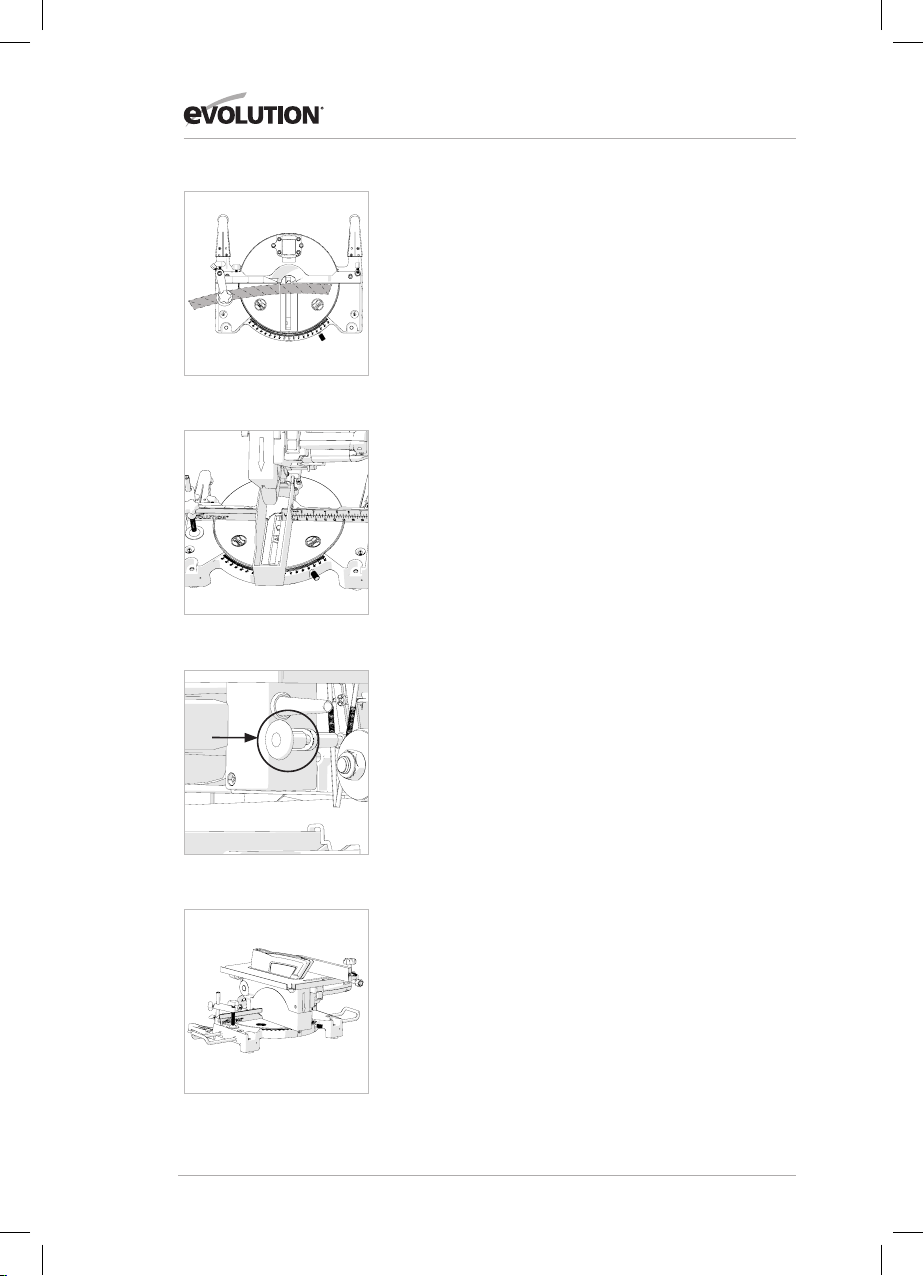

FENCE ASSEMBLY (Fig. 19)

The Fence Assembly consists of two (2) main parts:

• The Angle Gauge.

• The Rip Fence Face Plate.

Note: The ‘T’ slot in the Rip Fence Face Plate is not centrally located.

• Slide the Rip Fence Face Plate onto the two (2) mounting

screws found on the Angle Plate.

• Ensure that the wider (20mm) portion of the Fence Face is

downwards and will lie on the saw table when in use.

The Angle Plate can now be slid into the Rip Fence channel

found at the front of the machine table. (Fig. 20)

Slide in from the Right Hand side ensuring that the Locking Clamp

engages correctly with the front face of the Rip Fence channel.

FENCE ASSEMBLY AS A RIP FENCE

To use the Fence Assembly as a Rip Fence the Face Plate must

be accurately aligned with the blade.

WARNING: Only carry out this procedure with the machine

disconnected from the power supply.

To Align the Rip Fence:

• Ensure that the table is at its lowest setting (see Fig. 23a &23b)

• Set the Angle Gauge to an indicated 90˚.

• Slide the Fence Assembly up to the blade, raising the Blade

Guard by hand so that the Face Plate rests alongside the

blade and underneath the Blade Guard. (Fig.21)

• Gently tighten the Angle Gauge Locking Clamp Screw to lock

the Assembly into the Rip Fence channel.

• Check that the Face Plate is in exact alignment with the blade.

• If adjustment is required, loosen slightly the Angle

Clamping Screw and adjust the Angle Gauge until exact

alignment is achieved.

• Tighten the Angle Clamping Screw.

• Adjust the Angle Gauge Pointer if necessary to point exactly

to the 90˚ index mark.

• Use a #2 Phillips Head screwdriver to loosen the Angle

Pointer fixing screw. (Fig. 22) Adjust the pointer to suit and

then retighten the fixing screw.

• Loosen the Angle Clamp Locking Screw to allow the

Assembly to slide along the Rip Fence channel.

EN

height

Fig. 19

DE

Fig. 20

FR

Fig. 21

TR

Fig. 22

25

Page 26

www.evolutionpowertools.com

Basic Table Saw Operations

WARNING: Do not cut metal or metallic materials when the

machine is configured as a Table Saw.

WARNING: Never attempt freehand cuts on this machine.

Always use a correctly adjusted Rip Fence to minimise the

possibility of the blade binding and kickback.

Fig. 23a

Fig. 23b

Fig. 24

1. Adjusting the Table Height (Fig. 23a &23b)

The height of the Table above the machines motor can be

adjusted. This enables your Fury6 to mimic the rise and fall facility

found on many conventional table saws. The cutting depth of the

blade can thereby be adjusted from 0mm to 32mm.

WARNING: Only adjust the height of the table with the

machine disconnected from the mains power supply.

To adjust:

• Loosen the Height Adjustment Screw and adjust the table

height so that the saw blade protrudes through the table by

the required amount. Retighten the screw.

• We recommend that the saw blade protrudes through the

material to be cut by approximately 3mm.

WARNING: This machine is not suitable for cutting rebates or

stopped grooves.

Note: A workshop dust extraction device can be connected to

the extraction port found at the rear of the machine if required.

2. Table Saw On/Off Switches (Fig. 24)

The On/Off Switch is a two (2) button latching type. The buttons

are located on the Front Left Hand side of the Cutting Handle.

• Push the Green (I) button to start the motor.

• Push the Red (O) button to stop the motor.

3. Rip cutting

Note: The Fury6 in Table Saw mode is optimally suited for the

cutting of thin sheet material such as laminate flooring etc.

Rip cutting is cutting along the length of a piece of material

rather than across it.

26

Page 27

www.evolutionpowertools.com

Rip cutting should always be done with the Rip Fence set to the

desired width and on the RH side of the machines table.

Note: Check that the Rip Fence is locked in position and is

parallel to the saw blade. Check that the riving knife is properly

aligned with the saw blade.

When ripping small section material a Push Stick should be

used to feed/guide the final 300mm of the material past the

blade. A Push Stick should always be used when making cuts of

less than 300mm.

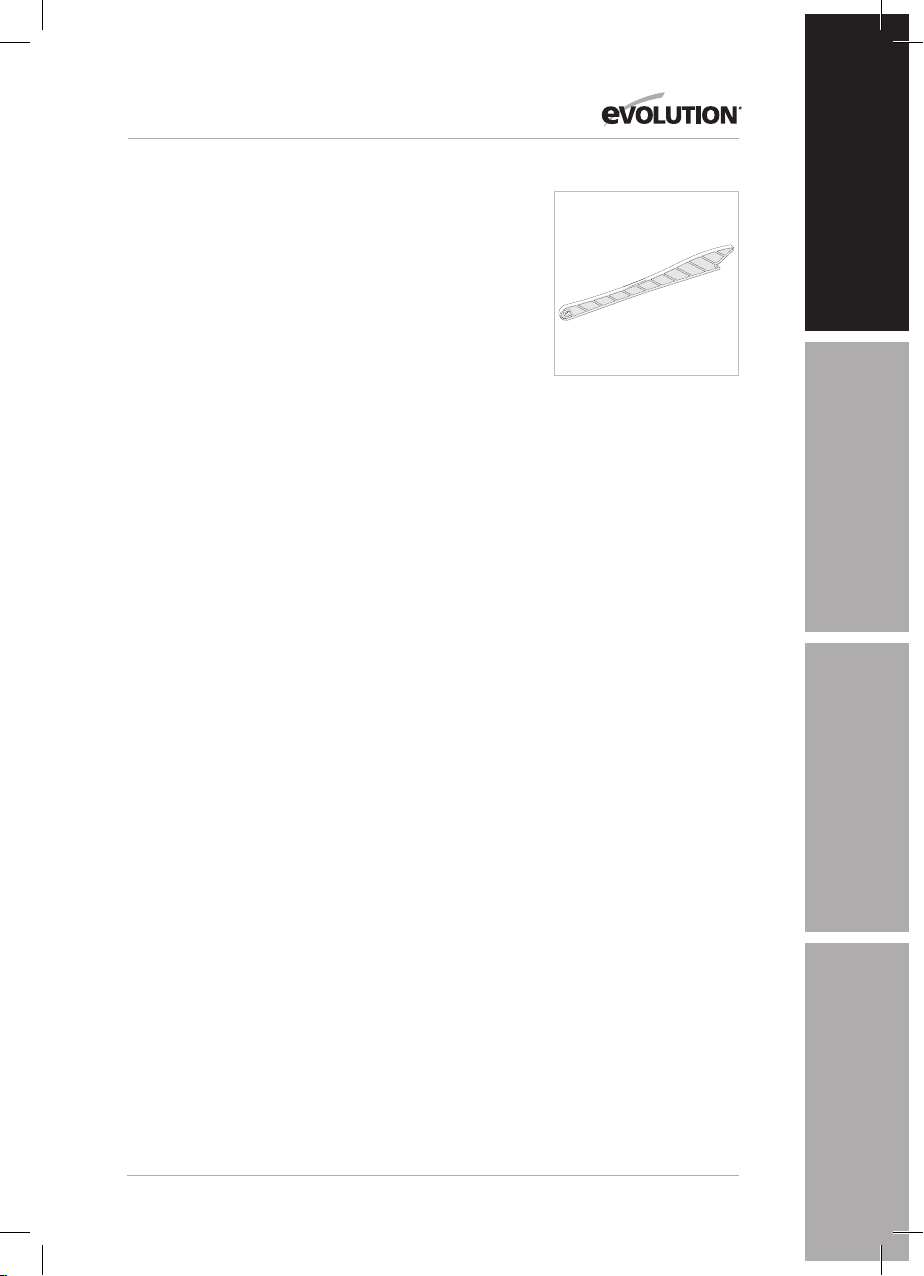

Note: A Push Stick (Fig. 25) is provided with the Fury6 and has

a dedicated storage position to the front of the machine.

We recommend that when not in use the Push Stick is stored on

the machine.

When ripping long boards or large panels always use a remote

work support or enlist competent trained help.

Feed the workpiece through the saw keeping it indexed against

the Rip Fence. Use smooth, steady pressure and employ a Push

Stick when necessary.

Hands should never be in line with the blade.

MAINTENANCE AND ADJUSTMENTS

EN

Fig. 25

DE

WARNING: Ensure that the machine is disconnected from

the mains supply before any maintenance tasks or adjustments

are attempted.

Cleaning

After each use the machine should be cleaned. Remove all

sawdust etc from the visible parts of the machine with a

vacuum cleaner. A vacuum cleaner can also be connected to

the machine dust extraction port at the rear of the machine.

This should remove debris from the inside of the machine.

Never use solvents to clean plastic parts, as solvents can

damage them. Clean only with a soft slightly damp cloth.

27

FR

TR

Page 28

Fig. 26

www.evolutionpowertools.com

Riving Knife

The Riving Knife is a very important component and comes

factory fitted and correctly aligned and adjusted. The Riving

Knife prevents the work from binding as it passes through the

blade. Inspect the Riving Knife at regular intervals and replace it

if it is worn or damaged.

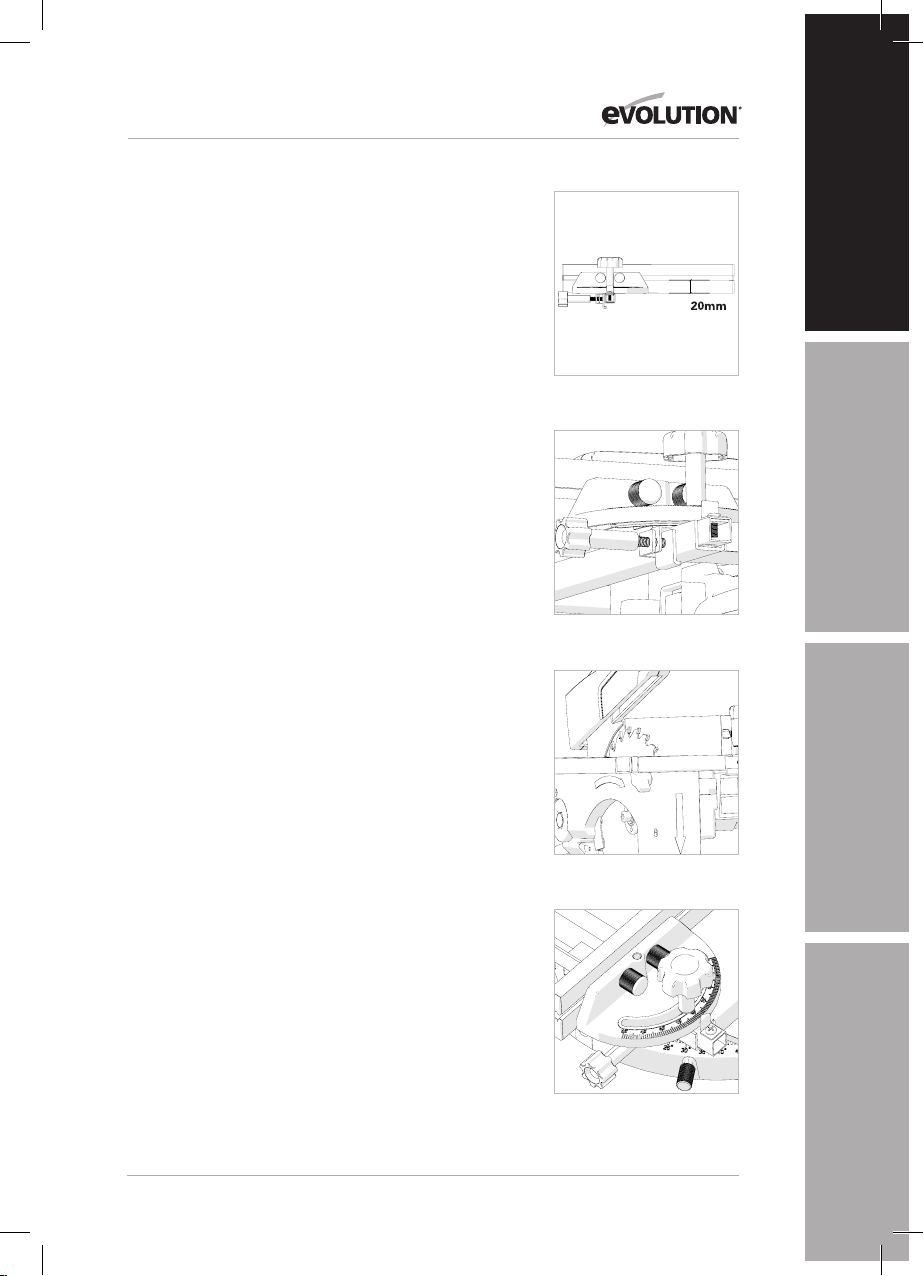

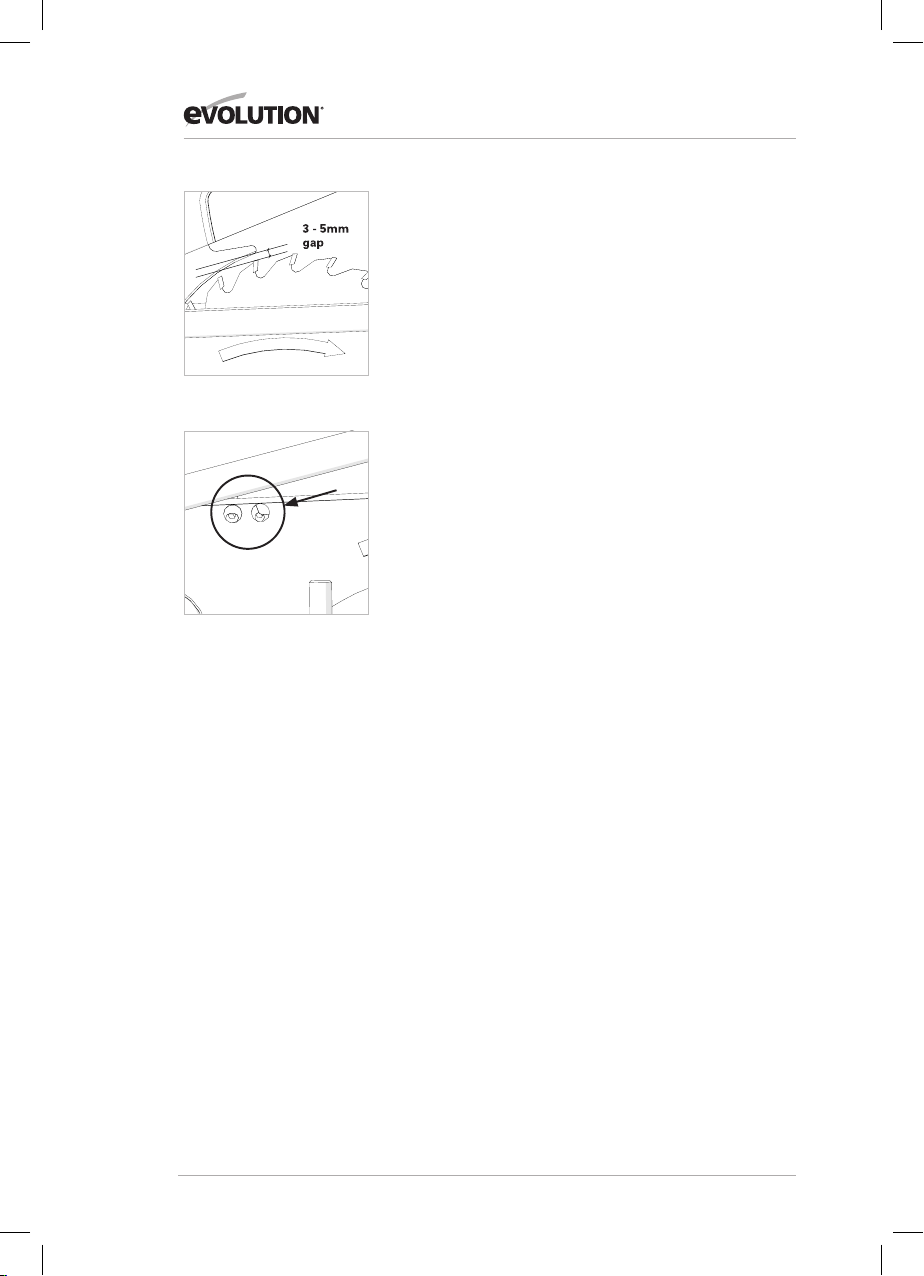

The Riving Knife should be adjusted so that the gap between

the tips of the blade teeth and the edge of the Riving Knife is

approximately 3-5mm. (Fig.26)

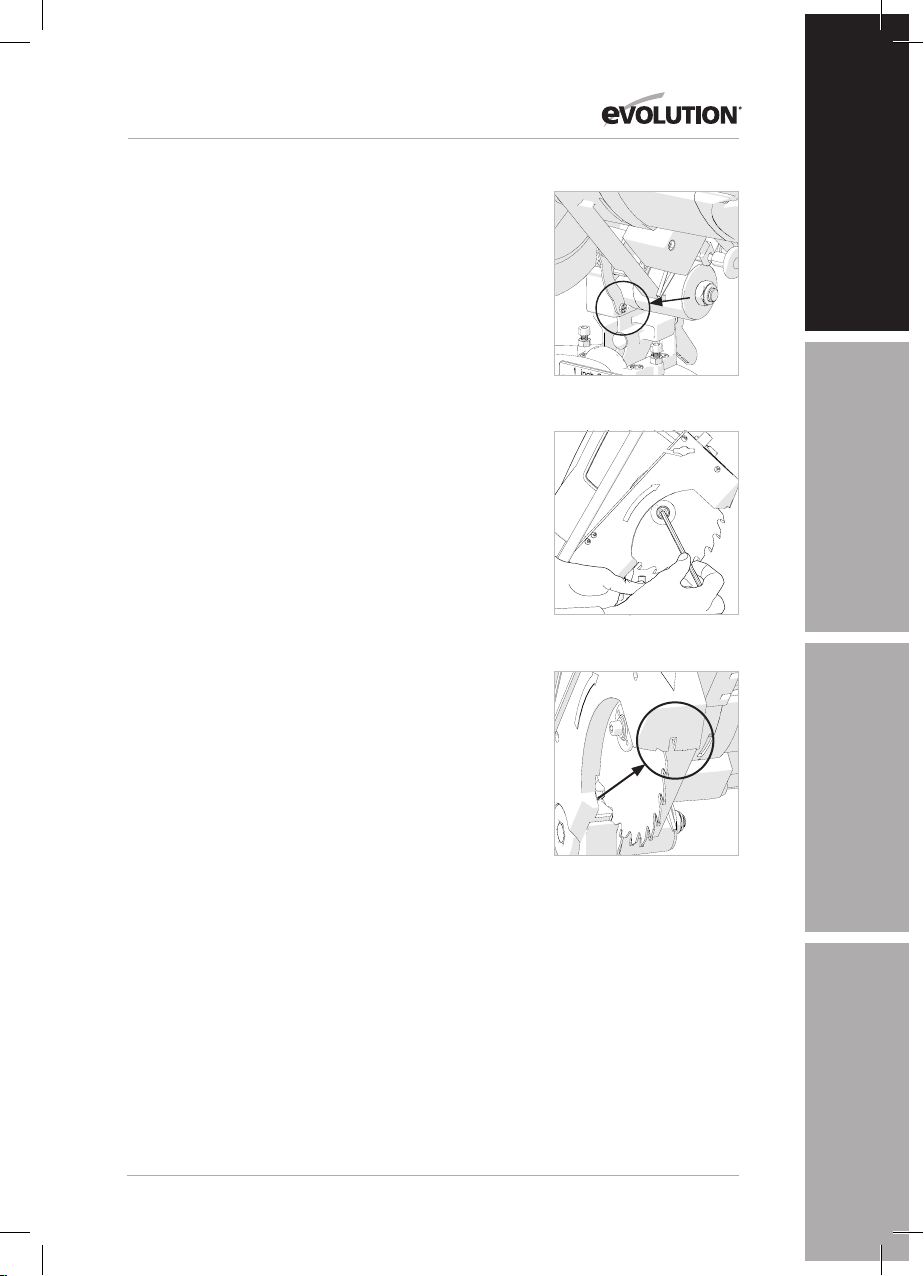

To adjust the Riving Knife loosen the two (2) fixing screws

(Fig. 27) slightly using an allen key. When correct alignment is

achieved tighten the fixing screws.

Note: Use only a genuine Evolution Riving Knife, as this is a

dedicated component for this machine. Non genuine parts could

be dangerous. If in any doubt, please contact the Helpline.

Push Stick

Fig. 27

A plastic push stick is provided with the machine. When not in

use store the push stick on the machine.

Note: If the push stick becomes damaged it should be replaced.

If the operator makes their own push stick, we recommend that

it follows the same pattern as that supplied. Replacement push

sticks are available from Evolution Power Tools.

INSTALLING or REMOVING a BLADE

WARNING: Only use genuine Evolution blades which are

designed for use in this machine. Ensure that the maximum

speed of the blade is compatible with the machine. Only

perform this operation with the machine disconnected from

the mains supply.

Note: It is recommended that the operator considers wearing

protective gloves when handling the blade during installation

or when changing the machines blade.

Note: The blade is a very precise fit within the Fury6 machine.

Be patient and methodical when changing the blade.

28

Page 29

www.evolutionpowertools.com

To change a blade:

• Ensure that the machine is in Mitre Saw Mode with the

Cutting Head in its upper position.

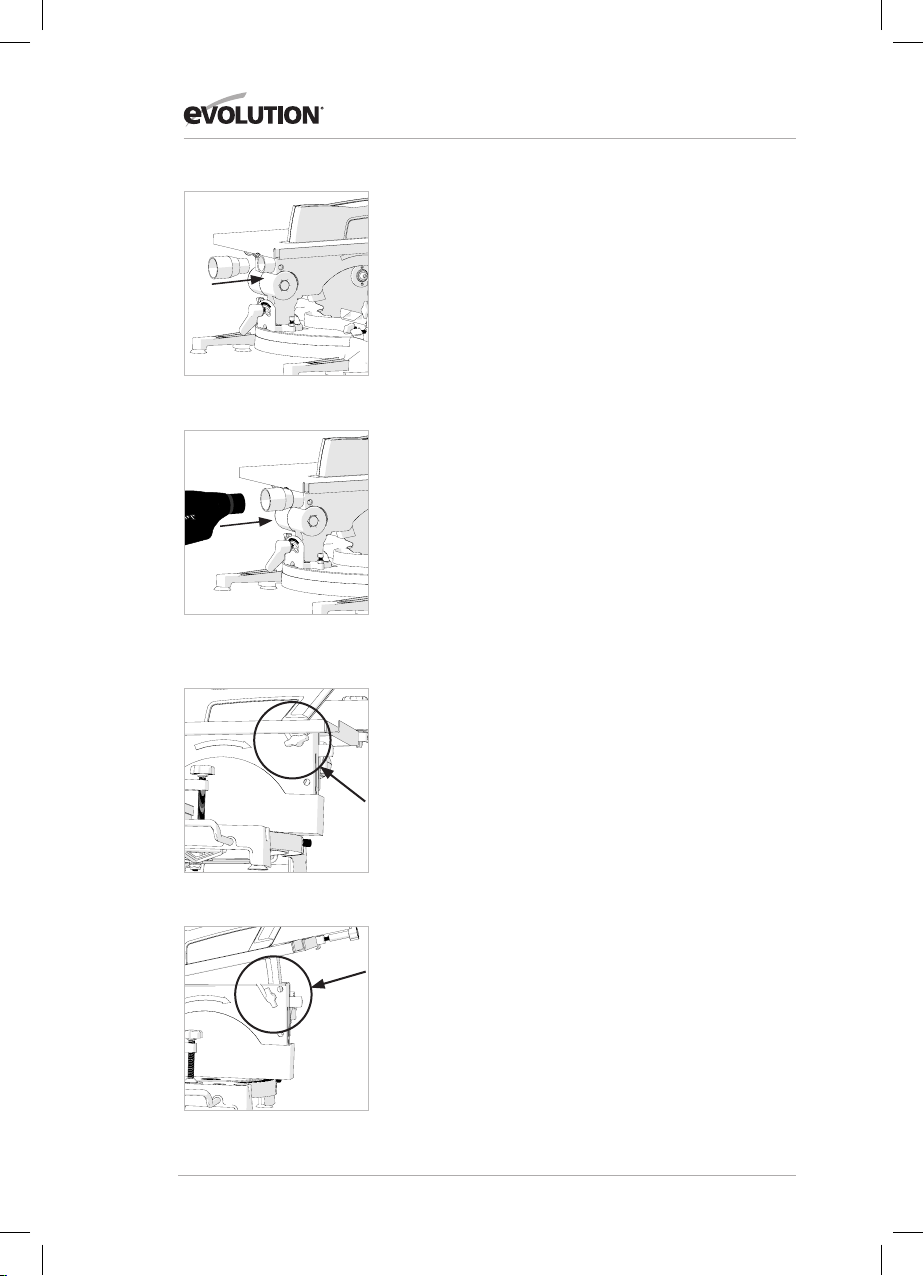

• Release the Retractable Lower Guard Operating Lever by

removing and safely storing its pivot screw. (Fig. 28)

• Use the pin spanner (provided) to hold the outer blade flange.

• Use the hex key (provided) to unscrew the arbor screw. (Fig. 29)

Note: The arbor screw has a Left Hand thread. Turn clockwise to

undo and counterclockwise to tighten.

• Remove the arbor screw, washer and outer blade flange.

• Manually operate the Lower Blade Guard and retract it fully

up into the body of the machine

• Remove the blade by withdrawing it outwards to clear the

end of the arbor and then downwards and forwards away

from the machine.

Note: The 5mm blade slot at the lower front of the Cutting

Head (Fig. 30) provides extra clearance when manoeuvring the

blade into or out of the machine.

To refit:

• Ensure that the blade is suitable for this machine.

• Ensure that the direction of rotation arrow on the blade

matches the direction of rotation arrow found on the

machines Side Blade Guard. The blade teeth should always

point downward at the front of the saw.

• Using the blade slot to provide maximum clearance and access

to the machine, carefully and gently manoeuvre the blade up

into the machine and locate it on the inner blade flange.

• Reinstall the outer blade flange, washer and arbor screw.

• Hand tighten the assembly.

• Hold the outer blade flange with the pin spanner.

• Tighten the arbor screw with the hex key.

• Check that the blade spins freely by rotating it by hand.

• Close the Retractable Blade Guard around the blade so the

blade teeth are completely covered.

• Re-connect the Retractable Blade Guard Operating Lever to

its service position using the pivot screw.

• Check the installation, particularly for the operation of all the

safety guards.

EN

Fig. 28

DE

Fig. 29

FR

Fig. 30

29

TR

Page 30

www.evolutionpowertools.com

CHECKING AND SETTING OF BEVEL ANGLES

WARNING: Before making any adjustments ensure that the

machine is disconnected from the power supply.

Note: While all angular settings have been factory set, checking

and adjustment may be required as a consequence of normal

operational wear and tear.

Fig. 31

Note: To check and adjust the Bevel Angles the machine must be

in Mitre Saw configuration.

0˚ BEVEL ANGLE

At 0˚ Bevel Angle the blade should be perpendicular and at

exactly 90˚ to the Rotary Table. An accurate engineers square

(not supplied) is needed to check the 0˚ Bevel Angle.

To check:

• Ensure that the Cutting Head is in the vertical position, against its

stop with the Bevel Pointer indicating 0˚ Bevel Angle.

• Tighten the Bevel Lock Handle.

• Lower the Cutting Head to its lowest position. The Retractable

Lower Blade Guard will rotate up into the machine.

• The engineers square can now be used to check the angle

between the blade and the Rotary Table.

If adjustment is required:

Note: The Cutting Head will need to be tilted to gain access to

the 0˚ Bevel Stop Adjustment Screw.

• Loosen slightly the 0˚ Bevel Stop Adjustment Screw locknut.

(Fig. 31)

• Use an Allen Key to turn the Bevel Stop Screw clockwise or

counterclockwise as required.

• When exact alignment between the

blade and Rotary Table is achieved, tighten the locknut.

45˚ BEVEL ANGLE

The 45˚ Bevel Angle can be checked in a similar manner to the

0˚ Bevel Angle. An accurate 45˚ Engineers Set Square

(not supplied) will be required.

30

Page 31

www.evolutionpowertools.com

To check:

• Ensure that the Cutting Head is tilted to the 45˚ position,

against its stop, with the Bevel Pointer indicating 45˚ Bevel

Angle.

• Tighten the Bevel Lock Handle.

• Lower the Cutting Head to its lowest position. The Retractable

Lower Blade Guard will rotate up into the machine.

• Use the Engineers 45˚ Set Square to check the angle of

between the blade and the Rotary Table.

If adjustment is required:

Note: The Cutting Head will need to be tilted to gain access to

the 45˚ Bevel Stop Adjustment Screw.

• Loosen slightly the 45˚ Bevel Stop Adjustment Screw locknut.

(Fig. 32)

• Use a Hex Key to turn the Bevel Stop Screw clockwise or

counterclockwise as required.

• When exact alignment between the

blade and Rotary Table is achieved, tighten the locknut.

FENCE ADJUSTMENT (Fig. 33a & 33b)

The Fence is fastened to the machines base by two (2) socket

head screws, one on either side. These Screws are located in

elongated holes, which enable the Fence to be repositioned

as required.

EN

Fig. 32

DE

Fig. 33a

The Fence should be set at exactly 90˚ to a correctly

installed blade.

An accurate Engineers Square (not supplied) will be required

to precisely position the Fence.

To reposition the Fence:

• Set the Rotary Table to 0˚ Mitre Angle.

• Set the Cutting Head to 0˚ Bevel Angle.

• Slightly loosen the two (2) Fence socket head screws.

• Lower the Cutting Head to its lowest position.

• Check the alignment of the Fence with the Blade using the

Engineers Square.

• Align the Fence as necessary and then tighten the socket

head screws.

31

FR

Fig. 33b

TR

Page 32

www.evolutionpowertools.com

FUSE AND PLUG REPLACEMENT

Should the fuse in the main plug of your machine need replacing

it should always be replaced with one of identical rating.

Check the voltage given on your machine matches the supply

voltage.

This machine is supplied with a fitted moulded plug. If you

should need to fit a new plug follows the protocol below.

IMPORTANT

The wire in the mains lead are coloured in accordance with the

following code:

Blue --- Neutral

Brown --- Live

The wire that is coloured blue must be connected to the

terminal that is marked with the letter N. The wire that is

coloured brown must be connected to the terminal that is

marked with the letter L.

A 13AMP (BS1363 or BS1363/A) plug must be used and a

13 AMP fuse must be fitted.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your Local Authority or retailer for recycling advice.

32

Page 33

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheeld, S20 3FR

The manufacturer hereby declares that the machine as detailed in this declaration fulls all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulls the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2004/108/EC. (valid until Apr 19th 2016) Electromagnetic Compatibility Directive,

2014/30/EU. (eective from Apr 20th 2016) Electromagnetic Compatibility Directive,

93/68/EC. The CE Marking Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive

2002/96/EC The Waste Electrical and Electronic Equipment (WEEE) Directive.

as amended

by 2003/108/EC.

And is in conformity with the applicable requirements of the following documents:

EN 61029-1 • EN 61029-2-11 • EN 55014-1 • EN 55014-2 • EN 61000-3-2 • EN 61000-3-3

Product Details

Description: FURY6 210mm MULTIPURPOSE TABLE/MITRE SAW

Evolution Model No: FURY62102 / FURY62102EU

Brand Name: EVOLUTION

Voltage: 230-240V~ 50Hz

Input: 1200W

EN

DE

FR

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and veries that our technical le contains the documents listed above and that they

are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Operations Director

Date: 01/03/16

33

TR

Page 34

Page 35

EN

DEUTSCH

Übersetzung Original Bedienungsanleitungen

DEUTSCH

Übersetzung Original Bedienungsanleitungen

DE

FR

TR

Page 36

www.evolutionpowertools.com

INHALTSVERZEICHNIS

English Page 2

Deutsch Seite 34

Français Page 68

Türk Sayfa 100

INHALTSVERZEICHNIS Seite 37

Garantie Seite 37

Technische Daten Seite 38

Vibration Seite 39

Kennzeichnungen und Symbole Seite 39

Bestimmungsgemäßer Gebrauch des Elektrowerkzeugs Seite 40

Nicht zulässiger Gebrauch des Elektrowerkzeugs Seite 40

SICHERHEITSVORKEHRUNGEN Seite 41

Elektrische Sicherheit Seite 41

Verwendung im Freien Seite 41

Allgemeine Sicherheitsanweisungen zu Elektrowerkzeugen Seite 43

Zusätzliche Sicherheitsanweisungen Seite 45

ERSTE SCHRITTE Seite 46

Auspacken Seite 46

Überblick Seite 47

Montage und Vorbereitung Seite 49

Betriebsanleitung Seite 49

WARTUNG Seite 65

Umweltschutz Seite 65

KONFORMITÄTSERKLÄRUNG Seite 66

36

Page 37

www.evolutionpowertools.com

1.3

WICHTIG

Bitte lesen Sie diese Betriebsanleitung und die

Sicherheitshinweise sorgfältig und vollständig.

Zu Ihrer eigenen Sicherheit, wenn Sie unsicher

über irgendeinen Aspekt der Verwendung dieser

Ausrüstung sind, bitte auf das entsprechende

Technische Helpline, kann die Anzahl der dem

auf die Evolution Power Tools Website gefunden

werden. Wir betreiben mehrere Helplines in

unserer weltweiten Organisation, sondern

Technische Hilfe ist auch von Ihren Lieferanten.

WEB

www.evolutionpowertools.com

(1.4)

Herzlichen Glückwunsch zum Kauf eines

Evolution Power Tools Machine. Bitte füllen

Sie Ihre Produktregistrierung ‘online’, wie

in der A4 Online Garantie Registrierung

Faltblatt mit dieser Maschine erklärt. Sie

können auch scannen den QR-Code auf der A4

Faltblatt mit einem Smart Phone gefunden.

Dies ermöglicht es Ihnen, Ihre Maschine

Garantiezeit über Evolutions Website durch

die Eingabe Ihrer Daten überprüfen und

sorgen so für schnellen Service, wenn es

notwendig. Wir danken Ihnen für die Auswahl

eines Produkts aus Evolution Power Tools.

EVOLUTION BEGRENZTE GARANTIE.

Evolution Power Tools behält sich das Recht

vor, Verbesserungen und Änderungen an

der Produktentwicklung ohne vorherige

Ankündigung vorzunehmen.

Bitte beachten Sie die GarantieRegistrierung Broschüre und / oder der

Verpackung Details zu den Bedingungen

und Konditionen der Garantie.

(1.5)

Evolution Power Tools wird, innerhalb der

Garantiezeit, und aus dem ursprünglichen

Kaufdatum, reparieren oder ersetzen Ware

mangelhaft befunden werden Material-oder

Herstellungsfehler. Diese Garantie ist ungültig,

wenn das Werkzeug zurückgegeben hat über

die Empfehlungen in der Bedienungsanleitung

oder wenn die Maschine durch einen Unfall,

Vernachlässigung oder unsachgemäße

Wartung beschädigt worden.

Diese Garantie gilt nicht für Maschinen und

/ oder Komponenten, die verändert wurden,

geändert oder in irgendeiner Weise verändert

oder ausgesetzt über die empfohlenen

Kapazitäten und Spezifikationen verwenden,

gelten. Elektrische Bauteile unterliegen

den jeweiligen Herstellergarantien. Alle

fehlerhaften Waren frachtfrei gilt für Evolution

Power Tools zurückgegeben werden. Evolution

Power Tools behält sich das Recht vor,

wahlweise reparieren oder ersetzen Sie es mit

dem gleichen oder gleichwertigen Artikel.

Es gibt keine Garantie - schriftlich oder

mündlich - für Verbrauchsmaterial Zubehör

wie (Liste ist nicht abschließend) Messer, Fräser,

Bohrer, Meißel oder Paddel etc. In keinem Fall

ist Evolution Power Tools Haftung für Verluste

oder Schäden, die direkt oder indirekt aus der

Verwendung unserer Ware oder aus einem

anderen Grund. Evolution Power Tools haftet

nicht für irgendwelche Kosten auf solche

Waren oder Folgeschäden verantwortlich. Kein

leitender Angestellter, Mitarbeiter oder Vertreter

von Evolution Power Tools ist berechtigt,

mündliche Erklärungen von Fitness zu machen

oder einem der vorhergehenden Verkaufs

verzichten und niemand wird verbindlich

Evolution Power Tools.

Fragen im Zusammenhang mit dieser

beschränkten Garantiesollte das Unternehmen

den Kopf gerichtet werdenBüro , oder rufen

Sie die entsprechende Nummer Helpline.

EN

DE

FR

TR

37

Page 38

www.evolutionpowertools.com

SPEZIFIKATION

MACHINE METRISCH IMPERIAL

Motor (230-240V~ 50 Hz) 1200W 5A

Leerlaufdrehzahl 3500min

Gewicht 9.45kg 20lb

SCHNEIDLEISTUNGEN METRISCH IMPERIAL

Stahlblech - Max Dicke 3mm 1/8”

-1

3500rpm

MAXIMALE SCHNITTLEISTUNG ALUMINIUM, HOLZ UND PVC

GEHRUNGSSÄGE CONFIGURATION

GEHRUNGSWINKEL ANSCHRÄGWINKEL

MAX

SCHNITTBREITE

MAX

SCHNITTTIEFE

90° 90° 115mm (4-1/2”) 55mm (2-1/8”)

45° 90° 65mm (2-1/2”) 55mm (2-1/8”)

45° 45° 40mm (1-9/16”) 25mm (15/16”)

MAXIMALE SCHNITTLEISTUNG TABLE SAW CONFIGURATION

SCHNEIDLEISTUNGEN METRISCH IMPERIAL

Holz - Max Dicke 32mm 1-1/4”

SÄGEBLATT ABMESSUNGEN METRISCH IMPERIAL

Durchmesser 210mm 8-1/4”

Bohrdurchmesser 25.4mm 1”

Anzahl der Zähne 20 20

Dicke 1.7mm 1/16”

GERÄUSCH & VIBRATION DATEN

Schalldruckpegel LPA 94.57dB(A) K=3dB(A)

Schallleistungspegel LWA 107.57dB(A) K=3dB(A)

Vibration Niveau 2.5m/s2 K=1.5m/s

2

(1.6) Hinweis: BS EN 61029-1: 2009+A11 Die Schwingungsmessung wurde unter

Standardbedingungen gemäß vorgenommen.

38

Page 39

www.evolutionpowertools.com

(1.7)

VIBRATION

WARNUNG: Beim Einsatz dieser Maschine

kann der Anwender hohen Vibrationspegeln

ausgesetzt sein, die sich auf Hand und Arm

übertragen. Es besteht die Möglichkeit, dass

sich beim Anwender die vibrationsbedingte

„Weissfingerkrankheit“ (Raynaud-Syndrom)

entwickelt. Dieser Zustand kann zu einer

reduzierten Temperaturempfindung der Hand

sowie einer allgemeinen Gefühllosigkeit führen.

Anwender, die Gehrungssägen langfristig oder

regelmässig benutzen, müssen den Zustand ihrer

Hände und Finger sorgfältig im Auge behalten.

Sollte eines dieser Symptome auftreten, muss

sofort ärztlicher Rat eingeholt werden.

a) Der tatsächliche Vibrationspegel

während des Gebrauchs hängt von der

Festigkeit/Härte des Werkstücks und vom

Zustand des verwendeten Schneidgeräts

ab. Diese Faktoren können die vom Anwender

empfundenen Vibrationen erhöhen. Vor

Beginn der Arbeiten muss jeder einzelne

Gebrauch des Werkzeugs hinsichtlich der

Wirkung dieser anwendungsabhängigen

Faktoren beurteilt werden.

c) Folgende Faktoren können den

Vibrationspegel beeinussen. Die

Einschränkung dieser Faktoren hilft bei der

Reduzierung der Vibrationsauswirkungen:

Handhabung:

• Kraftaufwand beim Pressen.

• Greifkraft abhängig von der

Arbeitsrichtung.

• Anpassung des Energieeinsatzes

(Vermeiden von übermässigem

Energieeinsatz).

Werkstück:

• Material des Werkstücks (Dichte, Festigkeit).

• Stabilität.

• Härte.

• Sicherheit.

1.8

WICHTIGE

SICHERHEITSANWEISUNGEN

WARNUNG: Nehmen Sie das Gerät

nicht in Betrieb, wenn keine Warn- und/oder

Hinweisetiketten vorhanden oder wenn sie

beschädigt sind. Wenden Sie sich an Evolution

Power Tools, um die Etiketten auszutauschen

bzw. zu ersetzen.

EN

DE

b) Die Messung und Bewertung der

Einwirkung von Schwingungen auf das

Hand-Arm-System des Menschen ist in

folgender Norm enthalten:

EN ISO 5349-1:2001 und

EN ISO 5349-2:2002

Anmerkung: Alle oder einige der folgenden

Symbole können sich in der Gebrauchsanweisung

oder auf dem Produkt befinden.

39

FR

TR

Page 40

www.evolutionpowertools.com

(1.9) LABELS & ZEICHEN

Symbol Beschreibung

V

Ampere

Hertz

Drehzahl

Wechselstrom

Leerlaufdrehzahl

Schutzbrille tragen

Gehörschutz tragen

Nicht berühren.

Hände fern halten.

Staubmaske tragen

Gebrauchsanweisung lesen

EG-Zertifizierung

Warnung

Entsorgung elektrischer und

elektronischer Geräte

Doppelte Isolierung Schutz

Hz

Min

n

A

-1

~

o

Volt

VERWENDUNGSZWECK DIESES

ELEKTROWERKZEUGS

WARNUNG: Bei diesem Produkt handelt

es sich um eine Vielzweck-Gehrungssäge mit

Zugfunktion, die für den Einsatz mit speziellen

Vielzwecksägeblättern von Evolution konzipiert

wurde. Verwenden Sie ausschliesslich

Sägeblätter, die für diese Maschine konzipiert

wurden und/oder diejenigen, die speziell von

Evolution Power Tools Ltd. empfohlen werden.

WENN DIESE MASCHINE MIT

DEM RICHTIGEN SÄGEBLATT

BESTÜCKT IST, EIGNET SIE SICH

ZUM SCHNEIDEN FOLGENDER

MATERIALIEN:

Holz

Produkte aus Holz (MDF, Sperrholz, Schichtholz,

Tischlerplatten, Hartfaserplatten etc.)

Aluminium

Baustahl (3 mm Dicke)

Anmerkung: Holz, das unverzinkte Nägel

oder Schrauben enthält, kann – vorsichtig –

ebenfalls sicher geschnitten werden.

Verbotene Verwendung dieses

Elektrowerkzeugs

WARNUNG: Bei diesem Produkt handelt

es sich um eine Vielzweck-Gehrungssäge mit

Zugfunktion, die nur als solche verwendet

werden darf. Sie darf in keiner Hinsicht

geändert werden oder für den Antrieb eines

anderen Geräts oder anderer Zubehörteile als

diejenigen verwendet werden, die in dieser

Gebrauchsanweisung erwähnt werden.

(1.13)

WARNUNG: Dieses Gerät darf weder von

Kindern noch von Personen mit eingeschränkten

körperlichen, sensorischen und geistigen

Fähigkeiten oder mangelndem Wissen benutzt

werden, es sei denn, sie werden durch eine für

ihre Sicherheit und den sicheren Gebrauch der

Maschine zuständigen Person beaufsichtigt oder

im Gebrauch des Geräts angewiesen.

40

Page 41

www.evolutionpowertools.com

(1.14) ELEKTRISCHE SICHERHEIT

Es befinden sich keine durch den Benutzer

austauschbaren Teile innerhalb des Produktes

mit Ausnahme derjenigen, die in dieser

Gebrauchsanleitung angegeben sind. Lassen

Sie Wartungsarbeiten immer nur durch

qualifiziertes Wartungspersonal durchführen.

Nehmen Sie niemals irgendein Teil des

Gehäuses ab, es sei denn, Sie sind dafür

qualifiziert; diese Maschine enthält

gefährliche Spannungen.

(1.15) BENUTZUNG IM FREIEN

WARNUNG: Um Sie vor Gefahren zu

schützen, wenn dieses Elektrowerkzeug im

Freien benutzt werden muss, darf es nicht dem

Regen ausgesetzt oder in feuchter Umgebung

verwendet werden. Stellen Sie das Werkzeug

nicht auf einen feuchten Untergrund. Verwenden

Sie eine saubere, trockene Werkbank, falls

vorhanden. Verwenden Sie als zusätzlichen

Schutz eine Fehlerstrom-Schutzeinrichtung (FISchalter), die die Stromzufuhr unterbricht, sobald

der Fehlerstrom gegen Erde 30 mA während 30

ms übersteigt. Prüfen Sie immer die Funktion

des FI-Schalters, bevor Sie die Maschine in

Betrieb nehmen. Wenn ein Verlängerungskabel

erforderlich ist, muss es für die Verwendung

im Freien geeignet und entsprechend

gekennzeichnet sein. Bei Verwendung eines

Verlängerungskabels müssen die Anweisungen

des Herstellers befolgt werden.

(2.1) ALLGEMEINE

SICHERHEITSANWEISUNGEN

FÜR ELEKTROWERKZEUGE

(Diese Allgemeinen Sicherheitsanweisungen

für Elektrowerkzeuge sind in den Normen

EN 60745-1:2009 sowie EN 61029-1:2009

aufgeführt.

WARNUNG: Lesen Sie alle Warnhinweise und

Sicherheitsanweisungen. Bei Nichtbeachtung

der nachfolgenden Warnhinweise und

Anweisungen besteht die Gefahr von

elektrischen Schlägen, Brand und/oder

ernsthaften Verletzungen.

Bewahren Sie alle Warnhinweise und

Sicherheitsanweisungen für spätere

Nachschlagezwecke auf.

Der Begriff “Elektrowerkzeug” in

den Warnhinweisen bezieht sich auf

Ihr netzbetriebenes (mit Kabel) oder

Ihr batteriebetriebenes (ohne Kabel)

Elektrowerkzeug.

(2.2) 1) Allgemeine Sicherheitswarnhinweise

[Arbeitsplatzsicherheit] für

Elektrowerkzeuge

• Sorgen Sie für einen sauberen und gut

beleuchteten Arbeitsplatz. Unordentliche

oder dunkle Bereiche fördern Unfälle.

• Verwenden Sie keine Elektrowerkzeuge in

explosionsgefährdeter Umgebung, in der

sich z. B. brennbare Flüssigkeiten, Gase

oder Stäube befinden. Elektrowerkzeuge

erzeugen Funken, die den Staub oder die

Gase entzünden können.

• Halten Sie Kinder und Zuschauer während

der Arbeit mit einem Elektrowerkzeug fern.

Ablenkung kann dazu führen, dass Sie die

Kontrolle über das Werkzeug verlieren.

(2.3) 2) Allgemeine Sicherheitswarnhinweise

[Elektrische Sicherheit] für Elektrowerkzeuge

• Der Anschlussstecker von Elektrowerkzeugen

muss in die Netzsteckdose passen.

• Nehmen Sie keinerlei Veränderungen

am Stecker vor. Verwenden Sie

keinerlei Adapterstecker für geerdete

Elektrowerkzeuge. Unveränderte Stecker

und passende Steckdosen verringern das

Risiko eines elektrischen Schlags.

• Vermeiden Sie jeden Körperkontakt mit

geerdeten Oberflächen wie Rohren,

Heizungen, Herden und Kühlschränken.

Es besteht ein erhöhtes Risiko für einen

elektrischen Schlag, wenn Ihr Körper

geerdet ist.

• Elektrowerkzeuge nicht dem Regen

aussetzen oder in feuchten Umgebungen

verwenden. Das Eindringen von Wasser in

ein Elektrowerkzeug erhöht das Risiko eines

elektrischen Schlags.

EN

DE

FR

TR

41

Page 42

www.evolutionpowertools.com

• Gehen Sie pfleglich mit dem Stromkabel

um. Verwenden Sie das Kabel niemals zum

Tragen oder Aufhängen des Werkzeugs, und

ziehen Sie den Netzstecker niemals am Kabel

aus der Netzsteckdose. Halten Sie das Kabel

fern von Hitze, Öl, scharfen Kanten oder sich

bewegenden Geräteteilen. Beschädigte oder

verhedderte Elektrokabel erhöhen das Risiko

eines elektrischen Schlags.

• Arbeiten mit einem Elektrowerkzeug im

Freien nur mit einem Verlängerungskabel

durchführen, das für die Verwendung

im Freien geeignet ist. Die Verwendung

eines für den Aussenbereich geeigneten

Verlängerungskabels vermindert das Risiko

eines elektrischen Schlags.

• Verwenden Sie eine FehlerstromSchutzeinrichtung, wenn Arbeiten mit

einem Elektrowerkzeug in einer feuchten

Umgebung nicht vermieden werden

können. Die Verwendung einer FehlerstromSchutzeinrichtung vermindert das Risiko

eines elektrischen Schlags.

(2.4) 3) Allgemeine Sicherheitswarnhinweise

[Persönliche Sicherheit] für

Elektrowerkzeuge

• Bleiben Sie wachsam, achten Sie darauf, was

Sie tun und gehen Sie mit Vernunft an die

Arbeit mit einem Elektrowerkzeug. Benutzen

Sie kein Elektrowerkzeug, wenn Sie müde

sind oder unter dem Einfluss von Drogen,

Medikamenten oder Alkohol stehen. Ein

Augenblick der Unaufmerksamkeit während

der Arbeit mit Elektrowerkzeugen kann zu

ernsthaften Verletzungen führen.

• Verwenden Sie eine persönliche

Schutzausrüstung. Tragen Sie immer

einen Augenschutz. Eine persönliche

Schutzausrüstung wie z. B. eine Staubmaske,

rutschfeste Sicherheitsschuhe, Helm oder

ein Hörschutz, die entsprechend der

Arbeitsbedingungen verwendet wird, kann

die Verletzungsgefahr vermindern.

• Vermeiden Sie ein unbeabsichtigtes

Einschalten des Werkzeugs. Vergewissern