Page 1

255 mm TCT Multi Purpose Sliding Compound Mitre Saw

Original

Instructions

Read instructions before operating this tool.

www.evolutionfury.com

®

21.10.10_V2

Page 2

2

www.evolutionfury.com

TABLE OF CONTENTS

EC - Declaration of Conformity 02

Important Information 03

12 Month Limited Warranty 03

General Safety Rules 03

Safety Instructions for all Saws 05

Additional Specific Safety Rules 06

Symbols and Labels 08

Specification 08

Machine Overview 10

Assembly 11

Operation 13

Maintenance 18

Environmental Protection 18

Service Parts Lists 19

EC - DECLARATION OF CONFORMITY

We, manufacturer and importer

Evolution Power Tools Ltd.

Venture One

Sheffield

S20 3FR

Declare that the product

Part numbers:

Part numbers: FURY32552, FURY32552EU

Evolution: FURY 3 XL Multi Purpose Sliding

Compound Mitre Saw

Complies with the essential requirements

of the following European Directives:

2006/42/EC – Machine Directive

2006/95/EC – Low Voltage Directive

2004/108/EC – EMC Directive

2002/95/EC – Restriction of the use of

Certain Hazardous Substances in Electrical

and Electric equipment.

The following standards have been applied:

EN 61029-1:2009

EN 61029-2-9:2002

EN 55014-1:2006+A1:2009

EN 55014-2:1997+A1:2001+A2:2008

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN 60825-1:2007

Authorised by

Mr Matthew J Gavins

Managing Director

1st June 2010

®

EC - DECLARATION OF CONFORMITY

GB

Page 3

3

www.evolutionfury.com

All documentation is held on file at

the above address and is available, on

request for review.

IMPORTANT

Please read these operating and safety

instructions carefully and completely. For your

own safety, before using this equipment check

that the voltage is correct and that all handles

and parts are firmly secured. If you are uncertain

about any aspect of using this equipment,

please contact our Technical Helpline.

Helpline.

Technical Helpline UK 0870 609 2297

Technical Helpline USA 1-866-EVO-TOOL

EVOLUTION 255mm FURY 3XL

Multipurpose Sliding Compound Mitre Saw

Congratulations on your purchase of an

Evolution Power Tool’s 255mm Multi Purpose

Compound Mitre Saw. Please complete your

product registration on line to validate your

machine’s warranty period and ensure prompt

service if needed. We sincerely thank you for

selecting a product from Evolution Power Tools.

12 MONTH LIMITED WARRANTY

Evolution Power Tools reserves the right to

make improvements and modifications to

design without prior notice.

Evolution Power Tools will, within twelve (12)

months from the original date of purchase,

repair or replace any goods found to be

defective in materials or workmanship. This

warranty is void if the tool being returned

has been used to cut materials beyond

the recommendations in the Instruction

Manual or if the saw has been damaged by

accident, neglect, or improper service. This

warranty does not apply to machines and

/ or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the

right to optionally repair or replace it with the

same or equivalent item. There is no warranty

– written or verbal – for saw blades. In no

event shall Evolution Power Tools be liable for

loss or damage resulting directly or indirectly

from the use of our merchandise or from any

other cause. Evolution Power Tools is not

liable for any costs incurred on such goods or

consequential damages. No officer, employee

or agent of Evolution Power Tools is authorised

to make oral representations of fitness or to

waive any of the foregoing terms of sale and

none shall be binding on Evolution Power Tools.

Questions relating to this limited warranty

should be directed to the company’s head

office, or call the appropriate Helpline number.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of electric shock, this

equipment is fitted with an approved cord

and plug for its intended country of use.

Do not change the cord or plug in any way.

GENERAL SAFETY RULES

WARNING!

When using electric tools, basic safety

precautions should always be followed to

reduce the risk of fire, electric shock and

personal injury.

Please read all of these instructions before

attempting to operate this machine. Save

this manual for future reference.

1. Keep work area clear. Cluttered work

areas invite accidents.

2. Consider work area environment. Do

not expose tools to rain. Do not use tools

in damp or wet locations. Keep work area

well lit. Never use tools near flammable

liquids or gases.

3. Protect yourself against electric shock.

Avoid body contact with earthed or

grounded surfaces.

4. Keep other people away. Do not let others,

especially children, come close to the work,

and touch the tool or the extension lead.

Keep them away from the work area.

IMPORTANT INFORMATION

GB

12 MONTH LIMITED WARRANTY

GB

GENERAL SAFETY RULES

GB

Page 4

4

www.evolutionfury.com

5. Store idle tools. When not in use, tools

should be stored in a dry locked-up place,

out of children’s reach.

6. Never force the tools. Your tools will be

more efficient and safer when used at the

rate for which they were intended.

7. Use the right tool. Do not force small

tools to do the job of a heavy duty

tool. Do not use tools for purposes not

intended; for example do not use circular

saws to cut tree limbs or logs.

8. Dress properly. Do not wear loose

clothing or jewellery which may get

caught in moving parts. Non-skid

footwear is recommended when working

outdoors. If you have long hair, tie it back

and wear protective hair covering.

9. Use protective equipment. Use safety

glasses. Use face or dust mask if cutting

operations create dust.

10. Connect dust extraction equipment.

If the machines have a connection for

dust extraction equipment, ensure these

are connected and properly used.

11. Do not damage the cable. Never

pull the power cable to disconnect the

machine. Keep the cable away from heat,

oil and sharp edges.

12. Secure workpiece. Where possible,

use clamps or a vice to hold the workpiece.

It’s much safer than using your hands.

13. Don’t over reach. Keep proper footing

and balance at all times.

14. Maintain tools in good working

condition. Keep cutting tools sharp and

clean for better performance and optimum

safety. Follow instructions for lubricating

and changing accessories. Inspect power

cables regularly and, if damaged, have

them replaced by an authorised service

centre. Inspect extension cables regularly

and replace immediately if damaged. Keep

handles dry, clean and free from oil and

grease at all times.

15. Disconnect tools. Disconnect tools

from the power supply when not in use,

before any maintenance operation and

when changing accessories such as

blades, bits, cutters, etc.

16. Remove adjusting keys and spanners.

Get into the habit of checking that adjusting

keys and spanners have been removed

from the machine before turning it on.

17. Avoid unintentional starting. Ensure

switch is in “off” position before plugging

in the machine.

18. Use proper extension leads. When the

tool is used outdoors, use only extension

leads intended for outdoor use and

labelled as such.

19. Stay alert. Concentrate on what you

are doing, use common sense and do not

operate the tool when you are tired.

20. Check that no part is damaged. Before

using a tool, make sure that it is in good

working order. Check the alignment and

condition of moving parts, mounting

and any other aspect that may affect its

operation. A guard or other part that is

damaged should be properly repaired

or replaced by an authorised service

centre unless otherwise indicated in this

instruction manual. Do not use the tool

if the switch does not turn on and off.

21. Warning. The use of any accessory or

attachment other than one recommended

in this instruction manual may present a

risk of personal injury.

22. Have your tool repaired at an authorised

service centre. This electric tool complies

with current safety rules. Repairs should

only be carried out by an authorised service

centre using original spare parts. Failing

this, the user could expose themselves to

considerable danger.

®

Page 5

5

www.evolutionfury.com

HEALTH ADVICE

Warning!

When drilling, sanding, sawing or grinding,

dust particles will be produced. In some

instances, depending on the materials you

are working with, this dust can be particularly

harmful to you (e.g. lead from old gloss

paint).You are advised to consider the risks

associated with the materials you are working

with and to reduce the risk of exposure.

You should:

-Work in a well-ventilated area.

-Work with approved safety equipment,

such as dust masks that are specially

designed to filter microscopic particles.

SAFETY INSTRUCTIONS FOR ALL SAWS

a) DANGER: Keep hands away from

cutting area and the blade. Keep your

second hand on the auxiliary handle, or

motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

b) Do not reach underneath the

workpiece. The guard cannot protect you

from the blade below the workpiece.

c) Adjust the cutting depth to the

thickness of the workpiece. Less than a

full tooth of the blade teeth should be visible

below the workpiece.

d) Never hold piece being cut in your hands

or across your leg. Secure the workpiece to

a stable platform. It is important to support

the work properly to minimize body exposure,

blade binding, or loss of control.

e) Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact

hidden wiring or its own cord. Contact

with a “live” wire will also make exposed

metal parts of the power tool “live” and

shock the operator.

f) When ripping always use a rip fence

or straight edge guide. This improves the

accuracy of cut and reduces the chance of

blade binding.

g) Always use blades with correct size

and shape (diamond versus round) of

arbor holes. Blades that do not match the

mounting hardware of the saw will run

eccentrically, causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw, for

optimum performance and safety of operation.

Further safety instructions for all saws

Causes and operator prevention of kickback:

Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator:

1. When the blade is pinched or bound

tightly by the kerf closing down, the blade

stalls and the motor reaction drives the unit

rapidly back toward the operator;

2. If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

workpiece causing the blade to climb out of

the kerf and jump back towards the operator.

Kickback is the result of saw misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a) Maintain a firm grip with both hands

on the saw and position your arms to

resist kickback forces. Position your body

to either side of the blade, but not in line

with the blade. Kickback could cause the

saw to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

b) If the blades are binding, or when

interrupting a cut for any reason, release

the trigger and hold the saw motionless

in the material until the blades come to a

complete stop. Never attempt to remove

the saw from the work or pull the saw

backward while the blades are in motion

or kickback may occur. Investigate and take

corrective actions to eliminate the cause of

blade binding.

SAFETY INSTRUCTIONS FOR ALL SAWS

GB

Page 6

6

www.evolutionfury.com

c) When restarting a saw in the

workpiece, centre the saw blade in the

kerf and check that saw teeth are not

engaged into the material. If saw blade is

binding, it may walk up or kickback from the

workpiece as the saw is restarted.

d) Support large panels to minimise

the risk of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the

panel on both sides, near the line of cut and

near the edge of the panel.

e) Blade depth and bevel adjusting locking

levers must be tight and secure before

making a cut. If blade adjustment shifts while

cutting. it may cause binding and kickback.

f) Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce a narrow kerf causing excessive

friction, blade binding and kickback.

g) Use extra caution when making a

“plunge cut” into existing walls or other

blind areas. The protruding blade may cut

objects that can cause kickback.

Safety instructions for saws

a) Check lower guard for proper closing

before each use. Do not operate the saw

if lower guard does not move freely and

close instantly. Never clamp or tie the

lower guard into the open position. If

saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the

retracting handle and make sure it moves

freely and does not touch the blade or any

other part, in all angles and depths of cut.

b) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use. Lower guard may operate

sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

c) Lower guard may be retracted

manually only for special cuts such as

“plunge cuts” and “compound cuts.”

Raise lower guard by retracting handle

and as soon as blade enters the material,

the lower guard must be released. For

all other sawing, the lower guard should

operate automatically.

d) Always observe that the lower guard

is covering the blade before placing saw

down on bench or floor. An unprotected,

coasting blade will cause the saw to walk

backwards, cutting whatever is in its path.

Be aware of the time it takes for the blade

to stop after switch is released.

ADDITIONAL SAFETY INSTRUCTIONS

Warning: Be sure to read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury.

a) Keep guards in place and in working order.

b) Remove adjusting keys and wrenches.

Form the habit of checking to see that keys

and adjusting wrenches are removed from

tool before turning it on.

c) Keep work area clean. Cluttered areas

and benches invite accidents.

d) Do not use in a dangerous environment.

Do not use power tools in damp or wet

locations, or expose them to rain. Keep work

area well lit.

e) Keep children away. All visitors should

be kept a safe distance from work area.

f) Do not force the tool. It will do the job

better and safer if used at the rate for which

it was designed.

g) Use proper extension cord. Make sure

your extension cord is in good condition.

When using an extension cord, be sure to

use one heavy enough to carry the current

your product will draw. An undersized cord

will cause a drop in line voltage resulting in

loss of power and overheating.

h) Wear proper apparel. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewellery which may get

caught in moving parts. Nonslip footwear

recommended. Wear protective hair

covering to contain long hair.

i) Always use safety glasses. Also use face

or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

®

ADDITIONAL SPECIFIC SAFETY RULES

GB

Page 7

7

www.evolutionfury.com

j) Secure work. Use clamps to hold work

when practical. It’s safer than using your

hand and it frees both hands to operate tool.

k) Do not overreach. Keep proper footing

and balance at all times.

l) Maintain tools with care. Keep tools

sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories. Do not

use High Speed Steel (HSS) saw blades, or

blades that are damaged or deformed.

m) Disconnect tools before servicing and

when changing accessories, such as blades.

n) Reduce the risk of unintentional

starting. Make sure switch is in off position

before plugging in.

o) Use recommended accessories.

Only use genuine Evolution accessories.

When fitted with the correct blade (Fury

3 Multi-purpose TCT Blade) this saw is

recommended to cut Mild Steel, Aluminium

and Wood.

p) Never stand on tool. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

q) Check damaged parts. Before further

use of the tool, a guard or other part that

is damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

r). Keep hands out of path of saw blade.

s) Never reach around saw blade.

t) Turn off tool and wait for saw blade

to stop before moving workpiece or

changing settings.

u) Disconnect power before changing

blade, servicing or cleaning.

v) To reduce the risk of injury, return

carriage to the full rear position after

each crosscut operation.

CARRYING YOUR MITRE SAW

Safety Advice

1. Although compact, this saw is heavy. To

reduce the risk of back injury, get competent

help whenever you have to lift the saw.

2. To reduce the risk of back injury, hold the

tool close to your body when lifting. Bending

your knees so you can lift with your legs, not

your back. Lift by using the handhold areas

at each side of the bottom of the base.

3. Never carry the mitre saw by the power

cord or the trigger grip of the handle.

Carrying the tool by the power cord could

cause damage to the insulation or the wire

connections resulting in electric shock or fire.

4. Before moving the saw tighten the slide

lock knob to guard against sudden movement.

WARNING!

Do not use the blade guard as a ‘lifting point’.

The power cord must be removed from the

power supply before attempting to move

the machine.

• Lockdowntheheadusingthehead

locking pin.

• Movethecuttingheadtoitsoutermost

position and lock in place by tightening the

slide lock knob.

• Loosenthemitreanglelockknob.Pullup

the mitre angle lever and rotate the table

to either of its maximum settings.

• Lockthetableinpositionusingthe

locking knob.

• Usethetwocarryhandlecut-outs

machined into either end of the machine

base, to transport the machine.

Place the saw on a secure stationary

work surface and check the saw over

carefully. Check particularly the operation

of all the machines safety features before

commissioning or operating the machine.

Page 8

8

www.evolutionfury.com

SAFETY LABELS & SYMBOLS

WARNING!

Do not operate machine if warning and

/ or instruction labels are missing or

damaged. Contact Evolution Power Tools for

replacement labels.

Symbol Description

V Volts

A Amperes

Hz Hertz

Min

-1

Speed

~ Alternating Current

n0

No Load Speed

Double Insulated

Wear Safety

Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Restriction

of Hazardous

Substances Directive

CE certification

Waste electrical and

electronic equipment

Only use genuine Evolution replacement

saw blades. Unauthorized blades may be

dangerous! Keep saw blades securely

fastened. Check the blade flanges for debris

before installing any new blade. Do not use

dull, broken or damaged blades. Check the

blade regularly for condition and wear. A

damaged or worn blade should be replaced

immediately. Beware of ejecting chips as

they may be HOT. Always make provision for

the safe handling of excess material. Keep

machine base and rotary table free from dirt

and other debris.

To obtain an additional copy of your manual,

please contact Evolution Power Tools at:

UK 0870 609 2297

USA 1-866-EVO-TOOL

WEB www.evolutionpowertools.com

ADDITIONAL SAFETY INSTRUCTIONS

FOR YOUR MITRE SAW

FURY 3 XL SPECIFICATION

Designed to cut:

Mild Steel Plate -

Max Thickness 3mm

Mild Steel Box Section -

Max Wall Thickness 3mm

Aluminium

Wood –

Max section 75mm x 300mm

Technical Data

Motor (230v ~ or 110v ~ 50/60 Hz) (Watts):

2000W (Soft Start)

RPM No Load (min

-1

):

2500

Recommended Maximum Duty Cycle

(Minutes):

30mins

Blade Dimensions

Diameter: (10”) 255mm

Number of Teeth: 24

Bore Diameter: (1”) 25.4mm

Thickness: 2mm

Maximum Cutting Capacity (Wood)

At 900 mitre x 900 bevel

300mm x 75mm

At 450 mitre x 900 bevel

210mm x 75mm

At 450 mitre x 450 bevel

210mm x 40mm

®

SYMBOLS AND LABELS

GB

SPECIFICATION

GB

Page 9

9

www.evolutionfury.com

Noise and Vibration Data

Sound pressure level: 88.1dB(A) K=3dB(A)

Sound power level: 99.8dB(A) K=3dB(A)

Vibration level: 1.059 m/s2 K =1.5dB(A)

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used. The need

to identify safety measures and to protect

the operator are based on an estimation of

exposure in the actual conditions of use (taking

account of all parts of the operating cycle, such

as the times the tool is switched off, when it is

running idle, in addition to trigger time).

ADDITIONAL ACCESSORIES

In addition to the standard accessories

supplied with this machine, other accessories

are available to improve its performance,

these include the following items:

1. Clamping System – the design of this

machine allows for the use of a front clamp

which can be fitted either side of the blade

in the sockets incorporated into the machine

base.

2. Diamond Blade – Convert this machine to

a ‘Tile Cutter’. By replacing the standard TCT

Blade with the optional Diamond Blade, this

machine becomes a tile cutter – suitable for

most ceramic / porcelain tiles.

Additional accessories can be obtained by

contacting your local dealer (or Evolution

Power Tools).

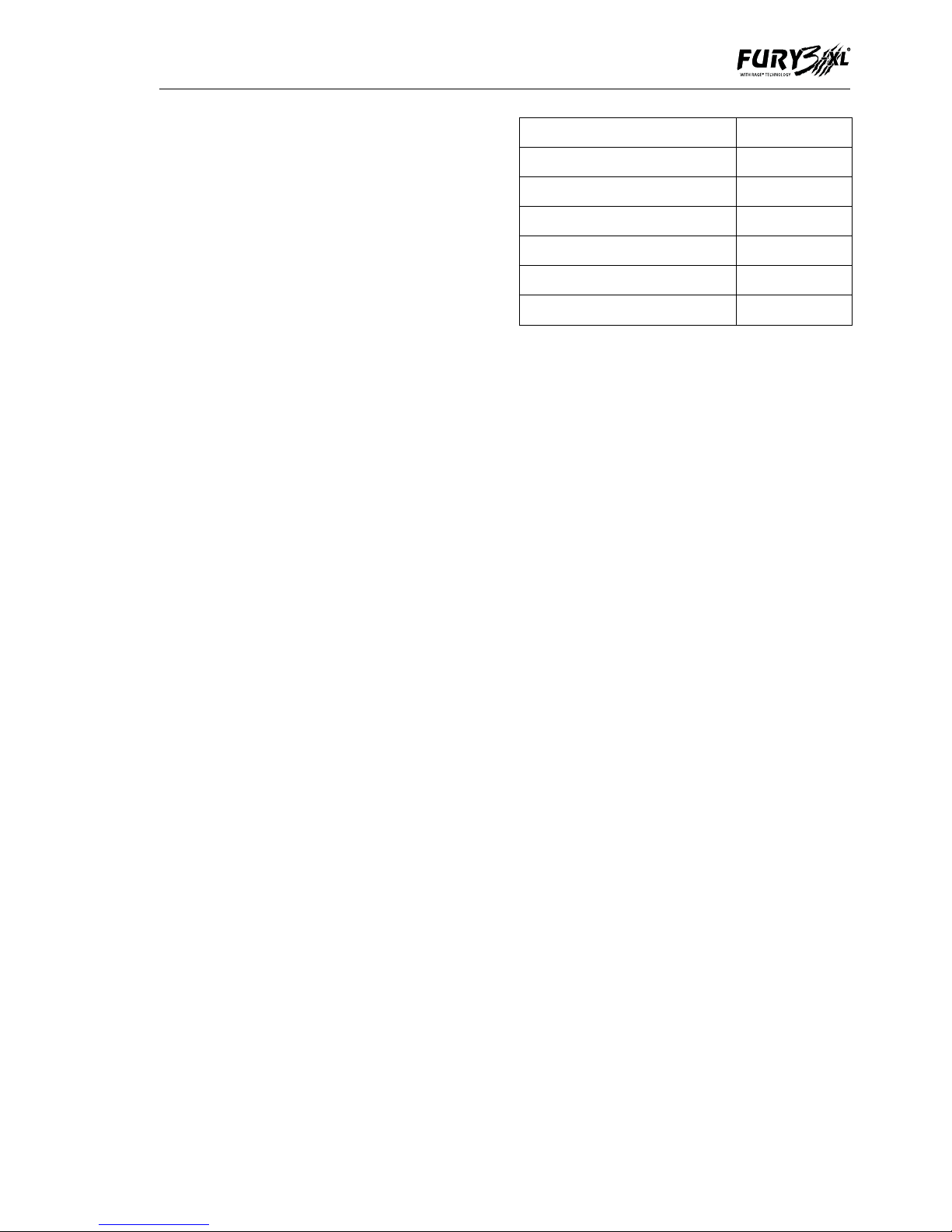

ITEM QUANTITY

Instruction Manual 1

Allen Key 1

Top Clamp 1

Multipurpose Blade 1 FURY3-XL

Support Bars 2

End Stop 1

Page 10

10

www.evolutionfury.com

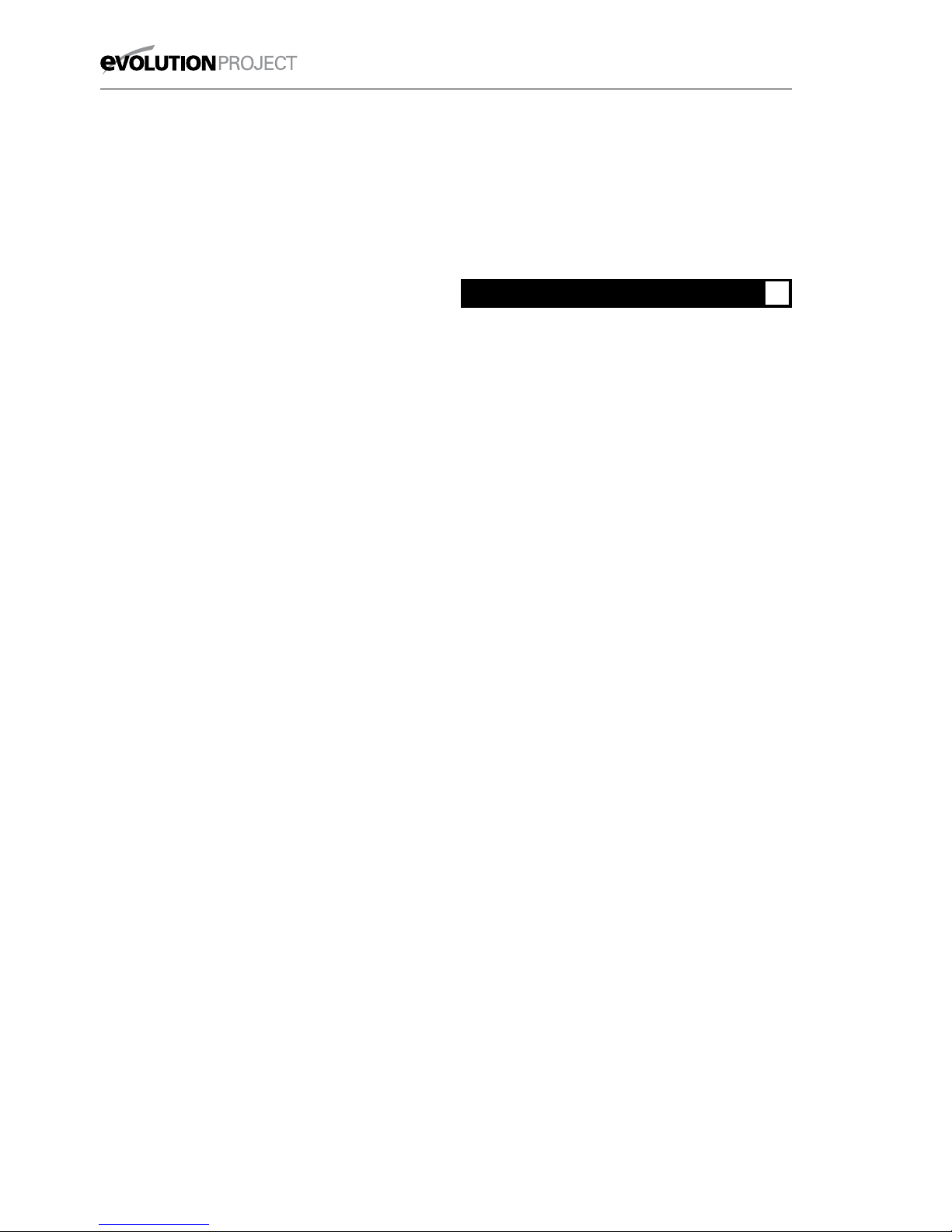

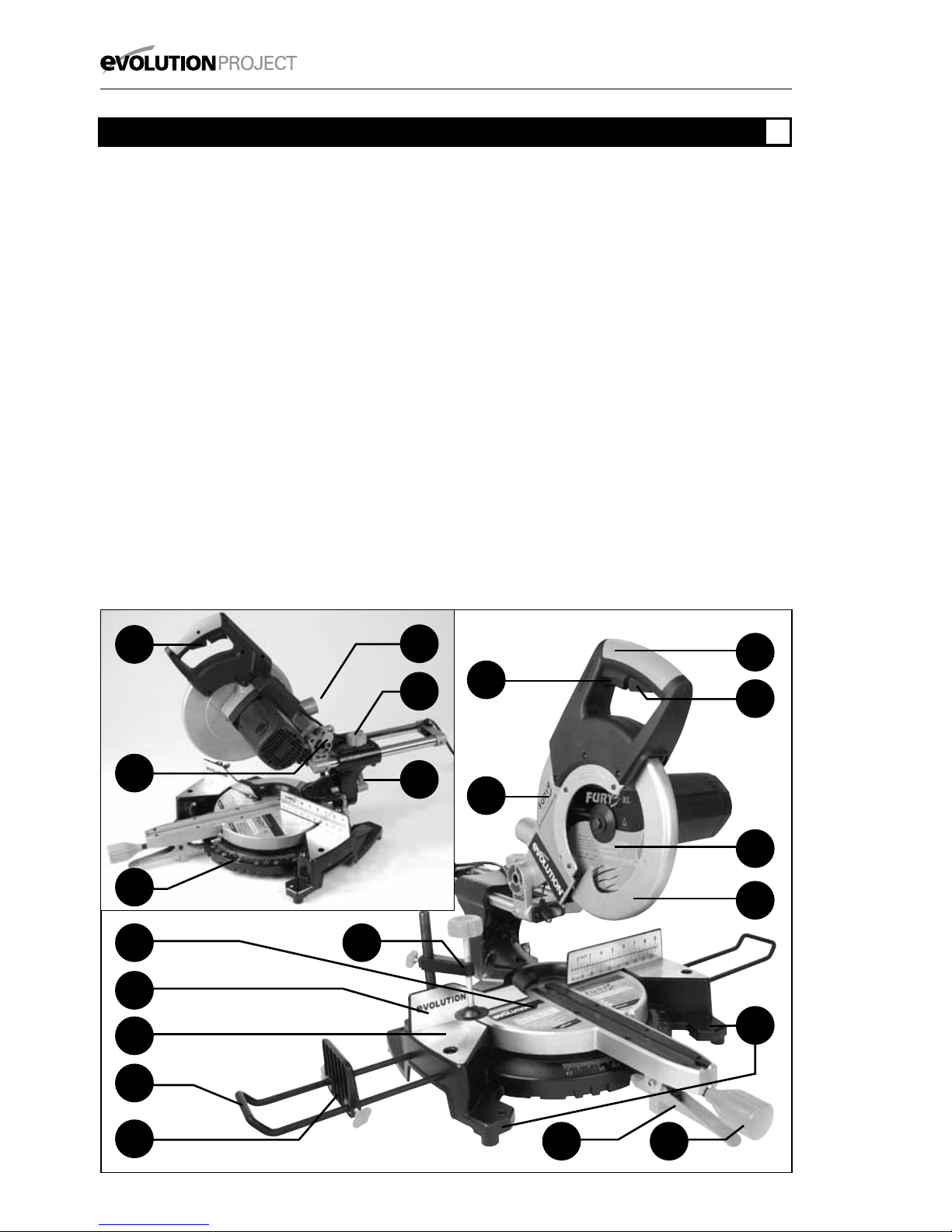

1. ON/OFF TRIGGER SWITCH

2. BLADE GUARD LOCKING TRIGGER

3. CUTTING HANDLE

4. DUST BAG EXTRACTION PORT

5. ROTARY TABLE

6. TABLE TOP

7. LOWER BLADE GUARD

8. UPPER BLADE GUARD

9. BLADE

10. SLIDE LOCKING KNOB

11. BEVEL LOCK LEVER

12. MITRE HANDLE

13. MITRE ANGLE SCALE

14. POSITIVE STOP LOCKING LEVER

15. WORKPIECE SUPPORT

16. REPEAT STOP

17. FENCE

18. TOP CLAMP

19. HEAD LATCHING PIN

20. MOUNTING HOLE

®

MACHINE OVERVIEW

GB

2

4

2

19

11

15

6

17

5

14

7

9

3

8

12

20

1

13

10

16

18

Page 11

11

www.evolutionfury.com

GETTING STARTED

CAUTION! ALWAYS DISCONNECT THE SAW FROM THE

POWER SOURCE BEFORE MAKING ANY ADJUSTMENTS.

Refer to the “Service Parts List Drawing”. Install a blade as

detailed in the “Installing or Removing the Blade” section.

1. Mounting the Mitre Saw

WARNING: To reduce the risk of injury from unexpected

saw movement, place the saw in the desired location either

on a workbench or other recommended leg set. The base

of the saw has four holes to mount the mitre saw. If the

saw is to be used in one location, permanently fasten it to

the workbench or leg set using appropriate bolts with lock

washers and nuts.

1. Tighten the slide, mitre and bevel locks.

2. Position the saw so other people cannot stand behind it.

Thrown debris could injure people in its path.

3. Place the saw on a firm, level surface where there is plenty

of room for handling and properly supporting the workpiece.

4. Support the saw so that the table is level and the saw

does not rock.

5. Bolt or clamp the saw to its support.

2. Installing or removing the blade

WARNING! Only use genuine Evolution blades which are

designed for this machine. Ensure that the maximum speed

of the blade is compatible with the machine. Only carry

out this operation with the machine disconnected from the

mains supply.

NOTE: It is recommended that the operator considers

wearing protective gloves when handling the blade during

installation or when changing the machines blade.

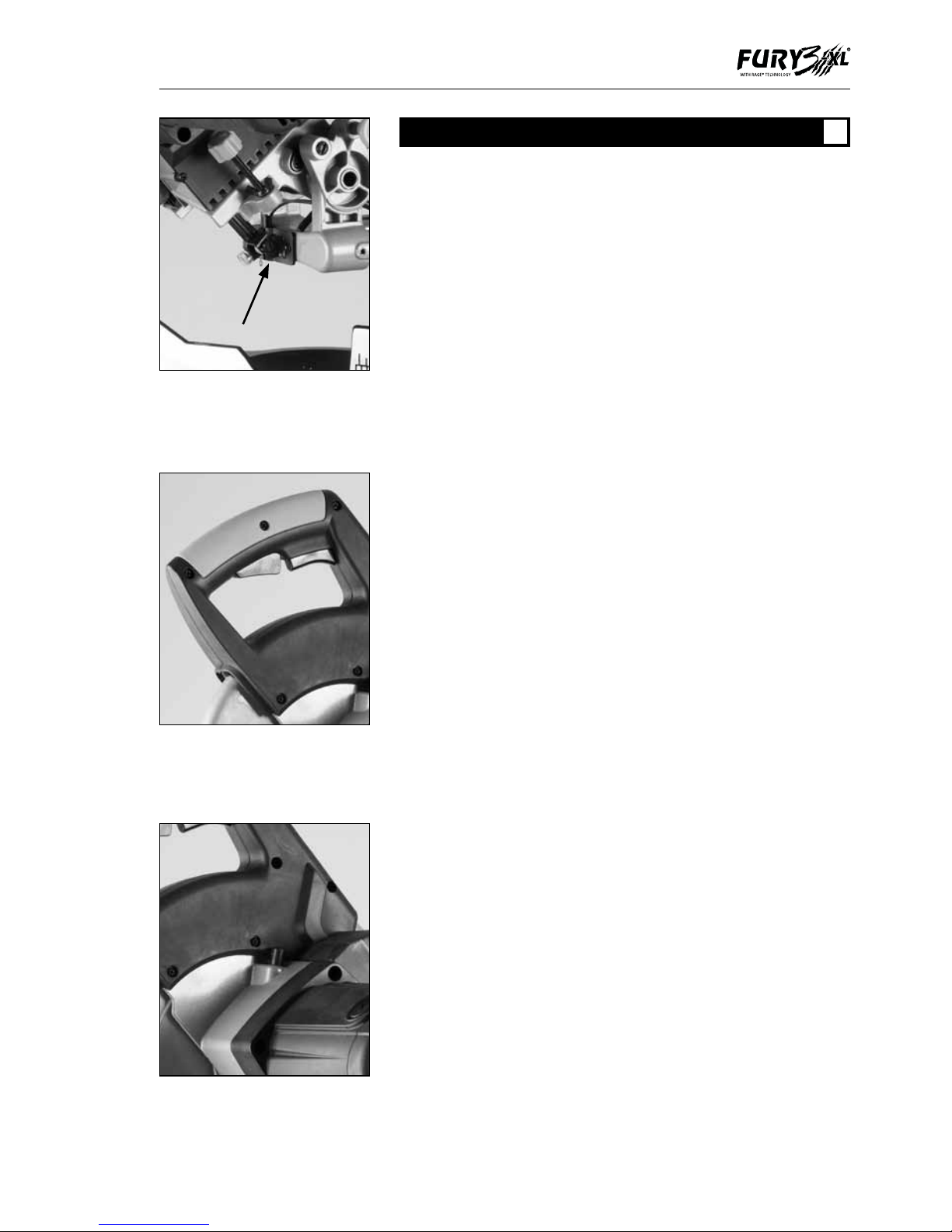

1. Ensure the cutting head is up.

2. Remove the guard operating arm retaining clip (Fig. 1).

Release the guard operating arm from its pivot.

3. Press the lower blade guard locking trigger and lift up the

lower blade guard. (Fig. 2)

4. Press the black arbor lock button to lock the arbor. (Fig. 3)

5. Using the supplied Allen Key, release the arbor screw to

remove the blade. (Fig. 4)

Note: The arbor screw has a LH thread.

Fig 1

Fig 2

Fig 3

ASSEMBLY

GB

Page 12

12

www.evolutionfury.com

6. Install the new 255 mm (10”) blade. Make sure the

rotation arrow on the blade matches the clockwise rotation

arrow on the upper guard.

NOTE: The blade teeth should always point downward at the

front of the saw.

7. Install the blade washer and arbor screw.

8. Lock the arbor and tighten the arbor screw using moderate

force, but do not overtighten.

9. Replace the guard operating arm and its retaining clip.

(Fig. 1)

10. Ensure the Allen Key is removed and the arbor lock has

released before operating.

11. Ensure the blade guard is fully functional before using

the machine.

NOTE: Spacers and spindle rings should not be used with

this machine and/or blade.

3. Debris collection bag

The Debris Collection Bag should be attached at the debris

extraction port.

1. Slide the frame of the collection bag on to the outlet of the

extraction port, ensuring that it is firmly connected.

2. To release the bag, slide the frame in the opposite direction.

NOTE: To ensure optimal dust collection, empty the dust bag

when it becomes approximately 2/3 full.

WARNING: Before cutting metal materials, the collection

bag should be removed and replaced with a blanking plug.

Reinstate the dust bag when cutting wood.

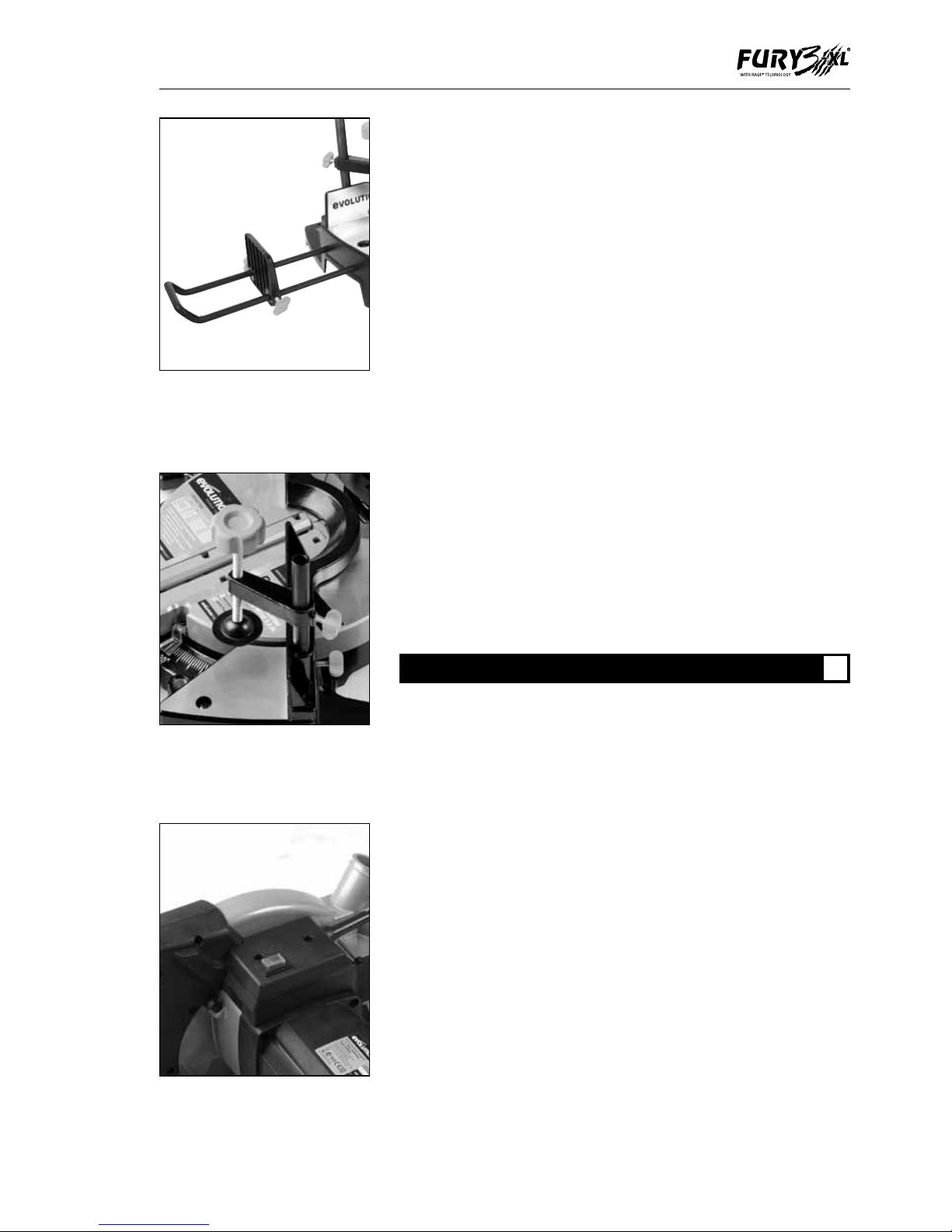

4. Fitting the Repeat Stop

1. Loosen the repeat stop thumb screws sufficiently to allow

the arms of the workpiece support to slide through the holes

in the repeat stop.

2. Tighten the thumb screws firmly to minimize movement

on the workpiece support. Position the repeat stop

approximately half way along the workpiece support.

3. Attach the workpiece support to the machine base as

detailed below.

NOTE: By loosening the thumb screws the repeat stop can

be adjusted to the required distance from the saw blade

for repetitive cutting operations etc. The repeat stop should

normally be positioned to the RH side of the blade.

Fig 4

®

Page 13

13

www.evolutionfury.com

5. Fitting the Workpiece Support (Fig.5)

Workpiece supports can be fitted to both sides of the

machine base if required.

1. Right Hand side. Loosen the support retaining screw

located in the top front of the machines base.

2. Insert the workpiece supports into the retaining holes in

the base. Ensure positive location.

NOTE: Approximately 70mm of the Workpiece Support

should slide into the base to provide positive location.

3. Tighten the retaining screw.

4. Repeat above for the LH side.

6. Fitting the Upper Workpiece Clamp (Fig.6)

Two sockets (one either side) are incorporated into the rear

of the machines fence.

1. Fit the clamp to the retaining socket that best suits the

cutting application, ensuring that it is fully pushed down.

2. Tighten the fence thumbscrew to lock the pillar into the socket.

3. Put the workpiece to be cut onto the saw bed.

4. Adjust the clamp using the thumbscrew and hand-wheel

so that it securely holds the workpiece to the saw bed.

Ensure that the clamp does not foul the blade.

OPERATING INSTRUCTIONS

CAUTION: The Mitre Saw should be inspected (particularly

for the correct functioning of the safety guards) before each

use. Do not connect the saw to the power supply until a

safety inspection has been carried out.

Ensure that the operator is adequately trained in the use,

adjustment and maintenance of the machine, before

connecting to the power supply and operating the saw.

WARNING: To reduce the risk of injury, always unplug the

saw before changing or adjusting any of the machines parts.

Compare the direction of the rotation arrow on the guard

to the direction arrow on the blade. The blade teeth should

always point downward at the front of the saw. Check the

tightness of the arbor screw.

Laser Guide

This saw is equipped with a laser cutting guide. This allows

the operator to preview the path of the blade through the

workpiece. The ON/OFF switch for the Laser Guide is

positioned on the top of the motor housing. (Fig 7)

Avoid direct eye contact, and do not use on material that

could reflect the laser beam.

Fig 5

Fig 6

Fig 7

OPERATION

GB

Page 14

14

www.evolutionfury.com

WARNING: Do not stare directly at the laser beam. A hazard

may exist if you deliberately stare into the beam, please

observe all safety rules as follows.

• Thelaserbeamshallnotbedeliberatelyaimedat

personnel and shall be prevented from being directed

towards the eyes of a person.

• Alwaysensurethelaserbeamisonlyaimedatworkpieces

without reflective surfaces, i.e. wood or rough coated

surfaces are acceptable.

• Donotchangethelasermoduleassemblywithadifferent

type.

• Repairstothelasermodulemustonlybeconductedby

Evolution Power Tools or their authorized agent.

Body and Hand Position

1. Never place hands near the cutting area and keep hands

away from the path of blade.

2. Hold the workpiece firmly to the fence to prevent

movement toward the blade. Use a clamp if necessary but

check that it is positioned so that it does not foul the blade.

3. Before making a cut. Make a dry run with the power off so

you can see the path of the blade.

4. Keep hands in position until the ON/OFF trigger has been

released and the blade has completely stopped.

1. Releasing the saw head

a) Gently press down on the cutting handle.

b) Pull out the head latching pin and allow the head to rise to

its upper position.

NOTE: We recommend that when the machine is not in

use the cutting head is locked in its down position, and the

latching pin fully engaged in its socket.

2. Starting the Machine

Connect the machine to a mains power supply. Make sure

that the mains cable cannot become entangled in any part

of the machine and is clear of the blade and machine table.

Press the lower guard locking trigger and squeeze the On/Off

trigger switch to turn the saw ON. Release the trigger switch

to turn the saw OFF.

Always allow the motor to reach full speed before attempting

to make a cut.

3. Preparing to make a cut

Caution: NEVER pull the saw toward you during a cut. The

blade can suddenly climb up on top of the workpiece and

force itself toward you.

•Avoidawkwardoperations&handpositionswhereasudden

slip could cause fingers or hand to move into the blade.

®

Page 15

15

www.evolutionfury.com

•Cutonlyoneworkpieceatatime.

•Cleareverythingexcepttheworkpieceandrelatedsupport

devices away from the blade before turning the mitre saw on.

•Secureworkpieceusingclampstoholdtheworkpiece

securely.

4. Slide Cutting

This saw is equipped with a sliding carriage system.

Loosening the slide lock knob will release the slide and

allow the cutting head to move forwards and backwards.

The saw blade is lowered into the workpiece and then

pushed to the rear of the saw to complete the cut.

This type of cut can be used for cutting wide pieces.

1. Put workpiece against fence and secure with clamps as

appropriate.

2. Loosen the slide lock knob.

3. Grasp the saw handle and pull the cutting head until the arbor

(centre of saw blade) is over the front edge of the workpiece.

4. Press the lower blade guard locking trigger for cutting

head release.

5. Switch on the saw and allow the saw to reach full speed.

6. Push the saw handle all the way down and cut through the

leading edge of the workpiece.

7. Gently push the saw handle towards the fence completing

the cut.

8. Push the cutting head to the full rear position after each cut.

9. Release the trigger to switch off the saw. Allow the blade

to come to a complete halt before moving hands or removing

the workpiece.

5. Chop Cutting - The slide lock knob is tightened to lock

the cutting head at its rearmost position. The saw handle is

pushed down to cut through the workpiece. This type of cut

is used mainly for narrow pieces.

1. Slide the cutting head to the rear as far as it will go.

2. Tighten the slide lock knob.

3. Place the workpiece on the table and against the fence

and secure with clamps as appropriate.

4. Grasp the saw handle.

5. Turn on saw and allow the saw to reach full speed.

6. Press the lower guard locking trigger for saw head release.

7. Push the saw handle down and cut through the workpiece.

8. After the cut is completed turn off the saw and allow the

blade to come to a complete halt before moving hands or

removing the workpiece.

WARNING: For your convenient use, the saw has a blade

brake. Never rely on it to replace proper use of the guard

on your saw.

Page 16

16

www.evolutionfury.com

6. Mitre Cut (Fig. 8)

An angle of up to 450 to the left or right can be obtained.

Positive stops are provided at 150, 22.50, 300 and 450 right

and left.

1. Loosen the slide locking knob, and push the cutting head

back as far as it will go and lock the slide.

2. Loosen the mitre angle lock knob.

3. Pull up the positive stop locking lever.

4. Turn the rotary table to the desired angle as indicated by

the mitre angle pointer.

5. Tighten the mitre angle lock knob to hold the desired angle.

6. If necessary unlock the cutting head by loosening the

slide locking knob. This will allow the cutting head to move

backwards and forwards (required when cutting wide boards).

7. Start the saw and allow it to reach full speed before

commencing operations.

7. Bevel Cut Left (Fig. 9)

1. Lock the cutting head down with the head latching pin.

2. Loosen the bevel lock lever.

3. Tilt the cutting head to the required angle. A protractor

scale and pointer is provided to aid setting. This is found just

behind the bevel lock lever.

4. Tighten the bevel lock.

5. Unlatch the cutting head.

6. Release the slide (if necessary) to cut wide workpieces.

7. Stand to the left side of the handle to make the cut

8. Compound Cut

A compound cut is a combination of a mitre and bevel cut.

When a compound cut is required, select the desired bevel

and mitre positions as previously explained.

9. Depth Stop (Fig.10)

Use of the depth stop allows the operator to cut slots in the

workpiece. The downward travel of the saw head can be set

so that the saw blade does not completely cut through the

workpiece.

Note: It is advisable that the depth of cut is checked using a

scrap piece of timber to ensure that the slot cut is correct.

By making a cut in the workpiece, and then repeating the

cut but with the workpiece slightly repositioned to the left or

right, it is possible to perform trenching cuts.

To use the depth stop:

1. Loosen the locking wing nut.

2. Adjust the thumb knob to limit the saw heads travel to the

required depth.

3. Once set to the desired depth, tighten the wing nut

against the retaining bracket to lock the depth stop and

Fig 9

Fig 10

®

Fig 8

Page 17

17

www.evolutionfury.com

ensure that there is no movement.

4. When cutting is complete re-adjust the depth stop so that

the cutting head can be locked in the down position by the

head latching pin.

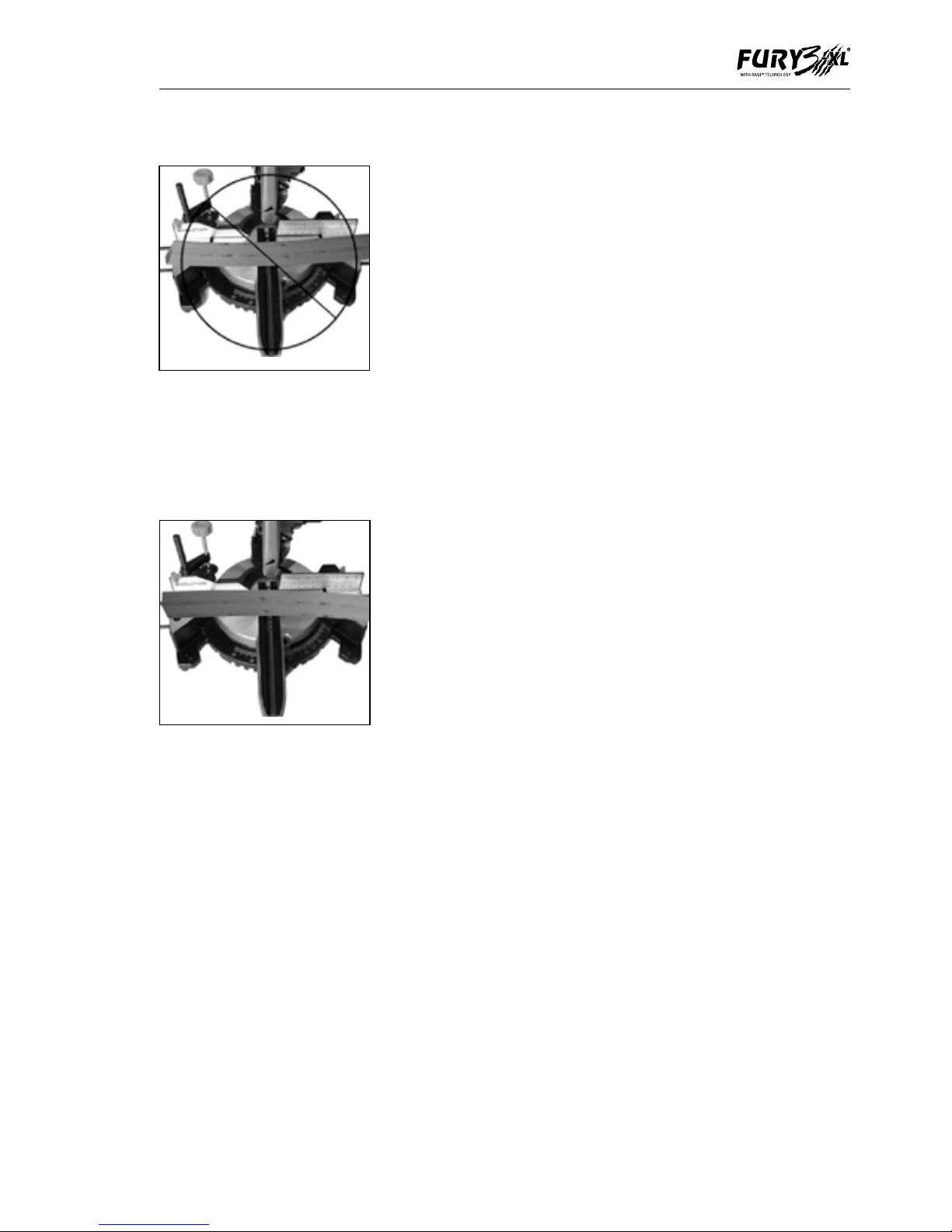

10. Cutting Bowed Material

Before cutting any workpiece, check to see if it is bowed.

If it is bowed the workpiece must be positioned and cut as

shown. See Figs 11 & 12

Do not position the workpiece incorrectly or cut the

workpiece without the support of the fence.

11. Clearing Jammed Material

1. Turn mitre saw “OFF” by releasing the trigger switch.

2. Allow the blade to come to a complete halt.

3. Unplug the mitre saw from the mains supply.

4. Remove any jammed material from the unit.

12. Transporting

When transporting the saw between locations make sure that:

1. The saw head is locked in the down position.

2. The rotary table mitre handle, the bevel locking lever and

the slide locking knob are all securely tightened.

3. The machines power cord is safely stored.

4. Use the transportation handle cut-outs on either side of

the machine base to lift the saw. Do not lift the saw by the

switch handle alone.

NOTE: Although compact this saw is quite heavy, Enlist

competent help, if necessary, when transporting this saw.

Fig 11

Fig 12

Page 18

18

www.evolutionfury.com

MAINTENANCE

Note

Any maintenance must be carried out with

the machine switched off and disconnected

from the mains power supply.

All motor bearings in this machine are

lubricated for life.

No further lubrication is required.

Apply light machine oil to the machines pivot

points and lower blade operating arm. Avoid

excessive oil, to which sawdust will cling.

Periodically, sawdust may accumulate under

the work table and the base. Use a vacuum

cleaner to remove this sawdust.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings in

the machines casings etc. The machines air

vents should be cleaned using compressed

dry air.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

®

MAINTENANCE

GB

ENVIRONMENTAL PROTECTION

GB

Page 19

19

www.evolutionfury.com

SERVICE PARTS LISTS

GB

Page 20

20

www.evolutionfury.com

TABLE DES MATIÈRES

Déclaration de conformité CE 20

Informations importantes 21

Garantie limitée de 12 mois 21

Règles de sécurité générales 21

Consignes de sécurité pour 22

toutes les scies

Règles de sécurité particulières 23

supplémentaires 25

Symboles et étiquettes de sécurité 27

Caractéristiques techniques 27

Vue d’ensemble de la machine 29

Assemblage 30

Fonctionnement 32

Maintenance 38

Protection environnementale 38

Listes de pièces de rechange 39

EC - DECLARATION OF CONFORMITY

Nous, fabricant et importateur,

Evolution Power Tools Ltd.

Venture One

Sheffield

S20 3FR

déclarons que le produit

Part numbers:

N° de référence : FURY32552, FURY32552EU

Evolution : Scie à onglet combiné à coulisse

multi-fonctions FURY 3 XL

est conforme aux prescriptions essentielles

des directives européennes suivantes :

2006/42/CE – Directive relative aux machines

2006/95/CE – Directive relative aux basses

tensions

2004/108/CE – Directive relative à la

compatibilité électromagnétique

2002/95/CE – Restrictions d’utilisation de

certaines substances dangereuses dans les

équipements électriques et électroniques

Cet outil est conforme aux normes

suivantes :

EN 61029-1:2009

EN 61029-2-9:2002

EN 55014-1:2006+A1:2009

EN 55014-2:1997+A1:2001+A2:2008

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN 60825-1:2007

Authorised by

M. Matthew J. Gavins

Directeur général

1er juin 2010

Toute la documentation est conservée à

l’adresse ci-dessus et est disponible pour

consultation sur demande.

®

DÉCLARATION DE CONFORMITÉ CE

FR

Page 21

21

www.evolutionfury.com

IMPORTANT

IMPORTANT

Lisez attentivement et intégralement

ces consignes d’utilisation et de sécurité

avant toute utilisation de l’outil. Pour votre

sécurité, vous devez vérifier, avant toute

utilisation, que la tension d’alimentation

est correcte et que toutes les poignées et

pièces de l’outil sont bien fixées. Si vous

avez la moindre incertitude concernant

l’utilisation de cet outil, n’hésitez pas

à contacter notre Service d’assistance

technique par téléphone.

Service d’assistance technique par

téléphone pour le Royaume-Uni

0870 609 2297

Service d’assistance technique par

téléphone pour les États-Unis

1-866-EVO-TOOL

Scie à onglet combiné à coulisse

multi-fonctions FURY 3XL de 255 mm

EVOLUTION

Nous vous félicitons d’avoir acheté une scie

à onglet combiné multi-fonctions de 255mm

d’Evolution Power Tools. Enregistrez votre

produit en ligne pour valider la période de

garantie de votre outil et bénéficier d’un

service rapide en cas de besoin. Nous vous

remercions sincèrement d’avoir choisi un

produit Evolution Power Tools.

GARANTIE LIMITEE DE 12 MOIS.

Evolution Power Tools se réserve le

droit d’apporter des améliorations et des

modifications à la conception de cet outil, et

ce sans préavis.

Evolution Power Tools réparera ou remplacera,

dans les douze (12) mois suivant la date

d’achat d’origine, tout article présentant

un vice de matériau ou un défaut de

fabrication. La présente garantie est sans

valeur si l’outil retourné a été utilisé pour

découper des matériaux non conformes

aux recommandations figurant dans le

présent manuel d’utilisation ou si la scie a été

endommagée par accident, par négligence ou

en raison d’un mauvais entretien. La présente

garantie ne s’applique pas aux machines et/

ou aux composants qui ont été altéré(e)s,

remplacé(e)s ou modifié(e)s d’une quelconque

manière, ou qui ont été utilisé(e)s sans

respecter les capacités et les spécifications

recommandées. Les composants électriques

sont couverts par les garanties offertes par

leurs fabricants respectifs. Tous les articles

défectueux doivent être retournés à Evolution

Power Tools en port prépayé. Evolution Power

Tools se réserve le droit, à sa seule discrétion,

de réparer l’outil ou de le remplacer par un

produit identique ou équivalent. Aucune

garantie – écrite ou verbale – ne couvre les

lames des scies. Evolution Power Tools

ne saurait en aucun cas être tenue pour

responsable des pertes ou dommages

découlant directement ou indirectement de

l’utilisation du produit ou de toute autre cause.

Evolution Power Tools ne saurait être tenue

pour responsable des coûts relatifs à ce produit

ou aux dommages accessoires y afférents.

Aucun cadre, employé ou agent de la société

Evolution Power Tools n’est habilité à faire

de déclarations verbales d’adéquation à un

usage particulier ou à déroger aux conditions

de vente précédentes : les déclarations de ce

type ne sauraient en aucun cas être opposées

à Evolution Power Tools. Toute question relative

à la présente garantie limitée doit être adressée

directement au siège social de la société.

Vous pouvez également appeler le Service

d’assistance technique téléphonique approprié.

CONSIGNES DE SÉCURITÉ IMPORTANTES

Afin de réduire le risque d’électrocution, cet

équipement est équipé d’un cordon électrique

et d’une fiche approuvés pour le pays

d’utilisation auquel il est destiné. Vous ne devez

en aucun cas changer le cordon ou la fiche.

RÈGLES DE SÉCURITÉ D’ORDRE GÉNÉRAL

Assurez-vous d’avoir lu et compris toutes

les consignes avant d’utiliser ce produit.

Le non-respect de toutes les consignes

énumérées ci-dessous pourrait entraîner des

décharges électriques, des incendies et/ou

des blessures graves.

INFORMATIONS IMPORTANTES

FR

GARANTIE LIMITÉE DE 12 MOIS

FR

RÈGLES DE SÉCURITÉ GÉNÉRALES

FR

Page 22

22

www.evolutionfury.com

CONSERVEZ CES CONSIGNES POUR

AVERTISSEMENT ! Lors de l’utilisation

d’outils électriques, les mesures de sécurité

de base devraient toujours être suivies afin

de réduire le risque d’incendie, de décharge

électrique et de blessures.

Lisez toutes ces consignes avant de tenter

d’utiliser cette machine. Conservez ce

manuel pour référence future.

1. Tenez votre lieu de travail propre.

Les endroits encombrés sont propices

aux accidents.

2. Pensez à l’environnement de votre lieu

de travail. N’exposez pas les outils à la pluie.

N’utilisez pas les outils dans des endroits

humides ou mouillés. Votre lieu de travail doit

être bien éclairé. N’utilisez jamais d’outils à

proximité de liquides ou de gaz inflammables.

3. Protégez-vous contre les décharges

électriques. Évitez le contact du corps avec

des surfaces mises à la terre ou à la masse.

4. Tenez les autres personnes à distance.

Ne laissez pas les autres, les enfants surtout,

s’approcher de votre travail et toucher l’outil

ou la rallonge. Tenez-les éloignés de votre lieu

de travail.

5. Rangez les outils quand vous avez fini

de vous en servir. Lorsque vous ne vous en

servez pas, rangez les outils dans un endroit

sec fermant à clé, hors de la portée des

enfants.

6. Ne forcez jamais les outils. Vos outils

seront plus efficaces et moins dangereux si

vous les utilisez à la puissance à laquelle ils

sont censés être utilisés.

7. Utilisez le bon outil. N’utilisez pas un petit

outil pour faire le travail d’un gros outil plus

puissant. N’utilisez pas les outils pour des

travaux pour lesquels ils ne sont pas prévus.

Par exemple, n’utilisez pas une scie circulaire

pour couper des arbres ou du bois.

8. Portez une tenue adaptée. Ne portez pas

de vêtements lâches ou de bijoux, car ils

pourraient se prendre dans des composants

mobiles. Portez de préférence des chaussures

antidérapantes lorsque vous travaillez à

l’extérieur. Si vous avez des cheveux longs,

attachez-les et couvrez-les.

9. Portez un équipement de protection.

Portez des lunettes de sécurité. Portez un

masque facial ou un masque à poussière si le

travail prévu va faire de la poussière.

10. Branchez un système d’extraction

de la poussière. Si la machine possède un

branchement pour un dispositif d’extraction

de la poussière, branchez-le et utilisez-le

correctement.

11. N’endommagez pas le cordon

électrique. Ne tirez jamais sur le cordon

électrique pour débrancher la machine.

Conservez le cordon éloigné de la chaleur,

de l’huile et des bords tranchants.

12. Bloquez la pièce. Si possible, utilisez des

pinces ou un étau pour la bloquer. Cela est

nettement moins dangereux que d’utiliser vos

mains.

13. N’essayez pas d’atteindre les endroits

inaccessibles. Veillez à toujours garder votre

équilibre.

14. Gardez vos outils en bon état de marche.

Gardez vos outils propres et affûtés pour des

résultats optimaux et pour travailler en toute

sécurité. Suivez les consignes de graissage et

de changement des accessoires. Inspectez

régulièrement les cordons d’alimentation. En

cas de dommage, faites-les remplacer par

un réparateur agréé. Inspectez les rallonges

périodiquement. Si elles sont abîmées,

remplacez-les. Gardez toujours les poignées

propres, sèches et sans huile ni graisse.

15. Débranchez les outils. Débranchez

les outils de la prise électrique lorsque

vous ne vous en servez pas, avant les

révisions/réparations et lors du changement

d’accessoires (lames, embouts, disques de

coupe, etc.).

16. Retirez les clavettes et clés de réglage.

Prenez pour habitude de contrôler que les

clavettes et clés de réglage ont été retirées de

l’outil avant de le mettre en marche.

17. Évitez les démarrages accidentels.

Contrôlez que l’interrupteur Marche/Arrêt est

sur la position Arrêt avant de brancher l’outil.

18. Utilisez des rallonges adaptées. Si vous

utilisez l’outil à l’extérieur, utilisez uniquement

une rallonge adaptée à une utilisation à

l’extérieur, ce qui doit être indiqué sur

l’étiquette de la rallonge.

®

CONSIGNES DE SÉCURITÉ POUR

TOUTES LES SCIES

FR

Page 23

23

www.evolutionfury.com

19. Restez alerte. Concentrez-vous sur ce

que vous faites, faites preuve de bon sens et

n’utilisez pas l’outil si vous êtes fatigué.

20. Contrôlez qu’aucun composant n’est

endommagé. Avant d’utiliser un outil,

assurez-vous qu’il est en bon état de marche.

Contrôlez l’alignement et l’état des pièces

en mouvement, les fixations et tous les

autres aspects susceptibles d’affecter son

fonctionnement. Si un carter de protection

ou un autre composant est endommagé,

faites-le réparer ou remplacer dans un centre

de réparation agréé, sauf indication contraire

figurant dans ce manuel. N’utilisez pas l’outil

si l’interrupteur ne le met pas en marche et à

l’arrêt.

21. Avertissement. L’utilisation d’accessoires

autres que ceux recommandés dans ce

manuel peut entraîner un risque de dommage

corporel.

22. Faites réparer votre outil dans un centre

de réparation agréé. Cet outil électrique est

conforme aux règles de sécurité en vigueur.

Les réparations ne doivent être effectuées que

par un réparateur agréé et avec des pièces de

rechange d’origine. Le non-respect de cette

consigne pourrait mettre l’utilisateur de l’outil

dans une situation très dangereuse.

CONSEILS DE SANTÉ

Avertissement !

Lorsque vous percez, poncez, sciez ou

meulez, des particules de poussière sont

produites. Dans certains cas, selon le

matériau utilisé, ces poussières peuvent

être très dangereuses pour la santé (plomb

contenu dans les anciennes peintures

brillantes, par exemple). Il est conseillé de

réfléchir aux risques associés aux matériaux

utilisés et de réduire le risque d’exposition.

Vous devriez :

- Travailler dans un endroit bien aéré.

- Travailler avec l’équipement de sécurité

approuvé, comme, par exemple, des

masques à poussière spécialement conçus

pour filtrer les particules microscopiques.

CONSIGNES DE SÉCURITÉ POUR

a) DANGER : Tenez vos mains éloignées

de la zone de coupe et de la lame. Placez

votre seconde main sur la poignée auxiliaire

ou sur le bloc moteur. En tenant la scie avec

vos deux mains, vous ne courrez aucun

risque d’être blessé par les lames.

b) Ne mettez pas vos mains sous la pièce

à couper. Le carter de protection ne peut

pas vous protéger de la lame dans ce cas.

c) Réglez la profondeur de coupe en

fonction de l’épaisseur de la pièce à

couper. Moins d’une dent entière de la lame

devrait être visible sous la pièce à couper.

d) Ne tenez jamais la pièce à couper dans

vos mains ou sur votre jambe. Bloquez la

pièce à couper sur un établi stable. Il importe

de soutenir correctement la pièce de façon à

réduire au minimum l’exposition du corps et

le risque de blocage de la lame ou de perte

de contrôle.

e) Tenez votre outil électrique par ses

surfaces de prise isolées lorsqu’il est

possible que l’outil de coupe entre en

contact avec des fils cachés ou son propre

cordon électrique. Le contact avec un fil

« sous tension » peut également mettre

les parties métalliques exposées de l’outil

électrique « sous tension » et vous risqueriez

alors de recevoir une décharge électrique.

f) Pour le sciage en long, utilisez toujours

un guide longitudinal ou un guide de chant.

Vous obtiendrez ainsi une coupe plus précise

et la lame risquera moins de se bloquer.

g) Utilisez toujours des lames avec des

trous d’arbre de la taille correcte et de

la forme appropriée (en losange/ronds).

Les lames qui ne sont pas adaptées au

dispositif de montage de la scie tourneront

excentriquement, ce qui vous fera perdre le

contrôle de l’outil.

h) N’utilisez jamais de rondelles ou

de boulons de lame endommagés ou

inadaptés. Les rondelles et le boulon des

lames ont été spécialement conçus pour

permettre à votre scie de développer des

performances optimales et pour offrir une

sécurité d’utilisation exemplaire.

CONSIGNES DE SÉCURITÉ SUPPLÉMENTAIRES

POUR VOTRE SCIE À ONGLET

FR

Page 24

24

www.evolutionfury.com

Autres consignes de sécurité pour toutes

les scies

Causes des reculs et comment les éviter :

Le recul est une réaction soudaine à une

lame de scie pincée, bloquée ou mal alignée,

qui amène une scie non contrôlée à se

soulever vers l’opérateur :

1. Lorsque la lame est pincée ou complètement

bloquée dans la saignée qui se referme, la

lame cale et la réaction du moteur ramène

rapidement la scie vers l’opérateur.

2. Si la lame se déforme ou devient mal

alignée dans la coupe, les dents du bord

arrière de la lame peuvent entrer dans la

surface supérieure de la pièce, ce qui peut

amener la lame à sortir de la saignée et à

sauter vers l’opérateur.

Le recul est le résultat d’une mauvaise

utilisation de la scie et/ou de conditions

ou procédures d’utilisation incorrectes. Il

peut être évité en prenant les mesures de

précaution décrites ci-dessous.

a) Tenez fermement la scie des deux mains

et positionnez vos bras de façon à résister

aux forces de recul. Positionnez votre corps

d’un côté ou de l’autre de la lame, mais pas

dans l’alignement de la lame. Le recul peut

amener la scie à sauter vers l’arrière, mais

vous pouvez maîtriser les forces de recul en

prenant certaines précautions.

b) Lorsque la lame se bloque, ou lors de

l’interruption de la coupe pour quelque

raison que ce soit, relâchez le déclencheur

et gardez la scie immobile dans le

matériau jusqu’à ce que la lame s’arrête

complètement. Ne tentez jamais de retirer

la scie de la pièce ou de tirer la scie vers

l’arrière lorsque la lame est en mouvement,

car la scie risque de reculer. Recherchez la

cause du blocage de la lame et prenez les

mesures correctives qui s’imposent.

c) Lorsque vous redémarrez une scie

dans la pièce à couper, centrez la lame

de la scie dans la saignée et contrôlez

que les dents de la scie ne sont pas

engagées dans le matériau. Si la lame se

bloque, elle risque de sauter ou de reculer au

redémarrage de la scie.

d) Soutenez les grands panneaux de

façon à réduire le risque de pincement

et de recul de la lame au minimum. Les

grands panneaux ont tendance à s’arquer

sous leur propre poids. Placez des supports

sous le panneau, des deux côtés, près de la

ligne de coupe et près du bord du panneau.

e) Contrôlez que les leviers de

verrouillage du réglage du biseau et de la

profondeur de la lame sont bien serrés et

bloqués avant de couper. Si le réglage de

la lame change pendant la coupe, il pourra y

avoir blocage et recul.

f) N’utilisez jamais de lames émoussées

ou endommagées. Des lames de scie

mal affutées ou mal posées produiront une

saignée étroite, ce dont il résultera une

friction excessive. La lame se bloquera alors

et reculera.

g) Faites extrêmement attention pendant

le « sciage en plongée » dans des murs

ou autres zones aveugles. La lame en

saillie peut couper des objets, ce qui peut

provoquer un recul.

Consignes de sécurité concernant les scies

a) Avant chaque utilisation, contrôlez

que le carter de protection inférieur se

ferme comme il faut. N’utilisez pas la

scie si le carter de protection inférieur ne

bouge pas librement et ne se ferme pas

instantanément. Ne bloquez jamais le carter

de protection inférieur en position ouverte.

En cas de chute accidentelle de la scie, le

carter de protection inférieur risque de se

déformer. Soulevez le carter de protection

inférieur au moyen de la poignée rétractable

et assurez-vous qu’il bouge librement et qu’il

n’est pas en contact avec la lame ou avec un

autre composant de l’outil, et ce à tous les

angles et profondeurs de coupe.

b) Contrôlez le fonctionnement du

ressort du carter de protection inférieur.

Si le carter de protection et le ressort ne

fonctionnent pas correctement, ils doivent

être réparés avant toute utilisation. Il est

possible que le carter de protection inférieur

ne fonctionne pas très bien en raison de

composants endommagés, de dépôts

collants ou d’une accumulation de débris.

c) Le carter de protection inférieur peut

être rentré manuellement uniquement

pour les coupes spéciales (en plongée,

combinée, etc.). Soulevez le carter de

®

Page 25

25

www.evolutionfury.com

protection inférieur par la poignée rétractable

et relâchez-le dès que la lame entre dans

le matériau. Pour toutes les autres coupes,

le carter de protection inférieur devrait

fonctionner automatiquement.

d) Contrôlez toujours que le carter de

protection inférieur couvre la lame avant

de poser la scie sur l’établi ou le sol. Une

lame non protégée qui continue à avancer

fera reculer la scie, qui coupera alors tout ce

qui se trouvera sur son chemin. La lame met

un peu de temps à s’arrêter après que vous

appuyez sur le bouton d’arrêt.

ADDITIONAL SAFETY INSTRUCTIONS

Avertissement : vous devez avoir lu et

compris toutes les consignes avant d’utiliser

cet outil. Le non-respect des consignes

énumérées ci-dessous pourrait entraîner des

décharges électriques, des incendies et/ou

des blessures graves.

a) Conservez tous les carters de protection

en place et en bon état de marche.

b) Retirez les clavettes et clés de réglage.

Prenez pour habitude de contrôler que les

clavettes et clés de réglage ont été retirées

de l’outil avant de le mettre en marche.

c) Tenez votre lieu de travail propre.

Les endroits et les établis encombrés sont

propices aux accidents.

d) N’utilisez pas l’outil dans des lieux

dangereux. N’utilisez pas les outils

électriques dans des endroits humides ou

mouillés et ne les exposez pas à la pluie.

Votre lieu de travail doit être bien éclairé.

e) Tenez les enfants à l’écart. Tous les

visiteurs devraient être tenus à bonne

distance du lieu de travail.

f) Ne forcez pas l’outil. Il fera un meilleur

travail et sera moins dangereux s’il est utilisé

à la puissance pour laquelle il a été conçu.

g) Utilisez une rallonge appropriée. Si

vous utilisez une rallonge, contrôlez qu’elle

est en bon état. Si vous utilisez une rallonge,

assurez-vous qu’elle est suffisamment forte

pour transporter le courant que votre outil

tirera. Si elle est trop faible, cela entraînera

une chute de la tension sectorielle, ce qui se

traduira par une perte de puissance et une

surchauffe de votre outil.

h) Portez une tenue adaptée. Ne portez

pas de vêtements flottants, de gants, de

foulards, de bagues, de bracelets ou autres

bijoux susceptibles de se prendre dans les

pièces en mouvement. Il est conseillé de

porter des chaussures non glissantes. Portez

quelque chose sur la tête pour maintenir vos

cheveux attachés s’ils sont longs.

i) Portez toujours des lunettes de

sécurité. Portez également un masque facial

ou un masque à poussière si le travail prévu

va faire de la poussière. Les verres des

lunettes ordinaires offrent une résistance

aux chocs uniquement. Ce NE sont PAS des

lunettes de sécurité.

j) Bloquez la pièce à découper. Utilisez

des pinces pour bloquer la pièce à découper

lorsque cela est possible. Cela est moins

risqué que de tenir la pièce avec vos mains et

cela libère vos deux mains pour manier l’outil.

k) N’essayez pas d’atteindre les endroits

inaccessibles. Veillez à toujours garder votre

équilibre.

l) Prenez soin de vos outils. Gardez vos

outils propres et affûtés pour des résultats

optimaux et pour travailler en toute sécurité.

Suivez les consignes de graissage et de

changement des accessoires. N’utilisez pas

de lames pour l’acier à coupe rapide ni de

lames endommagées ou déformées.

m) Débranchez l’outil avant toute

réparation et avant de changer des

accessoires (lames, etc.).

n) Réduisez le risque de démarrage

accidentel. Contrôlez que l’interrupteur

Marche/Arrêt est sur la position Arrêt avant

de brancher l’outil.

o) Utilisez les accessoires recommandés.

Utilisez uniquement des accessoires

d’origine Evolution garantie. Utilisée avec la

bonne lame (lame TCT multi-fonctions Fury

3), cette scie est recommandée pour couper

l’acier doux, l’aluminium et le bois.

p) Ne montez jamais sur l’outil. Des

blessures graves pourraient survenir si l’outil

bascule ou si vous entrez accidentellement

en contact avec l’outil de coupe.

q) Contrôlez qu’il n’y a pas de pièces

d’endommagées. Si vous constatez qu’un

carter de protection ou un autre composant est

endommagé, examinez-le soigneusement afin

RÈGLES DE SÉCURITÉ PARTICULIÈRES

SUPPLÉMENTAIRES

FR

Page 26

26

www.evolutionfury.com

de déterminer s’il fonctionnera correctement

et s’acquittera de sa fonction avant de

continuer à utiliser l’outil. Contrôlez que les

pièces en mouvement sont correctement

alignées et qu’elles ne sont pas bloquées,

qu’il n’y a pas de composants de cassés,

que la monture est en parfait état et qu’il n’y

a pas d’autres problèmes susceptibles de

nuire au bon fonctionnement de l’outil. Si un

carter de protection ou un autre composant

est endommagé, faites-le réparer par un

réparateur agréé ou remplacez-le.

r) Éloignez vos mains du parcours de la

lame de la scie.

s) N’approchez jamais vos mains de la lame.

t) Mettez l’outil hors tension et attendez

que la lame se soit arrêtée avant de

changer les pièces à découper de position

ou de modifier les réglages.

u) Débranchez l’outil de la prise électrique

avant de changer la lame, d’effectuer des

réparations ou de nettoyer l’outil.

v) Pour réduire le risque de blessures,

ramenez le chariot en position arrière

complète après chaque coupe transversale.

Comment transporter votre scie à onglet

Consignes de sécurité

1. Bien que compacte, la scie est lourde. Pour

ne pas vous faire mal au dos, faites-vous aider

chaque fois que vous devez la soulever.

2. Pour éviter de vous faire mal au dos,

tenez l’outil près de votre corps pour le

soulever. Pliez les genoux pour pouvoir

soulever l’outil avec vos jambes, au lieu de

votre dos. Soulevez l’outil en le prenant par

les zones de prise qui se trouvent sur le

dessous du socle, de chaque côté.

3. Ne portez jamais la scie à onglet en la tenant

par le cordon électrique ou par le déclencheur

de la poignée. Si vous la portez par le cordon,

vous risquez d’endommager l’isolation ou les

fils de raccordement, ce dont il peut résulter

une électrocution ou un incendie.

4. Avant de déplacer la scie, serrez le bouton

de blocage de la coulisse pour empêcher les

mouvements soudains.

AVERTISSEMENT !

Ne soulevez pas l’outil par le carter de lame.

Débranchez le cordon de la prise de courant

avant d’essayer de déplacer la machine.

• Bloquezlatêteàl’aidedelagoupillede

blocage de tête.

• Amenezlatêtedecoupeàsapositionla

plus éloignée et bloquez-la en serrant le

bouton de blocage de la coulisse.

• Desserrezleboutondeblocagedel’angle

d’onglet. Tirez le levier d’angle d’onglet et

faites tourner la table pour l’amener sur un

de ses réglages maximum.

• Bloquezlatableàl’aideduboutonde

blocage.

• Pourtransporterlamachine,servez-vous

des deux poignées découpées de chaque

côté du socle de la machine.

Posez la scie sur une surface de

travail fixe et sécurisée et inspectez

la scie soigneusement. Contrôlez tout

particulièrement le fonctionnement de tous

les dispositifs de sécurité de la machine

avant sa mise en service ou son utilisation.

®

Page 27

27

www.evolutionfury.com

SAFETY LABELS & SYMBOLS

AVERTISSEMENT !

N’utilisez en aucun cas la machine s’il

manque des autocollants contenant des

avertissements et/ou des consignes ou

si ces autocollants sont endommagés.

Contactez Evolution Power Tools pour

obtenir des étiquettes de rechange.

Symbole Description

V Volts

A Ampères

Hz Hertz

min

-1

Vitesse

~ Courant alternatif

n0

Vitesse à vide

Double isolation

Wear Safety

Goggles

Wear Ear Protection

Ne pas toucher

Portez une protection

contre la poussière

Directive relative

à la restriction

d'utilisation de

certaines substances

dangereuses

Certification CE

Déchets

d'équipements

électriques et

électroniques

Utilisez uniquement des lames de rechange

d’origine Evolution garantie. Les lames non

autorisées peuvent être dangereuses ! Les

lames de la scie doivent être solidement

fixées. Vérifiez qu’aucun débris ne se trouve

sur les flasques de la lame avant d’installer

une nouvelle lame. N’utilisez jamais de lames

émoussées, cassées ou endommagées.

Vérifiez fréquemment l’état et le degré

d’usure des lames. Les lames endommagées

ou usées doivent être remplacées

immédiatement. Faites attention aux copeaux

qui sont éjectés. Ils sont peut-être CHAUDS.

Manipulez toujours l’excédent de matériau

avec précaution. Le socle de la machine

et la table rotative doivent toujours rester

dépourvus de saletés et autres débris.

Pour obtenir un nouvel exemplaire du présent

manuel d’utilisation, contactez Evolution

Power Tools :

Royaume-Uni 0870 609 2297

États-Unis 1-866-EVO-TOOL

SITE WEB www.evolutionpowertools.com

FURY 3 XL SPECIFICATION

Peut couper :

Tôle en acier doux – Épaisseur max. : 3

mm

Profilés en caisson en acier doux –

Épaisseur de paroi max. : 3 mm

Aluminium

Bois – Section max. : 75 mm x 300 mm

Données techniques

Moteur (230 V ~ ou 110 V ~ 50/60 Hz) (Watts) :

2 000 W (démarrage progressif)

Vitesse de rotation à vide (min-1) :

2500

Cycle de service max. conseillé (minutes) :

30 minutes

Poids : 17,85 Kg

Dimensions de la lame

Diamètre : 255 mm

Nombre de dents : 24

Diamètre d’alésage : 25,4 mm

Épaisseur : 2 mm

Capacité de coupe maximale (bois)

À 900 (onglet) x 900 (biseau)

300 mm x 75 mm

À 450 (onglet) x 900 (biseau)

210 mm x 75 mm

À 450 (onglet) x 450 (biseau)

210 mm x 40 mm

SYMBOLES ET ÉTIQUETTES DE SÉCURITÉ

FR

SPECIFICATION

FR

Page 28

28

www.evolutionfury.com

Niveau sonore et vibrations

Niveau de pression acoustique :

88,1 dB(A) K=3 dB(A)

Niveau de puissance acoustique :

99,8 dB(A) K=3 dB(A)

Niveau de vibrations :

1,059 m/s2 K =1,5 dB(A)

La valeur de vibrations totale déclarée a été

mesurée selon une méthode d’essai standard

et peut être utilisée pour comparer un outil

avec un autre.

La valeur de vibrations totale déclarée peut

également servir d’évaluation d’exposition

préliminaire.

AVERTISSEMENT : la valeur d’émission

de vibrations pendant l’utilisation de l’outil

électrique peut être différente de la valeur

totale déclarée, selon la façon dont l’outil est

utilisé. Il est nécessaire de déterminer les

mesures de sécurité à adopter et de protéger

l’opérateur en fonction d’une estimation de

l’exposition dans les conditions effectives

d’utilisation (en tenant compte de toutes les

étapes du cycle d’exploitation, par exemple

lorsque l’outil est mis à l’arrêt, lorsqu’il tourne

au ralenti, en plus du déclenchement).

ACCESSOIRES SUPPLÉMENTAIRES

En plus des accessoires standard fournis

avec la machine, d’autres accessoires sont

disponibles pour améliorer ses performances,

à savoir :

1. Système de serrage – Cette machine a

été étudiée de façon à permettre l’utilisation

d’une pince avant qui peut être posée

d’un côté ou de l’autre de la lame dans les

logements du socle.

2. Lame de diamant – Transformez cette scie

en machine à couper les carreaux. Il suffit

de remplacer la lame TCT standard par la

lame de diamant en option pour transformer

cette scie en machine à couper les carreaux

compatible avec la plupart des carreaux en

céramique ou en porcelaine.

D’autres accessoires sont disponibles auprès

de votre concessionnaire local (ou d’Evolution

Power Tools).

ITEM QUANTITY

Manuel d'utilisation 1

Clé hexagonale 1

Pince supérieure 1

Lame multifonctions 1 FURY3-XL

Barres de soutien 2

Butée de fin de course 1

®

Page 29

29

www.evolutionfury.com

MACHINE OVERVIEW

FR

1. DÉCLENCHEUR MARCHE/ARRÊT

2. DÉCLENCHEUR DE BLOCAGE DU

CARTER DE LAME

3. POIGNÉE DE COUPE

4. SAC À POUSSIÈRE EXTRACTION DU PORT

5. TABLE ROTATIVE

6. DESSUS DE TABLE

7. CARTER DE LAME INFÉRIEUR

8. CARTER DE LAME SUPÉRIEUR

9. LAME

10. BOUTON DE BLOCAGE DE LA COULISSE

11. LEVIER DE BLOCAGE DU BISEAU

12. POIGNÉE D’ONGLET

13. RAPPORTEUR D’ONGLET

14. LEVIER DE BLOCAGE DE BUTÉE FIXE

15. SUPPORT DE PIÈCE

16. BUTÉE DE REPRISE

17. GUIDE

18. PINCE SUPÉRIEURE

19. GOUPILLE DE BLOCAGE DE TÊTE

20. TROU DE FIXATION

2

4

2

19

11

15

6

17

5

14

7

9

3

8

12

20

1

13

10

16

18

Page 30

30

www.evolutionfury.com

GETTING STARTED

MISE EN GARDE ! DÉBRANCHEZ TOUJOURS LA SCIE DU

SECTEUR AVANT DE PROCÉDER AU MOINDRE RÉGLAGE.

Refer to the “Service Parts List Drawing”. Install a blade as

detailed in the “Installing or Removing the Blade” section.

Reportez-vous au dessin de liste des pièces de rechange.

Mettez une lame en place en procédant comme indiqué dans

la section « Pose ou retrait de la lame ».

1. Montage de la scie à onglet

AVERTISSEMENT : afin de réduire le risque de blessures

causées par les mouvements inopinés de la scie, posez la

scie à l’endroit désiré, sur un établi ou autre table de travail

recommandée. À la base de la scie, vous verrez quatre trous

qui sont réservés au montage de la scie à onglet. Si la scie

est destinée à être utilisée à un seul endroit, fixez-la de

manière définitive sur l’établi ou la table de travail à l’aide de

boulons adaptés et de rondelles et écrous.

1. Serrez les systèmes de blocage d’onglet, de biseau et de

coulisse.

2. Placez la scie à un endroit où personne d’autre ne peut se