Page 1

®

®

EVO-SYSTEM

ENGINE

MAINTENANCE

RUBBER COUPLING

INSPECTION AND REPLACEMENT

instructions

tri-lobed sprocket

rubber coupling

simple to replace

*

Generic images shown to illustrate the Evo-System’

s functionality.

Engine and outputs may vary according to market destination.

Page 2

Note: This procedure is a two person

operation and must only be attempted

with the engine completely COLD!

The rubber coupling is part of the

transmission system of the Evo-engine. It is

a ‘wearing part’ and should be checked every

250 hours for serviceability. The following

instructions are intended for owner/operators

who are familiar with and have competence/

experience in the maintenance procedures

required for small capacity 4 stroke petrol

engines. If you do not feel completely

confident with the following instructions,

please contact our helpline for extra advice.

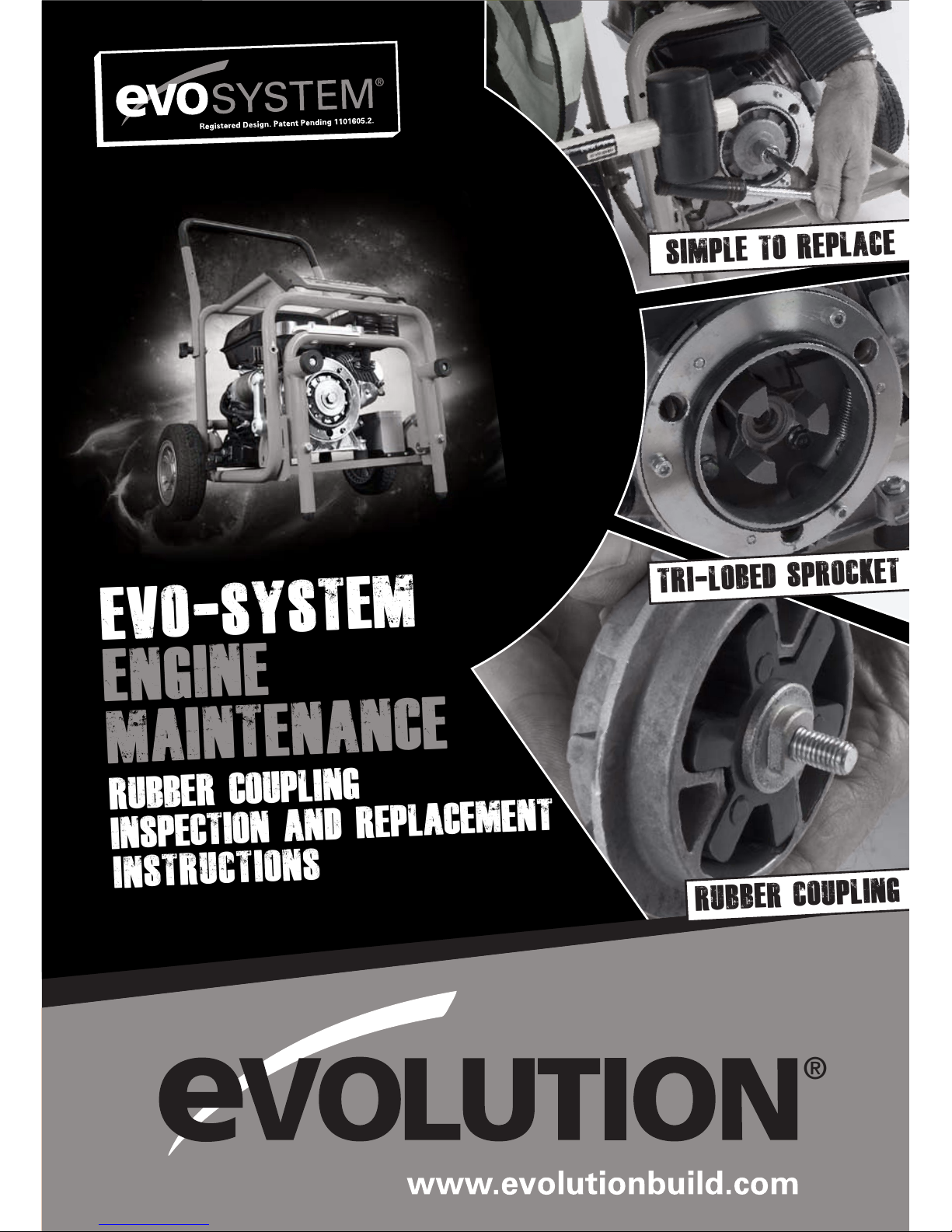

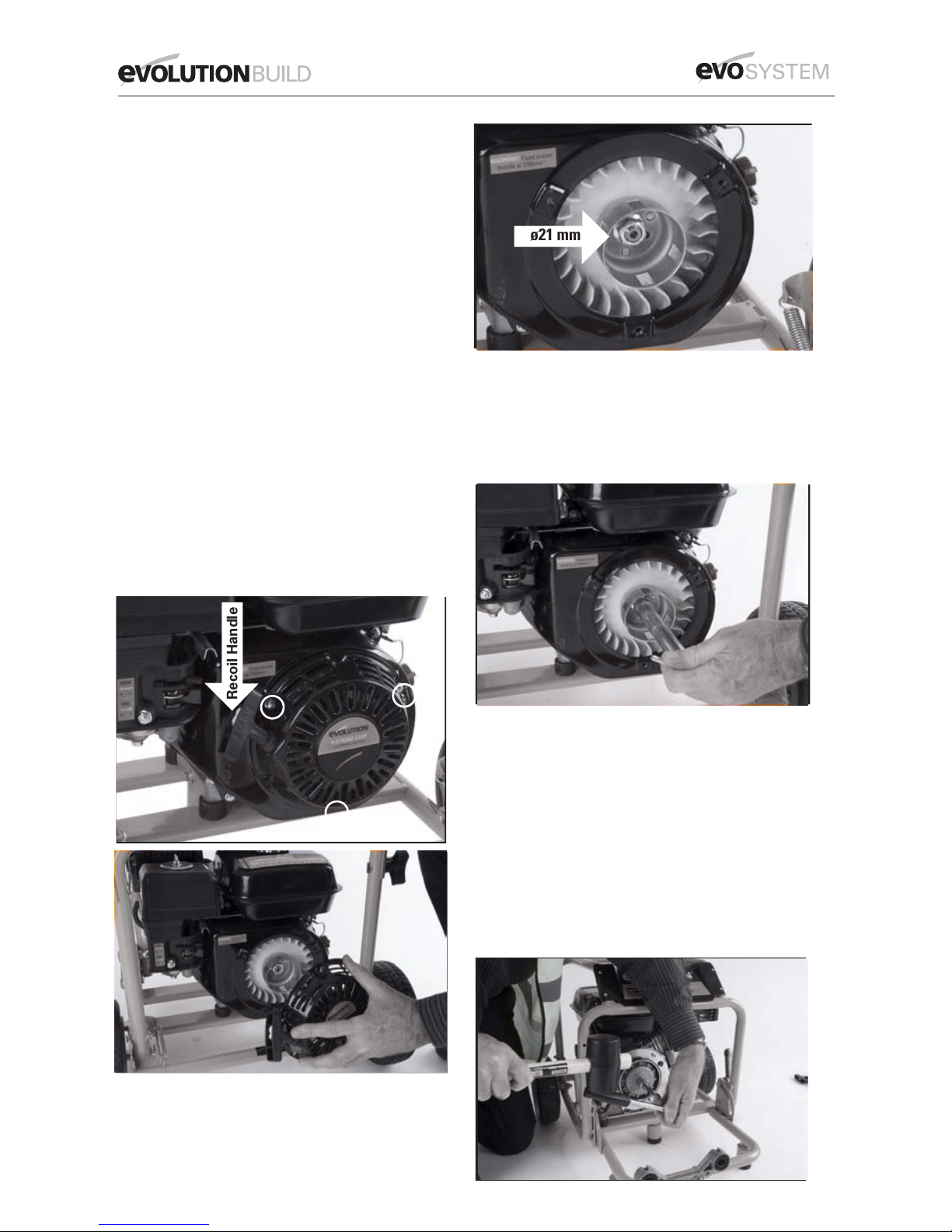

• Note the position of the recoil starting

handle for future re-installation. Remove

the recoil starting system by undoing and

removing the 3 x ø8 mm (Evolution

Engine) or 3 x ø10 mm (Mitsubishi Engine)

securing bolts and washers. Store these

and the recoil system safely.

Removing the recoil starting system will give

access to the ø21 mm nut on the end of the

engine crankshaft.

This nut can be held with a spark plug

spanner to prevent the crankshaft from

rotating.

• Hold the crankshaft securely to prevent it

from rotating.

• Loosen the ø19 mm AF bolt on the

opposite end of the crankshaft by using a

19mm socket with a tommy bar attached.

The socket can be ‘pushed’ into the

machine to gain extra security for the

socket on the bolt head.

The ø19 mm bolt is tightened to a

reasonably high torque and may need to be

‘shocked loose’ by subjecting the socket

tommy bar to a sharp blow (use a rubber

mallet).

2

http://www.evolutionpowertools.co.uk/evosystem

®

Recoil Handle

ø21 mm

®

Page 3

Between 6 – 8 full turns of the bolt head

should be sufficient for the dog clutch to be

disconnected from the engine crankshaft.

This however may not be apparent to the

operator as the bolt may not withdraw from

the dog clutch.

• Gently pull on the dog clutch and ease the

assembly from the engine.

The rubber coupling can now be inspected in

‘situ’ or removed from the inside of the dog

clutch for closer inspection. For close

inspection, gently ease the rubber coupling

from the inside of the dog clutch by pulling

it outwards. A at bladed screwdriver can be

used to help ease the rubber coupling from

the dog clutch, but exercise care so as not to

score or otherwise damage any of the parts.

Inspect the 6 ‘teeth’ of the rubber element for

wear or damage.

Slight surface hairline fractures of the

rubber compound are to be expected and are

acceptable. Cracks or missing rubber is not

acceptable, and if detected the element must

be replaced.

If you are at all doubtful of the serviceability

of the rubber element replace it as a matter

of course.

Replacement of the rubber element and dog

clutch is a reversal of the removal

procedure.

However note the following:

• The rubber element is a precise t within

the dog clutch.

• The rubber element within the dog clutch

must be aligned with the tri-lobed drive

sprocket on the engine crankshaft.

• The ø19 mm bolt must be screwed fully

‘home’ into the ‘top hat bush’

• Gently push the dog clutch into place

within the engine.

• Hold the crankshaft so that it cannot rotate.

• Tighten the ø19 mm bolt using a 19mm

socket and tommy bar drawing the dog

clutch into its operational position on the

output side of the engine.

• Tighten the ø19 mm bolt to ‘Hand

Tightness’. In operation the bolt is ‘self

tightening’.

• Replace the recoil starting system, which is

a reversal of the removal procedure.

• Ensure that the recoil system is re-tted

in the same position it occupied prior to

removal.

3

http://www.evolutionpowertools.co.uk/evosystem

®

®

Page 4

®

Did you know

you can also buy...

...with more outputs

available SOON!

®

PRESSURE WASHER OUTPUT

®

EVO-SYSTEM ENGINE

®

GENERATOR OUTPUT

®

WATER PUMP OUTPUT

4

*

Generic images shown to illustrate the Evo-System’

s functionality.

Engine and outputs may vary according to market destination.

Loading...

Loading...