Page 1

EN

355

SAW

Original Instructions

SAW

380

ES

FR

Date Published: 01 / 02 / 2017Written in UK English

Page 2

Page 3

ENGLISH

Original Instructions

EN

ES

FR

Page 4

www.evolutionpowertools.com

TABLE OF CONTENTS

English Page 2

Español Página 24

Français Page 48

INTRODUCTION

Guarantee Page 5

Machine Specifications Page 6

Vibration Page 7

Labels and Symbols Page 7

Intended use of this Power Tool Page 8

Prohibited use of this Power Tool Page 8

SAFETY PRECAUTIONS

Electrical Safety Page 9

Outdoor Use Page 9

General Power Tool Safety Instructions Page 9

Additional Safety Instructions Page 11

GETTING STARTED

Unpacking Page 13

Machine Overview Page 14

Assembly and Preparation Page 15

Operating Instructions Page 19

MAINTENANCE

Environmental Protection Page 21

DECLARATION OF CONFORMITY Page 22

4

Page 5

www.evolutionpowertools.com

1.2 THIS INSTRUCTION MANUAL

WAS ORIGINALLY WRITTEN IN ENGLISH

(1.3) IMPORTANT

Please read these operating and safety

instructions carefully and completely.

For your own safety, if you are uncertain

about any aspect of using this equipment

please access the relevant Technical Helpline,

the number of which can be found on the

Evolution Power Tools website. We operate

several Helplines throughout our worldwide

organization, but Technical help is also

available from your supplier.

WEB

www.evolutionpowertools.com

(1.4) Congratulations on your purchase of

an Evolution Power Tools Machine. Please

complete your product registration ‘online’

as explained in the A4 online guarantee

registration leaflet included with this machine.

You can also scan the QR code found on the

A4 leaflet with a Smart Phone. This will enable

you to validate your machine’s guarantee

period via Evolutions website by entering your

details and thus ensure prompt service if ever

needed. We sincerely thank you for selecting

a product from Evolution Power Tools.

EVOLUTION LIMITED GUARANTEE

Evolution Power Tools reserves the right

to make improvements and modifications

to the product design without prior notice.

Please refer to the guarantee registration

leaflet and/or the packaging for details of

the terms and conditions of the guarantee.

(1.5) Evolution Power Tools will, within

the guarantee period, and from the original

date of purchase, repair or replace any

goods found to be defective in materials or

workmanship. This guarantee is void if the

tool being returned has been used beyond the

recommendations in the Instruction Manual or

if the machine has been damaged by accident,

neglect, or improper service.

This guarantee does not apply to machine’s

and / or components which have been altered,

changed, or modified in any way, or subjected

to use beyond recommended capacities

and specifications. Electrical components

are subject to respective manufacturers’

warranties. All goods returned defective shall

be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the right

to optionally repair or replace it with the same

or equivalent item.

There is no warranty – written or verbal –

for consumable accessories such as (following

list not exhaustive) blades, cutters, drills,

chisels or paddles etc. In no event shall

Evolution Power Tools be liable for loss or

damage resulting directly or indirectly from

the use of our merchandise or from any other

cause. Evolution Power Tools is not liable

for any costs incurred on such goods

or consequential damages.

No officer, employee or agent of Evolution

Power Tools is authorized to make oral

representations of fitness or to waive any

of the forgoing terms of sale and none

shall be binding on Evolution Power Tools.

Questions relating to this limited guarantee

should be directed to the company’s head

office, or call the appropriate Helpline number.

EN

ES

FR

5

Page 6

www.evolutionpowertools.com

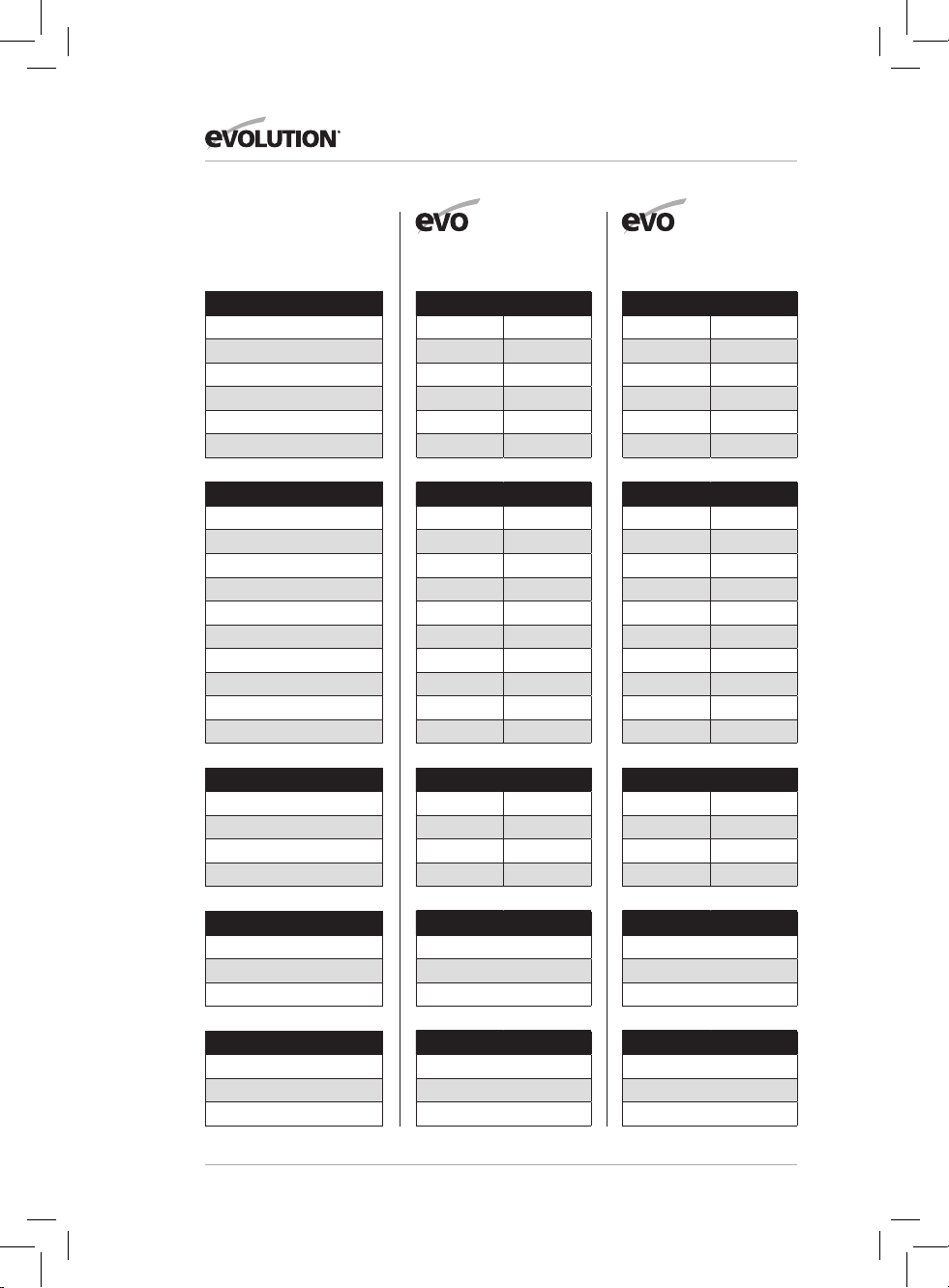

MACHINE SPECIFICATIONS

Motor UK (230-240V ~ 50 Hz)

Motor UK (110V ~ 50 Hz)

Motor USA (120V ~ 60 Hz)

Horsepower

Speed (No Load)

Weight

CUTTING CAPACITIES

Mild Steel Plate (Max Thickness)

Square Tube at 90° (Mild Steel)

Square Tube at 45° (Mild Steel)

Rectangle Tube at 90° (Mild Steel)

Rectangle Tube at 45° (Mild Steel)

Round Tube at 90° (Mild Steel)

Round Tube at 45° (Mild Steel)

Wood at 90° (Nominal Size)

Wood at 45° (Nominal Size)

Minimum Cut Off Piece Length

SAW

355mm (14”) STEEL

CUTTING CHOP SAW

METRIC IMPERIAL

2200W 10A

1800W 16A

1800W 15A

2.4 2.4

-1

1450min

28kg 62lb

METRIC IMPERIAL

12mm 1/2”

120mm 4-3/4”

80mm 3-1/8”

95 x 180mm 3-3/4 x 7-1/8”

78 x 110mm 3 x 4-3/8”

130mm 5-1/8”

105mm 4-1/8”

89 x 184mm 4 x 8”

64 x 89mm 3 x 4”

8mm 5/16”

355

1450rpm

SAW

380mm (15”) STEEL

CUTTING CHOP SAW*

METRIC IMPERIAL

2200W 10A

1800W 16A

1800W 15A

2.4 2.4

-1

1450min

28kg 62lb

METRIC IMPERIAL

12mm 1/2”

127mm 5”

90mm 3-1/2”

95 x 200mm 3-3/4 x 7-7/8”

78 x 110mm 3 x 4-3/8”

150mm 5-7/8”

127mm 5”

89 x 184mm 4 x 8”

89 x 89mm 4 x 4”

8mm 5/16”

380

1450rpm

BLADE

Diameter

Bore / Arbor

Number of Teeth

Kerf

NOISE & VIBRATION DATA

Sound Pressure Level L

Sound Power Level L

Vibration Level

MODEL PART NUMBERS

United Kingdom

United States

Europe

PA

WA

METRIC IMPERIAL

355mm 14”

25mm 1”

66 66

1.7mm .094”

108 dB (A) K = 3 dB(A)

121 dB (A) K = 3 dB(A)

1.39 m/s2 K = 0.5 m/s

230V: 080-0001 110V: 080-0002

080-0002

080-0003

2

METRIC IMPERIAL

380mm 15”

25mm 1”

70 70

1.7mm .094”

108 dB (A) K = 3 dB(A)

121 dB (A) K = 3 dB(A)

1.39 m/s2 K = 0.5 m/s

230V: 080-0007 110V: 080-0008

080-0004

080-0009

2

*Supplied with a 355mm (14”) Steel blade. To achieve maximum capacities stated, t with a 380mm (15”) industrial saw blade.

6

Page 7

www.evolutionpowertools.com

(1.6) Note: The vibration measurement

was made under standard conditions in

accordance with: BS EN 61029-1:2009.

The declared vibration total value has been

measured in accordance with a standard test

method and may be used for comparing one

tool with another.

The declared vibration total value may also be

used in a preliminary assessment of exposure.

(1.7)

VIBRATION

WARNING: When using this machine the

operator can be exposed to high levels of

vibration transmitted to the hand and arm.

It is possible that the operator could develop

“Vibration white finger disease” (Raynaud

syndrome). This condition can reduce the

sensitivity of the hand to temperature as

well as producing general numbness.

Prolonged or regular users of this machine

should monitor the condition of their hands

and fingers closely. If any of the symptoms

become evident, seek immediate

medical advice.

• The measurement and assessment of

human exposure to hand-transmitted

vibration in the workplace is given in:

BS EN ISO 5349-1:2001 and

BS EN ISO 5349-2:2002.

Handling

• Handle the machine with care, allowing

the machine to do the work.

• Avoid using excessive physical effort on

any of the machine’s controls.

• Consider your security and stability, and

the orientation of the machine during use.

Work Surface

• Consider the work surface material;

its condition, density, strength,

rigidity and orientation.

WARNING: The vibration emission during

actual use of the power tool can differ from

the declared total value depending on the

ways in which the tool is used.

The need to identify safety measures

and to protect the operator are based on

an estimation of exposure in the actual

conditions of use (taking account all parts

of the operating cycle, such as the times the

tool is switched off, when it is running idle,

in addition to trigger time).

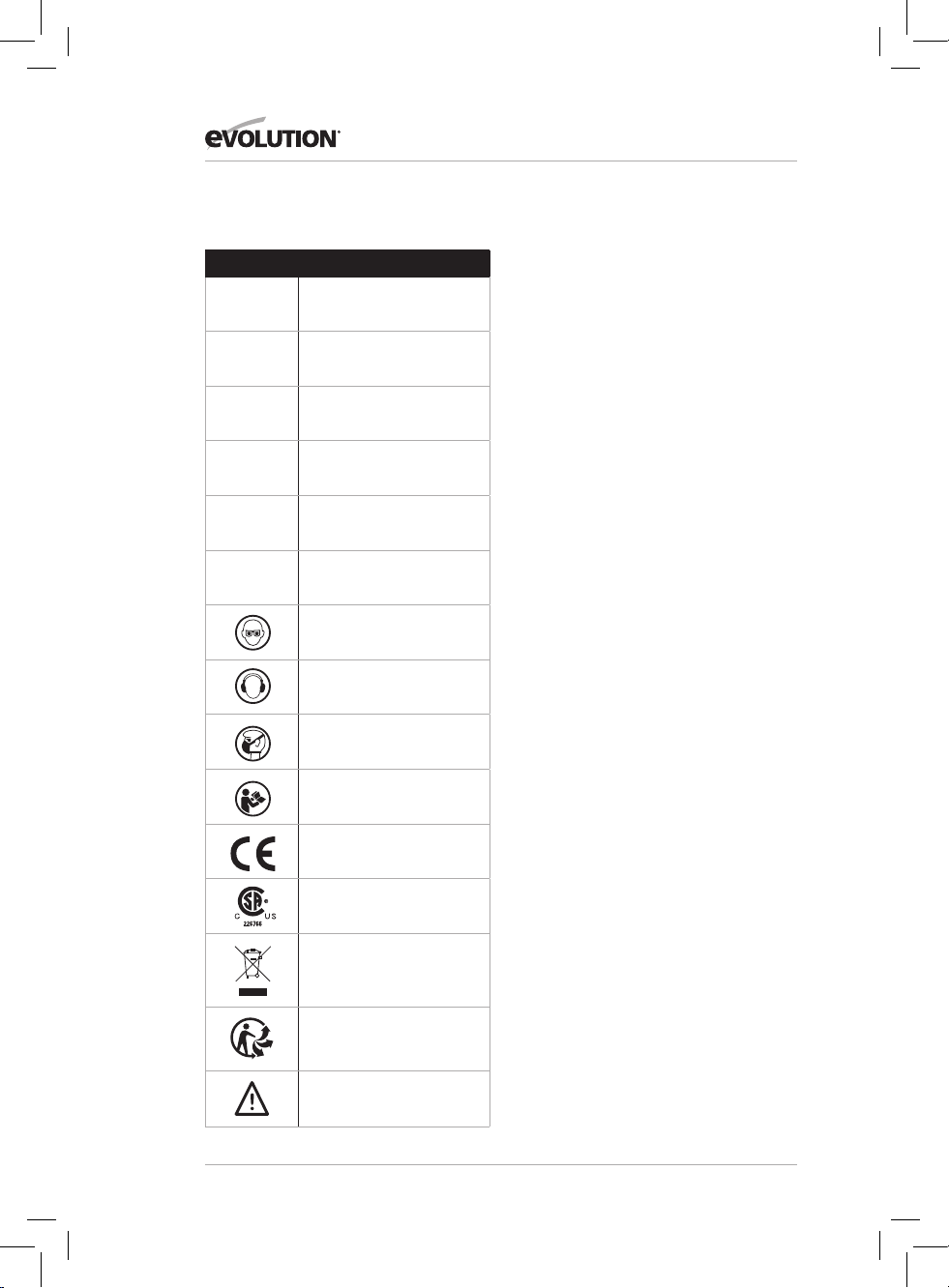

(1.8)

LABELS & SYMBOLS

WARNING: Do not operate this machine

if warning and/or instruction labels are

missing or damaged. Contact Evolution

Power Tools for replacement labels.

Note: All or some of the following symbols

may appear in the manual or on the product.

EN

ES

• Many factors can influence the actual

vibration level during operation e.g. the

work surfaces condition and orientation

and the type and condition of the machine

being used. Before each use, such factors

should be assessed, and where possible

appropriate working practices adopted.

Managing these factors can help reduce

the effects of vibration:

FR

7

Page 8

www.evolutionpowertools.com

(1.9)

Symbol Description

V

A

Amperes

Hz

-1

Min

~

n

o

Alternating Current

No Load Speed

Wear Safety Goggles

Wear Ear Protection

Wear Dust Protection

Read Instructions

CE certification

CSA certification

Volts

Hertz

Speed

(1.10) INTENDED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Chop Saw and has been designed to be

used with special Evolution blades. Only use

accessories designed for use in this machine

and/or those recommended specifically

by Evolution Power Tools Ltd.

When fitted with an appropriate blade

this machine can be used to cut:

Mild Steel

Aluminium

Wood

Stainless Steel

(1.11) PROHIBITED USE

OF THIS POWER TOOL

WARNING: This product is a Hand Operated

Chop Saw and must only be used as such. It

must not be modified in any way, or used to

power any other equipment or drive any other

accessories other than those mentioned in this

Instruction Manual.

(1.13) WARNING: This machine is not

intended for use by persons (including

children) with reduced physical, sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning the safe

use of the machine by a person responsible

for their safety and who is competent

in its safe use.

Waste electrical and

electronic equipment

Triman - Waste Collection

& Recycling

Warning

Children should be supervised to ensure

that they do not have access to, and are

not allowed to play with, this machine.

8

Page 9

www.evolutionpowertools.com

(1.14) ELECTRICAL SAFETY

This machine is fitted with the correct

moulded plug and mains lead for the

designated market. If the supply cord is

damaged, it must be replaced by a special

cord or assembly available from the

manufacturers or its service agent.

(1.15) OUTDOOR USE

WARNING: For your protection if this tool is to

be used outdoors it should not be exposed to

rain, or used in damp locations. Do not place

the tool on damp surfaces. Use a clean, dry

workbench if available. For added protection

use a residual current device (R.C.D.) that will

interrupt the supply if the leakage current to

earth exceeds 30mA for 30ms. Always check

the operation of the residual current device

(R.C.D.) before using the machine.

If an extension cable is required it must be a

suitable type for use outdoors and so labelled.

The manufacturer’s instructions should be

followed when using an extension cable.

(2.1) POWER TOOL GENERAL

SAFETY INSTRUCTIONS

(These General Power Tool Safety Instructions

are as specified in BS EN 60745-1:2009

& EN 61029-1:2009).

WARNING: Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/ or serious injury.

Save all warnings and instructions for

future reference. The term “power tool” in

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

(2.2) 1) General Power Tool

Safety Warnings [Work area safety]

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating power tool. Distractions can cause

you to lose control.

(2.3) 2) General Power Tool Safety

Warnings [Electrical Safety]

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce the risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of

electric shock.

EN

ES

FR

9

Page 10

www.evolutionpowertools.com

(2.4) 3) General Power Tool Safety

Warnings [Personal Safety].

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust masks, non-skid safety

shoes, hard hat or hearing protection used

for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

the power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of

a power tool may result in personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables better

control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure that these are connected and

properly used. Use of dust collection

can reduce dust-related hazards.

(2.5) 4) General Power Tool Safety

Warnings [Power tool use and care].

a) Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at a rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on or off. Any power tool

that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the power tool from the

power source and/or battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools. Such preventative safety measures

reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

Instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of moving parts and any other

condition that may affect the power tools

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

10

Page 11

www.evolutionpowertools.com

(2.6) 5) General Power Tool

Safety Warnings [Service]

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

(2.7)

HEALTH ADVICE

WARNING: When using this machine, dust

particles may be produced. In some instances,

depending on the materials you are working

with, this dust can be particularly harmful.

If you suspect that paint on the surface

of material you wish to cut contains lead,

seek professional advice. Lead based paints

should only be removed by a professional

and you should not attempt to remove it

yourself. Once the dust has been deposited

on surfaces, hand to mouth contact can result

in the ingestion of lead. Exposure to even

low levels of lead can cause irreversible brain

and nervous system damage. The young and

unborn children are particularly vulnerable.

You are advised to consider the risks

associated with the materials you are working

with and to reduce the risk of exposure. As

some materials can produce dust that may be

hazardous to your health, we recommend the

use of an approved face mask with replaceable

lters when using this machine.

You should always:

• Work in a well-ventilated area.

• Work with approved safety equipment, such

as dust masks that are specially designed to

lter microscopic particles.

(2.8)

WARNING: The operation of any power tool

can result in foreign objects being thrown

towards your eyes, which could result in

severe eye damage. Before beginning power

tool operation, always wear safety goggles

or safety glasses with side shield or a full face

shield where necessary.

(3.0)

ADDITIONAL SAFETY

INSTRUCTIONS

(3.1)

a) DANGER: Keep hands away from cutting

area and the blade. Keep your second

hand on auxiliary handle, or motor

housing. If both hands are holding the saw,

they cannot be cut by the blade.

b) Do not reach underneath the workpiece.

The guard cannot protect you from the blade

below the workpiece.

c) Adjust the cutting depth to the

thickness of the workpiece. Less than a

full tooth of the blade teeth should be visible

below the workpiece.

d) Never hold piece being cut in your

hands or across your leg. Secure the

workpiece to a stable platform. It is

important to support the work properly to

minimize body exposure, blade binding, or

loss of control.

e) Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will also make exposed metal parts of the

power tool “live” and shock the operator.

f) When ripping always use a rip fence

or straight edge guide. This improves the

accuracy of cut and reduces the chance of

blade binding.

g) Always use blades with correct size and

shape (diamond versus round) of arbor

holes. Blades that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

h) Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety of

operation.

i) Do not use High Speed Steel (HSS) saw

blades.

j) Inspect the machine and the blade

before each use. Do not use deformed,

cracked, worn or otherwise damaged blades.

EN

ES

FR

11

Page 12

www.evolutionpowertools.com

k) Never use the saw without the original

guard protection system. Do not lock the

moving guard in the open position. Ensure that

the guard operates freely without jamming.

l) Only use blades that comply with the

characteristics specied in this manual.

Before using accessories, always compare the

maximum allowed RPM of the accessory with

the RPM of the machine.

(3.2)

Causes and operator prevention of kickback:

Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator:

1. When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator.

2. If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the

workpiece causing the blade to climb out of

the kerf and jump back towards the operator.

(3.3)

Kickback is the result of saw misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a) Maintain a rm grip with both hands on

the saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line

with the blade. Kickback could cause the

saw to jump backwards, but kickback forces

can be controlled by the operator, if proper

precautions are taken.

b) If the blades are binding, or when

interrupting a cut for any reason, release

the trigger and hold the saw motionless

in the material until the blades come to a

complete stop. Never attempt to remove

the saw from the work or pull the saw

backward while the blades are in motion

or kickback may occur. Investigate and take

corrective actions to eliminate the cause of

blade binding.

c) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw

is restarted.

d) Support large panels to minimise the

risk of blade pinching and kickback. Large

panels tend to sag under their own weight.

Supports must be placed under the panel on

both sides, near the line of cut and near the

edge of the panel.

e) Blade depth and bevel adjusting

locking levers must be tight and secure

before making a cut. If the blade adjustment

shifts while cutting it may cause binding and

kickback.

f) Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce a narrow kerf causing excessive

friction, blade binding and kickback.

g) Use extra caution when making a

“plunge cut” into existing walls or other

blind areas. The protruding blade may cut

objects that can cause kickback.

h) Check lower guard for proper closing

before each use. Do not operate the saw

if lower guard does not move freely and

close instantly. Never clamp or tie the

lower guard into the open position. If saw

is accidentally dropped, lower guard may be

bent. Raise the lower guard with the retracting

handle (if equipped) and make sure it moves

freely and does not touch the blade or any

other part, in all angles and depths of cut.

12

Page 13

www.evolutionpowertools.com

i) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use. Lower guard may operate

sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

j) Lower guard may be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard

by retracting handle and as soon as blade

enters the material, the lower guard must

be released. For all other sawing, the lower

guard should operate automatically.

k) Always observe that the lower guard

is covering the blade before placing

saw down on a bench or the oor. An

unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in

its path. Be aware of the time it takes for the

blade to stop after switch is released.

(3.4)

WARNING: If any parts are missing, do not

operate your machine until the missing parts

are replaced. Failure to follow this rule could

result in serious personal injury.

(4.1)

GETTING STARTED - UNPACKING

Do not throw the packaging away;

keep it safe throughout the guarantee

period. Dispose of the packaging in an

environmentally responsible manner.

Recycle if possible.

Do not let children play with empty plastic

bags due to the risk of suffocation.

(4.2)

ITEMS SUPPLIED

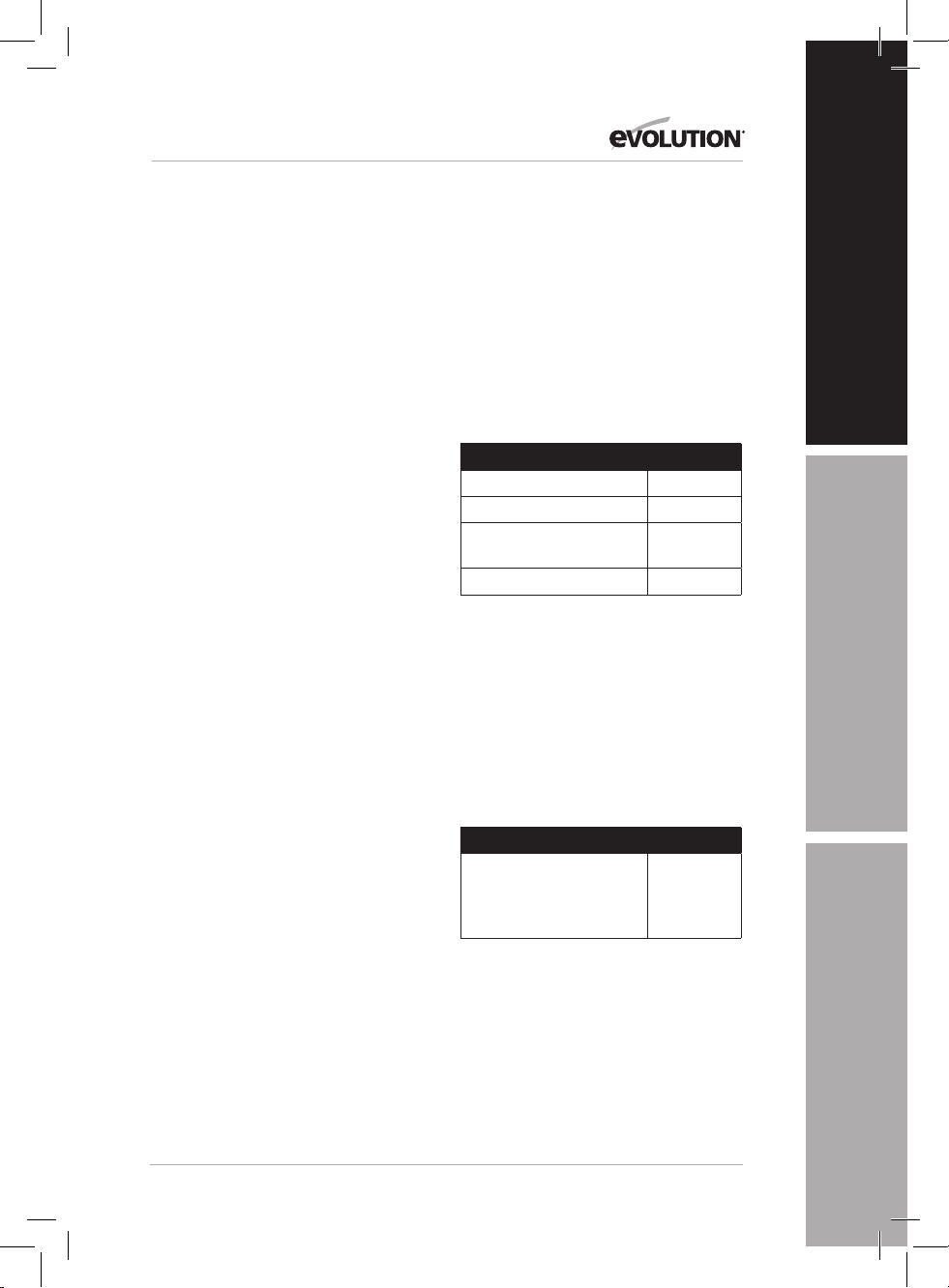

Description Quantity

Instruction Manual 1

Steel Cutting Blade 1

Hex Key 8mm

(Blade Change)

‘V’ Clamp Jaw 1

4.3

1

ADDITIONAL ACCESSORIES

In addition to the standard items supplied

with this machine the following accessories

are also available from the Evolution online

shop at www.evolutionpowertools.com

or from your local retailer.

EN

ES

Caution: This packaging contains sharp

objects. Take care when unpacking. Remove

the machine, together with the accessories

supplied from the packaging. Check carefully

to ensure that the machine is in good

condition and account for all the accessories

listed in this manual. Also make sure that all

the accessories are complete. If any parts

are found to be missing, the machine and its

accessories should be returned together in

their original packaging to the retailer.

(4.4)

Description Part No

Material specific cutting

blades (use only Evolution

Blades or Evolution approved

blades with this machine)

13

Specific to

blade type

FR

Page 14

www.evolutionpowertools.com

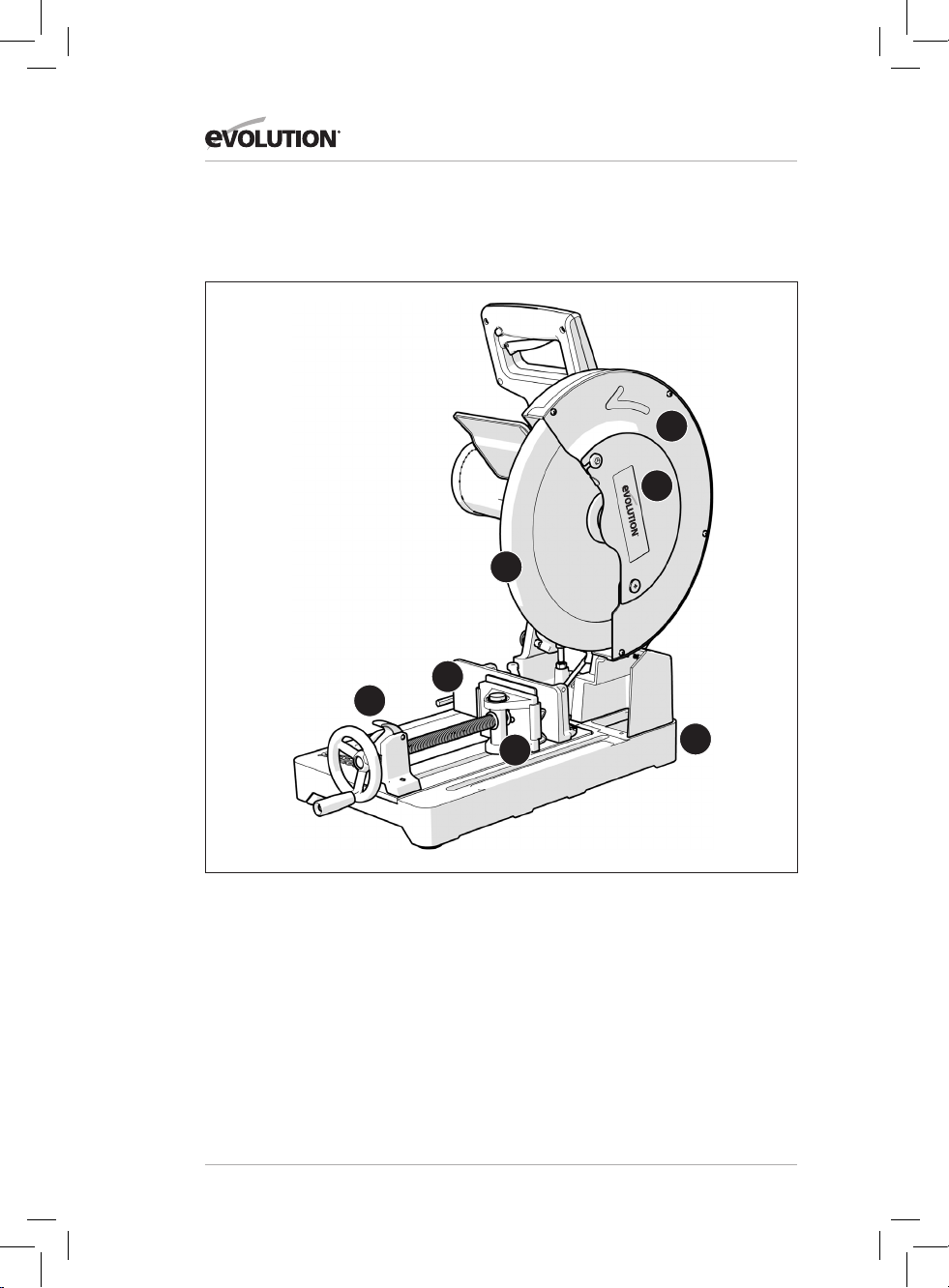

MACHINE OVERVIEW

A parts diagram can be downloaded from www.evolutionpowertools.com.

1

3

7

4

5

1. Lower Blade Guard

2. Front Swivelling Vise Jaw

3. Repositionable Rear Vise Jaw

4. Upper Blade Guard

2

5. Arbor Guard

6. Chip Collection Tray

7. Quick Release ‘Split Nut’

(North American Market Only).

14

6

Page 15

www.evolutionpowertools.com

(>5.5)

GETTING STARTED - PREPARATION

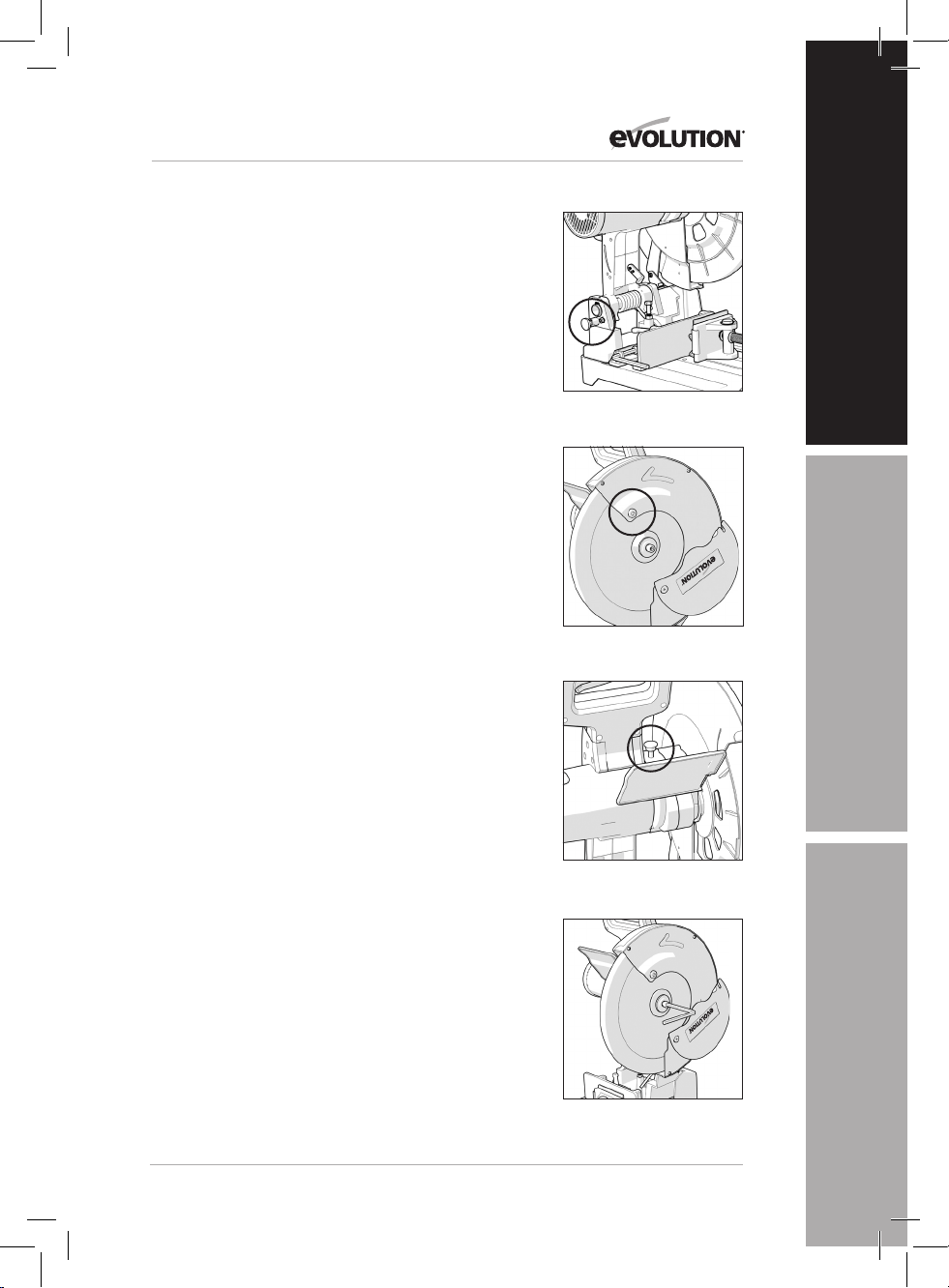

RELEASING the CUTTING HEAD

The cutting head will automatically rise to the upper position

once it is released from the locked down position.

To Release the cutting head from

the Locked Down position: (5.5<)

• Gently press down on the cutting handle.

• Pull out the head latching pin and lock in the outer position

(Fig. 1) Allow the cutting head to rise to its upper position.

If Release is Dicult:

• Gently rock the cutting head up and down.

• Pull the latching pin fully out and turn 1/4 of a turn to lock in

the outer position.

Note: We recommend that when the machine is not in use the

cutting head is locked in its down position with the latching pin

fully engaged in its socket.

(>5.1)

INSTALLING or REMOVING a BLADE

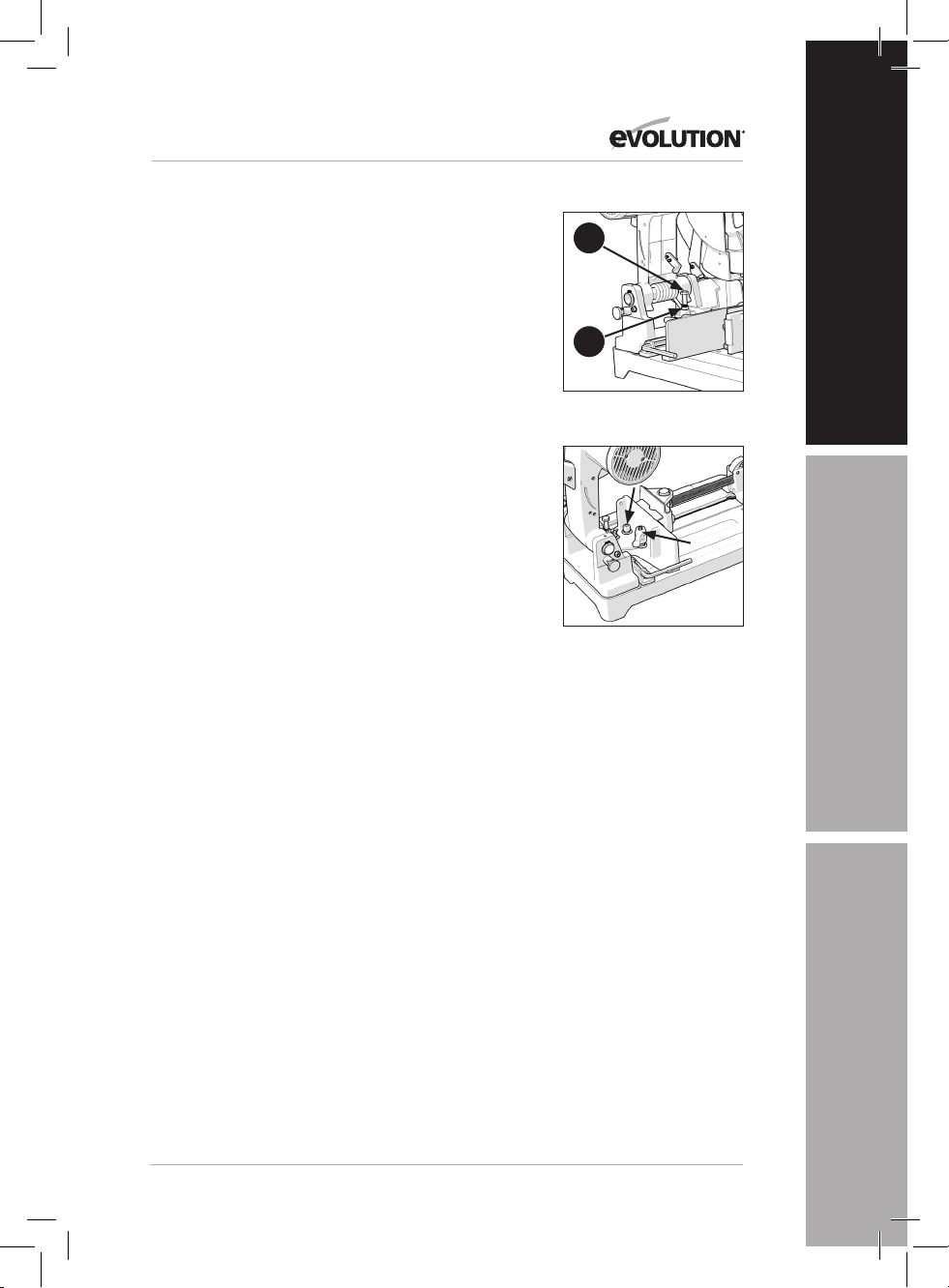

Fig. 1

Fig. 2

EN

ES

WARNING: Only use genuine Evolution blades, or Evolution

approved blades which are designed for this machine. Ensure

that the maximum recommended blade speed of the blade is

compatible with the machine.

WARNING: Only perform this operation with the machine

disconnected from the power supply.

Note: It is recommended that the operator considers wearing

protective gloves when handling the blade during installation

or when changing the machine’s blade. (< 5.1)

(5.6)

Removing a Blade:

• Ensure that the cutting head is in its upper position.

• Loosen the fastener screw securing the arbor guard and rotate

the guard upwards to reveal the machine’s arbor. (Fig. 2)

• Engage the arbor lock by pressing the arbor lock button.

(Fig. 3)

• Use the supplied hex key to loosen the arbor screw. (Fig. 4)

15

Fig. 3

FR

Fig. 4

Page 16

www.evolutionpowertools.com

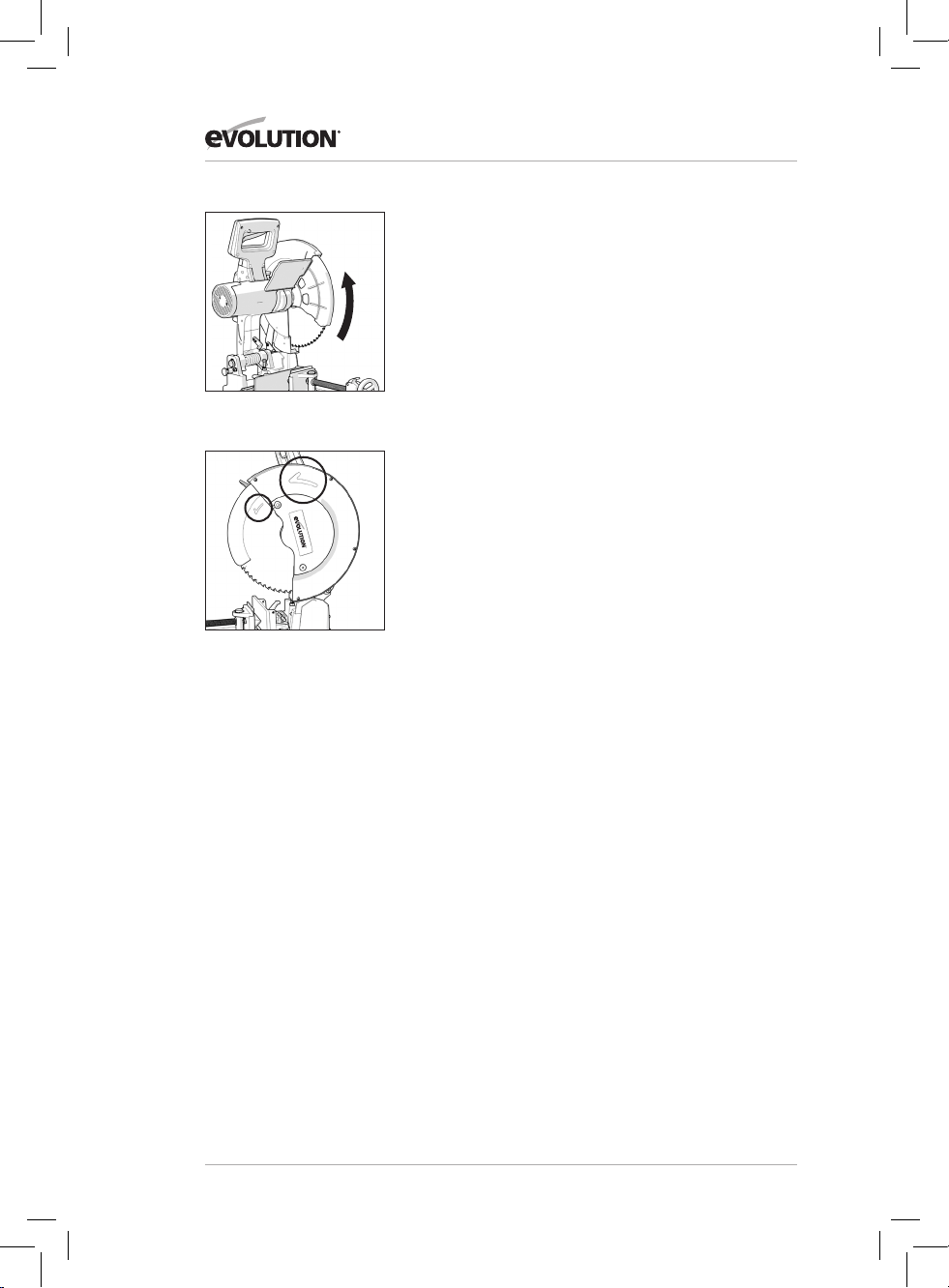

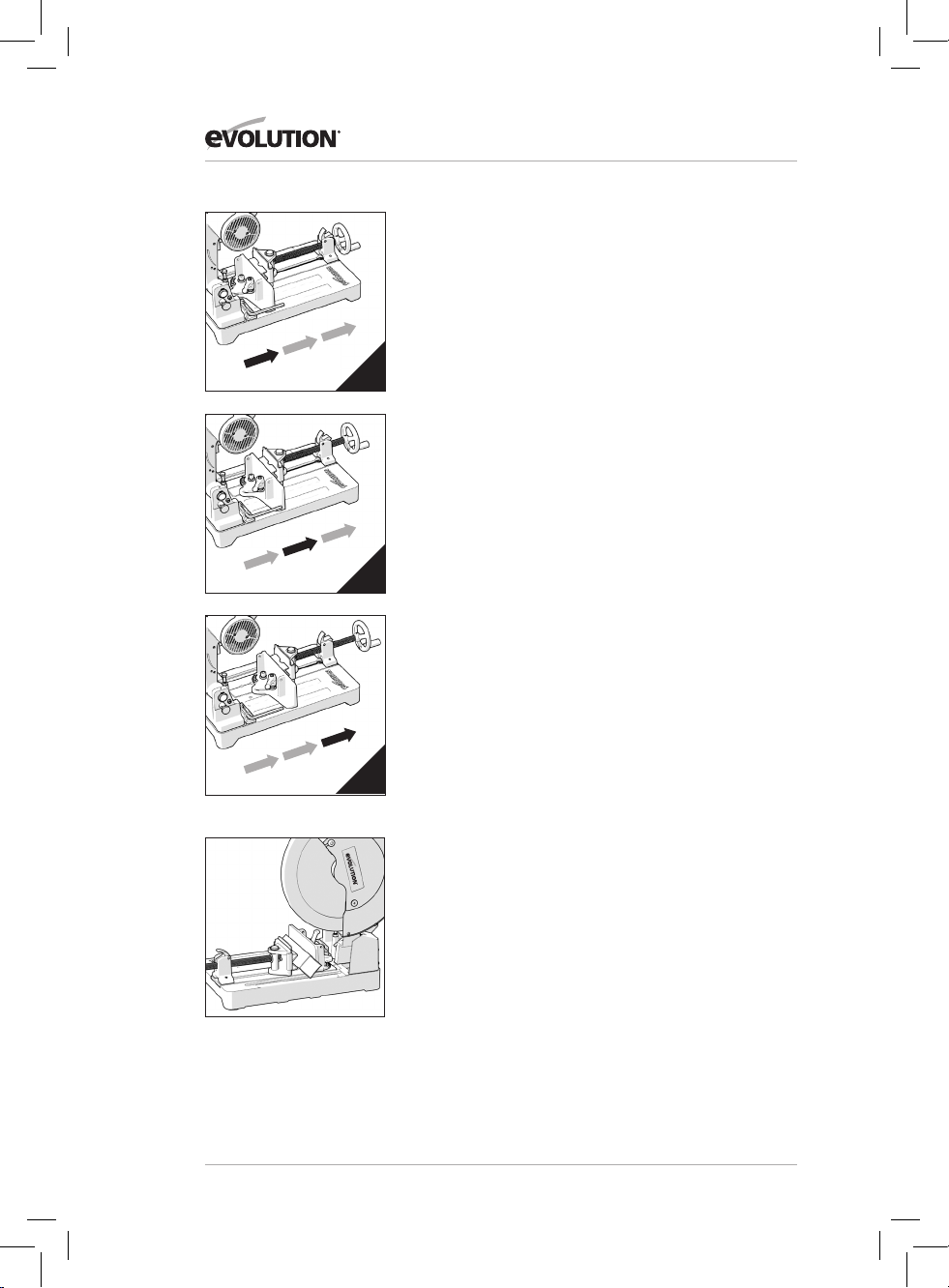

Note: The arbor screw has a right hand thread. Turn clockwise

to tighten. Turn counterclockwise to loosen.

• Remove the arbor screw, washer and outer blade ange and

store safely for future installation.

• Retract the lower blade guard up into the upper blade guard

by rotating it by hand. (Fig. 5)

• Remove the blade, leaving the inner blade ange in its

service position.

Fig. 5

Fig. 6

(5.7)

Installing a Blade:

• Ensure that all components are free from dirt and debris.

• Install the blade onto the inner blade ange and arbor,

ensuring that the direction and rotation arrow on the

blade matches the direction of arrow rotation found on the

machine’s upper blade guard. (Fig. 6)

• Reinstall the outer blade ange, washer and arbor screw.

• Lock the arbor by pressing the arbor lock button.

• Tighten the arbor screw using the 8mm hex key.

• Return the arbor guard to its service position and tighten the

cross head screw.

• Check that the arbor lock has been released by rotating the

blade by hand.

• Ensure that the hex key is removed from the arbor screw and

is safely stored for future use.

• Check the installation, and particularly the operation of the

retractable lower blade guards by lowering and raising the

cutting head a few times.

(5.8 )

WARNING: After installing a new blade, always run the

machine, without load, for a couple of minutes. Stand away

from the blade. If the blade were to contain an undetected aw,

it could shatter during this trial run.

16

Page 17

www.evolutionpowertools.com

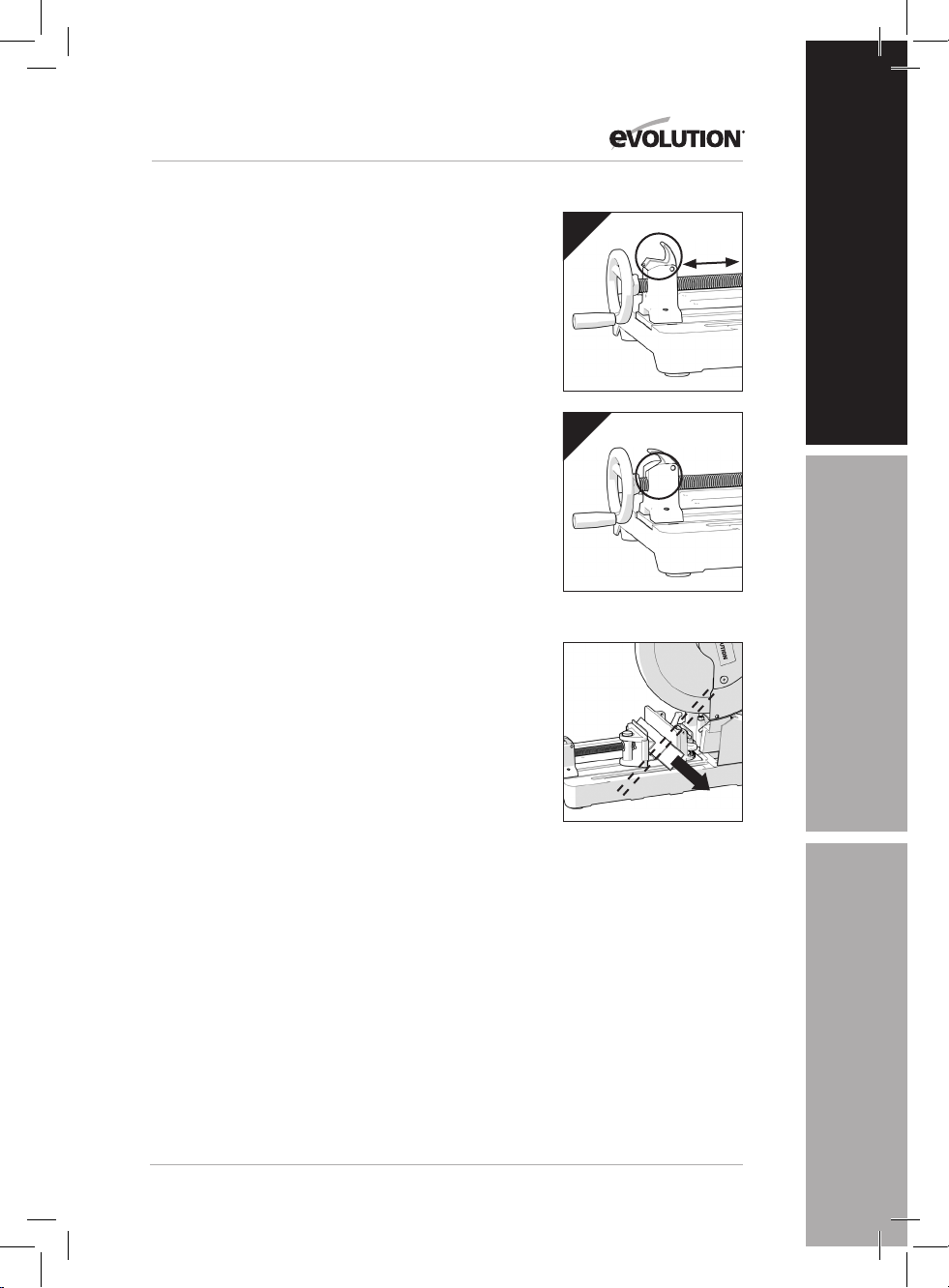

(5.9)

CUTTING HEAD TRAVEL

Cutting Head Downward Travel Adjustment

To prevent the blade from contacting any part of the

machine’s metal base the downward travel of the

cutting head can be adjusted.

Lower the cutting head and check for any blade contact with

the machine’s base.

If the downward travel of the cutting head needs to

be adjusted:

• Loosen the locknut on the downward travel stop screw.

(Fig. 7a)

• Turn the adjusting screw (Fig. 7b) out (counter-clockwise) to

decrease the downwards travel of the cutting head.

• Turn the adjusting screw in (clockwise) to increase the

downwards travel of the cutting head.

• Tighten the adjustment screw locknut when satisfactory

downward travel of the cutting head is achieved.

B

EN

A

Fig. 7

(5.10)

CUTTING ANGLE ADJUSTMENT

Note: The rear vise jaw can be turned through 450.

The rear vise jaw is factory set at 00 (at 900 to the blade) so that

the blade cuts squarely across material positioned in the vise.

For angled cuts, the rear vise jaw can be swung through (up to)

450, with a protractor scale being included on the vise jaw for

ease and accuracy of setting. (>5.10)

To angle the rear vise jaw:

• Loosen the M10 socket headed screw and the lever handled

locking screw. (Fig. 8)

• Turn the rear vise jaw to the required angle.

• Tighten the socket headed screw securely using the supplied

hex key and tighten the lever handled locking screw.

Note: The lever handle locking screw has a spring loaded

repositionable lever. Repositioning of the lever may be

necessary to ensure that the locking screw can be tightened

suciently when the rear vise jaw is angled. To reposition

the lever on the screw, pull the lever upwards and rotate the

lever to a convenient position (one that allows the screw to be

tightened) release the lever and tighten the screw. The front

vise jaw will automatically compensate for any set angle of the

rear jaw, or to accommodate irregular shaped workpieces.

17

Fig. 8

ES

FR

Page 18

Fig. 9

www.evolutionpowertools.com

REPOSITIONING THE REAR VISE JAW

The rear vise jaw can be removed from the machine’s base and

repositioned. (Fig.9)

To reposition:

• Remove the M10 socket headed screw and the lever handled

locking screw and all washers that secure the rear vise jaw to

1

2

the machine’s base.

• To remove the lever handled locking screw, pull the lever

upwards and hold against the spring while unscrewing the

locking screw from its service position using a flat bladed

screwdriver.

• Reposition the rear vise jaw; there are three (3) possible

positions available because of the six (6) threaded holes in

the machine’s base.

• Replace lever handled locking screw and the socket headed

screw into their new service positions. Ensure that all

standard and locking washers are correctly positioned.

Repositioning the rear vise jaw to the rear-most position will

enable wider pieces of material to be cut than is possible with

the rear vise jaw in either of the more forward positions.

‘V’ Clamp Jaw (If supplied)

The ‘V’ Clamp Jaw slips over the moving front vise jaw It should

be used when cutting round material as it provides greater

clamping security. It should also be used to cut square tube in a

diamond position (Fig. 10).

3

Fig. 10

18

Page 19

www.evolutionpowertools.com

QUICK VISE ADJUSTMENT MECHANISM

NORTH AMERICAN MARKET ONLY

For speed and convenience, the vise operating mechanism is

equipped with a ‘split nut’. Using this enables rapid adjustment

of the front vise jaw.

• Lift the ‘split nut’. (Fig. 11a)

• Slide the front jaw to the required position.

• Return the ‘split nut’ to its service position. (Fig 11b)

WARNING: The ‘split nut’ must be returned to its service position

and be fully engaged with the threads on the long vise screw.

Pulling back slightly on the vise handle just before the vise jaw

contacts the workpiece will help the correct seating of the ‘split

nut. Using this machine without the ‘split nut’ fully engaged with

the vise screw threads is dangerous and must not be attempted.

• Tighten the vise to secure the workpiece.

• Check the security of the workpiece before attempting a cut.

(>5.2)

OPERATING INSTRUCTIONS

PREPARING TO MAKE A CUT

Do not overreach. Keep good footing and balance. Stand

to one side so that your face and body are out of line

of a possible kickback.

Caution: The minimum cut o piece must be 8mm (5/16”) or

greater in length to avoid the piece falling through the blade

slot and causing any potential danger. (Fig 12)

WARNING: Freehand cutting is a major cause of accidents and

should not be attempted.

A

EN

B

Fig. 11

ES

8mm (5/16”) +

Fig. 12

• Ensure that the workpiece is rmly secured in the vise.

• The machine’s base should be clean and free from any swarf or

sawdust etc. before the workpiece is clamped into position.

• Ensure that the ‘cut-o’ material is free to move sideways away

from the blade when the cut is completed. Ensure that the ‘cut-o’

piece cannot become ‘jammed’ in any other part of the machine.

• Do not use this saw to cut small pieces. If the workpiece

being cut would cause your hand or ngers to be within

150mm of the saw blade, the workpiece is too small.

Angles should be clamped in an inverted position so that the

point of the section is uppermost. (<5.2)

19

FR

Page 20

www.evolutionpowertools.com

(5.4)

THE ON/OFF TRIGGER SWITCH

This machine is equipped with a safety start

trigger switch.

To start the tool:

• Push in the safety lock button on the side of

the handle with your thumb.

• Depress the main trigger switch to start the

motor.

WARNING: Never start the saw with the

cutting edge of the saw blade in contact with

the workpiece surface.

(5.3)

MAKING A CUT

• With the cutting head in the upper position,

switch on the motor and allow it to reach

full operational speed.

• Gently lower the cutting head.

• Introduce the blade into the material slowly,

using light pressure at rst to keep the

blade from grabbing.

• Gradually increase the pressure as a blade

enters the workpiece. Do not ‘force’ the

machine. Let the saw blade do the work.

Note: Cutting performance will not improve

by applying undue pressure on the machine,

and doing so may cause blade and motor life

to be reduced.

• Reduce the pressure as the blade begins to

exit the material.

• On completion of a cut allow the cutting

head to return to its upper position, and

turn o the motor.

• Only remove your hands, or the workpiece

from the machine, after the motor has

completely stopped and the stationary

blade is covered by the lower blade guard.

(6)

MAINTENANCE

(6.1)

Note: Any maintenance must be carried

out with the machine switched o and

disconnected from the mains/battery

power supply.

Check that all safety features and guards are

operating correctly on a regular basis. Only use

this machine if all guards/safety features are

fully operational.

All motor bearings in this machine are

lubricated for life. No further lubrication is

required.

Use a clean, slightly damp cloth to clean

the plastic parts of the machine. Do not use

solvents or similar products which could

damage the plastic parts.

WARNING: Do not attempt to clean by

inserting pointed objects through openings

in the machine’s casings etc. The machine’s

air vents should be cleaned using compressed

dry air.

Excessive sparking may indicate the presence of

dirt in the motor or worn out carbon brushes.

(>6.2)

If this is suspected have the machine serviced

and the brushes replaced by a qualied

technician with Evolution recommended

brushes. (<6.2)

20

Page 21

www.evolutionpowertools.com

CHIP COLLECTION TRAY

The chip collection tray should be emptied

at regular intervals. We recommend that for

eciency purposes the tray be emptied when

it is approximately 60% full.

To check the Chip Collection Tray:

• Turn the locking lever to the horizontal

position and withdraw the tray from the

machine to check the contents.

• Empty the contents of the tray into a

suitable recycling bin.

• It may be necessary to wear a dust mask

when emptying the chip collection tray.

• Replace the chip collection tray and return the

locking lever to the vertical position to secure

the tray within the machine’s base.

TRANSPORTATION/STORAGE

For ease and convenience, when transporting

or storing the machine, the cutting head can

be held in the ‘down’ position.

(6.4)

ENVIRONMENTAL PROTECTION

EN

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

local authority or retailer for recycling advice.

ES

To hold the cutting head down:

• Lower the cutting head to its lowest position.

• Rotate the cutting head Locking Pin 1/4 of

a turn and allow it to deploy to the ‘locked

down’ position.

FR

21

Page 22

www.evolutionpowertools.com

EC DECLARATION OF CONFORMITY

In accordance with EN ISO 17050-1:2004

The manufacturer of the product covered by this Declaration is:

Evolution Power Tools, Venture One, Longacre Close, Holbrook Industrial Estate, Sheffield, S20 3FR.

The manufacturer hereby declares that the machine as detailed in this declaration fulfils all the

relevant provisions of the Machinery Directive and other appropriate directives as detailed below.

The manufacture further declares that the machine as detailed in this declaration, where

applicable, fulfils the relevant provisions of the Essential Health and Safety requirements.

The Directives covered by this Declaration are as detailed below:

2006/42/EC. Machinery Directive.

2014/30/EU. Electromagnetic Compatibility Directive.

2011/65/EU. The Restriction of the Use of certain Hazardous

Substances in Electrical Equipment (RoHS) Directive.

2002/96/EC as The Waste Electrical and Electronic Equipment (WEEE) Directive.

amended by

2003/108/EC .

And is in conformity with the applicable requirements of the following documents:

EN13898:2003+A1:2009

EN 60204-1:2006+ A1:2009

EN 55014-1:2006+A1:2009+A2:2011

EN 55014-2:1997+A1:2001:A2:2008

EN 61000-3-2:2014

EN 61000-3-3:2013

SAW

355

Product Details

Description: EVOSAW355 355mm (14”) STEEL CUTTING CHOP SAW

Evolution Model No: 080-0001 / 080-0002 / 080-0003 / 080-0003A

Brand Name: EVOLUTION

Voltage: 230 - 240v ~ 50Hz

Input: 2200W

The technical documentation required to demonstrate that the product meets the requirements

of directive has been compiled and is available for inspection by the relevant enforcement

authorities, and verifies that our technical file contains the documents listed above

and that they are the correct standards for the product as detailed above.

Name and address of technical documentation holder.

Signed: Print: Matthew Gavins - Operations Director

Date: 01/02/2017

22

Page 23

www.evolutionpowertools.com

NOTES

EN

ES

23

FR

Page 24

Page 25

EN

ESPAÑOL

La traducción de la original

ES

FR

Page 26

www.evolutionpowertools.com

ÍNDICE

English Page 2

Español Página 24

Français Page 48

INTRODUCCIÓN

Garantía Página 27

Características técnicas de la máquina Página 28

Vibraciones Página 29

Etiquetas y símbolos Página 29

Uso previsto de esta herramienta eléctrica Página 30

Uso prohibido de esta herramienta eléctrica Página 30

PRECAUCIONES DE SEGURIDAD

Seguridad eléctrica Página 31

Uso en exteriores Página 31

Instrucciones generales de seguridad de la herramienta eléctrica Página 31

Instrucciones adicionales de seguridad Página 34

PRIMEROS PASOS

Desembalaje Página 37

Descripción general de la máquina Página 38

Montaje y preparación Página 39

Instrucciones de funcionamiento Página 43

MANTENIMIENTO

Protección medioambiental Página 45

DECLARACIÓN DE CONFORMIDAD Página 46

26

Page 27

www.evolutionpowertools.com

1.2

ESTE MANUAL DE

INSTRUCCIONES SE ESCRIBIÓ

ORIGINALMENTE EN INGLÉS

(1.3)

IMPORTANTE

Por favor, lea estas instrucciones de uso

y seguridad atentamente y por completo.

Por su propia seguridad, si no está seguro

de algún aspecto sobre el uso de este equipo

contacte con Asistencia Técnica. Puede

encontrar el número de teléfono en la página

web de Evolution Power Tools. Nuestra

organización dispone de varios teléfonos de

asistencia en todo el mundo. Su proveedor

también puede ofrecerle asistencia técnica.

WEB

www.evolutionpowertools.com

(1.4) Enhorabuena por adquirir una máquina

de Evolution Power Tools. Por favor, complete

el registro de su producto en línea como

se explica en el formulario de registro de

garantía en línea A4 que acompaña a esta

máquina. También puede escanear el código

QR impreso en el formulario A4 con un Smart

Phone. Esto le permitirá validar el periodo

de garantía de su máquina a través de la

página web de Evolution al introducir sus

datos y asi disponer de un servicio rápido si

fuera necesario. Le estamos sinceramente

agradecidos por escoger uno de nuestros

productos Evolution Power Tools.

GARANTÍA LIMITADA DE EVOLUTION

Evolution Power Tools se reserva el derecho

a hacer mejoras y modificaciones al diseño

del producto sin previo aviso.

Por favor, consulte el formulario de

registro de garantía y/o el embalaje para

más detalles acerca de los términos

y condiciones de la garantía.

(1.5)

Evolution Power Tools reparará

o cambiará, dentro del periodo de garantía

y desde la fecha original de compra, cualquier

producto que sea defectuoso en materiales o

calidad. Esta garantía es nula si la herramienta

devuelta se ha usado sin seguir las

recomendaciones del manual de instrucciones

o si la máquina se ha dañado por accidente,

descuido o uso inapropiado.

Esta garantía no es aplicable a máquinas

y/o componentes que hayan sido alterados,

cambiados o modificados de alguna manera

o sometidos a un uso que no figure en las

capacidades y especificaciones recomendadas.

Los componentes eléctricos están sujetos

a las garantías de sus respectivos fabricantes.

Todos los objetos defectuosos devueltos se

devolverán tras haber pagado con antelación

el importe de su transporte a Evolution Power

Tools. Evolution Power Tools se reserva

el derecho a reparar o sustituir el producto

de manera opcional con el mismo producto

o uno equivalente.

No existe garantía, escrita o verbal, para

accesorios consumibles como (la siguiente

lista no es exhaustiva) hojas, cortadores,

taladros, cinceles o varillas, etc. Evolution

Power Tools no se hace responsable en ningún

caso de la pérdida o el daño causado directa

o indirectamente por el uso de nuestros

productos o por cualquier otra causa. Evolution

Power Tools no se hace responsable de ningún

coste de estos productos o los posibles daños.

Ningún funcionario, empleado o agente

de Evolution Power Tools está autorizado a

realizar representaciones orales de idoneidad

o a renunciar a cualquiera de los términos

anteriores de la venta, ni tendrán carácter

vinculante para Evolution Power Tools.

Las cuestiones relativas a esta garantía

limitada deben dirigirse a la oficina central

de la empresa o consultarse en el número

de asistencia adecuado.

EN

ES

FR

27

Page 28

www.evolutionpowertools.com

ESPECIFICACIONES DE LA MÁQUINA

Motor UK (230-240V ~ 50 Hz)

Motor UK (110V ~ 50 Hz)

Motor USA (120V ~ 60 Hz)

Caballo De Fuerza

Velocidad (Sin Carga)

Peso

CAPACIDAD DE CORTE

Placa De Acero Dulce (Espesor Max)

Tubo Cuadrado En 90° (Acero Al Carbono)

Tubo Cuadrado En 45° (Acero Al Carbono)

Tubo Rectangular En 90° (Acero Dulce)

Tubo Rectangular En 45° (Acero Dulce)

Tubo Redondo De 90° (Acero Al Carbono)

Tubo Redondo De 45° (Acero Al Carbono)

Wood A 90° (Tamaño Nominal)

Wood At 45° (Nominal Size)

Cut Off mínimo pedazo de cuerpo entero

355

SAW

355 mm (14“) DE ACERO

CORTE SAW CHOP

METRICA IMPERIAL

2200W 10A

1800W 16A

1800W 15A

2.4 2.4

-1

1450min

28kg 62lb

METRICA IMPERIAL

12mm 1/2”

120mm 4-3/4”

80mm 3-1/8”

95 x 180mm 3-3/4 x 7-1/8”

78 x 110mm 3 x 4-3/8”

130mm 5-1/8”

105mm 4-1/8”

89 x 184mm 4 x 8”

64 x 89mm 3 x 4”

8mm 5/16”

1450rpm

SAW

380 mm (15“) DE ACERO

CORTE SAW CHOP*

METRICA IMPERIAL

2200W 10A

1800W 16A

1800W 15A

2.4 2.4

-1

1450min

28kg 62lb

METRICA IMPERIAL

12mm 1/2”

127mm 5”

90mm 3-1/2”

95 x 200mm 3-3/4 x 7-7/8”

78 x 110mm 3 x 4-3/8”

150mm 5-7/8”

127mm 5”

89 x 184mm 4 x 8”

89 x 89mm 4 x 4”

8mm 5/16”

380

1450rpm

BLADE

Diameter

Bore / Arbor

Number of Teeth

Kerf

NOISE & VIBRATION DATA

Sound Pressure Level L

Sound Power Level L

Vibration Level

MODEL PART NUMBERS

United Kingdom

United States

Europe

*Se suministra con una hoja de acero de 355 mm (14“). Para alcanzar las capacidades máximas indicadas, se ajustan a una

hoja de sierra industrial 380 mm (15“).

PA

WA

METRIC IMPERIAL

355mm 14”

25mm 1”

66 66

1.7mm .094”

108 dB (A) K = 3 dB(A)

121 dB (A) K = 3 dB(A)

1.39 m/s2 K = 0.5 m/s

230V: 080-0001 110V: 080-0002

080-0002

080-0003

2

METRIC IMPERIAL

380mm 15”

25mm 1”

70 70

1.7mm .094”

108 dB (A) K = 3 dB(A)

121 dB (A) K = 3 dB(A)

1.39 m/s2 K = 0.5 m/s

230V: 080-0007 110V: 080-0008

080-0004

080-0009

2

28

Page 29

www.evolutionpowertools.com

(1.6) Nota: la medición de la vibración se

hizo en condiciones normales según la norma:

BS EN 61029-1:2009. El valor total de

vibración citado se ha medido según el

método normal de examen y puede usarse

para comparar una herramienta con otra.

El valor total de vibración citado también

puede usarse en la evaluación preliminar

de la exposición humana.

(1.7)

VIBRACIONES

ADVERTENCIA: al utilizar esta máquina, el

operador puede estar expuesto a altos niveles

de vibración transmitidos a la mano y el brazo.

Es posible que el operador pueda desarrollar

la “enfermedad del dedo blanco inducido

por vibración” (síndrome de Raynaud). Esta

enfermedad puede reducir la sensibilidad de

la mano a la temperatura, así como producir

entumecimiento general. Los usuarios que

utilicen esta máquina de manera prolongada

o regular deben vigilar de cerca el estado de

sus manos y dedos. Si aparece alguno de los

síntomas, busque atención médica inmediata.

• La medición y evaluación de la exposición

humana a vibraciones transmitidas a la

mano en el lugar de trabajo se recogen en

las normas: BS EN ISO 5349-1:2001

y BS EN ISO 5349-2:2002.

• Pueden influir muchos factores en

el nivel real de vibración durante el

funcionamiento, por ejemplo, el estado y

la orientación de la superficie de trabajo,

así como el tipo y el estado de la máquina

que se esté utilizando. Antes de cada uso,

se deben evaluar dichos factores y adoptar

prácticas de trabajo adecuadas donde sea

posible. La gestión de estos factores puede

ayudar a reducir los efectos de la vibración:

Manipulación:

• Manipule la máquina con cuidado,

permitiendo que esta haga el trabajo.

• Evite un esfuerzo físico excesivo en

cualquiera de los controles de las

máquinas.

• Tenga en cuenta su seguridad

y estabilidad, así como la orientación

de la máquina durante su uso.

Superficie de trabajo:

• Tenga en cuenta la superficie de trabajo,

su estado, densidad, resistencia,

rigidez y orientación.

ADVERTENCIA: la emisión de vibraciones

al usar la herramienta eléctrica puede variar

del valor total citado dependiendo de

la manera en la que se use la herramienta.

La necesidad de identificar medidas de

seguridad y de proteger al operador se

basa en una estimación de las condiciones

reales de uso (teniendo en cuenta todas las

partes del ciclo operativo, como las veces

que se desconecta la máquina, cuando está

en reposo, además del tiempo que está

funcionando de forma seguida).

(1.8)

ETIQUETAS Y SÍMBOLOS

ADVERTENCIA: no utilice la máquina

si la advertencia y/o las etiquetas de

instrucciones faltan o están dañadas.

Póngase en contacto con Evolution

Power Tools para sustituir las etiquetas.

Nota: todos o algunos de los siguientes

símbolos pueden aparecer en el manual

o en el producto.

EN

ES

FR

29

Page 30

www.evolutionpowertools.com

(1.9)

Símbolo Descripción

V

Amperes

Hertz

Acelerar

Corriente Alterna

Velocidad Sin Carga

Use Gafas De Seguridad

Lleve Protección Auditiva

Lea Las Instrucciones

Certificación CE

Certificación CSA

Los Residuos Eléctricos

Y Equipos Electrónicos

Triman - Recolección y

Reciclaje de Residuos

Hz

Min

N

A

-1

~

o

Utilice Protección Contra El Polvo

Volts

(1.10)

USO PREVISTO DE ESTA

HERRAMIENTA ELÉCTRICA

ADVERTENCIA: Este producto es una sierra

ingletadora de uso manual y ha sido diseñada

para usarse con hojas especiales Evolution.

Solo use accesorios diseñados para el uso

de esta máquina y/o aquellos recomendados

específicamente por Evolution Power

Tools Ltd.

Equipada con una hoja adecuada,

esta máquina puede cortar:

Acero dulce

Aluminio

Madera

(1.11)

USO PROHIBIDO DE

ESTA HERRAMIENTA ELÉCTRICA

ADVERTENCIA: Este producto es una sierra

ingletadora de uso manual y debe usarse solo

como tal. No debe ser modificada de ninguna

manera ni usada para alimentar ningún otro

equipo, así como llevar ningún otro accesorio

que no se nombre en el manual

de instrucciones.

(1.13) ADVERTENCIA: esta máquina

no está diseñada para ser utilizada por

personas (niños incluidos) con discapacidad

psíquica, sensorial o mental, o con falta de

experiencia y conocimiento, a no ser que

hayan sido supervisadas o instruidas en el

uso seguro de la máquina por una persona

responsable de su seguridad y competente en

el uso seguro de la misma. Debe supervisarse

a los niños para asegurarse de que no tienen

acceso a la máquina ni pueden jugar con ella.

Advertencia

30

Page 31

www.evolutionpowertools.com

(1.14)

SEGURIDAD ELÉCTRICA

Esta máquina está equipada con el enchufe

moldeado y el cable de red correctos para el

mercado designado. Si el cable de suministro

se daña, debe reemplazarse por un cable

o ensamblaje especial por los fabricantes

o su agente de servicios.

(1.15)

USO EN EXTERIORES

ADVERTENCIA: para su protección, si va

a usar esta herramienta en exteriores no

debe exponerla a la lluvia o usarla en lugares

húmedos. No coloque la herramienta en

superficies húmedas. Si es posible, use un

banco de trabajo limpio y seco. Para obtener

una mayor protección, utilice un dispositivo

de corriente residual que interrumpa el

suministro si la corriente de fuga a tierra es

superior a 30 mA por 30 ms. Revise siempre el

funcionamiento del dispositivo de corriente

residual antes de usar la máquina. Si es

necesario un alargador, debe ser de un tipo

adecuado para en exteriores y etiquetado para

tal fin. Se deben seguir las instrucciones de los

fabricantes al utilizar un alargador.

ADVERTENCIA: lea todas las

advertencias e instrucciones de seguridad.

El incumplimiento de las instrucciones y

advertencias puede provocar una descarga

eléctrica, incendios y/o lesiones graves.

Guarde todas las advertencias e instrucciones

para poder consultarlas en el futuro.

El término “herramienta eléctrica” de las

advertencias se refiere a la herramienta

alimentada por la red de alimentación

(con cable) o con baterías (inalámbrica).

(2.2) 1) Advertencias generales de

seguridad de la herramienta eléctrica

[Seguridad en el área de trabajo]

a) Mantenga la zona de trabajo limpia

y bien iluminada. Las zonas desordenadas

u oscuras pueden provocar accidentes.

b) No utilice las herramientas eléctricas en

atmósferas explosivas, como en presencia

de líquidos inflamables, gases o polvo. Las

herramientas eléctricas producen chispas

que pueden incendiar el polvo o los gases.

c) Mantenga a los niños y transeúntes

alejados cuando utilice una herramienta

eléctrica. Las distracciones pueden hacerle

perder el control.

EN

ES

(2.1) INSTRUCCIONES

GENERALES DE SEGURIDAD

PARA HERRAMIENTAS ELÉCTRICAS

(Estas instrucciones generales de seguridad

para herramientas eléctricas son las que se

especifican en las normas

BS EN 60745-1:2009 y EN 61029-1:2009).

FR

31

Page 32

www.evolutionpowertools.com

(2.3) 2) Advertencias generales de

seguridad de la herramienta eléctrica

[Seguridad eléctrica]

a) Los enchufes de la herramienta eléctrica

deben corresponderse con las tomas de

corriente. No modifique el enchufe en ningún

modo. No utilice adaptadores de enchufe con

las herramientas eléctricas conectadas a tierra.

Si las tomas de corriente coinciden y los

enchufes no se modifican, se reduce el riesgo

de descarga eléctrica.

b) Evite el contacto corporal con superficies

conectadas a tierra tales como tuberías,

radiadores, estufas y refrigeradores. El

riesgo de descarga eléctrica aumenta si su

cuerpo está conectado a tierra.

c) No exponga las herramientas eléctricas a

la lluvia o a la humedad. La entrada de agua

en una herramienta eléctrica aumentará el

riesgo de descarga eléctrica.

d) No maltrate el cable. Nunca use el cable

para transportar, tirar odesenchufar la

herramienta eléctrica. Mantenga el cable

lejos del calor, el aceite, las esquinas cortantes

o las piezas móviles. Los cables dañados

o enredados aumentan el riesgo de

descarga eléctrica.

e) Cuando trabaje con la herramienta

eléctrica en exteriores, use un alargador

adecuado para uso en exteriores. El uso

de un cable adecuado para uso en exteriores

reduce el riesgo de descarga eléctrica.

f) Si utiliza una herramienta eléctrica en

un lugar húmedo, es necesario utilizar

una toma de corriente protegida con un

dispositivo de corriente residual. El uso

de un dispositivo de corriente residual

reduce el riesgo de descarga eléctrica.

(2.4) 3) Advertencias generales de

seguridad de la herramienta eléctrica

[Seguridad personal]

a) Manténgase alerta, tenga cuidado con lo

que hace y use el sentido común al utilizar

una herramienta eléctrica. No utilice una

herramienta eléctrica cuando esté cansado

o bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción

mientras utiliza las herramientas eléctricas

puede ocasionar lesiones personales graves.

b) Utilice el equipo de protección personal.

Utilice siempre protección para los ojos.

El uso de equipo de seguridad, como

la máscara para el polvo, el calzado

antideslizante, el casco o la protección

para los oídos en las circunstancias donde

corresponda, reducirá las lesiones personales.

c) Evite el encendido accidental. Asegúrese

de que el interruptor está en la posición de

apagado antes de conectarlo a la fuente

de alimentación o la batería, y al levantar

o transportar la herramienta. Transportar

herramientas eléctricas con el dedo sobre

el interruptor o activar las herramientas

eléctricas con el interruptor de encendido

puede provocar accidentes.

d) Quite las llaves de ajuste o inglesa antes

de encender la herramienta eléctrica.

Una llave, como la llave inglesa, colocada en

una pieza giratoria de la herramienta eléctrica

puede ocasionar lesiones personales.

e) No se extralimite. Mantenga la postura y

equilibrio en todo momento. Esto permitirá

un mejor control de la herramienta eléctrica

en situaciones inesperadas.

f) Vístase de manera adecuada. No use ropa

suelta ni joyas. Mantenga su cabello, la ropa

y los guantes alejados de las piezas móviles. La

ropa suelta, las joyas o el cabello largo pueden

quedar atrapados en las piezas móviles.

32

Page 33

www.evolutionpowertools.com

g) Si se proporcionan dispositivos para la

conexión de extracción y recolección de

polvo, asegúrese de que estén conectados

y que se utilizan correctamente.

El uso de estos dispositivos puede reducir

los riesgos derivados del polvo.

(2.5) 4) Advertencias generales de

seguridad de la herramienta eléctrica

[Uso y cuidado de la herramienta eléctrica].

a) No fuerce la herramienta eléctrica.

Utilice la herramienta correcta para su uso.

La herramienta correcta realizará el trabajo

de una forma más precisa y segura cuando

se emplee a la velocidad para la cual

fue diseñada.

b) No utilice la herramienta eléctrica si

el interruptor no se enciende ni se apaga.

Las herramientas eléctricas que no se puedan

controlar con el interruptor son peligrosas

y se deben reparar.

c) Desconecte la herramienta eléctrica de

la fuente de alimentación y/o el paquete

de baterías de la herramienta eléctrica

antes de hacer cualquier ajuste, cambio de

accesorios o de almacenar las herramientas

eléctricas. Estas medidas preventivas

de seguridad reducen el riesgo de que

la herramienta eléctrica se inicie de

forma accidental.

d) Guarde las herramientas eléctricas fuera

del alcance de los niños y no permita que

personas no familiarizadas con ellas o con

estas instrucciones puedan utilizarlas.

Las herramientas eléctricas son peligrosas

en manos de personas inexpertas.

e) Realice un mantenimiento de las

herramientas eléctricas. Verifique la

alineación y fijación de las piezas móviles,

la rotura de dichas piezas y cualquier

otra condición que pueda afectar al

funcionamiento de la herramienta eléctrica.

Si está dañada, repare la herramienta eléctrica

antes de utilizarla. Muchos accidentes se

producen debido a un mantenimiento

deficiente de las herramientas eléctricas.

f) Mantenga las herramientas de corte

limpias y afiladas. Las herramientas de corte

que se han mantenido con los bordes afilados

son menos propensas a trabarse y son más

fáciles de controlar.

g) Utilice la herramienta eléctrica, los

accesorios y útiles, etc., de acuerdo con

estas instrucciones, teniendo en cuenta las

condiciones de trabajo y el trabajo que se

va a realizar. El uso de la herramienta eléctrica

para operaciones diferentes a las pretendidas

podría dar lugar a una situación peligrosa.

(2.6) 5) Advertencias generales

de seguridad de la herramienta

eléctrica [Servicio]

a) Lleve la herramienta eléctrica a reparar

a un experto cualificado que utilice

solo piezas de repuesto originales.

Esto garantizará que se mantiene la seguridad

de la herramienta eléctrica correctamente.

EN

ES

33

FR

Page 34

www.evolutionpowertools.com

(2.7)

CONSEJOS PARA SU SALUD

ADVERTENCIA: al utilizar esta máquina

se pueden producir partículas de polvo.

En ocasiones, dependiendo de los materiales

con los que trabaje, este polvo puede ser

especialmente perjudicial. Si sospecha que

la pintura de la superficie del material que

desea cortar contiene plomo, busque ayuda

profesional. No intente quitar pintura

a base de plomo. Solamente un

profesional debería hacerlo.

Una vez que el polvo se ha depositado en una

superficie, el contacto de la mano con la boca

puede llevar a una ingestión de plomo. Incluso

la exposición a niveles bajos de plomo puede

causar daños irreversibles en el cerebro y el

sistema nervioso. Los niños y los nonatos son

especialmente vulnerables.

Se recomienda que considere el riesgo

asociado a los materiales con los que trabaje

para reducir el riesgo de exposición. Algunos

materiales pueden producir polvo dañino para

su salud. Recomendamos el uso de mascarillas

reguladas con filtros reemplazables cuando

use esta máquina.

Siempre debe:

• Trabajar en una zona bien ventilada.

• Trabajar con un equipo de seguridad

regulado, como mascarillas para el polvo

que hayan sido diseñadas para filtrar

partículas microscópicas.

2.8 ADVERTENCIA: el manejo de cualquier

herramienta eléctrica puede provocar que

se lancen objetos externos contra los ojos

que pueden ocasionar en daños graves en

los mismos. Antes de empezar a utilizar una

herramienta eléctrica, póngase siempre gafas

con protección lateral o una máscara que

cubra toda la cara cuando sea necesario.

(3.0)

INSTRUCCIONES

ADICIONALES DE SEGURIDAD

(3.1) a) PELIGRO: Mantenga las manos

lejos de la zona de corte y de la hoja.

Mantenga la otra mano en el mango adicional

o en la carcasa del motor. Si sujeta la sierra

con las dos manos, no se cortará con la hoja.

b) No toque por debajo de la pieza de

trabajo. La protección no puede protegerlo

de la hoja bajo la pieza de trabajo.

c) Ajuste la profundidad del corte al grosor

de la pieza de trabajo. Debajo de la pieza

de trabajo debe ser visible menos de un

diente de la hoja.

d) Nunca sostenga la pieza que esté

cortando con las manos o entre las piernas.

Asegure la pieza de trabajo a una plataforma

estable. Es importante sujetar la pieza

adecuadamente para minimizar la exposición

del cuerpo, las posibilidades de que la hoja

se atasque o la pérdida de control.

34

Page 35

www.evolutionpowertools.com

e) Mantenga la herramienta eléctrica en

superficies de adherencia aislada cuando

pudiera tocar cableado no visible o su

propio cable durante el corte. Si las partes

metálicas de la herramienta entran en

contacto con un cable en funcionamiento,

podrían electrocutar al operario.

f) Cuando corte, use siempre un tope-guía

o un carril guía. Esto mejora la precisión del

corte y reduce la posibilidad de que la hoja

se atasque.

g) Use siempre hojas con el tamaño y forma

del orificio del eje correctos (diamante

frente a circular). Las hojas que no encajan

con el equipo de montaje de la sierra

funcionan de forma extraña, provocando una

pérdida de control.

h) No utilice arandelas o tornillos dañados

o inapropiados. Los tornillos y arandelas

están diseñados para su sierra para conseguir

un rendimiento y seguridad óptimos.

i) No use hojas de sierra

de acero rápido (HSS).

j) Inspeccione la máquina y la hoja antes

de cada uso. No utilice hojas deformadas,

partidas, desgastadas o dañadas de

alguna manera.

k) Nunca utilice la sierra sin su sistema de

protección original. No bloquee la protección

móvil en la posición de apertura. Asegúrese

de que puede mover la protección libremente

y sin interferencias.

l) Solamente use hojas que cumplan con

las características especificadas en este

manual. Antes de usar accesorios, compare

siempre las RPM máximas permitidas del

accesorio con las RPM de la máquina.

3.2

CAUSAS Y PREVENCIÓN

DE CONTRAGOLPES:

Un contragolpe es una reacción inesperada

de una hoja de sierra atascada o mal

alineada que provoca que la sierra se dispare

descontroladamente de la pieza de trabajo

hacia el operario.

1. Si la hoja está atascada o fijada

firmemente por la ranura, ésta se

bloquea y la reacción del motor mueve

la unidad rápidamente hacia atrás

en dirección al operario;

2. Si la hoja se tuerce o se desajusta durante

el corte, los dientes del borde posterior de

la hoja puede tocar la superficie de la pieza

de trabajo provocando que la hoja se salga

de la ranura y se precipite hacia el operario.

3.3 EL CONTRAGOLPE ES EL RESULTADO

DE UN MAL USO DE LA SIERRA Y/O DE

PROCEDIMIENTOS O CONDICIONES

DE UN USO INADECUADO, Y PUEDE

EVITARSE TOMANDO LAS DEBIDAS

PRECAUCIONES QUE SE MUESTRAN

A CONTINUACIÓN.

a) Mantenga una sujeción firme con

ambas manos en la sierra y posicione

los brazos para resistir la fuerza del

contragolpe. Colóquese a un lado de la hoja;

no se posicione en la trayectoria de la hoja.

El contragolpe puede provocar que la sierra

salga disparada hacia atrás, pero la fuerza del

contragolpe puede controlarse por el operario

si se toman las medidas necesarias.

EN

ES

35

FR

Page 36

www.evolutionpowertools.com

b) Si las hojas se empiezan a atascar o

si se interrumpe el corte por cualquier

razón, suelte el gatillo y mantenga la sierra

firme en el material hasta que las hojas se

paren por completo Nunca intente retirar

la sierra de la pieza o tirar de la sierra

hacia atrás mientras las hojas continúen

en movimiento o podría producirse un

contragolpe. Investigue y tome las medidas

necesarias para eliminar la causa del

atascamiento de la hoja.

c) Cuando vuelva a encender la sierra en la

pieza de trabajo, centre la hoja de la sierra

en la ranura y compruebe que los dientes

de la hoja no están atascados en el material.

Si la hoja de la sierra se atasca, podría soltarse

o provocar un contragolpe cuando vuelva a

encender la sierra.

d) Fije los paneles grandes para minimizar

el riesgo de que la hoja se quede atascada

y provoque un contragolpe. Los paneles

grandes tienden a ceder por su propio peso.

La fijación debe colocarse por debajo del

panel en ambos lados, cerca de la trayectoria

de corte y del borde del panel.

e) Las palancas de bloqueo del ajuste de

profundidad y bisel deben ser firmes y

seguras antes de realizar un corte. Si el ajuste

de la hoja cambia durante el corte podría

causar su atascamiento y un contragolpe.

f) No use hojas desafiladas o dañadas.

Las hojas desafiladas o mal ajustadas

producen una ranura estrecha, causando

una fricción excesiva, atascamiento

de la hoja y contragolpes.

g) Extreme las precauciones cuando realice

un corte de inmersión en una pared u otras

zonas ciegas. La hoja saliente puede cortar

objetos que provoquen un contragolpe.

h) Compruebe que ha cerrado

correctamente la protección inferior

antes de cada uso. No utilice la sierra si la

protección inferior no se mueve sin problemas

y se cierra de forma instantánea. Nunca fije o

sujete la protección inferior en la posición de

apertura. Si la sierra se cae accidentalmente,

la protección inferior podría doblarse . Suba

la protección inferior con el tirador retráctil y

asegúrese de que se mueve libremente y no

toca la hoja o ninguna otra parte en cualquier

ángulo o profundidad de corte.

i) Compruebe el funcionamiento del muelle

de la protección inferior. Si la protección y

el muelle no funcionan correctamente, deben

ser arreglados antes de usar la máquina. La

protección puede funcionar lentamente

debido a que tenga partes dañadas, restos

pegajosos o una acumulación de desechos.

j) La protección inferior solo puede

retraerse manualmente para cortes

especiales, como “cortes de inmersión”

o “cortes compuestos”. Suba la protección

inferior con el tirador retráctil y, en cuanto la

hoja toque el material, suelte la protección

inferior. Para cualquier otro corte, la protección

inferior debe funcionar automáticamente.

k) Observe siempre que la protección

inferior cubre la hoja antes de colocar la

sierra en un banco o en el suelo. Una hoja

en movimiento y desprotegida hará que

la sierra vaya hacia atrás, cortando todo lo

que encuentre a su paso. Tenga en cuenta el

tiempo que necesita la hoja para pararse una

vez desconectada.

36

Page 37

www.evolutionpowertools.com

(3.4)

ADVERTENCIA: si faltan piezas, no utilice la

máquina hasta que estas se reemplacen. No

seguir esta indicación puede causar graves

daños personales.

(4.1)

PRIMEROS PASOS- DESEMBALAJE

Precaución: este paquete contiene objetos

punzantes. Tenga cuidado al desembalarlo.

Saque la máquina del embalaje junto con

los accesorios suministrados. Revise con

atención para comprobar que la máquina

está en buenas condiciones y cuenta con

todos los accesorios que se enumeran en este

manual. Asegúrese también de que todos los

accesorios estén completos. Si falta alguna

de las piezas, la máquina y los accesorios

se deben devolver juntos en su embalaje

original a su distribuidor. No tire el embalaje,

guárdelo durante el período de garantía. Sea

respetuoso con el medio ambiente cuanto

tire el embalaje. Si fuese posible, recíclelo. No

deje que los niños jueguen con las bolsas de

plástico vacías, debido al riesgo de asxia.

(4.2)

ELEMENTOS SUMINISTRADOS

Descripción Cantidad

Manual de instrucciones 1

Hoja de acero 1

Llave hexagonal 8 mm

(recambio de hojas)

Mordaza en forma de “v” 1

4.3

1

ACCESORIOS ADICIONALES

Además de los elementos estándar

suministrados con esta máquina, también

ponemos a su disposición los siguientes

accesorios que encontrará en la tienda

en línea de Evolution en

www.evolutionpowertools.com

o en su distribuidor local.

(4.4)

Descripción N.º De

Pieza

Hojas de corte especiales

(solo use hojas Evolution

o aprobadas por Evolution