Page 1

10cc

Evolution® Gas Engines

G A S/PETROL

Page 2

EN

2

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole

discretion of Horizon Hobby, Inc. For up-to-date product literature, visit horizonhobby.com

and click on the support tab for this product.

The following terms are used throughout the product literature to indicate various levels

of potential harm when operating this product:

NOTICE: Procedures, which if not properly followed, create a possibility of physical property

damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical

property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property

damage, collateral damage, serious injury or death OR create a high probability of

superficial injury.

Meaning of Special Language

WARNING: Read the ENTIRE instruction manual to become familiar with the features

of the product before operating. Failure to operate the product correctly can result

in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product and NOT a toy. It must be operated with caution and

common sense and requires some basic mechanical ability. Failure to operate this Product

in a safe and responsible manner could result in injury or damage to the product or other

property. This product is not intended for use by children without direct adult supervision.

Do not attempt disassembly, use with incompatible components or augment product in any

way without the approval of Horizon Hobby, Inc. This manual contains instructions for safety,

operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid

damage or serious injury.

CAUTION: This product can become extremely hot when in use, which could lead

to burns.

Age Recommendation: Not for children under 14 years. This is not a toy.

Safety Warnings

Model engines produce a substantial amount of power, which can create unsafe situations if not

used correctly. Always use common sense and observe all safety precautions when operating,

handling or performing any procedure involving your engine. Failure to follow safety precautions

could result in serious injury and property damage.

• Always ensure spectators, especially children, are at least 30 feet away when running

the engine.

• Always ensure that the propeller is securely attached to the engine shaft and all retaining

fasteners are tightened properly before EACH flight. Use of blue threadlock to tighten nuts

is advisable.

• Always keep small parts out of the reach of children as they can be choking hazards.

• Always secure the airplane before powering the engine.

• Always keep your face and body away from the path of the propeller blades when starting

or running your engine.

• Always stand behind the propeller when making carburetor adjustments.

• Always wear safety glasses or goggles when starting and running your engine.

Page 3

EN

3

• Always keep your fuel in a safe place away from sparks, heat or anything that can ignite.

• Always ensure the aircraft is secure and will not move once the engine is started.

• Always rebind your transmitter to your receiver(s) after setup and before rst ight.

• Always ensure the throttle failsafe is set to low throttle in your transmitter.

• Always perform a range check prior to ight.

• Always cut off the fuel supply (pinch or disconnect the fuel line to the carburetor) or use

the throttle linkage to shut off the air in order to stop the engine.

• Never use hands, ngers, or any other body part to stop the propeller.

• Never throw any object into a propeller to stop it.

• Never run the engine in the vicinity of loose small objects, such as gravel or sand, to avoid

the propeller uncontrollably throwing such materials.

• Never wear loose clothing or a loose neckstrap when operating your model engine as these

items could become entangled in the propeller.

• Never have loose objects such as screwdrivers, pencils, etc. in your pockets when operating

your model engine. These could fall into the propeller.

• Never allow fuel to come into contact with eyes or mouth. Gasoline and other fuels used

in model engines are poisonous.

• Always ensure gasoline and fuel are stored in a clearly marked container away from

the reach of children.

Precautionary Guidelines

• Always mount the engine securely on a bench mount or high-quality engine mount.

• Always use the correct size and pitch of propeller for your engine. Refer to the Propeller Chart

in this manual.

• Always conrm proper balance of your propeller prior to installation of the engine. Failure

to do so could result in damage to the engine and/or airframe.

• Always utilize an electric starter to start your engine.

• Always discard any propeller that is nicked, scratched, cracked or damaged in any way.

• Always run your model engine in a well-ventilated area. Model engines can produce possibly

harmful carbon monoxide fumes.

• Always store your fuel safely in a sealed, water-resistant container.

• Always store fuel in a cool, dry location. Do not allow fuel containers to come in direct

contact with concrete, as the fuel may absorb moisture.

• Always responsibly discard fuel if there is condensation and/or water inside the fuel

container.

• Never return unused fuel from the fuel tank back into the fuel container.

• Never attempt to repair or modify a propeller beyond its intended use.

• Never handle model engines, mufers and/or tuned pipes until they have had time to cool.

They can become extremely hot when in use.

Page 4

EN

4

Introduction

Congratulations on your forethought and decision to purchase the Evolution® brand’s first small

block gas engine in our new series. All of the Evolution brand gas engines are designed from the

start to provide you with excellent performance at a fraction of your previous operating costs. We

have painstakingly designed and tested each engine to insure a hassle free experience without

giving away anything in expected performance or durability. This manual, when read and followed will guide you through the simple steps to your success. Welcome to the Evolution family.

Small Block Gas Engine Design

Starting with our already proven 60NX glow engine, enjoyed by thousands around the world, we

endeavored to take that excitement and experience into the realm of gasoline fuel to provide

you with a complete package; great performance and low cost of operation.

Step 1 Start with a great engine. The 60NX was rst announced and sold in July 2009 and has

since provided thousands of users excellent performance.

Step 2 Design a new carburetor system that will be reliable and provide for hassle free use by the

owners. This new carburetor, with already proven technology, was modified to fit in the

available space in front of the cylinder and the unique needs of a gasoline fueled engine.

Built on to the front of the carburetor, is a crankcase-pressure driven regultar system.

This system takes fuel a muffler pressurized tank and meters it properly in all attitudes of

flight. A new cat’s eye style fuel metering system was added to allow for more contrallability to the low and mid-range throttle positions.

Step 3 Design the proper muffler system to handle the extra heat and expansion of the burnt gas

mixture when compared to a glow system. These changes included adding volume to the

muffler, including a much larger muffler through-bolt to handle the heat and stress, and

enlarging the outlet of the muffler to minimize backpressure while still providing noise

reduction.

Step 4 Design operating accessories that enhance the user experience. During our extensive

2-1/2 year testing program we discovered a lot of new techniques and obstacles that are

unique to gasoline fueled small block engines.

• Because the amount of fuel consumed is one third that of a comparable sized

glow engine the construction and reliability of the fuel delivery system to the

carburetor becomes three times as critical. Microscopic pieces of dirt that used

to safely pass through the larger fuel passages of a glow carburetor will wreak

havoc on a gasoline system. By using a quality inline filter like our Inline Filter

(EVOA105) we can take care of the dirt problem. One of these is included with

your engine.

• The same holds true for air bubbles from the tank or any small leak in the fuel

tubing; what would pass harmlessly through a glow carburetor simply is not tolerated in a gasoline system because the air bubbles are effectively three times

the size they used to be. We have developed and sourced an excellent felt filter

clunk that when used in the tank stops all the air bubbles from moving into the

fuel delivery tubes. This felt clunk is critical to successful and reliable operation.

One of these is included with your engine.

• We found that high mufer temperatures would destroy normal Tygon® tubing

(the go-to choice for gasoline engines) within minutes. We found that Neoprene

tubing would withstand the temperatures but it tended to degrade quickly

in use so we sourced the proper sized Viton® tubing (Gasoline Fuel Tubing

EVOA104) which withstands not only the high temperatures but its durability

is much greater than that of either Tygon or Neoprene. The added bonus is that

it fits and holds well to the fuel fittings without any need for additional wire or

tie-wrap keepers. We have included a supply of this tubing with your engine.

Page 5

EN

5

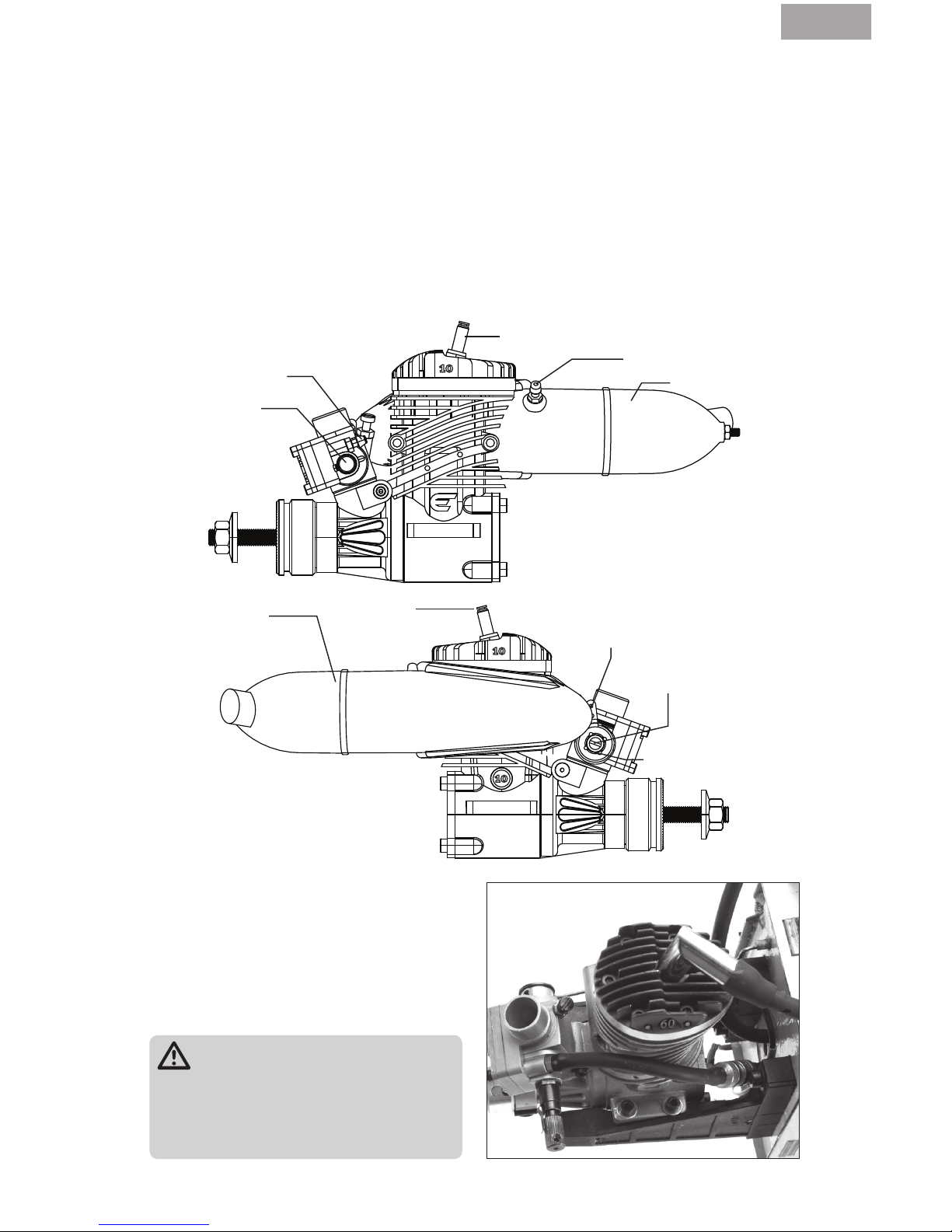

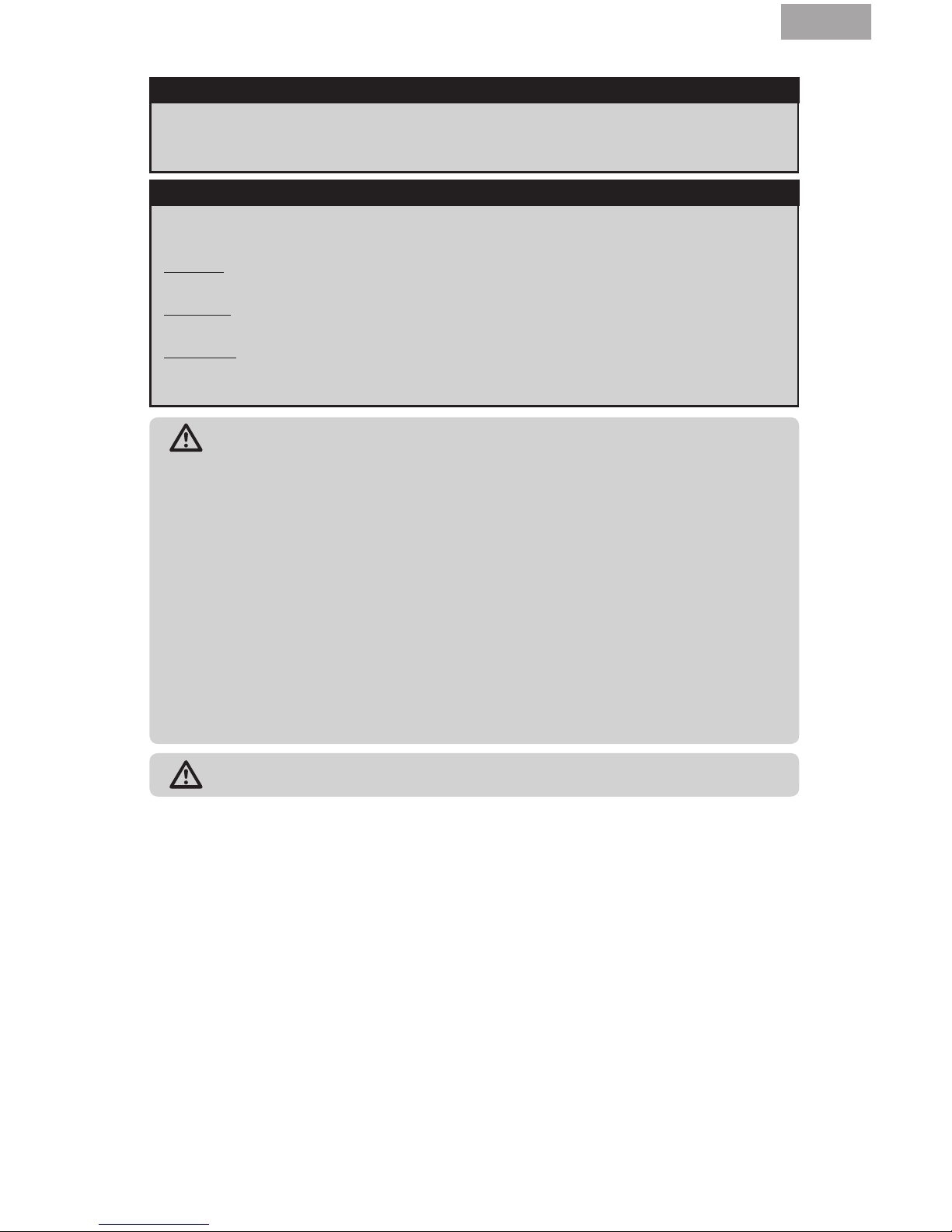

High-Speed

Needle

Muffler

Spark Plug

Muffler Nipple

Fuel Nipple

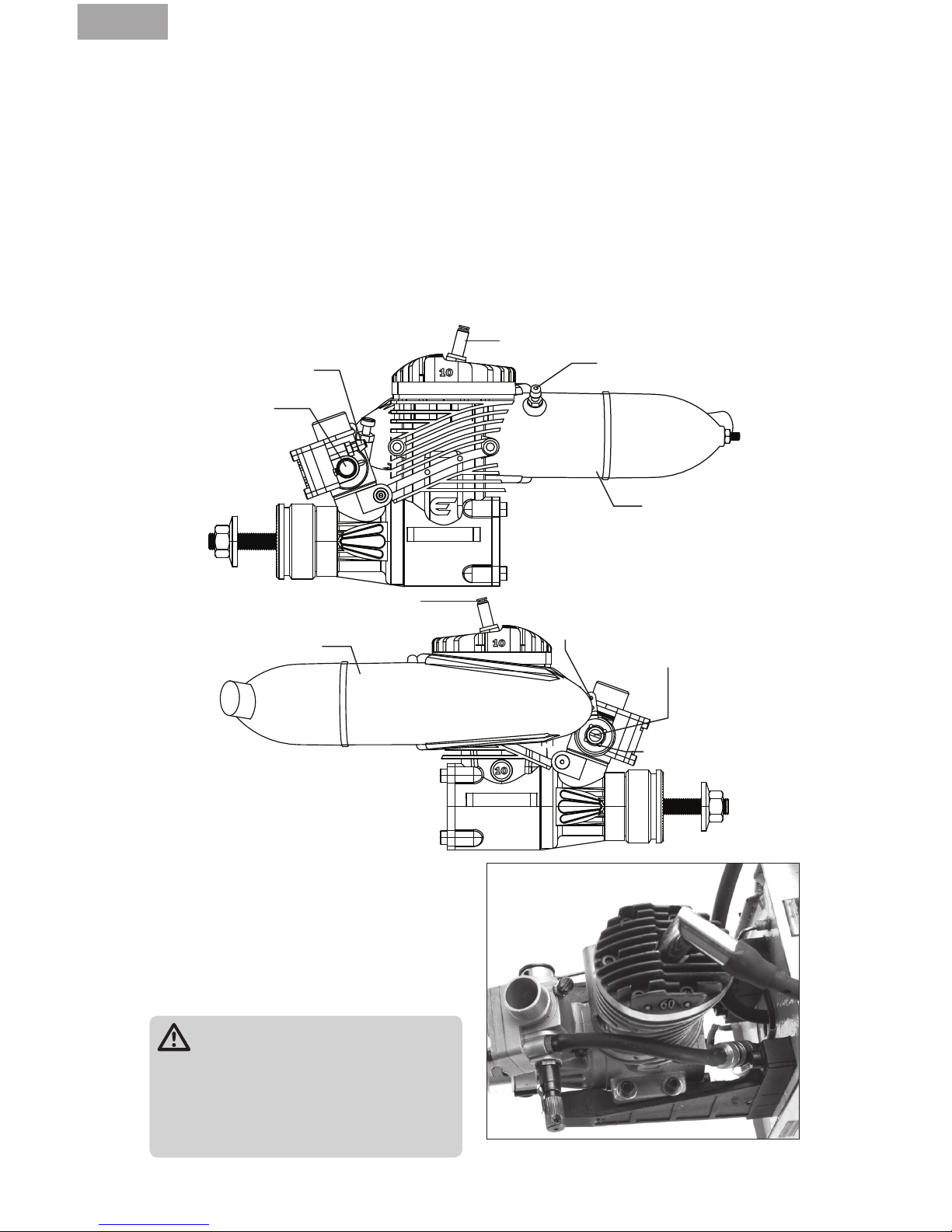

Installing the Engine

1. Secure the engine mount on the airplane

firewall. Tighten the engine mount screws

in the firewall.

2. Install the engine on the engine mount

according to the airplane manufacturer’s

instructions.

WARNING: Tighten all engine

mounting screws before each flight. If

you do not tighten the engine

mounting screws, the screws may

vibrate loose and cause the engine to

separate from the fuselage.

Low-Speed Needle

Needle Limit Collar

Muffler

Spark Plug

Throttle Arm

Included Content

ENGINE

• Mufer (EVO10601)

• Mufer Screws & Gasket (EVO100E46A)

• Spark Plug (EVOG10350)

• Evolution/Spektrum™ Telemetry RPM

adapter cable (EVOA107)

• Med Gas Fuel Tubing (EVOA104)

• In-Line Fuel Filter (EVOA105)

• In-tank Felt Filter/Clunk (EVOA106)

OPTIONAL ITEMS

• Tachometer (HAN156)

• Propeller 10 x 6 (EVO10060) for break-in;

12 x 6 (EVO12060) for normal ight

• EVOM1 High Performance Tuned Mufer:

EVO46-60

Page 6

EN

6

1. Use a secure method to attach the

throttle linkage to the throttle arm on the

carburetor.

2. Power on the transmitter and receiver.

3. Move the throttle stick to the middle stick

position.

4. Adjust the throttle arm so the arm is 90

degrees to the throttle pushrod.

5. Center the throttle servo. Install a servo arm

with a hole 11mm (7/16 in) from the center

of the arm.

6. Use a clevis to attach the throttle linkage to

the servo arm.

11mm

1.5mm

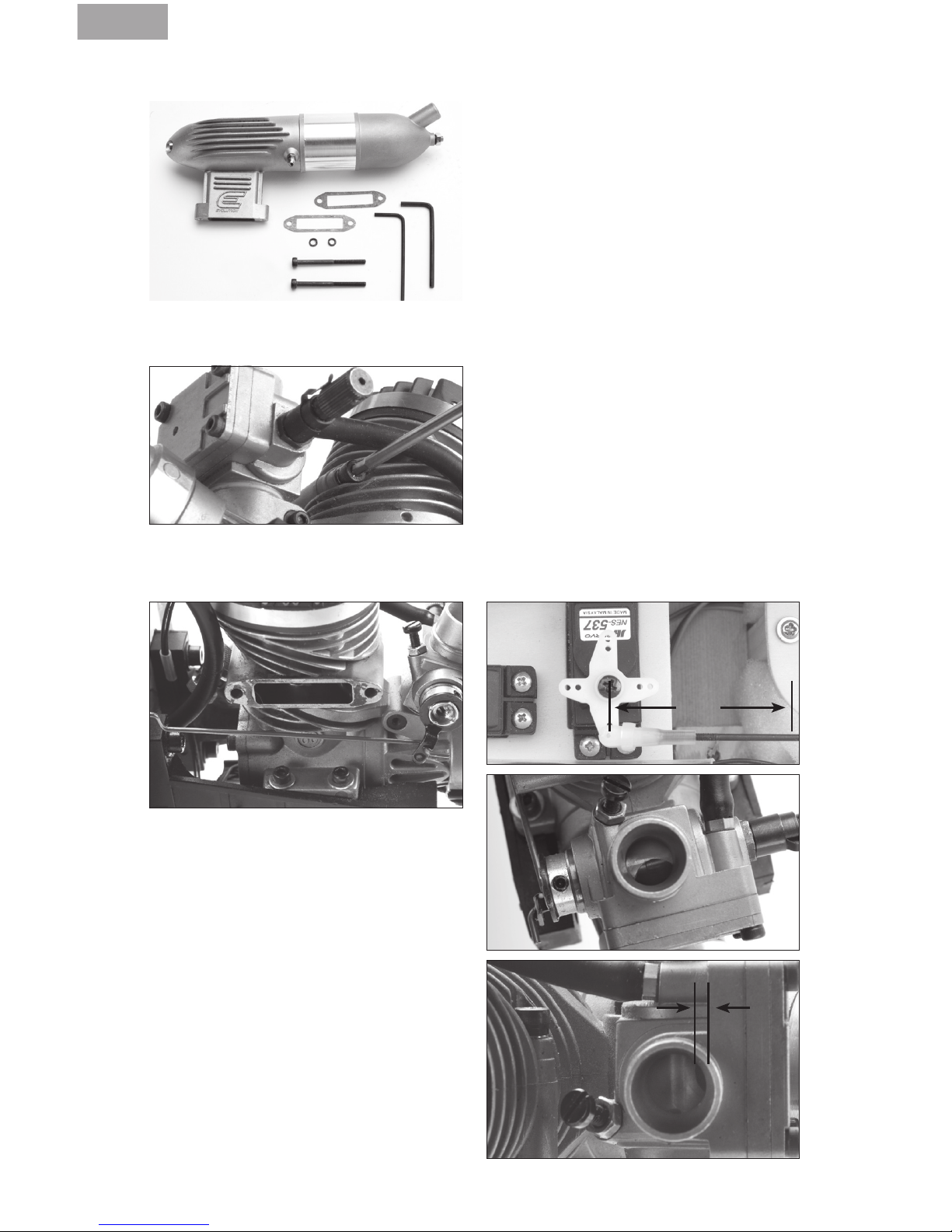

Installing the Muffler

The muffler mounting accessory package in-

cludes mounting screws (2), lock washers (2),

muffler gaskets (2) and L- wrenches (2).

1. Put a lock washer on each of the muffler

screws. Push the muffler screws through

the cylinder head.

2. Place the muffler gasket over the engine

mounting screws.

3. Align the mufer gasket with the exhaust

opening and the muffler mounting screws.

4. Tighten the muffler screws.

Important: Tighten the muffler screws after

five tanks of fuel. The muffler screws may

loosen from heat and vibration.

It is important that you tighten the muffler

through-bolt after each of the first three,

full tank engine runs. The heat will cause expansion of the through-bolt and muffler body

parts. After the third tightening, no further

muffler loosening should occur.

To tighten the muffler through-bolt:

1. Loosen the muffler lock nut.

2. Tighten the muffler through-bolt screw.

3. Tighten the mufer lock nut.

Connecting the Throttle Linkage

Page 7

EN

7

Adjusting the Throttle Opening

1. Lower the throttle and center the throttle

trim.

2. Adjust the length of the throttle linkage

until the throttle is open 1mm.

3. Move the throttle stick up to conrm the

throttle opens. If the throttle does not

open, reverse the throttle channel in your

transmitter.

4. Move the throttle stick and throttle trim

down to confirm the throttle closes.

5. If you reversed the throttle channel in your

transmitter and you are using a 2.4GHz

radio system, you must re-bind your radio

system to set the correct failsafe position.

Attaching the Fuel Lines

Fuel Line

Vent Line

1. Connect medium diameter Viton

®

fuel line

to the carburetor and the fuel tank supply

line.

2. Connect medium diameter Viton fuel line

to the muffler pressure nipple and the fuel

tank vent line.

Vent Line

Fuel Line

RECOMMENDED PROPELLERS

10 x 6–13 x 8 (12x6 has tested to be the best

performer with this engine although the

performance is very good throughout the

recommended range)

1. Remove the prop nut and prop washer from

the crankshaft.

2. Install the spinner backplate, followed by

the propeller, prop washer and prop nut.

3. Cover the propeller with a cloth and use an

adjustable wrench to tighten the prop nut.

4. Install the spinner cone. Make sure the

spinner cone is not touching the propeller.

Trim the propeller opening if necessary.

5. Tighten the spinner screw(s) to secure the

spinner cone.

Attaching the Propeller and Spinner

Page 8

EN

8

Connecting the Electronic Ignition

The Evolution Electronic Ignition Assembly is designed and engineered specifically for the

small block engine series. It is smaller and lighter so it fits into tighter spaces of the airplanes

the engines are designed to power. The battery voltage required is between 4.8v (4-cell Ni-MH

pack) and 8.4V (2S Li-Po battery) and no voltage regulators are needed with any of these

batteries. We recommend a 2S Li-Fe battery (such as the Team Orion® Avionics Li-Fe Receiver

Pack 1300mAh 6.6V (ORI60503)) and we have done extensive testing with these packs. The

maximum amp draw at full throttle is 450mAh, and our more typical average has been between

250–300mAh.

The assembly consists of:

• Ignition module with battery connector, ignition sensor connector, tachometer readout

connector and spark plug connector.

• Ignition sensor (already attached to your engine)

• Sensor magnet (already installed in the prop drive hub of your engine)

Mounting Your Electronic Ignition

• You can mount the unit in any orientation

and place that is convenient for your

installation. The module is sized to conveniently fit into the tank compartment of

most 46–50 sized airplanes alongside or

underneath the recommended 6–8 oz fuel

tanks. You can also mount it to the rewall

or under the engine firewall extension if

your airplane is so equipped. Keep in mind

that it should be mounted away from the

heat of the muffler.

• Secure the ignition module to your chosen

location with foam padding to provide

vibration isolation. We typically mount it

conveniently with tie wraps after wrapping

the ignition in lightweight 1/4-inch foam

rubber.

• You may need to route both the spark plug

connector wire and the ignition sensor

wire through the firewall so be sure to plan

ahead and provide adequate sized holes

that will allow you to pull either the ignition

sensor connector or the spark plug cap

connector through the holes for later

ignition removal.

• Mount a good quality radio receiver type

switch between the ignition unit and the

battery. Mount this switch in a convenient

place on the outer fuselage close to the

front of the airplane to make it easy to turn

the ignition on and off. Being able to easily

shut off the ignition is an important safety

consideration.

• Connect the ignition sensor wire to the

ignition module. The sensor wire will only

fit into one of the connectors so you cannot

connect it wrong.

• Connect the ON/OFF switch to the battery

connector lead of the ignition module. This

connector is the red connector.

• If desired you can connect either the

separately available tachometer readout or

the included Evolution/Spektrum Telemetry

Adapter Cable (EVOA107) to the tachometer

readout connector. Plug the other end of

the adapter cable into your telemetry module’s rpm input port.

• Connect the spark plug connector to the

spark plug. This adapter has a push on and

rotate clockwise 1/8 turn locking

mechanism to insure a solid connection.

Make sure you charge your ignition battery

and are now ready to operate your electronic

ignition with the engine.

Page 9

EN

9

Fuel

This engine requires a mix of 20:1 gas to oil

lubricant ratio to operate and last a long

time. The bronze bearing at the bottom end

of the conrod depends upon this lube ratio to

operate properly. Do not go higher than a 20:1

gas/oil ratio or the warranty on your engine

will be voided.

To properly mix the fuel add 6.75 oz of good

quality 2-stroke oil to one gallon (or 53 mL

of oil to one liter) of 87–93 octane fuel.

(EVOX1001Q Evolution 2-stroke oil is

recommended) We prefer to add the oil rst

to our fuel container and to add the gasoline

second. This helps to insure a good mixture of

the oil with the fuel at the outset.

We have tested our own Evolution 2-stroke oil,

Valvoline, Shell, RedLine and Husqvarna oils.

Other quality 2-stroke oils should work as

well. Do not use Amsoil synthetic oil in

any form.

Fuel Delivery System

It is very important to properly construct

your fuel supply system to the engine to

avoid operating problems with our engine.

Our experience has shown that many seemingly engine related operating problems are in

fact fuel delivery problems, not engine related

problems.

Fuel Filtering - Because of the incredibly small

amount of fuel that is being used by this

engine, filtration of the fuel is mandatory in

three different spots in the system:

1. Between the fuel jug and the tank

2. Within the fuel tank itself (with a ltered

clunk EVOA106)

3. Between the fuel tank and carburetor (with

an in-line fuel lter EVOA105.

Both of these lters (2 and 3) are included in

the engine package.

Tank Location - Because muffler pressure

is used to provide the pressurization to the

fuel regulating and metering carburetor, the

tank still needs to be mounted in line with

the carburetor, and as close to the rear of the

engine as possible. Care taken in mounting

the tank as described will provide trouble free

operations in all flight attitudes.

Tank Choice and Construction – Choose a

tank between 6–8 oz (170–240 mL). These

tanks will yield 17 minutes (for the smaller

tank) to 24 minutes (for the larger tank) of full

throttle flying time.

The clunk will not move around well if the tank

is smaller than 6 oz (170mL). Any tank larger

than 8 oz (240mL) will result in carrying extra

weight to no benet (unless you like to y for

a long time).

• Ensure you use a tank stopper made for

use with gasoline and/or smoke oil.

• We suggest a three-line tank system; one

for the line to the carburetor with the clunk

attached internally, one for the muffler

pressure to the tank, and one dedicated

to fueling/defueling the tank. We try to

avoid the T-fittings and other inline valves

because they can be a possible source of

air/fuel leaks.

• Ensure you use the provided Viton tubing in

all the plumbing of the tank, externally and

internally.

• Ensure you use the included felt lter clunk

inside the fuel tank.

• Ensure you use the included inline lter

between the tank and the carburetor.

• Ensure there is a good seal system for

the dedicated fueling/defueling line. We

highly recommend the HAN116 Fuel Filler

Assembly for its sleek look and ease of use

when installed on your airplane.

Page 10

EN

10

Engine Break-in

Your new engine needs to be broken-in to ensure a long life of all the components. The piston

and liner construction piston and liner construction is true ABC (Aluminum piston, Brass

Chromed liner), which requires a specic break-in procedure that cannot be fully accomplished

with bench runs.

Because the ABC piston and liner rely on the close fit of the piston to the liner to provide the

compression seal, the engines are built with a taper to the liner that requires the piston to

match the taper during the break-in process. For this to be accomplished, this process requires

repeated heating and cooling cycles, and must be done at a needle setting that is only slightly

rich of peak.

Breaking in an ABC piston and liner by running it rich does not provide the necessary parts

growth to accomplish the needed piston and liner fitting. Using a rich needle setting does not

allow for proper expansion of the liner, resulting in the connecting rod receiving the full force

of the piston when it moves past Top Dead Center (TDC). Allowing the engine to heat up will

expand the liner and reduce the load on the connecting rod, ensuring a proper engine break-in.

Doing the break-in with a light load on the engine (e.g. a smaller than normal propeller) makes

this task much easier. Please follow the steps below to ensure a successful experience.

1. Do the break-in process mounted on your

airplane and in the air.

2. Use a 10 x 6 prop for your break-in process.

This provides a light load, and high rpm

that when matched with the heat of the

engine will break-in the engine properly.

3. Use the proper recommended fuel with a

20:1 gas to oil ratio.

4. The proper break-in flight procedure is to

fly the airplane at full throttle through a

series of gure eight maneuvers (i.e. Cuban

Eight). These maneuvers in particular ben-

efit the engine because when climbing the

additional load on the engine will increase

the temperature and when diving the airplane the lighter load and higher rpm will

decrease the temperature, thus providing

the heating/cooling cycles required for the

break-in process.

5. Run two full tanks with the 10 x 6 prop and

then move to an 11 x 6 prop and repeat the

next two tanks.

6. You should now be ready to put on any of

the larger props and enjoy your engines full

performance.

Do not worry about an engine setting being

too rich during this process. When set

correctly, the engine will occasionally sound

as if it is misring (which it is). During the

climbing maneuvers this should go away and

might return during the diving maneuvers. If

it does not go away during the climbs then

land and adjust the high-speed needle by 1–2

clicks to the leaner position and take off and

fly again. Enjoy the break-in process—you are

doing a lot of flying.

Page 11

EN

11

Baseline Needle Valve Settings

Your engine comes from the factory with the

needles set at the first run baseline settings

(High-Speed: 2 1/4 turns out, Low-Speed: 5

3/8 turns out). No adjustment is necessary.

If you find you need to move the carburetor back to the baseline settings follow the

procedure below.

Tip: The O-ring seal on both needle valves is

very tight and it can make the first

adjustments of your engine settings difficult.

If you find the seal too tight, the best method

to free it up is to actually open (counterclockwise) the needle valve a couple of turns

before trying to turn the needle in (clockwise).

Now that you have the baseline needle valve

settings you are ready to start your engine for

the rst time. With the 10GX it is very

important to allow the temperature to

stabilize above 170°F (75°C) before making

any adjustments; adjusting prior to the engine

warming up will lead you to inaccurate

settings. As the engine warms up you will

notice the rpms naturally rising.

If you do not have a temp gun or have sensors

installed on your engine then allow the engine

to run at half throttle for at least 45 seconds

before attempting to set the high-speed

needle. If you have accurately set the lowspeed needle as described you should not

need to adjust it.

Priming

1. Make sure your ignition is off.

2. Open the throttle fully and either by holding a finger over the carburetor intake or

the muffler exhaust flip the propeller 4

times.

3. Remove your nger from either the carburetor or muffler exhaust and flip the engine

another 6 times.

4. Close the carburetor completely with your

throttle stick and then open it two detents

from closed. This will allow the engine to

start at a high throttle setting.

Because each fuel system and installation

is slightly different you may find the need

to modify the above procedure for your

individual setup. The above procedure should

work for most installations.

Low-Speed Needle Valve Setting

The low-speed needle valve should be set

5 3/8 turns from closed when the carburetor

barrel is completely closed. The proper way to

determine this is to:

1. Disconnect your throttle arm from the

throttle pushrod. Insert the included 1.5mm

needle valve extension into the carburetor

and close the barrel until it is stopped by

the extension. The needle valve extention

establishes a 1.5mm opening as a baseline

for adjusting the low-speed needle.

2. While holding the throttle arm turn the low

speed needle clockwise until you feel it

trying to force the throttle arm to move and

open the carburetor barrel. Be careful here

and do not force it past this point.

3. Turn the low speed needle valve counterclockwise (open/richen) by 5 3/8 turns.

This setting will be within +/– 1/16 of a

turn from a proper low-speed needle valve

setting.

4. Reconnect your throttle pushrod to the

throttle control arm.

High-Speed Needle Valve Setting

The baseline high-speed needle valve setting

for initial start-up is 2 1/4 full turns from

closed. The proper way to determine this is to:

1. Turn the high speed needle valve clockwise

until you reach its seat. Do not force it past

this point because you can damage the

needle and/or the needle seat.

2. Turn the high speed needle valve counterclockwise 2 full turns. This setting will be

rich by 1/4 to 1/2 turn but it will insure an

easy first start.

3. Our experience has been that the engine

likes to run between 1 1/2 and 1 3/4 turns

open once fully broken-in.

Starting and Operating the 10GX Engine

Page 12

EN

12

Until the engine is broken in use an electric

starter to start the engine. Once it is fully

broken in it can be started by hand but it is

easier and safer to start the engine with an

electric starter.

1. Turn on the ignition.

2. Rotate the propeller in a backwards direction against compression.

3. Push the starter rmly against the nose

cone and engage. The engine should start

relatively quickly, within 1-2 seconds. Once

the engine starts disengage the starter.

4. Let the engine run at mid-throttle for 45

seconds to stabilize the temperatures.

a. If the engine doesn’t start quickly disen-

gage the starter. Continuously running

the starter can flood the engine.

b. Check to make that fuel is moving

through the carburetor system.

c. If the engine appears not to have any

fuel, repeat the priming procedure

above.

d. Repeat 1–4 of Starting and Running the

Engine.

Because of the small amount of fuel actually

needed for this engine, needle adjustments

need to be made in small increments. It may

take 5 seconds or more before you will notice

a running change in your engine after making

it. Be patient. Use a tachometer, this is a very

important part of properly setting your highspeed needle valve.

The procedure below is for ground setting the

needles prior to flight. The final adjustments

need to be made after noting the performance

in the air.

1. With engine started and warmed up, open

the throttle fully and note the rpm. Listen to

the engine.

a. If the engine occasionally mis-fires but

maintains a fairly constant rpm after 5

seconds, your engine is rich. Reduce the

throttle to idle and turn in (clockwise)

the high-speed needle 2 clicks. Repeat

this until the engine stops mis-firing.

b. If the engine does not mis-fire and the

rpm steadily decreases from the highest

rpm achieved when you opened the

throttle, it is lean. Reduce the throttle

to idle and open (counterclockwise)

the high-speed needle 2 clicks. Repeat

this until the engine maintains the rpm

achieved when the throttle is wide open

Your goal here is to achieve a good

transition between high and low speed,

and that the high-speed rpm will be

steady on the ground.

2. Fly your aircraft for the in-air testing.

a. During flight, if the engine seems to slow

down or sag when climbing, your engine

is running slightly lean. Land the

airplane and open the high-speed

needle valve 2 clicks and take-off again.

b. During flight, if you hear the engine mis-

firing occasionally in level flight, this is

an indication it is running too rich. Land

the airplane and close the high-speed

needle valve 2 clicks and take-off again.

c. Repeat the above process until your

engine performance is steady and

repeatable. This high-speed needle

setting should not change more than

+/– 1–2 clicks in the future when using

the same propeller. If it does, something

is wrong in the fuel delivery system and

should be investigated.

If you are using onboard telemetry and have a

temperature monitor on the head of your en-

gine, your readings should be between 300°F

(150°C) and 330°F (165°C). See the section on

adding a temperature monitor to your engine

for the proper positioning of your sensor.

High-Speed Needle Adjustment

Starting and Running the Engine

Page 13

EN

13

If you have properly set the idle need, the

low-speed setting should be within 1/16th of

a turn from perfect. Remember we are talking

about minute amounts of fuel going through

the carburetor, any adjustments you now

make to the idle needle should be very, very

small.

Take into consideration the length in service

(e.g. break-in time) and the size of propeller

you are using. In the beginning using a smaller propeller, early in the break-in process, you

will not be able to achieve an idle much below

2800 rpm. The larger the propeller, the lower

your idle rpm will be, and the more broken in

your engine is will allow a lower idle rpm (13 x

6 should be about 22–2300 rpm).

Your engine will idle at low-speed needle settings from far to0 rich to far too lean without

any damage so the quality of the idle is not

a good indicator of the proper low-speed

needle settings. The transition from idle to full

throttle will be used to determine the position

of the low-speed needle.

1. With engine started and warmed up, open

the throttle fully then reduce to idle and

note the rpm. Listen to the engine.

2. Let the engine idle for ten seconds and

then rapidly advance the throttle to full

open. One of three things will occur:

a. The engine responds instantaneously.

Your low speed needle is set perfectly.

Now use your throttle trim to achieve the

lowest reliable idle.

b. The engine slowly accelerates to full

throttle. This indicates the low speed

needle is set two rich and that fuel is

building up in the crankcase. Shut the

engine off and lean (clockwise turn)

the low speed idle screw by an amount

equal to the thickness of the screwdriver

blade you are using to make the adjustment. Restart the engine and repeat

steps 1 and 2.

c. The engine stutters or stops on it way to

full throttle. This indicates the low speed

needle is set too lean. With the engine

off, richen (counter-clockwise turn) the

low speed idle screw by an amount

equal to the thickness of the screwdriver

blade you are using to make the adjustment. Restart the engine and repeat step

1 & 2.

3. Once you have achieved the instantaneous

throttle transition your low-speed needle is

set perfectly. Now go back and recheck your

high-speed needle valve setting. There is

some interaction between the two needles

so you might need to do this process (HS

and LS needle setting) a couple of times.

Patience here will reward you with an easy

to use engine. Don’t try to do this too

quickly.

4. Once you have achieved the instantaneous

throttle transition your low speed needle

is set perfectly and you should never have

to touch it again regardless of the propeller

you try to use.

Low-Speed Needle Adjustment

Page 14

EN

14

10GX Evolution Engines Specications

Item

Disp

(c.i.)

Bore

(mm)

Stroke

(mm)

Weight

(oz)

Crank K

(ISO)

Cylinder Propeller

EVOE10GX .60 24.0 21.5 15.3 1/4 x 28 ABC 12 x 6 @ 12,600 rpm

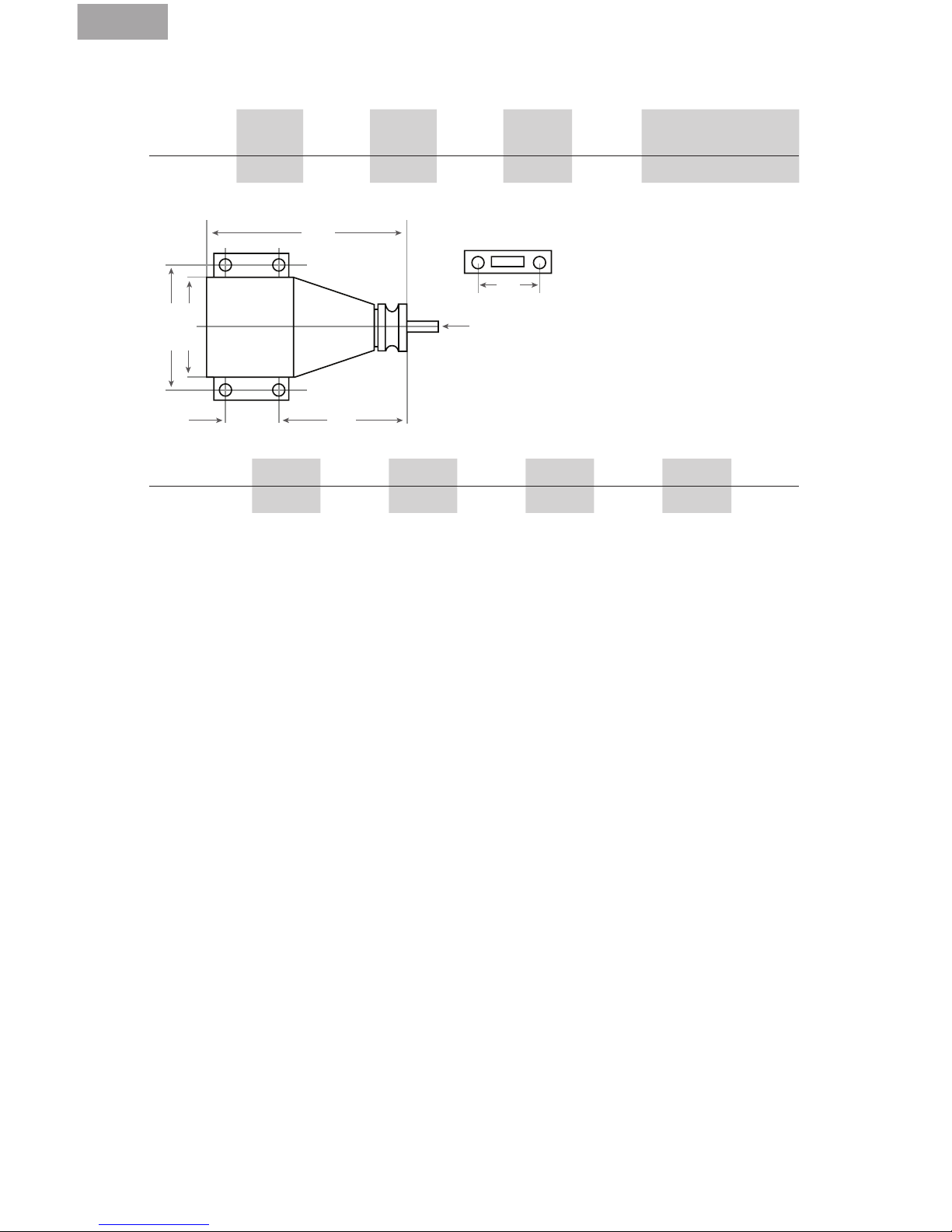

B A

C D

F

G

H

E = height*

F = length

G= crankshaft thread size

H = muffler bolt spacing

Dimensions A B C D E* F G H

EVOE10GX 36 44 17.5 5 7.4 72 88.5 1/4 x 28 37

* Height is from engine C/L to top of cylinder head.

Troubleshooting Guide

If the Engine Does Not Start

• Check and use a new spark plug if needed.

• Check fuel lines.

• Check for proper mechanical function by

turning the engine over.

• Check that the carburetor is correctly

installed.

• Check that the mufer pressure line is attached and free from any bends or

blockages.

Mechanical Faults

If the engine cannot be turned over easily

• The most likely cause is the engine is

flooded and by turning the engine over you

are trying to compress the fuel, not air.

1. Remove the spark plug.

2. Cover the cylinder head with a cloth or

paper towel and turn the propeller over

to expel all the excess fuel.

3. Replace the spark plug and try starting

again.

• A possible cause is the piston in the

cylinder is seized: loosen and unscrew the

cylinder head bolts.

1. Carefully remove the cylinder liner.

2. Visually examine the piston and cylinder

to find the possible cause of the engine’s

mechanical problem.

Mechanical repairs must ALWAYS be

completed by an authorized Horizon Hobby

service center.

Maintenance

After each flying session:

1. Fully drain the fuel from the tank.

2. Start the engine and run it until the fuel is

completely run out of the engine.

3. Try starting the engine three more times or

until it will no longer fire. This gets all the

fuel out of the engine.

If you need additional help or have any

questions, please call Horizon’s Support

Team. Horizon has trained technicians

who are qualified to answer your engine

questions.

Page 15

EN

15

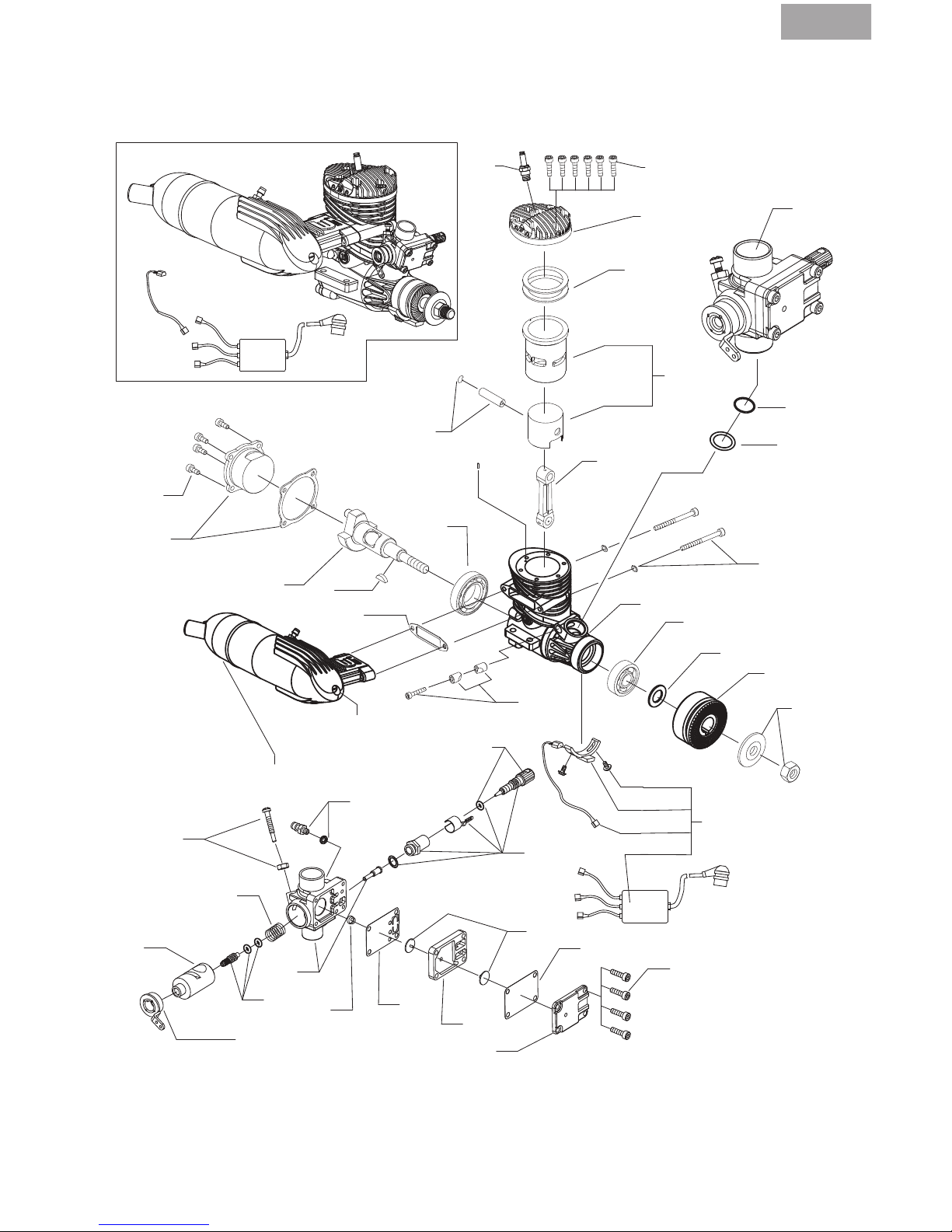

Exploded View

8

10

11

20

12

6

13

7

41

4

3

1

15

16

17

9

5

32

39

33

37

40

30

27

30

31

26

34

35

36

29

28

24

21

2

25

23

22

14

19

18

38

Page 16

EN

16

Parts List

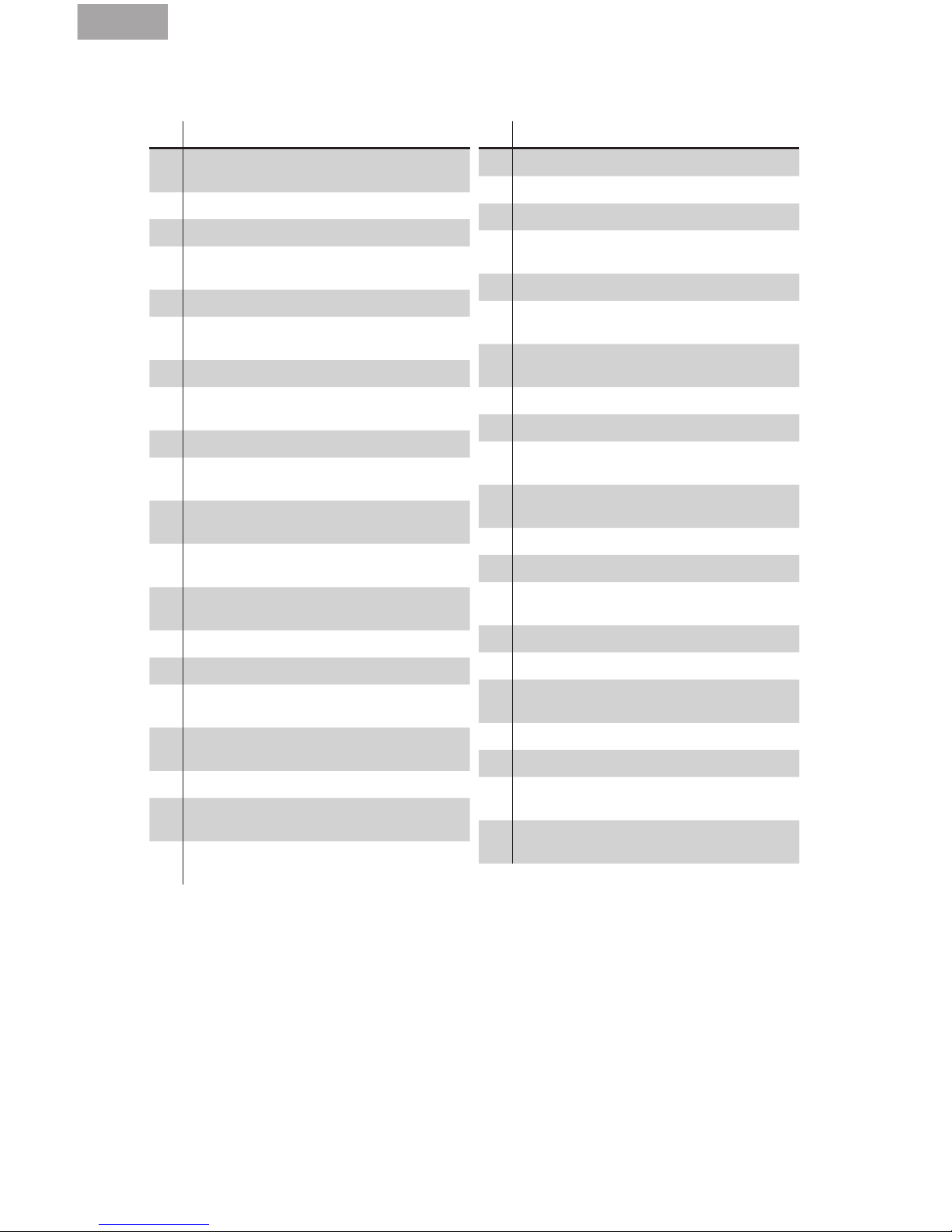

# Description Part

1 Cylinder Head Screws

(6) 10GX

EVO40120

2 Spark Plug ¼-32 thread EVOG10350

3 Cylinder Head 10GX EVOG10103

4 Cylinder Head Shim:

60NX, 10GX

EVO060112

5 Cylinder Piston Set 10GX EVOG10203

6 Wrist Pin with Clips:

52NX, 60NX, 10GX

EVO052213

7 Connecting Rod 10GX EVOG10204

8 Prop Washer & Nut:

1/4 x 28

EVO040228

9 Prop Driver 10GX EVOG10219

10 Spacer Washer;

120NX, 10GX

EVO91225

11 Front Bearing;

120NX, 10GX

EVO91109

12 Crankcase with index

pin 10GX

EVOG10101

13 BB, Rear (Open Race):

52NX, 60NX, 10GX

EVO052110

14 Drive Key; 120NX, 10GX EVO91218

15 Crankshaft 10GX EVOG10210

16 Rear Cover with Gasket:

52NX, 60NX, 10GX

EVOG10102

17 Back Cover Screw (4)

10GX

EVO40134

18 Mufer Assy 10GX EVOG10601

19 Muffler Long Screw

120NX, 10GX

EVO120616

20 Muffler Mounting

Screw Set

EVO100E46A

# Description Part

21 Carb Assy 10GX EVOG10801

22 Carb Mounting O-Ring EVOG10816

23 Carb base washer EVO46826

24 Carb Retainer (Drawbar)

10GX

EVOG10129

25 Evo 10GX Ignition Unit EVO10101

26 Carb Body & Spray Bar

10GX

EVOG10863

27 Regulator Case

mid-section 10GX

EVOG10872

28 Regulator Case Top 10GX EVOG10874

29 Regulator Spring 10GX EVOG10880

30 Regulator Gasket Set

10GX

EVOG10875a

31 Regulator Piston Set

10GX

EVOG10876a

32 Carb Barrel 10GX EVOG10813

33 Idle Needle Assy 10GX EVOG10810

34 High Speed Needle

Assembly 10GX

EVOG10812

35 Hi Speed Needle 10GX EVOG10829

36 Fuel Nipple-12114:A EVO100114

37 Idle Needle Stop

Screw-46825F:A

EVO100825F

38 Throttle Arm EVO100864A

39 Carb Barrel Spring 10GX EVOG10814

40 Carb regulator screws

(4) 10GX

EVOG12123

41 Engine Gasket Set:

60NX, 10GX

EVO060416

2 YEAR LIMITED WARRANTY

What this Warranty Covers - Horizon Hobby, Inc.,

(Horizon) warrants to the original purchaser that

the product purchased (the “Product”) will be free

from defects in materials and workmanship for a

period of 2 years from the date of purchase.

What is Not Covered - This warranty is not trans-

ferable and does not cover (i) cosmetic damage, (ii) damage due to acts of God, accident,

misuse, abuse, negligence, commercial use,

or due to improper use, installation, operation

or maintenance, (iii) modication of or to any

part of the Product, (iv) attempted service by

anyone other than a Horizon Hobby authorized

service center, (v) Product not purchased from

an authorized Horizon dealer, or (vi) Product not

compliant with applicable technical regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE,

HORIZON MAKES NO OTHER WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND

ALL IMPLIED WARRANTIES, INCLUDING, WITHOUT

LIMITATION, THE IMPLIED WARRANTIES OF NON-

Page 17

EN

17

INFRINGEMENT, MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET

THE REQUIREMENTS OF THE PURCHASER’S IN-

TENDED USE.

Purchaser’s Remedy - Horizon’s sole obligation

and purchaser’s sole and exclusive remedy shall

be that Horizon will, at its option, either (i) service,

or (ii) replace, any Product determined by Horizon

to be defective. Horizon reserves the right to in-

spect any and all Product(s) involved in a warranty

claim. Service or replacement decisions are at

the sole discretion of Horizon. Proof of purchase

is required for all warranty claims. SERVICE OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY.

Limitation of Liability - HORIZON SHALL NOT BE

LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY,

REGARDLESS OF WHETHER SUCH CLAIM IS BASED

IN CONTRACT, WARRANTY, TORT, NEGLIGENCE,

STRICT LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES. Further, in

no event shall the liability of Horizon exceed the

individual price of the Product on which liability

is asserted. As Horizon has no control over use,

setup, final assembly, modification or misuse, no

liability shall be assumed nor accepted for any resulting damage or injury. By the act of use, setup

or assembly, the user accepts all resulting liability.

If you as the purchaser or user are not prepared to

accept the liability associated with the use of the

Product, purchaser is advised to return the Product immediately in new and unused condition to

the place of purchase.

Law - These terms are governed by Illinois law

(without regard to conict of law principals). This

warranty gives you specific legal rights, and you

may also have other rights which vary from state

to state. Horizon reserves the right to change or

modify this warranty at any time without notice.

WARRANTY SERVICES

Questions, Assistance, and Services - Your local

hobby store and/or place of purchase cannot provide warranty support or service. Once assembly,

setup or use of the Product has been started, you

must contact your local distributor or Horizon directly. This will enable Horizon to better answer

your questions and service you in the event that

you may need any assistance. For questions or

assistance, please visit our website at www.horizonhobby.com, submit a Product Support Inquiry,

or call 877.504.0233 toll free to speak to a Product

Support representative.

Inspection or Services - If this Product needs to

be inspected or serviced and is compliant in the

country you live and use the Product in, please

use the Horizon Online Service Request submission process found on our website or call Horizon

to obtain a Return Merchandise Authorization

(RMA) number. Pack the Product securely using

a shipping carton. Please note that original boxes

may be included, but are not designed to withstand the rigors of shipping without additional

protection. Ship via a carrier that provides tracking and insurance for lost or damaged parcels, as

Horizon is not responsible for merchandise until

it arrives and is accepted at our facility. An Online

Service Request is available at http://www.horizonhobby.com/content/_service-center_renderservice-center. If you do not have internet access,

please contact Horizon Product Support to obtain

a RMA number along with instructions for submitting your product for service. When calling Horizon, you will be asked to provide your complete

name, street address, email address and phone

number where you can be reached during business hours. When sending product into Horizon,

please include your RMA number, a list of the

included items, and a brief summary of the problem. A copy of your original sales receipt must be

included for warranty consideration. Be sure your

name, address, and RMA number are clearly written on the outside of the shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If

you have any issue with a LiPo battery, please

contact the appropriate Horizon Product Support

office.

Warranty Requirements - For Warranty consideration, you must include your original sales receipt

verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product

will be serviced or replaced free of charge. Service

or replacement decisions are at the sole discretion

of Horizon.

Non-Warranty Service - Should your service not

be covered by warranty, service will be completed

and payment will be required without notification

or estimate of the expense unless the expense

exceeds 50% of the retail purchase cost. By sub-

mitting the item for service you are agreeing to

payment of the service without notification. Ser-

vice estimates are available upon request. You

must include this request with your item submitted for service. Non-warranty service estimates

will be billed a minimum of ½ hour of labor. In addition you will be billed for return freight. Horizon

accepts money orders and cashier’s checks, as

Page 18

EN

18

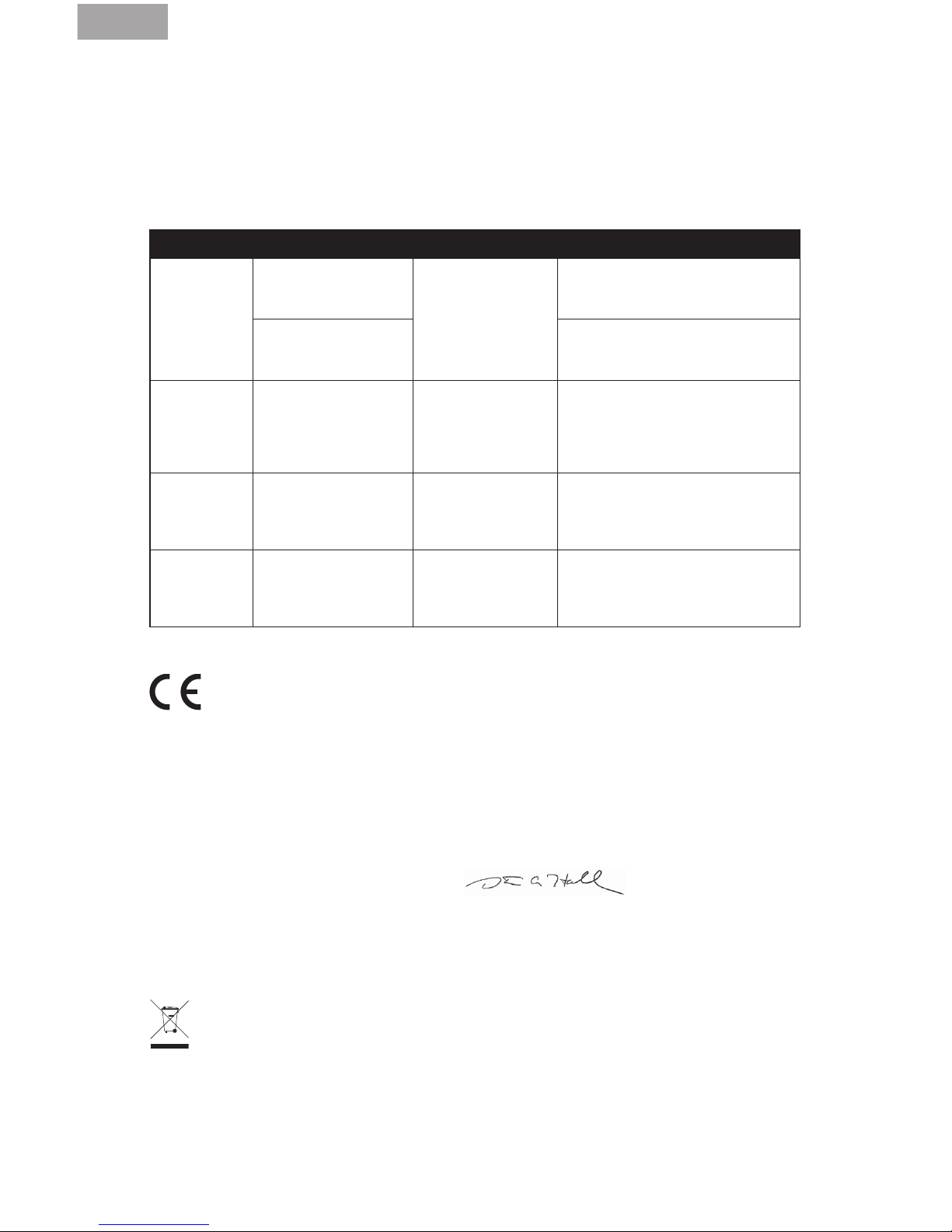

COMPLIANCE INFORMATION FOR THE EUROPEAN UNION

Declaration of Conformity (in accordance with ISO/IEC 17050-1)

No. HH2012092301

Product(s): EVO 10cc (.60 cu. in.) Gas RC Engine

Item Number(s): EVOE10GX

The object of declaration described above is in conformity with the requirements of the

specications listed below, following the provisions of the European EMC Directive 2004/108/EC:

EN55022:2010

EN55024:2010

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

September 23, 2012

Instructions for disposal of WEEE by users in the European Union

This product must not be disposed of with other waste. Instead, it is the user’s responsibil-

ity to dispose of their waste equipment by handing it over to a designated collections point

for the recycling of waste electrical and electronic equipment. The separate collection and recycling

of your waste equipment at the time of disposal will help to conserve natural resources and ensure

that it is recycled in a manner that protects human health and the environment. For more information about where you can drop off your waste equipment for recycling, please contact your local city

office, your household waste disposal service or where you purchased the product.

WARRANTY AND SERVICE CONTACT INFORMATION

Horizon Hobby Address Phone Number/Email Address

United States

of America

Horizon Service Center

(Electronics and

engines)

4105 Fieldstone Rd

Champaign, Illinois,

61822 USA

877-504-0233

Online Repair Request: visit

www.horizonhobby.com/service

Horizon Product

Support

(All other products)

877-504-0233

productsupport@horizonhobby.com

United

Kingdom

Horizon Hobby Limited

Units 1-4 , Ployters

Rd, Staple Tye,

Harlow, Essex,

CM18 7NS, United

Kingdom

+44 (0) 1279 641 097

sales@horizonhobby.co.uk

Germany

Horizon Technischer

Service

Christian-Junge-

Straße 1

25337 Elmshorn,

Germany

+49 (0) 4121 2655 100

service@horizonhobby.de

France Horizon Hobby SAS

11 Rue Georges

Charpak

77127 Lieusaint,

France

+33 (0) 1 60 18 34 90

infofrance@horizonhobby.com

well as Visa, MasterCard, American Express, and

Discover cards. By submitting any item to Horizon

for service, you are agreeing to Horizon’s Terms

and Conditions found on our website http://www.

horizonhobby.com/content/_service-center_render-service-center.

NOTICE: Horizon service is limited to Product

compliant in the country of use and ownership. If

non-compliant product is received by Horizon for

service, it will be returned unserviced at the sole

expense of the purchaser.

Steven A. Hall

Executive Vice President and Chief Operating Ofcer

International Operations and Risk Management

Horizon Hobby, Inc.

Page 19

DE

19

HINWEIS

Alle Anweisungen, Garantien und anderen zugehörigen Dokumente können im eigenen Ermessen von Horizon Hobby, Inc. jederzeit geändert werden. Die aktuelle Produktliteratur finden Sie

auf horizonhobby.com unter der Registerkarte „Support“ für das betreffende Produkt.

Die folgenden Begriffe werden in der gesamten Produktliteratur verwendet, um auf unterschiedlich hohe Gefahrenrisiken beim Betrieb dieses Produkts hinzuweisen:

HINWEIS: Wenn diese Verfahren nicht korrekt befolgt werden, können sich möglicherweise

Sachschäden UND geringe oder keine Gefahr von Verletzungen ergeben.

ACHTUNG: Wenn diese Verfahren nicht korrekt befolgt werden, ergeben sich wahrscheinlich

Sachschäden UND die Gefahr von schweren Verletzungen.

WARNUNG: Verfahren können bei nicht ordnungsgemäßer Durchführung möglicherweise

Schäden an Eigentum, Kollateralschäden UND schwere Verletzungen bis zum Tot ODER

höchstwahrscheinlich oberflächliche Verletzungen verursachen.

Spezielle Bedeutungen

WARNUNG: Lesen Sie die GESAMTE Bedienungsanleitung, um sich vor dem Betrieb

mit den Produktfunktionen vertraut zu machen. Wird das Produkt nicht korrekt

betrieben, kann dies zu Schäden am Produkt oder persönlichem Eigentum führen

oder schwere Verletzungen verursachen.

Dies ist ein hochentwickeltes Hobby-Produkt. Es muss mit Vorsicht und gesundem Menschenverstand betrieben werden und benötigt gewisse mechanische Grundfähigkeiten. Wird

dieses Produkt nicht auf eine sichere und verantwortungsvolle Weise betrieben, kann dies

zu Verletzungen oder Schäden am Produkt oder anderen Sachwerten führen. Dieses Produkt

eignet sich nicht für die Verwendung durch Kinder ohne direkte Überwachung eines Erwachsenen. Versuchen Sie nicht ohne Genehmigung durch Horizon Hobby, Inc., das Produkt

zu zerlegen, es mit inkompatiblen Komponenten zu verwenden oder auf jegliche Weise zu

erweitern. Diese Bedienungsanleitung enthält Anweisungen für Sicherheit, Betrieb und

Wartung. Es ist unbedingt notwendig, vor Zusammenbau, Einrichtung oder Verwendung alle

Anweisungen und Warnhinweise im Handbuch zu lesen und zu befolgen, damit es bestimmungsgemäß betrieben werden kann und Schäden oder schwere Verletzungen vermieden

werden.

ACHTUNG: Dieses Produkt kann bei dem Betrieb extrem heiß werden was zu

Verbrennungen führen kann.

Nicht geeignet für Kinder unter 14 Jahren. Dies ist kein Spielzeug.

Sicherheitswarnungen

Modellmotoren haben eine erhebliche Leistung, die bei unsachgemäßer Verwendung eine Gefährdung darstellen kann. Nutzen Sie bei dem Betrieb immer den gesunden Menschenverstand

und beachten alle Sicherheitshinweise bei dem Umgang mit dem Motor, oder allen Tätigkeiten

in diesem Zusammenhang. Das nicht befolgen der Sicherheitsbestimmungen kann zu ernsthaften Personen- und Sachbeschädigungen führen.

• Stellen Sie immer sicher dass Zuschauer, insbesondere Kinder, mindestens 9,90 Meter

entfernt sind wenn Sie den Motor laufen lassen.

• Stellen Sie vor JEDEM Flug sicher, dass der Propeller fest mit der Kurbelwelle verbunden ist

und alle Halter/Befestigungen sicher angezogen/befestigt sind. Verwenden Sie zum sichern

von Schrauben und Muttern blauen Schraubensicherungslack.

• Halten Sie Kleinteile immer aus der Reichweite von Kindern, da diese verschluckt

werden können.

• Sichern Sie immer das Flugzeug bevor Sie den Motor starten.

• Halten Sie immer das Gesicht und den Körper weg vom Propellerkreis wenn Sie den Motor

Page 20

DE

20

starten oder wenn er läuft.

• Stellen Sie sich immer hinter den Propeller wenn Sie Einstellungen am Vergaser vornehmen.

• Tragen Sie immer eine Schutzbrille beim Starten oder Laufen lassen des Motors.

• Bewahren Sie ihren Kraftstoff immer an einem sicheren Ort weit weg von möglicher

Funkenbildung, Hitze oder zündfähigen Stoffen auf.

• Stellen Sie immer sicher, dass das Luftfahrzeug korrekt gesichert ist und sich bei Motorstart

nicht bewegen/anrollen kann.

• Führen Sie nach den Einstellungen vor dem Erstug den Bindevorgang erneut aus.

• Stellen Sie immer sicher dass die Failsafeeinstellung des Gaskanal auf Motor aus/

Leerlauf steht.

• Führen Sie immer vor dem Flug einen Reichweitentest durch.

• Unterbrechen Sie die Kraftstoffversorgung (durch trennen oder abdrücken der

Kraftstoffleitung) oder schließen Sie mit Gasgestänge die Vergaserdrosselklappe

um den Motor zu stoppen.

• Gebrauchen Sie niemals Ihre Hände, Finger oder andere Körperteile um den Propeller

zu stoppen.

• Werfen Sie niemals etwas in den Propeller um ihn zu stoppen.

• Lassen Sie niemals den Motor über losen Untergrund wie Sand oder Kies laufen, damit

nicht die Gefahr besteht dass der Motor kleine Teile unkontrolliert hochschleudert.

• Tragen Sie niemals bei dem Betrieb des Modells lose Kleidung oder ein loses Nackenband/

Umhängegurt, da sich diese Teile im Propeller verfangen können.

• Führen Sie niemals bei Betrieb oder Umgang mit dem Motor lose Gegenstände wie

Schraubendreher, Stifte, etc.. in Ihren Taschen. Diese könnten in den Propeller fallen.

• Lassen Sie niemals Kraftstoff in Berührung mit Mund oder Augen kommen da dieser giftig ist.

• Lagern Sie Kraftsoff in eindeutig bezeichneten Behältnissen ausserhalb der Reichweite

von Kindern.

Sicherheitsrichtlinien

• Montieren Sie den Motor korrekt auf einer geeigneten Werkbank oder einem qualitativ

hochwertigen Motorträger.

• Verwenden Sie immer Propeller mit der richtigen Größe und Steigung. Sehen Sie dazu

in die Propellerliste in dieser Anleitung.

• Überprüfen Sie immer vor der Montage des Propellers dass dieser einwandfrei gewuchtet ist.

Das nichtbeachten könnte zu Motorschäden oder zu Schäden am Flugzeug führen.

• Verwenden Sie immer falls möglich einen Elektrostarter.

• Verwenden Sie keine Propeller die Knicke, Risse, Brüche oder sonstige Beschädigungen

aufweisen.

• Lassen Sie den Motor nur in gut belüfteten Bereichen laufen. Modellmotoren produzieren

giftige Kohlenmonoxid Abgase.

• Lagern Sie Kraftstoff nur in kühlen trockenen Orten. Lassen Sie Kraftstoffbehälter nicht in di-

rekten Kontakt mit Beton kommen, da der Kraftstoff dadurch Feuchtigkeit aufnehmen könnte.

• Entsorgen Sie immer verantwortungsvoll Kraftstoff der durch Kondensation Feuchtigkeit (Was-

ser) aufgenommen hat.

• Schütten Sie niemals ungebrauchten Kraftstoff aus dem Tank in den Kanister.

• Modizieren, verändern und reparieren Sie niemals Propeller.

• Hantieren Sie nicht mit Modellmotoren, Schalldämpfern, Auspuffen oder Resorohren

bis diese vollständig abgekühlt sind. Diese können bei Betrieb extrem heiß werden.

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres ersten Evolution-Small Block-Benzinmotors unserer

neuen Serie. Sämtliche Evolution-Benzinmotoren sind dafür ausgelegt, Ihnen ab dem ersten

Tag hervorragende Leistung zum Bruchteil Ihrer vorherigen Betriebskosten zu geben. Wir haben

jeden einzelnen Motor mit äußerster Sorgfalt konstruiert und geprüft, um einen problemlosen

Betrieb ohne Kompromisse in der Leistung oder Langlebigkeit einzugehen. Dieses Handbuch

führt Sie, wenn Sie es lesen und befolgen, durch einfache Schritte zu einer erfolgreichen

Anwendung. Herzlich willkommen bei der Evolution-Produktfamilie.

Page 21

DE

21

Small Block-Benzinmotorkonstruktion

Begonnen haben wir mit dem vielfach bewährten 60NX-Glühkerzenmotor, der von Tausenden

von Kunden auf der ganzen Welt eingesetzt wird; jetzt haben wir unsere Erfahrung in das Bereich

der Benzinmotoren eingebracht, um Ihnen ein vollständiges Paket, hervorragende Leistung und

niedrige Betriebskosten liefern zu können.

Schritt 1 Beginn mit einem hervorragenden Motor. Der 60NX wurde im Juli 2009 erstmalig

angekündigt und seitdem an Tausende von Anwendern erfolgreich verkauft; er liefert

exzellente Leistung.

Schritt 2 Konstruktion eines neuen, zuverlässigen Vergasersystems für einen problemlosen

Betrieb beim Anwender. Dieser neue Vergaser, der bereits mit bewährter Technologie

aufwartet, wurde modifiziert, um in den verfügbaren Bauraum vor dem Zylinder

zu passen und um die speziellen Anforderungen eines benzinbetriebenen Motors

zu erfüllen. An der Vorderseite des Vergasers befindet sich ein durch den Druck im

Kurbelgehäuse angetriebenes Regelsystem. Dieses System umfasst einen über den

Schalldämpfer unter Druck gesetzten Tank, der den Kraftstoff in allen Flughöhen richtig

zumisst. Ein neues Katzenaugen-Kraftstoffmesssystem wurde hinzugefügt, um in den

unteren und mittleren Gasstellungen für mehr Steuerbarkeit zu sorgen.

Schritt 3 Konstruktion eines eigenen Schalldämpfersystems zur Abfuhr der zusätzlichen Hitze

und Wärmeausdehnung des verbrannten Benzingemisches im Vergleich zu einem

Glühsystem. Diese Änderungen umfassten das Vergrößern des Schalldämpfervolumes

einschließlich einer wesentlich größeren Schalldämpfer-Durchgangsschraube zur

Ableitung von Hitze und Spannung sowie die Vergrößerung des Schalldämpferausgangs

zur Minimierung des Rückstaus, ohne die Schalldämpfung zu beeinträchtigen.

Schritt 4 Konstruktion von Betriebszubehör zur Verbesserung des Anwendererlebnisses.

Während unseres umfangreichen, 2-1/2-jährigen Testprogramms haben wir eine

Reihe von neuen Techniken und auch von Hindernissen entdeckt, die typisch für

benzinbetriebene Kleinmotoren sind.

• Da die Menge des verbrauchten Kraftstoffs nur etwa ein Drittel der eines

vergleichbaren Glühkerzenmotors ist, sind Konstruktion und Zuverlässigkeit des

Kraftstoffversorgungssystems zum Vergaser dreimal so kritisch. Mikroskopisch

kleine Schmutzteilchen, die problemlos durch die größeren Querschnitte eines

Glühkerzenmotor-Vergasers fließen, richten in einem Benzinsystem verheerende

Schäden an. Dieses Schmutzproblem lösen wir durch einen Qualitäts-

Leitungslter wie z. B. unseren Leitungslter (EVOA105). Unser Motor ist mit

diesem Filter ausgerüstet.

• Das Gleiche gilt für Luftblasen aus dem Tank oder für kleine Lecks in der

Benzinleitung; was problemlos durch einen Glühkerzenmotor-Vergaser geht, wird

in einem Benzinsystem nicht toleriert, da die Luftblasen dreimal soviel Wirkung

zeigen wie vorher. Wir haben einen exzellenten Filzlterklotz entwickelt und

verbaut, der Luftblasenbildung in der Benzinleitungen verhindert. Dieser Filzklotz

ist für einen zuverlässigen und erfolgreichen Betrieb äußerst wichtig. Unser Motor

ist mit diesem Filter ausgerüstet.

• Wir haben herausgefunden, dass hohe Schalldämpfertemperaturen die

normalen Tygonleitungen (die erste Wahl für Benzinmotoren) innerhalb von

Minuten zerstören würde. Wir haben herausgefunden, dass Neoprenleitungen

den hohen Temperaturen zwar widerstehen, sich aber zu schnell degenerieren

würden; darum haben wir Viton-Leitungen der richtigen Größe verwendet

(Benzinleitung EVOA104). Sie widerstehen nicht nur den hohen Temperaturen,

ihre Widerstandsfähigkeit ist auch wesentlich größer als die von Tygon oder

Neopren. Ein weiterer Vorteil dieser Leitungen besteht darin, dass sie ohne

zusätzliche Drähte oder Schlauchschellen gut an den Benzinleitungsanschlüssen

halten. Ihr Motor ist mit einem Satz dieser Leitungen ausgerüstet.

Page 22

DE

22

Nadel für

hohe Drehzahl

Schalldämpfer

Zündkerze

Schalldämpfernippel

Kraftstoffnippel

Einbau des Motors

1. Motorträger am Brandschott des Flugzeugs

befestigen. Die Motorträgerschrauben im

Brandschott festziehen.

2. Den Motor gemäß der Angaben des

Flugzeugherstellers am Motorträger

befestigen.

WARNUNG: Ziehen Sie vor jedem Flug

alle Motorbefestigungsschrauben

nach. Wenn Sie die

Motorbefestigungsschrauben nicht

nachziehen, können sie sich durch die

Vibrationen lockern und der Motor

kann sich vom Rumpflösen.

Nadel für niedrige

Drehzahl

Nadelanschlag

Schalldämpfer

Zündkerze

Gasarm

Mitgelieferter Inhalt

MOTOR

• Schalldämpfer (EVO10601)

• Schalldämpferschrauben, -dichtung

(EVO100E46A)

• Zündkerze (EVOG10350)

• Evolution/Spektrum Telemetrie-RPMAdapterkabel (EVOA107)

• Med. Kraftstofeitung (EVOA104)

• Leitungsmontierter Kraftstofflter (EVOA105)

• Tankmontierter Filzlter/Klotz (EVOA106)

OPTIONALE ARTIKEL

• Drehzahlmesser (HAN156)

• Propeller 10 x 6 (EVO10060) für das

Einlaufen; 12 x 6 (EVO12060) für Normalug

• EVOM1 Getunter

Hochleistungsschalldämpfer: EVO46-60

Page 23

DE

23

Verbindung des Gasgestänges

1. Verwenden Sie zum Anbringen des

Gasgestänges an den Gasarm des

Vergasers eine sichere Methode.

2. Schalten Sie den Sender und den

Empfänger ein.

3. Bewegen Sie den Gashebel auf die mittlere

Hebelstellung.

4. Stellen Sie den Gasarm so ein, dass

er einen Winkel von 90 Grad zum zur

Gasschubstange bildet.

5. Zentrieren Sie den Gas-Servomotor.

Montieren Sie einen Gasarm mit einer

Bohrung im Abstand von 11 mm vom

Mittelpunkt des Armes.

6. Verwenden Sie einen Gabelkopf zum

Anbringen des Gasgestänges an den

Servoarm.

11mm

1,5mm

Einbau des Schalldämpfers

Das Schalldämpfer-Montagevorbereitung umfasst

Montageschrauben (2), Sicherungsscheiben (2),

Schalldämpferdichtungen (2) und Inbusschüssel

(2).

1. Setzen Sie auf jede Schalldämpferschraube

eine Sicherungsscheibe. Schieben Sie

die Schalldämpferschrauben durch den

Zylinderkopf.

2. Positionieren Sie die Schalldämpferdichtung

über die Motormontageschrauben.

3. Richten Sie die Schalldämpferdichtung

zur Auspufföffnung und den

Schalldämpfermontageschrauben aus.

4. Ziehen Sie die Schalldämpferschrauben fest.

Wichtig: Ziehen Sie die

Schalldämpferschrauben nach 5 Betankungen

nach. Die Schalldämpferschrauben lösen sich

durch Wärme und Vibration.

Die Schalldämpfer-Durchgangsschraube muss

nach jeder der ersten drei Vollbetankungen

nachgezogen werden. Die Wärme bewirkt eine

Ausdehnung der Durchgangsschraube und der

Schalldämpfergehäuseteile. Nach dem dritten

Nachziehen sollte keine weitere Lockerung des

Schalldämpfers auftreten.

Nachziehen der SchalldämpferDurchgangsschraube:

1. Die Schalldämpfer-Sicherungsmutter lösen.

2. Die Schalldämpfer-Durchgangsschraube

festziehen.

3. Die Schalldämpfer-Sicherungsmutter

festziehen.

Page 24

DE

24

1. Senken Sie den Gashebel und zentrieren

Sie die Gastrimmung.

2. Stellen Sie die Länge des Gasgestänges

so ein, dass der Vergaserschieber 1 mm

geöffnet ist.

3. Bewegen Sie den Gashebel nach oben, um

festzustellen, ob der Vergaserschieber sich

öffnet. Wenn der Vergaserschieber sich

nicht öffnet, invertieren Sie den Gaskanal

in Ihrem Sender.

4. Bewegen Sie den Gashebel und die

Gastrimmung nach unten, um festzustellen,

ob der Vergaserschieber sich schließt.

5. Wenn Sie den Gaskanal in Ihrem Sender

invertiert haben und ein Funksystem mit

2,4 GHz verwenden, müssen Sie es neu

anbinden, um die richtige Failsafe-Position

einzustellen.

Kraftstoffleitung

Belüftungsleitung

1. Schließen Sie die Viton

®

-Kraftstoffleitung

mit mittlerem Durchmesser an den Vergaser

und die Tankversorgungsleitung an.

2. Schließen Sie die Viton-Kraftstoffleitung

mit mittlerem Durchmesser an den

Schalldämpfer-Drucknippel und die

Tankentlüftungsleitung an.

Belüftungsleitung

Kraftstoffleitung

EMPFOHLENE PROPELLER

10 x 6–13 x 8 (12 x 6 wurde als der Propeller

mit der für diesen Motor besten Leistung

getestet; die Leistung ist jedoch über den

gesamten empfohlenen Bereich sehr gut)

1. Entfernen Sie die Propellermutter und die

Propellerscheibe von der Kurbelwelle.

2. Montieren Sie die Spinner-Grundplatte,

dann den Propeller, die Propellerscheibe

und die Propellermutter.

3. Decken Sie den Propeller mit einem Tuch

ab und ziehen Sie die Propellermutter mit

einem verstellbaren Schraubenschlüssel

fest.

4. Montieren Sie den Spinnerkonus. Der

Spinnerkonus darf den Propeller nicht

berühren. Stellen Sie, falls erforderlich, die

Propelleröffnung ein.

5. Ziehen Sie die Spinnerschraube(n) fest, um

den Spinnerkonus zu sichern.

Anbringen von Propeller und Spinner

Einstellung des Vergaserschiebers

Anbringen der Kraftstoffleitungen

Page 25

DE

25

Anschließen der elektronischen Zündung

Die elektronische Zündung von Evolution wurde speziell für die

Small Block-Motorreihe konstruiert und gebaut. Sie ist kleiner und leichter und passt daher in

kleinere Einbauräume der Flugzeuge, welche die Motoren antreiben sollen. Die erforderliche

Batteriespannung liegt zwischen 4,8 V (Ni-MH-Pack mit 4 Zellen) und 8,4 V (2S Li-Po-Batterie);

für keine dieser Batterien sind Spannungsregler erforderlich. Wir empfehlen eine 2S Li-FeBatterie (wie z. B. die Team Orion Avionics Li-Fe Receiver Pack 1300 mAh 6,6 V (ORI60503)); mit

diesen Packs haben wir umfangreiche Versuche durchgeführt. Die maximale Stromabgabe bei

Vollgas beträgt 450 mAh, die typische Durchschnittsabgabe liegt zwischen 250 und 300 mAh.

Die Baugruppe besteht aus:

• Zündmodul mit Batterieanschluss, Zündsensoranschluss, Drehzahlmesseranschluss und

Zündkerzenstecker.

• Zündsensor (bereits an Ihrem Motor angebaut)

• Sensormagnet (bereits in der Propeller-Antriebsnabe Ihres Motors eingebaut)

Montage Ihrer elektronischen Zündung

• Sie können das Zündmodul in jeder Lage

und an jeden Ort bauen, der für Ihre

Installation geeignet ist. Das Modul hat

eine Größe, die es bequem längs in das

Tankabteil der meisten Flugzeuge der

Größen 46–50 oder unter den empfohlenen

180–240 ml-Tank passen lässt. Sie können

sie auch an das Brandschott oder unter

die Motorschottverlängerung bauen,

wenn Ihr Flugzeug so ausgestattet ist.

Beachten Sie, dass die Zündanlage aus

Hitzeschutzgründen nicht in die Nähe des

Schalldämpfers montiert werden darf.

• Sichern Sie das Zündmodul an dem

von Ihnen gewählten Montageort

mit Schaumstoffpolsterung, um

Vibrationsschutz zu schaffen. Wir

befestigen das Zündmodul normalerweise

mit Kabelbindern, nachdem wir es in

leichtes, 6,35mm dickes Schaumgummi

eingewickelt haben.

• Möglicherweise müssen Sie sowohl

das Zündkerzenkabel als auch das

Zündsensorkabel durch das Brandschott

verlegen; darum planen Sie gut voraus

und bohren Sie Löcher ausreichender

Größe, damit Sie den Zündsensoranschluss

bzw. den Zündkerzenstecker durch die

Bohrungen bekommen, wenn Sie das

Zündmodul später einmal ausbauen

wollen.

• Montieren Sie einen

Radioempfängerschalter hoher Qualität

zwischen das Zündmodul und die Batterie.

Montieren Sie diesen Schalter an einen gut

zugänglichen Ort vorn an den Außenrumpf,

um das Zündmodul einfach ein- und

ausschalten zu können. Die Zündung

schnell ausschalten zu können, ist

sicherheitsrelevant.

• Schließen Sie das Zündsensorkabel an

das Zündmodul an. Das Sensorkabel

passt nur auf einen der Anschlüsse; ein

Falschanschluss ist nicht möglich.

• Schließen Sie den EIN-/AUS-Schalter

an das Batterieanschlusskabel des

Zündmoduls an. Dieser Anschluss ist rot.

• Falls gewünscht, können Sie

entweder den separat erhältlichen

Drehzahlmesserausgang oder das im

Lieferumfang enthaltene Evolution/

Spektrum Telemetrie-Adapterkabel

(EVOA107) an den Drehzahlmesser-

Ausgangsanschluss anschließen. Stecken

Sie das andere Ende des Adapterkabels

in den Drehzahl-Eingangsanschluss Ihres

Telemetriemoduls ein.

• Stecken Sie den Zündkerzenstecker auf die

Zündkerze auf. Dieser Adapter hat einen

Verschlussmechanismus, der nach dem

Aufstecken um 1/8 Drehung verdreht wird,

um eine sichere Verbindung zu erreichen.

Laden Sie Ihre Zündbatterie auf; jetzt können

Sie Ihre elektronische Zündung mit dem

Motor verwenden.

Page 26

DE

26

Kraftstoff

Dieser Motor benötigt ein Kraftstoff-

Öl-Gemisch von 1:20, um eine

langfristige Funktion sicherzustellen. Die

ordnungsgemäße Funktion des Bronzelagers

am unteren Ende der Pleuelstange hängt von

diesem Mischungsverhältnis ab. Verwenden

Sie keine dünneren Kraftstoff-Öl-Mischungen

als 20:1, anderenfalls erlischt die Garantie auf

Ihren Motor.

Sie stellen die richtige Mischung her, indem

Sie 53 ml Öl mit einem Liter Kraftstoff mit

87–93 Oktan mischen. (Das Zweitaktöl

EVOX1001Q Evolution 2 wird empfohlen.) Wir

füllen erst das Öl in den Kraftstofftank und

geben dann den Kraftstoff hinzu. Hierdurch

wird von Anfang an eine gute Durchmischung

des Öls mit dem Kraftstoff erreicht.

Wir haben unser eigenes Evolution-Zweitaktöl,

Valvoline, Shell, RedLine sowie HusqvarnaÖle getestet. Andere qualitativ hochwertige

Zweitaktöle sollten ebenso gut funktionieren.

Verwenden Sie niemals Amsoil, in keiner

Form.

Kraftstoffzufuhrsystem

Es ist sehr wichtig, das

Kraftstoffversorgungssystem zum Motor gut

zu konzipieren, um Betriebsprobleme des

Motors zu vermeiden. Unsere Erfahrung hat

uns gezeigt, das viele scheinbare Probleme

beim Betrieb des Motors in Wirklichkeit

Kraftstoffzufuhr- und keine Motorprobleme

sind.

Kraftstofffilterung - Aufgrund der unglaublich

kleinen Kraftstoffmenge, die dieser Motor

braucht, ist eine Filtrierung des Kraftstoffs

an drei verschiedenen Stellen des Systems

vorgeschrieben:

1. Zwischen Kraftstoffkanne und Tank

2. Im Kraftstofftank selbst (mit einem

Filterklotz EVOA106)

3. Zwischen Kraftstofftank und Vergaser

(mit einem in der Leitung verbauten

Kraftstofflter EVOA105).

Beider Filter (2 und 3) sind im Motorpaket

enthalten.

Einbauort des Tanks - Da zur

Kraftstoffregulierung und Vergaserbemessung

der Schalldämpferdruck verwendet wird,

muss der Tank in einer Linie mit dem Vergaser

und so nah wie möglich an das Ende des

Motors gebaut werden. Eine Montage des

Tanks in der beschriebenen Weise sorgt für

problemlosen Betrieb in allen Flughöhen.

Tankauswahl und Tankkonstruktion – Wählen

Sie einen Tank zwischen 170 und 240 ml

Inhalt. Dieser Tankinhalt schafft eine Flugzeit

von 17 Minuten (kleinerer Tank) bis 24

Minuten (größerer Tank) bei Vollgas.

Wenn der Tank kleiner als 170 ml ist, kann sich

der Klotz nicht frei bewegen. Tanks, die größer

als 240 ml sind, sind lediglich schwerer,

bringen aber keine weiteren Vorteile (außer

wenn Sie längere Zeit fliegen wollen).

• Verwenden Sie einen Tankverschluss für

Benzin und/oder Rauchöl.

• Wir schlagen ein Tanksystem mit drei

Leitungen vor: Eine Leitung zum Vergaser

mit dem innen befestigten Klotz, eine

für den Schalldämpferdruck zum Tank,

und eine zum Befüllen/Entleeren des

Tanks. Wir versuchen, T-Stücke und

andere innere Ventile zu vermeiden, da

diese eine Ursache von möglichen Luft-/

Kraftstoffleckagen sein können.

• Verwenden Sie die mitgelieferten Viton-

Leitungen für das gesamte Leitungssystem

des Tanks, innen und außen.

• Verwenden Sie unbedingt den

mitgelieferten Filzlterklotz im Tank.

• Verwenden Sie unbedingt den

mitgelieferten Leitungsfilter zwischen Tank

und Vergaser.

• Verwenden Sie unbedingt ein gutes

Dichtsystem für die Leitung zum Befüllen

und Entleeren des Tanks. Wir empfehlen

die Kraftstoffbefüllungsbaugruppe HAN116;

ihr schlankes Design sieht an Ihrem

Flugzeug gut aus, und sie ist einfach zu

verwenden.

Page 27

DE

27

Einlaufen des Motors

Ihr neuer Motor muss eingelaufen werden, um eine lange Lebensdauer aller Komponenten

sicherzustellen. Die Kolben sind aus Aluminium und die Laufbuchsen aus verchromtem

Messing; hierfür ist ein spezieller Einlaufprozess erforderlich, der mit Prüfstandsläufen nicht

vollständig erreicht werden kann.

Da Kolben und Laufbuchse ein enges Zusammenspiel zueinander haben müssen, um die

Kompression zu erreichen, sind die Motoren mit einer konischen Laufbuchse versehen;

während des Einlaufprozesses muss sich der Kolben an die Laufbuchse anpassen. Um dies zu

erreichen, sind wiederholte Erhitzungs- und Abkühlungszyklen erforderlich; außerdem ist eine

nur leicht fette Nadelstellung erforderlich.

Die Einlaufprozedur einer Kolben-Laufbuchsen-Kombination aus Aluminium/verchromten

Messing bei fetter Einstellung liefert nicht das Teilchenwachstum, das für die Passung zwischen

Kolben und Laufbuchse erforderlich ist Die Verwendung einer fetten Nadeleinstellung ermöglicht

nicht die erforderliche Ausdehnung der Laufbuchse, was dazu führt, dass das Pleuel beim

Überfahren des oberen Totpunkts (OT) die volle Kraft des Kolbens erfährt. Das Aufwärmen des

Motors führt zur Ausdehnung der Laufbuchse und reduziert die Last auf dem Pleuel, wodurch

ein gutes Einlaufergebnis erzielt wird. Die Verwendung einer geringeren Last auf dem Motor

(z. B. ein etwas kleinerer Propeller) macht diese Aufgabe noch einfacher. Befolgen Sie die

nachfolgenden Schritte, um ein erfolgreiches Einlaufen sicherzustellen.

1. Führen Sie die Einlaufphase im Flugbetrieb

durch.

2. Verwenden Sie für das Einlaufen einen 10

x 6-Propeller. Dies führt zu einer geringen

Last und hohen Drehzahl; Aufgrund der

Betriebstemperatur wird so ein gutes

Einlaufergebnis erzielt.

3. Verwenden Sie das empfohlene Kraftstoff-

Öl-Gemisch von 1:20.

4. Die richtige Einlauf-Flugprozedur besteht

darin, das Flugzeug mit Vollgas eine Serie

von Achten iegen zu lassen (d. h. die

Kubanische Acht). Von diesen Manövern

profitiert der Motor besonders, da die

zusätzliche Last auf den Motor beim

Steigflug die Temperatur erhöht und die

geringere Last und höhere Drehzahl beim

Sinkflug die Temperatur senkt; dies liefert

die für den Einlaufprozess notwendigen

Heiz- und Kühlzyklen.

5. Fliegen Sie zwei Tankfüllungen mit dem

Propeller 10 x 6; montieren Sie dann einen

Propeller 11 x 6 und fliegen Sie zwei weitere

Tankfüllungen.

6. Jetzt sollten Sie in der Lage sein, einen der

größeren Propeller zu verwenden und die

volle Leistung Ihre Motors zu genießen.

Machen Sie sich keine Sorgen über

eine während dieses Prozesses zu fette

Motoreinstellung. Wenn der Motor richtig

eingestellt ist, hört er sich an, als ob er

Fehlzündungen produziert (was er auch tut).

Im Steigug hören die Fehlzündungen auf; sie