Page 1

www.evolutionsteel.com

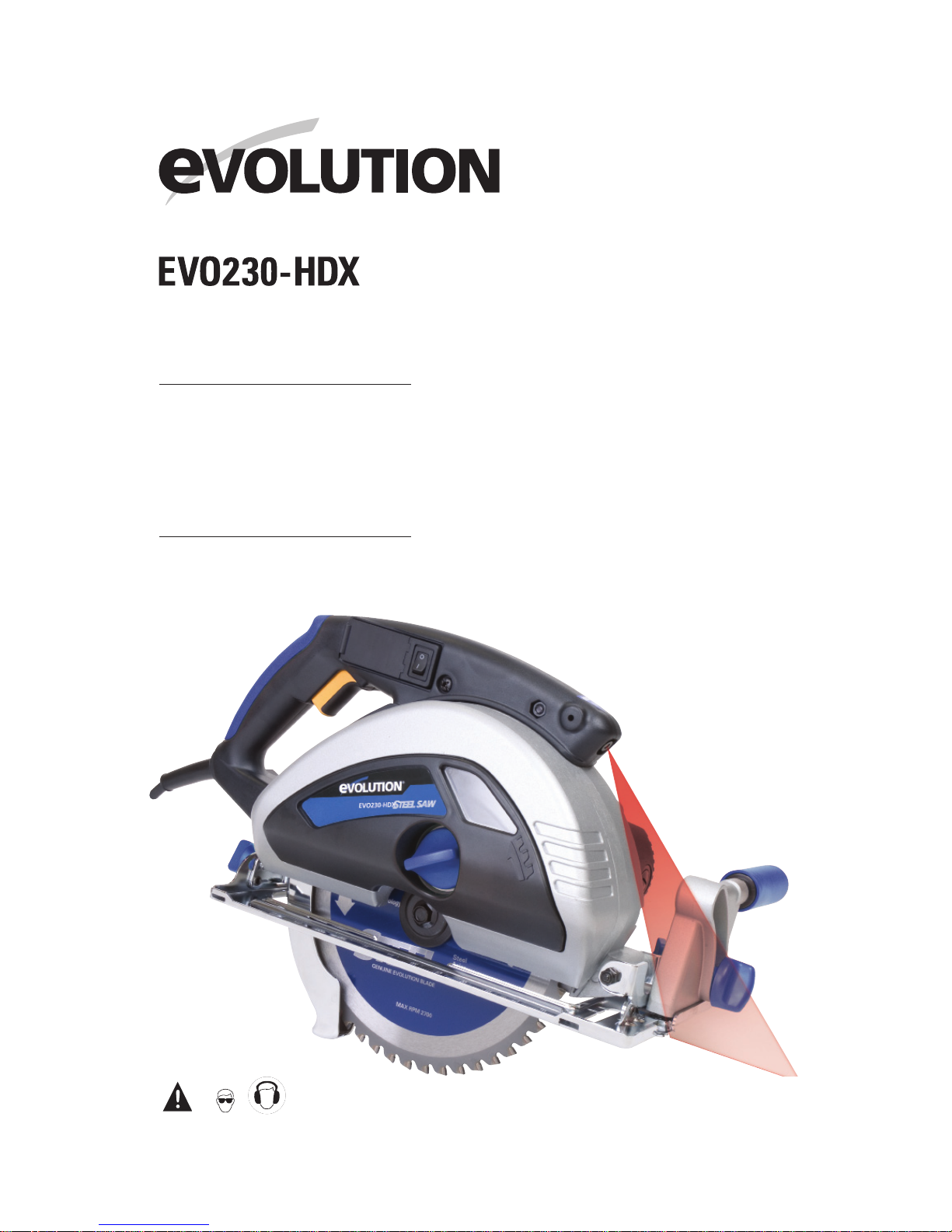

230mm (9”) TCT

Steel Cutting Circular Saw

Instruction

Manual

Read instructions before operating this tool.

Page 2

www.evolutionsteel.com

2

We, Evolution Power Tools Limited, Venture One,

Longacre Close, Sheffield, S20 3FR as the supplier of the

product listed below:

EVO230-HDX 230mm TCT Steel Cutting Circular Saw

Part Number EVO230X1/EVO230X2/EVO230X2EU

Voltage 110/230v

Power 1750W

Declare, under our sole responsibility that the equipment

to which this document relates, is in conformity with the

following standards or other normative documents:

EN60335-1: 1994+A1+A2+A11-A16

EN55014-1: 2000+A1+A2

EN55014-2: 1997+A1

EN61000-3-2: 2000

EN61000-3-3: 1995+A1

EN61000-3-11: 2000

EN60745-1/A1:2003

EN60745-2-5:2003

And thereby conforms to the protection requirements of

Council Directive 73/23/EEC amended by 93/68/EEC

relating to the Low Voltage Directive, Council Directive

98/37/EEC relating to the Machine Directive and Council

Directive 89/336/EEC relating to the EMC Directive, and is

compliant with Council Directive 2002/95/EC in relation to the

Restriction of Hazardous Substances in electrical & electronic

equipment (RoHS). EU Directive 2002/95/EC restricts the

use of the 6 substances below in the manufacture of specific

types of electrical equipment. Whilst this restriction does not

legally apply to components, it is recognized that component

‘compliance’ is relevant to many customers.

Evolution Power Tools definition of RoHS Compliance:

• The product does not contain any restricted substances in

concentrations and applications banned by the directive and

for components, the product is capable of being worked at

the higher temperatures required by lead-free soldering.

• The restricted substances and maximum allowed

concentrations in homogenous materials are, by weight:

Lead – 0.1%

Mercury – 0.1%

PBB (Polybrominated Biphenyis) – 0.1%

PBDE (Polybrominated Diphenyl Ethers) – 0.1%

Hexavalent Chromium – 0.1%

Cadmium – 0.01%

Level of Sound pressure according to

86/188/EEC, 98/37/EEC & 2000/14/EC

Guaranteed Sound Power Level 108.7 dB(A)

All Relevant technical documentation is held at Evolution

Power Tools Ltd, Sheffield, United Kingdom.

Authorised By

Mr Matthew J Gavins

Managing Director

9th May 2007

EC - DECLARATION OF CONFORMITY

Page 3

www.evolutionsteel.com

3

Please read these operating and safety instructions carefully

and completely. For your own safety, before using this

equipment check that the voltage is correct and that all

handles and parts are firmly secured. If you are uncertain

about any aspect of using this equipment, please contact our

Technical Helpline.

Technical Helpline UK 0870 609 2297

Technical Helpline USA 1-866-EVO-TOOL

Congratulations on your purchase of an Evolution Power

Tools Circular Saw. Please complete and mail your

product registration card or register on line to validate

your machine’s warranty period and ensure prompt

service if needed. We sincerely thank you for selecting a

product from Evolution Power Tools.

12 MONTH LIMITED WARRANTY.

Evolution power tools reserves the right to make

improvements and modifications to design without

prior notice.

Evolution Power Tools will, within twelve (12) months from

the original date of purchase, repair or replace any goods

found to be defective in materials or workmanship, provided

the product warranty registration card has been returned

to Evolution Power Tools. This warranty is void if the tool

being returned has been used to cut materials beyond the

recommendations in the Instruction Manual or if the saw has

been damaged by accident, neglect, or improper service. This

warranty does not apply to machines and / or components

which have been altered, changed, or modified in any way,

or subjected to use beyond recommended capacities

and specifications. Electrical components are subject to

respective manufacturers’ warranties. All goods returned

defective shall be returned prepaid freight to Evolution Power

Tools. Evolution Power Tools reserves the right to optionally

repair or replace it with the same or equivalent item. There

is no warranty – written or verbal – for saw blades. In no

event shall Evolution Power Tools be liable for loss or damage

resulting directly or indirectly from the use or merchandise or

from any other cause. Evolution Power Tools is not liable for

any costs incurred on such goods or consequential damages.

No officer, employee or agent of Evolution Power Tools is

authorised to make oral representations of fitness or to waive

any of the foregoing terms of sale and none shall be binding

on Evolution Power Tools. Questions relating to this limited

warranty should be directed to the company’s head office, or

call the appropriate Helpline number.

SAVE THESE INSTRUCTION FOR FUTURE REFERENCE.

WARNING!

Read and understand all instructions before operating

this product. Failure to follow all instructions listed

below, may result in electric shock, fire and / or serious

personal injury.

When using electric tools basic safety precautions should

always be followed to reduce the risk of fire, electric shock

and personal injury including the following.

Read all these instructions before attempting to operate

this product and save these instructions.

The term “power tool” in the warnings refers to your mains-

operated (corded)

1) Work Area Safety

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) Electrical Safety

a) Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is earthed

or grounded.

c) Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away from

heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a residual current device (RCD) protected supply. Use of

an RCD reduces the risk of electric shock.

IMPORTANT

EVO230-HDX 230mm (9” )TCT CIRCULAR SAW

GENERAL SAFETY RULES

Page 4

www.evolutionsteel.com

4

3) Personal Safety

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power tool

while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source and/or

battery pack, picking up or carrying the tool. Carrying power

tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep

your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction

and collection facilities, ensure these are connected and properly

used. Use of dust collection can reduce dust-related hazards.

4) Power Tool Use & Care

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or

the battery pack from the power tool before making any

adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into account the

working conditions and the work to be performed. Use of

the power tool for operations different from those intended

could result in a hazardous situation.

5) Service

a) Have your tool repaired by a qualified person. This electric

tool complies with the relevant safety rules. Repairs should

only be carried out by qualified persons using original spare

parts, otherwise this may result in considerable danger to

the user.

b) When servicing a tool, use only genuine Evolution

replacement parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or failure

to follow Maintenance Instructions may create a risk of

electric shock or injury.

Page 5

www.evolutionsteel.com

5

WARNING!

Do not operate machine if warning and / or instruction labels

are missing or damaged. Contact evolution power tools for

replacement labels.

Symbol Description

V Volts

A Amperes

Hz Hertz

Min Minutes

~ Alternating Current

No No Load Speed

Double Insulated

Only use genuine Evolution replacement blades.

Unauthorized blades may be dangerous! Keep saw blades

securely fastened. Check blade flanges for debris before

installing any new blade. Do not use dull or broken blades.

Check blades often for condition and wear. Damaged or

worn blades should be replaced immediately. Check chip

collector cover for proper fit to minimize the risk of flying

debris. Loose fitting or damaged collector must be replaced

immediately. Beware of ejecting chips as they may be HOT.

Always make provisions for safe handling of excess material.

Keep bottom of base plate free from dirt and other debris.

To obtain an additional copy of your manual, please

contact Evolution Power Tools at :

UK 0870 609 2297

USA 1-866-EVO-TOOL

WEB www.evolutionpowertools.com

a) DANGER: Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary handle, or motor

housing. If both hands are holding the saw, they cannot be

cut by the blade.

b) Do not reach underneath the workpiece. The guard cannot

protect you from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece.

Less than a full tooth of the blade teeth should be visible

below the workpiece.

d) Never hold piece being cut in your hands or across your

leg. Secure the workpiece to a stable platform. It is important

to support the work properly to minimize body exposure,

blade binding, or loss of control.

e) Hold power tool by insulated gripping surfaces when

performing an operation where the cutting tool may contact

hidden wiring or its own cord. Contact with a “live” wire will

also make exposed metal parts of the power tool “live” and

shock the operator.

f) When ripping always use a rip fence or straight edge

guide. This improves the accuracy of cut and reduces the

chance of blade binding.

g) Always use blades with correct size and shape (diamond

versus round) of arbour holes. Blades that do not match the

mounting hardware of the saw will run eccentrically, causing

loss of control.

h) Never use damaged or incorrect blade washers or bolt.

The blade washers and bolt were specially designed for your

saw, for optimum performance and safety of operation.

SPECIFIC SAFETY RULES & SYMBOLS ADDITIONAL SPECIFIC SAFETY RULES

Page 6

www.evolutionsteel.com

6

Causes & Operator Prevention Of Kickback:

- kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to lift up

and out of the workpiece toward the operator;

- when the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor reaction drives

the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the top

surface of the wood causing the blade to climb out of the

kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below.

a) Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position your

body to either side of the blade, but not in line with the

blade. Kickback could cause the saw to jump backwards, but

kickback forces can be controlled by the operator, if proper

precautions are taken.

b) When blade is binding, or when interrupting a cut for any

reason, release the trigger and hold the saw motionless

in the material until the blade comes to a complete stop.

Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may

occur. Investigate and take corrective actions to eliminate

the cause of blade binding.

c) When restarting a saw in the workpiece, centre the saw

blade in the kerf and check that saw teeth are not engaged

into the material. If saw blade is binding, it may walk up or

kickback from the workpiece as the saw is restarted.

d) Support large panels to minimise the risk of blade pinching

and kickback. Large panels tend to sag under their own

weight. Supports must be placed under the panel on both

sides, near the line of cut and near the edge of the panel.

e) Do not use dull or damaged blades. Unsharpened or

improperly set blades produce narrow kerf causing excessive

friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be

tight and secure before making cut. If blade adjustment

shifts while cutting, it may cause binding and kickback.

g) Use extra caution when making a “plunge cut” into

existing walls or other blind areas. The protruding blade may

cut objects that can cause kickback.

a) Check lower guard for proper closing before each use. Do

not operate the saw if lower guard does not move freely and

close instantly. Never clamp or tie the lower guard into the

open position. If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not touch

the blade or any other part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they must be

serviced before use. Lower guard may operate sluggishly due

to damaged parts, gummy deposits, or a build-up of debris.

c) Lower guard may be retracted manually only for special

cuts such as “plunge cuts” and “compound cuts.” Raise

lower guard by retracting handle and as soon as blade enters

the material, the lower guard must be released. For all other

sawing, the lower guard should operate automatically.

d) Always observe that the lower guard is covering the blade

before placing saw down on bench or floor. An unprotected,

coasting blade will cause the saw to walk backwards, cutting

whatever is in its path. Be aware of the time it takes for the

blade to stop after switch is released.

Caution!

Always unplug saw before changing blades, servicing,

cleaning or adjusting the saw.

FURTHER SAFETY INSTRUCTIONS FOR ALL SAWS SAFETY INSTRUCTIONS FOR SAWS

Page 7

www.evolutionsteel.com

7

Model EVO230-HDX Specifications

Motor (230v or 115v 50/60 Hz) (Watts) 1750

Maximum Box (1/4” 6mm Wall 900) 84mm

Maximum Box (1/4” 6mm Wall 450) 53mm

Optimum Cutting Thickness (Mild Steel Plate) 12mm

RPM No Load (min-1) 2700

Recommended Maximum Duty Cycle 30mins

Sound Pressure Level (Under Load) (dB(A)) 108.7

Vibration Level (Under Load) (m/s2) 3.9

Weight 19.0kg

Maximum Dimensions 370x400x500

Minimum Dimensions 250x325x500

Blade Dimensions

Maximum Diameter 230mm

Bore Diameter 25.4mm

Thickness 2mm

Your Evolution Power Tools saw is shipped complete.

Remove all contents from the box and inspect to ensure

no damage was incurred during shipping, and that the

items listed below are included.

Description Qty

Instruction Manual 1

Spanner (Attached To Unit) 1

Edge Guide 1

Side Handle 1

Carry Case 1

Batteries 2

GETTING STARTED

CAUTION! ALWAYS DISCONNECT THE SAW FROM

POWER SOURCE BEFORE MAKING ADJUSTMENTS.

Refer to the “Service Parts List Drawing”. If required,

assemble edge guide to shoe plate, and adjust edge guide to

desired position. Secure with thumb screws. Install a blade

as detailed in the “Changing Saw Blades” section. Always

adjust both front and back bevel lock knobs and tighten

before cutting.

What You Should Know Before Sawing:

Warning!

Never start the saw with cutting edge of saw blade contacting

work surface. Do not retract blade guard manually. Guard

retracts automatically.

Mounting / Removing TCT Saw Blades

Remove the chip collection cover from the machine by

undoing the hexagonal screw. Loosen the screw that retains

the spanner to the machine and remove the spanner. Undo

the M13 bolt that secures the blade (fig. 3) and remove the

blade flange. Note: Use spindle lock. Replace blade, making

sure that the arrow for the direction of rotation of the blade

matches that of the machine then tighten the M13 bolt

with the flange in the correct position. Note: Check that the

spindle lock is fully released by manually rotating the blade

before use. Refit the spanner to the holder on the machine

and tighten the retaining screw.

Adjustment Of The Cutting Depth

Release the handle to adjust to the required cutting depth.

Ensure that the blade protrudes a maximum of 3/16” (4mm)

through the material being cut. Tighten the handle to lock in

position. Note: The safety guard (fig. 1) is marked in increments

from 0 – 84mm to assist in setting the depth of cut.

Adjustment Of The Cutting Angle

Release both locking handles (fig. 2) and adjust to the

required cutting angle by lining up the mark with the printed

scale. Tighten both handles to lock in position. Note: There

are certain compound cuts on which it may be necessary to

manually retract the guard to allow the blade to enter into

and / or through the cut.

Line Of Cut Guide Slots

Guide slots are provided at the front of the saw base. The

left slot is used to follow a line when making a 90-degree

cut. The right slot is used to follow a line when making a

45-degree cut.

SPECIFICATIONS

ASSEMBLY

OPERATION

Page 8

www.evolutionsteel.com

8

Operating Advice

Always clamp the work piece on a rigid support such as a

bench or saw horses where possible. This tool is equipped

with a safety start feature – to start the tool, you must

first push in the switch on the side of the handle with your

thumb – you can then depress the main trigger switch to

power the motor. Do not force the tool – let the speed of

the saw blade do the work. Cutting performance will not

improve by applying more pressure on the tool and blade

life will be reduced. When using the parallel guide, ensure

that it is parallel with the blade and not the base of the tool,

as otherwise the blade and motor could become damaged.

To set the guide, loosen the two retaining screws, and slide

it up snugly against the side of the work piece. Retighten

the screws to secure it in the desired position. Place front

edge of saw squarely on work before starting motor. When

starting a cut, sight the cutting line with the line of cut guide

taking care to introduce the blade to the material slowly, so

as not to damage its teeth. Use both hands to move the saw

forward through the work piece.

Laser Sight Guide System

An additional feature of this machine is the laser sight system,

which is intended as a guide only and should not be relied upon

for the accuracy of a cut. Remove the battery compartment

cover and fit the supplied batteries, taking care to observe the

correct polarity, then replace the cover. Press the switch to

the on position to activate, and remember to turn off the laser

when you have finished a cut. Before use the sight must be

aligned by means of the adjustment screw. Important Notice:

Do not point the laser at anyone and NEVER look into the laser

light, as serious eye damage may occur.

Chip Collection

This tool is provided with a chip collector compartment.

When the chips accumulate up to the see-through window,

remove the cover, clean out the cover, then replace it, and

tighten the knobs. Notice: The metal chips inside the cover

may be very hot and sharp - do not touch with bare hands.

Ear and eye protection MUST be worn while operating this

equipment. Do NOT touch the blade while it is in motion.

Always follow the Personal Protection Equipment (PPE)

recommendations while operating this tool. This machine is

designed for cutting steel using the appropriate TCT (Tungsten

Carbide Tipped) blades and accessories. It should NOT be

modified and / or used for any application other than for which

it was intended, including powering other equipment.

Ensure that the total work area can be viewed from the

operating position. Use barriers to keep people away. Do

not operate the tool in explosive environments – power tools

create sparks that may ignite flammable materials or gases.

Do not operate the tool in damp or wet conditions, as electric

shocks may result. Always use both hands to operate the

tool. Always ensure that the material you are working on is

securely clamped.

• This tool is equipped with an approved cord and plug for its

intended Country of use.

• Remove plug from power supply before replacement of

the blade, making adjustments or other maintenance work.

• Use only genuine EVOLUTION brand saw blades.

• Inspect the machine and blade before each use and do not

use deformed, cracked, worn or otherwise damaged blades.

• Ensure the blade is correctly mounted and is appropriate

for the material to be cut.

• Do not use blades made of high-speed steel.

• Do not use blades that do not comply with the characteristics

specified in these instructions.

• Do not stop the blade by lateral pressure on the disc.

• Ensure that moveable guards operate freely without jamming.

• Never use the tool without the original protection guard system.

Do not lock the moving guard in the open position.

• Always keep the power cord away from moving parts of the tool.

• When you put the tool away, switch off the motor and ensure

that all moving parts have come to a complete standstill.

• In case of jamming, immediately switch off the tool and

disconnect the plug.

• Before using accessories, always compare the maximum

allowed RPM of the accessory with the RPM of the tool.

• Ensure that the cutting depth adjustment handle, angle

adjustment handle, and side handle are rmly xed whilst

using the tool (fig. 1).

• Only use the anges and washers that are supplied with the

tool, and replace them if they become damaged or scored.

Adjustment Of The Cutting Depth

Release the handle to adjust to the required cutting depth.

Ensure that the blade protrudes a maximum of 3/16” (4mm)

through the material being cut. Tighten the handle to lock in

position. Note: The safety guard (fig. 1) is marked in increments

from 0 – 84mm to assist in setting the depth of cut.

Adjustment Of The Cutting Angle

Release both locking handles (fig. 2) and adjust to the required

cutting angle by lining up the mark with the printed scale. Tighten

both handles to lock in position. Note: There are certain compound

cuts on which it may be necessary to manually retract the guard

to allow the blade to enter into and / or through the cut.

Line Of Cut Guide Slots

Guide slots are provided at the front of the saw base. The left slot

is used to follow a line when making a 90-degree cut. The right

slot is used to follow a line when making a 45-degree cut.

Page 9

www.evolutionsteel.com

9

Maintenance & Troubleshooting

Keep tool, cord, and carry case clean and free from chips.

Avoid using cleaning products, which include benzene,

trichloroethelene, chloride, or ammonia as these can damage

plastic parts. In case of electrical or mechanical malfunction,

immediately switch off the tool and disconnect the plug.

Excessive sparking may indicate the presence of dirt in

the motor or worn out carbon brushes. Check for wear and

replace when they reach 1/4” (6mm). For all other service

take machine to your local dealer, or to Evolution Power

Tools USA, Iowa, if bought in the USA.

Lubrication

Your machine gearbox is lubricated at the factory. To check

and / or add lubricant, it is necessary to dismantle the tool.

This operation should always be handled by the nearest

SERVICE CENTER or Evolution Power Tools USA, Iowa,

if in the USA. All repairs and servicing made by these

centers are fully guaranteed against defective materials and

workmanship.

40T 9” (230mm) TCT Wood Blade

48T 9” (230mm) TCT Mild Steel Blade

60T 9” (230mm) TCT Stainless Steel Capable Blade

80T 9” (230mm) TCT Aluminium Blade

Notice:

Fair wear and tear and damage caused by misuse is not

covered under the 12-Month guarantee.

Recycle unwanted materials instead of disposing of them

as waste. All tools, hoses and packaging should be sorted,

taken to the local recycling center and disposed of in an

environmentally safe way.

Recyclable Materials Analysis List

Material Weight(Kg) Percentage (%)

Aluminum 1.94 24.40

Cast Iron 0.0 0.00

Iron Plate 3.61 47.00

Plastics 1.96 25.70

Others 0.10 1.30

Total 7.61

Major Packaging Materials

Material Weight(Kg)

Carton 1.23

Polystyrene 0.0

Plastic 4.50

Polypropylene 0.001

Others 0.0

Total 5.731

EVOLUTION BLADE ACCESSORIES

MAINTENANCE ENVIRONMENTAL PROTECTION

Page 10

www.evolutionsteel.com

10

EVO230-HDX CUTTING THROUGH 1/2” MILD STEEL PLATE

Page 11

www.evolutionsteel.com

11

EVO230-HDX TRIGGER SWITCH EVO230-HDX FIGURE 1

EVO230-HDX 1750W MOTOR EVO230-HDX FIGURE 3

EVO230-HDX TILTING BLADE EVO230-HDX FIGURE 2

Loading...

Loading...