Instruction Manual

gyM

sy...

CON 11 & CON 110

Handheld Conductivity/TDS/Temperature/RS232C Meter

68X361303

Rev. 1 - 12/03

Technol o

adeEa

Preface

This manual serves to explain the use of the CON 11/110 Conductivity/TDS

handheld meters. It functions as a handy reference step by step guide to help you

operate the meter. It is written to cover as many anticipated application of the CON

11/110 meters as possible. If there are doubts in the use of the meter, please do not

hesitate to contact the nearest Authorised Distributor.

Eutech Instruments / Oakton Instruments cannot accept any responsibility for

damage or malfunction of the meter caused by improper use of the instruments.

The information presented in this manual is subjected to change without notice as

improvements are made, and does represent a commitment on the part of Eutech

Instruments Pte Ltd / Oakton Instruments.

Copyright © 2003 All rights reserved.

Eutech Instruments Pte Ltd

Oakton Instruments

Rev 1 - 12/03

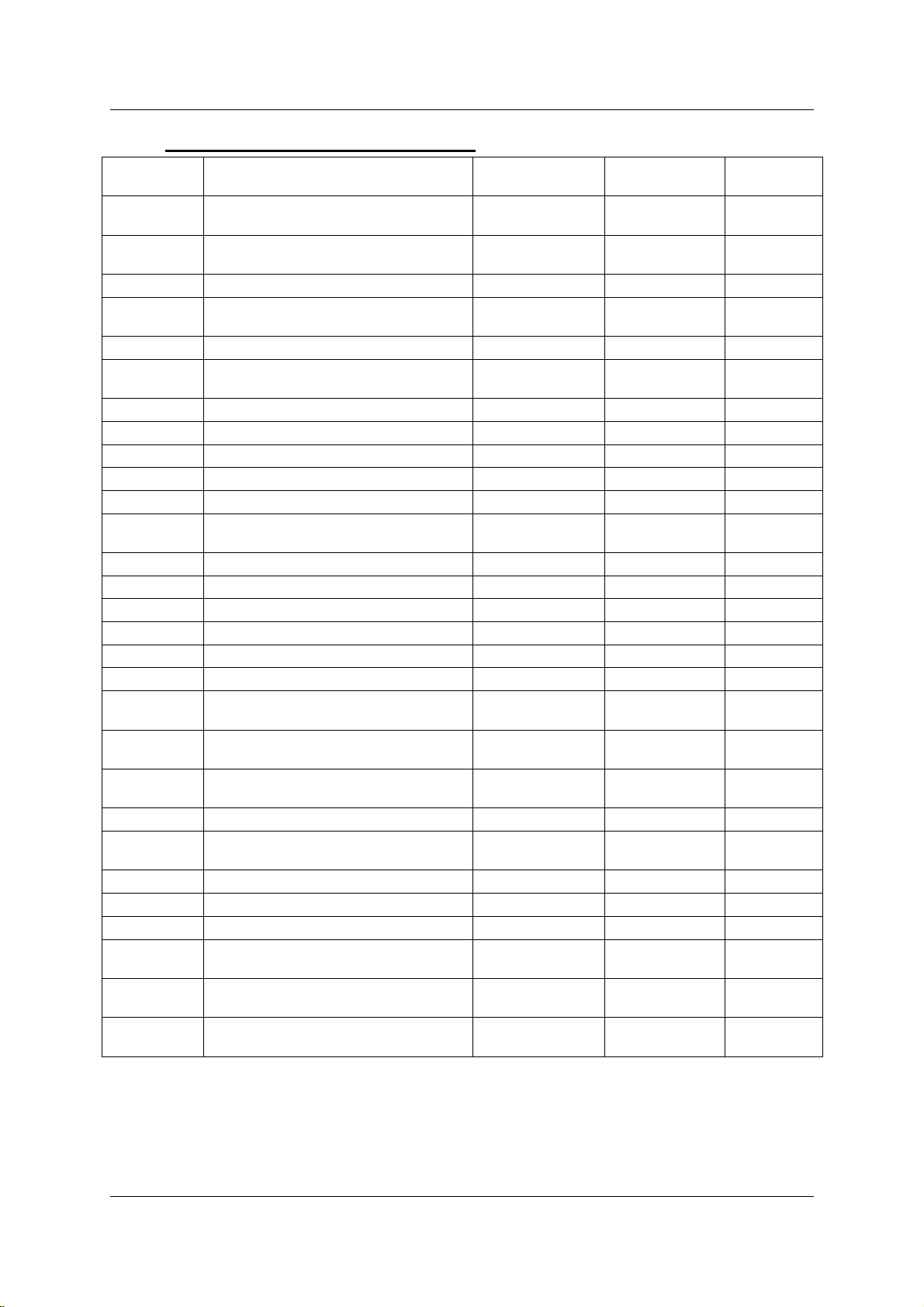

Table of Contents

1 INTRODUCTION....................................................................................................................................... 1

2 DISPLAY AND KEYPAD FUNCTIONS.................................................................................................. 2

2.1 DISPLAY ...............................................................................................................................................2

2.2 KEYPAD................................................................................................................................................ 3

3 PREPARATION.......................................................................................................................................... 5

3.1 INSERTING THE BATTERIES................................................................................................................... 5

3.2 CONDUCTIVITY ELECTRODE INFORMATION.......................................................................................... 6

3.3 CONNECTING THE ELECTRODE TO THE METER ...................................................................................... 7

3.4 ATTACHING THE ELECTRODE HOLDER TO THE METER ......................................................................... 8

3.4.1 Inserting the electrode into the electrode holder ............................................................................. 8

3.5 CONNECTING THE AC/DC ADAPTER .................................................................................................... 9

3.6 CONNECTING THE RS232C CABLE (ONLY FOR CON 110) ................................................................... 9

3.6.1 RS232C Configuration.................................................................................................................. 10

4 CALIBRATION ........................................................................................................................................ 11

4.1 IMPORTANT INFORMATION ON METER CALIBRATION......................................................................... 11

4.2 PREPARING THE METER FOR CALIBRATION ........................................................................................ 12

4.3 TEMPERATURE CALIBRATION............................................................................................................. 13

4.4 SELECTION OF AUTOMATIC OR MANUAL CALIBRATION..................................................................... 14

4.5 AUTOMATIC CALIBRATION (FOR CONDUCTIVITY CALIBRATION ONLY) ............................................ 15

4.6 MANUAL CALIBRATION (FOR CONDUCTIVITY & TDS CALIBRATION) ............................................... 17

4.7 TDS CALIBRATION............................................................................................................................. 18

4.7.1 Calibrating for TDS Using Conductivity Standards & adjusting TDS factor............................... 18

4.7.2 Setting the TDS Conversion Factor...............................................................................................18

4.7.3 Calibrating for TDS using TDS standards.................................................................................... 19

5 MEASUREMENT..................................................................................................................................... 20

5.1 AUTOMATIC TEMPERATURE COMPENSATION ..................................................................................... 20

5.2 MANUAL TEMPERATURE COMPENSATION.......................................................................................... 21

5.2.1 Setting the manual temperature compensation value.................................................................... 22

5.3 TAKING MEASUREMENTS ................................................................................................................... 23

5.3.1 Taking measurements with READY indicator selected on............................................................ 23

5.3.2 Taking measurements with the Auto HOLD feature selected on................................................... 23

5.4 USING MANUAL RANGING FUNCTION ................................................................................................ 24

5.4.1 Selecting manual range................................................................................................................. 24

5.5 HOLD FUNCTION............................................................................................................................... 25

6 MEMORY FUNCTION............................................................................................................................ 26

6.1 MEMORY INPUT.................................................................................................................................. 26

6.2 MEMORY RECALL............................................................................................................................... 27

7 PRINT FUNCTION (FOR CON 110 ONLY)......................................................................................... 28

7.1 USING CON 110 METER WITH PRINTER OR COMPUTER...................................................................... 28

7.2 SENDING DATA TO COMPUTER OR PRINTER....................................................................................... 29

7.2.1 Printing Current Data Manually................................................................................................... 30

7.2.2 Print Data on Timed Interval........................................................................................................ 30

7.2.3 Print Data from Stored Memory ...................................................................................................32

8 ADVANCED SETUP FUNCTION.......................................................................................................... 34

8.1 ADVANCED SETUP MODE OVERVIEW............................................................................................... 36

8.2 P1.0: UNIT CONFIGURATION (COF).................................................................................................... 38

8.2.1 P1.1: Selection of READY and Auto HOLD function.................................................................... 38

8.2.2 P1.2: Selection of °C or °F ........................................................................................................... 39

8.2.3 P1.3: Selection of Automatic or Manual Temperature Compensation.......................................... 40

8.2.4 P1.4: Selection of TDS Conversion Factor................................................................................... 41

8.3 P2.0: VIEWING CALIBRATION DATA.................................................................................................... 42

8.4 P3.0 VIEWING ELECTRODE DATA....................................................................................................... 43

8.5 P4.0: AUTO OFF.................................................................................................................................. 44

8.6 P5.0: RESET TO FACTORY DEFAULTS .................................................................................................. 45

8.6.1 P5.1: Calibration Reset................................................................................................................. 45

8.6.2 P5.2: User Reset............................................................................................................................ 46

8.7 P6.0: MEMORY CLEAR........................................................................................................................ 47

8.8 P7.0: TEMPERATURE........................................................................................................................... 48

8.8.1 P7.1: Setting the temperature coefficient...................................................................................... 48

8.8.2 P7.2: Setting the normalisation temperature ................................................................................ 49

8.9 P8.0: SELECTION OF CELL CONSTANT ................................................................................................. 50

8.10 P9.0: AUTOMATIC AND SINGLE POINT CALIBRATION ......................................................................... 51

8.10.1 P9.1: Selection of Automatic or Manual Calibration............................................................... 51

8.10.2 P9.2: Selection of Single or Multi Point Calibration ............................................................... 52

9 CYBERCOMM PORTABLE DAS (FOR CON 110 ONLY)................................................................. 53

9.1 SYSTEM REQUIREMENTS..................................................................................................................... 53

9.2 LOADING CYBERCOMM PORTABLE DAS............................................................................................ 53

9.3 RUNNING CYBERCOMM PORTABLE .................................................................................................... 59

9.3.1 Buttons & Check-Box.................................................................................................................... 60

9.3.2 Menu.............................................................................................................................................. 61

9.3.3 Communication Settings................................................................................................................ 62

9.4 CAPTURING AND PRINTING DATA INTO COMPUTER USING DATA ACQUISITION................................ 63

9.5 TROUBLE-SHOOTING GUIDE ............................................................................................................... 64

10 ELECTRODE CARE AND MAINTENANCE....................................................................................... 65

11 ERROR MESSAGES................................................................................................................................ 66

12 TROUBLE SHOOTING........................................................................................................................... 67

13 LIST OF ACCESSORIES........................................................................................................................ 68

13.1 REPLACEMENT METER AND METER ACCESSORIES.............................................................................. 68

13.2 CALIBRATION SOLUTIONS .................................................................................................................. 68

14 FACTORY DEFAULT SETTINGS ........................................................................................................69

14.1 CON 11 FACTORY DEFAULT SETTING................................................................................................ 69

14.2 CON 110 FACTORY DEFAULT SETTING.............................................................................................. 70

15 SPECIFICATIONS................................................................................................................................... 71

16 CALIBRATION TIPS............................................................................................................................... 73

17 CALCULATING TDS CONVERSION FACTORS............................................................................... 73

18 CALCULATING TEMPERATURE COEFFICIENTS........................................................................ 74

19 WARRANTY............................................................................................................................................. 75

20 RETURN OF ITEMS................................................................................................................................ 75

Instruction Manual CON 11/110

1 INTRODUCTION

Thank you for selecting the CON 11/110 Conductivity/TDS handheld meter. These

meters are microprocessor-based instruments and are designed to be handy,

capable of allowing one-hand operation. Each has a large customised LCD for clear

and easy reading. It also has user-friendly features, all of which are accessible

through the splash-proof membrane keypad. It is a unique and intelligent instrument

and has the capability to cater to the preferences of the discerning individual. You

have one of the two models:

• CON 11 meter

• CON 110 meter

Your meter includes a conductivity electrode (ECCONSEN91W electrode constant K

= 1.0) with built-in temperature sensor and batteries.

The basic model is the CON 11 which is capable of measuring Conductivity, TDS and

Temperature.

The deluxe model is the CON 110 which measures the Conductivity, TDS and

Temperature and has a RS232C port that allows the meter to be connected to a

computer or a printer via a cable for transferring data.

For power requirements, you can either use the 4 AAA-sized batteries or an AC/DC

power adapter (sold separately).

Please read this manual thoroughly before operating your meter.

1

Instruction Manual CON 11/110

2 DISPLAY AND KEYPAD FUNCTIONS

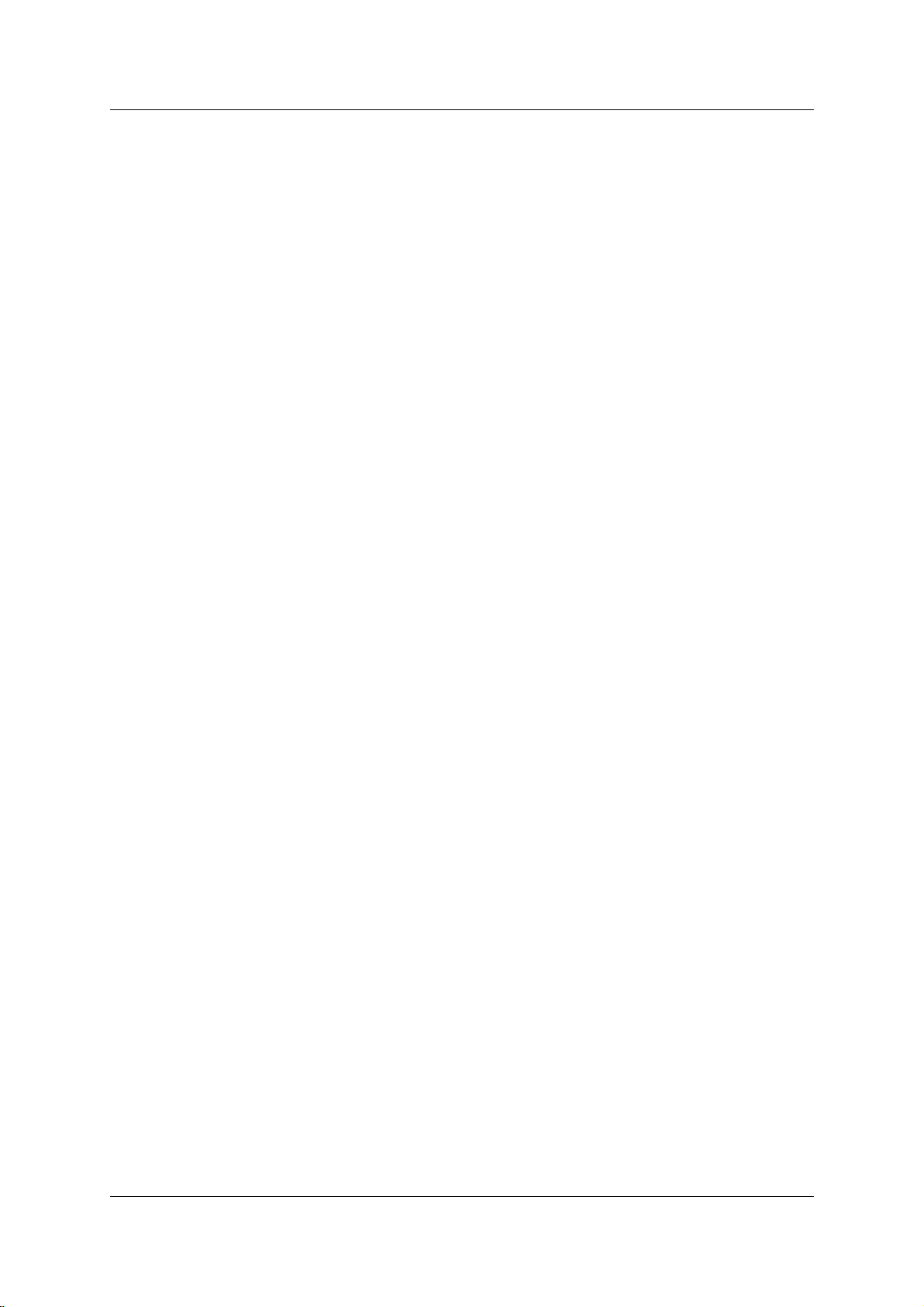

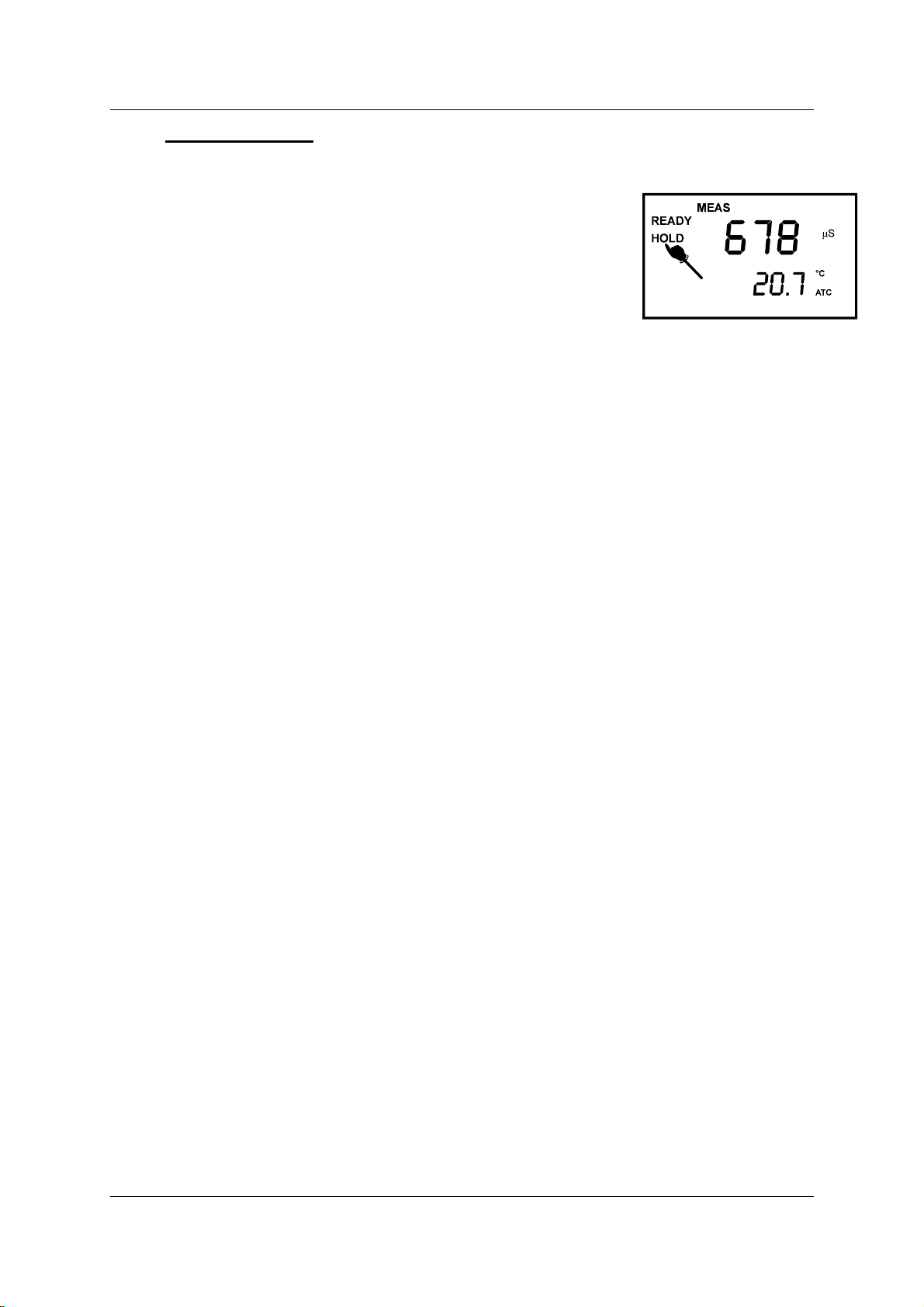

2.1 Display

The LCD has a primary and secondary display.

• The primary display shows the measured Conductivity/TDS values.

• The secondary display shows the measured temperature.

The display also shows error messages, keypad functions and program functions.

Primary Display

1

2

3

4

18

17

16

15

14

1. SETUP - Setup mode

indicator

2. MEAS - Measurement

mode indicator

3. CAL - Calibration mode

indicator

4. MEM - Memory recall

mode indicator

5. ms - Mill siemens

indicator

6. µs - Micro siemens

indicator

SETUP MEAS

READY

HOLD

K =

ON

OFF

1.8.8.8

ERR

1.8.8.8

Figure 1: Active LCD display

CAL MEM

Secondary Display

mS

µ

S

ppt

ppm

°C °F

ATC

101113 12

5

6

7

8

9

7. ppt - Parts per thousand

indicator

8. ppm - Parts per million

indicator

9. °C°F - Temperature indicator 15. ON – READY/Auto HOLD set up

10. ATC - Automatic

Temperature

Compensation indicator

11. ERR - Error indicator 17. HOLD – Hold indicator

- Low battery indicator

12.

- Electrode indicator

13.

14.

OFF – READY set up disable indicator

16. K = - Cell Constant indicator.

18. READY – Ready indicator

- Calibration solution indicator

enable indicator.

2

Instruction Manual CON 11/110

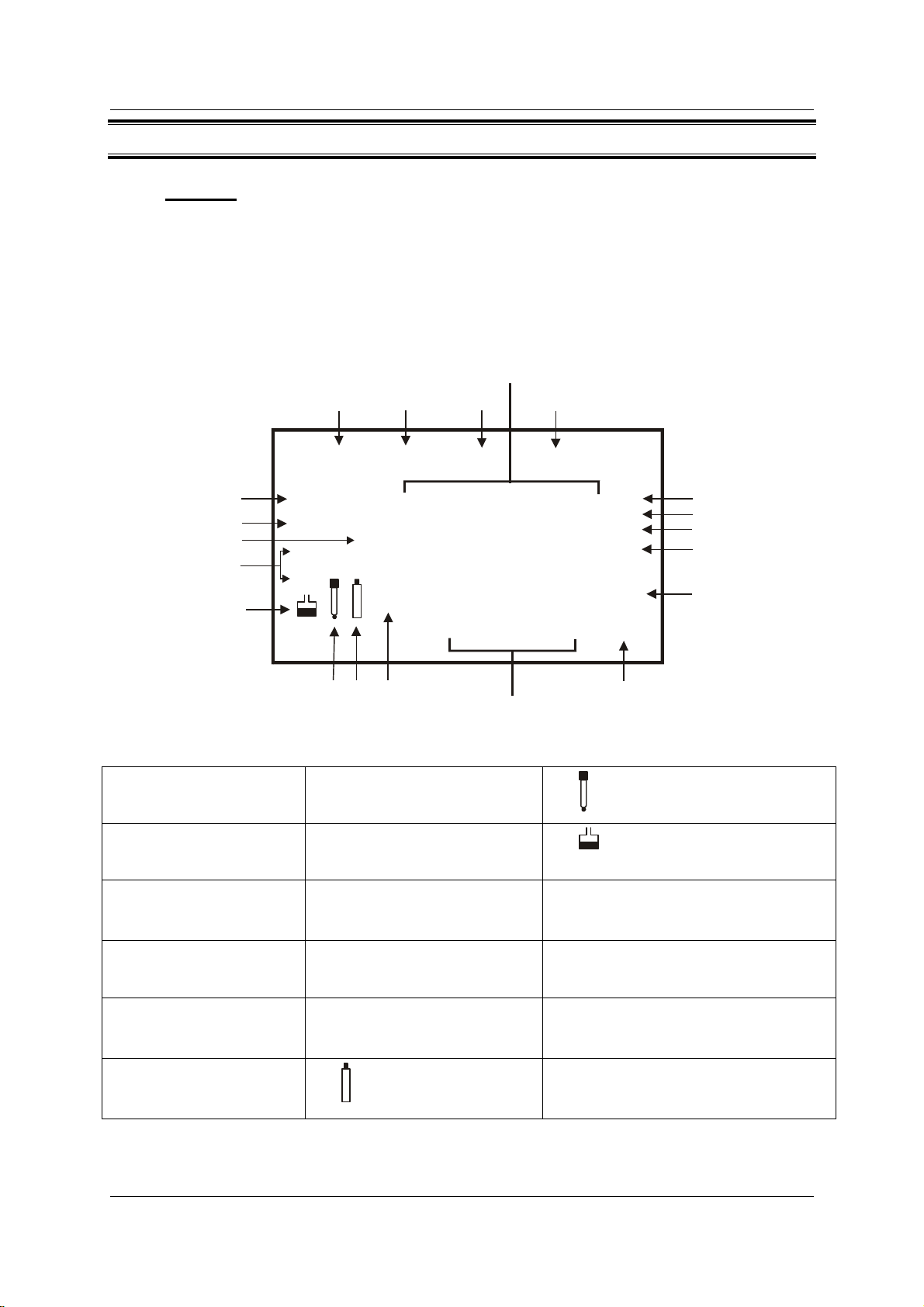

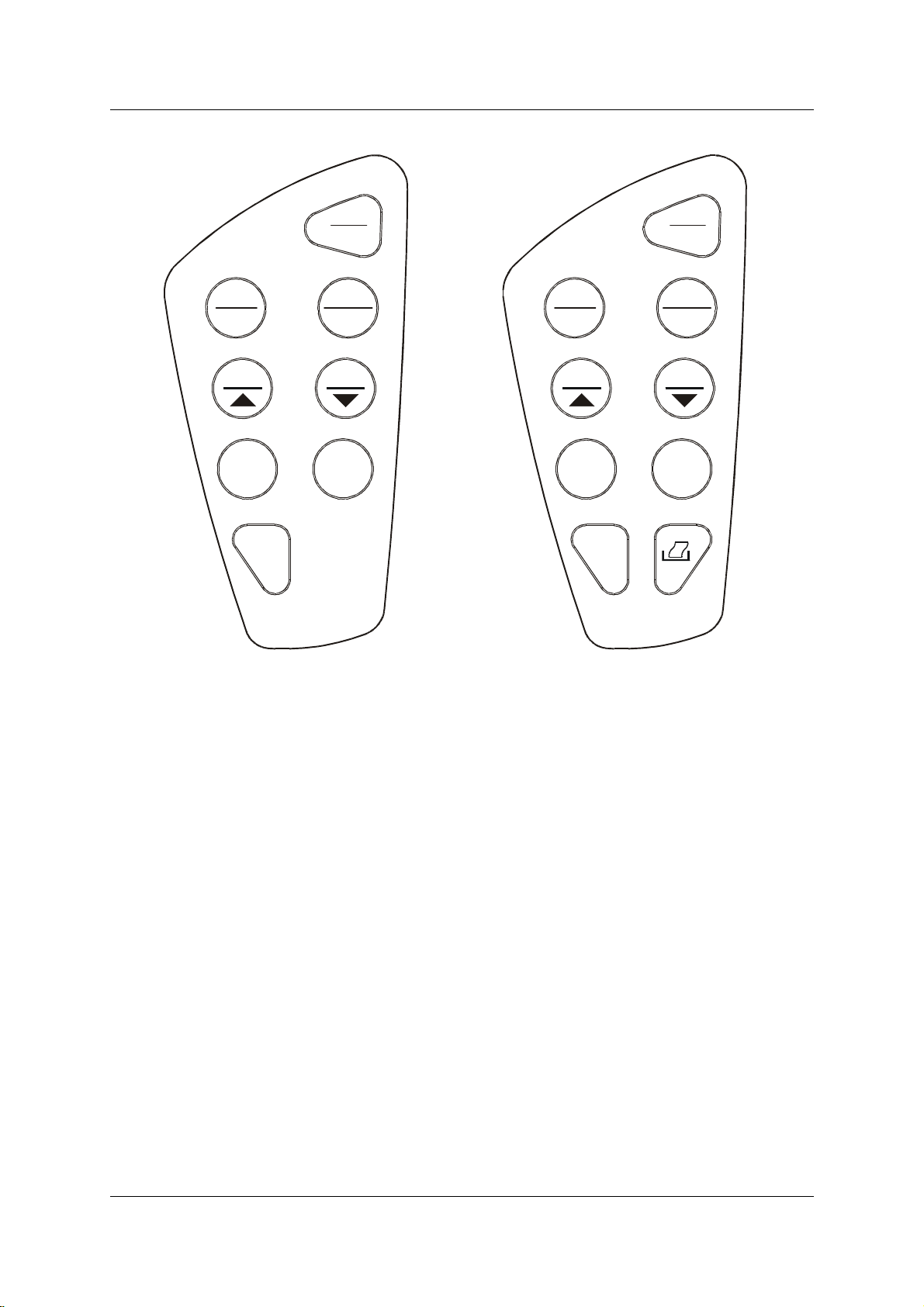

2.2 Keypad

A large membrane keypad with tactile feedback makes the instruments easy to use

(Figure 2). Each button, when pressed, has a corresponding graphic indicator on the

LCD. Some button has several functions depending on its mode of operation.

KEY FUNCTION

ON

OFF

CAL

MEAS

HOLD

ENTER

MI

MR

• ON/OFF - Powers on and shuts off the meter. The meter will start in the

measurement mode it was in when last switched off.

• CAL - Activates the Conductivity or TDS calibration mode and when used

with the MODE key, it activates the temperature calibration mode.

• MEAS - Allows return to measurement mode when canceling or

terminating any operation.

• HOLD - Activates/Deactivates freezing of the measured reading while in

measurement mode.

• ENTER - Confirms the calibration values in Calibration mode and the

selection in SETUP and Print Function mode.

Scroll through the memory location and the stored data during memory

recall.

• MI (Memory Input) - Captures the measured readings of the Conductivity

or TDS with its corresponding temperature values and stores them in

the memory.

• MR (Memory Recall) - Retrieves the stored data from memory.

• ▲▼ - Sets the calibration values during the manual Conductivity, TDS

and Temperature calibration.

Scrolls through each SETUP and its sub group menu.

Scroll through Print Function menu and its parameters.

SETUP

MODE

RANGE

(CON110 only)

• SETUP- Activates the parameter setting menu to allow you to customise

meter configuration, view calibration points and electrode offset data,

select auto power off, reset meter, clear memory, set temperature

coefficient and normalisation temperature, select electrode cell

constants and set auto & single point calibration selections.

• MODE - Select the measurement parameter option between Conductivity

and TDS. When used during Conductivity or TDS calibration mode, it

activates the temperature calibration mode.

• RANGE – Allows entry to Manual range selection.

• PRINT - Allows transfer of current measurement or stored data to either

the printer or the computer.

3

Instruction Manual CON 11/110

CAL

MEAS

MI MR

SETUP MODE

RANGE

HOLD

ENTER

ON

OFF

CAL

MEAS

SETUP

RANGE

ON

OFF

HOLD

ENTER

MRMI

MODE

Keypad for CON 11 meter Keypad for CON 110 meter

Figure 2: CON 11 and CON 110 keypads

4

Instruction Manual CON 11/110

3 PREPARATION

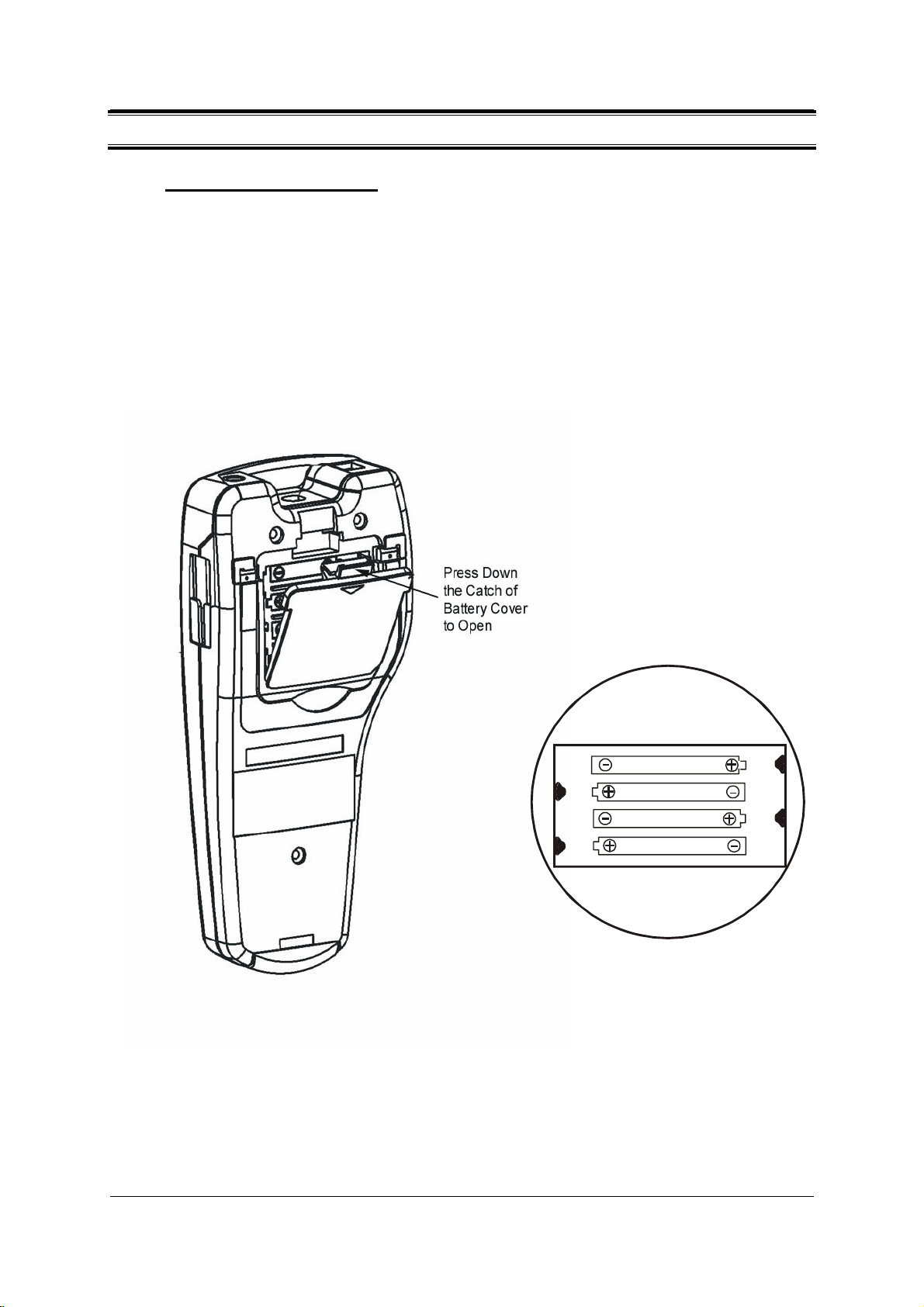

3.1 Inserting the Batteries

This meter is packaged with 4 “AAA” alkaline batteries required for its operation. To

insert the batteries into the meter, follow the procedure outlined below.

1. Open the battery compartment by pressing down the catch of the battery

cover.

2. Insert the batteries correctly according to the marked polarity of the battery

compartment.

3. Close the battery cover, ensuring the catch is locked in position.

Your hand held meter is now ready for operation.

Figure 3: Open Battery Cover

LR03 'AAA' (AM4)

MADE IN S'PORE

Figure 4: Note Battery

Polarity

5

Instruction Manual CON 11/110

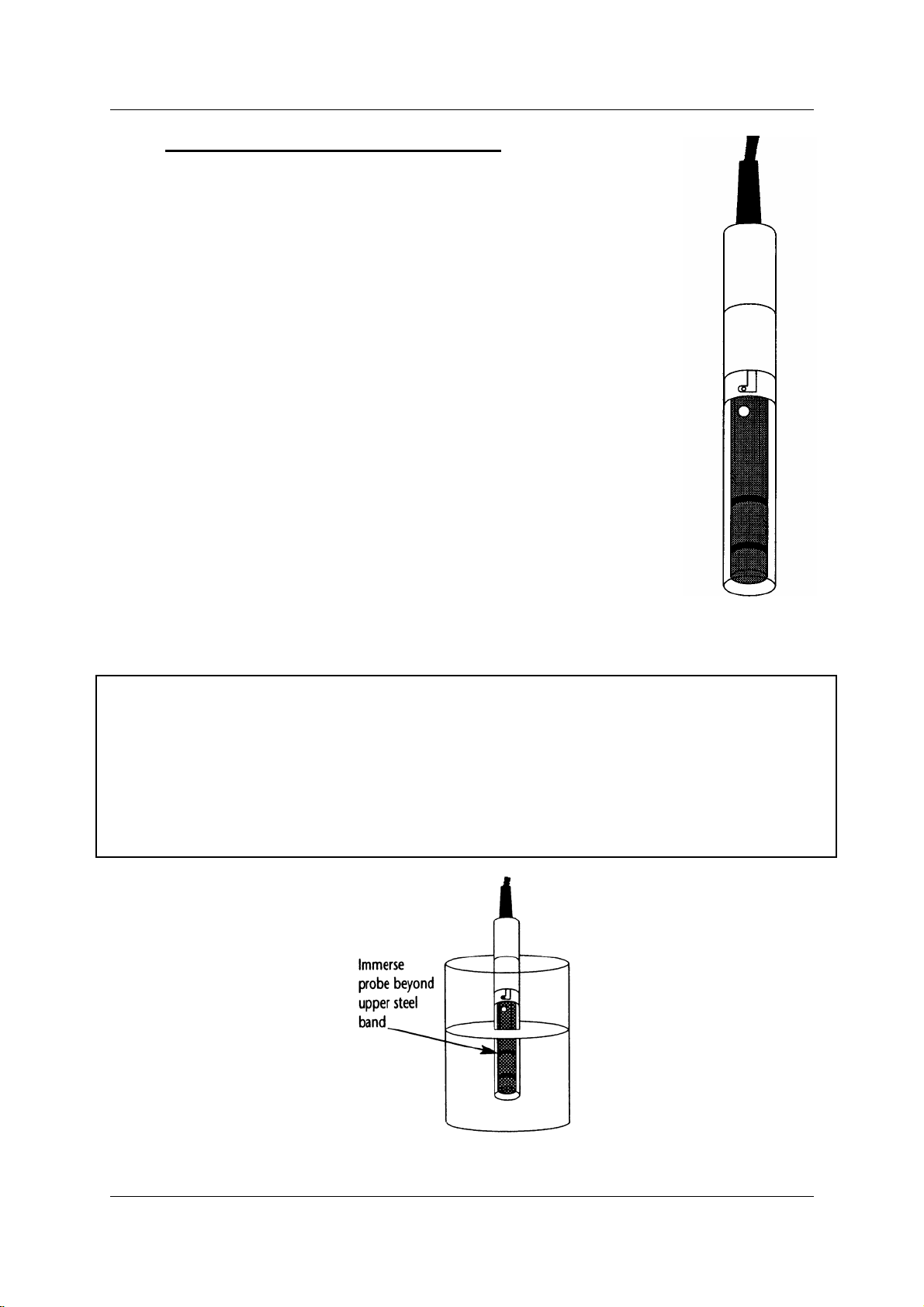

3.2 Conductivity Electrode Information

Your meter includes a conductivity electrode (Part No: ECCONSEN91W/ 35608-50) Ultem / Stainless Steel electrodes with

an electrode constant of K = 1.0. This conductivity / TDS electrode

features a built-in temperature sensor for Automatic Temperature

Compensation (ATC). It has a specially designed housing that

provides fast temperature response and reduces air bubble

entrapment, which makes it easy to obtain accurate, stable

readings.

Wetted parts include:

1. Polyetherimide PEI (Ultem®)

2. Polybutylene Terephthalate PBT (Valox®)

3. Stainless Steel (SS 304)

Proper use of electrode is essential to ensure that the optimum

measurement is taken in a short time.

The removable protective plastic electrode guard is meant for

simple periodic maintenance and it must be kept in tact during

measurement and calibration.

Always immerse the electrode beyond upper steel band.

Figure 5: Conductivity

Electrode (EC-CONSEN91W/

35608-50)

NOTE:

1. DO NOT remove the protective electrode guard during measurement and

calibration as it may affect your readings.

2. We recommend that you do not submerge the electrode above the protective

yellow cap. You can submerge the cable for brief periods of time, but not

continuously.

Figure 6: Electrode immersion level

6

Instruction Manual CON 11/110

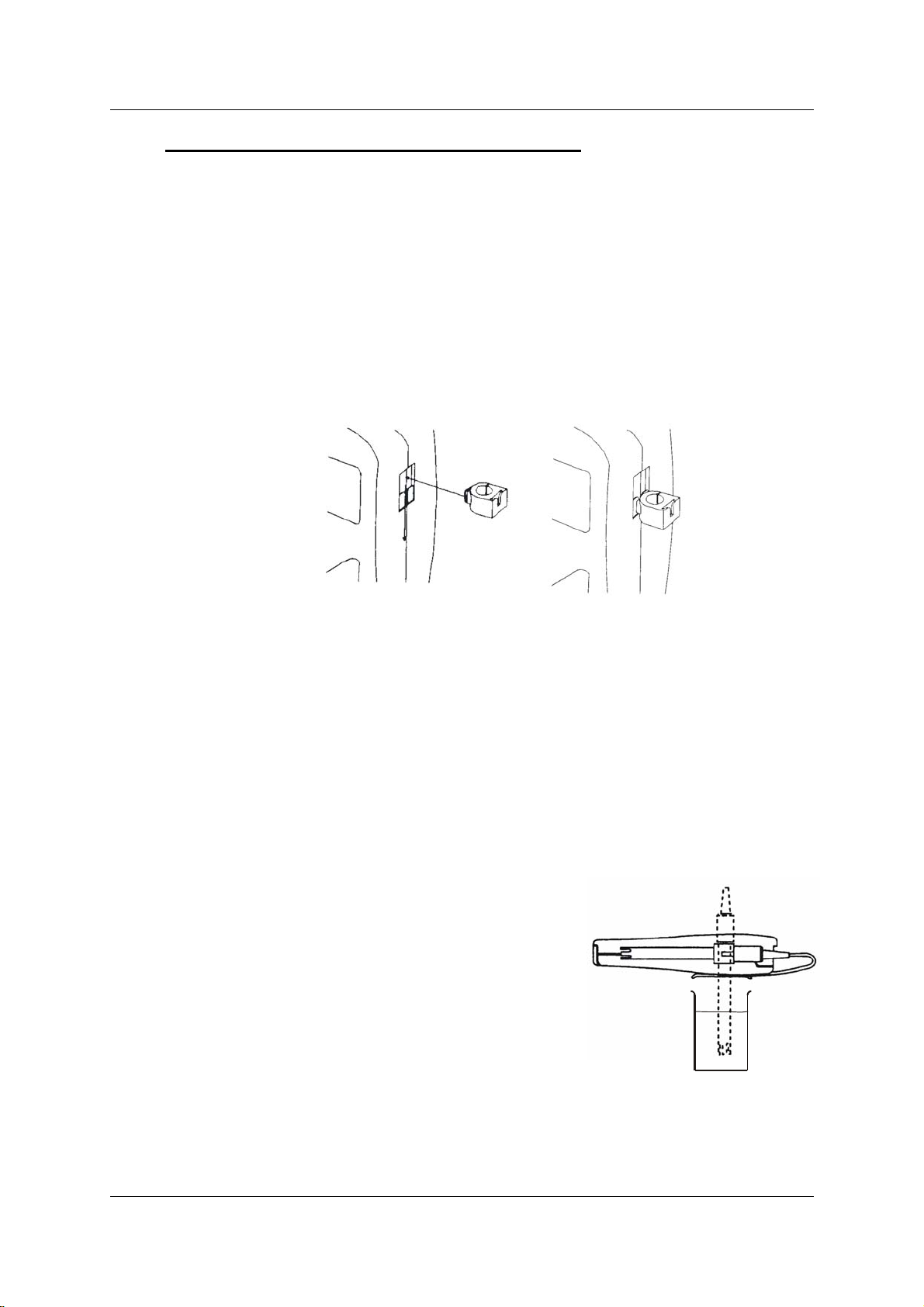

3.3 Connecting the electrode to the meter

The CON 11 / 110 meter use the Conductivity / TDS electrode with a sturdy 6 pin

connector which is easy to connect.

1. Insert the 6 pin female connector of the electrode to the 6 pins male

connector on the meter. Rotate the locking ring clockwise until it locks.

2. To remove the electrode, simply rotate the connector’s locking ring

counterclockwise and pull away gently for a complete removal.

CAUTION: Do not pull on the electrode cord to avoid internal wire breakages.

top view of 6-pin

connector

Turn the Locking Ring

clockwise or counterclockwise

for attachment or detachment

of electrode

Figure 7: Turn the locking ring to lock into place

7

Instruction Manual CON 11/110

3.4 Attaching the Electrode Holder to the Meter

The CON meter is designed to allow you to do a one hand operation for any

measurement or calibration. For that purpose, one electrode holder is provided. They

are designed for easy use and installation. Care must be taken to avoid use of

excessive force in the process of attaching this component.

1. Locate the slot on the right side of the meter.

2. Gently slide the flange of the holder into the slot of the meter. Make sure the

holder is secured properly into the slot.

3. The design of the electrode holder allows you to attach it to the meter in

different positions.

Figure 8: Insert electrode holder

3.4.1 Inserting the electrode into the electrode holder

The holder is designed for electrodes 16 mm in diameter. Electrodes larger than 16

mm may not fit in the holder. Forcing the electrode into the opening may damage the

holder or your electrode.

1. Do not use excessive force when inserting

electrode into the holder.

2. Insert the conductivity electrode into the

opening of the holder until the top housing of

the electrode touches the top of the holder.

The electrode holder can be attached in different

positions for greater flexibility in measurement and

storage purposes.

1. Slide the electrode holder out from the slot of

the meter.

2. Reorient its position into appropriate orientation

before putting back into the slot of the meter

8

Figure 9: One hand

operation

Instruction Manual CON 11/110

3.5 Connecting the AC/DC Adapter

Besides using the 4 “AAA” alkaline batteries as the power source, the CON 11/110

meter can also operate from the power mains using the AC/DC power adapter either

at 120/220 VAC (sold separately) This is extremely useful if you have an AC power

source available ( e.g. laboratory)

Please ensure that the meter and the power source of the adapter are switched off

before plugging in as a safety precaution that should be adhered to safeguard your

meter.

1. Switch off the meter and power sources.

2. Select the correct AC/DC Adapter either at 120/220 VAC which matches your

input mains voltage.

3. Select the correct output voltage of the AC/DC adapter. (Output Voltage: 9 to

15 V DC, Current: >=50 mA).

4. Gently insert the power adapter D.C. jack into the meter power socket.

5. Switch on the power source of the adapter followed by the meter.

3.6 Connecting the RS232C Cable (Only for CON 110)

The CON 110 meter provides an RS232C output for you to transmit your readings

either to a printer or a computer via a cable. This is useful in instances where the

meter is used for continuous monitoring of a certain process or experiment. Data

output to the printer or the computer can be then evaluated.

The output data is in the ASCII format. This format allows the data to be imported by

a variety of software that reads ASCII data (e.g. Microsoft’s Excel, Lotus, Quattro-pro

etc.). A complimentary Data Acquisition Software (DAS) is provided and it captures

data transmitted into an ASCII file for later use.

1. Gently detach the printer port cover located at the bottom end of the meter.

2. Plug the RS232C male connector into the RS232C port of the meter ensuring

the correct orientation.

3. Secure the RS232C connector by fastening the two screws at the side of the

male RS232C connector.

Figure 10: Location of RS232C

9

Instruction Manual CON 11/110

3.6.1 RS232C Configuration

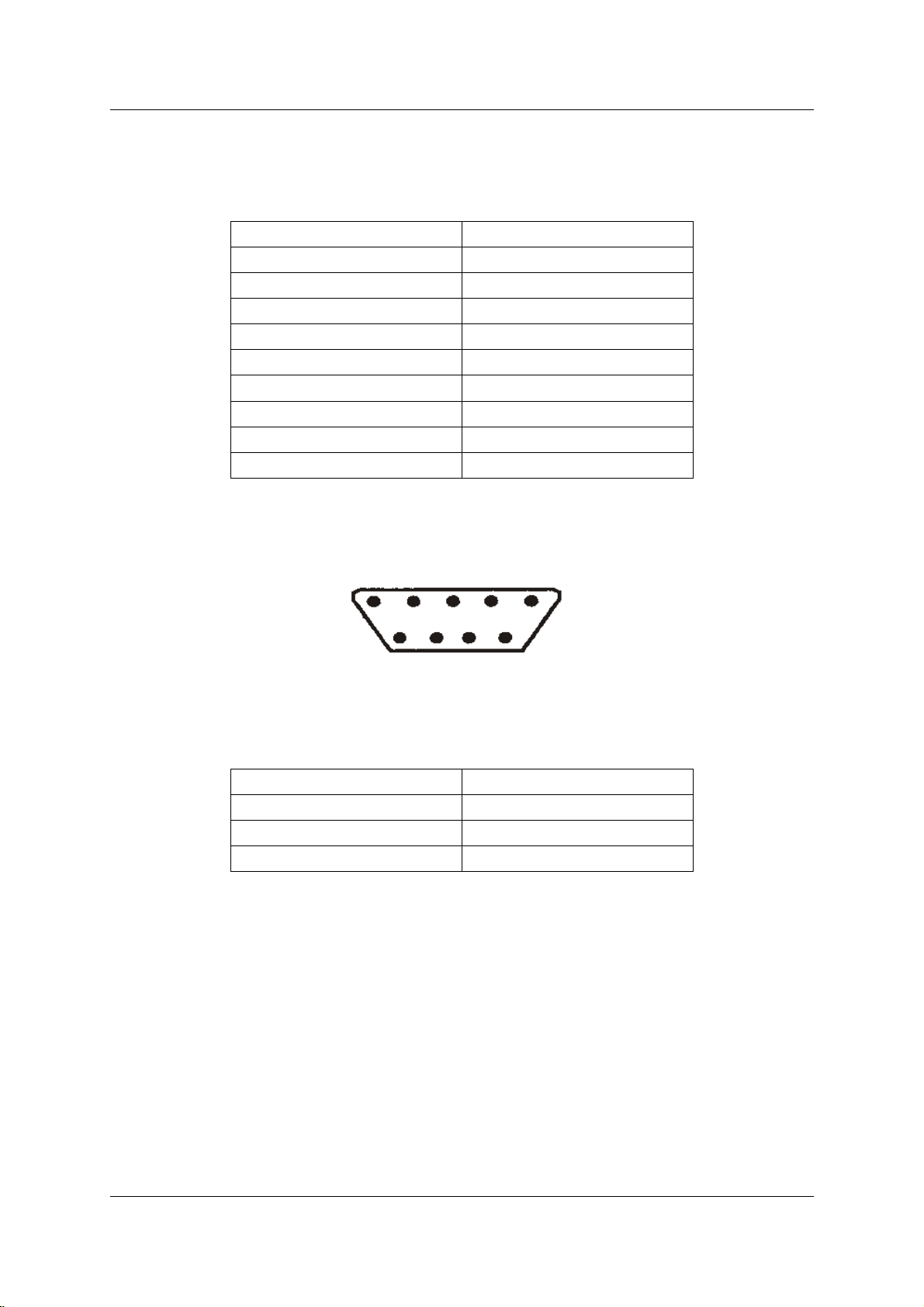

The CON 110 meter has a 9 pin female RS232C connector with the following pin out.

PIN NO. DESCRIPTION

1 -

2 Transmit Data

3 -

4 -

5 CTS (Clear to Send)

6 -

7 GND (Ground)

8 -

9 -

A one to one connection can be made with a 9 pin RS232C port of the computer.

5

4

3

8

9

7

1

2

6

In case CON 110 meter’s output has to be sent to a 25 pin RS232C connector, the

following cable configuration may be used:

CON 110 25 pin connector

2 (TxD) (RxD) 3

5 (CTS) (RTS) 4

7 (GND) (GND) 7

10

Instruction Manual CON 11/110

4 CALIBRATION

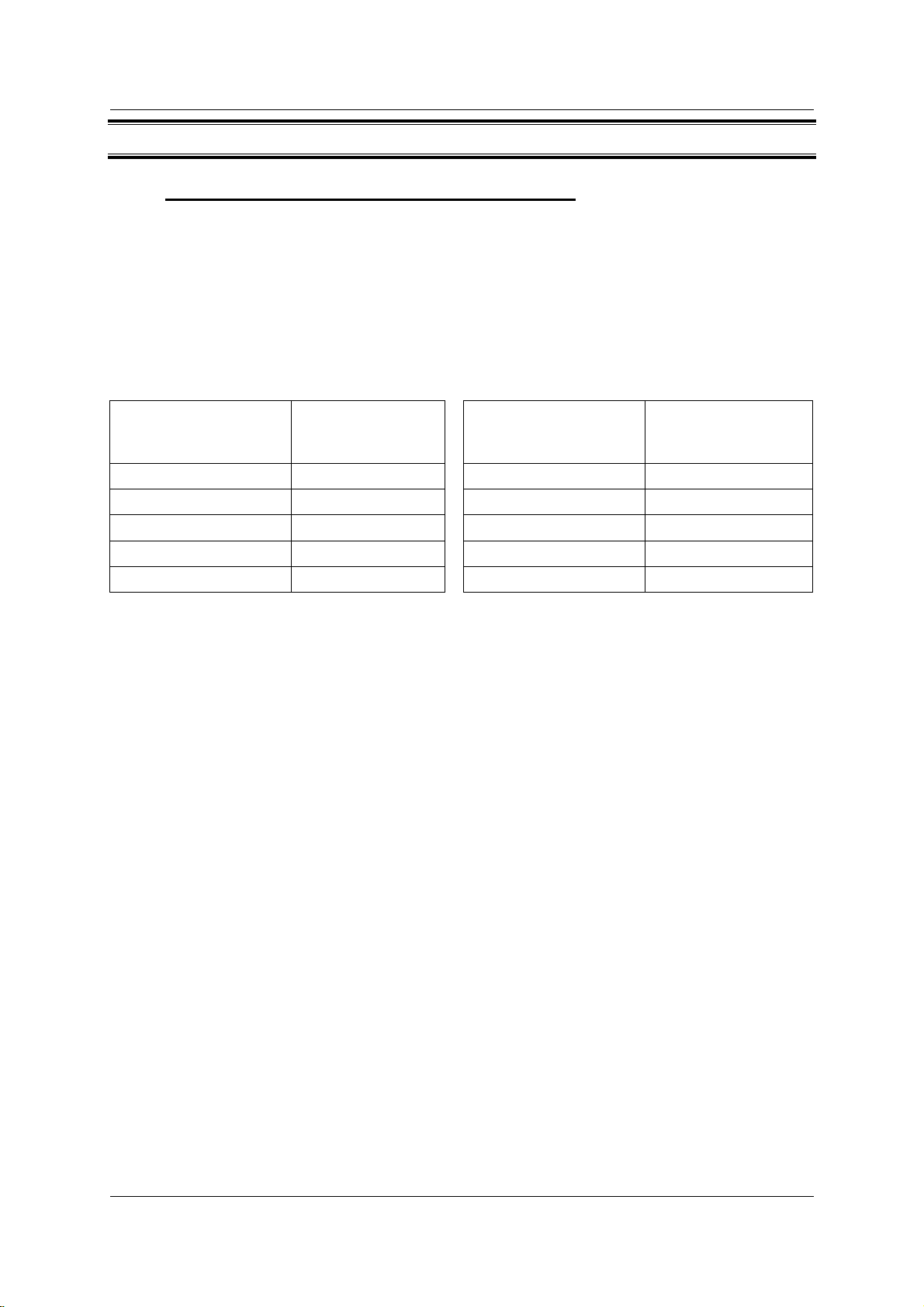

4.1 Important Information on Meter Calibration

Your meter has five measuring ranges. You have an option of calibrating your meter

in a single point calibration for all the five ranges or for better accuracy; you can

calibrate one point in each of the measuring ranges (up to five points). This selection

of single point calibration and multi point calibration can be set in the SETUP menu

Program P9.2. See page 52 .

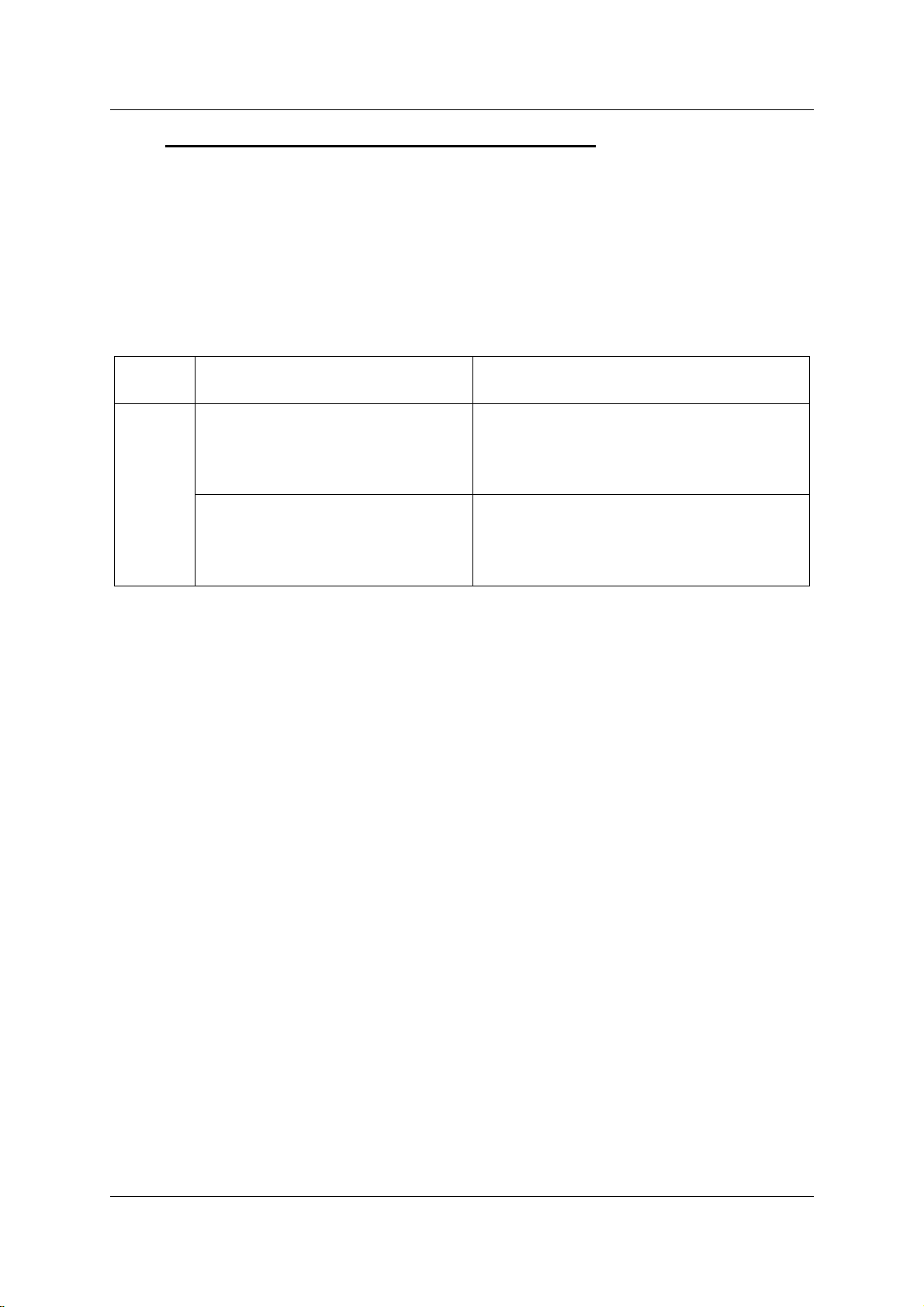

The following table lists the corresponding conductivity and TDS ranges. For either

the single or multi point calibration, you should calibrate using a solution that falls

between the values in the “recommended calibration solution range” column.

Conductivity Range Recommended

Calibration

Solution Range

0 to 19.99 µS/cm, 6.00 to 17.00 µS 0.00 to 9.99 ppm 3.00 to 8.50 ppm

20.0 to 199.9µS/cm, 60.0 to 170.0 µS 10.0 to 99.9 ppm 30.0 to 85.0 ppm

200 to 1999 µS/cm; 600 to 1700 µS 100 to 999 ppm; 300 to 850 ppn

2.00 to 19.99 mS/cm, 6.00 to 17.00 mS 1.00 to 9.99 ppt 3.00 to 8.50 ppt

20.0 to 199.9 mS/cm 60.0 to 170.0 mS 10.0 to 99.9 ppt 30.0 to 170.0 ppt

Table 1: Recommended Calibration Solution Range in correspond to Conductivity / TDS

TDS Range Recommended

Calibration Solution

Range

In single point calibration, when you recalibrate your meter, the old calibration will be

replaced by the new one even if the new calibration is done in a different range from

the old calibration. For example, if you have previously calibrated your conductivity

meter at 1413 µS in 0 to 2000 µS range, and you recalibrate at 12.88 mS in 0 to

20.00 mS range, the new calibration will override the previous calibration in 0 to 2000

uS range.

In the case of multi point calibration, when you recalibrate your meter, old calibrations

are replaced only on a range basis. For example, if you previously calibrated your

conductivity meter at 1413 µS in 0 to 2000 µS range and you recalibrate at 1500 µS

(also in 0 to 2000 µS range), the meter will replace only the old calibration data (1413

µS) in that range. The meter will retain all calibration data in other ranges.

To completely recalibrate your meter, or when you use a replacement electrode, it is

best to clear all calibration data. See page 45 for more information on calibration data

clearance.

11

Instruction Manual CON 11/110

4.2 Preparing the Meter for Calibration

Before starting calibration, make sure you are in the correct measurement mode.

For best results, select a standard value close to the sample value you are

measuring. Alternatively use a calibration solution value that is approximately 2/3 the

full-scale value of the measurement range you plan to use. For example, in the 0 to

2000 µS conductivity range, use a 1413 µS solution for calibration.

Perform calibration for all measurement ranges to ensure the highest accuracy

throughout all measurement range. Note that CON 11/110 will not accept calibration

values less than 2 µS/cm (1.0 ppm).

If you are measuring in solutions with Conductivity lower than 100 µS/cm or TDS

lower than 50 ppm, calibrate the meter at least once a week to get good accuracy. If

you are measuring in the mid ranges and you wash the electrode in deionised water

and store it dry, calibrate the meter once a month. If you take measurements at

extreme temperatures, calibrate at least once a week.

Ensure that you use new Conductivity standard solutions or sachets during

calibration. Do not reuse standard solutions as it may be contaminated and affect the

calibration and accuracy of measurements. Use fresh calibration solution each time

you calibrate your meter. Keep solutions in a dry and cool environment if possible.

Always rinse the electrode with either tap water or rinse solution before and after

each calibration/sample measurement to avoid cross-contamination.

NOTE: These meters are factory set to a temperature coefficient of 2.1%

per °C. For most applications this will provide good results.

NOTE: The factory default value for normalisation temperature is 25 °C.

12

Instruction Manual CON 11/110

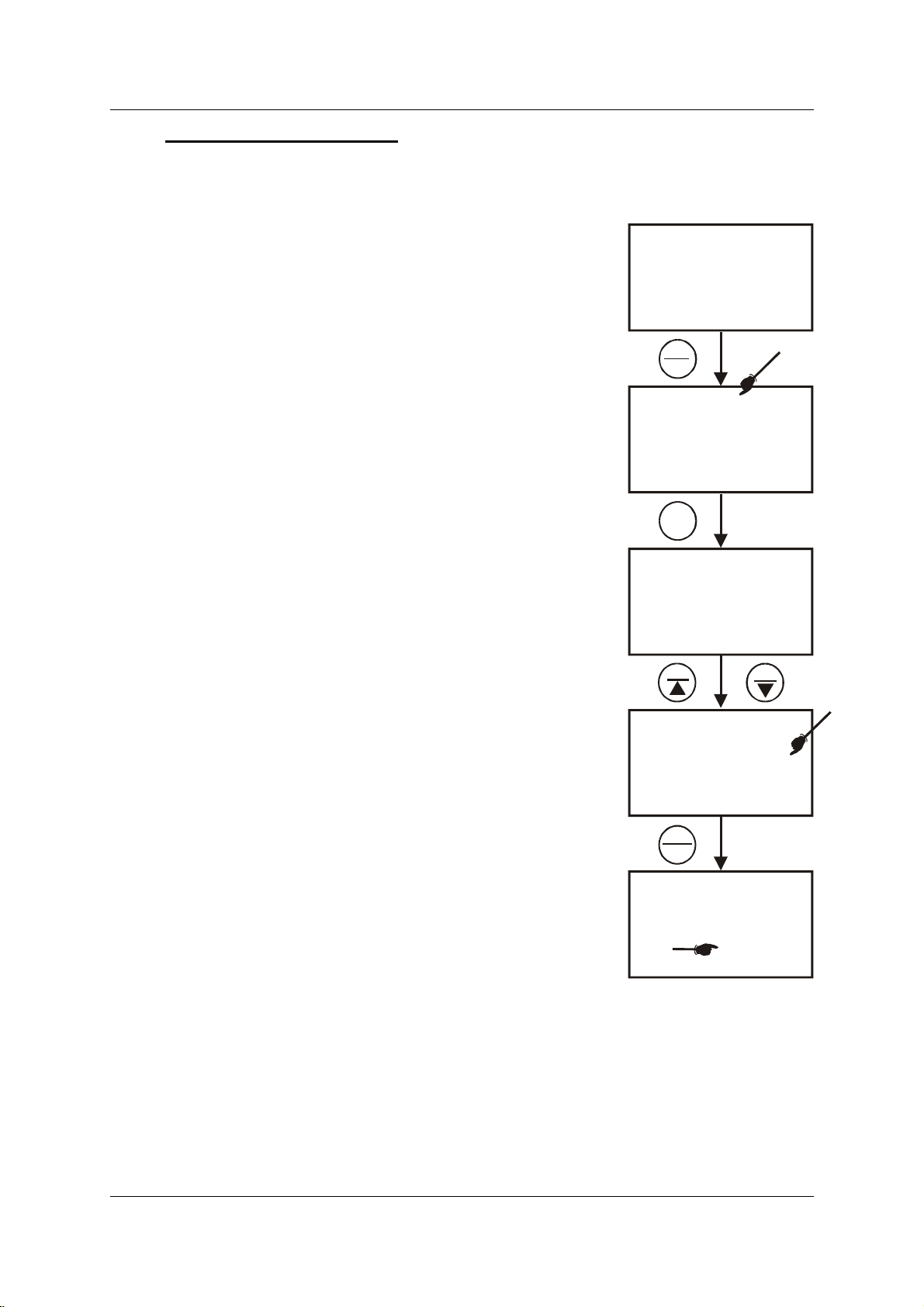

A

4.3 Temperature Calibration

Your electrode features a built-in temperature sensor. The temperature sensor is

factory calibrated. Calibrate your sensor only if you suspect temperature errors may

have occurred over a long period of time or if you have a

replacement electrode.

1. Make sure the electrode is attached to the 6-pin

connector. The ATC annunciator will appear at the

bottom right-hand corner of the LCD.

2. Switch the meter on. Press the CAL/MEAS key to

enter conductivity or TDS calibration mode. The CAL

indicator appears above the primary display.

3. While in conductivity or TDS calibration mode, press

the MODE key to enter temperature calibration

mode. The primary display shows the current

measured temperature reading based on the last set

offset and the secondary display shows the current

measured temperature reading based on factory

default calibration.

4. Dip the electrode into a solution of known

temperature (i.e. a temperature bath). Allow time for

the built-in temperature sensor to stabilise.

5. Scroll with the MI/▲ or MR/▼ keys to set the correct

temperature value (i.e. the temperature of the

temperature bath). You can adjust the reading in

increments of 0.1 °C.

6. Once you have selected the correct temperature,

press the HOLD/ENTER key to confirm. The meter

will be calibrated and return to the measurement

mode.

MEAS

1413

CAL

MEAS

1413

MODE

22.3

MI

22.0

22.3

CAL

1413

CAL

22.3

CAL

22.3

MR

°C

ATC

µ

S

µ

S

°C

TC

°C

ATC

NOTES:

• To exit this program without confirming the

temperature calibration value, DO NOT press

HOLD/ENTER. Press CAL/MEAS instead.

• If the ATC indicator does not light up, see SETUP

menu Program P1.3 to switch it on. See page 40.

• Since temperature readings affect the accuracy of

conductivity / TDS measurements, it is strongly

recommended to carry out a conductivity / TDS

calibration after a temperature calibration is done.

13

HOLD

ENTER

MEAS

READY

µ

S

1425

°C

22.0

Figure 11: Temperature

Calibration

ATC

Instruction Manual CON 11/110

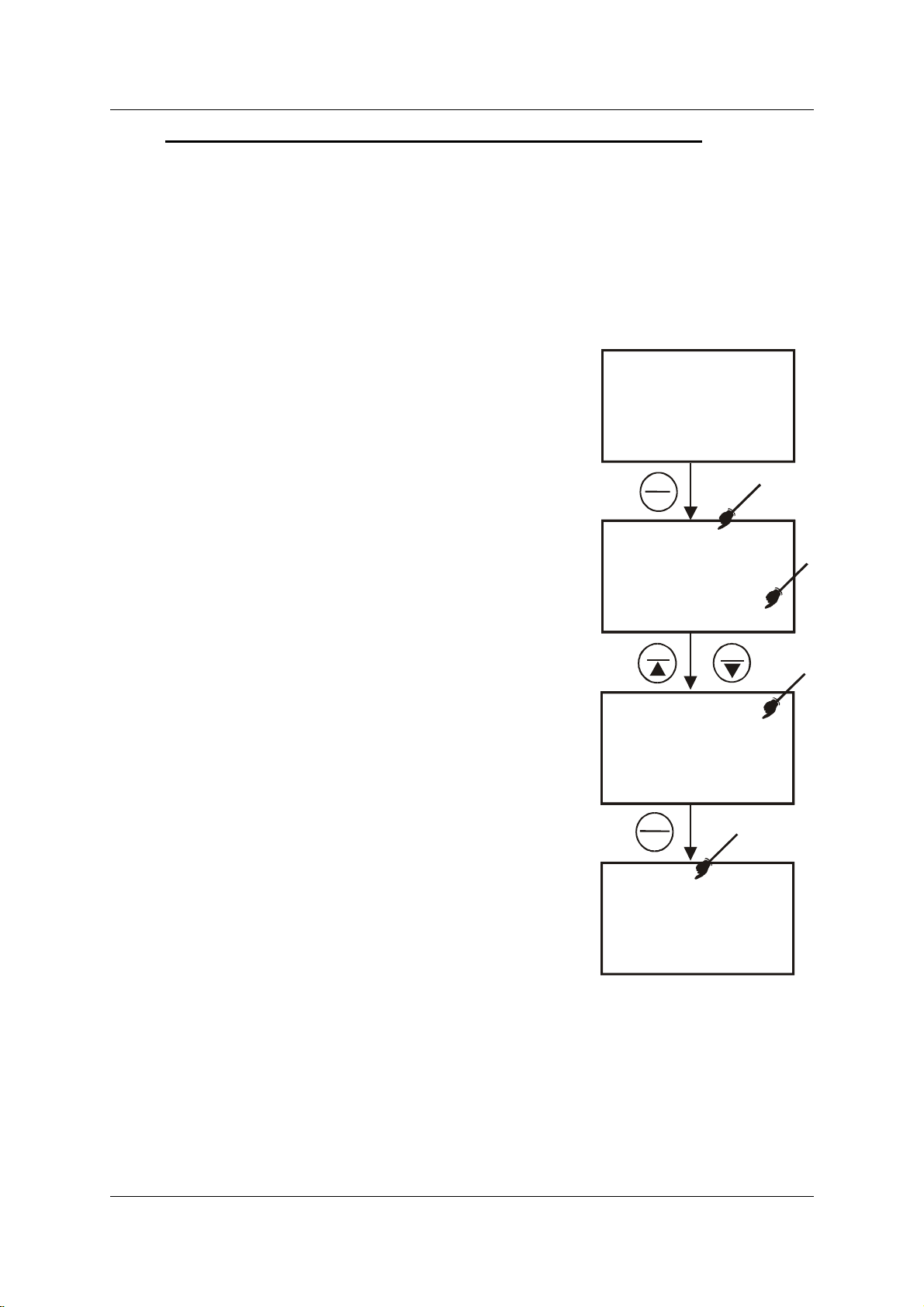

4.4 Selection of Automatic or Manual Calibration

This meter is capable of performing either automatic conductivity calibration or

manual conductivity / TDS calibration.

In the automatic calibration mode, the meter automatically detects and verifies the

appropriate known calibration standards solutions before accepting these particular

calibration standards as one of its calibration values in a specific measurement

range. This automatic calibration mode frees you from cumbersome calibration

procedure.

The known calibration standards used for automatic calibration are:

Meter Temperature Normalisation

(tnr °C)

CON

11/110

25.0 °C 84 µS (for 0 – 200 µS/cm)

20.0 °C 76 µS (for 0 – 200 µS/cm)

Table 2: Conductivity Calibration Standards for Auto calibrations

Calibration Standards (Range)

1413 µS (for 0 – 2000 µS/cm)

12.88 mS (for 0.00 – 20.00 mS/cm)

111.8 mS (for 0.0 – 200.0 mS/cm)

1278 µS (for 0 – 2000 µS/cm)

11.67 mS (for 0.00 – 20.00 mS/cm)

102.1 mS (for 0.0 – 200.0 mS/cm)

In the manual calibration, non-standard calibration values can be used for calibration.

You can manually input the appropriate values as your desired calibration standards

in each specific range. This is useful when you have a customised calibration

standard specifically unique for your application.

14

Instruction Manual CON 11/110

4.5 Automatic Calibration (For Conductivity Calibration Only)

In the Automatic Calibration mode, the meter is capable of accepting either singlepoint or up to 4 points for multi-point calibration with maximum of 1 point per specific

measurement range. Set up the automatic calibration mode in the SETUP menu

Program P9.1 by setting to “YES”. See page 51 for the set up procedure.

The following procedure describes the method for a single point calibration to a 1413

µs conductivity calibration standard. Set the single point calibration mode to on in the

SETUP menu Program 9.2 by setting to ‘YES”. See page 52 for the single point

calibration set up procedure.

1. If necessary, press the MODE key to select conductivity mode.

2. Rinse the electrode thoroughly with de-ionised water or a rinse solution, and

then rinse with a small amount of calibration

standard.

3. Dip the electrode into the calibration standard.

Immerse the electrode tip beyond the upper steel

band. Stir the electrode gently to create a

homogeneous sample. Allow time for the reading

to stabilise.

4. Press CAL/MEAS to enter conductivity calibration

mode. The CAL indicator will appear in the upper

corner of the display. The current measured

value will be displayed in the primary display

whereas the value of the calibration standard will

appear in the secondary display.

5. Press the HOLD/ENTER to confirm the

calibration value. The meter returns automatically

to the measurement mode with the new

calibrated value.

This single point calibration will apply to all the five

ranges.

As for multi point calibration, set up the multi point

calibration mode in the SETUP menu Program P9.2 by

setting to ‘NO”.

Repeat step 1 to 5 for every calibration point in each

measuring ranges using the known calibration solutions until all points have been

calibrated if necessary.

MEAS

µ

S

1356

°C

22.3

CAL

MEAS

CAL

ATC

µ

S

1356

1413

HOLD

ENTER

READY

MEAS

µ

S

1413

°C

22.3

Figure 12: Automatic

Conductivity Calibration

ATC

15

Instruction Manual CON 11/110

IMPORTANT NOTES:

1. Meter allows a tolerance range of ±40% of its calibration standard.

If the calibration standard is detected out of the tolerance range

during the calibration mode, the meter will prompt by the toggling of

the secondary display continuously between various calibration

standard values. An error message “ERR” will be displayed for 3

seconds if you attempt to calibrate with a solution whose value is

outside the tolerance range.

For instance: For 1413 µS conductivity calibration standard, 40%

tolerance is from 848 µS to 1978 µS.

2. All new calibration data will over-ride existing stored calibration data

for each measuring range calibrated.

3. It is important to use new conductivity calibration standards.

4. Low conductivity standard solution (less than 20 µS /cm) cannot be

available easily. Such low conductivity standard will be

contaminated as soon as it is exposed to the air. It is therefore for

this reason automatic calibration in the first measurement range

(0.00 to 20.0 µS /cm) of this meter is not possible.

16

Instruction Manual CON 11/110

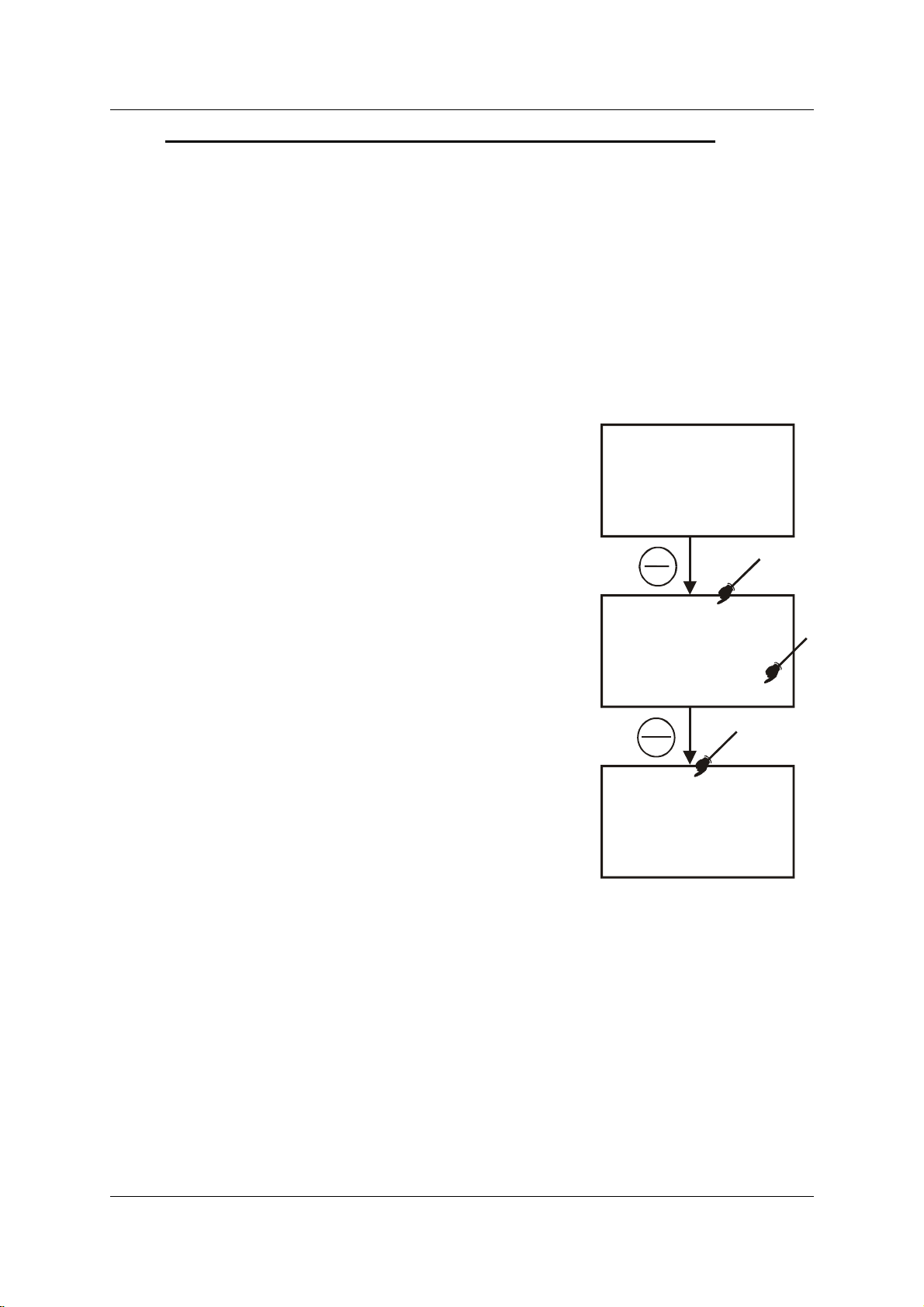

4.6 Manual Calibration (For Conductivity & TDS Calibration)

In Manual Calibration mode, you can use customised Conductivity / TDS calibration

standards (specific to your own application) and calibrate the meter. The following

example shows the calibration sequence to 12.00 mS conductivity calibration

standard. Set up the manual calibration mode in the SETUP menu Program P9.1 by

setting to “NO”. See page 51.

The following procedure describes the method for a single point calibration. Set the

single point calibration mode to on in the SETUP menu Program 9.2 by setting to

‘YES”. See page 52 for the single point calibration set up procedure.

1. If necessary, press the MODE key to select

MEAS

conductivity mode.

2. Rinse the electrode thoroughly with de-ionised

11.87

water or a rinse solution, and then rinse with a

small amount of calibration standard.

3. Dip the electrode into the calibration standard.

Immerse the electrode tip beyond the upper steel

CAL

MEAS

band (see Figure 6 in page 6). Stir the electrode

gently to create a homogeneous sample. Allow

time for the reading to stabilise.

11.87

4. Press CAL/MEAS key to enter conductivity

calibration mode. The CAL indicator will appear

in the upper corner of the display. The upper

(primary) display shows the measured value

which is with respect to the last calibration while

the lower (secondary) display shows the

measured value with respect to the default

calibration.

NOTE: To exit calibration without confirmation, press

CAL/MEAS key again to go back to measurement

mode.

5. Wait for the value to stabilise and press MI/▲ or

MR/▼ key and adjust the value in the upper

display to the calibration standard used.

6. Press the HOLD/ENTER key to confirm. The

meter returns to measurement mode with the

new calibrated value.

This single point calibration will apply to all the five ranges.

As for multi point calibration, set up the multi point

calibration mode in the SETUP menu Program P9.2 by setting to ‘NO”.

MI MR

12.00

HOLD

ENTER

MEAS

READY

12.00

Figure13: Manual

Calibration

22.3

CAL

11.87

CAL

11.87

22.3

mS

°C

ATC

mS

mS

mS

°C

ATC

Repeat step 1 to 6 for every calibration point (one in each measuring range) using

the desired calibration solutions until all points have been calibrated.

17

Instruction Manual CON 11/110

4.7 TDS Calibration

4.7.1 Calibrating for TDS Using Conductivity Standards & adjusting TDS factor

It is important to note that the increase in concentration of salts dissolved in solution

increases the conductivity of that solution. This relationship varies from salt to salt

and is roughly linear over a given range for a given salt. The TDS conversion factor is

the number used by the meter to convert from conductivity to TDS.

Instead of calibrating for TDS directly using TDS calibration standard solutions, you

can have TDS calibration by using the conductivity calibration method and enter the

appropriate TDS conversion factor into the meter.

For more information regarding TDS Conversion Factor determination, please refer to

page 73.

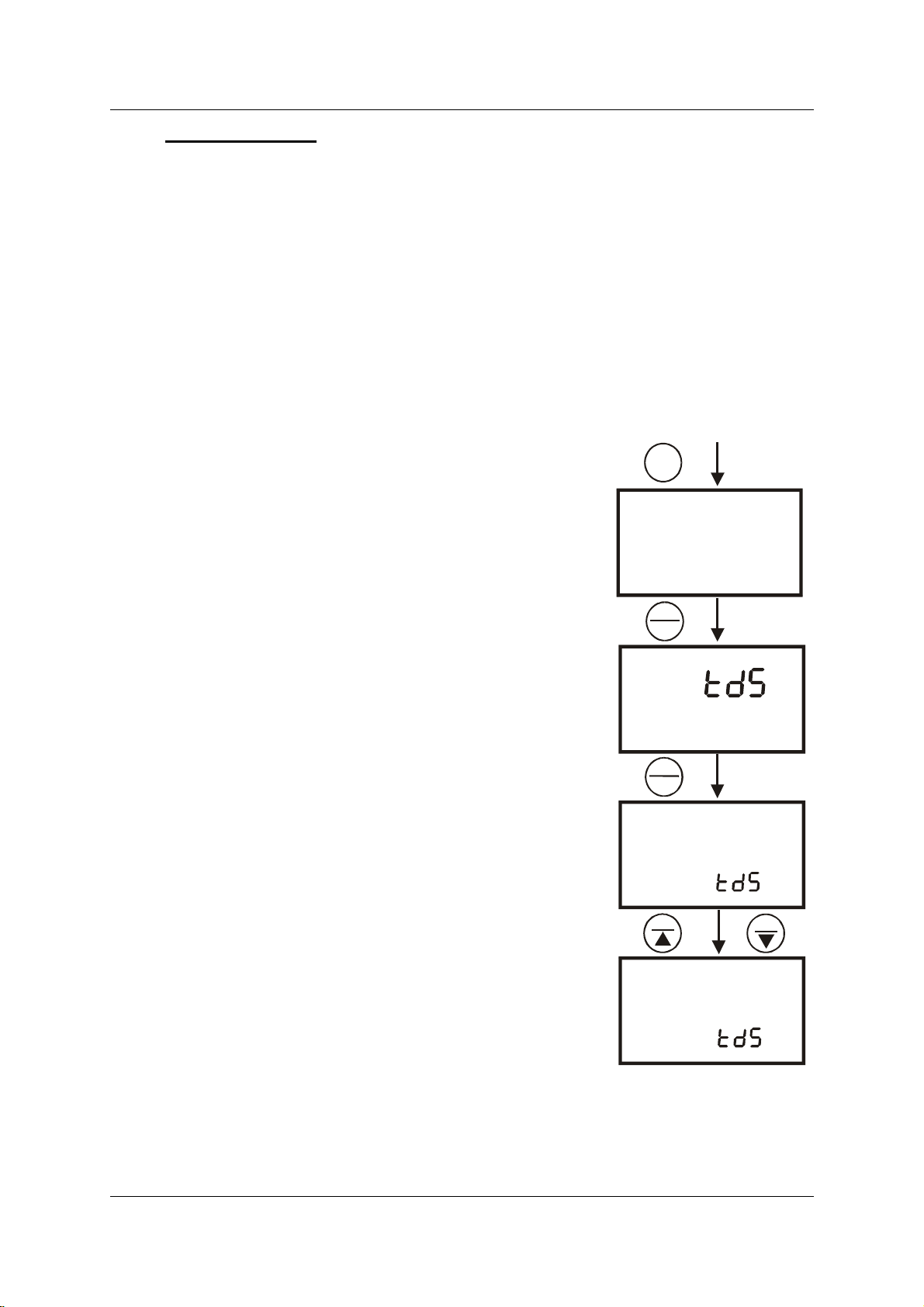

4.7.2 Setting the TDS Conversion Factor

The factory default setting for TDS conversion factor is 0.5.

If your solution has a different TDS factor, you can improve

calibration accuracy by setting the TDS factor prior to

calibration.

1. Press MODE key to select TDS mode.

2. Press Setup key to enter SETUP Menu.

3. Press the HOLD/ENTER key a few times to scroll

through the sub programs until you view Program

P1.4

4. Press the HOLD/ENTER key again. The upper

display shows a value and the lower display shows

“tdS”.

5. Press the MI/▲ or MR/▼ keys to select your

calculated TDS conversion factor.

6. Press the HOLD/ENTER key to confirm selection

and to return to the subgroup menu.

Only from TDS Measurement Mode

SETUP

SETUP

cof

p 1.0

HOLD

ENTER

SETUP

ppt

ppm

p 1.4

HOLD

ENTER

SETUP

0.50

ppt

ppm

7. Press the CAL/MEAS key to return to

measurement mode.

NOTE: The set up program P1.4 for setting the TDS

conversion factor is only activated when set up menu is

entered while the meter is in the TDS measurement mode.

18

MI

SETUP

0.75

Figure 14: Setting the TDS

Conversion Factor

MR

ppt

ppm

Instruction Manual CON 11/110

4.7.3 Calibrating for TDS using TDS standards

After setting the correct TDS Factor, you can commence calibration in the TDS

mode.

From the measurement mode,

1. If necessary, press the MODE key to select the TDS mode.

2. For the rest of the calibration process, repeat the similar step 2 to 6 as in the

section of Manual Calibration on page 17, this time using the TDS calibration

standards.

NOTE: You can offset the TDS reading up to ± 40% from the default setting. If your

measured value differs by more than ± 40%, clean or replace electrode as needed.

19

Instruction Manual CON 11/110

5 MEASUREMENT

This meter is capable of taking measurements with automatic (ATC) or manual

(MTC) temperature compensation. Factory default is ATC on.

5.1 Automatic Temperature Compensation

READY

MEAS

1413

22.3

°C

ATC

µ

S

For automatic temperature compensation (ATC), simply attach

the conductivity/TDS electrode to the meter. Ensure that the

ATC mode has been selected in the SETUP menu. The ATC

indicator will light on the LCD.

NOTE: If the conductivity/TDS electrode is not properly

attached to the meter or it has been damaged, the ATC

indicator will blink and the temperature display will show

“Ur”.

Figure 15: Automatic

Temperature Compensation

If the ATC indicator does not light and the temperature

display shows a reading, ATC mode may have been replaced with the manual

temperature compensation mode in the meter’s SETUP menu. See page 21 Section

5.2 on Manual Temperature Compensation.

Automatic Temperature Compensation mode can be restored by setting the SETUP

Menu Program P1.3 to YES.

20

Instruction Manual CON 11/110

A

5.2 Manual Temperature Compensation

To select the Manual Temperature Compensation (MTC) option, set up the Manual

Temperature Compensation mode in the SETUP menu Program P 1.3 by setting to

‘NO”.

1. Press SETUP key to enter Set Up mode. The display shows “COF” at “P

1.0”.

2. Press the HOLD/ENTER key to scroll through subgroups until you view

“ATC” at “P1.3” with small annunciators of “°C” and “ATC” or “°F” and “ATC”.

3. Press the HOLD/ENTER key again. The upper display shows “ATC” and the

lower display shows “YES”.

4. Press the MI/▲ or MR/▼ key to select the lower display to show “NO”.

5. Press the HOLD/ENTER key to confirm selection and to return to the

subgroup menu.

6. Press the CAL/MEAS key to return to measurement mode.

SETUP

SETUP

READY

ON

SETUP

SETUP

HOLD

ENTER

HOLD

ENTER

cof

p 1.0

p 1.1

C

p 1.2

HOLD

ENTER

SETUP

YES

MI

SETUP

HOLD

ENTER

SETUP

°C

cof

°C

TC

MR

°C

p 1.0

HOLD

ENTER

SETUP

CAL

MEAS

A C

p 1.3

°C

Figure 16: Manual Temperature

Compensation Set Up sequence

21

No ‘ATC’

Instruction Manual CON 11/110

5.2.1 Setting the manual temperature compensation value

To use manual temperature compensation (MTC), you need to enter the temperature

value of your sample into the meter. This is the temperature value at which the

measured readings will be manually temperature compensated. You can select any

temperature between -10.0 to 110.0 °C (14.0 to 230 °F). Default value is 25 °C.

1. Switch the meter on. If necessary, set up the MTC by selecting ATC off as

described in page 21. The ATC indicator will not appear on the display.

2. Press the CAL/MEAS key to enter conductivity or

TDS calibration mode. The CAL indicator will appear

above the primary display.

3. While in conductivity or TDS calibration mode, press

the MODE key to enter temperature calibration

mode. The primary display act as the adjustable

MI

MR

temperature setting and the secondary display

shows the default temperature value of 25 °C or

indicates the last set temperature setting. Check the

temperature of your sample using an accurate

thermometer.

4. Press the MI/▲ or MR/▼ keys to offset the

temperature to the measured value from step 3.

5. Press HOLD/ENTER to confirm the selected

temperature and to return to the Conductivity or TDS

measurement mode.

The meter will now compensate Conductivity or TDS

readings for manually set temperature.

NOTES:

To exit this program without confirming the manual

temperature compensation value, DO NOT press

HOLD/ENTER in step 5. Press CAL/MEAS instead.

ENTER

Figure 17: Select Manual

Temperature

Compensation Value

22

Instruction Manual CON 11/110

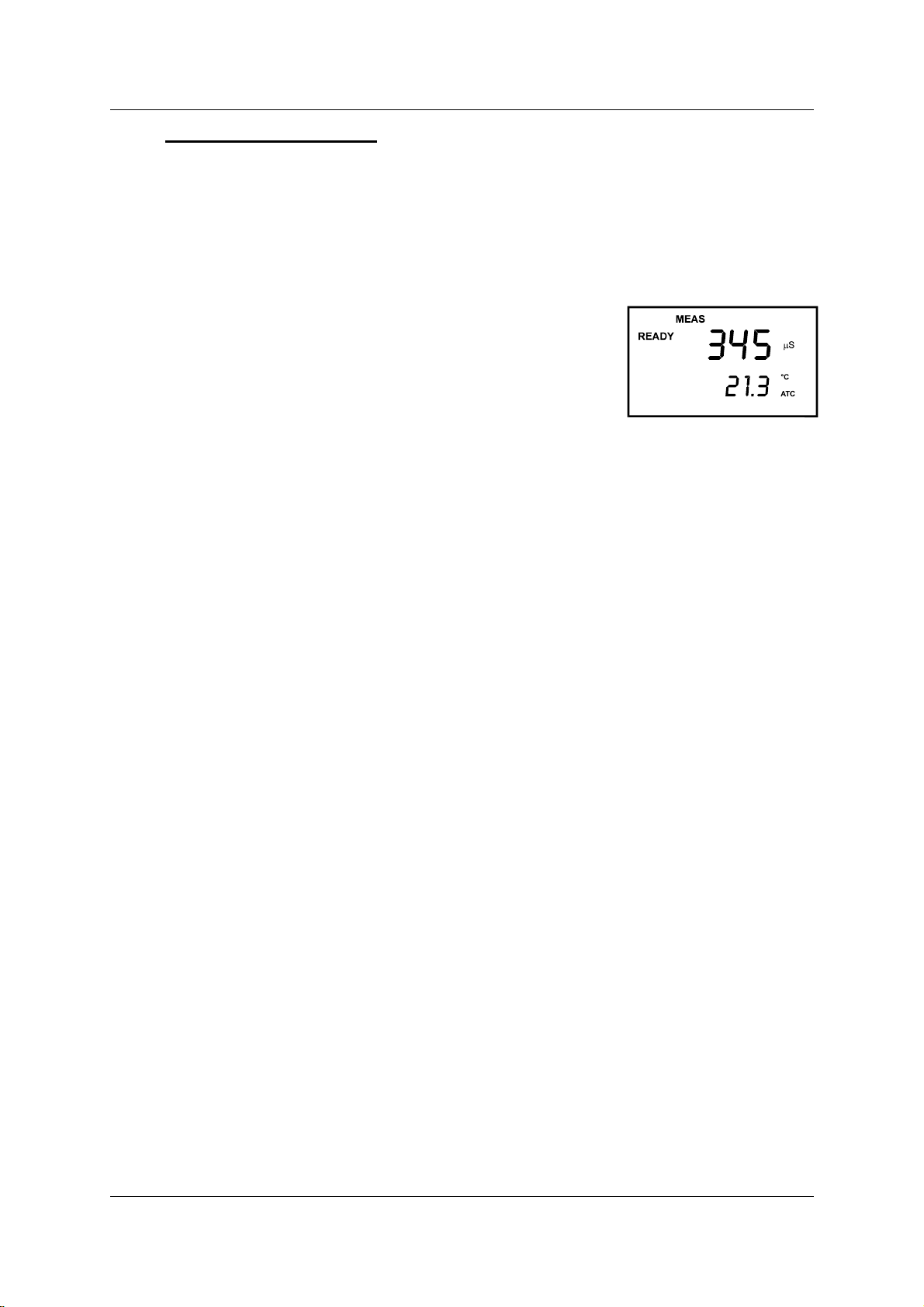

5.3 Taking Measurements

1. Rinse the electrode with de-ionised or distilled water before use to remove

any impurities adhering to the electrode body. Shake or air dry. To avoid

contamination or dilution of your sample, rinse electrode with a small volume

of your sample liquid.

2. Press ON to switch on meter.

3. Dip the electrode into the sample.

When dipping the electrode into the sample, take care to

ensure that the liquid level is above its upper steel band. Stir

the electrode gently in the sample to create a homogenous

sample.

4. Allow time for the reading to stabilise. Note the

reading on the display.

5. Press the MODE key to toggle between

conductivity and TDS readings.

Figure 18:

Measurement Mode

5.3.1 Taking measurements with READY indicator selected on

If the READY indicator has been activated, the READY annunciator lights when the

reading is stable. Switch the READY indicator on or off in SETUP program P 1.1.

See page 38 for directions.

5.3.2 Taking measurements with the Auto HOLD feature selected on

This feature is only available in CON 110.

When a reading is stable for more than 5 seconds, the Auto HOLD feature will

automatically “hold” the reading. The “HOLD” indicator appears on the left side of the

display. Press the HOLD/ENTER key to release the reading. To activate the Auto

HOLD feature in SETUP program P 1.1, see page 38 for directions.

23

Instruction Manual CON 11/110

µ

µ

5.4 Using Manual Ranging Function

Your meter automatically selects the range in which your readings appear. The

manual ranging function lets you select the specific range you want to work in:

Meter Range Symbol Conductivity Range TDS Range

r1 0 to 19.99 µS/cm, 0.00 to 9.99 ppm

r2 20.0 to 199.9µS/cm 10.0 to 99.9 ppm

r3 200 to 1999 µS/cm; 100 to 999 ppm

r4 2.00 to 19.99 mS/cm, 1.00 to 9.99 ppt

r5 20.0 to 199.9 mS/cm 10.0 to 99.9 ppt

5.4.1 Selecting manual range

1. To select the desired measuring range,

press the RANGE key while in

measurement mode. A momentary display

of either “r1” to “r5” will flash indicating the

READY

MEAS

1413

22.3

S

°C

ATC

range you are in. The range selected will

appear on the display and the “MEAS”

MEAS Blinking

RANGE

indicator blinks indicating that you are in

manual range.

READY

MEAS

S

1413

2. Press the range key again (if needed) until

desired range is selected. To re-select the

auto-ranging function, repeatedly press the

range key until the “MEAS” indicator appears

without blinking.

22.3

Figure 19: Selecting Manual

Range

°C

ATC

NOTES

If the value of the solution you are measuring is higher than the range selected, “Or”

will appear on the primary display. Press RANGE until the correct range is selected.

The meter resets to the Auto-ranging function once it is

MEAS

READY

22.3

Figure 20: Out of

Range

µ

°C

ATC

turned off. You will have to reset the manual ranging function

each time you turn the meter off.

S

24

Instruction Manual CON 11/110

5.5 HOLD Function

This feature lets you freeze the display for a delayed observation. HOLD/ENTER can

be used any time in MEAS mode.

1. To hold a measurement, press the HOLD/ENTER key

while in measurement mode. “HOLD” will appear on

the display.

2. To release the held value, press the HOLD/ENTER

again. Continue to take measurements.

NOTE:

• If the meter is shut off either automatically or

manually, the HOLD value will be lost. For longer storage, use the memory

functions (see pages 26).

Figure 21: HOLD freezes

measurement

25

Instruction Manual CON 11/110

µSµ

6 MEMORY FUNCTION

6.1 Memory Input

CON 11/110 meter stores up to 50/100 set of data

respectively. Data sets can include both conductivity and

TDS measurement values and its temperature.

1. During any measurement function (MEAS), press

MI/▲ key to input any data into the memory. MEM,

“StO” and memory number will appear for a

moment after which the meter then returns to

measurement mode.

2. If necessary, measure the next sample solution

and press MI/▲ key to input the next data into the

memory.

NOTE: If the memory is full, the display will flash “FUL”

momentarily. The first value stored will be erased to create

space for the new value.

MEM

READY

READY

MEAS

823

MI

MEAS

21.3

MEM

1

°C

ATC

823

FUL

21.3

°C

ATC

S

MEM

1

Figure 23: Memory full

MI

MEM

2

Figure 22: Data storage

in memory

26

Instruction Manual CON 11/110

µSµ

6.2 Memory Recall

This function recalls the previous readings stored in the

memory. You can access memory recall function from the

measurement mode only. Memory recall is in "Last In First

Out" order.

1. Press the MR/▼ key once to retrieve the last reading

stored. The memory location screen – MEM, “LOC”

and the memory number – will be on the display.

2. Press the HOLD/ENTER key to recall the reading

stored under that memory number.

3. Press HOLD/ENTER key again to return to the

"memory location" screen. The display automatically

moves to the next memory location screen.

4. If necessary, press the MI/▲ or MR/▼ keys to select

the next "memory location" screen or press the

HOLD/ENTER key repeatedly to select the previous

"memory location" screen.

5. To exit Memory Recall, press CAL/MEAS key to

return to Measurement mode.

NOTES:

Readings stored in memory are retained even if the units are

turned off. To erase all readings stored in memory, use the

SETUP menu Program P6.0 on page 47.

READY

MEAS

MR

HOLD

ENTER

HOLD

ENTER

716

22.3

MEM

loc

2

MEM

569

22.4

MEM

°C

ATC

S

°C

ATC

loc

1

Figure 24 : Memory

recall

27

Instruction Manual CON 11/110

7 PRINT FUNCTION (FOR CON 110 ONLY)

The CON 110 meter is equipped with an RS232 communication port and a PRINT

( ) key that facilitate the printing of data from the meter to a printer or computer.

7.1 Using CON 110 Meter with Printer or Computer

1. To use the CON 110 directly with a printer, the printer should have either

a 9 pin or a 25 pin RS 232C serial port.

2. Communication settings of the printer or computer’s data acquisition

software (CyberComm Portable DAS) MUST match the following

parameters:

a. Baud Rate: 9600

b. Parity Bit: None

c. Stop Bit: One

d. Data Bit: 8

e. Flow Control: None

Please refer to your printer’s or computer’s instruction manual for more information

on its communication setup protocol.

3. Use 9-pin cable (Refer to section –List OF Accessories on page 68) to

connect the meter to the printer. If the printer has a 25 pin connector, use

the 9 to 25 pin cable or make your own cable taking note of the

connection parameters as described in section 3.6- Connecting the

RS232C Cable (Only for CON 110) on page 9.

4. Turn on CON 110 meter and note the following:

a. For printer, ensure it is powered on and paper is loaded.

b. For computer, ensure that Eutech Instruments’ CyberComm

Portable Data Acquisition Software is installed and activated. See

section 9.3- Running CyberComm Portable on page 59.

5. To send data to the printer or computer, press the PRINT ( ) key.

28

Instruction Manual CON 11/110

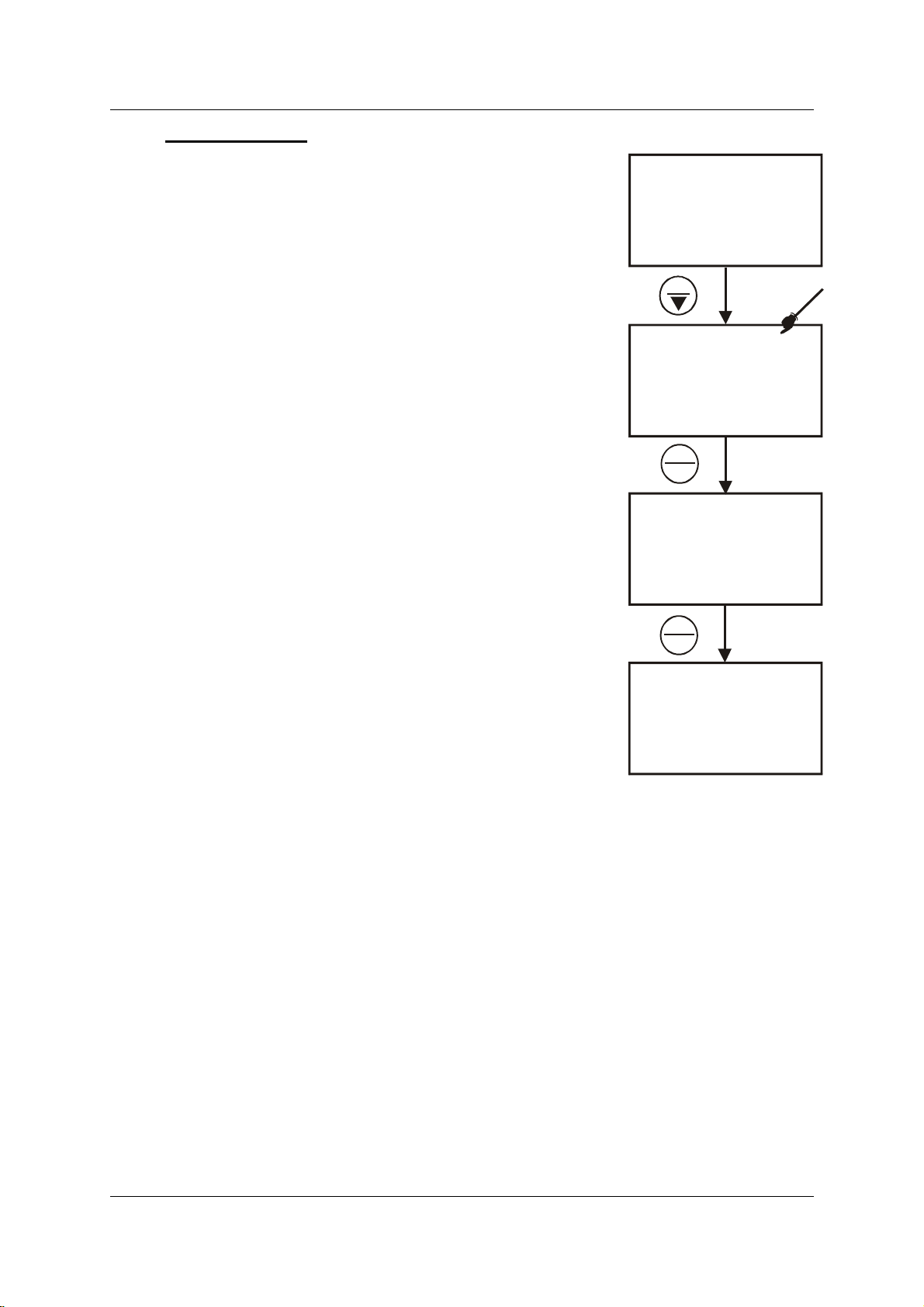

7.2 Sending Data To Computer or Printer

When the PRINT ( ) key is pressed, there are two options:

1. dAt / CUr: Prints current data on timed interval basis. The function enables

the meter to continuously print the current data automatically based on the

pre-set timing from 5 to 30 seconds.

2. dAt / StO: Prints stored data from memory. This function lets you print all the

memorised data from memory previously stored in the meter. Each set of

stored data will be send for printing based on preset timing from 0 to 30

seconds.

From Coductivity or TDS measurement mode.

HOLD

ENTER

MR

MI

HOLD

ENTER

Figure 25: Print data based on timed interval or from memory

29

Instruction Manual CON 11/110

7.2.1 Printing Current Data Manually

To manually print any data that is currently being measured:

1. From measurement mode, press HOLD/ENTER key

to freeze reading.

2. Press PRINT ( ) key.

3. The “Prn – CUr” annunciator will appear and flash

for about 0.5 seconds. The data is transmitted to the

printer or computer.

4. The meter returns to measurement mode.

5. Repeat steps 1 to 3 for next measurement.

7.2.2 Print Data on Timed Interval

This feature is useful to automate printing and downloading

‘live’ measurement values into computer. The time interval

setting can range from 5 to 30 seconds.

1. From conductivity or TDS measurement mode, press

PRINT ( ) key.

2. The “dAt/Cur” screen appears .Press the

HOLD/ENTER key.

3. The “SEC 5” screen appears. The default value is 5

seconds time interval.

4. Press MI/▲ or MR/▼ key to set a value suitable for

your application.

5. Press HOLD/ENTER key.

6. The meter goes into measurement mode with MEM

annunciator flashing.

MEAS

READY

µ

S

1413

°C

ATC

µ

S

HOLD

ENTER

READY

HOLD

22.3

MEAS

1413

°C

ATC

µ

S

READY

22.3

Flash for 0.5 seconds

MEAS

1413

°C

22.3

Figure 26: Print

Current data manually

ATC

7. At a pre-set time interval, the screen flashes “Prn/CUr” momentarily (printing

data) and switches back to measurement mode with MEM annunciator

flashing.

8. To stop printing, press PRINT ( ) key. The MEM annunciator disappears

and the meter is on measurement mode.

30

Instruction Manual CON 11/110

"MEM" annunicator will keep

flashing during measurement

From measurement mode

mode & data will be printed on

pre-set timed interval.

To stop, press PRINT key

HOLD

ENTER

sec

MR

sec

READY

5

MI

HOLD

ENTER

Set timed interval for

printing, eg, every 10

10

seconds

Figure 27: Print data on timed interval

READY

MEAS MEM

1413

21.0

Print on set timed

interva l

Flash for 0.5 s econds

MEAS MEM

1413

21.0

ATC

µ

°C

°C

ATC

S

µ

S

31

Instruction Manual CON 11/110

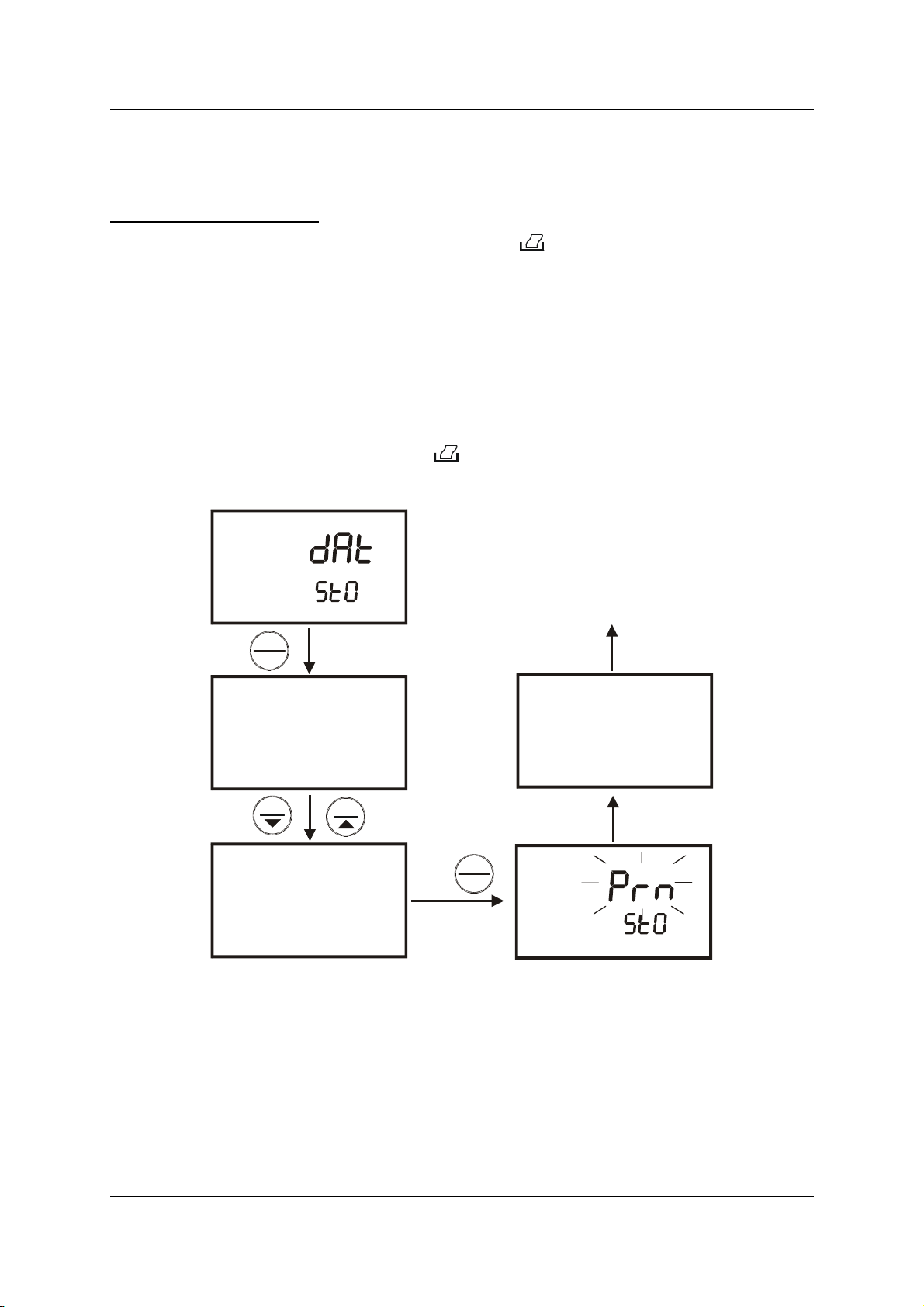

7.2.3 Print Data from Stored Memory

The CON 110 meter can print data that is stored in the memory. You can print out all

stored data or selected data based on its memory location.

To Print All Stored Data

1. From measurement mode, press PRINT ( ) key.

2. Use MI/▲ or MR/▼ key, select “dAt – StO” option and press HOLD/ENTER

key.

3. At the “SEC – 0” option, use MI/▲ or MR/▼ key to select number of seconds

to print each data stored data. This setting gives flexibility to match the meter

to a printer’s or computer’s ability to accept data.

4. Press HOLD/ENTER key. The “Prn” primary display will flash until all data is

printed.

5. To stop printing, press PRINT ( ) key and exit to measurement mode.

NOTE: All stored memory will remain in the meter after printing.

"Prn" display will keep flashing

until all stored data are printed. .

To stop, press PRINT key

HOLD

ENTER

sec

MR

0

MEAS

READY

1413

21.0

MI

HOLD

ENTER

Flash until all stored

data are downloaded.

ATC

µ

S

°C

sec

Set timed interval to

download stored data

10

Figure 28: Print all stored data

to printer or computer

32

Instruction Manual CON 11/110

To print Selected Stored Data

1. From measurement mode, press MR/▼ key.

2. A “MEM” indicator appeared and the last memory input location is displayed.

3. Press MI/▲ or MR/▼ key to select a specific memory location, and press

HOLD/ENTER key.

4. When ready, press PRINT ( ) key.

5. The screen flashes “Prn/CUr” for about 0.5 seconds and switches back to the

stored data of the specific memory location.

6. Press HOLD/ENTER key. The meter is now ready to recall the next stored

data in the following memory location.

During measurement mode

MEAS

µ

ATC

S

°C

Repeat print procedure or

press CAL to exit

READY

1200

21.0

MR

MEM

loc

9

Moves to next

memory location

MEM

22.4

°C

ATC

µ

S

loc

20

MR

loc

10

HOLD

ENTER

MEM

Last memory input

location

MI

MEM

For exampl e,select

memory locat ion 10

MEM

µ

S

HOLD

ENTER

1413

Flash for 0.5 seconds

1413

°C

22.4

Figure 29: Print based on selected stored data from memory

ATC

For more information about Eutech Instruments’ CyberComm Portable Data

Acquisition Software programme, see page 53 - CYBERCOMM PORTABLE DAS

(FOR CON 110 ONLY)

33

Instruction Manual CON 11/110

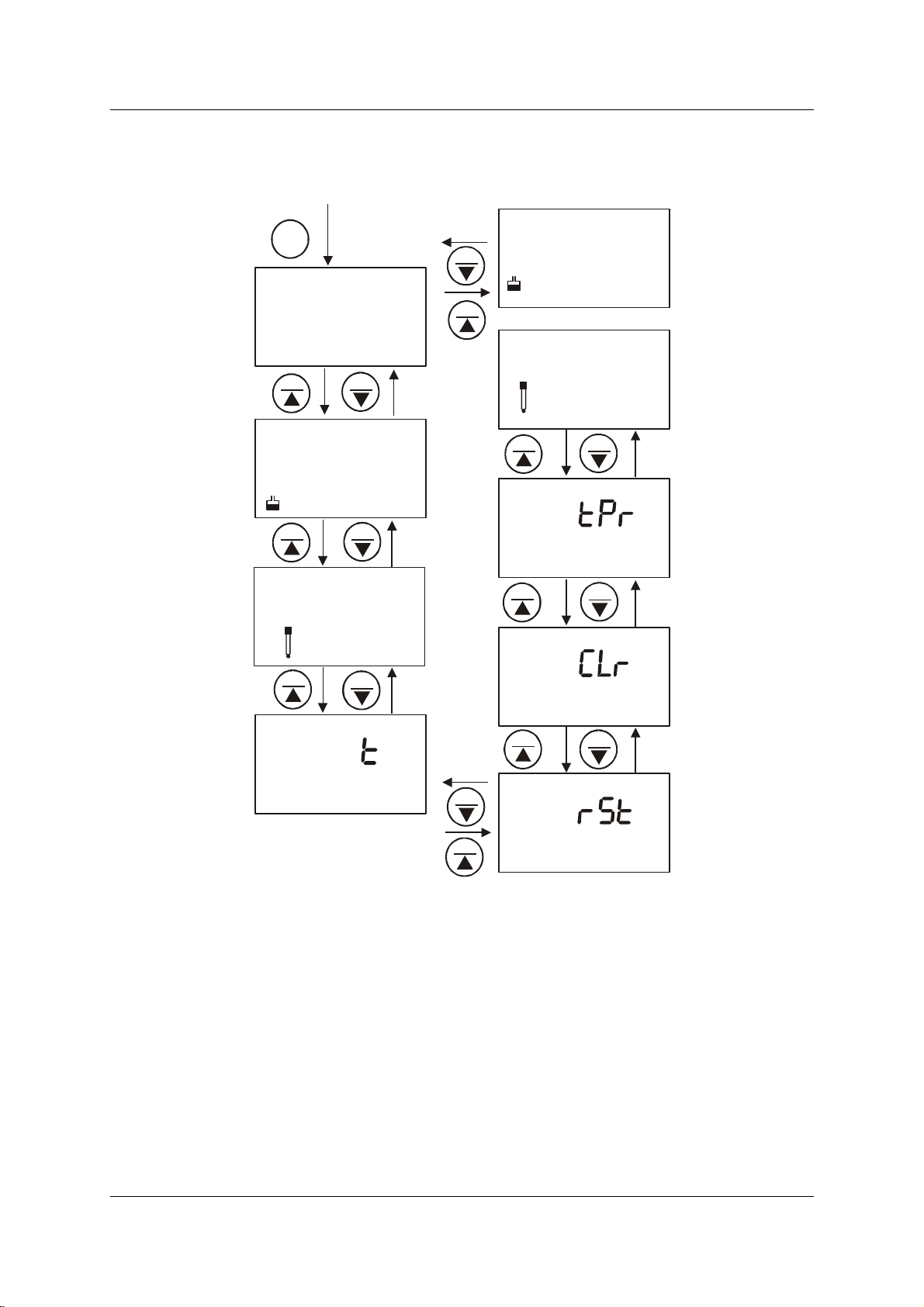

8 ADVANCED SETUP FUNCTION

The advanced setup mode lets you customised your meter’s preferences and

defaults. The CON 11/110 meter features different sub-groups that organise setup

parameters.

The sub-groups are:

1. P1.0: Unit Configuration (COF)

2. P2.0: Viewing previous calibration data (CAL)

3. P3.0: Viewing electrode data (ELE)

4. P4.0: Auto Power OFF (AtO)

5. P5.0: Reset to factory defaults (rSt)

6. P6.0: Memory Clear (CLr)

7. P7.0: Temperature (tPr)

8. P8.0: Selection of cell constant (CEL)

9. P9.0 : Automatic and Single point Calibration (ASC)

34

Instruction Manual CON 11/110

SETUP

SETUP

Asc

P 9.0

CEL

SETUP

MI

COF

P 1.0

MR

MR

MI

SETUP

P 8.0

SETUP

MI

MR

CAL

P 2.0

SETUP

MI

SETUP

MR

P 7.0

MI

MR

°C °F

ELE

MEM

P 6.0

MR

SETUP

P 3.0

MI

MR

SETUP

MI

A o

P 4.0

Figure 30: Overall view of advanced SET UP Programs

MR

MI

SETUP

P 5.0

35

Instruction Manual CON 11/110

8.1 Advanced SETUP Mode Overview

1. Press the SETUP key to enter Set Up menu.

2. Press the MI/▲ or MR/▼ keys to scroll through sub groups.

3. Press HOLD/ENTER key to enter a particular parameter.

SETUP

SETUP

SETUP

SETUP

COF

P 1.0

CAL

P 2.0

ELE

P 3.0

A o

P1.0: Unit Configuration

P1.1 Selection of READY and *Auto HOLD function (*CON

110 Only).

P1.2 Selection of °C or *°F (*CON 110 Only)

P1.3 Selection of Automatic or Manual Temperature

Compensation

P1.4 Selection of TDS Conversion Factor (This mode only

appears when SETUP Menu is chosen while in the

TDS measurement mode)

P2.0: Viewing previous calibration data

P2.1 First range calibration point

P2.2 Second range calibration point

P2.3 Third range calibration point

P2.4 Fourth range calibration point

P2.5 Fifth range calibration point

P3.0: Viewing electrode data

P3.1 Effective cell constant for first range

P3.2 Effective cell constant for second range

P3.3 Effective cell constant for third range

P3.4 Effective cell constant for fourth range

P3.5 Effective cell constant for fifth range

P4.0: Auto Off

P4.0 Selection of automatic power off function

SETUP

SETUP

SETUP

P 4.0

P 5.0

MEM

P 6.0

P 7.0

°C °F

P5.0: Reset to factory defaults

P5.1 Resetting of all calibration and clear all

calibration data

P5.2 Resetting of all User settings to factory

defaults condition

P6.0: Memory clear

P6.0 Clearance of all stored readings

P7.0: Temperature

P7.1 Setting of temperature coefficient

P7.2 Setting of normalisation temperature

36

Instruction Manual CON 11/110

SETUP

SETUP

CEL

P 8.0

Asc

P 9.0

P8.0: Selection of cell constant

P8.0 Selection of cell constant:

K = 1.0, 10, or 0.1

P9.0: Automatic and Single Point Calibration

P9.1 Selection of Automatic or Manual Calibration

(This mode only appears when SETUP Menu is

chosen while in the Conductivity measurement mode

P9.2 Selection of Single or Multi Point Calibration

37

Instruction Manual CON 11/110

8.2 P1.0: Unit Configuration (COF)

8.2.1 P1.1: Selection of READY and Auto HOLD function

Program P1.1 gives you an option to on or off the “READY” display which indicates

the measurement stability during a measuring process.

Program P1.1 also gives an option to activate the Auto

HOLD function (Only for CON 110). Activating the auto

HOLD function lets the meter to “hold” your measurement

when it is stable for more than 5 seconds. The display

automatically freezes, and HOLD indicator appears on the

left side of the display. Press the HOLD key to release the

display and access other functions. Deactivate the auto

HOLD function if you do not want this feature.

From measurement mode

1 Press SETUP key to enter Set Up menu.

SETUP

cof

p 1.0

ENTER

SETUP

READY

ON

2 Press the HOLD/ENTER key to view parameter

P1.1.

3 Press the MI/▲ or MR/▼ keys to select the

configuration you require.

• “ON” activates the READY function.

• “OFF” deactivates the READY function.

• “ON” and “HOLD” activates the Auto HOLD

function.

4 Press HOLD/ENTER key to confirm selection.

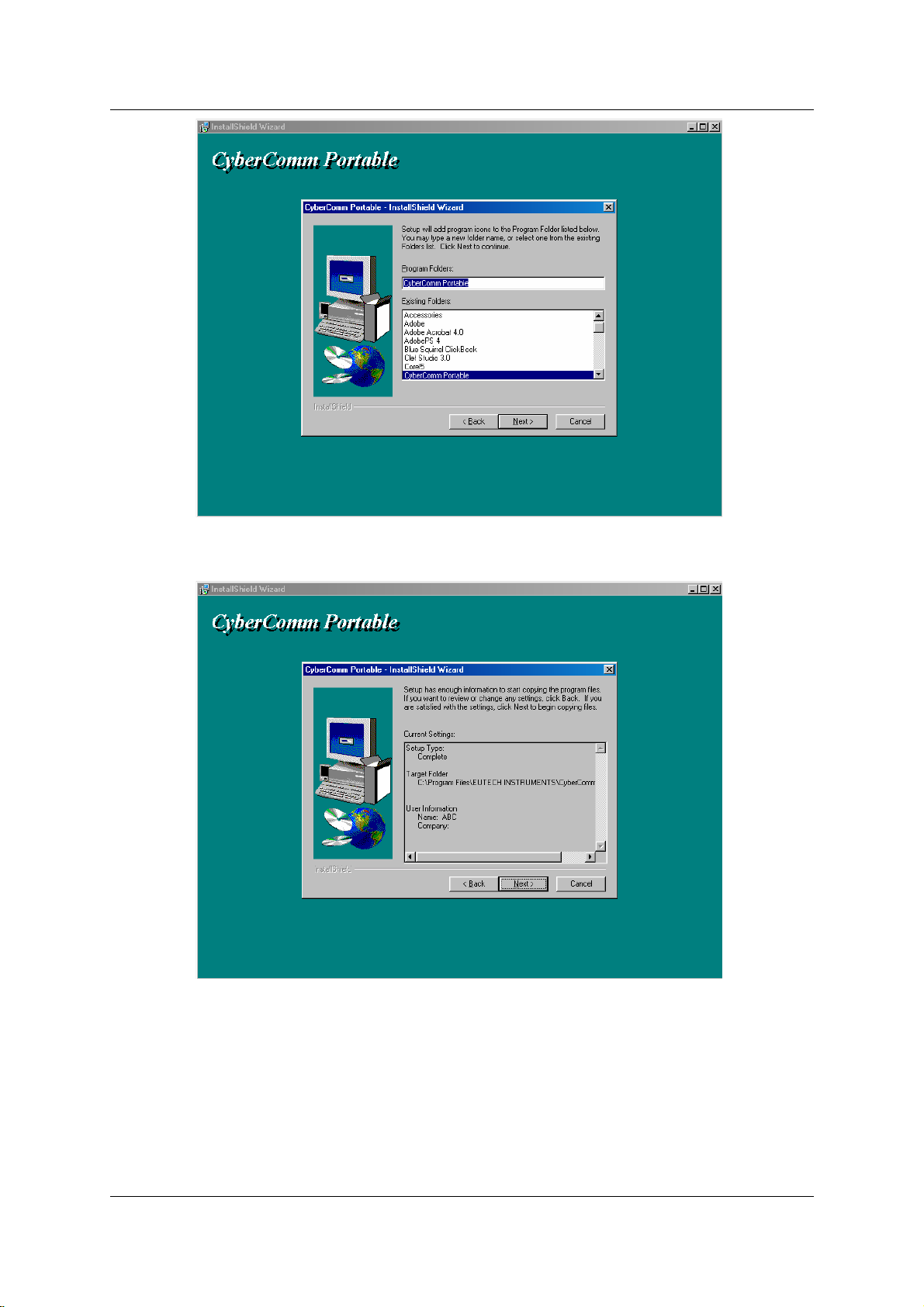

5 Press the CAL/MEAS key to return to measurement

mode.

NOTE: Meter default is set for Ready function on, and auto

HOLD function off.

p 1.1

MI

SETUP

READY

OFF

MR

p 1.1

SETUP

READY

HOLD

ON

MI

MR

p 1.1

Figure 31: P1.1-

Configure READY ON,

OFF or HOLD

38

Instruction Manual CON 11/110

8.2.2 P1.2: Selection of °C or °F

Available in CON 110 only

You can select between °C and °F units for temperature

readings. Meter default is °C.

From measurement mode

1. Press SETUP key to enter Set Up menu.

2. Press the HOLD/ENTER keys until you view

parameter P1.2.

3. Press the MI/▲ or MR/▼ key to select between °C

and °F.

4. Press the HOLD/ENTER key to confirm selection.

5. Press the CAL/MEAS key to return to measurement

mode.

HOLD

ENTER

SETUP

C

p 1.2

MI

SETUP

°C

MR

F

p 1.2

Figure 32: P1.2-Select

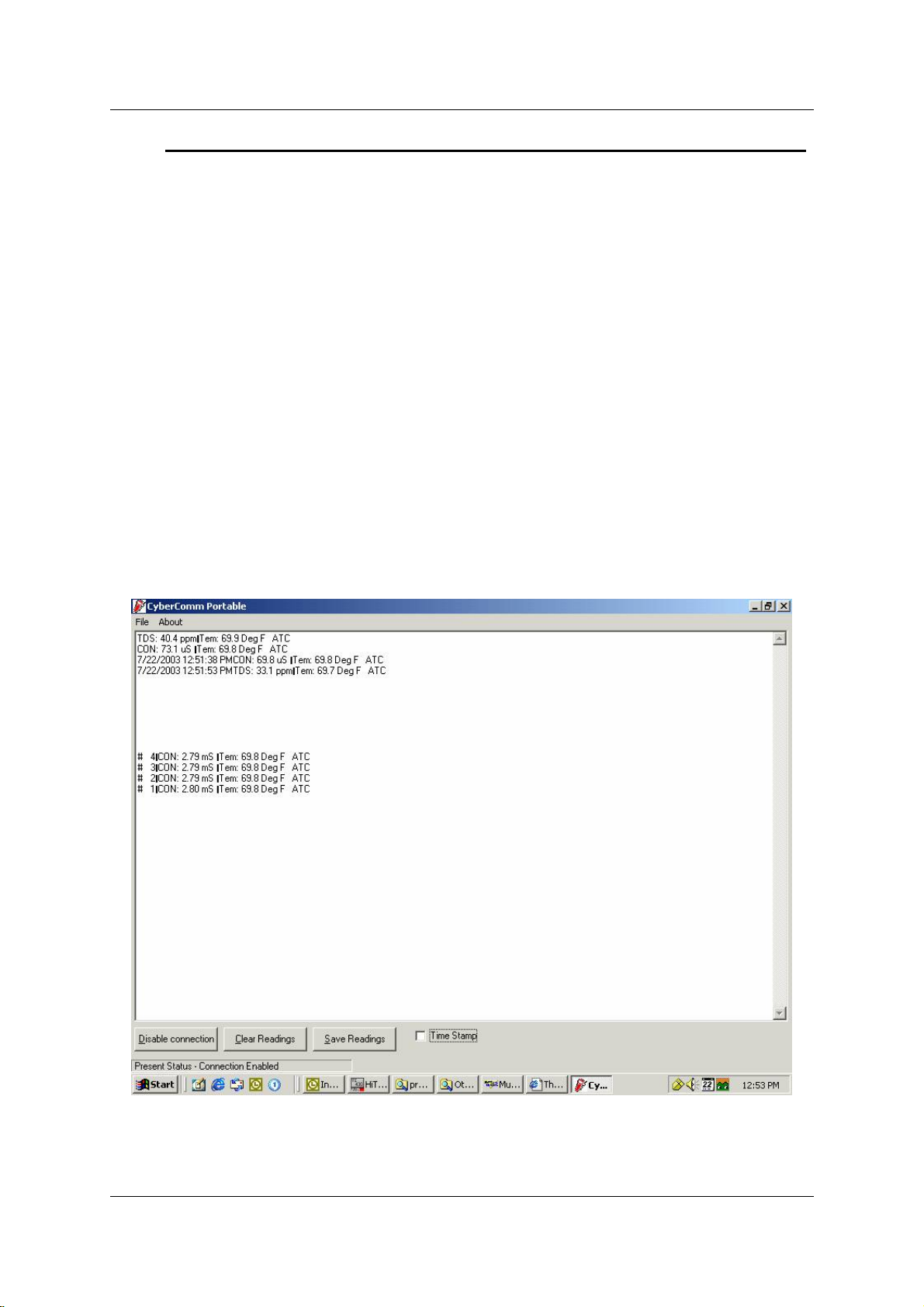

°C or °F

°F

39

Instruction Manual CON 11/110

8.2.3 P1.3: Selection of Automatic or Manual Temperature Compensation

This feature lets you select between Automatic Temperature Compensation (ATC)

and Manual Temperature Compensation (MTC). Meter default is ATC.

From measurement mode

1 Press SETUP key to enter Set Up menu.

2 Press the HOLD/ENTER keys until you view

parameter P1.3.

3 Press the HOLD/ENTER key again. The upper display

shows “ATC” and the lower display shows “YES” or

“NO”.

4 Press MI/▲ or MR/▼ keys to select between

Automatic and Manual Temperature Compensation.

• “YES” activates the Automatic Temperature

Compensation function.

• “NO” activates the Manual Temperature

Compensation function.

5 Press the HOLD/ENTER key to confirm selection and

to return to the subgroup menu.

6 Press the CAL/MEAS key to return to measurement

mode.

SETUP

P 1.3

HOLD

ENTER

SETUP

YES

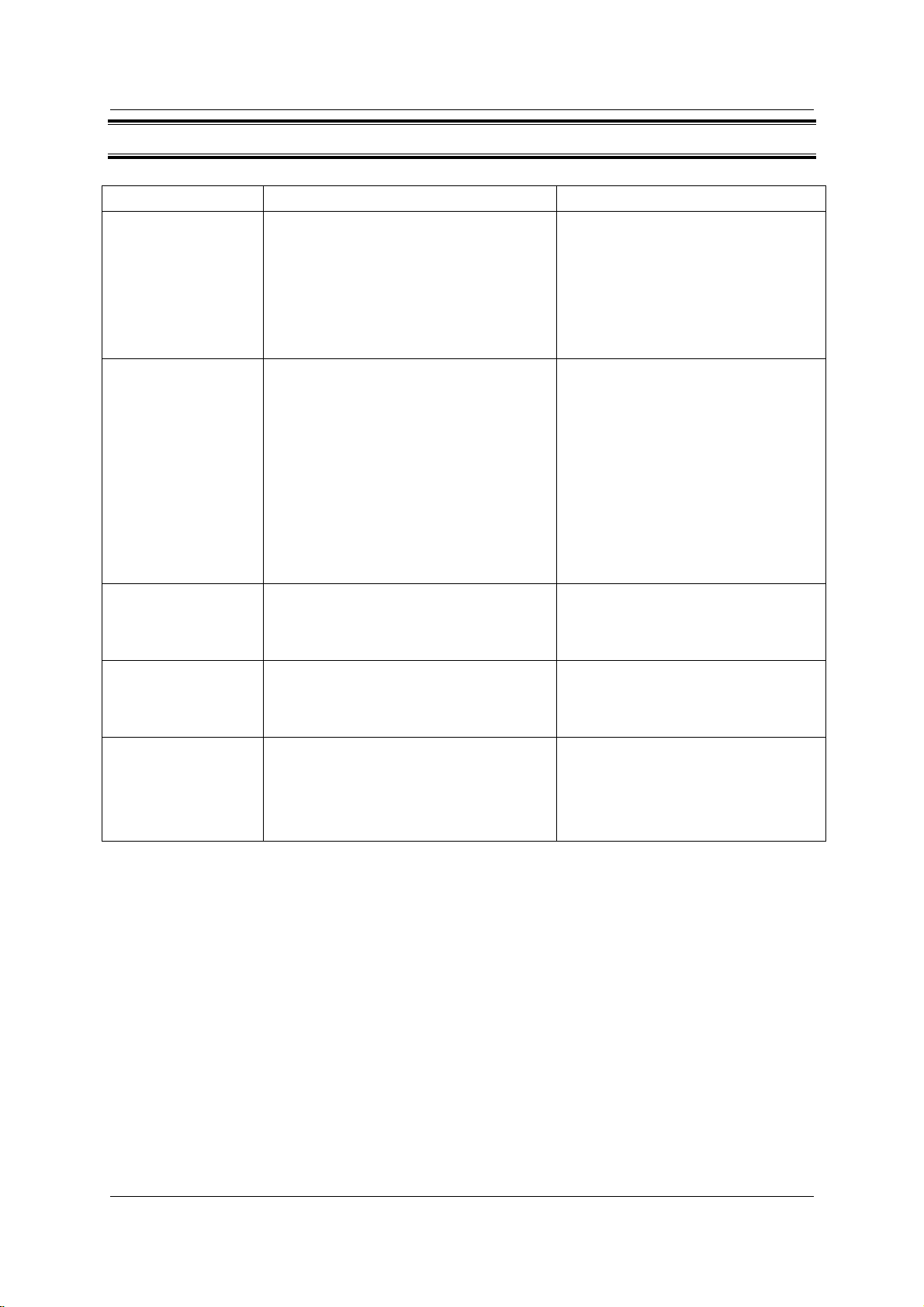

MI

SETUP

Figure 33: P1.3-

Select Automatic or

Manual Temperature

Compensation

MR

°C

ATC

°C

ATC

°C

40

Instruction Manual CON 11/110

8.2.4 P1.4: Selection of TDS Conversion Factor

You can set the TDS conversion factor between 0.40 and

1.00; meter default is 0.50.

SETUP

NOTE: Your meter has to be in the TDS measurement mode

before you can make the selection of the TDS Conversion

Factor in the SETUP menu.

Only from TDS measurement mode

1. Press SETUP key to enter Set Up menu.

2. Press the HOLD/ENTER keys until you view

parameter P1.4.

3. Press the HOLD/ENTER key again. The upper

display shows a value and the lower display shows

“tdS”.

4. Press the MI/▲ or MR/▼ keys to select your

calculated TDS conversion factor.

5. Press the HOLD/ENTER key to confirm selection

and to return to the subgroup menu.

6. Press the CAL/MEAS key to return to measurement

mode.

ppt

ppm

p 1.4

HOLD

ENTER

SETUP

0.50

MI

SETUP

0.75

Figure 34: P1.4 -Select

TDS Conversion

Factor

ppt

ppm

MR

ppt

ppm

41

Instruction Manual CON 11/110

µ

8.3 P2.0: Viewing calibration data

This mode lets you recall the previous calibration data on each of the five measuring

ranges. This is a “view only” mode.

From measurement mode:

1. Press the SETUP key to enter Set Up menu.

2. Press the MI/▲ or MR/▼ key until you view

parameter P2.0.

3. Press the HOLD/ENTER key repeatedly to view the

previous calibration data on each of the five

measuring ranges.

4. Once you have scrolled through all calibration data,

you will automatically return to the subgroup menu.

5. Press CAL/MEAS key to return to the measurement

mode.

NOTES: If there is no previous calibration data at a particular

point, the primary display will show “----“.

SETUP

cal

p 2.0

HOLD

ENTER

SETUP

---

p 2.1

HOLD

ENTER

SETUP

S

84.0

p 2.2

Figure 35: P2.0 –Viewing

previous calibration data

for each measurement

range

42

Instruction Manual CON 11/110

8.4 P3.0 Viewing Electrode Data

Program 3.0 has five “view only” options that let you check the electrode’s

parameters for diagnostic purposes. These options show you the effective cell

constant for each range. The cell constant is adjusted

according to your calibration.

SETUP

From measurement mode

1. Press the SETUP key to enter Set Up menu.

2. Press the MI/▲ or MR/▼ keys until you view

parameter P3.0.

3. Press the HOLD/ENTER key repeatedly to view the

effective cell constant for each range.

4. When you have scrolled through all the electrode

data, you will automatically return to the subgroup

menu.

5. Press the CAL/MEAS key to return to measurement

mode.

NOTES: Cell constants will degrade with time and usage.

You can use this feature to alert you to the need for a new

electrode prior to total failure.

ele

p 3.0

ENTER

SETUP

K=

1.00

p3.1

ENTER

SETUP

1.00

K=

p 3.2

Figure 36: P3.0-Viewing

electrode data for each

measurement range

43

Instruction Manual CON 11/110

8.5 P4.0: Auto Off

In Program P4.0 you can activate the Auto Off option to automatically switch off the

instrument 20 minutes after the last key selection. This feature is useful for

conserving battery power. Under default conditions, the

instrument has this option activated.

SETUP

1. Press the SETUP key to enter Set Up mode.

2. Press the MI/▲ or MR/▼ keys until you view

parameter P4.0.

3. Press the HOLD/ENTER key. The upper display

shows “AtO” and the lower display shows “YES” or

“NO”.

4. Press MI/▲ or MR/▼ keys to select options

• YES – activates the Auto Off function

• NO - deactivates the Auto Off function

5. Press the HOLD/ENTER key to confirm and return

to subgroup menu.

6. Press the CAL/MEAS key to return to measurement

mode.

P 4.0

HOLD

ENTER

SETUP

yes

MR

SETUP

Figure 37: P4.0-

Selection of Auto

Power Off function

O

O

MI

O

NOTE:

For datalogging using interval measurements, it is often desirable to use

an AC adapter and disable the auto-off feature.

44

Instruction Manual CON 11/110

8.6 P5.0: Reset to factory defaults

Program 5.0 reset functions lets you have an option to only reset all the meter’s

calibrations and its data that have been stored or reset all calibrations, its stored

data, memory, and any other setup functions that you might have changed back to

factory default settings. See Factory Default Settings at page 69 and 70.

8.6.1 P5.1: Calibration Reset

This reset function clears all the calibrations and its data that

have been set by you. All other setup parameters that you

have changed are not reset.

From measurement mode

1. Press SETUP key to enter Set Up menu.

2. Press the MI/▲ or MR/▼ keys to until you view

parameter P5.0.

3. Press the HOLD/ENTER key to enter parameter

P5.1 with the upper display showing “CAL”.

4. Press the HOLD/ENTER key again to enter the

calibration reset selection mode.

5. Press the MI/▲ or MR/▼ keys to toggle between NO

and YES.

• NO retains current settings

• YES clears all calibrations and its data.

6. Press the HOLD/ENTER key to confirm selection

and to return to measurement mode. Otherwise

press CAL/MEAS key to return to measurement

mode without resetting the calibration data.

SETUP

ENTER

SETUP

ENTER

SETUP

SETUP

HOLD

HOLD

MI

p 5.0

cal

p 5.1

cal

MR

cal

yes

Figure 38: P5.1-Clear all

calibration and its data

45

Instruction Manual CON 11/110

8.6.2 P5.2: User Reset

This reset function clears all the calibrations, memory and

all other setup parameters that you have changed back to

SETUP

cal

factory defaults condition.

From measurement mode

1. Repeat step 1 to 4 to enter the calibration reset

selection mode.

2. Press the MI/▲ or MR/▼ keys to select NO.

3. Press the HOLD/ENTER key to enter parameter

P5.2. The upper display will show “USr”.

4. Press the HOLD/ENTER key again to enter user

reset selection mode.

5. Press the MI/▲ or MR/▼ keys to toggle between

NO and YES.

• NO retains current settings

• YES resets to factory default settings.

6. Press the HOLD/ENTER key after confirming reset

selection and to return to the measurement mode.

Otherwise press CAL/MEAS key to return to

measurement mode without resetting to factory

default.

NOTE: See page 69 and 70 for Factory Default

Settings.

HOLD

ENTER

SETUP

HOLD

ENTER

SETUP

MR

SETUP

P 5.2

MI

yes

Figure 39: P5.2-Clear

all setups to factory

default

46

Instruction Manual CON 11/110

8.7 P6.0: Memory Clear

Use this program to clear all memory values when you

need to store a new series of values. This is to avoid

confusion between the old values and the new ones.

From measurement mode:

1. Press the SETUP key to enter Set Up menu.

SETUP MEM

p 6.0

2. Press the MI/▲ or MR/▼ keys until you view the

parameter P6.0.

3. Press the HOLD/ENTER key to enter parameter

P6.0.

4. Press the MI/▲ or MR/▼ keys to toggle between

NO and YES.

• NO retains current memory.

• YES clears all memory.

5. Press the HOLD/ENTER key to confirm selection

and return to the subgroup menu.

6. Press CAL/MEAS key to return to measurement

mode.

HOLD

ENTER

SETUP MEM

MI

SETUP MEM

MR

yes

Figure 40: P6.0-Clearance of

all stored memory

47

Instruction Manual CON 11/110

8.8 P7.0: Temperature

8.8.1 P7.1: Setting the temperature coefficient

The temperature coefficient is the amount of change in conductivity per degree of

temperature; it is expressed in percent per °C.. Entering the exact temperature

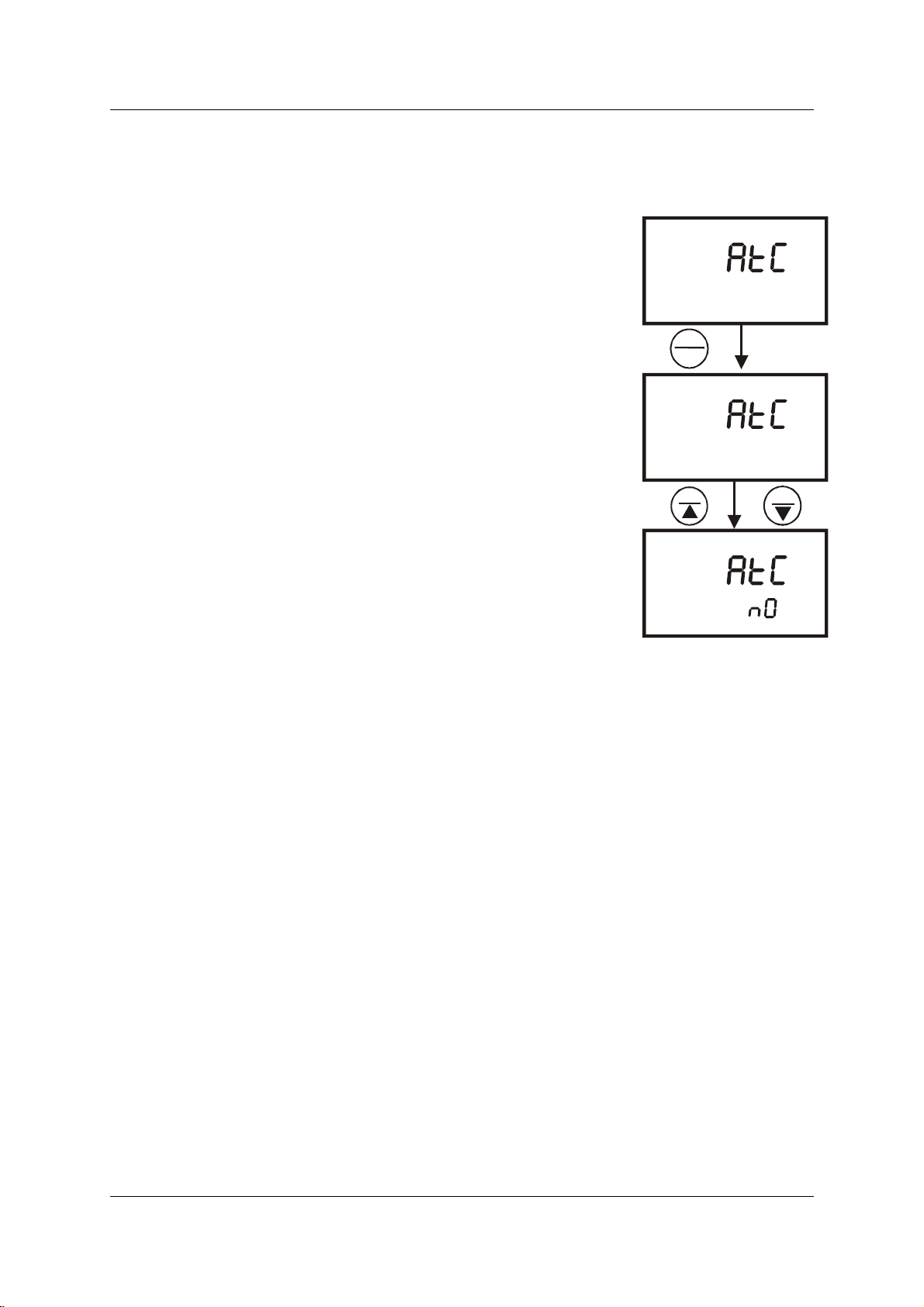

coefficient of your solution lets you accurately compensate