Page 1

AAllpphhaa CCOONN 110000 CC//CCX

v

viittyy

CCoonndduucctti

i

X

CCoonnttrroolllleerr // TTrraannssmmiitttteer

INSTRUCTION MANUAL

MODE

68X103704

6/98

uS/mS

888

o

SETU

C

Technology Made Easy ...

READY

ENTER

RELAY

r

Page 2

Preface

This manual serves to explain the use of the Alpha CON

100 Conductivity Controller/Transmitter. The units

covered are Alpha C and CX Conductivity Controller/

Transmitter.

The instruction manual functions in two ways: first, as a

step by step guide to help you operate and understand

the operation of the unit and second, as a handy

reference guide.

The information presented in this manual is subject to

change as improvements are made, and does not

represent a commitment of Eutech Instruments Pte Ltd.

This instruction manual is written to cover as many

anticipated applications of the Alpha CON 100 C/CX

Conductivity Controller/Transmitter as possible. If there

are doubts in the use, please do not hesitate to contact

the nearest Eutech Instruments’ Authorized Distributor.

Eutech Instruments cannot accept any responsibility for

damage or malfunction of the unit due to improper use

of instrument.

Copyright 1998 Eutech Instruments Pte Ltd.

Version 1.1

Eutech Instruments (S) Pte Ltd

Blk 55, Ayer Rajah Crescent #04-16/24, Singapore 139 949

Tel: (65) 778 6876; Fax: (65) 773 0836

E-MAIL: INFO@EUTECHINST.COM;

WEB PAGE : HTTP://WWW.EUTECHINST.COM

1

Page 3

TABLE OF CONTENTS

1. INTRODUCTION 1

2. GETTING ACQUAINTED 3

2.1 Front Panel 3

2.2 The Back Panel 4

2.3 Selecting Conductivi ty Measurement Range 4

2.4 Wiring 5

3. OPERATING THE CONTROLLER 6

The Main Display 6

4. SETTING UP THE CONTROLLER 7

4.1 Setting and Changing the Password 7

4.2 Setting the Controller Range (S oftware) 9

5. CALIBRATING THE CONTROLLER 10

5.1 The Lower Level Menus 10

5.2 Calibrating for Conductivity Measurement 10

5.3 Calibrating the Controller for Temperature

Measurement 12

5.4 Setting the Alarm Feature 14

5.5 Setting Temperature Coef f i cient 18

6. SETTING TO FACTORY DEFAULT 19

7. USING THE CONTROLLER CURRENT LOOP

FOR DATALOGGING (FOR TRANSMITTER

MODEL ONLY) 20

8. ADDITIONAL INFORMATION 21

Appendix 1 23

Appendix 2 24

Technical Specifications 25

Page 4

1. INTRODUCTION

The alpha CON 100 series Conductivit y Controller/Transmitter

is an addition to the line of process controllers from Eutech

Instruments. Incorporated with the ASIC (Application Specific

Integrated Circuit) microprocessor technology, this panelmounted on-line controller provides m any user-friendl y features

desirable in conductivit y Cont rol l e rs.

This versatile conductivity control ler can be used for m easuring

and controlling the Conductivity of a wide range of solutions in

process streams.

Conductivity Ranges :

Range Resolution Cell Constant

0 - 99.9 uS

0 - 999 uS

0 - 999 uS

0 - 9.99 mS

0 - 99.9 mS

0 - 200 mS

0 - 200 mS

0.1 uS

1 uS

1 uS

0.01 mS

0.1 mS

1 mS

1 mS

0.1

0.1

1.0

1.0

1.0

1.0

10.0

1

Page 5

Some of the features of this Controller are :

• Automatic temperature compensation (with PT 100)

• Manual temperature compensation setting without the

temperature probe

• Adjustable temperature coefficient from 0. 0 to 10.0%

• Push button calibration with cell correction function

• High and Low alarm triggering relays

• User-defined Password feature to prevent unauthorized

entry to change the calibration data, hysteresis function,

high and low setpoints information

• Alarm and operational message annunciators

• Hysteresis function t o prevent chattering of relays around

the setpoint

• High-end transmitter model with 4-20 mA current output

for datalogging purposes

• Built-in memory backup to ensure that calibration and

other information will not be erased if power supply fails

• Switchable mains voltages of 110 VAC or 220 VAC via

user selectable internal ju mper

2

Page 6

2. Getting Acquainted

C

R

2.1 Front Panel

The front panel consists of a 3 digit LED display together with 5

LED annunciators. There are also 4 k eys as shown below.

MODE

888

ENTE

o

uS /mS

The keys available are the ▲ (UP/INCREMENT), ▼

(DOWN/DECREMENT), MODE and ENTER keys.

The annunciators are µS/mS, °C, SETUP, READY, and

RELAY. The µS/mS annunciator lights up in Conductivity

measurement mode. The READY annunciator lights up when

the Conductivity stabilizes. RELAY lights up when any of the HI

SET or LO SET relays is activated.

The MODE key allows you to select between Conductivity

display, the temperat ure display or the SETUP menu display.

While in one of the SETUP menus, it also functions as an

ESCAPE key. For example, while sett ing the Hi SET point , you

can press MODE key to return to the measurem ent mode.

You can confirm changes or enter into further levels of the

lower menu by pressing the ENTER key. The ▲

(UP/INCREMENT) and ▼ (DOWN/DECREMENT) keys allow

you to change information or t o select between different menus.

Holding down the key increases the scrolling speed, i.e.

changeover of 1st digit (ones) t o 2nd (tens) and then 3rd digit

(hundreds).

SETUP

R E ADY REL AY

3

Page 7

2.2 The Back Panel

The back panel consists of t wo connectors . The f irs t one is a 4way screw terminal and the second is a 12-way screw term inal.

Refer to the label on top of the unit for diagram.

The connection for the 4-way screw termi nals are (from the left

to right):

1. PT 100 connection

2. PT 100 connection

3. Conductivity input (Inner core)

4. Conductivity input (Outer shield)

The connections for the 12-way screw term inals are (from left

to right),

5. High Set Relay deactivat ed position

6. High Set Relay center pole

7. High Set Relay activat ed position

8. Low Set Relay deactivated posit i o n

9. Low Set Relay center pole

10. Low Set Relay activated posit i o n

11. 4-20 mA - ve connection (for transmitter m odel s only)

12. 4-20 mA + ve connection (for transmitter model s only)

13. Protective earth

14. Protective earth

15. Neutral

16. Live

4

Page 8

2.3 Selecting Conductivity Measurement Range

You can set the appropriate conductivity measurement range

from the front panel. See S ection 4.2 for details on Setting the

Controller Range (Software). Note that for “mA” the LED

display shows “mA”.

2.4 Wiring

Connect the power supply to the GND (EARTH) - 13 or 14,

NEUTRAL - 15 and LIVE - 16 screw terminals. Make sure that

the power supply jumper setting matches the mains voltage

(110 VAC or 220 VAC). See Appendix 2 for the jum per setting

for the voltage selecti on.

Connect the Conductivity electrode to the 4-way sc rew terminal

at the back panel and the PT 100 tem perature probe to the PT

100 connections.

Power on the controller and the display automatically s hows the

Conductivity reading. The uS/m S annunciator lights up. Once

the reading is stable, the READY annunciator lights up.

However, if the PT 100 temperature probe is not connected,

automatic temperature compensation does not function. You

can set the temperature at a selected value. The tem perature is

set to factory default at 25.0

NOTE : Eutech Instruments will not be responsible f or incorrect

application of the controller using improper voltage

sources or wrong jumper settings.

o

C.

5

Page 9

3. Operating the Controller

R

o

R

R

The Main Display

Press MODE key to switch to

SETUP

MODE

three main displays - the

ENTE

Conductivity display, the

temperature display and “SEt”

display.

MODE

Press MODE key once to get into

ENTE

the temperature measurement.

The °C annunciat or lights up when

you are measuring temperature.

The display shows current

measured temperature (with ATC)

MODE

or the temperature that was set in

ENTE

MTC mode. Press MODE key

again and the display toggles to

the “SEt” for SETUP menu.

7.4

uS/mS

24.0

C

SEt

Press ENTER key to go into the lower-level setup m enus while

the display shows "SEt". These lower-level menus allow

calibration of Conductivit y, Temperature and other parameters

including set password, Hi or Lo Setpoints, Hi and Lo

Hysteresis values and temperature coefficient.

6

Page 10

4. Setting Up the Controller

R

R

R

R

R

4.1 Setting and Changing the Password

4.1.1 Setting New Password

To set a password, press MODE key

until the “SEt” is displayed.

1. Press ENTER key and the

CAL

display shows "CAL” and

“Con” alt ernately. Press ▲ key

once and the display shows

“Set” “id”.

2. Press ENTER to enter your

desired password. Follow the

Con

steps below (e.g. using a

password “123”).

3. Initially, the display shows "000"

with the first digit blinking.

4. Use ▲ (UP/INCREMENT) key to

SEt

SETUP

enter “1” on the 1st digit of the

password. Press ENTER once

and the second digit will blink.

Similarly, enter the second digit

of the password “2” and press

ENTER key again. Repeat with

SETUP

the third digit accordingl y.

5. Press ENTER key and the

display shows “CAL” and ”COn”

alternately. Use ▲ or ▼ key to

get into the “SEt” and “id” menu,

123

press ENTER and set your

desired password by following

the above steps.

6. Once com pleted, press ENTER to conf irm and then press

MODE key to return to the Conductivity display.

SETUP

SETUP

SETUP

id

MODE

ENTE

MODE

ENTE

MODE

ENTE

MODE

ENTE

MODE

ENTE

7

Page 11

To calibrate the controller at any time, you may have to enter

the password that you set, in order to access the c alibration

mode. Once you have entered the password correctly, the

display shows "CAL COn” indicating that you are in one of the

lower-level SETUP menus.

If you enter the wrong password, the display revert s bac k t o t he

Conductivity display. Alternatively, if you prefer no password

protection, set the pass word to “000”, "CAL COn" immediately

displays after you press ENTER key while you are in the "SEt"

menu.

NOTE : The user set password is a prot ection c ode. Thus, it i s

very important to keep this password strictly confidential to

authorized personnel. You are advised to remember the

password that you have set, in order to protect the controller

settings and prevent any unauthorized tampering to the system!

IMPORTANT : In case the password set is forgotten, use

the master password “555”.

4.1.2 Changing the Password

Enter the Set id menu with already set password or “555”.

Change a new password as per steps mentioned for setting the

password.

8

Page 12

4.2 Setting the Controller Range (Software)

R

R

R

R

R

R

R

At the measurement mode, press

both ▲ and ▼ keys simultaneously

until the “CLr” display shows. Press ▲

or ▼ key to select the appropriate

Conductivity measurement range.

Press ENTER key to confirm.

Cell Constant either 0.1 or 1.0 blinks

when the 999 uS range is selected

100

uS/mS

MODE

ENTE

Value scrolls from uS to mS, indicati ng

the measurement range or

100

uS/mS

MODE

ENTE

uS/mS

uS/mS

uS/mS

uS/mS

uS/mS

nnS

CLr

999

1.0

uS

MODE

ENTE

MODE

ENTE

MODE

ENTE

MODE

ENTE

MODE

ENTE

9

Page 13

5. Calibrating the Controller

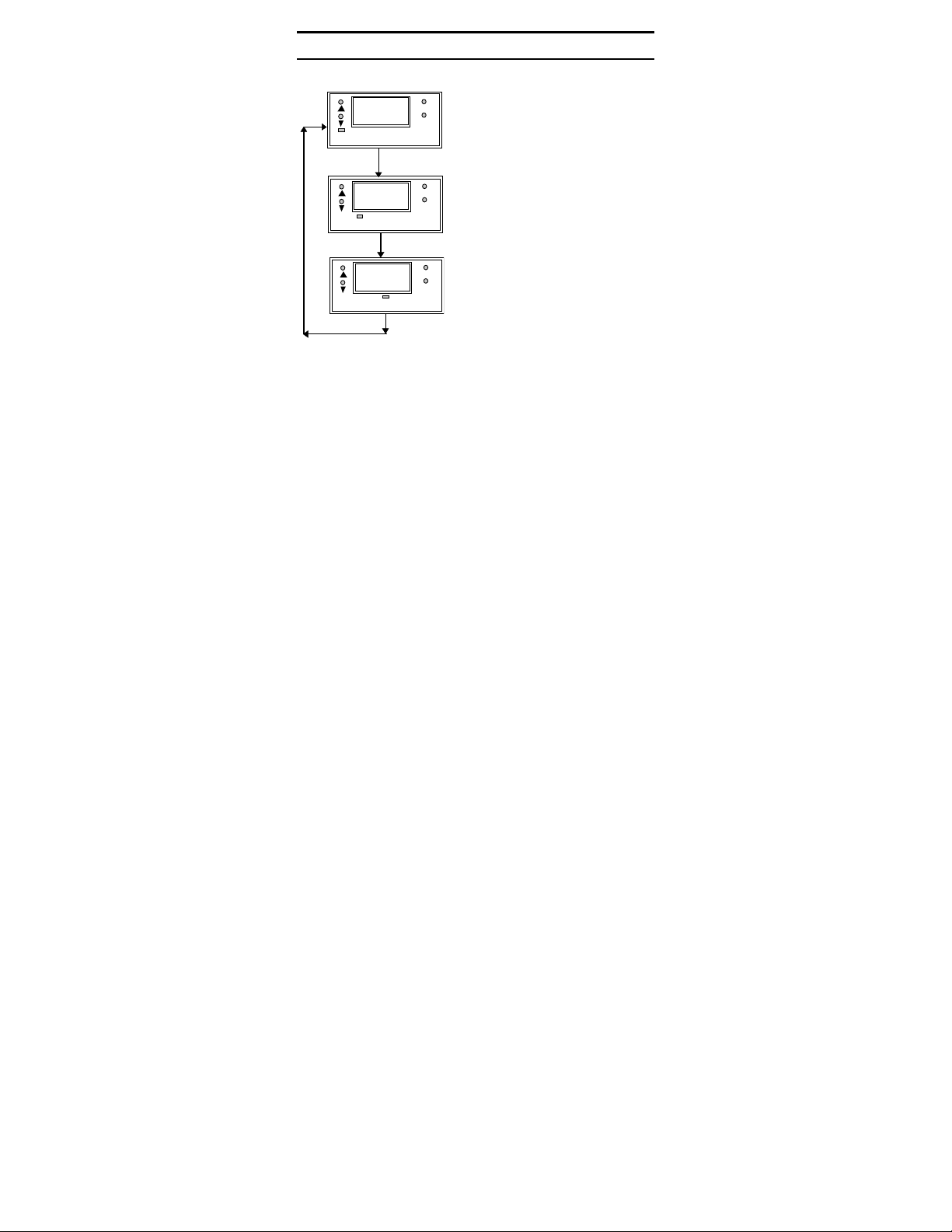

5.1 The Lower Level Menus

The "CAL COn" display is the fi rst menu seen upon entering

the lower-level menus. Press ▲ or ▼ key to display the various

menus as shown in the figure below. Pres s ENTER key to go

to the lower level menus.

START

CAL COn

CAL oC

Hi

SEt

Set id

Hys

Hi

Lo

SEt

SEt tC

Hys

Lo

5.2 Calibrating for Conductivity Measurement

5.2.1 The CAL COn menu

1. Enter this menu by pressing the MODE key twice to the

“SEt” display from the measurement mode.

2. Press ENTER key. If the pas sword has been set earlier,

key in the password using the m et hod desc ribed in sec ti on

4.1. Press ENTER once to confirm. After you set the

correct password, you can see the “CAL” and “COn”

display blink alternat el y.

3. Press ENTER key to enter the Conductivity calibration

mode. Dip both the Conductivity electrode and

temperature probe in the standard solution

4. NOTE: The Conductivity standard solution should

have a conductivity value between 40% to 100% of its

full scale range selected

10

Page 14

5. When “CAL COn” displays, press ENTER key to vi ew the

R

R

R

R

R

R

default cell constant at 100%.

Press ENTER key again to show

the measured conducti vity value.

Use ▲ and ▼ keys to scroll to

the standard’s Conductivi ty value

o

C.

at 25

6. Press ENTER key to calibrate

the Conductivity value shown.

Display will show the new cell

constant being displayed. This

CAL

COn

MODE

ENTE

SETUP

MODE

ENTE

SETUP

value will be between 70% to

130%. Otherwise an error

message “CAL“ and “Err“

alternatively blinks to indicate

out of calibration range.

7. Press ENTER key to complete

CEL

MODE

ENTE

SETUP

the calibration, and you will

return to “CAL” and “COn”

menu.

8. Press MODE key and it brings

you to the Measure mode.

100

MODE

ENTE

SETUP

NOTE : Gently stir the elect rode in

a container filled with calibrating

standard, and ENSURE that no

bubble is trapped during the

calibration process to avoid

erroneous reading.

CEL

MODE

ENTE

SETUP

IMPORTANT : The correct

Temperature Coefficient should be

selected prior to Conductivity

calibration. (Refer to Sec tion 5.5 for

Setting Temperature Coeff i cient).

99

SETUP

MODE

ENTE

11

Page 15

5.3 Calibrating the Controller for Temperature

R

R

R

R

A

R

R

Measurement

5.3.1 The CAL °°°°C menu

1. Enter this menu by pressing

MODE

SEt

SETUP

CAL

SETUP

o

C

SETUP

ON and ATC OFF.

tc

SETUP

On

SETUP

23.5

SETUP

MODE key twice to the “SEt” display

ENTE

if you are in measurement mode.

2. Press ENTER key. If the

password has been set earlier, key i n

the password using the method

described in section 4.1. Press

MODE

ENTER once to confirm. After you

ENTE

set the correct password, you see

the “CAL” and “COn” display blinks

alternatively. Press ▼ key once, the

display shows “CAL” “

MODE

1. Press ENTER and the display

ENTE

alternatively shows “Atc” and “On”

or “Atc” and “OFF”. Use ▲ and ▼

keys to choose between both ATC

ATC O N : If a PT 100 i s connected,

MODE

use ▲ and ▼ keys to adjust the

ENTE

temperature offset of t he PT 100 by ±

5 °C. Dip the probe into the sample

liquid. Make sure that the display is

set to ATC ON, press ENTER and

the display now shows the actual

MODE

temperature reading (blinking).

ENTE

Use ▲ and ▼ keys to adjust the

reading to its actual tem perature - as

measured by an external

thermometer. Once done, press

MODE

ENTER key and the display will flash

ENTE

“CAL” “Con” alternatively.

o

C” blinking.

12

Page 16

ATC O F F : If a PT 100 i s not used,

R

A

R

R

then the ATC should be set to OFF.

In step 3 above, choose by

pressing ▲ and ▼ keys to select

ATC OFF. Then press ENTER.

The display will now show the

default of 25

o

C or the last set val ue

(blinking). Use ▲ and ▼ keys to set

your desired value. Press ENTER

to confirm and the display shows

“CAL” “Con”.

tc

SETUP

OFF

SETUP

MODE

ENTE

MODE

ENTE

Note : For ATC OFF, you can

adjust the set temperature values

from 0.0 to 99.9

o

C. This value will

be used for its temperature

compensation e.g. Conductivity in

the MTC mode.

25.0

SETUP

MODE

ENTE

13

Page 17

5.4 Setting the Alarm Feature

R

R

R

This menu allows you to change the Hi and Lo Setpoint and

Hysteresis values. S ee Section 8 for hysteresis applications.

IMPORTANT : When SETUP mode is entered, the 4-20 mA

output (only for transmitter model) freezes and the relay deactivates (if it was in an alarm condition).

5.4.1 The Hi SET Menu

SEt

SETUP

Hi

SETUP

900

SETUP

4. Press ENTER key to access the Hi SET menu and the

display shows the last Hi SET value or default (90% of Full

Scale). Use ▲ and ▼ keys to change t he value of the Hi

SET point.

5. Press ENTER to confirm the value of the Hi SET point.

6. Press MODE key to exit to the measurement mode. You

can press MODE key (as an ESCAPE key) to revert to the

measurement value if ENTER is not pressed; the set value

is not stored into memory.

MODE

1. Enter this menu by pressing

ENTE

MODE key twice to the “SEt”

display if you are in measurement

mode.

2. Press ENTER key. If the

password has been set earlier, key

MODE

in the password using the method

ENTE

described in section 4.1. Press

ENTER once to confirm.

3. After you set the correct

password, you see the “CAL” and

“COn” display blinks alternately.

MODE

Press ▼ key twice, the display

ENTE

shows “Hi” “SEt” blinking

alternately.

14

Page 18

5.4.2 The Hi HYS Menu

R

R

R

1. Enter this menu by press ing the

MODE key to the “SEt” display

if you are in the measurement

mode.

2. Press ENTER key. If the

password has been set earlier,

key in the password using the

method described in s ection 4. 1.

Press ENTER once to confirm.

After you set the correct

password, you see the “CAL”

and “COn” display blinks

alternatively. Press ▼ key thrice,

the display shows “Hi” “HYS”

blinking.

3. Press ENTER key to access the

Hi HYS menu and the display

shows the last Hi HYS value or

default (2% of Full Scale). Use

▲ and ▼ keys to change the

value of the Hi HYS point.

4. Press ENTER to confirm the

value of the Hi HYS.

5. Press MODE key to exit to

measurement mode. You can

press MODE key (as an

ESCAPE key) to revert to the

measurement value if ENTER is

not pressed; the set value is not

stored into mem ory.

HYS

SETUP

Hi

SETUP

02

SETUP

MODE

ENTE

MODE

ENTE

MODE

ENTE

NOTE : The

maximum value of

Hysteresis is 4% of its

Full Scale (FS)

selected. The HI HYS

hysteresis is spread

equally on either side

of the Hi SET point.

15

Page 19

5.4.3 The Lo SEt Menu

R

R

R

SEt

SETUP

Lo

SETUP

50

SETUP

MODE

ENTE

MODE

ENTE

MODE

ENTE

NOTE : The Lo SEt

relay activates if the

current Conductivity

reading exceeds Lo

SET point - ½ Lo HYS

value. The Lo SET

value cannot be higher

than the Hi SET value.

1. Enter this menu by pressing

MODE key twice to the “SEt”

display if you are in meas urement

mode.

2. Press ENTER key. If the

password has been set earli er, k ey

in the password usi ng the method

described in section 4.1. Press

ENTER once to confirm.

3. After you set the correct

password, you see the “CAL” and

“COn” display blinks alternately.

Press

▼ key four times, the display

shows “Lo” “SEt” blinking

alternately.

4. Press ENTER key to access

the Lo SET menu and the displ ay

shows the last Lo SET value or

default (5% of Full Sc ale). Use

and ▼ keys to c hange t he value of

the Lo SET point.

5. Press ENTER to confirm the

value of the Lo SET point.

6. Press MODE key to exit to

measurement mode. You can

press MODE key (as an ESCAPE

key) to revert to t he measurement

value if ENTER is not pres s ed; the

set value is not stored into

memory.

▲

16

Page 20

5.4.4 The Lo HYS Menu

R

R

R

1. Enter this menu by pressing

the MODE key to the “SEt”

display if you are in the

measurement mode.

HYS

SETUP

MODE

ENTE

2. Press ENTER key. If the

password has been set

earlier, key in the password

using the method described

in section 4.1.

3. Press ENTER once to

Lo

SETUP

MODE

ENTE

confirm. After you set the

correct password, you see

the “CAL” and “COn”

display blinks alternatively.

Press

▼ key five times, the

display shows “Lo” “HYS”

blinking alternately.

4. Press ENTER key to access

the Lo HYS menu and the

display shows the last Lo

HYS value or default (2% of

Full Scale). Use

▲ and ▼

keys to change the value of

02

NOTE : The maximum

value of Hysteresis is

4% of its Full Scale

(FS) selected. The Lo

HYS hysteresis is

spread equally on either

side of the Lo SET

point.

MODE

ENTE

SETUP

the Lo HYS point.

5. Press ENTER to confirm the value of the Lo HYS.

Press MODE key to exit to the measurement mode.

You can press MODE key (as an ESCAPE key) to

revert to the measurement value if ENTER is not

pressed; the set value is not stored into memory.

IMPORTANT : The Lo SET + ½ Lo HYS should be less than

Hi SET - ½ Hi HYS i.e. Hi SET and Lo SET value (in

consideration of the hysteres is band) can never overlap. Lo

HYS and Hi HYS can be set independent of each other ; thi s

allows non-symmetrical hysteresis option.

17

Page 21

5.5 Setting Temperature Coefficient

R

R

R

5.5.1 Temperature Coefficient

This menu allows you to set the Temperature Coefficient

corresponding to the solution whose Conductivity is being

measured. In most control lers, this i s fixed at 2.10% per

However, for alpha CON 100 C/CX models, it is adjust able

from 0.0 to 10.0% per

o

C (please refer to Appendix 3 for

Temperature Coefficient determination and limits).

1. Enter this menu by pressing

the MODE key to the “SEt”

SEt

SETUP

MODE

display if you are in the

ENTE

measurement mode.

2. Press ENTER key to access

the SETUP menu. Press

twice to enter t he “SEt tc” menu. I f

tc

SETUP

change and keep the Temperature

ENTE

Compensation as the previous

you do not wish to effect any

MODE

value, press MODE key. This will

take you out of this mode and back

to its measurement mode.

MODE

2.10

SETUP

3. Press ENTER and the di splay

ENTE

shows the current value of

Temperature Coefficient (blinking).

4. Use

▲ or ▼ key to change the

value of the Temperature Coeff icient. Pres s ENTER to

confirm the value to be used. Press MODE key to exit

to measurement mode.

o

▲ key

C.

18

Page 22

6. Setting to Factory Default

R

R

R

All the controller settings and user-defined password, except

calibration data will be cleared when you enter into the “Usr”

“Clr” menu.

Press both the ▲ and ▼ keys

simultaneously while you are in any

mode menu. The unit requests for the

password if it was set previously.

CLr

SETUP

MODE

ENTE

Enter the password and press

ENTER. The display will show “CLr”.

Press ENTER to confirm. The display

will blink briefly - the password is

reset to its fact ory defaul t and toggles

to its measurement mode.

Ent

SETUP

MODE

ENTE

The Master Password is “555” and

default user set password is “000”.

The Master Password can be used

even if any other password was set

previously.

SETUP

id

MODE

ENTE

Key the master pass word “555” after entering into the “Ënt”

“id” display, you will see “Usr” and “Clr” display alternately.

Press ENTER to confirm and the display returns to its

measurement m ode.

19

Page 23

7. Using the Controller Current Loop

for Datalogging (for Transmitter

Model Only)

The 4-20 mA Current Loop

A 4-20 mA current loop can be connected if a remote data

logging is required. The current will be proportional to the

Conductivity displayed on the panel display. The 4-20 mA

current loop can drive a load resist ance of no more than 200Ω.

If the calculated Conduc tivit y is less than 0 uS (due t o incorrect

TC and temperature setting), the current will be set to

approximately 0 mA. If Conductivit y exceeds the val ue that can

be measured in the range, current will be set to approximately

21 mA. In this way, the rem ot e data l ogger can det ect when out

of range conditions arise. Please note that the 4-20 mA loop is

not galvanically isolated f rom the source.

20

Page 24

8. Additional Information

A

A

The controller allows you to set High and Low alarms that

switch on or off relays, and ac tivating or deactivating devices

linked to the controller. In cases where the Conduc tivity values

fluctuate close to the high or low setpoints, the relays will

continuously switch on/off very quickly and may cause

problems to the linked devi ces. The hysteres is band allows you

to set an allowable range of fluctuat ions to prevent the relays

from activating and deac tivating too quickly. See bel ow.

It is not possible t o set t he high set poi nt lower than the l ow set

point and vice versa (taking the hysteresis band into

consideration). For example, when the high set point is 8.50

mS and the high hysteresi s band is set at 0.40 mS , then the

low setpoint cannot be set at hi gher than 8.50 - ½ Hi HYS.

NOTE : The shaded area indicates the hys teresis band.

D

Hi

Hys

Cond.

B

C

Hysteresis Band

E

ctual

Hi

Set

Lo

Hys

Hysteresis Band

F

H

Lo

Set

G

21

Page 25

Explanation of the diagram in the previous page

F

A - Reading reaches (Hi SET - ½ HI HYS), the Hi-Set relay

remains inactivat ed.

B - Reading reaches above High Setpoint but below (Hi SET +

½ Hi HYS), Hi-Set relay remains inactivated.

C - Reading reaches between (Hi SET - ½ Hi HY S), the Hi-Set

relay remains inacti vated.

D - Reading reaches above (Hi SET + ½ Hi HYS), and the Hi-

Set relay is activat ed.

E - The Hi-Set relay is inac tivated only when the reading falls

below (Hi SET - ½ Hi HYS).

F - Reading reaches between (Lo SET - ½ Lo HYS), the Lo-

Set relay remains inactivated.

G - Reading reaches below (Lo SET - ½ Lo HYS), the Lo-Set

relay is activated.

H - The Lo-Set relay remains activated unt il the reading goes

above the (Lo SET + ½ Lo HYS)

22

Page 26

Appendix 1

Jumper Positions - Internal to the Controller

JP1 Selects the input volt age between 110 VAC or

Fuse Note that there is a fuse internal to the

220 VAC.

Controller. Before opening the uni t, ENSURE

that the power cable is physically separated

from the mains s upply. Replace the fu se with

the one recommended by the manufacturer.

Front

LED

Display

220VAC

2

Fuse

JP 1

Back

23

Page 27

Appendix 2

(

)

Temperature Coefficient

The Temperature Coefficients (TC) of most solutions vary

between 1.8 to 2.4 % per

when the Conductivity exceeds about 100 uS. Thus, the def ault

value of TC will be set to 2.10 % per

o

C. This is true of most salt solutions

o

C when the Controller is

shipped from the factory. However, if the Temperature

Coefficient is known to be dif ferent from the default, the user

can set this value.

Temperature Coefficient can also be determined by taking 2

uncompensated readings at known temperatures.

Uncompensated readings can be taken by setting TC t o 0.0 %

or setting the temperature to 25

o

C by changing ATC ON to

ATC OFF.

If G1 and G2 are the conductivity measured at two

temperatures T1 and T2, then TC is gi ven by the relation:

% TC = ----------------------------------------

G2 - G1

T2 - 25) - G2(T1-25

G1

* 100

24

Page 28

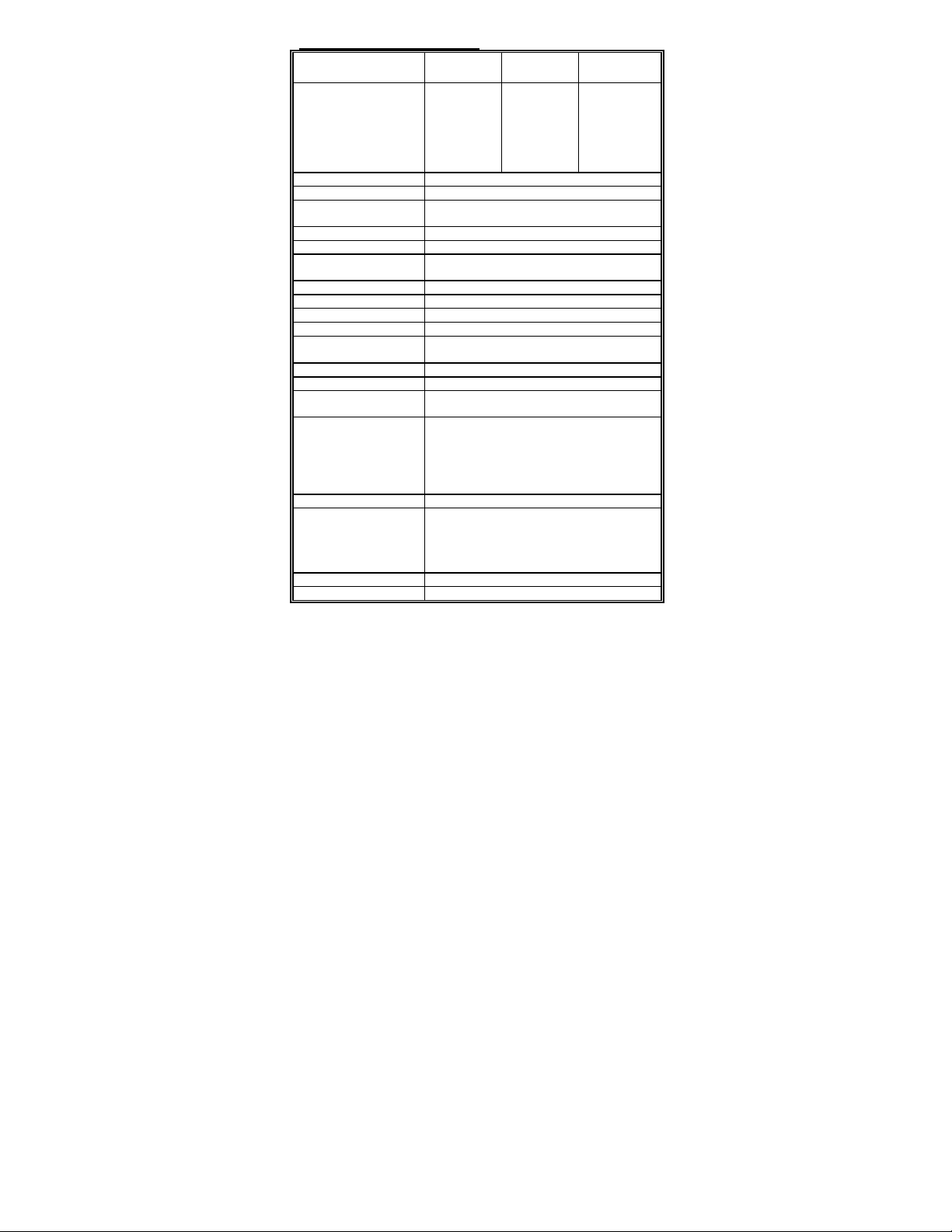

Technical Specifications

Specifications Range Resolution Cell

Conductivity Range 0 - 99.9 uS

0 - 999 uS

0 - 999 uS

0 - 9.99 mS

0 - 99.9 mS

0 - 200 mS

0 - 200 mS

0.1 uS

1 uS

1 uS

0.01 mS

0.1 mS

1 mS

1 mS

Relative Accuracy +/- 1% full scale

Cell Constant 0.1, 1.0 or 10.0

Measurement Range 7 separate ranges (software selectable,

non auto-ranging)

Calibration Push-button (cell constant correction function)

Temperature Coefficient 0.0 to 10.0 % from 5 to 50 oC

Temperature

Automatic / Manual (0 to 100.0 oC)

Compensation

Temperature 0 to 100 oC

Resolution

Relative Accuracy

Sensor

0.1

+/- 0.5

PT 100

o

C

Output 4-20 mA, screw terminals (non-isolated);

Max. load 200 Ω

Display LED, 3 digits

Inputs screw terminals

Recommended Input

Less than 5 meters

Cable Length

Relays

No. Of Relays

Maximum Voltage

Maximum Current

High Hys. Band

Low Hys. Band

2 - High set & Low set SPDT

240 VAC

3A

4% of Full Scale Reading

4% of Full Scale Reading

Power Requirements 110 VAC or 220 VAC (Jumper selectable)

Environmental

Requirements

Operating

Storage

Humidity Limits

10 to 95% RH (non condensing)

0 to 50

-10 to 60

Storage Temp. Range 0 to 50 oC

Dimensions 1/8 DIN size; 96 (L) x 48 (H) mm (Front panel)

Constant

0.1

0.1

1.0

1.0

1.0

1.0

10.0

o

C

o

C

o

C

25

Page 29

NOTES

26

Loading...

Loading...