Page 1

Alpha RES 1000

Controller/Transmitter

Resistivity

Page 2

ROSS and the COIL trade dress are trademarks of Thermo Fisher Scientific Inc. U.S. patent 6,793,787.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, Per pHecTion, pHISA, pHuture,

Pure Water, Sage, Sensing the Future, SensorLink, ROSS, ROSS Ultra, Sure-F low, Titrator PLUS and

TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTO-CAL, AUTO

DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free,

CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal, DuraProbe, E nviro nmental Pro duct

Authority, Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy, KAP,

LabConnect, LogR, Low Maintenance Triode, Minimum Stir Requirement, MSR, NISS, One-Touch, OneTouch Calibration, One-Touch Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS,

pHuture Pentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution,

SAOB, SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator 21, Stat Face,

The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are trademarks

of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

PerpHecT meters are protected by U.S. patent 6,168,707. PerpHecT ROSS elec trodes are protected by

U.S. patent 6,168,707. ORION Series A meters and 9 00A printer are protected by U.S. pat ents 5,198,093 ,

D334,208 and D346,753.ionplus elec trodes and Optimum Results solutions are protec ted by U.S. patent

5,830,338.ROSS Ultra electrodes are protec ted by U.S. patent 6,793,787.ORP standard is protec ted by

U.S. patent 6,350,367. No Cal electrodes are protected by U.S. patent 7,27 6,142.© 2009 Thermo Fisher

Scientific Inc. All rights reserved. All trad emarks are the property of Thermo Fisher Scie ntific Inc. and its

subsidiaries.The specifications, descr iptions, drawings, ordering information and part numbers within this

document are subject to change without notice.This publication supersedes all previous publications on this

subject.

Page 3

Preface

This instruction manual serves to explain the use of the Alpha RES 1000 series Resistivity

controller/transmitter. The manual functions in two wa ys: firstly as a step by step guide to help the user

operate the instrument. Secondly, it serves as a handy reference guide. This instruction manual is writ ten

to cover as many anticipated ap plications of the Alpha RES 1000 Resi stivity controller/transmitter. If you

have doubts in the use of the ins trument, please do not hesita te to contact the nearest Thermo Scientific

Authorised Distributor.

The information presented in this m anual is subject to chan ge without notice as improve ments are made,

and does not represent a commitment on part of Thermo Fisher Scientific.

Thermo Fisher Scientific cannot accept any responsibility for damage or malfunction of the unit due t o

improper use of the instrument.

All rights reserved.

Page 4

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................1

1.1 DESCRIPTION OF UNIT ....................................................................................1

1.2 APPLICATIONS................................................................................................1

2 ASSEMBLY AND INSTALLATION.....................................................................2

2.1 MEASUREMENT AND CONTROL SYSTEM............................................................2

2.2 UNIT DIMENSIONS ..........................................................................................2

3 ELECTRICAL CONNECTION.............................................................................3

3.1 CONNECTION DIAGRAM...................................................................................3

3.2 BACK PANEL..................................................................................................4

4 OVERVIEW.........................................................................................................5

4.1 KEYPAD AND DISPLAY.....................................................................................5

4.1.1 Keypad................................................................................................................... 5

4.1.2 Display ................................................................................................................... 5

4.2 FUNCTION GROUPS ........................................................................................6

4.3 CONTROL CONCEPT .......................................................................................7

5 MEASUREMENT ................................................................................................8

5.1 ISPLAY IN MEASUREMENT MODE ....................................................................8 D

5.1.1 Check electrode performance................................................................................ 8

5.1.2 Checking set points................................................................................................ 8

5.2 ECURITY CODES...........................................................................................8 S

5.2.1 How to enter and change parameters in Calibration mode.................................... 8

5.2.2 How to enter and change parameters in Advanced Setup mode .......................... 9

6 CALIBRATION MODE......................................................................................10

6.1 RESISTIVITY CALIBRATION.............................................................................10

7 ADVANCED SET-UP MODE............................................................................10

7.1 TEMPERATURE COEFFICIENT SUB-FUNCTION...................................................11

7.1.1 Selecting Pure-water or Linear Temperature Coefficient..................................... 11

7.2 EMPERATURE CALIBRATION (ATC MODE ONLY)..............................................12 T

7.2.1 Setting manual temperature compensation ......................................................... 12

7.3 ONTROL RELAY A/CONTROL RELAY B (SP1/SP2) SUB-FUNCTION ..................13 C

7.3.1 Entering the Set point 1 (Set point 2) sub-function .............................................. 13

7.3.2 Selecting the set point values .............................................................................. 13

7.3.3 Choosing High or Low set points ......................................................................... 13

7.3.4 Selecting a hysteresis (dead band) value (0.000 to 0.200 m

Setting an on-delay time lag................................................................................. 14

7.3.5

7.3.6 Setting an off-delay time lag................................................................................. 15

Ω

or 0.00 to 2.00 m

Ω

)1 3

7.4 ONTROLLER (CNTR) SUB-FUNCTION .............................................................15 C

7.4.1 Entering the Controller sub-function..................................................................... 15

7.4.2 Choosing the controller type (limit or proportional) .............................................. 15

7.4.3 Choosing break/make contact relay type............................................................. 16

7.4.4 Selecting proportional range value Xp................................................................. 16

7.4.5 Maximum Pulse Length (tPL) or Maximum Frequency (FPF).............................. 17

Page 5

7.5 MEASUREMENT RANGE SUB-FUNCTION...........................................................17

7.5.1 Entering the Measuring Range sub-function........................................................ 17

7.5.2 Selecting Measuring Range sub-function ............................................................ 17

7.5.3 Measurement Range available in the Controller.................................................. 18

7.5.4 Current Output (rng) sub-function........................................................................ 18

7.5.5 Choosing the output type..................................................................................... 18

7.5.6 Selecting Resistivity value at 0(4)mA................................................................... 18

7.5.7 Selecting Resistivity value at 20mA..................................................................... 19

7.6 ONFIGURATION (CONF) SUB-FUNCTION ........................................................19 C

7.6.1 Entering Configuration sub-function..................................................................... 19

7.6.2 Selecting Filter Function and the Alarm or Wash Function.................................. 19

7.6.3 Selecting the alarm time lag (if the relay 3 is set to Alarm).................................. 20

7.6.4 Selecting steady or pulse contact for the alarm relay (if the relay 3 is set to Alarm)20

7.6.5 Wash Contact (if the relay 3 is set to Wash)........................................................ 20

7.6.6 Input Line Resistance Adjust................................................................................ 21

7.6.7 Reverting to factory default settings..................................................................... 21

7.7 ALIBRATION (CAL) SUB-FUNCTION ...............................................................21 C

7.7.1 Entering Calibration mode from Advanced Set-up mode..................................... 21

8 AUTO/MANUAL MODE....................................................................................22

8.1 AUTO MODE (MODE AFTER SWITCH-ON)...........................................................22

8.2 MANUAL MODE.............................................................................................22

9 TECHNICAL SPECIFICATIONS....................................................................... 23

10 GENERAL INFORMATION...........................................................................24

10.1 PACKAGING .................................................................................................24

10.2 RETURN OF GOODS......................................................................................24

10.3 GUIDELINES FOR RETURNING UNIT FOR REPAIR ..............................................24

11 APPENDICES...............................................................................................25

APPENDIX 1 – JUMPER POSITIONS.............................................................................25

APPENDIX 2 – CONDUCTIVITY / RESISTIVITY OF VARIOUS AQUEOUS SOLUTIONS AT 25OC26

APPENDIX 3 - SIMPLE EXPLANATION ON THE FUNCTION OF HYSTERESIS ........................26

APPENDIX 4 – PURE WATER CURVE...........................................................................27

Page 6

Operating Instructions Alpha RES 1000

1 Introduction

1.1 Description of Unit

Thank you for purchasing the Alpha ¼ DIN Alph a RES 1000 Resistivity process controllers. This unit is

used for measuring the Resistivity of a solution in meg a-ohms. You c an use this unit t o me asure Resis tivity

with limit control. This controller has many user-friendly and safety features which include:

• Menu-driven program that simplifies set-up

• Two ranges of Resistivity measurements-software selectable (Section 7.5.3).

• Built-in memory backup to ensure that calibration data and other information are not erased if

power supply fails

• Automatic temperature compensation (ATC) with Pt100 or Pt 1000

• Manual temperature compensation with independent setting for calibration and process

temperature

• Temperature coefficient variable between 0.00 to 10.00 % per

curve stored in memory. Reference temperature at 25

• 0 to 1999 second time delay adjustment on all relays – minimise false alarms

• Separately adjustable high and low set point hysteresis (dead bands) prevent chattering of relays

around the set points.

• Three control modes: limit, proportional pulse length or proportional pulse frequency.

• Large dual display LCD for easy reading with clear multiple annunciators, alarm status and

operational message annunciators

• Two switching contacts as set-point triggering relays and an alarm output relay

• Separate alarm relay alerts you when set points have exceeded the limits and if the Pt100/Pt10 00

wires are broken or disconnected during the ATC function

• Hold function freezes output current (0/4...20mA) and releases control relays

• LED indicators signal control activities to monitor controller status from a distance

Selectable Filter function stabilises rapid measurement changes.

• Protection against electromagnetic interference - galvan ically isolated 0/4.. 20mA output provides

safety for data logging and control purposes

1.2 Applications

Use this controller in panel mounted enclosures for applications in Pure water and R.O. Systems.

o

o

C. Separate pure water compensation

C.

1

Page 7

Operating Instructions Alpha RES 1000

A

A

p

p

2 Assembly and Installation

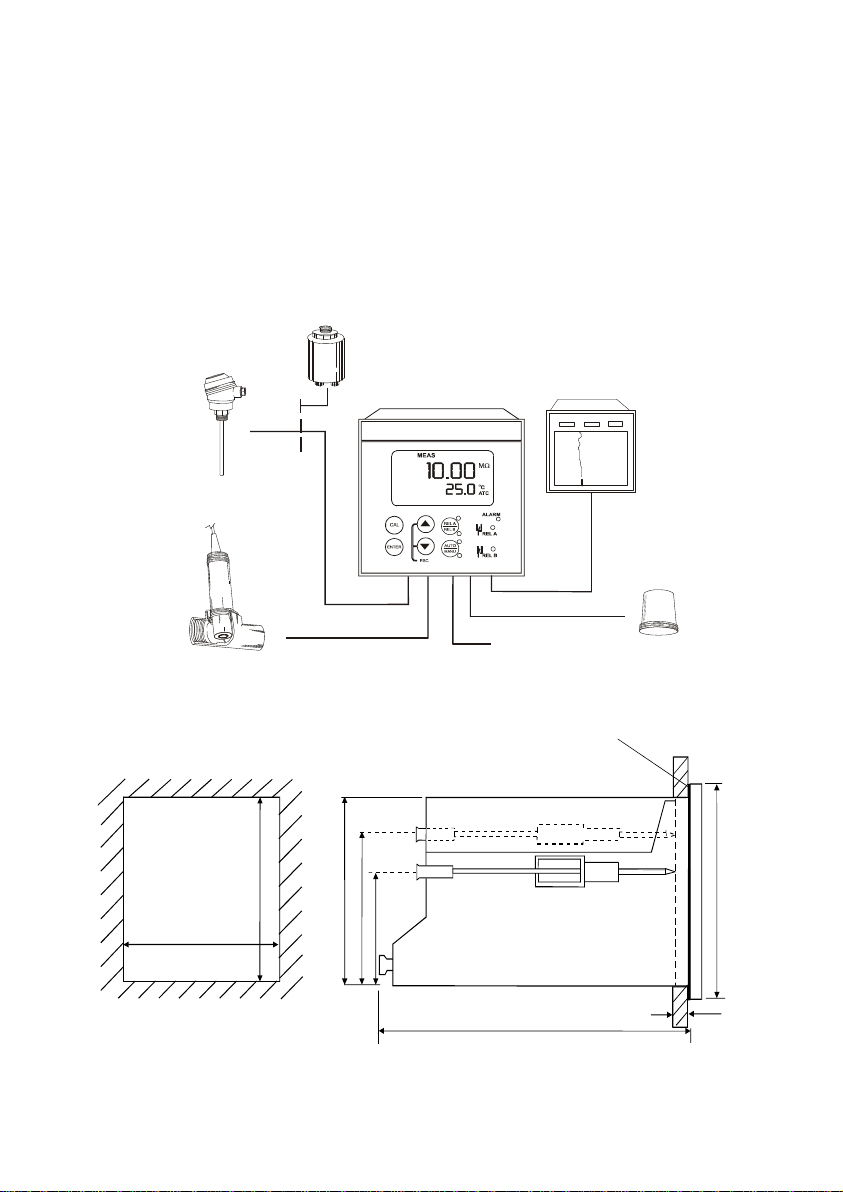

2.1 Measurement and Control System

A typical measurement system consists of:

• an Alpha RES 1000 process controller

• a suitable Resistivity electrode with the appropriate Cell constant a nd integrated temperature sensor Pt

1000 or Pt 100,

• an immersion, flow or process assembly

• a final control element such as pump or valve and

• a chart recorder

Flow Assembly

to Dosing Pumps

Pt100/Pt1000

Temperature Sensor

Process Assembly

with Electrode

2.2 Unit Dimensions

92+ 0.5

92+ 0.5

Mounting Cut-Out

The field-tested control panel housing is 96 x 96 mm; with protection class IP 54 (front).

92

56

Chart Recorder

rollerAlpha RES 1000 Cont

lpha RES 1000

larm / Siren

System

Power Mains

(220/110 VAC)

Flat Gasket (1mm)

(TobeInsertedByCustomer)

Note: The Ta

ed CornersHaveto BeOnTo

96

32

max. 175

max. 45

2

Page 8

Operating Instructions Alpha RES 1000

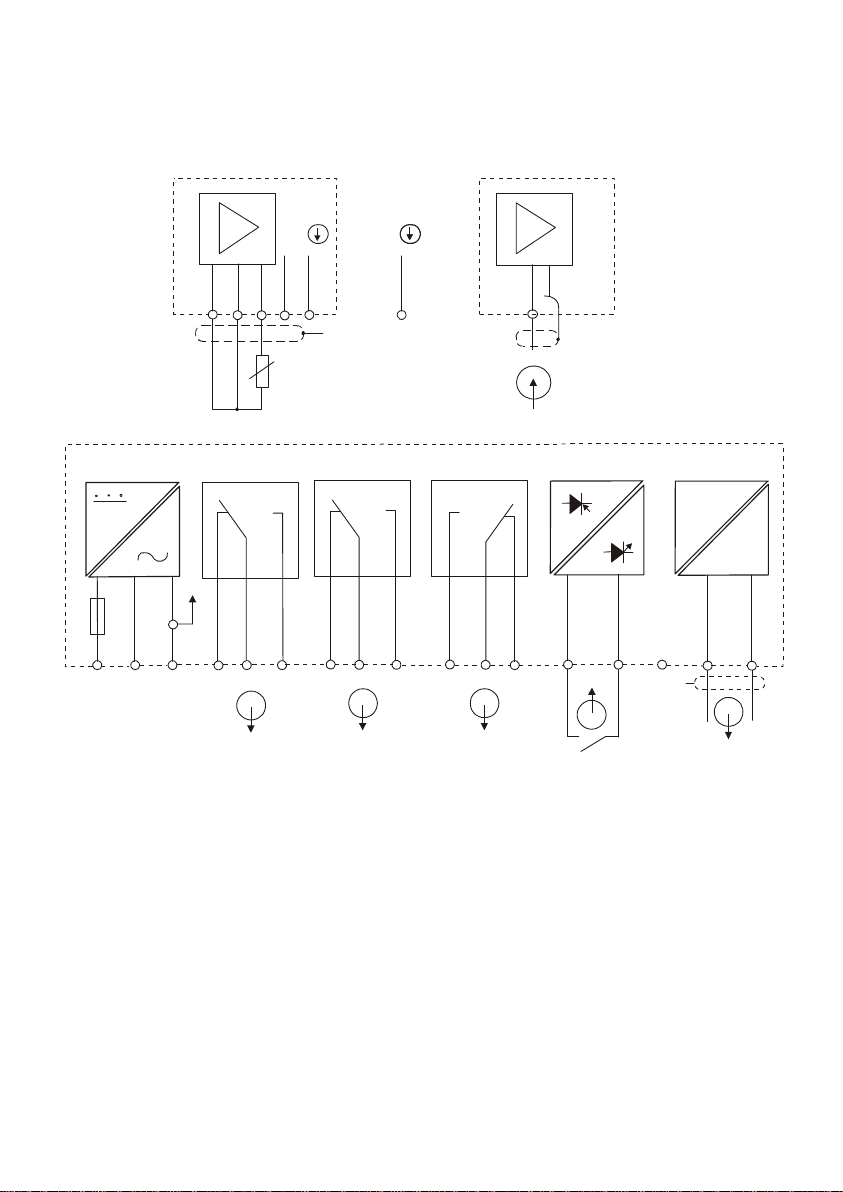

3 Electrical Connection

3.1 Connection Diagram

Res.

S/

V

S/S/

Power Mains

2

1

18 19 20

Pt100/Pt1000

36

PEAC: NL

4

Relay 1

5

21 22

PE/S

Relay 2

78 9

Signal Input Resistivi

Alarm

10

11

12 13

* ) indicated contact positions are for currentless or no er

ty

151715

14

PE/S

ror conditions

Signal Outputput Hold In

Res.

-

mA

+

16

3

Page 9

Operating Instructions Alpha RES 1000

/

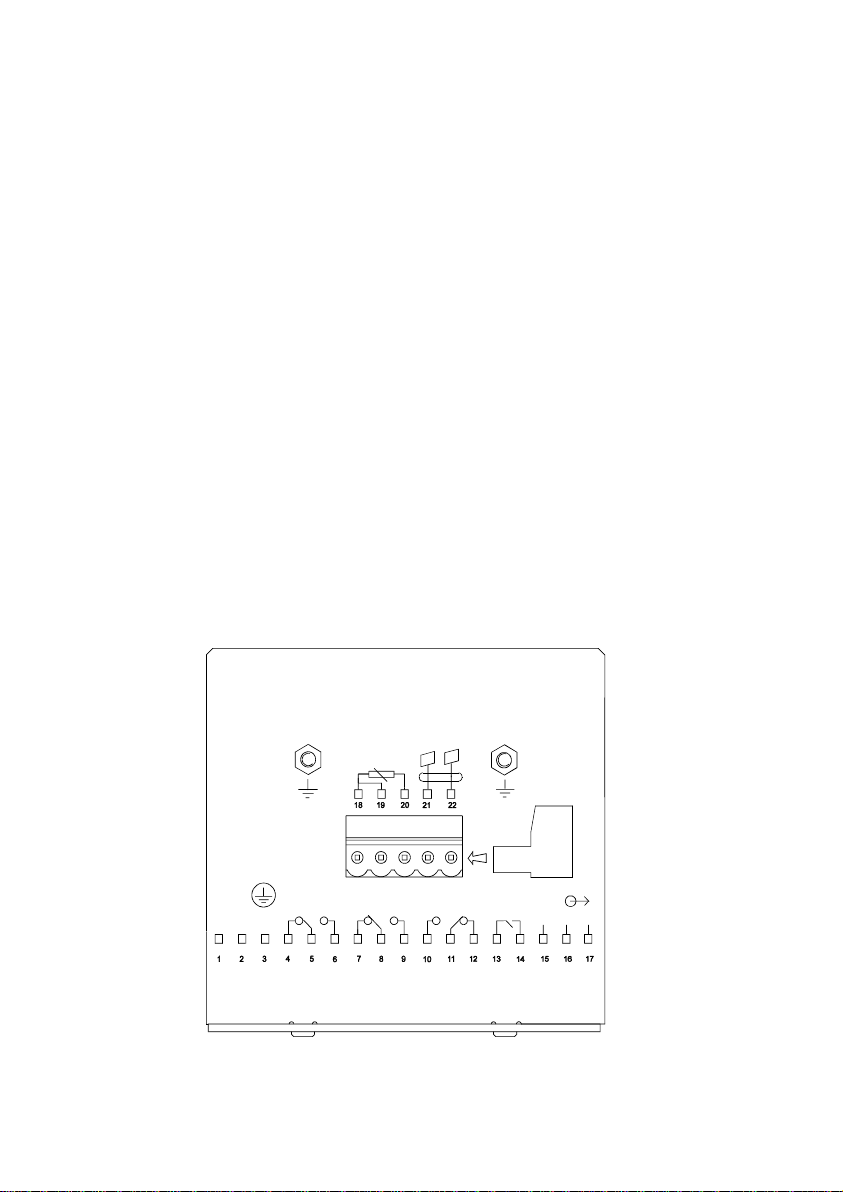

3.2 Back Panel

The back panel consists of two connectors. The first connector is the 17-way PCB edge connector and the

other is the 5-way connector.

Connection for the 17-way screw terminals (from left to right):

1. AC mains live wire 10. Alarm/Wash relay resting position (NO)

2. AC mains neutral wire 11. Alarm/Wash relay common

3. AC mains protective earth wire 12. Alarm/Wash relay working position (NC)

4. Relay 1 relay resting position (NC) 13. Hold function switch terminal 1

5. Relay 1 relay common 14. Hold function switch terminal 2

6. Relay 1 relay working position (NO) 15. No connection

7. Relay 2 relay resting position (NC) 16. 0/4 - 20 mA for -ve connection

8. Relay 2 relay common 17. 0/4 - 20 mA for +ve connection

9. Relay 2 relay working position (NO)

Connections for the 5-way screw terminals:

18. Pt1000/Pt100 lead 1 terminal (red)

19. Pt1000/Pt100 sense lead terminal (short 18 & 19 if using a two-wire system)

20. Pt1000/Pt100 lead 2 terminal (green)

21. Resistivity lead 1 (black)

22. Resistivity lead 2 (white)

*cable wire colours stated above are applicable to EC-CS10 series. For other electrodes, please check

electrode specifications.

IMPORTANT: The

Alarm relay functions

as an “Active Low”

device i.e. it switches

OFF under Alarm

condition. Therefore

the Alarm display

device should be

connected to the ‘NC’

contacts of the relay. If

the relay is configured

as “wash”, then it

+

works in the ‘Active

High’ mode. Therefore

the wash pump has to

be connected across

its “NO” contacts.

FUSE 250VAC

100 mA

(F)

LNPE

RELAY1

Pt100

Pt1000

RELAY2

cell

ALARM

J2

HOLD

-

NC

4

Page 10

Operating Instructions Alpha RES 1000

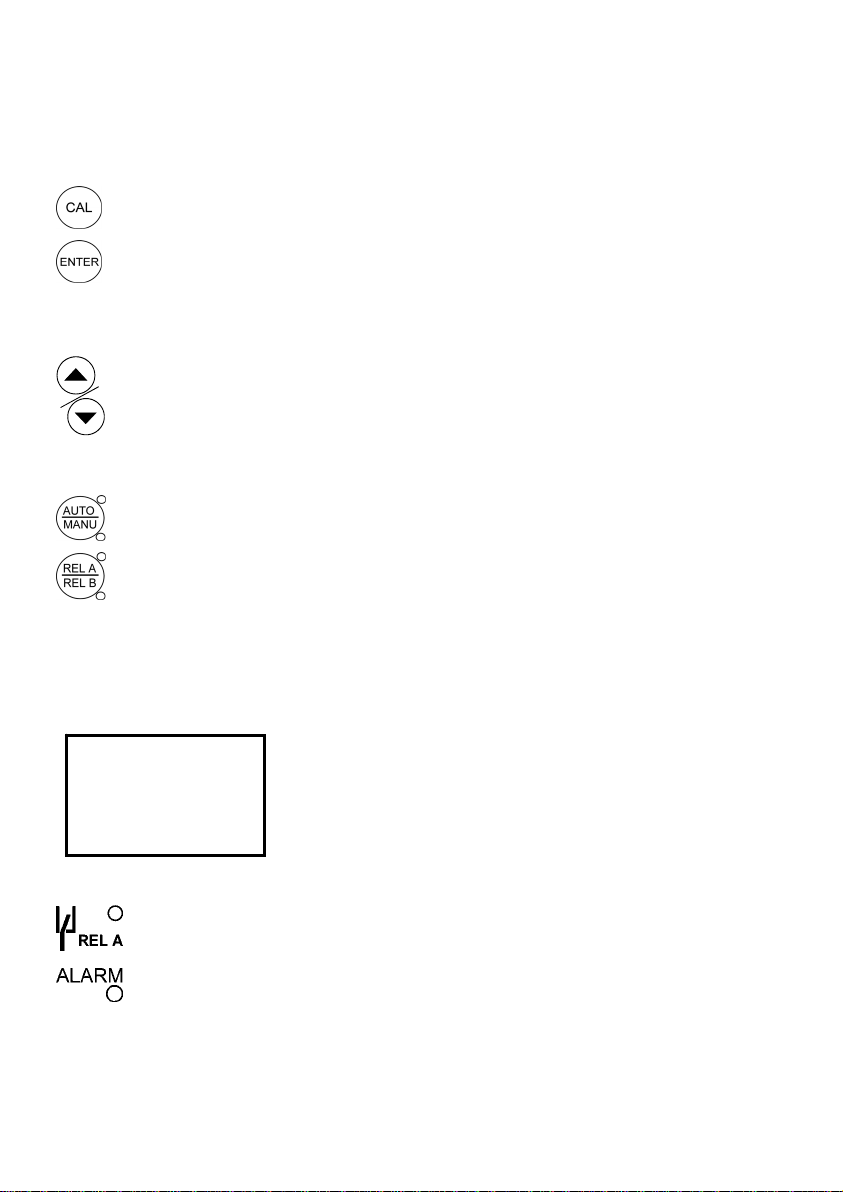

4 Overview

4.1 Keypad and Display

4.1.1 Keypad

•

Perform rapid calibration

•

Allows entry to Set up mode

• Select individual functions within the function group of Set up mode

• Store input data in the Set up mode

• Start calibration in the calibration mode

•

Select various function groups in the Set up mode.

• Set parameters and numerical values in sub functions of Set up mode

If pressed continuously, the setting speed increases

• Control the relays in the MANUAL function

• Return to the Measurement mode when both keys are pressed together

Switch between AUTO and MANUAL relay operation using a code

•

•

Display set-point values for the switch contacts in AUTO operation mode

• Switch between RELAY A and RELAY B in MANUAL relay operation mode

4.1.2 Display

The LCD display features two numerical displays that show status messages and measured val ues for easy,

quick reference. The display provides short-text information for setting parameters and configuration.

HOLD SETUP MEA

READY

-8.8.8.8

8

•

• Alarm display if limit value overshoot or the ATC connection is broken.

S CAL

Display for RELAY A/B. Green LED indicates measured value within limit while

RED LED indicates measured value outside limit.

• HOLD: Relay position and current output are frozen

• SETUP: Set-up mode of function groups

• MEAS: Measurement mode

mΩ

• CAL: Calibration mode of Resistivity

• READY: Comes on after a successful calibration

o

C

• ATC: Comes on in the ATC mode. Disappears in the

Manual temperature Compensation mode. “ ATC” flashes

if the temperature probe is faulty in its ATC mode

• Range No.: Indicates the measurement range selected

5

Page 11

Operating Instructions Alpha RES 1000

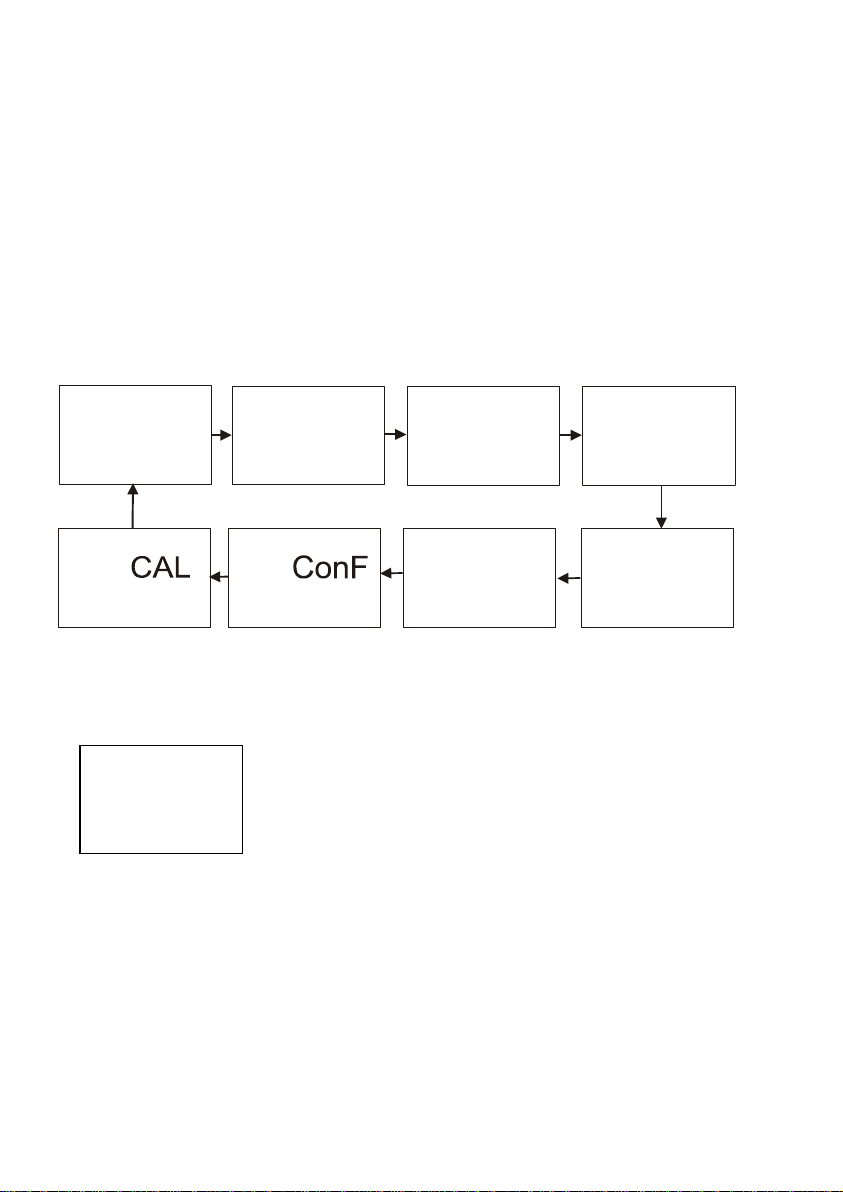

4.2 Function Groups

The main function and sub-function groups are organised in a matrix format for configuration and selection of

parameters. The main function groups are:

1) Temperature Coefficient settings (tC)

2) Temperature Measurement / compensation settings (SEt

3) Control relay 1 configuration (SP1)

4) Control relay 2 configuration (SP2)

5) Control type (Cntr)

6) Current output (rng)

7) Configuration (ConF)

8) Calibration (CAL rES)

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

o

C)

HOLD

SETUP

SETUP

SEt

o

C

HOLD

tc

SETUPHOLD

HOLD SETUP

SP1

rng

HOLD

SP2

SETUP

Cntr

rES

Set-up parameters can be viewed or changed by entering a security code. See Section 5.2 for security code

information.

4.2.1 How to view operating parameters without access to change them:

000

S.Cd

d) Press ENTER key at a particular sub-function to view in detail.

e) Press ENTER key to return to sub-function menu.

f) Press Δ and ∇ keys simultaneously (Escape key) at any time to return to Measurement mode.

Note: To simplify operations, the controller will n ot display parameters t hat are not releva nt to a particular subfunction.

a) Press ENTER key. Display will prompt to enter security code (S.Cd).

Leave security code at “000” (do not enter a security code).

b) Press ENTER key again. This allow s for viewing (not change) any sub-

functions’ settings.

c) Press Δ or ∇ keys to scroll through sub-functions.

6

Page 12

Operating Instructions Alpha RES 1000

4.3 Control Concept

The main function and sub-function groups are organ ised in a m atrix format as shown below. These functions

can be accessed via the front keypad for configuration and selection of parameters.

Controller offers three levels of password pr otection: (1) for viewing all SE TUP Configurati on without the faci lity

to make changes; (2) for direct access to calibration functio n; and (3) for setting or editing specific controller

parameters or functions in SETUP mode.

Note: Passwords are not user-defined and are s et by factory. Please keep passwords confidential to avoid

unauthorised tampering of the system.

7

Page 13

Operating Instructions Alpha RES 1000

5 Measurement

5.1 Display in Measurement mode

When controller is powered on, it automatically enters into the Measurement mo de after large dual LCD briefly

displays all segments.

The upper display shows the measured Resistivity value, while lower display shows temperature value.

Annunciators at right side of the dis play indicate mΩ and

side of the display shows current status of controller, e.g. “HOLD”, “SETUP”, “MEAS”, “CAL”, “READY”, etc.

5.1.1 Check electrode performance

To read current electrode condition without changing them:

1) Press the CAL key followed by the ENTER key without adjusting the security code (leave code at “000” ).

The upper display shows the last cell constant as a percentage with the lower displ ay shows “CEL” . Press

ENTER key and the next upper display shows the last calibration factor.

Note: If security code is changed to a value other than “000”, pressing ENTER key will return to

Measurement mode, without displaying electrode information.

2) Press ENTER key a second time to return to Measurement mode.

5.1.2 Checking set points

To read current set point values without changing them:

Press RELAY Selection (Rel A / Rel B) key. Upper display shows set poi nt for Relay A; l ower display show s

“SP1”.

After two seconds upper display shows set-point value for Relay B; lower display shows “SP2”.

After an additional two seconds, controller returns to Measurement mode.

5.2 Security Codes

Two levels of security protection with separate securi ty codes are provided. First level allows entry into the

Calibration mode: security code = 11; second allows entry into SETUP mode: security code = 22.

Security codes protect controller from unauthorised tampering. Parameters cannot be changed unless the

security code is entered.

5.2.1 How to enter and change parameters in Calibration mode

1) Press CAL key. Upper display shows “000” and lower display

shows “C.Cd” to prompt for Calibration security code.

2) Press Δ or ∇ ke ys to scroll upper display to Calibration security

code “11”.

3) Press ENTER key. Display shows “CAL RES”.

4) Press ENTER again to begin calibration. Refer to Section 6 for full details on calibration.

5) Press Δ and ∇ keys simultaneously (escape) to return to Measurement mode.

NOTE: To view (not change) electrode condition, push ENTER key when the security code reads “000”.

o

C. Similarly annunciators or icons at the top or left

1 1

C.Cd

8

Page 14

Operating Instructions Alpha RES 1000

5.2.1.1 Clearing Calibration security code from display

The calibration security code automatically resets from “11” to “000” after returning to Measurement mode.

5.2.2 How to enter and change parameters in Advanced Setup mode

1) Press ENTER key once. Upper display shows “000” and lower display shows “S.Cd” to prompt for

Advanced Setup security code.

2) Press Δ or ∇ keys to scroll displa y to Setup security code “22” . NOTE: Pressing ENTER key at a value

other than “22” causes the controller to revert to Measurement mode.

3) Press ENTER key.

4) Upper display reads “tc”. You are now in the Advanced Setup mode. See Section 7 for complete

instructions. To return to Measurement mode, press Δ and ∇ keys simultaneously (escape).

NOTE: If to view (not change) set up parameters, push ENTER key when security code reads “000”.

5.2.2.1 Clearing Advanced Setup security code from display

Having entered the security code and r eturned to the Measurement mo de, security code “22” s till appears on

display whenever ENTER key is pressed. To conceal the sec urity code, it must be manually reset. To clear

Advanced Setup security code from display:

1) Press ENTER key in Measurement mode.

2) Set to any security code (not 11 or 22) and complete by pressing ENTER.

NOTE: When you enter the Calibration mode with code “ 11” or Advanced Setup mode with security c ode

“22”, unit automatically enters into HOLD mod e until you return back to Measurement mode. T he HOLD

annunciator is displayed at the upper left of t he display. While on HOLD, current (0/4..20mA) output is

frozen and set point relays are deactivated.

9

Page 15

Operating Instructions Alpha RES 1000

6 Calibration Mode

Calibration mode can be accessed directly from Me asurement mode by pressing CAL key and entering the

Calibration security code; or from the Advanced Setup mode.

6.1 Resistivity Calibration

Calibration is always carried out in the specific ran ge selected. The Resistivity Controller allows a one-point

calibration.

1) Enter Calibration mode. While in Measurement mode, press CAL

HOLD SETUP

1

HOLD CAL

100.0

1

HOLD C

18.20

25.0

1

HOLD CAL

CAL

S rE

CEL

AL

mΩ

oC

ATC

1.01

FCt

1

calibration error, the controller displays “ERR” annunciator. To recalibrate repeat step 3. To exit from

calibration, push both Δ and ∇ keys (escape) to resume to Measurement mode.

5) Press ENTER key. If you entered calibration mode using CAL key, control ler will return to Measureme nt

mode. If you entered calibration mode from Advanc ed Set-up mode, controller will return to sub-function

menu.

Note: When calibrating with manual te mperature compensation, controller a utomatically changes from preset

process temperature to calibration t emperature. After leav ing the Calibratio n mode, contr oller switches back to

process temperature (for setting calibration temperature and process temperature, see section 7.2).

key and scroll to Calibration code “11”. Press ENTER key. The

upper display reads “CAL” and lower display, “rES”.

2) Press the ENTER key. The controller displays its last set Cell

Constant (k) of the cell as a percentage of the theoretical value.

Using the up and down key, the value can be s et to anywhere from

80 to 120%. Press the ENTER key again to carry out calibration.

3) Immerse the Conductivity cell in a suitable standard solution,

%

whose value is within the measurement range selected in the

controller. Agitate the Cell in the sol ution to r emove any trapped a irbubbles. Note: The calibration standard should hav e a value that is

between 20% to 100% of the range sel ected. For example, if the

range in the controller is selected to be 19. 99 mΩ (range 1), then

the calibration standard value should be 4.00 mΩ to 19.99 mΩ.

4) Once the reading has stabilized, use the Δ or ∇ keys to adjust the

measured value to that of the sta ndard solution. Press the ENTER

key to accept the value and the controller displays the revised

condition of the probe The lower display shows the factor “FCt”

while the upper display shows the ratio of ideal to adjusted

calibration value.

Note: The acceptable calibration window is ±40% of the displayed

(default) value. If the displayed is 10.00 mΩ standard, the values to

which it can be adjusted is 6.00 to 14.00 mΩ. If there is a

7 Advanced Set-Up Mode

10

Page 16

Operating Instructions Alpha RES 1000

7.1 Temperature Coefficient sub-function

This sub-function allows you to sele ct correct temperature coeff icient for optimum opera tions. For application s

in pure water or ultra-pure water industries, select “Pur” temperature coefficient option. For all other applications,

select “Lin” temperature coefficient. Controller allows further input of temperature coefficient values,

independently for process and for calibrating solutions. Default is “Pur”.

HOLD SETUP

tc

HOLD SETUP

Lin

tC

HOLD SETUP

2.10

P.tC

%

ATC

HOLD SETUP

2.10

C.tC

%

ATC

HOLD SETUP

Pur

tC

7.1.1 Selecting Pure-water or Linear Temperature Coefficient

1) Enter Advanced set-up mode. Push ENTER key and scroll to

Advanced Set-up security code “22”. Push ENTER key. Controller

displays “tC”. Press ENTER key again. Controller displ ays “Pur” in upper

display and “tC” in lower display. Default is “Pur”.

2) Press Δ or ∇ keys to select between “Pur” and “Lin” temperature

coefficients. If “Lin” tC is to be selected, press ENTER key when

controller displays “Lin”.

3) If “Lin” is selected, upper display shows “2.10%”, while lower display

show “P.tC”. This option allows input of Process Te mperature co efficient,

from 0 to 10%. Default is 2.10%. Use Δ or ∇ keys to enter required

temperature coefficient value.

4) Press ENTER key. Next, enter the calibration solution temperature

coefficient value, “C.tC”, from 0 to 10%. Default is 2.10%.

5) Press Δ or ∇ keys to input desired calibration solution temperature

coefficient.

6) Press ENTER key to accept.

7) Continue with additional Advance setup procedures or return to

Measurement mode by pressing Δ and ∇ keys (escape) simultaneously.

HOLD SETUP

tc

HOLD SETUP

Lin

tC

HOLD SETUP

2.10 %

P.tC ATC

HOLD SETUP

2.10 %

C.tC ATC

11

Page 17

Operating Instructions Alpha RES 1000

7.2 Temperature calibration (ATC mode only)

1) Enter Advanced Set-up mode. Push the ENTER key and scroll to

Advanced Set-up security code “22”. Push the ENTER key again.

2) Press the Δ or ∇ keys to scroll through the sub-menus until the d isplay

shows “Set

3) Press the Δ or ∇ keys to scroll until the upper display shows “ ATC”, and

the lower display shows “on”. Default setting is “ATC on”.

4) Press the ENTER key. In this mode, the ATC probe can be calibrated. The

upper display indicates the current t emperature offset. The current measured

temperature is shown in the lower display.

5) Compare the current measured temperature on the c ontroller display to a

thermometer known to be accurate. Note down the correct temperature value.

6) Press the Δ or ∇ keys to scroll the lower display to match the correct value.

The upper display will now show the offset value. You can offs et temperature

up to ± 10

7) Press the ENTER key to confirm your selection.

8) Continue with additional Advanced Set-up procedures, or return to the

Measurement mode by pressing the Δ and ∇ keys (escape) simultaneously.

7.2.1 Setting manual temperature compensation

HOLD SETUP

HOLD SETUP

HOLD SETUP

6) Press Δ or ∇ keys to adjust calibration temperature value, –9.9 to 125

7) Continue with additional Advanced Set-up procedures, or return to Measurement mode by pressing Δ and

∇ keys (escape) simultaneously.

o

C”. Press the ENTER key.

o

C.

Note: This parameter is unavailable if ATC is selected.

oFF

Atc

For manual temperature compensation, two di fferent temperatur es: proce ss and

calibration can be input independently. Example: setting a calibration

temperature of 25

even if process temperature is different.

1) Enter Advanced set-up mode. Push ENTER key and scroll to Advanced

25.0

P.C

25.0

C.C

2) Pressing the Δ or ∇ keys keys toggle between ATC ‘on’ or ‘off’ (default

3) Press ENTER key. Upper display shows current process temperature and

4) Press Δ or ∇ keys to adj ust process temperature v alue from –9.9 to 125

5) Press ENTER key. Upper display shows current calibration te mperature

o

C lets you calibrate using standard buffer solutions at 25 oC,

Set-up security code “22”. Push ENTER key and Press Δ or ∇ keys to

scroll till display shows “Set oC”. Press ENTER.

setting is ATC on). Select “ATC off”.

lower display shows “P.

o

C.

and lower display shows “C.

o

C” to indicate process temperature.

o

C” to indicate calibration temperature.

HOLD SETUP

HOLD SETUP

HOLD SETUP

o

C. Press ENTER key.

Set

o

C

on

Atc

0.0

25.0

o

C

ATC

12

Page 18

Operating Instructions Alpha RES 1000

7.3 Control Relay A/Control Relay B (SP1/SP2) sub-function

SP1 option sets operating parameters for Relay A; and SP2 for relay B. Since these gro ups have the same

set-up parameters, they are described together.

On.d

HOLD SETUP HOLD SETUP HOLD SETUP HOLD SETUP HOLD SETUP HOLD SETUP

0

0

Of.d

SP 1

1.00

SP 1

Lo

SP 1

0.20

HYS

7.3.1 Entering the Set point 1 (Set point 2) sub-function

1) Enter Advanced Set-up mode. Push the ENTER key and

scroll to Advanced Set-up security code “22”. Push the

ENTER key again.

2) Press the Δ or ∇ keys to scroll until the upper display

shows SP1 (SP2).

7.3.2 Selecting the set point values

This lets you choose the value that will ca use your controller to

activate (Default: SP1 = 1.00 mΩ; SP2 = 19.00 mΩ).

1) Follow directions in 7.3.1 to enter Control Relay mode. If

you are in this mode, skip to step 2.

2) Press the ENTER key. The upper display shows the

current set point value and the lower display shows SP1

(SP2).

3) Press the Δ or ∇ keys to select your value for Set point 1

(Set point 2). Your controller will activate at the v alue you

select.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.3.3, or return to Measurement mode by pressing the Δ and ∇ keys simultaneously (escape).

HOLD SETUP

HOLD SETUP

HOLD SETUP

SP 1

1.00

SP 1

Lo

SP 1

mΩ

7.3.3 Choosing High or Low set points

When ‘Lo’ is selected, the control relay is ac tivated when the value is lower than SP1 (SP2). When ‘Hi’ is

selected, the control relay is activated whe n the value is higher than the set point (SP1/SP2). Using both SP 1

and SP2, you can select lo/lo, lo/hi, hi/lo, or hi/hi set points (Default: SP1 = Lo; SP2 = Hi).

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Press the ENTER key until the upper display shows Lo or Hi (for low or high set point) and the lower

display shows SP1 (SP2).

3) Press Δ or ∇ keys to select low (lo) or high (hi) set point for SP1 (SP2). Press ENTER key.

4) Proceed to 7.3.4, or return Measurement mode by pressing Δ and ∇ keys simultaneously (escape).

7.3.4 Selecting a hysteresis (dead band) value (0.000 to 0.200 mΩ or 0.00 to 2.00 mΩ)

Hysteresis prevents rapid contact switching if the value is fluctuating near the set point. It does this by

overshooting the set point value to a spec ified hysteresis value (default is 0.20 mΩ). You can set the hysteresis

value from 0.000 to 0.200 mΩ or 0.00 to 2.00 mΩ.

13

Page 19

Operating Instructions Alpha RES 1000

Example: Set point 1 (Lo) is at 1.00 mΩ and hysteresis limit value is at 0.20 mΩ. If measured value

undershoots low set point of 1.00 mΩ, relay activ ates, which in turn activates an external device such as a

pump or valve. Actions of the external d evice will caus e the value to r ise above 1.00 mΩ. When the value has

increased to 1.20 mΩ, relay, and hence the pump will switch off.

HOLD SETUP

20

HYS

4) Press ENTER key to confirm your selection.

5) Proceed to 7.3.5, or return to Measurement mode by pressing the Δ and ∇ keys simultaneously (escape).

NOTE: Please refer to Appendix 4 for a graphical representation of the Hysteresis

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Push the ENTER key. The upper display shows the hysteresis (dead

μS

band) value and the lower display shows “HYS”.

3) Press Δ or ∇ keys to enter hyster esis value for Set point 1 (Set point 2).

Controller will activate at the value s elec te d. Note: All settings for SP1 and

SP2 are completely independent of each other.

.

7.3.5 Setting an on-delay time lag

You can set as time delay for each relay, which sto ps the relay from switching on the moment the set point is

exceeded. This controller lets you set a 0 to 1999 seconds time delay before the relay activates.

HOLD SETUP

0

On.d

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.3.6, or return to Measurement mode by pressing the Δ and ∇ keys simultaneously (escape).

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Push the ENTER key. The upper display shows “0” time and the lower

display shows “On.d”.

3) Press the Δ or ∇ keys to enter on-delay time for Set point 1 (Set point

2). The controller will delay activation for the number of seconds (0 to

1999) you select.

14

Page 20

Operating Instructions Alpha RES 1000

7.3.6 Setting an off-delay time lag

You can set as time delay for each relay, which stops the relay from switching off the moment the value

reached the set point and hysteresis. This controller lets you set a 0 to 1999 seconds ti me delay before your

relay deactivates.

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Push the ENTER key. The upper display shows “0” time and the

lower display shows “OF.d”.

3) Press the Δ or ∇ keys to enter on-delay time for Set point 1 (Set

point 2). Controller will delay activation f or the number of seconds

(0 to 1999) selected (Default off delay is 0).

4) Press the ENTER key to confirm your selection.

5) Continue with Advanced Set-up mode procedures, or return to Measurement mode by pre s s ing th e Δ and

∇ keys simultaneously (escape).

HOLD SETUP

0

OF.d

7.4 Controller (Cntr) sub-function

You can set the controller’s parameters in this sub-function.

7.4.1 Entering the Controller sub-function

1) Enter Advanced Set-up mode. Push ENTER key and scroll to Advanced set-up security code “22”.

Push ENTER key.

2) Press Δ or ∇ keys to scroll until upper display shows “Cntr”.

HOLD SETUP

Cntr

L.Ct

tYP

HOLD SETUP

oFF

tYP

HOLD SETUP

PLC

tYP

HOLD SETUP

PFC

tYP

7.4.2 Choosing the controller type (limit or proportional)

This mode lets you choose your con troller type: li mit control, pu lse length pr oportional con trol, pulse freq uency

proportional control, or control off.

- Use limit control with pumps or values for fast response.

- Use pulse frequency proportional control to operate your pumps smoothly.

- Use pulse length proportional control for precise control of proportioning valves.

- Use control off to operate controller as a monitor only or to keep relays from switching.

15

Page 21

Operating Instructions Alpha RES 1000

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. The upper display shows the current contr oller type and the lower disp lay shows

“tYP”.

3) Press the Δ and ∇ keys to select your controller type.

- L.Ct = limit value pickup (on/off control).

- oFF = controller off.

- PLC = pulse length control.

- PFC = pulse frequency control.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.4.3 step 3, or return to Meas urement mode by press ing the Δ and ∇ keys simultaneously

(escape).

7.4.3 Choosing break/make contact relay type

Note: If the controller type “oFF” is set, the parameters listed in 7.4.4 and 7.4.5 are blanked out.

This mode lets you determine the relay-state under Non-Alarm condition – dEEN (de-energised) or EN

(energised).

HOLD SETUP

dEEn

rEL

HOLD SETUP

En

rEL

Note: If the controller type “oFF” or “L.Ct” is set, the parameters listed in 7.4.4 and 7.4.5 are blanked out.

This mode lets you set a band as a percentage of its full scale value. You can select this range from 10 to

200%, and the lower display shows “PrP”.

HOLD SETUP

100

PrP

5) Proceed to 7.4.5 step 3, or return to Measurement mode by pressing t he Δ and ∇ keys simultaneously

(escape).

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the lower dis play shows “ rEL” and th e

upper display shows the current selection (de-energised = dEEN or

energised = EN).

3) Press the Δ or ∇ keys to choose de-energised or energised relay state.

4) Press the ENTER key to confirm your selection.

5) Continue with Advanced Set-up mode procedures, or return to

Measurement mode by pressing the Δ and ∇ keys simultaneously

(escape).

7.4.4 Selecting proportional range value Xp

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the upper display shows the

proportional range (a number from 10 t o 200%), and the lower dis play

shows “PrP”.

3) Press the Δ and ∇ keys to choose the proportional range value Xp.

4) Press the ENTER key to confirm your selection.

16

Page 22

Operating Instructions Alpha RES 1000

g

7.4.5 Maximum Pulse Length (tPL) or Maximum Frequency (FPF)

Note: If the controller type “oFF” or “L.Ct” is set, the parameters listed in 7.4.4 and 7.4.5 are blanked out.

This mode lets you set the maximum pulse length or the maximum frequency at which the relay will operate.

HOLD SETUP

HOLD SETUP

10.0

t.PL

60

F.PF

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the lower display shows “t.PL” or

“F.PF”.

- In PLC (pulse length) mode: The lower display shows “t.PL” to indic ate

pulse length. The upper display shows y our current pulse length. You

can select any value from 0.5 to 20 seconds.

- In PFC (pulse frequency) mode: The lower display shows F.PF to

indicate pulse frequency. The upper display shows your current

maximum pulse rate. You can select any value from 60 to 120 pulses

per minute. When the measured value ex ceeds the Proportional Band

in 7.4.4, the controller will pulse the relay at this rate.

3) Press the Δ and ∇ keys to choose the period duration or maximum

frequency, depending on your mode.

4) Press the ENTER key to confirm your selection and to return to

Advanced Set-up mode, or return to Measur ement mode by pressing the

Δ and ∇ keys simultaneously (escape).

7.5 Measurement Range sub-function

In this sub-function, appropriate range is selected with the appropriate cell constant.

7.5.1 Entering the Measuring Range sub-function

1) Enter Advanced Set-up mode. Push ENTER key and scroll to Advanced Set-up security c ode “22”.

Push ENTER key.

2) Press Δ or ∇ keys to scroll until upper display shows “rng”.

HOLD SETUP

HOLD SETUP

1

rn

20.00

0.01

7.5.2 Selecting Measuring Range sub-function

1) Follow directions in 7.5.1 to enter Controller mode and press ENTER

key.

2) Press Δ or ∇ ke ys to select correct range. (Please refer to 7.5.3 for full

list of measurement ranges). Note the upper display shows maximum

measurement range, while lower display shows Cell constant. Lower le ftcorner of LCD displays the number corresponding to the respective range.

3) Press ENTER key to confirm.

mΩ

4) Proceed to 7.5.4 to set current output or return to Measurement mode by

pressing Δ and ∇ keys simultaneously (escape).

17

Page 23

Operating Instructions Alpha RES 1000

7.5.3 Measurement Range available in the Controller

Range No. Range Resolution Default cell K

1

2

0.000 – 19.99 mΩ 0.01 mΩ

0.00 – 1.999 mΩ 0.001 mΩ

0.01

0.1

7.5.4 Current Output (rng) sub-function

This sub-function lets you set the transmitter current output range of this unit. The difference between the upper

and lower range has to be a minimum of 20% of Full Scale, anywhere on the scale.

1) Follow directions in 7.5.2 to enter Controller mode.

2) Press ENTER key. Please refer to 7.5.5 for current output

sub-function.

7.5.5 Choosing the output type

This parameter lets you choose between 0-20 mA or 4-20 mA

output.

1) Follow directions in 7.5.4 to enter Current Output mode.

2) Scroll with the ENTER key until the upper display shows the

output type (0-20 or 4-20), and the lower display shows “out”.

3) Press the Δ or ∇ keys to select your output type: 0-20 or 4-20

mA.

4) Press ENTER key to confirm your selection.

5) Proceed to 7.5.6, or return to Measurement mode by pressing

the Δ and ∇ keys simultaneously (escape).

1

1

HOLD SETUP

HOLD SETUP

HOLD SETUP

1

4-20

out

0.00

r.4

20.00

r.20

mΩ

mΩ

7.5.6 Selecting Resistivity value at 0(4)mA

This parameter selects the resistivity value at which transmitter output will be 0(4) mA. Follow directions in

7.5.4 to enter Current Output mode.

1) Press ENTER key until upper display shows a resistivity value and lower display shows “r.0(4)”.

2) Press Δ or ∇ keys to select required resistivity value t o be equivalent to 0(4) (Default is 0.00 m

Please note that difference between value at 4mA and 20mA must be at least 20% of F.S. Press ENTER

key.

3) Press ENTER key to return to Advanced Set-up mode, or return to Measurement mode by pressing Δ

and ∇ keys simultaneously (escape).

Ω

).

18

Page 24

Operating Instructions Alpha RES 1000

7.5.7 Selecting Resistivity value at 20mA

This parameter selects the resistivity value at which transmitter output will be 20mA.

4) Follow directions in 7.5.4 to enter Current Output mode.

5) Press the ENTER key until upper display shows a resistivity value and lower display shows “r.20”.

6) Press the Δ or ∇ keys to select the required resistivity value to be equ ivalent t o 20 mA (Default is 20.00

mΩ).Note that difference between the value at 4mA and 20mA must be at least 20% of F.S.

7) Press the ENTER key to confirm your selection.

8) Press the ENTER key to return to Advanced Set-up mode, or return to Measur ement mode by pressing

the Δ and ∇ keys simultaneously (escape).

7.6 Configuration (ConF) sub-function

This group of parameters lets you configure the controller to suit your requirements.

7.6.1 Entering Configuration sub-function

1) Enter Advanced Set-up mode. Push ENTER key and scroll to Advanced Set-up security c ode “22”.

Push ENTER key.

2) Press Δ or ∇ keys to scroll until upper display shows “ConF”. Press ENTER key to enter configuration

sub-function.

7.6.2 Selecting Filter Function and the Alarm or Wash Function

In this configuration sub-function, y ou have the ‘F ilter’ selectio n which lets you filter

rapid measurement changes and stabilisin g the measurement. This configuration

sub-function also allows you to use the A larm relay as Was h or Clean contact. The

Wash (Clean) contact is used in combination with automatic cleaning systems.

During the wash cycle, the analog output is set on hold.

1) In Filter selection mode, use the arrow keys to choose filter "on" or "off".

2) Press the ENTER key to confirm. Display will now show “ALr” or “CLn”.

3) Press the Δ or ∇ keys to choose "ALr" (Alarm) or "CLn" (Clean) function.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.6.3, or return to Measurement mode by pressing the Δ and ∇ keys

simultaneously (escape).

Note: The factory default setting for the Filter selection is "on".

19

Page 25

Operating Instructions Alpha RES 1000

7.6.3 Selecting the alarm time lag (if the relay 3 is set to Alarm)

This parameter group lets you select a period of time before the alarm activates when your set point has been

overshot. You can select from 0 to 1999 seconds.

HOLD SETUP

30

AL.d

7.6.4 Selecting steady or pulse contact for the alarm relay (if the relay 3 is set to Alarm)

This parameter group selects whether a larm con tact w ill operat e as a s teady c ontac t or a f leeti ng (sing le pu lse)

contact. Pulse contact closing time is 1 second.

1) Follow directions in 7.6.1 to enter Configuration mode. Press

ENTER key until the upper display shows “Stdy” or “FLEt” and

lower display shows “AL.C.”.

AL.C = alarm contact

StdY = steady contact

FLEt = fleeting (single pulse) contact

2) Press Δ or ∇ keys to select steady or pulse contact. Press

ENTER key.

3) Proceed to 7.6.5, or return to Measurement mode by pressing Δ

and ∇ keys simultaneously (escape).

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key until the upper display shows a num erical value

(in seconds) and the lower display shows “AL.d”.

3) Press the Δ or ∇ keys to select how long of an alarm delay (0 to 1999

seconds) you want.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.6.4, or return to Measurement mode by pressing t he Δ and

∇ keys simultaneously (escape).

HOLD SETUP

Stdy

AL.C

HOLD SETUP

FLEt

AL.C

7.6.5 Wash Contact (if the relay 3 is set to Wash)

HOLD SETUP

CLn

rL3

1) Follow directions in 7.6.1 to enter Configuration mode. Press the

ENTER key when choosing CLn.

2) Press the Δ or ∇ keys to select the wash cycle (int. 0.1 to 199.9 ho urs).

3) Press the ENTER key to confirm your selection.

4) Press the Δ or ∇ keys to select the wash duration (1 to 1999 s econds )

and press ENTER to confirm.

5) Proceed to 7.6.6, or return to Measurement mode by pressing the Δ

and ∇ keys simultaneously.

20

Page 26

Operating Instructions Alpha RES 1000

7.6.6 Input Line Resistance Adjust

This function compensates for the line resistance of the cable to its cell.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press ENTER key until upper display shows “0.0” and lower

display shows “L.Ad”. L.Ad = line adjuster resistance (0.0 to

100.0)

3) Press Δ or ∇ keys to input value. Press ENTER key.

4) Proceed to 7.6.7, or return to Measurement mode by pressing

Δ and ∇ keys simultaneously (escape).

HOLD SETUP

0.0

L.Ad

7.6.7 Reverting to factory default settings

Use this parameter to reset all settings or calibratio n v alu es only to f ac to ry defau lt. Changing from “no” to “YES”

and pressing the ENTER key resets all settings to factory reset.

HOLD SETUP

no

dEF

4) Press the ENTER key to confirm your s election and to return to Advanced Set-up mo de, or return to

Measurement mode by pressing the Δ or ∇ keys simultaneously (escape).

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key. The upper display shows “no” or “YES” , the lower

display shows “deF” (default).

3) Press the Δ or ∇ keys to select “no” or “YES”. WARNING: Press the

ENTER key resets all settings and the calibration values will be

overwritten as a result!

7.7 Calibration (CAL) sub-function

The calibration procedure in Advan ced Set-up mode is identical to procedure in Calibrat ion mode. The only

difference is that the controller will revert bac k to Set- up mode (i nstead of Meas urement mode) a fter succ es sful

calibration.

7.7.1 Entering Calibration mode from Advanced Set-up mode

1) Enter Advanced Set-up mode. Push ENTER key and scroll to Advanced Set-up security c ode “22”.

Push ENTER key again.

2) Press Δ or ∇ keys to scroll until upper display s hows “CAL”. See section 6 for complete calibration

procedures.

21

Page 27

Operating Instructions Alpha RES 1000

8 Auto/Manual Mode

Regardless of mode, control device s connected to Relay A or Relay B can be operate d from front panel of

controller. In Automatic mode, controller’s set point values activa te relays. In Manual mode, m anual control of

relays is possible to prime the pump or check pump status.

8.1 Auto mode (mode after switch-on)

To view set-point values:

1) Press RELAY SELECTION (Rel A/Rel B) key. Upper display shows set-point value for Relay A; lower

display shows “SP1”.

2) After two seconds upper display shows set-point value for Relay B; lower display shows “SP2”.

3) After an additional two seconds controller returns to Measurement mode.

8.2 Manual mode

1) Press RELAY CONTROL (auto/manu) key. Upper display shows “000”; lower display shows “ S.Cd” to

prompt to enter Advanced Set-up code.

2) Press Δ or ∇ keys to scroll upper display until it reads “22”.

3) Press ENTER key. Manual indicator by the RELAY CONTROL key lights up.

Note: Pressing ENTER key at a value other than “22” will cause control ler to r evert to Mea sureme nt mode, a nd

relays will remain in automatic mode.

4) Press RELAY SELECTION key to select either Relay A or Relay B. LED next to currently selected relay

(A or B) will light.

The manual control options are now available.

- Limit control sel ected: Upper display reads current measured va lue. Lower display sho ws “oFF” or “on”

depending on relay status of currently selected relay.

5) Press Δ or ∇ keys to change Relay on/off status. LED indicators at the right of controller will also change

between Red and Green to indicate Relay status.

Note: If you wish to manually change the status of bot h rel ay s , pres s RELAY SELECTION key at this point and

repeat step 5 for second relay. This first relay will remai n un der m anu al c o ntrol wh ile y o u are s etting the second

relay.

6) Press RELAY CONTROL key to return to Measurement mode. Rela ys are now back under automatic

control.

22

Page 28

Operating Instructions Alpha RES 1000

9 Technical Specifications

Resistivity Range Resolution Default Cell Constant, K

0.00 to 19.99 mΩ/cm 0.01 mΩ/cm

0.000 to 1.999 mΩ/cm 0.001 mΩ/cm

Temperature -9.9 to 125 oC

Resolution 0.1 oC

Relative Accuracy

Sensor Pt 1000/Pt 100

Temperature Compensation Auto / manual (reference at 25.0 oC)

Set-point and Controller Functions

Controller characteristics Limit/Proportional controller

Pickup / Dropout delay 0 to 1999 sec.

Switching Condutivity hysteresis 0 to 10% of Full Scale

Contact outputs, controller 2 potential-free change-over contacts

Switching voltage max. 250 VAC

Switching current max. 3A

Switching power max. 600 VA

Alarm/Wash Functions

Function (switchable) Latching / pulse

Pickup delay 0 to 1999 sec.

Switching voltage max. 250 VAC

Switching current max. 3A

Switching power max. 600 VA

Electrical Data and Connections

Power Requirements 110 / 220 VAC (jumper selectable)

Frequency 48 to 62 Hz

Signal Output 0/4 to 20 mA, galvanically isolated

Signal Output Load

Connection terminal Terminal blocks 5-pole / 17-pole, removable

Mains fuse / fine wire fuse slow-blow 250 V / 100 mA

EMC Specifications

Emissions According to EN 50081-1

Susceptibility According to EN 50082-1

Environmental Conditions

Ambient temp. operating range 0 to 50 oC

Relative humidity 10 to 95%, non-condensing

Mechanical Specifications

Dimensions (control panel housing - L x H x W) 175 x 96 x 96 mm

Weights (control panel housing) max. 0.7 kg

Material ABS with polycarbonate (front housing)

Insulation (Front / Housing) IP 54 / IP 65

0.01

0.1

o

C

± 0.5

max. 600 Ω

23

Page 29

Operating Instructions Alpha RES 1000

Accessories

Assembly Accessories

Product Description Code no.

Resistivity Cell, up to 20mΩ; Cell constant, K=0.01 with integrated Pt 100,

Material SS316 and 25ft cable (open-ended)

Resistivity Cell, up to 20mΩ; Cell constant, K=0.01 with integrated Pt 100,

Material Titanium and 25ft cable (open-ended) – Ultrapure water applications

Resistivity Cell, 0.10 – 2.00mΩ; Cell constant, K=0.1 with integrated Pt 100,

Material SS316 and 25ft cable (open-ended)

Note: Above Resistivity Cells can has a pressure tolerance of up t o 6 bar. Please ask your authorised

distributor or dealer for prices.

EC-CS10-0-01S

EC-CS10-0-01T

EC-CS10-0-1S

10 General Information

Thermo Scientific Instruments warrants this product to be free from significant deviations in material and

workmanship for a period of one year from the date of purchas e. If repair is necessary and has not been the

result of abuse or misuse within the warranty perio d, please return by freight pre-paid an d amendment will be

made without any charge. Thermo Scientific Instruments’ Customer Service Dept. will determine if product

problem is due to deviations or customer abuse. Out of warranty products will be repaired on a charge basis.

10.1 Packaging

The instrument is packaged in a corrugated box with a warran ty card, instruction manual and the following

accessories:

17-way and 5-way (right-angled) terminal block [1 unit each]

side threaded rod with catch [2 units]

receptacle cable lug [1 unit]

rubber gasket [1 unit]

10.2 Return of Goods

Authorisation must be obtained from Thermo Scienti fic Instruments’ Customer Service Dept. to issue a RGA

(Return of Goods Authorisation) number b efor e retur ning i tems for any reason. When app lying for authoris ation ,

please include data requiring the reason of return. Items must be carefully packed to prevent damage in

shipment and insured against possible dama ge or loss. Thermo Scientific Instruments will not b e responsible

for any damage resulting from careless or in sufficient packing.

Warning: Shipping damage as a result of inadequate packaging is the user/distributor’s

responsibility, whoever applicable. Please follow the guidelines below before shipment.

10.3 Guidelines for Retur ning Unit for Repair

Use the original packaging material, if poss ible when ship ping the u nit for repair. Oth erwise wrap it wit h bubbl e

pack and use a corrugated box for better protection. Inc lude a brief description of any faul ts suspected for the

convenience of Customer Service Dept., if possible.

24

Page 30

Operating Instructions Alpha RES 1000

11 Appendices

Appendix 1 – Jumper Positions

Jumper Positions - Internal to the controller

JP 1 Selects the input voltage 220 VAC.

JP 2 Selects the input voltage 110 VAC.

JP 6 Selects the temperature sensor for Pt1000/Pt100

Fuse Note that there is a fuse (slow-blow 100mA) internal to the controller. Before

opening the unit, ENSURE that the power cable is physically separated from

the power supply. Replace fuse with the recommended type only.

JP2

JP1

Fuse

110 VAC

220VAC

Rear

View from the Top o

f Main PCB

JP6

View from front of the Analog PCB

25

Page 31

Operating Instructions Alpha RES 1000

00

0

8.80

00

V

A

o

Appendix 2 – Conductivity / Resistivity of Various Aqueous Solutions at 25

C

Pure Water 0.05 uS/cm 18

Power Plant Boiler Water 0.05 - 1 uS/cm 1 - 18

Distilled Water 0.5 uS/cm 2

De-ionized Water 0.1 - 10 uS/cm 0.1 - 10

De-mineralised Water 1 - 80 uS/cm 0.01 - 1

Mountain Water 10 uS/cm 0.1

Drinking Water 0.5 - 1 mS/cm 1 - 2

Waste-water 0.9 - 9 mS/cm 0.1 - 1

Potable Water Maximum 1.5 mS/cm 0.7

Brackish Water 1 - 80 mS/cm 0.01 - 1

Industrial Process Water 7 - 140 mS/cm rarely stated

Ocean Water 53 mS/cm rarely stated

Conductivity Resistivity

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

MΩ-cm

Appendix 3 - Simple Explanation on the Function of Hysteresis

SP1 Set to LO

SP2 Set to HI

REL

YON

RELAYOFF

1.

1.2

SP1

FORWARD DIRECTION

ERSE DIRECTION

RE

1

STERESIS BAND

HY

19.

SP2

m

Ω

The controller relay activates when the set-point is reac hed. In the reverse direction, it does not de-activate

when the value reaches the set-point. Instead, it contin ues to be active til l the value reach es the amount set by

the Hysteresis band.

26

Page 32

Operating Instructions Alpha RES 1000

Appendix 4 – Pure Water Curve

Resistivity of Pure Water

100

90

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Temp °C

27

Page 33

Page 34

Water Analysis Instruments

North America

166 Cummings Center

Beverly, MA 01915 USA

Toll Free: 1-800-225-1480

Tel: 1-978-232-6000

Dom. Fax: 1-978-232-6015

Int’l Fax: 978-232-6031

Europe

P.O. Box 254, 3860 AG Nijkerk

Wallerstraat 125K, 3862 CN Nijkerk,

Netherlands

Tel: (31) 033-2463887

Fax: (31) 033-2460832

Asia Pacific

Blk 55, Ayer Rajah Crescent

#04-16/24, Singapore 139949

Tel: 65-6778-6876

Fax: 65-6773-0836

www.thermo.com/process

© 2009 Thermo Fisher Scientific Inc.

All rights reserved. Thermo Fisher Scientific Inc.

68X216807 Rev 5

Loading...

Loading...