Page 1

EUTECH INSTRUMENTS

ααααlpha-pH800

pH and ORP Controller/Transmitter

Operating Instructions

68X216813

03/99

Page 2

Preface

Thank you for purchasing the αlpha-pH800 series pH/ORP

controller/transmitter.

This manual serves to explain the us e of th e αlpha-pH800 series pH/ORP

controller/transm itter. The manual functions in two ways, fir stly as a ste p

by step guide to help t he user op erate the instr um ent. Second l y, it serv es

as a handy referenc e guide. T his instr uctio n m anual is writ ten to c over as

many anticipated applications of the αlpha-pH800 pH/ORP

controller/transmitter. If you have doubts in the use of the instrument,

please do not hesitate to contact the nearest Eutech Instruments’

Authorised Distributor.

The information presented in this manual is subject to change without

notice as improvements are made, an d does not r eprese nt a com m itment

on part of Eutech Instruments Pte Ltd.

Eutech Instruments cannot accept any responsibility for damage or

malfunction of the unit due to improper use of the instrument.

Copyright 1999 Eutech Instruments Pte Ltd. Version 1.0. All

rights reserved.

Eutech Instruments Pte Ltd. Blk 55, Ayer Rajah Crescent #04-14/24,

Singapore 139 949. Tel: (65) 778 6876; Fax: (65) 773 0836; e-mail:

marketing@eutechinst.com; Home page: http://www.eutechinst.com

Page 3

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................ 1

1.1 Description of Unit.................................................................................... 1

1.2 Applications................................................................................................ 2

2 ASSEMBLY AND INSTALLATIONS............................................................. 3

2.1 Measurement and Control System........................................................ 3

2.2 Unit Dimensions.......................................................................................3

3 ELECTRICAL CONNECTIONS....................................................................... 4

3.1 Connection Diagram................................................................................ 4

3.2 Back Panel................................................................................................ 6

4 OVERVIEW....................................................................................................... 8

4.1 Keypad and Display................................................................................. 8

Function Groups................................................................................................... 9

4.2 Control Concept ....................................................................................... 9

5 MEASUREMENT............................................................................................ 10

5.1 Display in Measurem ent m ode ............................................................ 10

6 CALIBRATION............................................................................................... 11

6.1 pH Calibration......................................................................................... 11

6.2 ORP – mV Calibration........................................................................... 13

7 ADVANCED SET UP MODE......................................................................... 14

7.1 Electrode Offset (OFS) sub-function................................................... 14

7.2 Setting temperature (Set

7.3 Control Relay A/Control Relay B (SP1/SP2) sub-function............... 18

7.4 Configuration (ConF) sub-function ...................................................... 22

7.5 Calibration (CAL) sub-function............................................................. 23

8 TECHNICAL SPECIFICATIONS................................................................... 24

9 ACCESSORIES ............................................................................................... 25

10 GENERAL INFORMATION....................................................................... 25

10.1 Warranty.................................................................................................. 25

10.2 Packaging ............................................................................................... 25

10.3 Return of Goods..................................................................................... 26

10.4 Guidelines for Returning Unit for Repair ............................................ 26

11 APPENDICES.............................................................................................. 27

11.1 Appendix 1.............................................................................................. 27

11.2 Appendix 2.............................................................................................. 28

11.3 Appendix 3.............................................................................................. 29

o

C) sub-function ......................................... 15

Page 4

Page 5

1 INTRODUCTION

1.1 Description of Unit

Thank you for purchasing Eutech’s ¼ DIN alpha-800 series pH/ORP

process controllers. This unit is used for measuring either pH or ORP

parameter one at a time, and the oper atio nal m ode is switc hab le fr om the

menu. You can use this unit to measure pH or ORP with limit control.

This controller has many user-friendly and safety features which include:

• Menu-driven program that simplifies set-up

• Built-in non-volatile memory backup to ensure that calibr ation and

other information are not erased if power supply fails

• Push-button two-point calibration and electrode offset

adjustment from the keypad

• Automatic temperature compensation (ATC)

• Manual temperature comp ensation setting without the ATC probe,

with independent setting for calibration and process temperature

• 0 to 2000 second time delay adjustment on all relays – minimise

false alarms

• Separately adjustable high and low set point hysteresis (dead

bands) prevent chattering of relays around the set points

• Asymmetrical/symmetrical input for pH/ORP operation

• Large dual display LCD for easy reading with clear multiple

annunciators, alarm status, operational and error messages

• Two switching contacts as set-point triggering relays

• Hold function freezes output current (4/20mA) and control relays

• LED indicators signal control activities to monitor controller status

from a distance

• Protection against electromagnetic interference – Input and

output are free from external inference

1

Page 6

1.2 Applications

Use this controller in panel mounted enc losures for applica tions such as

water treatment and monitoring, galvanic-decontamination, chemical

processing food processing, clean or waste water control and

neutralisation process

.

2

Page 7

2 ASSEMBLY AND INSTALLATIONS

(

)

(

r

)

y

p

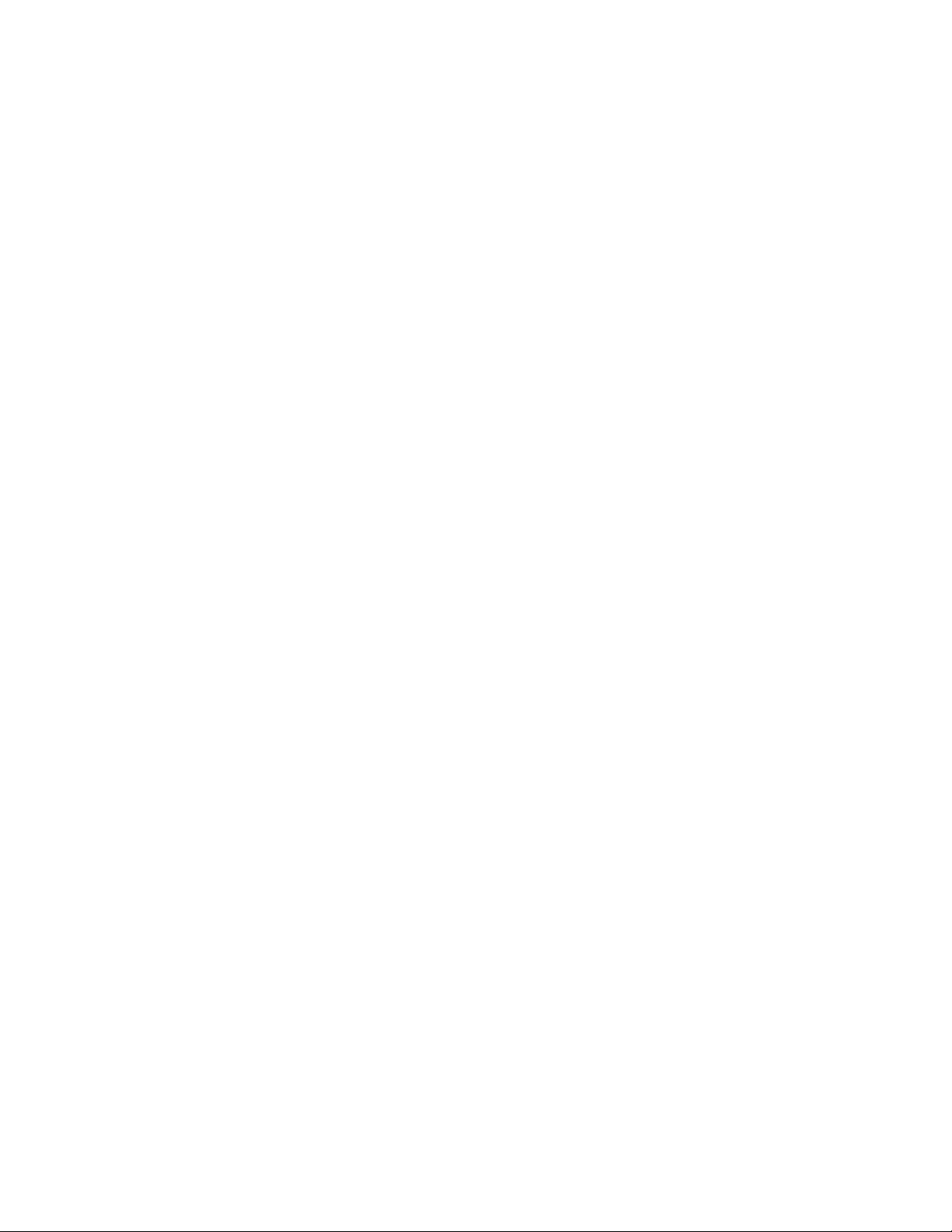

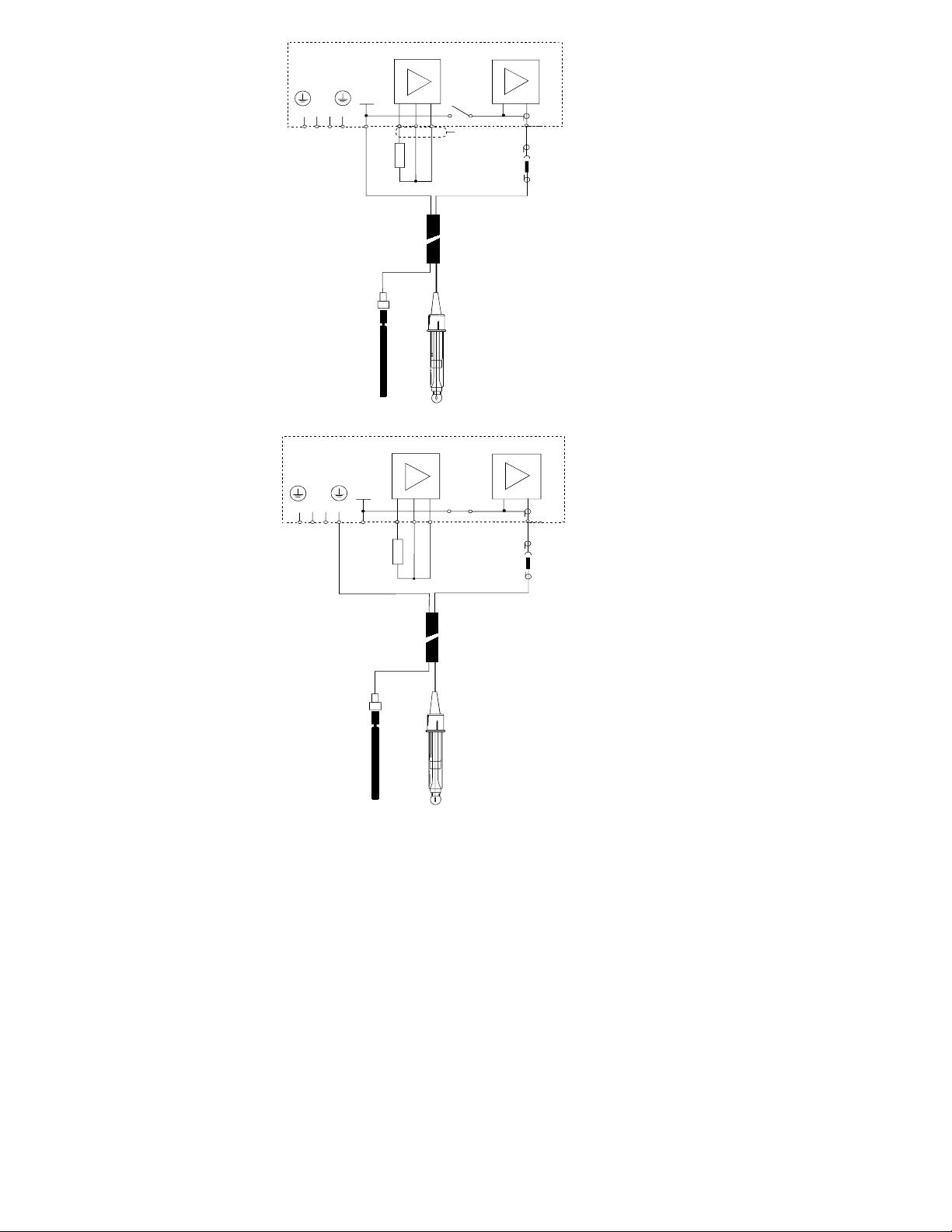

2.1 Measurement and Control System

A typical measurement system consists of:

• a pH/ORP process controller

• a pH/ORP combination electrode with integrated or separate

temperature sensor Pt 100/1000,

• an immersion, flow or pr ocess assembly with or without a potential

matching pin (PMP)

• a final control element such as pump or valve

• a recorder

Flow Assemb

l

Measurement Cable

H Contr oller

Power Mains

Chart Record

er

2.2 Unit Dimensions

max. 175

1mm

max. 45

Flat Gasket

To be Inserted ByCustome

Note: The Taped Corners Have to Be On Top

92 + 0.5

92 + 0.5

MountingCut-Out

92

56

32

The field-tested control panel housing is 96 x 96 mm; with protection class IP 54 (front).

96

3

Page 8

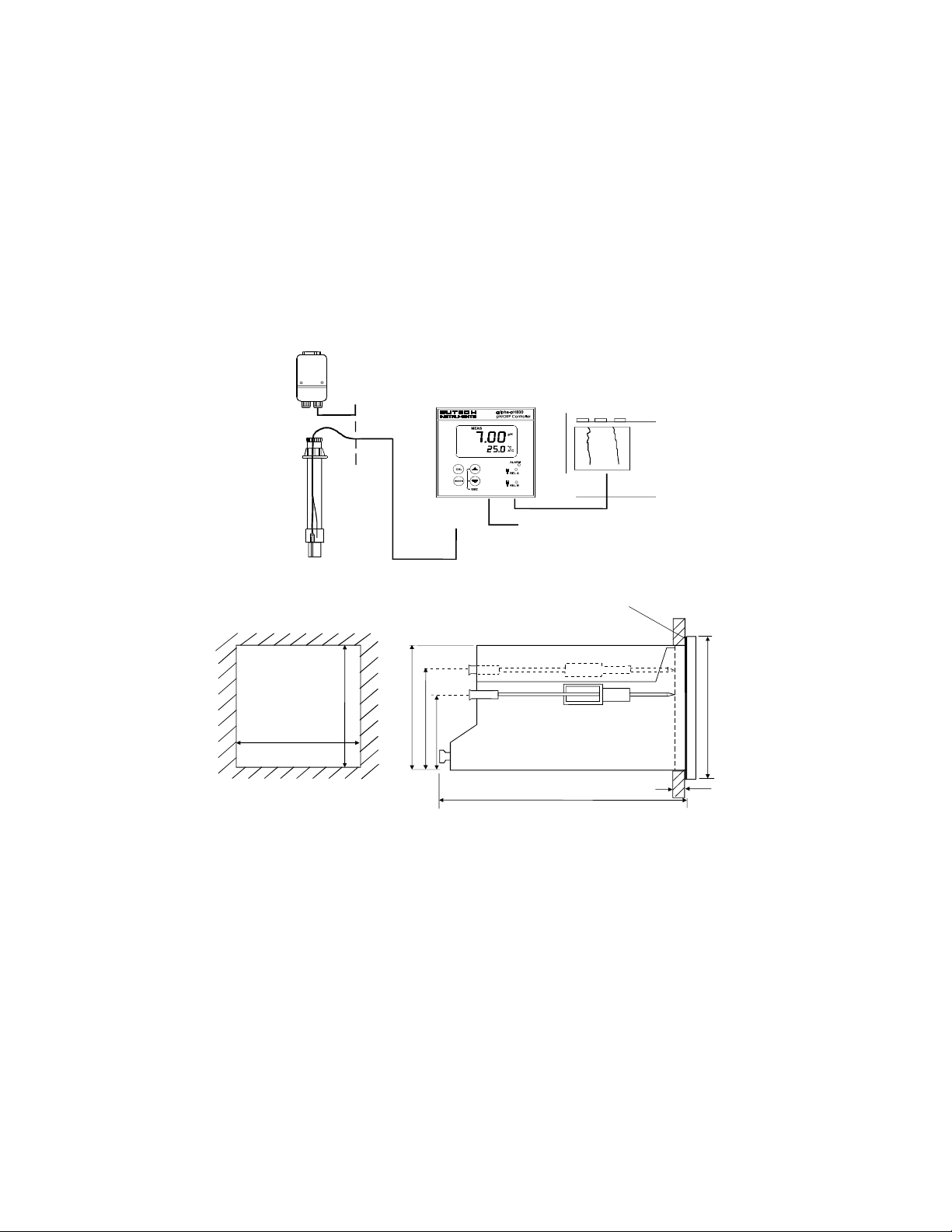

3 ELECTRICAL CONNECTIONS

w

A

3.1 Connection Diagram

S/

V

S/S/

pH

AC:

Po

er Mains

1

18 19 20 21 22

Pt 100

Relay A

2

36

PE

NL

5

4

* ) indicated contact positionsare for currentlessc onditions

PE/S

Potential M atching Pin (PMP)

RelayB

78 9

SignalInput pH/ORP

10

11

BNC

12 13

Signal OutputHold Input

pH

m

+

-

16

151715

14

PE/S

4

Page 9

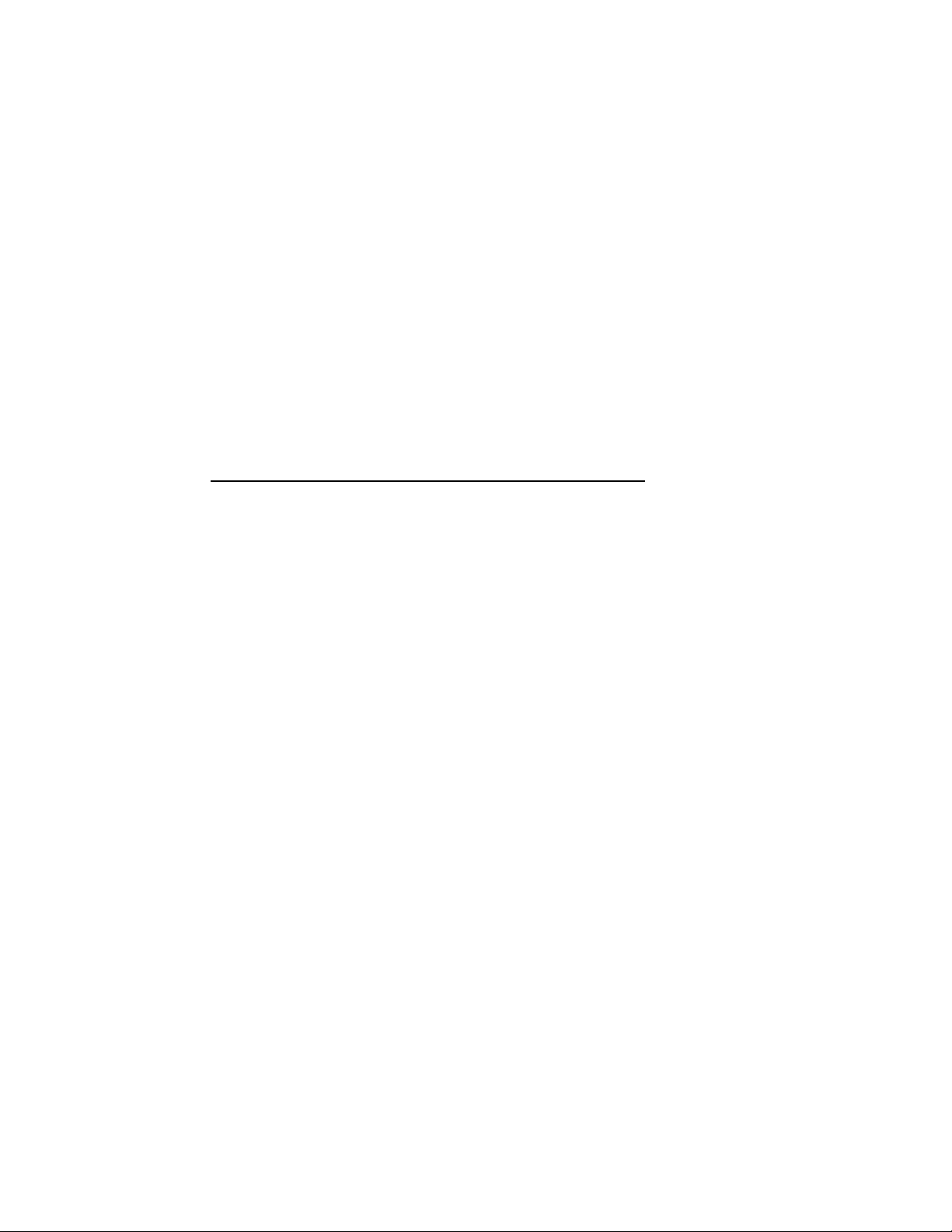

PENL

Temp.

S

0/PA

20

21

123

22

19 18

S

pH

BNC

Symmetrical high-impedance

connections

Measuring Cable

Potential

Matching Pin (PM)

N

LS

PE

22

123

Potential

Matching Pin (PM)

0/PA

21

pH Combination

Electrode

Tem p .

20

19 18

pH

BNC

Asymmetrical connections

Measuring Cable

pH Combination

Electrode

5

Page 10

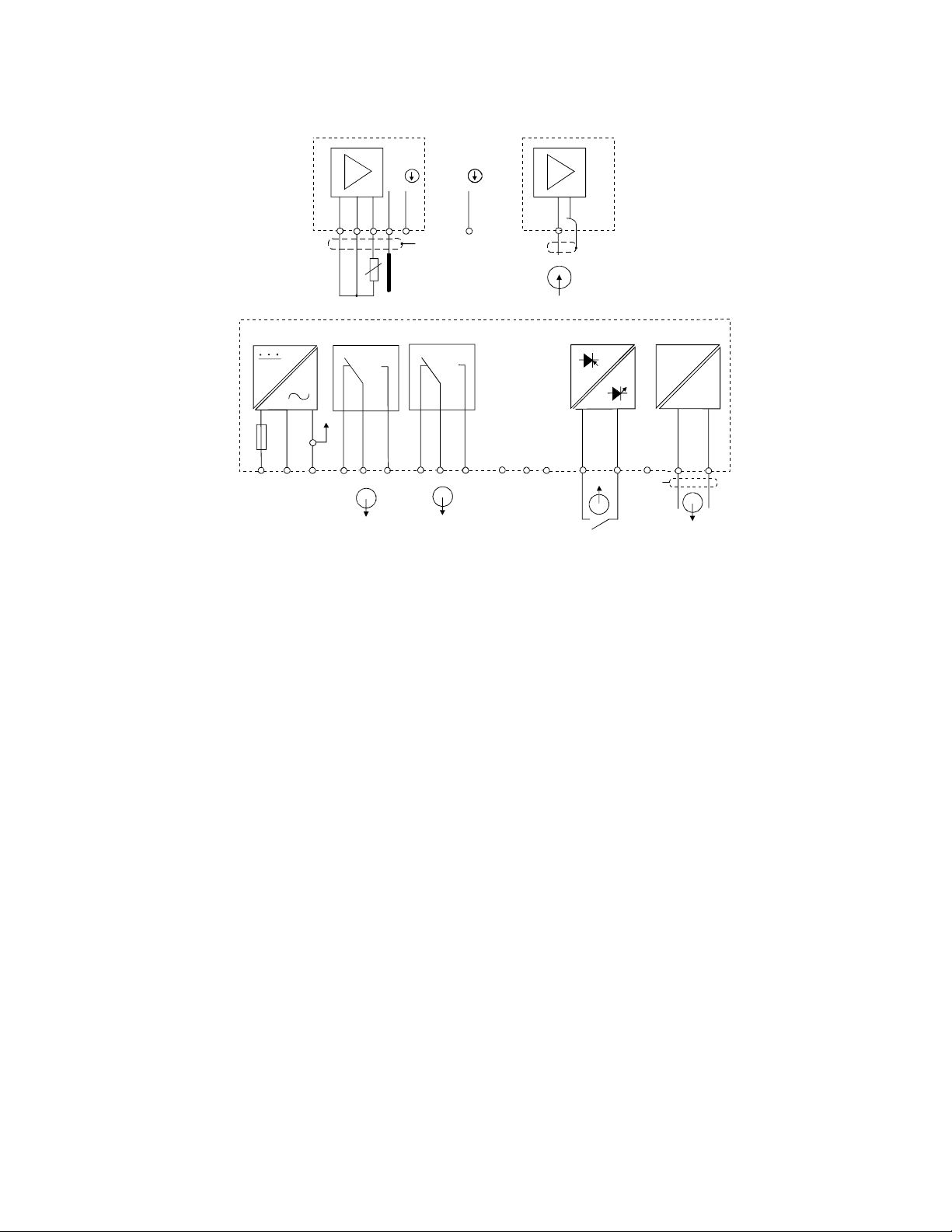

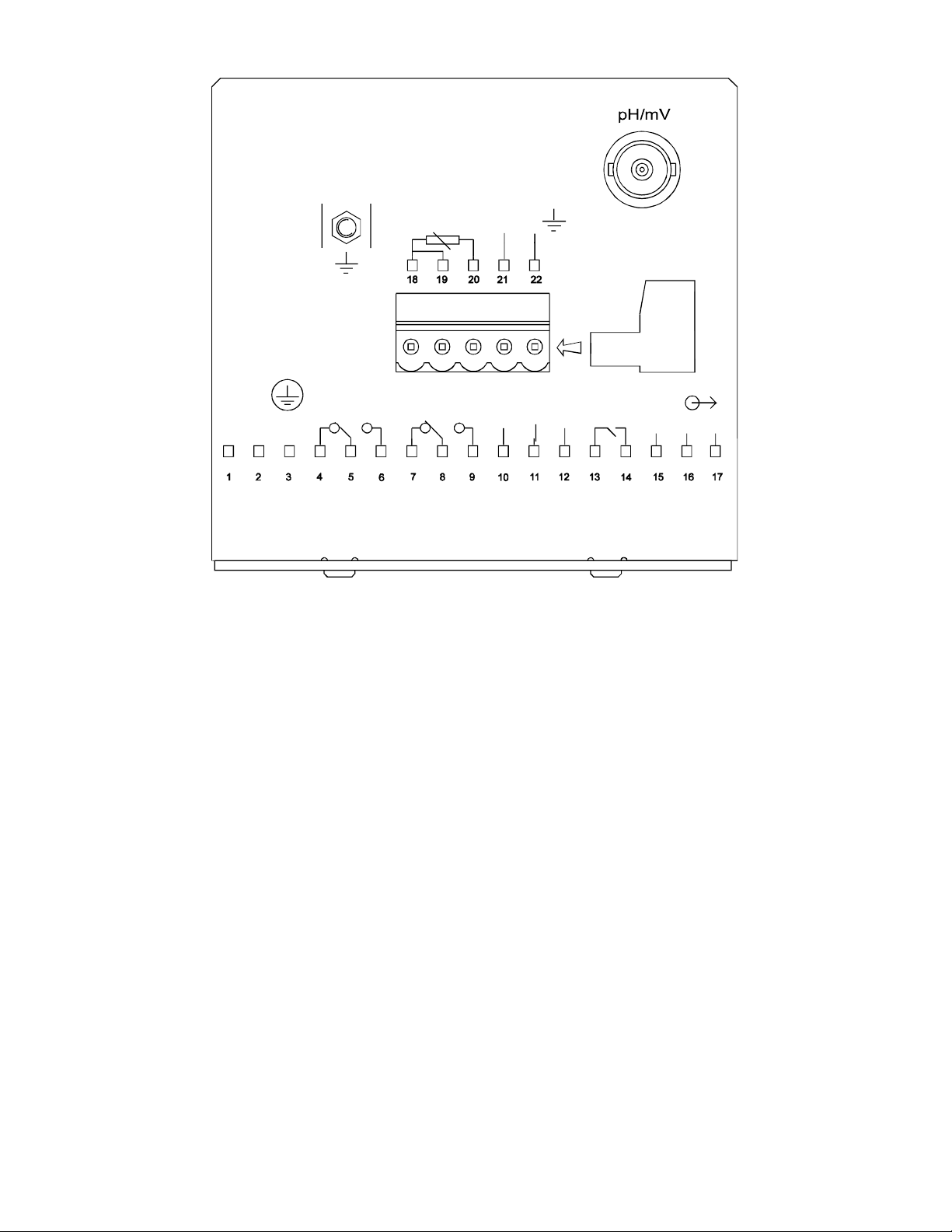

3.2 Back Panel

The back panel consists of two conn ectors . The f irs t connector is the 17-wa y

PCB edge connector and the other is the 5-way connector.

Connection for the 17-way screw terminals (from left to right):

1.AC mains live wire 10.No connection

2.AC mains neutral wire 11.No connection

3.AC mains protective earth wire 12.No connection

4.Low set relay resting position (NC) 13.Hold function switch terminal 1

5.Low set relay common 14.Hold function switch terminal 2

6.Low set relay working position (NO) 15.No connection

7.High set relay resting position (NC) 16.4 - 20 mA for -ve connection

8.High set relay common 17.4 - 20 mA for +ve connection

9.High set relay working position (NO)

Connections for the 5-way screw terminals:

18. Pt100/Pt1000 lead 1 terminal

19. Pt100/Pt1000 sense lead terminal

20. Pt100/Pt1000 lead 2 terminal

Note: If using a two-wire RTD, short terminal 19 to terminal 18.

Pt 100/Pt 1000 is s electable via an internal jum per. Fac tory def ault is Pt1 00.

See Appendix 1 for directions on switching the RTD type.

21. pH/ORP (potential matching pin)

21. pH/ORP (shield)

6

Page 11

/

Pt100

/

/

Pt1000

0V

PAL

S

FUSE 250VAC

(F)

100mA

LNPE

RELAY A

RELAY B

NC NCNC

HOLD

NC

+

-

7

Page 12

4 OVERVIEW

4.1 Keypad and Display

4.1.1 Keypad

• Perform rapid 2-point calibration and view electrode status

• Allows entry to Set up mode

• Selec t individual functions with in the function group of Set up

mode

• Store input data in the Set up mode

• Start calibration in the calibration mode

• Select various function groups in the Set up mode.

• Set parameters and n umerical values in sub functions of Set

up mode

If pressed continuously, the setting speed increases

• Return to th e Meas urem ent m ode when bo th k eys are pr ess ed

together

4.1.2 Display

The LCD display features two numerical displa ys t hat sh ow status messages

and measured values for easy, quick reference. The dis play provides shor ttext information for setting parameters and configuration.

SETUP

READY

HOLD

MEAS

CAL

7.00

25.0 ATC

CON

pH

o

C

•••• MEAS: Measurement mode

•••• SETUP: Set-up mode of function groups

•••• CAL: Calibration mode of pH/ORP

•••• READY: Comes on after a successful

calibration

•••• HOLD: Relay position and c urrent output

are frozen

•••• ATC: Comes on in the ATC mode.

Disappears in the Manual temperature

Compensation mode.

“ATC” flashes if the temperature probe is

faulty in its ATC mode

• Display for RELAY A/B. Green LED indicates measured

value within lim it while RED LED in dicates measured value

outside limit.

• Alarm display if limit value overshoot or the ATC probe fails.

8

Page 13

Function Groups

The main function an d sub-function gr oups are orga nised in a matrix format

for configuration and selection of parameters. The main function groups are:

1) Offset adjustment (OFS)

2) Temperature Measurement / compensation settings (Set

3) Control relay 1 configuration (SP1)

4) Control relay 2 configuration (SP2)

5) Configuration (ConF)

6) Calibration (CAL pH)

o

C)

4.2 Control Concept

The main function an d sub-function gr oups are orga nised in a matrix format

as shown below. These functions can be access ed via the front keypad for

configuration and selection of parameters.

9

Page 14

5 MEASUREMENT

5.1 Display in Measurement mode

When the controller is initially powered on, it automatically enters into the

Measurement mode after the large dual LCD displays all segments briefly.

The upper display s hows the measured pH or ORP valu e, while the lower

display shows either the temperature value if the controller is set for pH

measurement or “OrP” if it is set for ORP measurement.

Annunciators at the r ight s ide of the disp la y indicate whether the contr ol ler is

set for pH or mV measurement..

Similarly annunc iat or s or ic o ns at th e t op or lef t side of the disp lay shows the

current status of contro ller, e.g. “MEAS”, “S ETUP”, “CAL”, “READ Y”, etc. In

addition, error messages also guide the user i n time of any fau lty conditions

as indicated by “ERR” or icons flashing.

5.1.1 Check electrode performance

To read current electrode slope and offset values:

1) Press the CAL key followed by the ENTER key. The upper display

shows electrode slop e. T he lower d ispla y read ing s hows t he p H r eadin g at 0

mV.

2) Press the ∆

∆ and ∇∇∇∇ keys to return to Measurement mode.

∆∆

10

Page 15

6 CALIBRATION

Direct Calibration from the Measurement m ode is possible via the CAL key.

The Calibration procedure c an also be accessed from the Advanced Setup

mode.

6.1 pH Calibration

This unit features f ive preset buffer values (1.00, 4.00, 6.86 or 7.00, 9.00,

9.18 and 10.00) for qu ick, two-point auto calibratio n. When calibrating this

instrument, standard pH buffer solutions must be used.

1) Enter Calibration mode. While in the

Measurement mode, push the CAL key. The upper

and lower display reads “CAL” & “pH”. Push the

ENTER or CAL key again. The controller displays

the electrode status based on the previous

calibration. Electrode s lope and offset information is

displayed.

NOTE: If the display reads “CAL OrP”, see section

7.4 for procedures on how to switc h from ORP to p H

readings.

2) Press the ENTER key again to begin

calibration. The “CA L” indicator a ppears at th e top of

display and the buffer ind icator app ear s in the bottom

left corner of the dis p lay. The upper dis p lay is the online pH value as measured by the electrode. The

lower display indicates the first compulsory

calibration value, pH 7.00 (or 6.86).

3) Immerse the clean e lectr ode in th e buffer solution.

In ATC, the temperature probe must also be

SETUP

HOLD

READY

HOLD

HOLD

SETUP

HOLD

READY

HOLD

CAL

PH

CAL

57.2 mV

6.88

CAL

6.96

7.00

CAL

4.02

4.00

CAL

59.0 mV

7.00

pH

pH

pH

pH

pH

pH

immersed in the buffer solution. Likewise for

11

Page 16

symmetrical mode, immerse the potential matching pin in the buffer.

4) Press the ENTER key to start the ca libration at pH 7 (or pH 6. 86). The

electrode indicator and CAL indica tor both f lash. T he controller automatic all y

adjusts the reading to match the buffer value.

5) The lower dis play will now show its nex t lower ‘pH’ buf fer. Use ∆∆∆∆ and ∇∇∇∇

keys to select the sec ond buffer f rom one of the 5 remaining preset va lues.

Remove the electrode f rom the first buf fer, wash and then imm erse into the

second buffer, Once the upper d isplay stab ilises pre ss the ENTER key, the

electrode and CAL indicat or will flash. The controll er adjusts the reading to

the buffer.

6) After calibrating to a second buffer value, the controller automatically

displays electrode slope and offset. The zero point and slope are redetermined after each calibration.

7) Press the ENTER key. If the calibrat ion mode was access ed using the

CAL key, the controller will return to the Measurement mode. If the

calibration mode was accessed from the Advanced Set-up mode, the

controller will return to the sub-function menu.

Note: If there is a calibration error, the controller displays “ERR”. If this

happens, push both and (escape) to restart the calibration beginning from

step 1.

Note: When calibrating with manual temperature compensation, the

controller automatic ally changes from the preset process temperature to the

calibration temperature. After leaving the Calibration mode, the controller

switches back to proces s temperature (for settin g th e c al ibra tio n temperature

and the process temperature, see section 7.2.3).

12

Page 17

6.2 ORP – mV Calibration

This mode allows one-point calibration.

1) Enter Calibration mode. While in Measurement

mode, push the CAL key. Press the ENTER key.

The upper and lower display reads “CAL OrP”.

Note: If the upper and lo wer display read “ CAL PH”,

see section 7.4 for procedur es on ho w to s witch f rom

SETUP

HOLD

CAL

OrP

pH to ORP mV readings.

2) Place sensor in the ORP solution.

3) Press the ENTER key to begin calibration. The

“CAL” indicator appears on the display. The upper

display shows the current m V output of the electrode

without any offset adjustment.

4) Press the ∆∆∆∆ and ∇∇∇∇ keys to adjust the m V value to that of the standard

solution.

5) To confirm, press the ENTER key. The controller calculates the

correction factor and returns to the Measurement mode.

HOLD

CAL

226

mV

13

Page 18

7 ADVANCED SET UP MODE

7.1 Electrode Offset (OFS) sub-function

This option is available only in the pH mode. An allowance of ±120mV is

allowed to correct for electrode deviations. This feature is useful for

prolonged on-line applications.

The controller will add or subtract the value from the measured pH and

display the correct value. Should the offset value be too high, consider

performing maintenance on the electrode followed by calibration. If the

calibration is unsuccessful, please replace the electrode.

SETUP

HOLD

SETUP

HOLD

Ofs

Ofs

OfsOfs

-0.05

-0.05

-0.05-0.05

7.00

5) Press the ENTER key. The SETUP annunciator appears at the top of the

display. The lower displa y shows the on-l ine meas ured pH value. T he upper

display shows the current offset value.

6) Press the ∆∆∆∆ or ∇∇∇∇ keys until the pH val ue coincides with the correc t pH

value noted in Step 2. As the ∆∆∆∆ or ∇∇∇∇ keys is pressed to adjust th e pH valu e,

the ‘offset’ value in the upper display also changes.

7) Press the ENTER key to enter the offset value.

Note: The offset value is reset during full calibration . See section 6 for full

calibration instructions.

1) Tak e a sample from the system and note t he pH

reading displayed on the control ler .

2) Measure the pH of the sa mple using a calibrated

pH tester, hand-held meter, or bench m eter. Record

the correct pH value.

3) Enter Advanced set-up mode. Press ENTER.

4) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll until the upper

display shows OFS.

Note: The offset parameter is blanked out during ORP operation.

14

Page 19

7.2 Setting temperature (Set oC) sub-function

7.2.1 Selecting automatic or manual temperature compensation

1) Enter Advanced Set-up mode by pressing the ENTER key.

2) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll until the

display shows “Set

3) Press the ENTER key. The lower display

shows “Atc”; the upper display shows “on” or

“oFF” depending on whether or not ATC is

selected.

4) Press the ∆∆∆∆ or ∇∇∇∇ keys to toggle between

ATC on and off.

5) Proceed with additional Advanced Set-up

procedures (press ENTER again) or return to

Measurement mode by pressing the ∆∆∆∆ and ∇∇∇∇

keys (escape) simultaneously.

o

C”.

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

7.2.2 Temperature calibration (ATC mode only)

1) Select “ATC on” as described above in

Section 7.2.1.

2) Press the ENTER key. The upper display

SETUP

HOLD

SEt

SEt

SEtSEt

oooo

on

on

onon

Atc

oFF

oFF

oFFoFF

Atc

on

on

onon

indicates the current temperature offset. The

current measured temperature is shown in the

lower displa y.

3) Compar e the current m easured tem perature

on the controller display to a thermometer

known to be accurate. Note down the correct

temperature value.

15

SETUP

HOLD

0.0

0.0

0.00.0

25.0

ATC

o

C

Page 20

4) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll the lower display to match the correct

value. The upper display will now show the offset value. You can offset

o

temperature up to ± 5

5) Press the ENTER key to confirm your selection.

6) Continue with additional Advanced Set-up procedures, or return to the

Measurement mode by pressing the ∆∆∆∆ and ∇∇∇∇ keys (escape) simultaneously.

C.

7.2.3 Setting manual temperature compensation

Note: This option is not available when the controller is set for ATC

SETUP

oFF

oFF

HOLD

oFFoFF

Atc

SETUP

25.0

25.0

HOLD

25.025.0

P.C

SETUP

25.0

25.0

HOLD

25.025.0

C.C

shows the current proces s temperature and the lo wer display shows “P.

to indicate process temperature.

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to adjust the process temperature value, bet ween

–9.9 and 125

o

C.

operation.

For manual temperature compensation, two

different temperatures: process and

calibration, can be input independently. This

allows calibration at a temperature other than

the process temperature. Example: setting a

calibration temperature of 25

calibration using standard buffer solutions at

o

25

C, even if the process temperature is

different.

1) Select “ATC oFF” as described above in

section 7.2.1

2) Press the ENTER key. The upp er disp la y

o

C allows

o

C”

4) Af ter settin g the pr ocess tem perature valu e, pr ess the ENTER ke y. The

upper display shows the current calibration temperature and the lower

display shows “C.

o

C”.

16

Page 21

5) Press the ∆∆∆∆ or ∇∇∇∇ keys to adjust the calibration temperature value,

between –9.9 and 125

o

C.

6) Press the ENTER key to confirm.

7) Continue with additional Advanced Set-up procedures, or return to

Measurement mode by pressing the ∆∆∆∆ and ∇∇∇∇ keys (escape) simultaneously.

17

Page 22

7.3 Control Relay A/Control Relay B (SP1/SP2) subfunction

The SP1 option sets th e operating parameters for Relay A; the SP2 option

sets the operating parameters for relay B. Since these groups have the

same set-up parameters, they are described together.

7.3.1 Entering the Set point 1 (Set point 2) sub-function

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

2) Press the ENTER key. The upper display shows the curr ent set point

value and the lower display shows SP1 (SP2).

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to enter the value for Set point 1 (Set point 2).

4) Press the ENTER key to confirm.

5) Proc eed to 7.3.3 step 3, or r eturn t o Meas urem ent m ode b y pressing th e

∆∆∆∆ and ∇∇∇∇ keys simultaneously (escape).

SP1

SP1

SP1SP1

4.00

SP1

Lo

SP1

pH

1) Enter Advanced Set-up mode. Push the

ENTER key.

2) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll until the

upper display shows SP1 (S P2).

7.3.2 Selecting the set point values

This lets you choos e the value that will cause

your controller to activate the respective relays.

1) Follow directions in 7.3.1 to enter Control

Relay mode. If you are in this mode, skip to

step 2.

7.3.3 Choosing High or Low set points

Select a “lo” to activate relay wh en the pH/ORP value undersho ots the set

point; select a “Hi” to activat e rela y when th e va lue ov ershoots the s et po int.

Using both SP1 and S P2, the following configurati on for the set points can

be selected: lo/lo, lo/hi, hi/lo, or hi/hi.

18

Page 23

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Press the ENTER key until the upper disp lay shows Lo or Hi and the

lower display shows SP1 (SP2).

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to select l ow (lo) or high (hi) set point for SP1

(SP2).

4) Press the ENTER key to confirm.

5) Proceed to 7.3.4 step 3, or retur n Measurement mode b y pressing the

∆∆∆∆ and ∇∇∇∇ keys simultaneously (escape).

7.3.4 Selecting a hysteresis (dead band) value

Hysteresis prevents rapid co ntact switching if your value is fluctuati ng near

the set point. It does this by overshooting the set po int value to a specified

hysteresis valu e. You can set the h ysteresis va lue from 0.1 to 1.0 pH, 10 to

100mV.

Example: You have set your high set point at pH 9.0 and your hysteresis

limit value at pH 0.5. If your m easured value overshoots the high s et point

pH 9.0, the controller’s relay activates, which in turn activates external

devices such as a pump or valve. The actions of the external device will

cause the solution’s pH to drop. W hen the pH drops to 8.5 pH, t he rela y and

hence the pump will switch off.

1) Follow directions in 7.3.1 to enter Control

Relay mode.

2) Press the ENTER key. Scroll with the ∆∆∆∆ or ∇∇∇∇

SETUP

HOLD

0.50

pH

keys until the upper display shows the h ysteresis

(dead band) value and the lower display shows

“HYS”.

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to enter your hysteresis value for Set point 1 (S et

point 2). Your controller will acti vate at the valu e you selec t.

4) Press the ENTER key to confirm your selection.

19

Page 24

5) Proceed to 7.3.5 step 3, or return to Measurement mode by press ing

the ∆∆∆∆ and ∇∇∇∇ keys simultaneously (escape).

NOTE: Please refer to Appendix 3 for a graphical representation of the

Hysteresis.

7.3.5 Setting an on-delay time lag

You can set as time delay for each relay, which stops the relay from

switching on the moment the set p oint is exceeded. This c ontroller lets you

set a 0 to 2000 second time delay before the relay activates.

SETUP

HOLD

0

On.d

1) Follow directions in 7.3.1 to enter Control

Relay mode.

2) Press the ENTER key. Scroll with the ∆∆∆∆ or ∇∇∇∇

keys until the upper displ ay shows “on delay” tim e

and the lower display shows “On.d”.

3) Press the ∆∆∆∆ and ∇∇∇∇ keys to enter o n-dela y tim e for Set p oin t 1 (Set point

2). The controller wil l delay activat ion for the n umber of seconds ( 0 to 2000)

you select.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.3.6 step 3, or return to Measurement mode by press ing

the ∆∆∆∆ and ∇∇∇∇ keys simultaneously (escape).

7.3.6 Setting an off-delay time lag

You can set a time delay for each relay, which delays the relay from

switching off the moment the val ue re ac hes th e set point and hysteres is . T he

controller allows a timer delay from 0 to 2000 seconds time delay before

deactivating.

SETUP

HOLD

0

OF.d

1) Follow directions in 7.3.1 to enter Control

Relay mode.

2) Press the ENTER key. Scroll with the ∆∆∆∆ or ∇∇∇∇

keys until the upper displa y shows “of f delay” tim e

and the lower display shows “OF.d”.

20

Page 25

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to enter of f-delay time for Set point 1 (Set point

2). The controller wil l delay activat ion for the n umber of seconds ( 0 to 2000)

you select.

4) Press the ENTER key to confirm your selection.

5) Continue with Advanced Set-up mode procedures, or return to

Measurement mode by pressing the ∆∆∆∆ and ∇∇∇∇ keys simultaneously (escape).

21

Page 26

7.4 Configuration (ConF) sub-function

The options available in this sub-function allows the controller to be

configured as a pH or ORP controller.

7.4.1 Entering the Configuration sub-function

1) Enter Advanced Set-up mode. Press the ENTER key.

2) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll until the upper display shows “ConF”.

7.4.2 Selecting pH or ORP mV measurement

SETUP

ConF

HOLD

SETUP

HOLD

SETUP

HOLD

PH

SY

PH

ASY

SETUP

HOLD

SETUP

HOLD

OrP

SY

OrP

ASY

mV

mV

Besides selecting the contro ll er to f unc tion as a pH or ORP ( mV) controller, it

also allows the selection of the type of input: symmetric al or asymmetrical.

Symmetrical m ode is used in conjunction with a potential matching pi n – in

an electrically noisy environment. Please refer to section 3, page 6 for a

graphical representation.

1) Follow directions in 7.4.1 to enter Configuration mode.

2) Press the ENT ER ke y. Scroll with the ∆∆∆∆ or ∇∇∇∇ keys until th e upper displa y

shows the mode of op eration (pH or ORP mV and the lower displa y shows

symmetrical (SY) or asymmetrical (ASY) input type.

3) Proceed to 7.4.3, or return to Measurement mode by pressing the ∆∆∆∆ and

∇∇∇∇ keys simultaneously (escape).

22

Page 27

7.4.3 Reverting to factory default settings

Use this parameter to r es et all s ett ings t o f ac tory default. Changing f r om “ no”

to “YES” and pressing the ENTER key resets all settings to factory default.

WARNING: If “Yes” is selected, all settings input

will be overwritten!

1) Follow directions in 7.4.1 to enter Configuration

mode.

2) Press the ENTER key. Scroll with the ∆∆∆∆ or ∇∇∇∇ keys until the upper

display shows “no” or” YES”, and the lower display shows “deF” (default).

3) Press the ∆∆∆∆ or ∇∇∇∇ keys to select no or yes. Selecting “YES” a nd pres s ing

the ENTER key will overwrite all user-settings and automatically return to

Measurement mode.

4) Press the ENTER key to confirm your select ion and r eturn to Ad vanced

Set-up mode, or return to Measur ement m ode by press ing the ∆∆∆∆ and ∇∇∇∇ keys

simultaneously (escape).

SETUP

HOLD

no

dEF

7.5 Calibration (CAL) sub-function

The calibration procedure in Advanced Set-up mode is identical to the

procedure in the Calibration m ode. The only difference is that the control ler

will revert back to Set-up mode (instead of Measurement mode) after

calibration is com pleted.

7.5.1 Entering Calibration mode from Advanced Set-up mode

1) Enter Advanced Set-up mode. Press the ENTER key.

2) Press the ∆∆∆∆ or ∇∇∇∇ keys to scroll until the upper display shows “CAL”.

3) See section 6 for complete calibration procedures.

23

Page 28

8 TECHNICAL SPECIFICATIONS

pH Range -2.00 to 16.00 pH

Resolution 0.01 pH

Relative Accuracy

mV Range - 1000 to +1000 mV

Resolution 1 mV

Relative Accuracy

Temperature - 9.9 to + 125.0 oC

Resolution 0.1 oC

Relative Accuracy

Sensor Pt 100 /Pt 1000 (jumper selectable)

Temperature Compensation Auto / manual (reference at 25.0 oC)

Set-point and Controller Functions

Function (switchable) Set-point controller

Controller charac teristics Limit controller

Pickup / Dropout delay 0 to 2000 sec.

Switching pH hysteresis 0.1 to 1 pH

Switching ORP hysteresis 10 to 100 mV

Contact outputs, controller 2 potential-free change-over contacts

Switching voltage max. 250 VAC

Switching current max. 3A

Switching power max. 600 VA

Electrical Data and Connections

Power Requirements 110 / 220 VAC (jumper selectable)

Frequency 48 to 62 Hz

Signal Output 4 to 20 mA, galvanically isolated

Load

pH / ORP input BNC

Connection terminal Terminal blocks 5-pole / 17-pole, removable

Mains fuse / fine wire fuse slow-blow 250 V / 100 mA

EMC Specifications

Emissions According to EN 50081-1

Susceptibility According to EN 50082-1

Environmental Conditions

Ambient temp. operating range 0 to +50 oC

Relative humidity 10 to 95%, non-condensing

Mechanical Specifications

Dimensions (control panel housing - L x H x W) 175 x 96 x 96 mm

Weights (control panel housing) max. 0.7 kg

Material ABS with polycarbonate (front housing)

Insulation (Front / Housing) IP 54 / IP 40

± 0.01 pH

± 1 mV

± 0.5 oC

max. 500 Ω

24

Page 29

9 ACCESSORIES

Product Description Code no.

Ryton-body pH combination elec tr ode withou t AT C,

without potential matching pin

Ryton-body pH combination elec tr ode withou t AT C,

without potential matching pin, high temperature

and pressure rating

Ryton-body pH combination elec tr ode withou t AT C,

with potential matching pin

Ryton-body pH com bination electr ode with ATC (Pt

100), with potential matc hing pin

Ryton-body ORP Gold com bination electrode with

potential matching pin

Ryton-body ORP Platnium combination electrode

with potential matching pin

Note: Above pH/ORP electrodes can withstand a pressure up to 6 bar

(except for ECARHTTSO05B – 9 bar). These electrodes have

integral 5 meter measuring cable. Please ask your authorised

distributor or dealer for the prices, extension cables, tee joints,

electrode assembly and buffer solutions.

EC-ARTSO05B

EC-ARHTTSO05B

EC-ARGTSO05B

EC-100GTSO05B

EC-HTAUTSO05B

EC-HTPTTSO05B

10 GENERAL INFORMATION

10.1 Warranty

Eutech Instruments warrants this product to be free from significant

deviations in material and workmanship for a period of one year

from the date of purchase. If repair is necessary and has not been

the result of abuse or misuse within the warranty period, please

return by freight pre-paid. Eutech Instruments’ Customer Service

Dept. will determine if problem is due to deviations or customer

abuse. Out of warranty products will be repaired on a charge basis.

10.2 Packaging

The instrument is packaged in a corrugated box with a warranty

card, instruction manual and the following accessories:

• 17-way and 5-way (right-angled) terminal block [1 unit each]

• side threaded rod with catch [2 units]

• receptacle cable lug [1 unit]

• rubber gasket [1 unit]

25

Page 30

10.3 Return of Goods

Authorisation must be obtained from Eutech Instruments’

Customer Service Dept. to issue a RGA (Return of Goods

Authorisation) number before returning items for any reason. When

applying for authorisation, please include data requiring t he reason

of return. Items must be carefully packed to prevent damage in

shipment and insured against possible damage or loss. Eutech

Instruments will not be responsible for any damage resulting from

careless or insufficient packing.

Warning: Shipping damage as a result of inadequate packaging is

the user/distributor’s responsibility, whoever applicable.

Please follow the guidelines below before shipment.

10.4 Guidelines for Returning Unit for Repair

Use the original packaging material, if possible when shipping the unit

for repair. Otherwise wrap it with bubble pack and use a corrugated

box for better protection. Include a brief description of any faults

suspected for the convenience of Customer Service Dept., if possible.

26

Page 31

11 APPENDICES

11.1 Appendix 1

Jumper Positions - Internal to the controller

JP 1 Selects the input voltage 220 VAC.

JP 2 Selects the input voltage 110 VAC.

JP 3 Solder bridge selects between Pt100 and Pt1000.

Fuse Note that there is a fuse (slow-blow 100mA) internal

to the controller. Before opening the unit, ENSURE

that the power cable is physically separated from the

power supply. Replace fuse with the recommended

type only.

27

Page 32

11.2 Appendix 2

The following table shows the various pH values at different

temperature of the solution during calibration.

Temperature

o

C)

(

0 1.67 4.01 6.98 7.12 9.47 10.32

5 1.67 4.01 6.95 7.09 9.38 10.25

10 1.67 4.00 6.92 7.06 9.32 10.18

15 1.67 4.00 6.90 7.04 9.27 10.12

20 1.68 4.00 6.88 7.02 9.22 10.06

25 1.68 4.01 6.86 7.00 9.18 10.01

30 1.69 4.01 6.85 6.99 9.14 9.97

35 1.69 4.02 6.84 6.98 9.10 9.93

40 1.70 4.03 6.84 6.97 9.07 9.89

45 1.70 4.04 6.83 6.97 9.04 9.86

50 1.71 4.06 6.83 6.97 9.01 9.83

55 1.72 4.08 6.83 6.97 8.99 9.81

60 1.73 4.10 6.84 6.98 8.96 9.79

70 1.74 4.12 6.85 6.99 8.92 9.76

80 1.77 4.16 6.86 7.00 8.89 9.74

90 1.80 4.20 6.88 7.02 8.85 9.73

pH 1.68

(oxalate)

pH 4.01

(phthalate)

pH 6.86

(tetraoxalate)

pH 7.00

(neutral

phosphate)

pH 9.18

(tetra borate )

pH 10.01

(carbonate)

28

Page 33

11.3 Appendix 3

Simple Explanation on the Function of Hysteresis

SP1 Set to LO

SP2 Set to HI

4.0 4.5 9.5 10.0

SP1

FORWARD DIRECTION

REVERSE DIRECTION

The controller relay activates when the set-point is reached. In the

reverse direction, it does not de-activate when the value reaches the

set-point. Instead, it continues to be active till the value reaches the

amount set by the Hysteresis band.

RELAY ON

RELAY OFF

7.0

SP2

HYSTERESIS BAND

(DEFAULT = 0.5 pH)

29

Page 34

CALIBRATION RECORD

Calibration Date Electrode Slope Electrode Offset

Loading...

Loading...