Page 1

Alpha pH 550

Monitor

pH / ORP

Page 2

ROSS and the COIL trade dress are trademarks of Thermo Fisher Scientific Inc.

U.S. patent 6,793,787.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT,

PerpHecTion, pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink,

ROSS, ROSS Ultra, Sure-Flow, Titrator PLUS and TURBO2 are registered

trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTOBAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTOSTIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT,

DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental Product Authority,

Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy,

KAP, LabConnect, LogR, Low Maintenance Triode, Minimum Stir Requirement,

MSR, NISS, One-Touch, One-Touch Calibration, One-Touch Measurement,

Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture Pentrode, pHuture

Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB,

SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator

21, Stat Face, The Enhanced Lab, ThermaSense, Triode, T RIUMpH, Unbreakable

pH, Universal Access are trademarks of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

PerpHecT meters are protected by U.S. patent 6,168,707. PerpHecT ROSS

electrodes are protected by U.S. patent 6,168,707. ORION Series A meters and

900A printer are protected by U.S. patents 5,198,093, D334,208 and

D346,753.ionplus electrodes and Optimum Results solutions ar e protected by U.S.

patent 5,830,338.ROSS Ultra electrodes are protected by U.S. patent

6,793,787.ORP standard is protected by U.S. patent 6,350,367. No Cal electrodes

are protected by U.S. patent 7,276,142.© 2009 Thermo Fisher Scientific Inc. All

rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and

its subsidiaries.The specifications, descriptions, drawings, ordering information and

part numbers within this document are subject to change without notice.This

publication supersedes all previous publications on this subject.

Page 3

Preface

This manual serves to explain the use of the Al pha pH 550 Monitor. The manual

functions in two ways, firstly as a step by step guide to help the us er operate the

instrument. Secondly, it serves as a handy reference guide. This instruction manual

is written to cover as many anticipated applications of the Alpha pH 550 Monitor. If

you have doubts in the use of the instrument, please do not hesitate to contact your

nearest Alpha Authorised Distributor.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on part of Thermo

Scientific.

Thermo Scientific cannot accept any responsibilit y for damage or malfunction of the

unit due to improper use of the instrument.

Copyright © 2006

All rights reserved

Page 4

TABLE OF CONTENTS

1 INTRODUCTION 1

1.1 Before You Begin...........................................................................................1

1.2 Intended Use..................................................................................................1

1.3 Safety Instructions..........................................................................................2

1.4 Taking Out of Service / Correct Disposal of the Unit .....................................2

2 GETTING STARTED 3

2.1 Description of Instrument...............................................................................3

2.2 Measurement System....................................................................................4

2.3 Connecting Peripherals.............................................................................5

2.4 Installation....................................................................................................9

2.5 Di sp l ay & K ey p ad .......................................................................................11

3 OPERATION 14

3.1 Measurement mode.......................................................................................14

3.2 Menu Overview..............................................................................................15

4 CALIBRATION MODE 16

4.1 Preparing the Monitor & Electrode for Calibration.........................................16

4.2 Entering pH/ORP Calibration Mode...............................................................16

4.3 pH Calibration ................................................................................................17

4.4 ORP Calibration .............................................................................................21

4.5 Temperature Calibration ................................................................................ 22

5 SETUP MODE 23

5.1 Enter Setup mode ..........................................................................................23

5.2 E

lectrode Offset Setti

ngs ...............................................................................24

5.3 Temperature Settings.....................................................................................25

5.4 Buffer Selection Settings................................................................................27

5.5 Configuration Settings....................................................................................28

5.6 Viewing Electrode Properties.........................................................................30

6 TECHNICAL SPECIFICATIONS 32

7 LIST OF ACCESSORIES 33

7.1 Thermo Scientific Order Codes......................................................................33

7.2 Eutech Instruments Order Code ....................................................................34

8 TROUBLESHOOTING 35

9 GENERAL INFORMATION 36

9.1 Warranty.........................................................................................................36

9.2 Return of Goods.............................................................................................36

9.3 Guidelines for Returning Unit for Repair........................................................36

9.4 Maintenance and Cleaning............................................................................37

10 APPENDICES 38

10.1 Appendix 1 – pH Buffer Values at Various Temperatures............................. 38

10.2 Appendix 2 – Abbreviations Used in LCD......................................................38

Page 5

1 INTRODUCTION

1.1 Before You Begin

Thank you for purchasing the Alpha pH 550 Monitor.

The construction of the Alpha pH 550 Monitor employs leading edge technology

and complies with safety regulations currently in force. Notwithstanding this,

improper use could lead to hazards for the user or a third-party, and/or adverse

effects on the plant or other equipment. Therefore, the operating instructions must

be read and understood by the persons involved before working with the pH

Monitor.

The instruction manual must always be stored close at ha nd, in a place accessible

to all people working with the pH Monitor.

If you have questions, which are not or insufficiently answered in this instruction

manual, please contact your authorized supplier. They will be glad to assist you.

1.2 Intended Use

Alpha pH 550 Monitors are intended solely for pH or ORP and temperature

measurement, as described in this instruction manual.

Any other use, or use not mentioned here, that is incompatible with the technical

specifications is deemed inappropriate. The oper ator is solely responsible for any

damage arising from such use.

Other prerequisites for appropriate use include:

– Comply with the instructions, notes and requirements set out in this instruction

manual.

– Comply with all local safety regulations concerning safety at work.

– Comply with all information a nd warnings in the documentation deali ng with the

products used together with the pH Monitor (housing, sensors, etc.).

– Comply with the local environmental and operational conditions.

- 1 -

Page 6

1.3 Safety Instructions

The Alpha pH 550 Monitor should be installed and

operated only by personnel familiar with the instrument

and who are qualified for such work.

A defective pH Monitor must neither be installed nor put

into service.

The Alpha pH 550 must only be operated under the

specified operating conditions (see section 6).

The Alpha pH 550 must not be repaired by the

customer.

No modifications to the Alpha pH 550 are allowed. T he

manufacturer/supplier accepts no responsibility for

damage caused by unauthorized modifications. The risk

is borne entirely by the user.

1.4 Taking Out of Service / Correct Disposal of the Unit

Taking out of Service

First disconnec t the unit from the power supply and then un do all electrical

connections.

Remove the unit from the wall.

Correct Disposal of the Instrument

When the Alpha pH 550 is permanently taken out of service, obey the local

environmental regulations for correct disposal or send the instrument to your local

distributor, they will take care of proper disposal.

- 2 -

Page 7

2 GETTING STARTED

2.1 Description of Instrument

The Alpha pH 550 Monitor is used for meas uring pH and temperature values. T he

pH values can be measured using industrial combination pH sensors. The

temperature values can be measured using 3-wire Pt100 / Pt1000 sensors. The

monitor can be used for applications such as water treatment and monitoring,

galvanic-decontamination, chemical processing, food processing, clean or

wastewater control and neutralization processes.

The pH Monitor has many user-friendly and safety features which include:

• Push-button keypad for calibration and setup

• Built-in non-volatile memory to ensure that calibration and other

information are not erased if power supply fails

• Menu-driven program that simplifies setup

• 1 or 2 point calibration with selectable USA or NIST standard pH

buffer set

• Automatic temperature compensation (ATC)

• Manual temperature compensation setting without the ATC probe,

with independent setting for calibration and process temperature

• Large dual display LCD for easy reading with clear multiple

annunciators, operational mode indicators and error indicators.

- 3 -

Page 8

A

2.2 Measurement System

A typical measurement system consists of:

• A pH process monitor

• A pH sensor with integrated or separate Pt100/Pt1000 temperature

sensor

• An appropriate measurement cable

• An immersion, flow or process assembly

lpha pH 550 Monitor

ESC

CAL

pH Monitor

lpha pH550

ENT

Power Adaptor

Housing and

Sensors

Measur ement Cable

(+9 V DC)

- 4 -

Page 9

2.3 Connecting Peripherals

2.3.1 Connection Terminals

Remove Back Cover:

Remove the screws from the four corners at the back of the pH Monitor. Remove

the back cover. The connectors are exposed on the back PCBA as shown in the

Figure 1 below.

Connectors:

• J11 – 24V DC power

• J8 – 9V DC power

J10 - pH electrode & Temperature probe connections (wiring has to be done in

J11 Connections

1. +ve

2. Gnd

J10 Connections

1. pH Sense

2. pH Reference

3. No Connection

4. No Connection

5. Pt 100 Compensate

6. Pt 100 Sense

7. Pt 100 GND

8. Potential Matching Pin

the detachable connector

24V DC

1)+v

J10

J8

9V DC Power

Screw

Figure 1: Outer Side of Back PCBA

- 5 -

Page 10

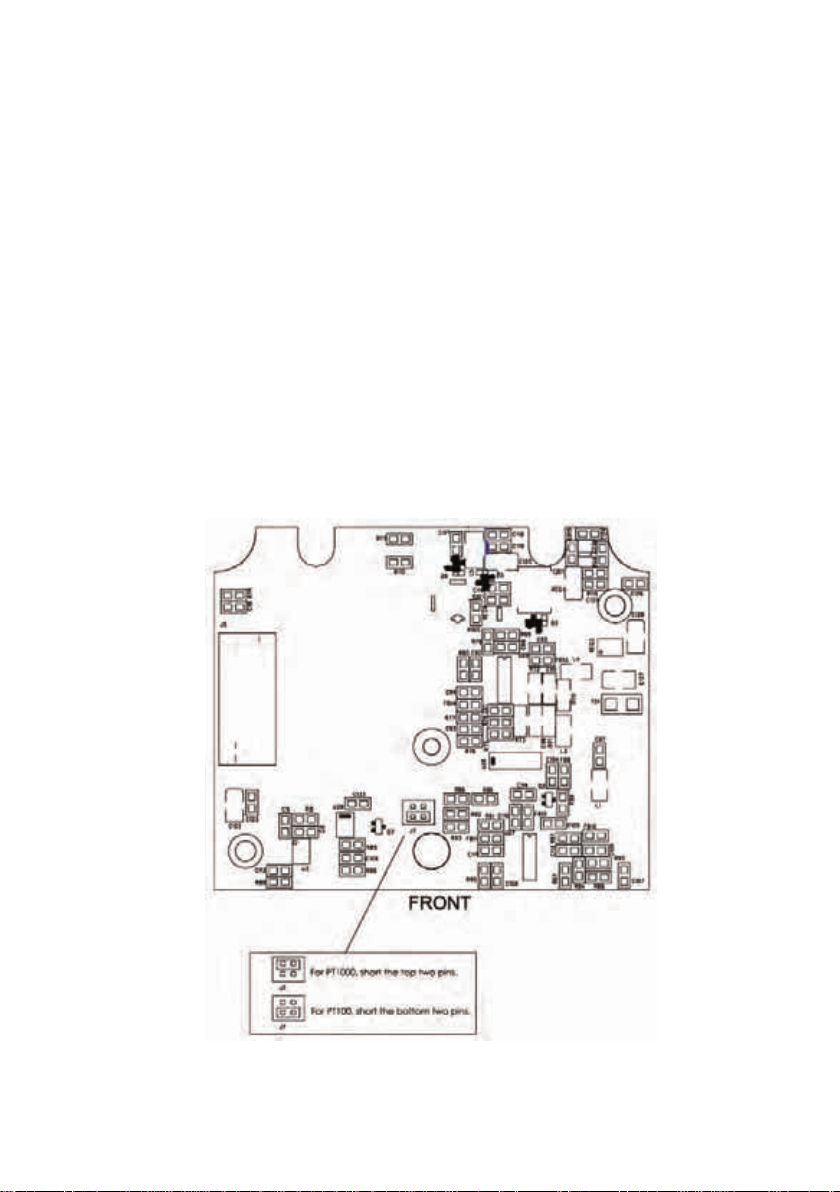

2.3.2 Switching Between PT100 & PT1000 Temperatu re Sensors

The Monitor supports both Pt100 & Pt1000 (2-wire or 3-wire) temperature sensors.

The default factory setting is Pt100. If you need to use Pt1000 temperature sensor,

you have to change the jumper setting (J7) as described below.

Remove Back Cover:

Remove screws from the four corners at the back of the pH Controller. Remove th e

back cover.

Remove Back PCBA:

Remove the screw located center of the back PCBA (Figure 1). Detach the back

PCBA from the Controller. Turn over the back PCBA. Locate J7 jumper on the inner

side of the back PCBA as shown in

Figure

2 below.

Figure 2: Inner Side of Back PCBA

Set Jumper J7:

Set the J7 jumper to required sensor (Pt100 or Pt1000) type

- 6 -

Page 11

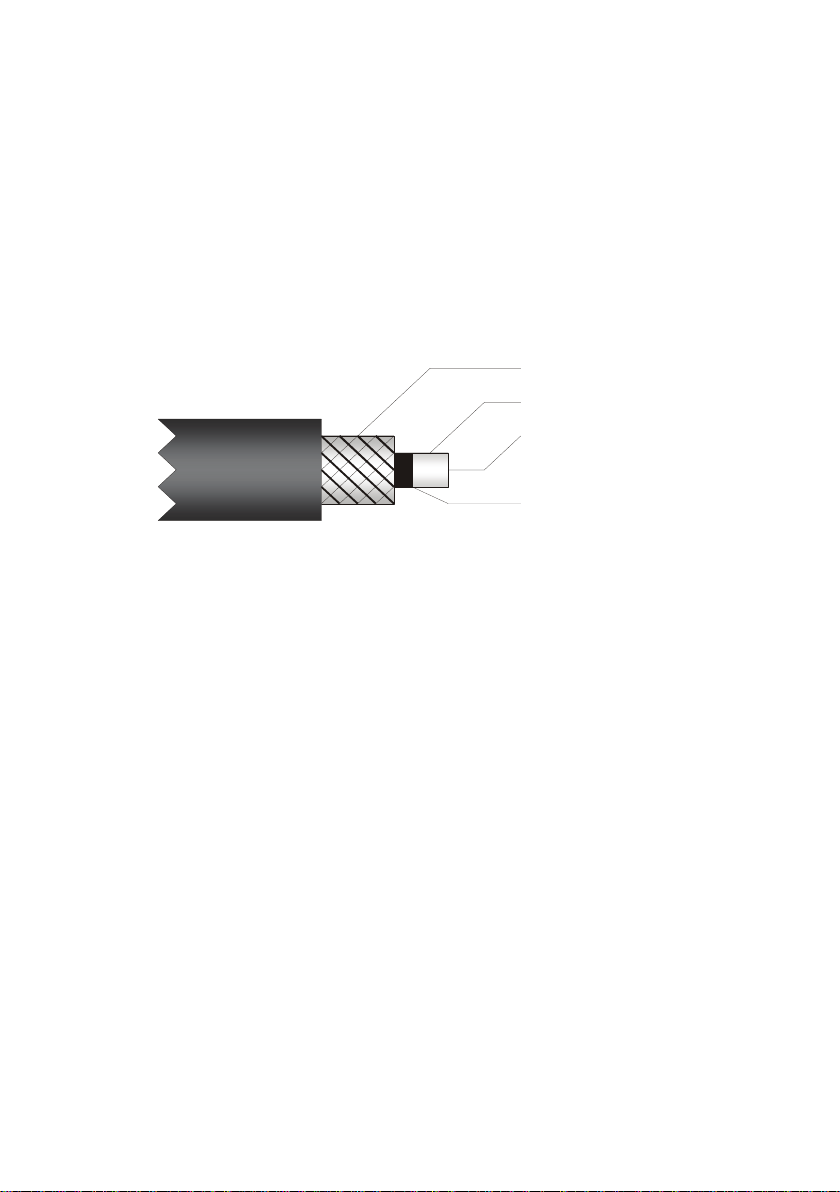

2.3.3 Connecting pH/ORP Electrode

1. If the pH/ORP electrode has a BNC connector, remove the BNC

connector from the cable.

NOTE: Oakton Instruments offers an optional ‘BNC to Spade Lug

adapter’ (Order code: 05994-90) that can be used with pH/ORP

electrode without removing the BNC connector.

2. Strip the insulation of the cable so that the bare wires are exposed

enough for connection as shown in Figure 3.

Insulation

Figure 3 : pH/ORP Electrode Cable

NOTE: Make sure to strip inner black layer (screen) to expose the

clear sheath.

3. Connect pH sensing wire to Pin 1 of J10 connector

4. Connect pH reference wire to Pin 2 of J10 connector

pH Reference Wire

Clear sheath

pH Sensing Wire

Screen

- 7 -

Page 12

2.3.4 Connecting Temperature Probe

For Automatic Temperature Compensated (ATC) pH readings, a 100Ω Pt RTD

temperature probe (2-wire or 3-wire) can be connected to the Controller.

3-Wire Probe:

1. Connect PT100 compensate wire to Pin 5 of J10 connector

2. Connect PT100 sense wire to Pin 6 of J10 connector

3. Connect PT100 GND wire to Pin 7 of J10 co nnector

2-Wire Probe:

1. Short Pin 5 & 6 of J10 connector using a small piece of wire

2. Connect PT100 sense wire to Pin 6 of J10 connector

3. Connect PT100 GND wire to Pin 7 of J10 connector

2.3.5 Connect Potential Matching Pin (PMP)

If using an electrode with a PMP, connect the additional wire (PMP) from the pH

electrode to Pin 8 of J10 connector. This liquid electrical reference wire is only used

when the pH Controller is configured to ‘Symmetrical mode of operation’. Refer

section 5.5 for details on symmetrical mode of operation.

- 8 -

Page 13

2.4 Installation

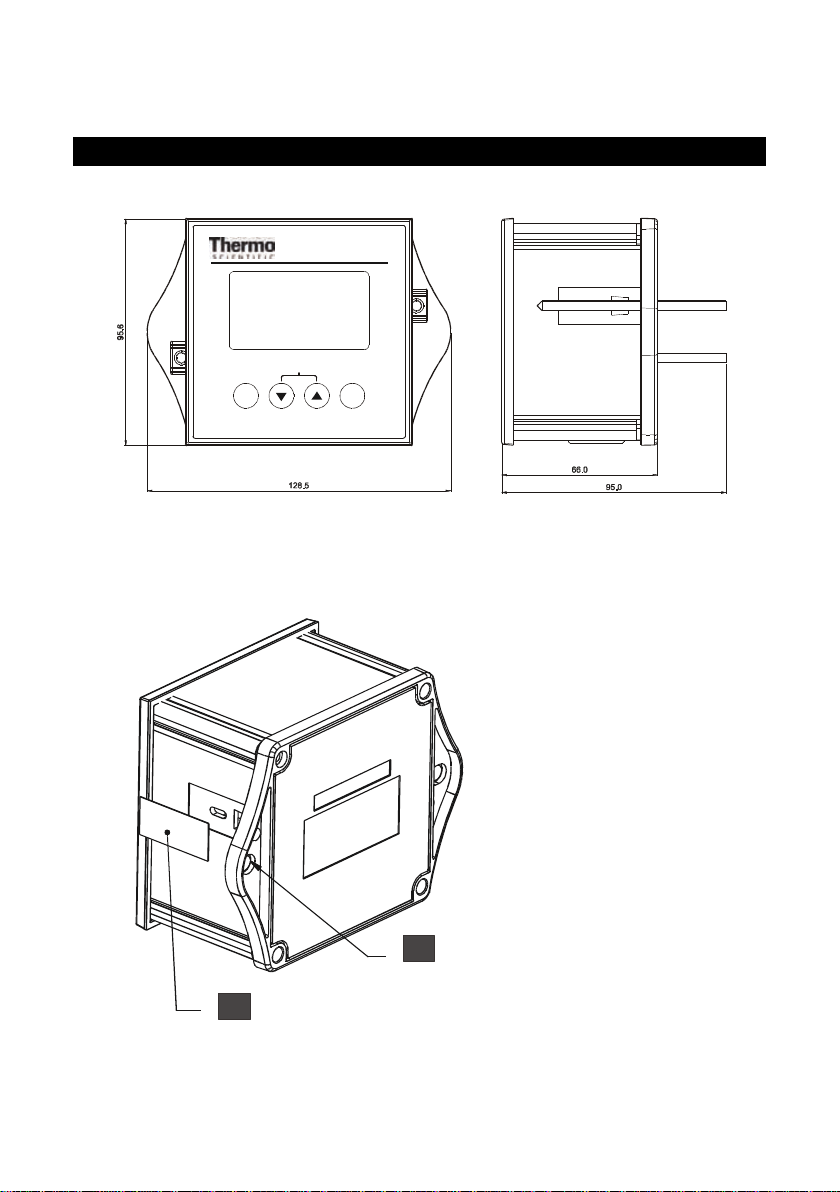

2.4.1 Mechanical Dimensions

CAL

PH/ORP RF Transmitter

2.4.2 Wall Mount

2

Alpha pH 550

Alpha pH 600

ESC

ENT

pH Monitor

Pierce through holes at both sides

11

Cover the catch slots at both sides

with overlays

- 9 -

Page 14

f

f

A

r

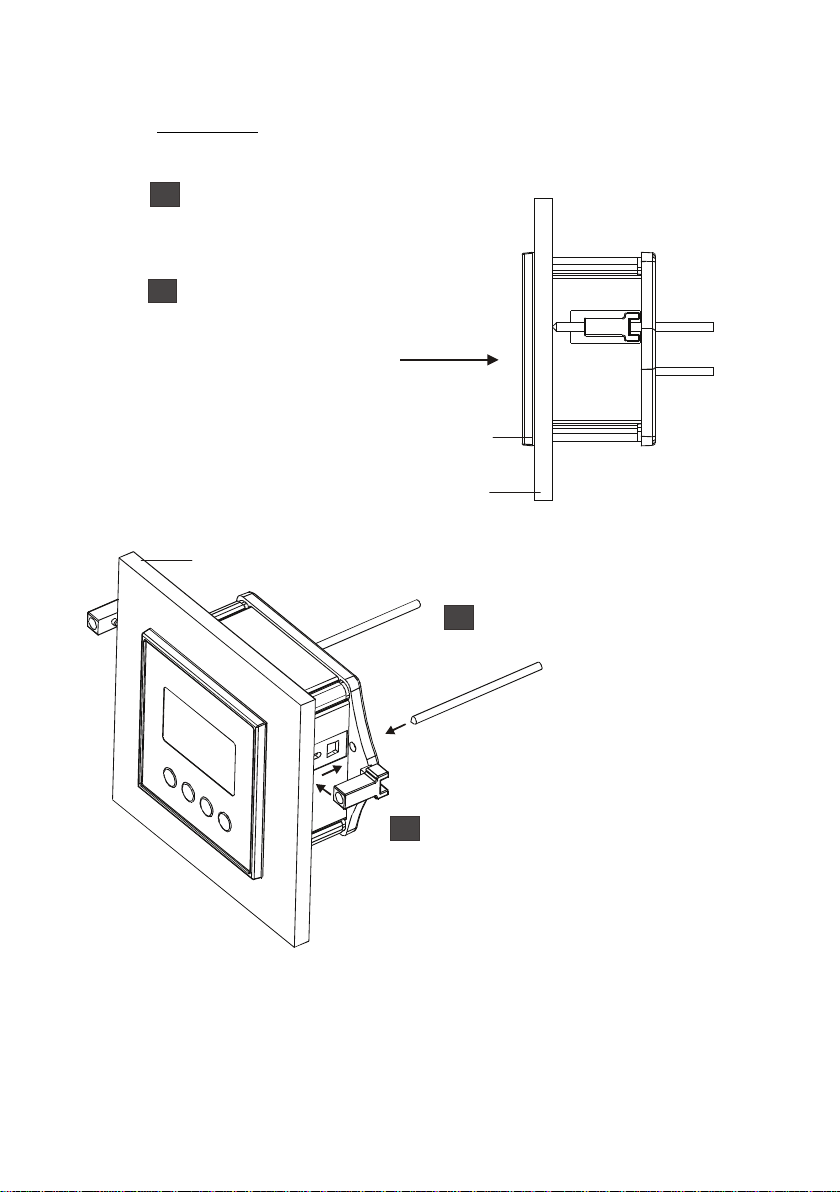

2.4.3 Panel Mount

Prepare panel cut-out o

1

1

92.0 mm X 92.0 mm

Remove back cover o

2

pH Monitor and slide it

through panel cut-out

Panel

Gasket

Panel

Insert threaded rods through catch

4

until pH Meter is held against panel

ttach catch to both sides

3

of pH Mete

- 10 -

Page 15

A

2.5 Display & Keypad

2.5.1 Display Overview

The Liquid Crystal Display (LCD) of Alpha pH 550 has two alpha-numerical displa ys

(Upper and a Lower).

• Upper display: Measured pH, mV or relative mV value are

displayed when the Monitor is in normal operation (measurement)

mode.

• Lower display: Measured temperature value is displayed whe n the

Monitor is in normal operation (measurement) mode. In pH

Calibration mode, standard pH buffer values are displayed here:

while measured mV values are displayed in the ORP Calibration

mode.

The two displays indicate function names, options & settings in Setup m ode. Refer

‘Appendix 2 – Abbreviations Used in LCD’ for more details.

The LCD also consists of various mode indicators, status annunciators and unit of

measurement indicators.

SETUP MEAS CAL

READY

ERR

-8.8.8.8

-8.8.8.8

- 11 -

R.mV

pH

°C

pH

TC

°F

Page 16

Mode Indicators

MEAS

SETUP

CAL

Status Annunciators

READY

ATC

ERR

Measurement mode; blinks in Symmetric mode

(Refer Section 3.1& 5.5 )

Setup mode (Refer Section 5)

Calibration mode (Refer Section 4)

Appears when the reading is stable

Appears when Automatic Temperature Compensation (ATC) is

enabled.

Not visible when Manual Temperature Compensation (MTC) is

enabled.

Flashes if the temperature probe is faulty in its ATC mode.

(Refer Section 5.3)

Appears when an error occurs (Eg. wrong key pressed)

Electrode annunciator. Appears when viewing electrode properties

or during calibration error

Buffer annunciator. Appears in calibration mode

Units of Measurement Indicators

mV

R.mV

pH

ºC

ºF

Millivolt. Appears in ORP measurement / calibration modes

(Refer Section 3.1, 4.4)

Relative Millivolt

Appears in pH measurement/calibration modes

(Refer Section 3.1,4.3)

Temperature in Celsius (Refer Section 5.3)

Temperature in Fahrenheit (Refer Section 5.3)

- 12 -

Page 17

2.5.2 Key Functions

Alpha pH 550

Alpha pH 60 0

ESC

Key Description

CAL

Enter Calibration mode.

Enter Setup mode

Access sub screens (parameters) within a group of settings in

ENT

Setup mode

Confirm (save) setup parameters and numerical values

Start/Confirm calibration in Calibration mode.

Select a group of settings in Setup mode.

Select parameters and increment/decrement numerical values in

Setup and Calibration modes.

(When pressed continuously, speed of value increment/decrement

increases)

Returns to Measurement mode when both keys are pressed

simultaneously.

CAL

pH Monitor

PH/ORP RF Tra n smitter

ENT

- 13 -

Page 18

3 OPERATION

3.1 Measurement mode

When the pH Monitor is powered on, the display shows all the LCD segments

briefly, and then automatically enters into the Measurement mode.

MEAS

READY

pH

7.00

°C

25.0

The mode indicator ‘MEAS’ at the top of the displa y indicat es that the pH monitor is

in Measurement mode; ‘MEAS’ blinks when in Symmetric mode. The upper alph anumerical display shows the measured pH or mV value, while the lower display

shows the temperature value. The indicator “pH” or “mV” at the upper right side of

the display indicates the current measurement mode. (Refer Section 5.5 for

switching measurement modes)

NOTE:

From measurement mode you can access:

For more details, refer section 4 for Calibration mode and section 5 for Setup

mode.)

To guarantee accurate readings, the measuring system (the pH

Transmitter and the sensor) must be calibrated regularly.

• Calibration mode (by pressing CAL key)

• Setup mode (by pressing ENT key)

ATC

- 14 -

Page 19

3.2 Menu Overview

3.2.1 Alpha pH 550

READY

MEAS

CAL

ENT

SETUP

SETUP

SETUP

SETUP

SETUP

CAL

ENT ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

pH

°C

ATC

- 15 -

Page 20

4 CALIBRATION MODE

4.1 Preparing the Monitor & Electrode for Calibration

Before starting calibration, make sure that the pH Monitor is in appropriate

measurement mode (pH or ORP). When the monitor is switched on, it starts up with

the measurement mode last used. For example, if the pH Monitor is switched off in

ORP measurement mode, it starts up in ORP mode when it is switched on. (Refer

Section 5.5 for switching measurement modes)

Be sure to remove the protective electrode storage bottle or rubber cap of the

electrode before calibration or measurement. If the electro de has been stored dry,

wet the electrode in tap water for 10 minutes before calibrating or taking readings to

saturate the pH electrode surface and minimize drift.

Rinse the electrode in de-ionized water after use, and store in electrode storage

solution. If storage solution is not available, use pH 4.01 or 7.00 buffer solution.

Do not reuse buffer solutions after calibration. Contaminants in the solution can

affect the calibration, and the accuracy of the measurements.

The pH Monitor features two internationally recognized pH buffer standards. Select

the buffer standard you require in the setup mode. (Refer Section 5.4) Available

buffer options are:

• USA buffers --- pH 4.01, 1.68, 7.00, 10.01 and 12.45

• NIST buffers --- pH 4.01, 1.68, 6.86, 9.18 and 12.45

4.2 Entering pH/ORP Calibration Mode

While in measurement mode, press the CAL key to access calibration mode. LCD

indicates ‘CAL PH’ (when measurement mode is pH) or ‘CAL OrP’ (when

measurement mode is ORP).

READY

MEAS

pH

°C

ATC

CAL

CAL

HOLD

To quit Calibration Mode

- 16 -

ENT

Calibration Mode

pH Calibration

OPR Calibration

Temp. Calibration

&

- See Section 4.3

- See Section 4.4

- See Section 4.5

Page 21

NOTES:

• T o exit calibration mode at any time durin g calibration, press ▲

and ▼ keys simultaneously (escape). The pH Monitor returns

to the measurement mode and the old calibration values re main

active

• The calibration is always carried out in the units of

measurement (pH or mV), selected in setup mode

4.3 pH Calibration

The pH Monitor is capable of calibration of up to 2 points usin g USA or NIST pH

buffer standards. All new calibration values will automatically override existing

calibration data. pH buffer values are referenced to 25

measurement mode is set to pH. (Refer Section 5.5 for switching measurement

modes). All pH buffer values have window of up to ± 1 pH tolerance during

calibration. Calibration error can be occurred if the measur ed pH val ue e xceeds this

window. If you wish to abort the pH calibration, press ▲ and ▼ keys simultaneously

and the pH Monitor reverts to pH measurement mode.

4.3.1 For USA Standard Buffer

Make sure that the pH Monitor is set to accept USA standard buffer in the Setup

mode. (Refer Section 5.4 for Buffer Selection Settings) The factory default is USA

standard. It is recommended that you perform 2-point calibration at room

temperature (25

o

C), starting with the first buffer at pH 7.00 followed by any other

buffer value. (pH 4.01, 1.68, 10.01 or 12.45)

1-Point Calibration:

CAL

2

pH

CAL

pH

CAL

HOLD

HOLD

CAL

1

ENT

READY

HOLD

From pH measurement mode press CAL key to enter calibration mode as

11

described in section 4.2. The LCD shows ‘CAL PH’. Press ENT key to

begin calibration.

Place the electrode in pH 7.00 buffer. Immerse the temperature probe in

2

the buffer solution if ATC mode is enabled. Immerse the potential matching

pin in the buffer if symmetrical mode is enabled. The buffer annunciator

appears in LCD. Lower display shows pH 7.00 (USA standard buffer).

o

C. Make sure the

3

mV

ENT

pH

READY

MEAS

4

PH

°C

ATC

- 17 -

Page 22

3

4

2-Point Calibration:

1

CAL

ENT

Upper display shows the current uncalibrated pH reading. Allow the reading

to stabilize. LCD shows ‘READY’ annunciator when the reading is stable.

Press CAL key to confirm the reading.

The calibration is completed. The pH Monitor re-calculates electrode

properties based on the calibration. The new slope (in mV) is shown in the

upper display and pH reading at 0mV (pH7.00 ± offset) is shown in the

lower display.

Press ENT key to exit from the calibration.

The pH Monitor reverts to pH measurement mode.

NOTE:

Refer notes at the end of this section for additional

information and possible error indicators of calibration

process

4

mV

CAL

pH

MEAS

READY

ENT

READY

2

CAL

pH

ENT

READY

pH

READY

3

CAL

pH

ENT

CAL

pH

3

CAL

pH

ENT

pH

CAL

5

PH

°C

ATC

3

CAL

pH

READY

READY

CAL

ENT

pH

CAL

3

pH

ENT

pH

CAL

From pH measurement mode press CAL key to enter calibration mode as

11

described in section 4.2. The LCD shows ‘CAL PH’. Press ENT key to

begin first calibration point.

Place the electrode in pH 7.00 buffer. Immerse the temperature probe in

2

the buffer solution if ATC mode is enabled. Immerse the potential matching

pin in the buffer if symmetrical mode is enabled. The buffer annunciator

appears in LCD. Lower display shows pH 7.00 (USA standard buffer).

Upper display shows the current uncalibrated pH reading. Allow the reading

to stabilize. LCD shows ‘READY’ annunciator when the reading is stable.

- 18 -

Page 23

Press ENT key to confirm the reading.

The pH Monitor moves to the second calibration point. The lower display

3

shows next standard buffer value (pH 4.01). Use ▲ and ▼ keys to select

your second buffer from one of the preset values: pH 4.01 or 1.68 or 10.01

or 12.45. Remove the electrode from the first buffer, rinse and then

immerse it into the second buffer. Allow the reading to stabilize. LCD shows

‘READY’ annunciator when the reading is stable.

Press ENT key (or CAL key) to confirm the reading.

The calibration is completed. The pH Monitor re-calculates electrode

4

properties based on the calibration. The new slope (in mV) is shown in the

upper display and pH reading at 0mV (pH7.00 ± offset) is shown in the

lower display.

Press ENT key to exit from the calibration.

The pH Monitor reverts to pH measurement mode.

55

NOTES:

• To exit from pH calibration mode without confirming cali bration, press

▲ and ▼ keys together.

• When confirming the buffer measurement, if measured pH value is not

within ±1.00pH from selected buffer value, the electrode annunciator

blinks and ERR indicator appears in the display. This error can also

occur if non-standard buffers are used or the electrode has worn out.

If this happens, press both ▲and ▼ keys together to restart the

calibration beginning from Step1.

• When calibrating with manual temperature compensation, the meter

automatically changes from the preset ‘process temperature’ to the

‘calibration temperature’. After leaving the calibration mode, the pH

Monitor reverts back to ‘process temperature’.

4.3.2 For NIST Buffer

Make sure that the pH Monitor is set to accept NIST standard buffer in the Setup

mode. (Refer Section 5.4 for Buffer Selection Settings) The factory default is USA

standard. It is recommended that you perform 2-point calibration at room

temperature (25

o

C), starting with the first buffer at pH 6.86 followed by any other

buffer value. (pH 4.01, 1.68, 9.18 or 12.45)

- 19 -

Page 24

1-Point Calibration:

1

CAL

HOLD

ENT

From pH measurement mode press CAL key to enter calibration mode as

11

described in section 4.2. The LCD shows ‘CAL PH’. Press ENT key to

begin calibration.

Place the electrode in pH 6.86 buffer. Immerse the temperature probe in the

2

buffer solution if ATC mode is enabled. Immerse the potential matching pin

in the buffer if symmetrical mode is enabled. The buffer annunciator

appears in LCD. Lower display shows pH 6.86 (NIST standard buffer).

Upper display shows the current uncalibrated pH reading. Allow the reading

to stabilize. LCD shows ‘READY’ annunciator when the reading is stable.

Press CAL key to confirm the reading.

The calibration is completed. The pH Monitor re-calculates electrode

3

properties based on the calibration. The new slope (in mV) is shown in the

upper display and pH reading at 0mV (pH7.00 ± offset) is shown in the

lower display.

Press ENT key to exit from the calibration.

The pH Monitor reverts to pH measurement mode.

4

2-Point Calibration:

1

CAL

ENT

READY

READY

HOLD

CAL

CAL

2

pH

CAL

HOLD

pH

CAL

3

mV

ENT

pH

READY

MEAS

4

PH

°C

ATC

2

pH

ENT

READY

pH

3

CAL

pH

ENT

pH

CAL

4

mV

CAL

READY

ENT

pH

MEAS

5

PH

°C

ATC

3

CAL

pH

READY

READY

READY

CAL

CAL

ENT

pH

CAL

3

pH

ENT

pH

CAL

3

pH

ENT

pH

CAL

- 20 -

Page 25

From pH measurement mode press CAL key to enter calibration mode as

11

described in section 4.2. The LCD shows ‘CAL PH’. Press ENT key to

begin first calibration point.

Place the electrode in pH 6.86 buffer. Immerse the temperature probe in the

2

buffer solution if ATC mode is enabled. Immerse the potential matching pin

in the buffer if symmetrical mode is enabled. The buffer annunciator

appears in LCD. Lower display shows pH 6.86 (NIST standard buffer).

Upper display shows the current uncalibrated pH reading. Allow the reading

to stabilize. LCD shows ‘READY’ annunciator when the reading is stable.

Press ENT key to confirm the reading.

The pH Monitor moves to the second calibration point. The lower display

3

shows next standard buffer value (pH 4.01). Use ▲ and ▼ keys to select

your second buffer from one of the preset values: pH 4.01 or 1.68 or 9.18 or

12.45. Remove the electrode from the first buffer, wash and then immerse it

into the second buffer. Allow the reading to stabilize. LCD shows ‘READY’

annunciator when the reading is stable.

Press ENT key (or CAL key) to confirm the reading.

The calibration is completed. The pH Monitor re-calculates electrode

4

properties based on the calibration. The new slope (in mV) is shown in the

upper display and pH reading at 0mV (pH7.00 ± offset) is shown in the

lower display.

Press ENT key to exit from the calibration.

The pH Monitor reverts to pH measurement mode.

55

NOTES:

• To exit from pH calibration mode without confirming cali bration, press

▲ and ▼ keys together

• When confirming the buffer measurement, if the measured pH value is

not within ±1.00pH from selected buffer value, the electrode

annunciator

blinks and ERR indicator appears in the display. This

error can also occur if non-standard buffers are used or the electrode

has worn out. If this happens, press both ▲and ▼ keys together to

restart the calibration beginning from Step1

When calibrating with manual temperature compensation, the meter automatically

changes from the preset process temperature to the c alibration temperature. After

leaving the calibration mode, the pH Monitor reverts back to process temperature.

4.4 ORP Calibration

The pH Monitor allows a single point ORP calibration. ORP calibration process is

available only when the measurement mode is set to ORP. (Refer Section 5.5 for

switching measurement modes).

- 21 -

Page 26

CAL

3

mV

ENT

READY

MEAS

R.mV

4

°C

ATC

HOLD

CAL

1

ENT

READY

HOLD

CAL

2

mV

READY

HOLD

From ORP measurement mode press CAL key to enter calibration mode

11

as described in section 4.2. The LCD shows ‘CAL OrP’. Press ENT key to

begin calibration.

Place the electrode in a standard ORP solution of known OPR value.

2

Immerse the temperature probe in the buffer solution if ATC mode is

enabled. Immerse the potential matching pin in the buffer if symmetrical

mode is enabled. The buffer annunciator

& electrode annunciator

appear in LCD. The upper display shows the current mV output of the

electrode with offset adjustment (if any). The lower display shows the

default (uncalibrated) mV output of the electrode. Allow the reading to

stabilize. LCD shows ‘READY’ annunciator when the reading is stable.

Press ▲ or ▼ key to set the upper display value to the ORP value of the

solution. Allowable range: -150mV to 150mV.

Press ENT key to confirm the value.

3

The pH Monitor reverts to ORP measurement mode.

4

4.5 Temperature Calibration

Calibrate temperature probe only if temperature value displayed on the pH Monitor

is different from that of a calibrated thermometer. Refer to section 5.3 for further

information temperature settings.

- 22 -

Page 27

5 SETUP MODE

5.1 Enter Setup mode

The setup mode allows you to customize the settings of the pH Monitor to suite your

requirements. While in measurement mode, press the ENT key to access setup

mode. LCD shows ‘SETUP’ mode indicator and the first page of setup (OFS – offset

settings). Press ▲ or ▼ key to access other pages of the setup mode.

READY

MEAS

ENT

pH

°C

ATC

SETUP

ENT

ENT

SETUP

SETUP

SETUP

SETUP

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

NOTES:

• To exit setup mode at any time press ▲ and ▼ keys

simultaneously (escape). The pH Monitor returns to the

measurement mode.

- 23 -

Page 28

5.2 Electrode Offset Settings

NOTE:

In applications where continuous pH measurement is required, it may not be

convenient to remove the electrode for calibration. In such cases, an on-line offset

adjustment is recommended. The pH Monitor allows you set an offset of up to ±

2.00pH to compensate for errors in the pH electrode.

The pH Monitor adds or subtracts the offset value from the measured pH value and

displays the corrected value. However, if you need to offset the value beyond the

average offset you would expect in your application type, consider a full calibrati on

or even electrode replacement.

To Determine the Offset Value:

1. Take a sample from the liquid of pH measurement. Record the pH reading

2. Measure the pH value of your sample using another calibrated pH meter

‘Electrode Offset Setting’ is not available when the pH Monitor is

configured for ORP measurement mode. (Refer Section 5.5 for

switching measurement modes)

of the pH Monitor at the time the sample was taken.

having its own electrode (pH tester, hand-held meter or bench meter)

3. The difference between these two readings is the offset

SETUP

1

From pH measurement mode press ENT key to enter setup mode as

11

described in section 5.1. The LCD shows the first screen of setup mode

ENT

SETUP

READY

(OFS). Press ENT key to access electrode offset setting (OFS).

The upper display shows the last configured offset value (if any), otherwise

2

zero. The lower display shows currently measured pH reading (including

last configured offset value). Allow the reading to stabilize. LCD shows

‘READY’ annunciator when the reading is stable.

Press ▲ or ▼ key to set the upper display to the newly calculated offset

value.

As the upper display value (offset) changes, the pH Monitor adjust the lower

3

reading automatically to suit the new offset value. Up to ± 2.00 pH offset is

- 24 -

2

pH

pH

SETUP

READY

3

pH

pH

ENT

Page 29

A

allowed.

Press ENT key to confirm the value. The pH Monitor reverts to OFS

screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

5.3 Temperature Settings

Automatic Temperature Compensation (ATC):

The pH values other than pH 7.00 are affected by temperature. Use ATC feature of

the pH Monitor to compensate for pH changes when the temperature of the sample

or process liquid fluctuates. Connect a separate temperature probe (Pt100/pt1000)

to the pH Monitor if an integrated pH/Temperature probe is not available.

Manual Temperature Compensation (MTC):

Set the pH Monitor to MTC (disable ATC) when the temperature of sample or

process liquid is constant and a temperature probe is not available. If you disable

ATC, the pH Monitor allows you to set your process temperature (P.ºC) and

calibration temperature (C.ºC). This allows calibration at a different temperature

other than the process temperature. Example: Setting calibration temperature of

25°C lets you calibrate using standard solutions at 25°C, even if your process

temperature is different from 25°C.

SETUP

1

SETUP

ENT

2

SETUP

ENT

°C

3

SETUP

ENT

°C

4

SETUP

°C

TC

5

°C

ATC

ENT

SETUP

2

SETUP

ENT

°F

3

SETUP

ENT

°C

6

From pH or ORP measurement mode press ENT key to enter

11

setup mode as described in section 5.1. The LCD shows the first

SETUP

ENT

7

ENT

screen of setup mode (OFS). Press ▲ or ▼ key to select

Temperature settings screen (SET ºCF).

Press ENT key to access temperature settings (SET ºCF).

- 25 -

Page 30

Selecting unit of measurement for temperature: The upper

2

display shows ‘Unit’ and the lower display shows the last configured

unit of measurement for temperature.

Press ▲ or ▼ key to select the desired units for temperature (ºC

or ºF). Press ENT key to confirm your selection.

Enable/disable ATC: The lower display shows ‘AtC’ and the upper

3

display shows the last configured ATC selection (‘On’ or ‘OFF’).

Press ▲ or ▼ key to enable (ATC On) or disable (ATC OFF)

automatic temperature compensation. Press ENT key to confirm

your selection.

If ATC enabled (ATC On):

Setting temperature offset: The upper display shows the

4

last configured temperature offset value (if any), otherwise the

default is zero. The lower display shows currently measured

temperature reading (including last configured offset value).

LCD shows ‘ATC’ annunciator in lower-right corner.

Place a thermometer, which is known to be accurate, in your

sample or process liquid. Make sure your temperature probe

is placed in the same liquid. Compare the stabilized

temperature reading displayed on the monitor with the

thermometer. If there is a difference between the two readings

(offset), you can adjust the reading of the monitor. Press ▲ or

▼ key to adjust the lower display to the correct temperature

value.

As the lower display value changes, the pH Monitor adjust the

55

upper display reading automatically to suit the new offset

value. Up to ± 10 ºC/ ± 18 ºF offset is allowed.

Press ENT key to confirm the value. The pH Monitor reverts

to SET ºCF screen.

If ATC disabled (ATC OFF):

Setting process temperature: The lower display shows

6

‘P.ºC’ and the upper display shows the last configured

process temperature. Press ▲ or ▼ key to adjust the upper

display to desired process temperature. Allowable range: –

10.0 to 125.0°C / 14.0 to 257°F.

Press ENT key to confirm the process temperature.

Setting calibration temperature: The lower display shows

7

‘C.ºC’ and the upper display shows the last configured

calibration temperature. Press ▲ or ▼ key to adjust the

upper display to desired calibration temperature. Allowable

range: –10.0 to 125.0°C / 14.0 to 257°F.

Press ENT key to confirm the calibration temperature. The

pH Monitor reverts to SET ºCF screen.

- 26 -

Page 31

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

To exit from any intermediate steps, press ▲ and ▼ keys simultaneously

(escape). The pH Monitor returns to the first screen of temperature settings SET

ºCF.

5.4 Buffer Selection Settings

NOTE:

This allows you to set the pH Monitor to accept either USA or NIST pH buffer

standard group during pH calibration.

The buffer selection setting is only available if the monitor is

configured for pH measurement mode.

Buffer Group pH Buffer Points

USA pH 4.01, 1.68, 7.00, 10.01 & 12.45

NIST pH 4.01, 1.68, 6.86, 9.18 & 12.45

SETUP

HOLD

1

SETUP

ENT ENT

HOLD

SETUP

HOLD

2

2

ENT

From pH measurement mode press ENT key to enter setup mode

11

as described in section 5.1. The LCD shows the first screen of

setup mode (OFS). Press ▲ or ▼ key to select buffer settings

screen (bUFF).

Press ENT key to access buffer settings (bUFF).

Selecting buffer group: The lower display shows the last

2

configured buffer group. Press ▲ or ▼ key to select the required

buffer group (‘USA’ or ‘nST’).

- 27 -

Page 32

Press ENT key to confirm your selection. The pH Monitor reverts

to bUFF screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

5.5 Configuration Settings

Configuration settings let you configure the pH Monitor to different measurement &

operation modes & reset the pH Monitor to factory defaults.

Asymmetrical Operation Mode (ASY):

This is the default mode of operation of the pH Monitor, which is suitable for most

applications where sample (or process) liquid is not interfered by adjac ent electrical

noise.

Symmetrical Operation Mode (SY):

This is mode of operation is recommended for applications where sample (or

process) liquid is subjected to high electrical interference and therefore the pH

reading becomes unstable. When the pH Monitor is set to s ymmetrical mode, you

should immerse the potential matching pin in the sample (or process) liquid or use a

pH electrode with built-in potential matching pin. The ‘MEAS’ indicator blinks when

the pH Monitor is set to Symmetric mode.

- 28 -

Page 33

SETUP

1 2

SETUP

ENT

SETUP

SETUP SETUP

ENT

2

SETUP

ENT

3

ENT

3

ENT

From pH (or ORP) measurement mode press ENT key to enter

11

setup mode as described in section 5.1. The LCD shows the first

screen of setup mode (OFS). Press ▲ or ▼ key to select

configuration settings screen (Cnfg).

Press ENT key to access configuration settings (Cnfg).

Select measurement mode: The upper display shows the last

2

configured measurement mode (‘PH’ or ‘OrP’).

Press ▲ or ▼ key to select your desired measurement mode.

Press ENT key to confirm your selection.

NOTE: When the measurement mode is changed, the relay

operation parameters (described in section Error! Reference

source not found.) will be reset back to their default values.

Select operation mode: The upper display shows the last

3

configured operation mode. (‘ASY’ or ‘SY’).

Press ▲ or ▼ key to select your desired operational mode.

Press ENT key to confirm your selection.

Reset to factory defaults: The display shows ‘nO dEF’.

4

Press ▲ or ▼ key to select:

nO dEF :

No default reset of the pH Monitor. User configured

values remain active, when confirmed by pressing

ENT key.

FCt dEF:

Reset all settings of the pH Monitor to factory

defaults, when confirmed by pressing ENT key.

SETUP

SETUP

READY

MEAS

4

4

ENT

4

ENT

pH

°C

ATC

- 29 -

Page 34

CAL dEF:

Reset all calibration settings of the pH Monitor to

factory defaults, when confirmed by pressing ENT

key.

Press ENT key to confirm your selection.

- If ‘nO dEF’ was selected, the pH Monitor reverts to Cnfg screen.

Press ▲ or ▼ key to access other setup screens or

press ▲ and ▼ key simultaneously (escape) to return

to measurement mode.

- If ‘FCt dEF’ or ‘CAL dEF’ was selected, the pH Monitor performs

the selected reset and returns to measurement mode.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

To exit from any intermediate steps, press ▲ and ▼ keys simultaneously

(escape). The pH Monitor returns to the first screen configuration settings (Cnfg).

5.6 Viewing Electrode Properties

Each time you calibrate your pH electrode, the pH Monitor re-calculates slope &

offset of the electrode and shown in the LCD at the end of cal ibration. The setup

mode allows you to view slope & offset values at any time.

NOTE:

When the measurement mode is set to ORP, only the offset value of

the electrode is displayed.

SETUP

HOLD

1

SETUP

ENT

For pH measurement mode

SETUP

For ORP measurement mode

2

mV

ENT

pH

2

mV

ENT

- 30 -

Page 35

From pH (or ORP) measurement mode press ENT key to enter

11

setup mode as described in section 5.1. The LCD shows the first

screen of setup mode (OFS). Press ▲ or ▼ key to select viewing

electrode properties screen (CdAt).

Press ENT key to view electrode properties (CdAt).

2

Electrode status: The electrode annunciator

LCD. For pH measurement mode, the slope (in mV) is shown in the

upper display and pH reading at 0mV (pH7.00 ± offset) is shown in

the lower display.

For ORP measurement mode, the offset value (in mV) of the

electrode is shown in the upper display.

Press ENT key to quit from electrode properties screen. The pH

Monitor reverts to CdAt screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

appears in the

- 31 -

Page 36

6 TECHNICAL SPECIFICATIONS

General Specification

(a) pH

Measuring Range 0.00 to 14.00 pH

Resolution 0.01 pH

Accuracy ± 0.01 pH

(b) mV

Measuring Range -1000 to 1000 mV

Resolution 1 mV

Accuracy ± 1 mV

(c) Temperature

Measuring range -10.0 to +125.0 oC or +14.0 to +257 oF

Resolution 0.1

Relative accuracy ±0.5 oC

Sensor 2 wire / 3 wire - Pt100 or Pt1000 (Jumper

Compensation Automatic or Manual

Calibration

(a) pH

Number of calibration points 1 or 2 points

Number of calibration buffers USA: 1.68,4.01, 7.00, 10.01,12.45

(b) Temperature

Offset Adjustment ± 10 ˚C/ ± 18 ˚F

Input /Output

Input Asymmetrical / Symmetrical

Output None

Display

LCD 7 segments display with symbols for status

Electrical Data and Connections

pH/mV Input Screw Terminal (3.5mm pitch)

Connection terminal 8-pin & 2-pin terminal blocks

Other

Power Input Universal +9 V DC Adaptor and 24V DC

Dimensions (W x H x D) 96mm x 96mm x 66 mm

Weight (Estimated) 210g

Ambient Temp. operating range 0 to 40 oC

Maximum Relative Humidity 80% up to 31 oC decreasing linearly to 50% at

o

C

0.1 oF (Resolution is 0.1 oF up to 199.9 oF and

1 oF for 200 oF and above)

o

F

±1.0

Selectable)

NIST: 1.68,4.01, 6.86, 9.18 ,12.45

information

Supply

o

C

40

- 32 -

Page 37

7 LIST OF ACCESSORIES

7.1 Thermo Scientific Order Codes

pH Monitor Replacement and Accessories

Item Description Order Code

Alpha pH 550 Monitor TSPHCP0550

Combination pH electrode with 5m cable EC-ARTSO-05B

Combination pH electrode with PMP and 5m cable EC-ARGTSO-05B

Combination pH electrode with PT 100, PMP and 5m cable EC-100GTSO-05B

Combination pH electrode, submersible, with 5m cable EC-DA93506-05B

Combination Gold ORP electrode with PMP and 5m cable EC-HTAUTSO-05B

Combination Platinum ORP electrode with PMP and 5m cable EC-HTPTTSO-05B

Calibration Solutions

Item Description Order Code

pH 4.01 buffer solution, 480 ml bottle EC-BU-4BT

pH 7.00 buffer solution, 480 ml bottle EC-BU-7BT

pH 10.01 buffer solution, 480 ml bottle EC-BU-10BT

pH 4.01 buffer sachets, 20 ml x 20 pcs. EC-BU-4BS

pH 7.00 buffer sachets, 20 ml x 20 pcs. EC-BU-7BS

pH 10.01 buffer sachets, 20 ml x 20 pcs. EC-BU-10BS

pH De-ionized water rinse sachets, 20 ml x 20 pcs EC-RIN-WT

pH sachet assortment pack – 5 each of pH 4.01, pH 7.00, pH 10.01 and

de-ionized water sachets per box.

Protein cleaning solution for pH electrode EC-DPC-BT

Storage solution for pH electrode EC-RE-005

NOTE:

• pH buffer solutions (480 ml bottle) have ±0.01 pH accuracy at 25 °C

• pH buffer sachets are individually sealed, single use pouch containing 20

ml of fresh, contamination free calibration solution

• pH buffer sachets have ±0.01 pH accuracy at 25°C

EC-AST-PK

- 33 -

Page 38

7.2 Eutech Instruments Order Code

pH Monitor Replacement and Accessories

Item Description Order Code

Alpha pH 550 Monitor 56717-30

pH/Temp electrode with PMP and 10-ft cable 35807-20

Platinum ORP electrode with 10-ft cable 35801-21

BNC to spade lug adapter 05994-90

Calibration Solutions

Item Description Order Code

pH 4.01 calibration buffer, 500 ml 00654-00

pH 7.01 calibration buffer, 500 ml 00654-04

pH 10.01 calibration buffer, 500 ml 00654-08

pH 4.01 calibration buffer solution pouches, 20/box 35653-01

pH 7.00 calibration buffer solution pouches, 20/box 35653-02

pH 10.00 calibration buffer solution pouc hes, 20/box 35653-03

pH De-ionized water rinse sachets, 20 ml x 20 pcs 35653-00

Assortment pack – 5 each of pH 4.01, pH 7.00 and pH 10.00 solution

pouches.

Electrode cleaning solution 00653-06

Electrode storage solution 00653-04

35653-04

NOTE:

• To order Eutech accessories, contact the nearest Oakton distributor

- 34 -

Page 39

8 TROUBLESHOOTING

Problem Cause Solution

Power on, but no display a) Loose connections

b) Incorrect output voltage of

the power adaptor

Unstable pH reading a) Dirty electrode

b) Electrical noise

interference

Oscillating temperature

readings

Slow response a) Dirty / Oily electrode a) Clean electrode

Blinking ATC a) No temperature probe

Blinking electrode

annunciator

Or (pH) a) pH electrode is not

Or (Temperature) a) Temperature probe is not

a) Electrical noise

interference

connection during ATC

mode

a) Error in calibration a) Ensure calibration standard

connected

connected when ATC

enabled

a) Ensure cables make good

contact

b) Use an power adaptor with

specified output voltage

a) Clean electrode and

recalibrate

b) Switch to Symmetric mode

a) Ensure shield wire is

properly connected to pin 7

a) Ensure temperature sensing

cable makes good contact

solution is not contaminated.

Ensure electrode is clean.

a) Ensure electrode makes

good contact with

Transmitter

a) Ensure electrode makes

good contact with

Transmitter

- 35 -

Page 40

9 GENERAL INFORMATION

9.1 Warranty

This monitor is supplied with a one-ye ar warranty against significant deviations in

material and workmanship from date of purchase and a six-month warranty for

probe. Each instrument will have a warranty card with a specific ser ial nu mber. T he

warranty card must be endorsed by the Authorized Distributor at the point of sale.

If repair or adjustment is necessary and has not been the result of ab use or misuse

within the designated period, please return – freight pre-paid – and c orrection will

be made without charge. Thermo Scientific/ Eutech will determine if the product

problem is due to deviations or customer misuse.

Out of warranty products will be repaired on a charged basis.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

• Improper or inadequate maintenance by customer

• Unauthorized modification or misuse

• Operation outside of the environment specifications of the products

9.2 Return of Goods

Authorization must be obtained from our Customer Service Department or

authorized distributor before returning items for any reason. A “Return Goods

Authorization” (RGA) form is available through our authorized distributor. Please

include data regarding the reason the items are to be returned. For your protection,

items must be carefully packed to prevent damage in shipm ent and insured against

possible damage or loss. Thermo Scientific will not be responsible for damage

resulting from careless or insufficient packing. A restocking charge will be ma de on

all unauthorized returns.

NOTE: Thermo Scientific reserves the right to make improvements in design,

construction, and appearance of products without notice.

9.3 Guidelines for Returning Unit for Repair

Use the original packaging material if possible when shipping the unit for repair.

Otherwise wrap it with bubble pack and use a corrugated box for additional

- 36 -

Page 41

protection. Include a brief description of any faults suspected for the c onvenie nce of

Customer Service Dept., if possible.

9.4 Maintenance and Cleaning

Maintenance

The Alpha pH 550 Monitor contains no user repairable components. Please

contact your authorized distributor if there is any problem with the unit.

Cleaning

To remove dust, dirt and spots, the external surfaces of the pH Monitor may be

wiped with a damp, lint-free cloth. A mild household cleaner can also be used if

necessary.

- 37 -

Page 42

10 APPENDICES

10.1 Appendix 1 – pH Buffer Values at Various Temperatures

The following table shows the various pH values at different temperature of the

solution during calibration.

Temperature

(oC)

0 4.01 6.98 7.12 9.47 10.32

5 4.01 6.95 7.09 9.38 10.25

10 4.00 6.92 7.06 9.32 10.18

15 4.00 6.90 7.04 9.27 10.12

20 4.00 6.88 7.02 9.22 10.06

25 4.01 6.86 7.00 9.18 10.01

30 4.01 6.85 6.99 9.14 9.97

35 4.02 6.84 6.98 9.10 9.93

40 4.03 6.84 6.97 9.07 9.89

45 4.04 6.83 6.97 9.04 9.86

50 4.06 6.83 6.97 9.01 9.83

55 4.08 6.83 6.97 8.99 9.81

60 4.10 6.84 6.98 8.96 9.79

70 4.12 6.85 6.99 8.92 9.76

80 4.16 6.86 7.00 8.89 9.74

90 4.20 6.88 7.02 8.85 9.73

pH 4.01 pH 6.86 pH 7.00 pH 9.18 pH 10.01

10.2 Appendix 2 – Abbreviations Used in LCD

Abbreviation Description

ASy

AtC

bUFF

CAL

C.ºC

CdAt

Asymmetrical mode

Automatic Temperature Compensation

Buffer

Calibration

Calibration temperature

Electrode properties

- 38 -

Page 43

CnFg

dEF

FCt

OFS

Or

OrP

P.ºC

PH

Set

Sy

tyP

Ur

Configuration

Default values

Factory (defaults)

Offset

Reading is over range

Oxidation Reduction Potential

Process temperature

pH

Setting

Symmetrical mode

Type

Reading is under range

- 39 -

Page 44

Water Analysis Instruments

North America

166 Cummings Center

Beverly, MA 01915 USA

Toll Free: 1-800-225-1480

Tel: 1-978-232-6000

Dom. Fax: 1-978-232-6015

Int’l Fax: 978-232-6031

Europe

P.O. Box 254, 3860 AG Nijkerk

Wallerstraat 125K, 3862 CN Nijkerk,

Netherlands

Tel: (31) 033-2463887

Fax: (31) 033-2460832

Asia Pacific

Blk 55, Ayer Rajah Crescent

#04-16/24, Singapore 139949

Tel: 65-6778-6876

Fax: 65-6773-0836

www.thermo.com/process

© 2009 Thermo Fisher Scientific Inc.

All rights reserved. Thermo Fisher Scientific Inc.

68X216869 Rev 3

Loading...

Loading...