Eutech Instruments ALPHA PH 190 User Manual

gyM

sy...

Instruction Manual

αlpha pH 190

1/8 DIN pH / ORP Controller with

Temperature display and Transmitter

68X276106 Rev 0 11/2004

Technolo

adeEa

Preface

This manual serves to explain the use of the αlpha pH 190 controller/transmitter.

This manual functions in two ways: first, as a step-by-step guide to help you

operate the meter; second, it serves as a handy reference guide.

This manual is written to cover as many anticipated applications of the αlpha pH

190 controller/transmitter as possible. If there are doubts in the use of the αlpha

pH 190 controller/transmitter, do not hesitate to contact the nearest Eutech

Instruments Authorized Distributor.

Eutech Instruments cannot accept any responsibility for damage or malfunction to

the controller/transmitter caused by improper use of the instrument. Remember to

fill in the guarantee card and mail it to your Authorized Distributor or Eutech

Instruments Pte Ltd.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on the part of

Eutech Instruments Pte Ltd.

©

Copyright

Nov 2004

Eutech Instruments Pte Ltd. All rights reserved.

Rev 0 11/2004

TABLE OF CONTENTS

1 INTRODUCTION ...........................................................................................1

2 SAFETY INFORMATION..............................................................................2

3 OVERVIEW.................................................................................................... 3

3.1 FRONT PANEL.......................................................................................3

3.2 BACK PANEL......................................................................................... 4

3.3 WIRING.................................................................................................5

3.4 PANEL-MOUNTING THE CONTROLLER.....................................................6

4 MEASUREMENT MODE...............................................................................7

4.1 MEASUREMENT MODE DISPLAY..............................................................7

4.2 SET POINTS ADJUSTMENTS...................................................................7

5 PASSWORD..................................................................................................9

6 PH CALIBRATION......................................................................................11

7 ORP CALIBRATION ................................................................................... 14

8 TEMPERATURE CALIBRATION................................................................15

9 SETUP MODE.............................................................................................16

9.1 GENERAL INFORMATION......................................................................16

9.2 SETUP MODE OVERVIEW .....................................................................17

9.3 SET POINT 1 – P1.0............................................................................18

9.4 SET POINT 2 – P2.0............................................................................20

9.5 CONFIGURATION – P3.0...................................................................... 22

9.6 VIEWING CALIBRATION POINTS: PH OR ORP – P4.0 ............................24

9.7 VIEWING PH ELECTRODE DATA – P5.0................................................25

9.8 VIEWING ORP ELECTRODE DATA – P5.0 ............................................26

9.9 CONTROLLER RESET – P6.0...............................................................27

10 RELAYS.......................................................................................................28

11 TRANSMITTER FUNCTION ....................................................................... 28

12 ERROR MESSAGES...................................................................................28

13 SPECIFICATIONS....................................................................................... 29

14 ACCESSORIES........................................................................................... 30

15 GENERAL INFORMATION.........................................................................35

1 INTRODUCTION

Thank you for purchasing the αlpha pH 190 ⅛ DIN pH/ORP Controller. This

controller is part of a series of quality process controllers available from Eutech

Instruments. These sturdy, economical pH/ORP controllers are designed with the

features and reliability of a much more expensive instrument.

Your controller includes:

• Removable terminal blocks for easy connections;

• Two mounting brackets for easy panel mounting;

When shipped, the controller is set to the pH mode. See Setup program P3.1 for

directions on selecting ORP mode.

Some features of this controller are:

• Two set points, two SPDT relay operation

• Scrolling, 14-segment LED guides user easily through setup functions

• Reliable power supply from 85 to 260 V AC, 50/60 Hz or DC withstands

voltage fluctuations

• Push-button operation from the front panel

• Two-point pH calibration, offset temperature and ORP calibration

• Adjustable hysteresis band prevents rapid contact switching near set-point

• Selectable automatic or manual temperature compensation

• Two-level password protection

• Removable terminal strips for quick and easy connections

• Built-in non volatile memory retains setup even if power fails, and lets you

configure unit before installation

• Isolated 4-20 mA output for remote monitoring or hard copy recording

- 1 -

2 SAFETY INFORMATION

The Eutech Controller/Transmitter shall be installed and operated only in the

manner specified in the Instruction manual. Only skilled, trained or authorized

person should carry out installation, setup and operation of the instrument.

Before powering up the unit, make sure that power source it is connected to, is as

specified in the top label. Failure to do so may result in a permanent damage to the

unit.

The unit has live and exposed parts inside. If it has to be opened, make sure that

the power to the unit is off and disconnected.

The unit is Fuse protected. In the event the fuse has to be replaced, use only those

as specified in the manual.

The degree of protection against electric shock will be achieved only by

observance of the corresponding installation rules.

- 2 -

3 OVERVIEW

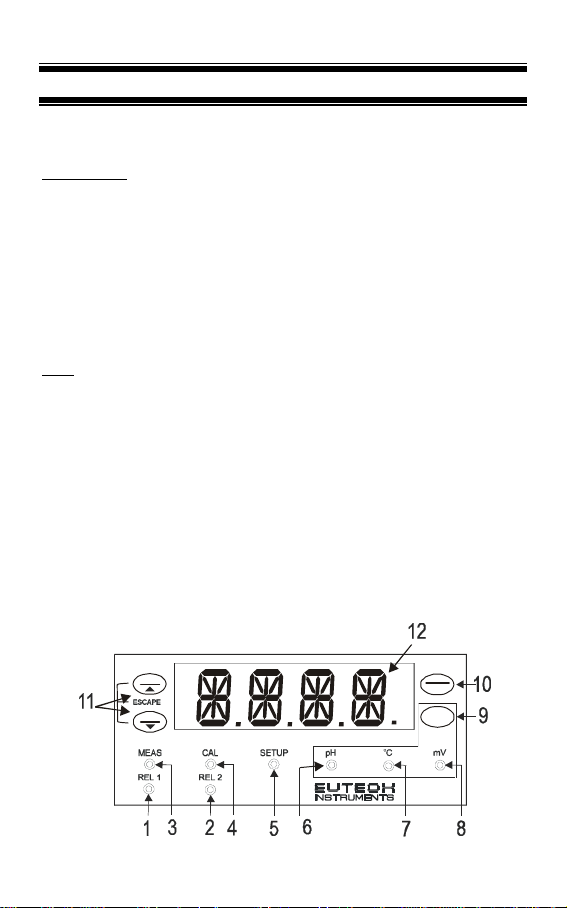

3.1 Front Panel

The front panel consists of a 4-digit LED display, 8 LED annunciators and 4 keys.

Annunciators

1. REL 1 Displayed when Relay 1 is activated.

2. REL 2 Displayed when Relay 2 is activated.

3. MEAS Displayed in measurement mode.

4. CAL Displayed in calibration mode.

5. SETUP Displayed in setup mode.

6. pH Unit of the displayed parameter (pH).

o

C Unit of the displayed parameter (temperature).

7.

8. mV Unit of the displayed parameter (ORP).

Keys

9. MODE Use to toggle between Measurement modes

10. CAL / ENTER Use to enter Calibration mode.

11. SP1 / ▲

SP2 / ▼

12.14-segment display

(pH/ORP and temperature).

Use also to enter into levels of the Setup mode

and to confirm changes made.

Use to enter Set Point 1 (SP1) or Set Point 2

(SP2) adjustment mode.

Use as increment or decrement keys during

Calibration and Setup modes.

Use both keys together in Calibration and Setup

modes to escape to Measurement mode.

SP1

SP2

- 3 -

CAL

ENTER

MODE

pH 190 Series

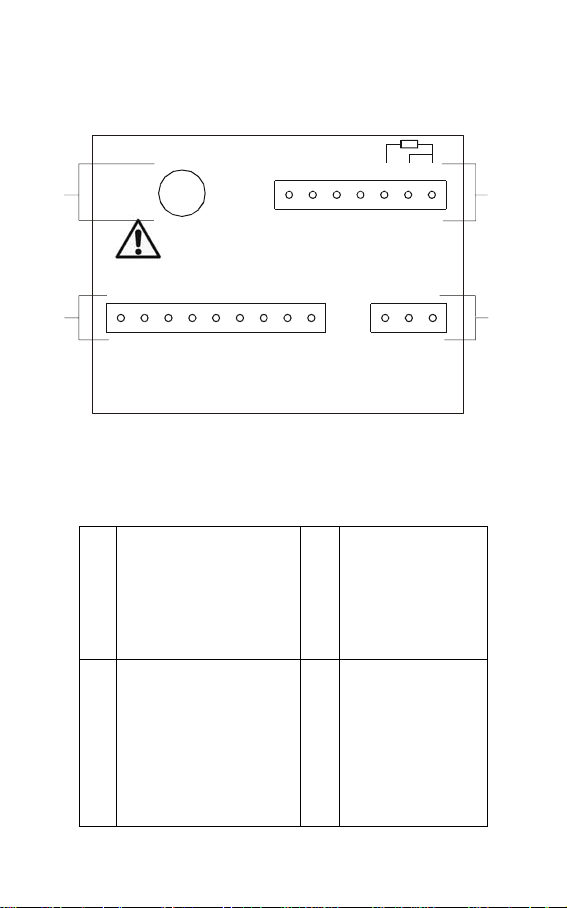

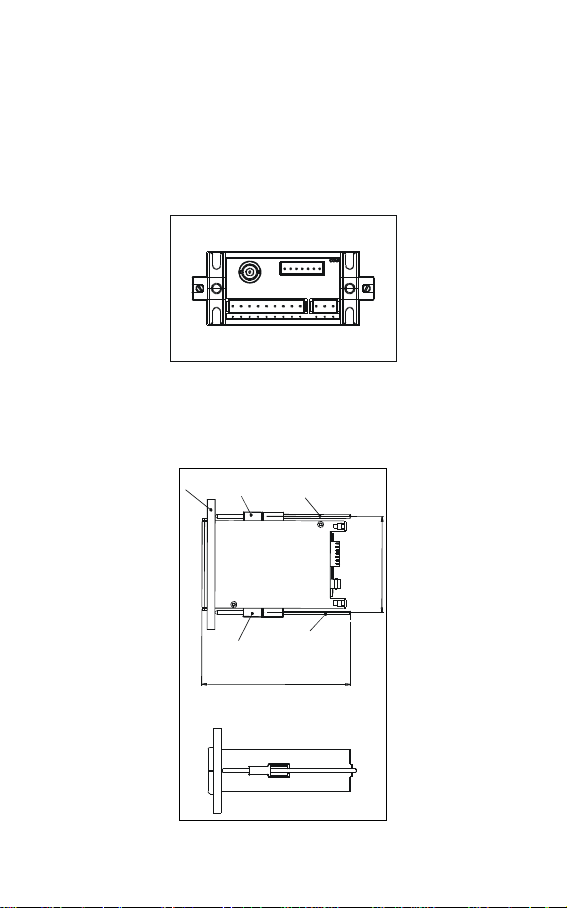

3.2 Back Panel

A

A

The back panel consists of four different connectors that can be used with

removable terminal blocks (included):

19

18

171916815714613

D

B

J2

pH/ORP

WARNING

12

11

+

-

4 - 20 mA

4 - 20 m

RELAY 1 - NO

NCNCNC

54

RELAY 1 - POLE

RELAY 2 - NO

RELAY 1 - NC

RELAY 2 - POLE

RELAY 2 - NC

LIQUID GND

Pt 100 - GND

NC

3

GROUND

J3

Pt 100 - IN

Pt 100 - SENSE

210

N

C

J1

L

A. 3 pin connector (for power supply)

B. 9 pin connector (for relays)

C. 7 pin connector (for temperature sensor)

D. BNC connector (for pH or ORP electrode)

A. 1. L- Live

2. N- Neutral

3. E- Earth Ground

B. 4. Liquid GND

5. RELAY 2- NC

6. RELAY 2- POLE

7. RELAY 2- NO

8. RELAY 1- NC

9. RELAY 1- POLE

10. RELAY 1- NO

11. – 4 to 20 mA

12. +4 to 20 mA

C. 13. Pt 100- SENSE

14. Pt 100- IN

15. Pt 100-GND

16. NC

17. NC

18. NC

19. NC

D. BNC for pH/ORP

- 4 -

3.3 Wiring

Caution: Ensure electrical mains are disconnected before proceeding.

1. Connect the power supply to the three-pin terminal block (A)

• VAC protective ground wire = 3

• VAC neutral wire = 2

• VAC live wire = 1

The αlpha pH 190 controller accepts voltages from 85 to 260 VAC, 50/60 Hz or

DC.

2. Connect the Pt 100 leads to terminals 13 and 15 (terminal block C). Either wire

can be connected to either terminal. Terminals 13 and 14 must be shunted

unless using a 3-wire RTD.

NOTE: pH 190 is factory set for manual temperature compensation. ATC can be

selected in Setup mode of Program P3.3.

3. Slide the BNC connector of the pH (ORP) probe to the BNC connector on the

back of the controller.

Turn the notches of the connector until they lock into place.

4. Power on the controller. The display automatically shows the pH (ORP) reading,

and the pH (ORP) annunciator lights.

NOTE: In the event Pt 100 is not connected or the connection is broken in the ATC

mode, the pH/ORP display flashes to alert you.

- 5 -

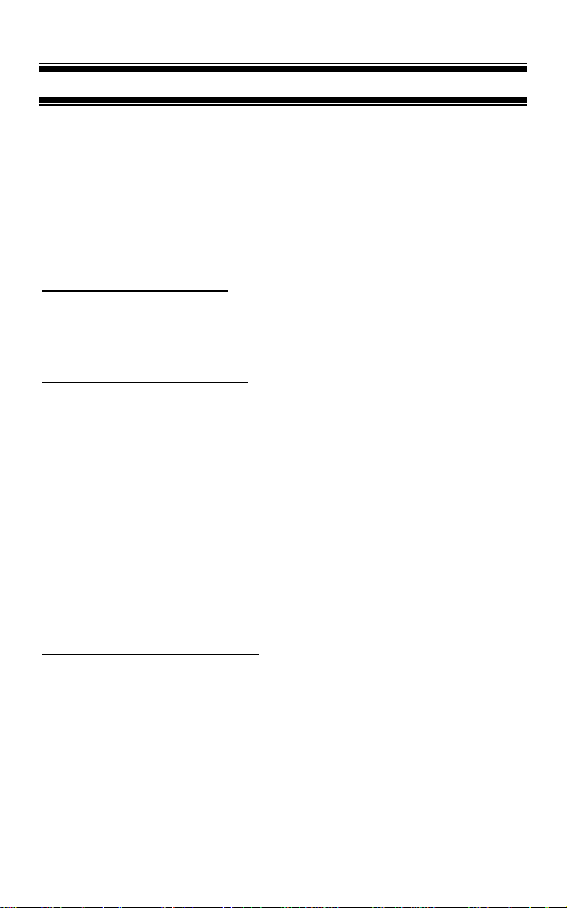

3.4 Panel-mounting the controller

a

d

The supplied mounting hardware allows surface mounting to all panels and

protective enclosures. Mounting cut-out size is 91 x 45 mm.

To attach the mounting to the controller:

1. Align the catch to the side of the controller, and insert threaded rods through

catch.

BACK VIEW

2. Screw the threaded-rod through the catch in a clock-wise direction. Tighten

until the catch holds the controller firmly against the back of the panel or

protective housing. Repeat on the other side.

p

l

l

h

a

c

t

W

a

C

h

c

t

a

C

e

d

a

e

r

h

T

0

0

1

.

x

o

r

p

p

a

d

o

r

d

e

d

a

e

r

h

T

1

5

2

4

0

.

.

x

p

o

p

a

r

TOP VIEW

SIDE VIEW

- 6 -

4 MEASUREMENT MODE

The αlpha pH 190 controller is capable of taking pH (or ORP) measurement with

Automatic (ATC) or Manual (MTC) Temperature Compensation.

The measurements are displayed distinguishingly by the annunciators on the front

panel.

4.1 Measurement mode display

Press the MODE key to toggle between pH (or ORP) and Temperature

measurement mode.

pH (ORP) measurement mode

The controller starts up in the mode when last powered off (pH or ORP).The pH (or

ORP) annunciator will light up.

For selection of pH or ORP measurement mode, see Setup program P3.1.

Temperature Measurement mode

Press MODE key once to view the temperature measurement. The °C annunciator

lights up. The display shows ATC or MTC, then the current measured temperature.

For selection of temperature compensation ATC or MTC, see Setup program P3.3.

NOTE: After pressing the MODE key to display Temperature, if there is no further

key-press, the controller will automatically revert to pH (ORP) measurement mode

after about 30 seconds.

4.2 Set Points Adjustments

You can make quick set points adjustments with the direct access of the Set Points

adjustment modes (SP1 and/or SP2). By just pressing the SP1/▲ or SP2/▼key,

you can enter the Set Point adjustment mode and set a new pH (or ORP) value

that will cause your controller to activate.

Set Point 1 (SP1) adjustment mode

This lets you adjust the pH (or ORP) value in Set Point 1. If this value is crossed,

the set point relay 1 LED will light.

1. Press the SP1/▲ key. The screen will scroll P1.1, SP1, and then the current

set point value.

2. Press the ▲ or ▼ keys and adjust first relay set point. You can adjust it in

0.01 increments from 0.00 to 14.00 pH (-999 to 1000 mV).

3. Press ENTER to confirm and return to the measurement mode.

NOTE: Press ▲ and ▼ keys together (ESCAPE) at anytime, to return to

Measurement mode.

- 7 -

Set Point 2 (SP2) adjustment mode

This lets you adjust the pH (or ORP) value in Set Point 2. If this value is crossed,

the set point relay 2 LED will light.

1. Press the SP2/▲ key. The screen will scroll P2.1, SP2, and then the current

set point value.

2. Press the ▲ or ▼ keys and adjust second relay set point. You can adjust it

in 0.01 increments from 0.00 to 14.00 pH (-999 to 1000 mV).

3. Press ENTER to confirm and return to the measurement mode.

NOTE: Press ▲ and ▼ keys together (ESCAPE) at anytime, to return to

Measurement mode.

NOTE: These modes are only for adjusting relay 1 and/or relay 2 set points values.

To set the relays as low or high set points or to set its hysteresis values, you have

to make the adjustments from the Setup mode as in Section 9.3 and Section 9.4.

- 8 -

5 PASSWORD

The Setup mode is to be accessed by entering a password code. The direct

accessed Set Point adjustment mode (SP1 and SP2) and the Calibration mode

can also be accessed through this password code procedure.

The αlpha pH 190 controller features two separate passwords:

• pH (or ORP) calibration mode and temperature offset password = 011

• Setup program password = 022

To enter the password:

1. Press the MODE key, and within 1 second, press the CAL/ENTER key. The

display reads P.WRD.

2. Press ENTER again. The display reads “P.000”. The first “0” flashes.

3. Press ENTER again to leave the first digit “0” and to scroll to the next

number.

4. Press the ▲or ▼keys to change the second digit to the desired password

number (1 or 2). Press ENTER.

5. Press the ▲or ▼keys to change the second digit to the correct password

number (1 or 2). Press ENTER. The display flashes the password that has

been entered.

NOTE: If you enter an incorrect digit, press MODE to step backward.

6. Press ENTER again. You are now in Calibration mode or Setup mode,

depending on password entered.

NOTE: In the Password Entry mode, if there is no key-press for more than 30

seconds, Controller will automatically revert to measurement mode.

- 9 -

Loading...

Loading...