Eutech instruments Alpha DO 500 User Manual

Alpha DO 500

Transmitter

Dissolved Oxygen

ROSS and the COIL trade dress are trademarks of Thermo Fisher Scientific Inc. U.S. patent

6,793,787.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, PerpHecTion,

pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink, ROSS, ROSS Ultra,

Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTOCAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTO-STIR, Auto-Test, BOD

AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal,

DuraProbe, Environmental Product Authority, Extra Easy/Extra Value, FAST QC, GAP,

GLPcal, GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode,

Minimum Stir Requirement, MSR, NISS, One-Touch, One-Touch Calibration, One-Touch

Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture Pentrode,

pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB,

SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator 21, Stat

Face, The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal

Access are trademarks of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

PerpHecT meters are protected by U.S. patent 6,168,707. PerpHecT ROSS electrodes are

protected by U.S. patent 6,168,707. ORION Series A meters and 900A printer are protected

by U.S. patents 5,198,093, D334,208 and D346,753.ionplus electrodes and Optimum Results

solutions are protected by U.S. patent 5,830,338.ROSS Ultra electrodes are protected by

U.S. patent 6,793,787.ORP standard is protected by U.S. patent 6,350,367. No Cal

electrodes are protected by U.S. patent 7,276,142.© 2009 Thermo Fisher Scientific Inc. All

rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its

subsidiaries.The specifications, descriptions, drawings, ordering information and part

numbers within this document are subject to change without notice.This publication

supersedes all previous publications on this subject.

Preface

This manual serves to explain the use of the Alpha DO 500 transmitter. It functions in

two ways, firstly as a step by step guide to help you to operate the transmitter.

Secondly, it serves as a handy reference guide. It is written to cover as many

anticipated applications of the transmitter as possible. If there are doubts in the use

of the transmitter, please do not hesitate to contact the nearest Authorized

Distributor.

Thermo Scientific will not accept any responsibility for damage or malfunction to the

transmitter caused by improper use of the instrument.

Remember to fill in the guarantee card and mail it back to your authorized distributor.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on the part of

Thermo Scientific.

Copyright 2009 All rights reserved.

Table of Contents

1. Introduction ...........................................................................................................1

1.1 Before You Begin ................................................................................................................... 1

1.2 Intended Use .......................................................................................................................... 1

1.3 Safety Instructions.................................................................................................................. 2

1.4 Taking Out of Service / Correct Disposal of the Unit ............................................................. 2

2. Getting Started ......................................................................................................3

2.1 Description of Instrument .......................................................................................................3

Power Supply Requirements (SL2 Position) ................................................................................... 3

2.2 Measurement and Control System......................................................................................... 4

2.3 Connecting Peripherals..........................................................................................................5

2.3.1 Connection Terminals.................................................................................................... 5

2.3.2 Connecting Dissolved Oxygen Electrode ...................................................................... 6

2.3.3 Connecting Temperature Probe .................................................................................... 6

2.4 Installation .............................................................................................................................. 7

2.4.1 Mechanical Dimensions................................................................................................. 7

2.4.2 Wall Mount..................................................................................................................... 7

2.4.3 Panel Mount................................................................................................................... 8

2.5 Display & Keypad ................................................................................................................... 9

2.5.1 Display Overview........................................................................................................... 9

2.5.2 Key Functions.............................................................................................................. 10

3. Normal Operation ................................................................................................11

3.1 Measurement mode ............................................................................................................. 11

3.2 Menu Overview .................................................................................................................... 12

4. Calibration Mode .................................................................................................13

4.1 Entering Calibration Mode.................................................................................................... 13

4.2 Calibration in mg/l or ppm of Oxygen................................................................................... 14

4.2.1 1-Point Calibration ....................................................................................................... 14

4.2.2 2-Point Calibration ....................................................................................................... 15

4.3 Calibration in% Saturation of Oxygen .................................................................................. 17

4.3.1 1-Point Calibration ....................................................................................................... 17

4.3.2 2-Point Calibration: ...................................................................................................... 18

5. Setup Mode ..........................................................................................................20

5.1 Enter Setup mode ................................................................................................................20

5.2 Configuration Settings..........................................................................................................21

5.3 Offset Settings...................................................................................................................... 23

5.4 Temperature Settings........................................................................................................... 25

5.5 Range Settings..................................................................................................................... 27

5.6 Hold Settings ........................................................................................................................ 28

5.7 Out of Range Settings.......................................................................................................... 29

5.8 Viewing Calibration Point ..................................................................................................... 30

5.9 Viewing Electrode Condition ................................................................................................ 31

5.10 Resetting .............................................................................................................................. 32

6. Technical Specifications.....................................................................................33

7. List of Accessories .............................................................................................35

7.1 Thermo Scientific.................................................................................................................. 35

7.2 Eutech Instruments ..............................................................................................................36

8. Troubleshooting ..................................................................................................37

9. General Information ............................................................................................38

9.1 Warranty............................................................................................................................... 38

9.2 Return of Goods ................................................................................................................... 38

9.3 Guidelines for Returning Unit for Repair .............................................................................. 38

9.4 Maintenance and Cleaning .................................................................................................. 38

10. Appendices .......................................................................................................39

10.1 Appendix 1 – Salinity vs. Temperature (@ 760mmHg)........................................................ 39

10.2 Appendix 2 – Abbreviations Used in LCD............................................................................ 40

Instruction Manual Alpha DO 500

1. Introduction

1.1 Before You Begin

We thank you for purchasing the Alpha DO 500 Transmitter.

The construction of the Alpha DO 500 Transmitter employs leading edge

technology and complies with safety regulations currently in force.

Notwithstanding this, improper use could lead to hazards for the user or a

third-party, and/or adverse effects on the plant or other equipment. Therefore,

the operating instructions must be read and understood by the persons

involved before work is started with the Alpha DO 500 Transmitter.

The instruction manual must always be stored close at hand, in a place

accessible to all people working with the Alpha DO 500 Transmitter.

If you have questions, which are not or insufficiently answered in this

instruction manual, please contact your authorized supplier. They will be glad

to assist you.

1.2 Intended Use

Alpha DO 500 Transmitters are intended solely for dissolved oxygen (DO)

and temperature measurement, as described in this instruction manual.

Any other use, or use not mentioned here, that is incompatible with the

technical specifications is deemed inappropriate. The operator is solely

responsible for any damage arising from such use.

Other prerequisites for appropriate use include:

– Comply with the instructions, notes and requirements set out in this

instruction manual.

– Comply with all local safety regulations concerning safety at work.

– Comply with all information and warnings in the documentation dealing

with the products used together with the Alpha DO 500 Transmitter

(housings, sensors, etc.).

– Comply with local environmental and operational conditions.

1

Instruction Manual Alpha DO 500

1.3 Safety Instructions

- The Alpha DO 500 Transmitter should be installed and operated

only by personnel familiar with the instrument and who are

qualified for such work.

- A defective Transmitter must neither be installed nor put into

service.

- The Alpha DO 500 Transmitter must only be operated under the

specified operating conditions (see section 5.9).

- The Alpha DO 500 Transmitter must not be repaired by the

customer.

- No modifications to the Alpha DO 500 Transmitter are allowed. The

manufacturer/supplier accepts no responsibility for damage

caused by unauthorized modifications. The risk is borne entirely

by the user.

1.4 Taking Out of Service / Correct Disposal of the Unit

Taking out of Service

x First disconnect the unit from the power supply and then undo all electrical

connections.

x Remove the unit from the wall / panel.

Correct Disposal of the Instrument

When the DO Transmitter is permanently taken out of service, obey the local

environmental regulations for correct disposal or send the instrument to your

local distributor, they will take care of proper disposal.

2

Instruction Manual Alpha DO 500

2. Getting Started

2.1 Description of Instrument

The Thermo Scientific Alpha DO 500 Transmitter is used for measuring

dissolved oxygen and temperature values. The dissolved oxygen values can

be measured using industrial dissolved oxygen sensors. The temperature

values can be measured using 2-wire or 3-wire Pt100 sensors. The DO

Transmitter can be used for applications such as water treatment and

monitoring, galvanic-decontamination, chemical processing, food processing,

clean or wastewater control and neutralization processes.

The Alpha DO 500 Transmitter has many user-friendly and safety features

which include:

x Push-button keypad for calibration and setup

x Built-in non-volatile memory to ensure that calibration and other

information are not erased if power supply fails

x Menu-driven program that simplifies setup

x Automatic temperature compensation (ATC)

x Manual temperature compensation setting without the ATC probe, with

independent setting for calibration and process temperature

x Large dual display LCD for easy reading with clear multiple

annunciators, operational mode indicators and error indicators.

x Galvanically isolated current output of 4 to 20mA

x Hold function to freeze output current (22mA)

x Out of range current indication (3.8mA)

x Protection against electromagnetic interference

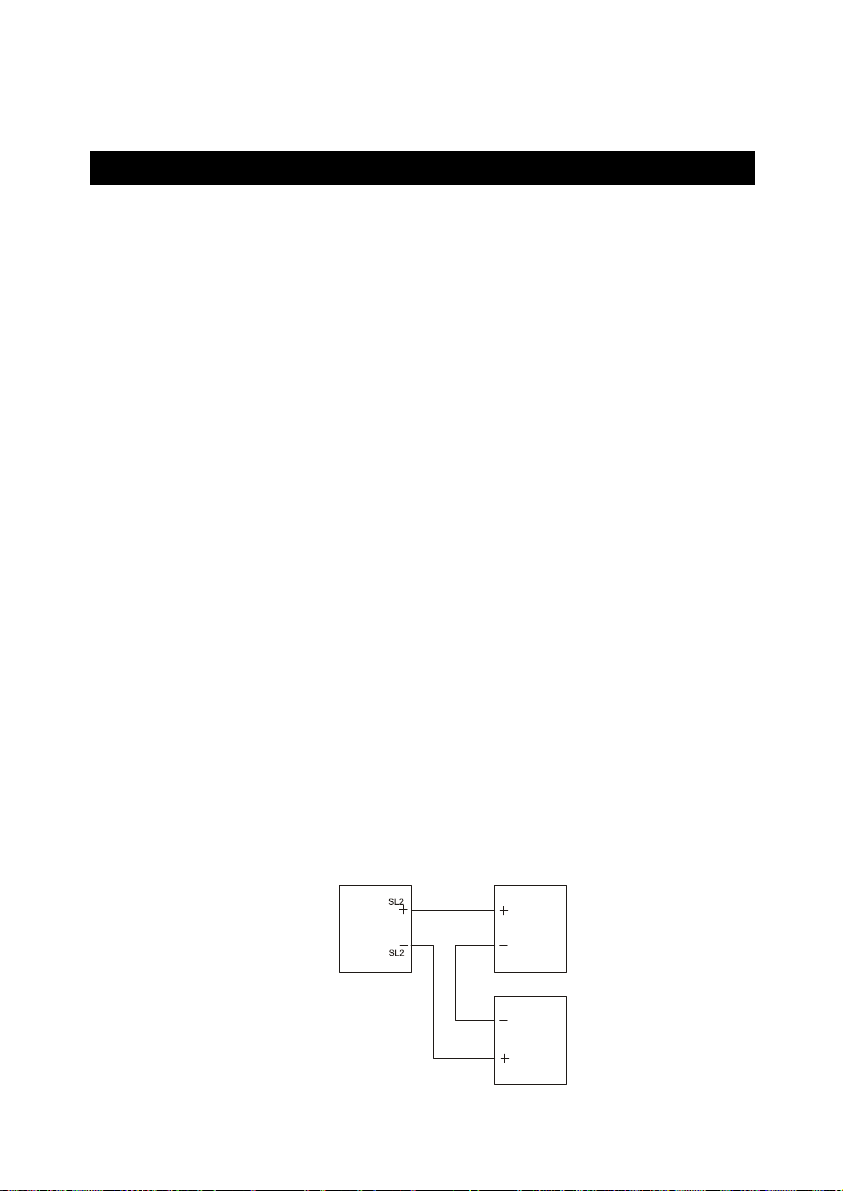

Power Supply Requirements (SL2 Position)

This transmitter requires a 12 to 24V DC power supply. Other Transmitters

and/or a chart recorder may be connected in series.

1. Insert positive loop wire from power supply to pin 1, tighten screw.

2. Insert negative loop wire to pin 2, tighten screw. This wire may be linked to a

chart recorder or to negative terminal of power supply.

Alpha pH500

1

2

Power Su pply

Chart recorde r

3

Instruction Manual Alpha DO 500

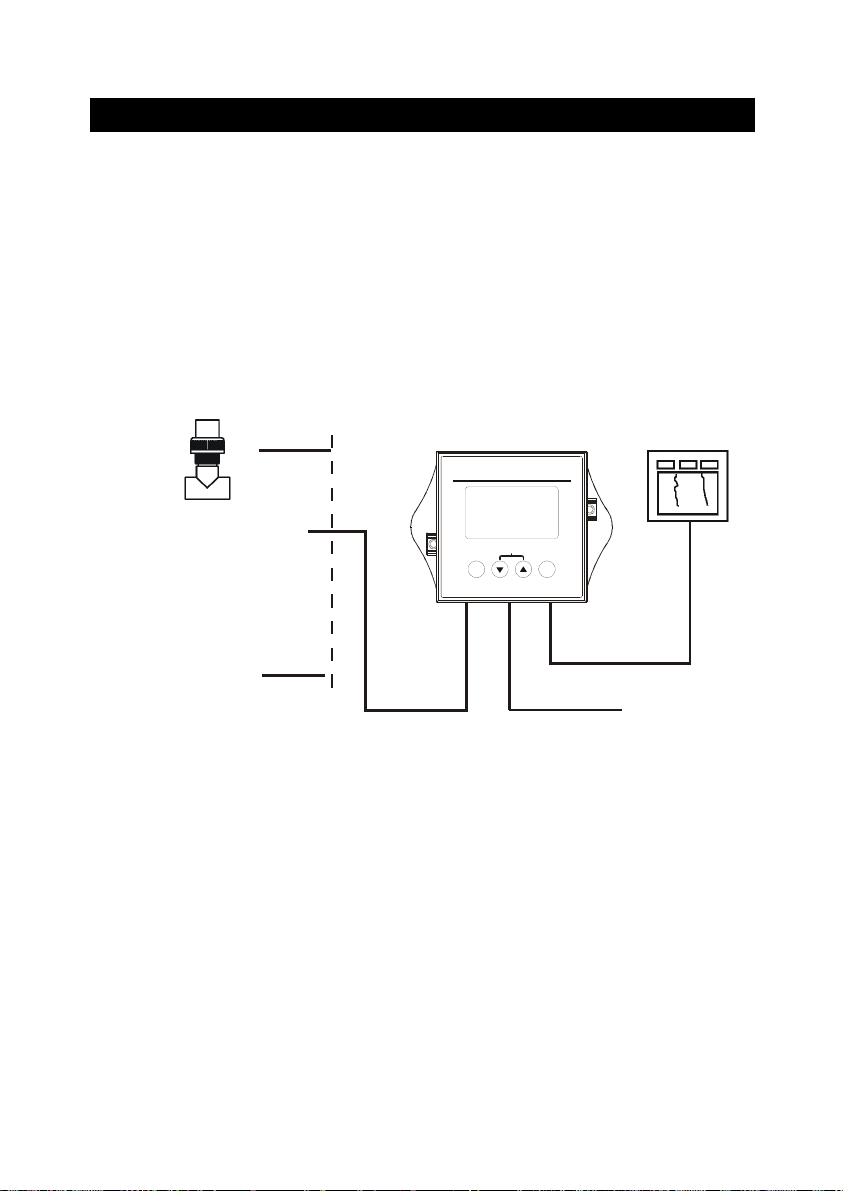

2.2 Measurement and Control System

A typical measurement system consists of:

x A Alpha DO 500 Transmitter

x A dissolved oxygen sensor with integrated or separate Pt100

temperature sensor

x An appropriate measurement cable

x An immersion, flow or process assembly

x A chart recorder

Housing and

Sensors

Alpha DO500 Transmitter

2-wire Dissolved Oxygen Transmitter

Measurement Cable

Chart Recorder

Alpha DO500

ESC

CAL

ENT

4 - 20 mA

Power Adaptor

(12 to 24 V DC)

4

Instruction Manual Alpha DO 500

2.3 Connecting Peripherals

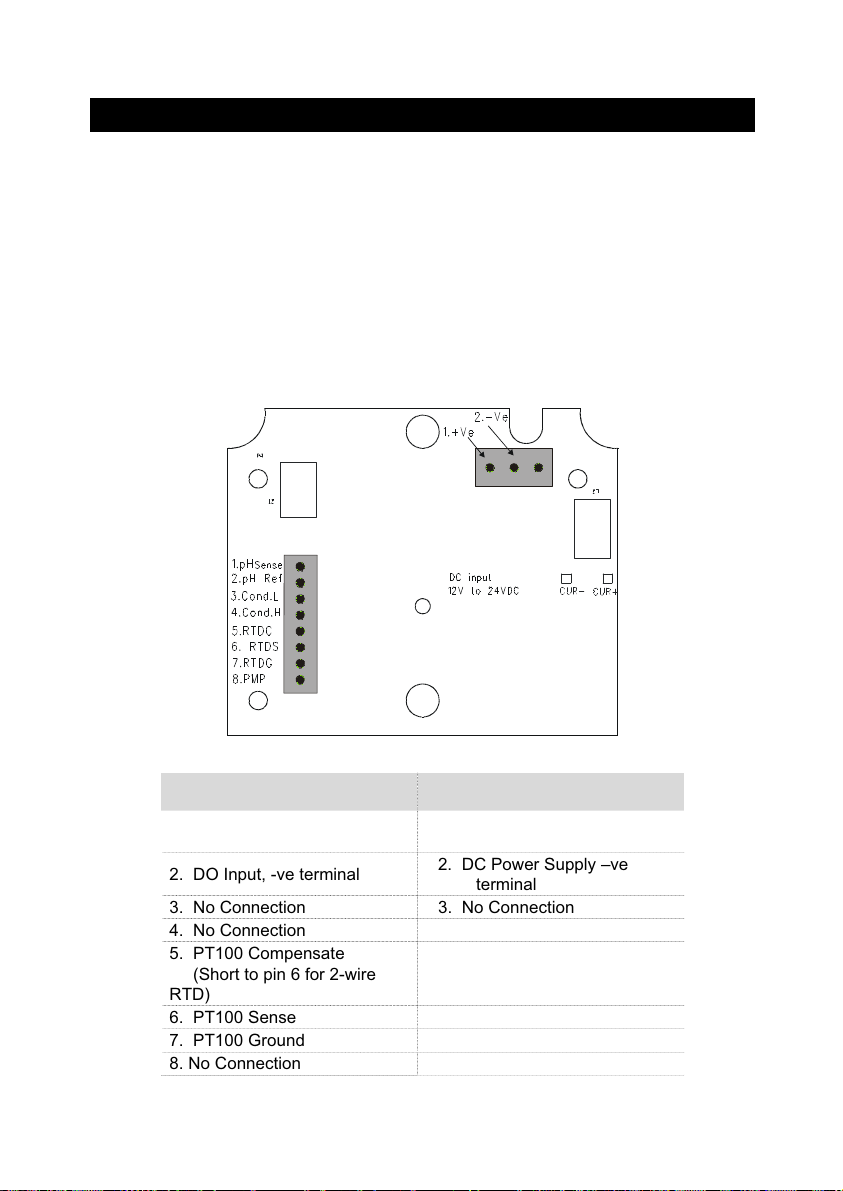

2.3.1 Connection Terminals

Remove Back Cover:

Remove the screws from the four corners at the back of the DO Transmitter.

Remove the back cover. The connectors are exposed on the back PCBA as

shown in the Figure 1 below.

Connectors:

x SL2 – 12 to 24 V DC power

x SL1 – Dissolved Oxygen electrode & Temperature probe connections

(wiring has to be done in the detachable connector

SL2

SL1

Figure 1: Outer Side of Back PCBA

SL1 Connections SL 2 Connections

1. DO Input, +ve terminal

2. DO Input, -ve terminal

1. DC Power Supply +ve

terminal

2. DC Power Supply –ve

terminal

3. No Connection 3. No Connection

4. No Connection

5. PT100 Compensate

(Short to pin 6 for 2-wire

RTD)

6. PT100 Sense

7. PT100 Ground

8. No Connection

5

Instruction Manual Alpha DO 500

2.3.2 Connecting Dissolved Oxygen Electrode

Refer the instruction sheet that comes with your Dissolve Oxygen electrode

to identify polarity (+ve and –ve) of DO wires.

1. Connect DO +ve wire to Pin 1 of SL1 connector

2. Connect DO -ve wire to Pin 2 of SL1 connector

2.3.3 Connecting Temperature Probe

For Automatic Temperature Compensated (ATC) readings, a 100: Pt RTD

temperature probe (2-wire or 3-wire) can be connected to the Transmitter.

3-Wire Probe:

1. Connect PT100 compensate wire to Pin 5 of SL1 connector

2. Connect PT100 sense wire to Pin 6 of SL1 connector

3. Connect PT100 GND wire to Pin 7 of SL1 connector

2-Wire Probe:

1. Short Pin 5 & 6 of SL1 connector using a small piece of wire.

2. Connect PT100 sense wire to Pin 6 of SL1 connector

3. Connect PT100 GND wire to Pin 7 of SL1 connector

6

Instruction Manual Alpha DO 500

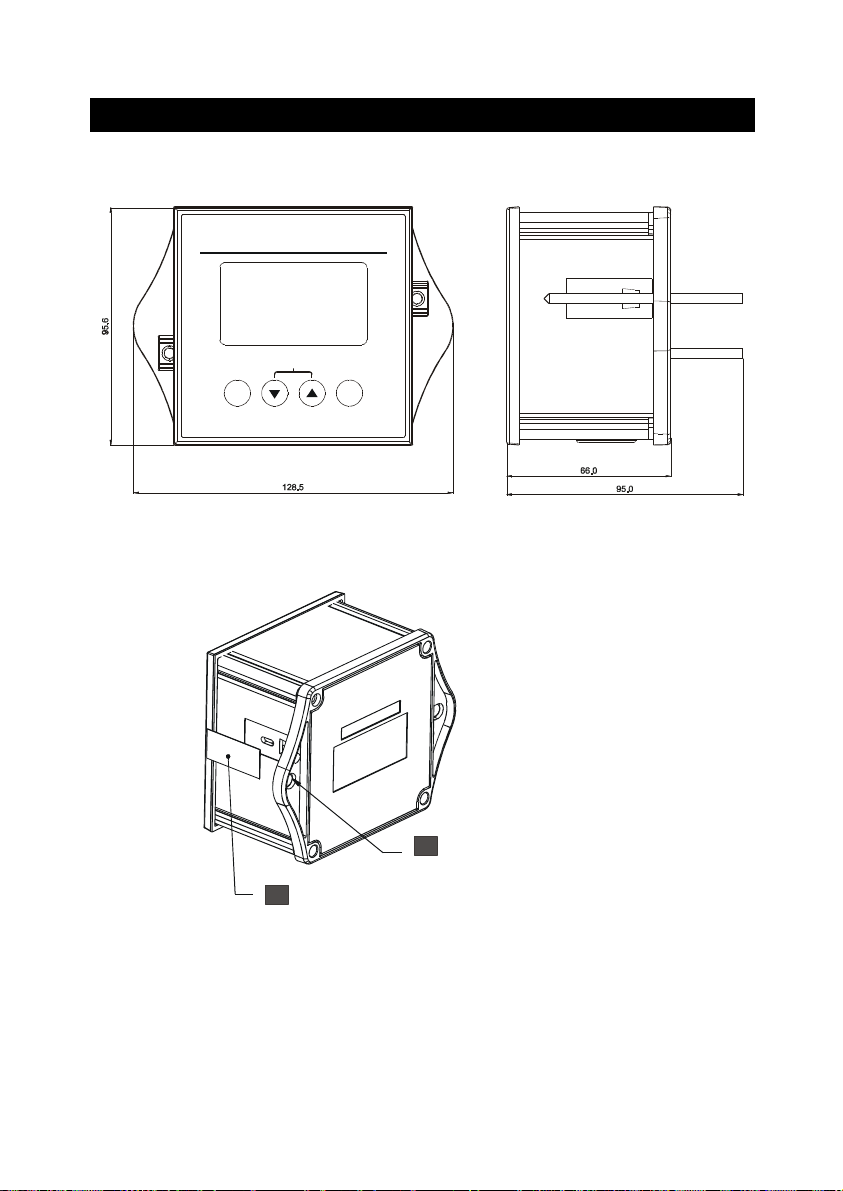

2.4 Installation

2.4.1 Mechanical Dimensions

Alpha DO 500

ESC

CAL

2-wire Dissolved Oxygen Transmitter

ENT

2.4.2 Wall Mount

Cover the catch slots at

2

both sides with overlays

Pierce through holes at

11

both sides

7

Instruction Manual Alpha DO 500

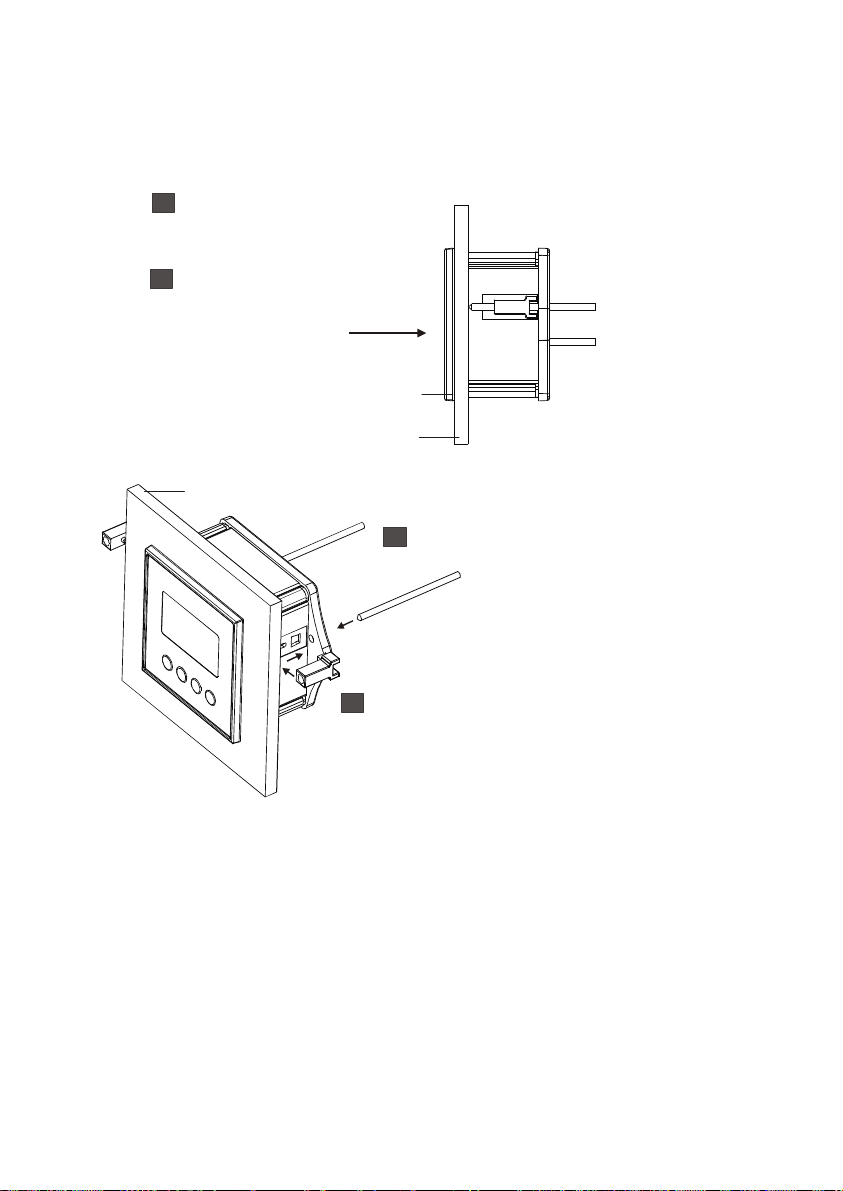

2.4.3 Panel Mount

Prepare panel cut-out of

1

1

92.0 mm X 92.0 mm

Remove back cover of

2

DO Transmitter and slide it

through panel cut-out

Gasket

Panel

Panel

Insert threaded rods through catch

4

until DO Transmitter is held against panel

Attach catch to both sides

3

of DO Transmitter

8

Instruction Manual Alpha DO 500

2.5 Display & Keypad

2.5.1 Display Overview

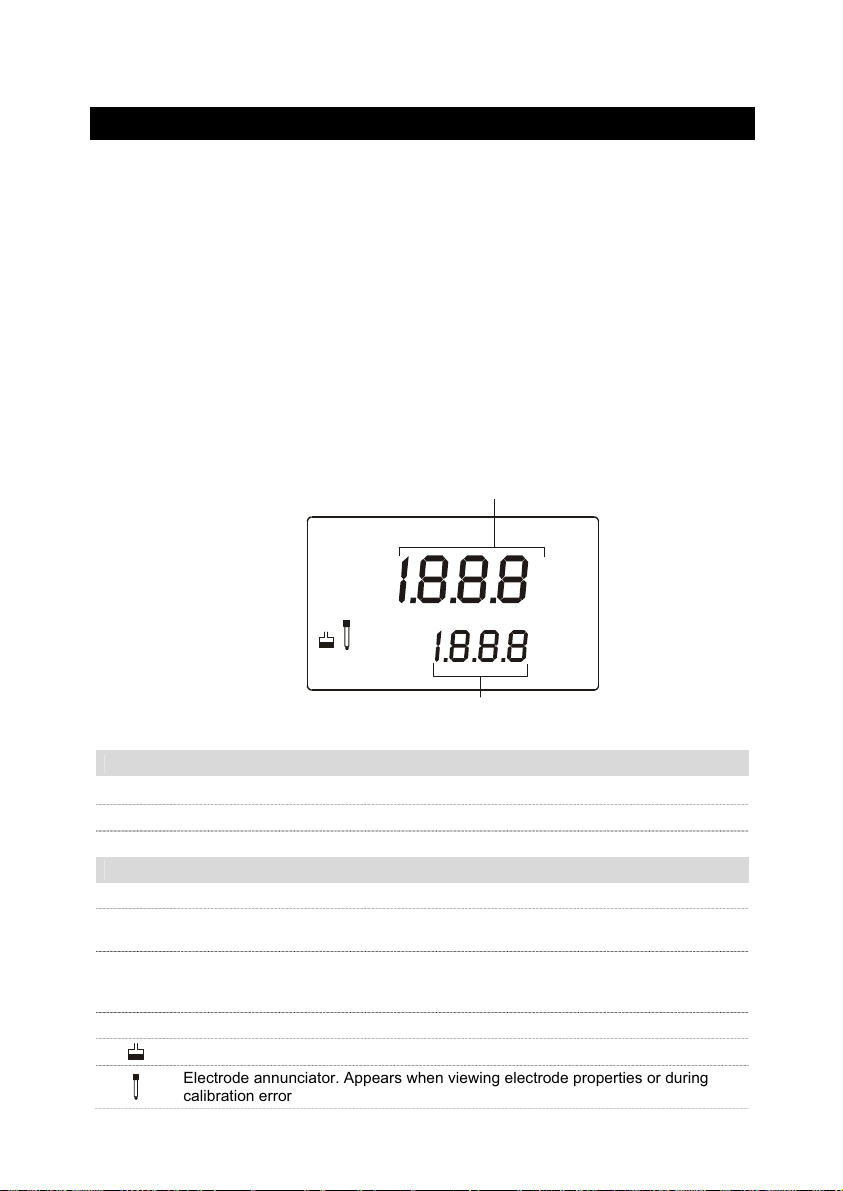

The Liquid Crystal Display (LCD) of the Alpha DO 500 Transmitter has two

alpha-numerical displays (Upper and a Lower).

x Upper display: Measured dissolved oxygen reading (in % saturation or

ppm or mg/l) is displayed when the Transmitter is in normal operation

(measurement) mode.

x Lower display: Measured temperature value is displayed when the

Transmitter is in normal operation (measurement) mode. In Calibration

mode, calibration points are displayed here.

The two displays indicate function names, options & settings in Setup mode.

Refer ‘Appendix 2 – Abbreviations Used in LCD’ for more details.

The LCD also consists of various mode indicators, status annunciators and

unit of measurement indicators.

Upper Display

Mode Indicators

MEAS

SETUP

CAL

Measurement mode (Refer Section 3.1)

Setup mode (Refer Section 5)

Calibration mode (Refer Section 4)

Status Annunciators

READY

HOLD

ATC

ERR

Appears when the reading is stable

Appears in Setup mode and Calibration mode to indicate that the relay function

is frozen

Appears when Automatic Temperature Compensation (ATC) is enabled.

Not visible when Manual Temperature Compensation (MTC) is enabled.

Flashes if the temperature probe is faulty in its ATC mode.

Appears when an error occurs

Buffer annunciator. Appears in calibration mode or viewing calibrated point

Electrode annunciator. Appears when viewing electrode properties or during

calibration error

SETUP MEAS

READY

HOLD

K=

-

ERR

-

CAL

Lower Display

%

ppm

mg/l

°C

ATC

(Refer Section 5.4)

9

Loading...

Loading...