Page 1

Alpha CON 550

Conductivity Monitor

mS/µS/ºC/ºF meter

Page 2

Page 3

Preface

This manual serves to explain the use of the Alpha-CON 550 Industrial

Conductivity Monitor. The manual functions in two ways, firstly as a step by step

guide to help the user operate the instrument. Secondly, it serves as a handy

reference guide. This instruction manual is written to cover many anticipated

applications of the Alpha-CON 550 monitor. If you have doubts in the use of the

instrument, please do not hesitate to contact the nearest Alpha Authorised

Distributor.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on part of Thermo

Scientific.

Thermo Scientific cannot accept any responsibility for damage or malfunction of the

unit due to improper use of the instrument.

Copyright ©2006

All rights reserved.

Page 4

Page 5

TABLE OF CONTENTS

1. Introduction ...........................................................................................................1

1.1 Before You Begin................................................................................................................... 1

1.2 Intended Use.......................................................................................................................... 1

1.3 Safety Instructions.................................................................................................................. 2

1.4 Taking Out of Service / Correct Disposal of the Unit ............................................................. 2

2. Getting Started ......................................................................................................3

2.1 Description of Instrument....................................................................................................... 3

2.2 Measurement System ............................................................................................................ 4

2.3 Connecting Peripherals.......................................................................................................... 5

2.3.1 Connection Terminals.................................................................................................... 5

2.3.2 Switching Between Pt100 & Pt1000 Temperature Sensors.......................................... 6

2.3.3 Connecting Conductivity Probe..................................................................................... 7

2.3.4 Connecting Temperature Probe.................................................................................... 7

2.4 Installation.............................................................................................................................. 8

2.4.1 Mechanical Dimensions................................................................................................. 8

2.4.2 Wall Mount..................................................................................................................... 8

2.4.3 Panel Mount................................................................................................................... 9

2.5 Display & Keypad................................................................................................................. 10

2.5.1 Display Overview......................................................................................................... 10

2.5.2 Key Functions.............................................................................................................. 11

3. Operation .............................................................................................................12

3.1 Measurement mode ............................................................................................................. 12

3.2 Menu Overview .................................................................................................................... 13

4. Calibration Mode.................................................................................................14

4.1 About Calibration.................................................................................................................. 14

4.2 Calibration............................................................................................................................ 15

5. Setup Mode..........................................................................................................17

5.1 Enter Setup mode ................................................................................................................ 17

5.2 Temperature Coefficient Settings......................................................................................... 18

5.3 Temperature Settings........................................................................................................... 19

5.4 Measuring Range Settings................................................................................................... 21

5.5 Configuration Settings.......................................................................................................... 22

5.6 Viewing Electrode Properties............................................................................................... 24

6. Technical Specifications.....................................................................................25

7. List of Accessories .............................................................................................27

8. Troubleshooting..................................................................................................28

9. General Information ............................................................................................29

9.1 Warranty............................................................................................................................... 29

9.2 Return of Goods................................................................................................................... 29

9.3 Guidelines for Returning Unit for Repair.............................................................................. 29

10. Appendices.......................................................................................................30

10.1 Appendix 2 Conductivity of various aqueous solutions....................................................... 30

10.2 Appendix 4 - Abbreviations Used in LCD............................................................................. 31

Page 6

Page 7

Instruction Manual Alpha-CON 550

1. Introduction

1.1 Before You Begin

We thank you for purchasing the Alpha CON 550 monitor.

The construction of the CON 550 monitor employs leading edge technology

and complies with safety regulations currently in force. Notwithstanding this,

improper use could lead to hazards for the user or a third-party, and/or

adverse effects on the plant or other equipment. Therefore, the operating

instructions must be read and understood by the persons involved before

working with the monitor.

The instruction manual must always be stored close at hand, in a place

accessible to all people working with the conductivity monitor.

If you have questions, which are not or insufficiently answered in this

instruction manual, please contact your authorized supplier. They will be glad

to assist you.

1.2 Intended Use

Alpha CON 550 monitors are intended solely for conductivity and

temperature measurement, as described in this instruction manual.

Any other use, or use not mentioned here, that is incompatible with the

technical specifications is deemed inappropriate. The operator is solely

responsible for any damage arising from such use.

Other prerequisites for appropriate use include:

– Comply with the instructions, notes and requirements set out in this

instruction manual.

– Comply with all local safety regulations concerning safety at work.

– Comply with all information and warnings in the documentation dealing

with the products used together with the conductivity monitor (housings,

sensors, etc.).

– Comply with local environmental and operational conditions.

1

Page 8

Instruction Manual Alpha-CON 550

1.3 Safety Instructions

- The Alpha CON 550 monitor should be installed and operated only

by personnel familiar with the instrument and who are qualified for

such work.

- A defective CON monitor must neither be installed nor put into

service.

- The Alpha CON 550 must only be operated under the specified

operating conditions (see section 6).

- The Alpha CON 550 must not be repaired by the customer.

- No modifications to the Alpha CON 550 are allowed. The

manufacturer/supplier accepts no responsibility for damage

caused by unauthorized modifications. The risk is borne entirely

by the user.

1.4 Taking Out of Service / Correct Disposal of the Unit

Taking out of Service

• First disconnect the unit from the power supply and then undo all electrical

connections.

• Remove the unit from the wall / panel.

Correct Disposal of the Instrument

When the Alpha CON 550 monitor is permanently taken out of service, obey

the local environmental regulations for correct disposal or send the

instrument to your local distributor, they will take care of proper disposal.

2

Page 9

Instruction Manual Alpha-CON 550

2. Getting Started

2.1 Description of Instrument

The Alpha CON 550 monitor is used for measuring conductivity and

temperature values. The monitor can be used for applications such as water

treatment and controlling, galvanic-decontamination, chemical processing,

food processing, clean or wastewater control and neutralization processes.

The monitor has many user-friendly and safety features which include:

• Push-button keypad for calibration and setup

• Built-in non-volatile memory to ensure that calibration and other

information are not erased if power supply fails

• Menu-driven program that simplifies setup

• Automatic temperature compensation (ATC)

• Manual temperature compensation setting without the ATC probe, with

independent setting for calibration and process temperature

• Large dual display LCD for easy reading with clear multiple annunciators,

operational mode indicators and error indicators

3

Page 10

Instruction Manual Alpha-CON 550

A

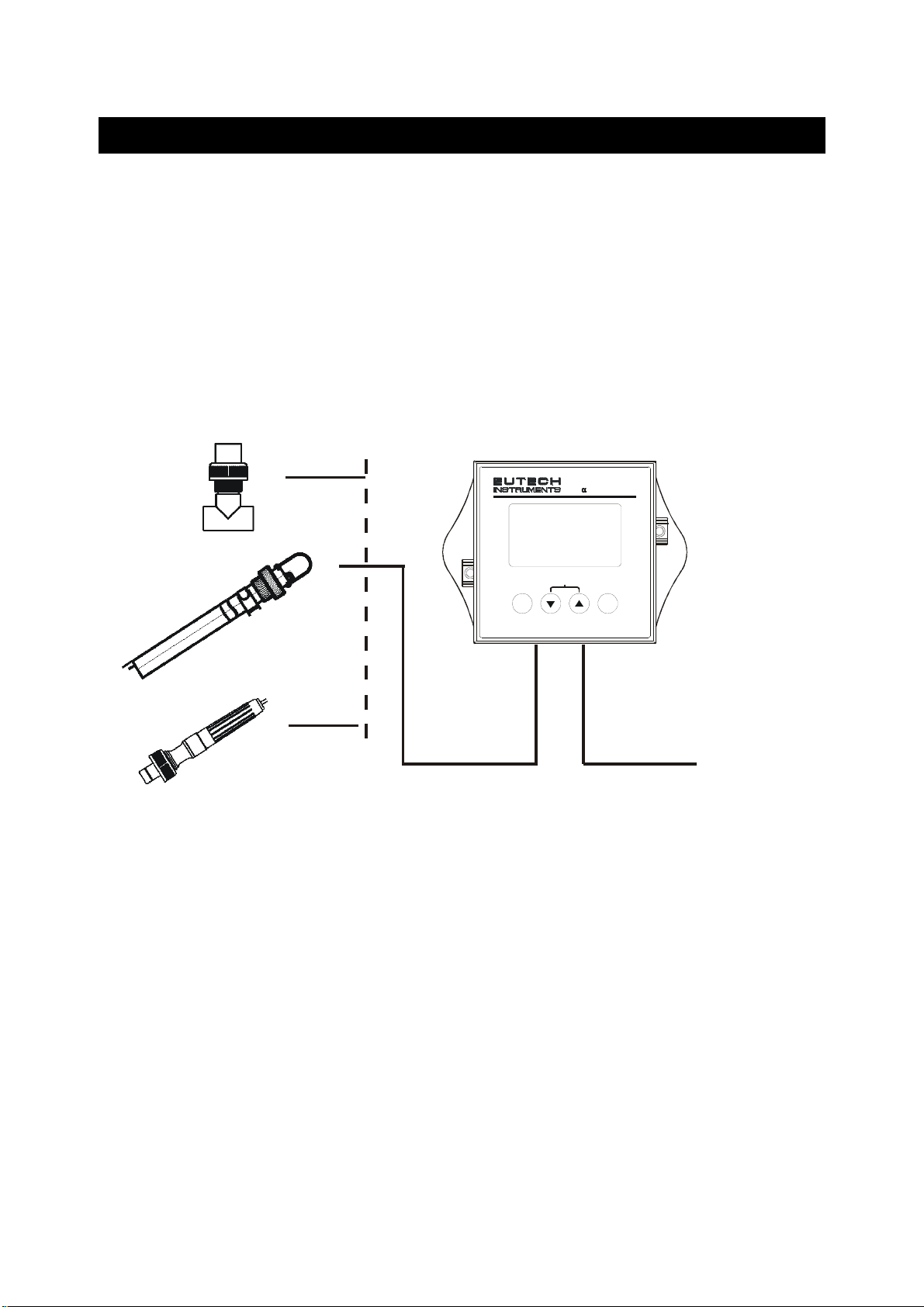

2.2 Measurement System

A typical measurement system consists of:

• A conductivity process monitor

• A conductivity sensor with integrated or separate Pt100/Pt1000

temperature sensor

• An appropriate measurement cable

• An immersion, flow or process assembly

lpha CON 550 Monito r

lpha pH560

ESC

CAL

pH Monitor

ENT

Power Adap tor

Housing and

Sensors

Meas u r ement C able

(+9 V DC)

4

Page 11

Instruction Manual Alpha-CON 550

2.3 Connecting Peripherals

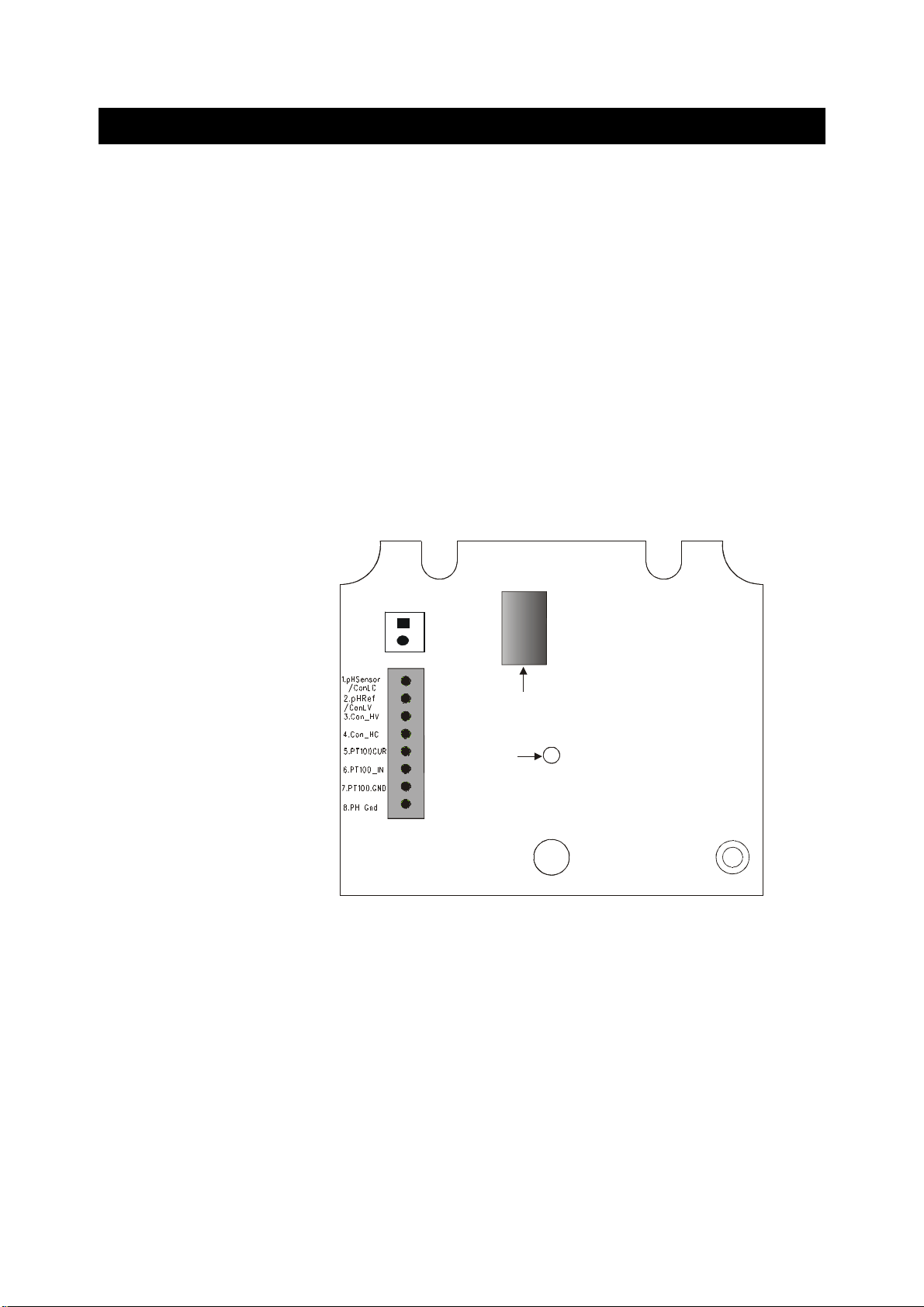

2.3.1 Connection Terminals

Remove Back Cover:

Remove the screws from the four corners at the back of the conductivity

monitor. Remove the back cover. The connectors are exposed on the back

PCBA as shown in the Figure 1 below.

Connectors:

• J11 – 24V DC power connector

• J8 – 9V DC power connector (1.2mm diameter)

• J9 – Relay connections

• J10 - Conductivity electrode & Temperature probe connections (wiring has

to be done in the detachable connector

J11 Connections

1. +ve

2. Gnd

J10 Connections

1. CON Low Current

2. CON Low Voltage

3. CON High Voltage

4. CON High Current

5. Pt 100 Compensate

6. Pt 100 Sense

7. Pt 100 GND

8. (No connection)

Figure 1: Outer Side of Back PCBA

24V DC

1)+ve

2)Gnd

J10

J11

J8

9V DC Power

Screw

5

Page 12

Instruction Manual Alpha-CON 550

2.3.2 Switching Between Pt100 & Pt1000 Temperature Sensors

The conductivity monitor supports both Pt100 & Pt1000 (2-wire or 3-wire)

temperature sensors. The default

factory setting is Pt100. If you need to use

Pt1000 temperature sensor, you have to change the jumper setting (J7) as

described below.

Remove Back Cover:

Remove screws from the four corners at the back of the conductivity monitor.

Remove the back cover.

Remove Back PCBA:

Remove the screw located center of the back PCBA (

Figure 1). Detach the back PCBA from the monitor. Turn over the back PCBA.

Locate J7 jumper on the inner side of the back PCBA as shown in Figure 2

below.

Figure 2: Inner Side of Back PCBA

Set Jumper J7:

Set the J7 jumper to required sensor (Pt100 or Pt1000) type.

6

Page 13

Instruction Manual Alpha-CON 550

2.3.3 Connecting Conductivity Probe

Any industrial conductivity probe (2-cell or 4-cell) can be connected to the

conductivity monitor.

2-Cell Conductivity

Probe:

1. Short Pin 1 & 2 of J10 connector using a jumper wire.

2. Connect CON low input wire (white) to Pin 2 of J10 connector.

3. Connect CON high input wire (black) to Pin 3 of J10 connector.

4. Short Pin 3 & 4 of J10 connector using a jumper wire.

4-Cell Conductivity Probe:

1. Connect CON low input wire (black) to Pin 1 of J10 connector

2. Connect CON low input wire (white) to Pin 2 of J10 connector.

3. Connect CON high input wire (orange) to Pin 3 of J10 connector.

4. Connect CON high input wire (blue) to Pin 4 of J10 connector.

2.3.4 Connecting Temperature Probe

For Automatic Temperature Compensated (ATC) conductivity readings, an

in-built temperature sensor is usually integrated with industrial conductivity

probes. Alternatively, a separate 100Ω Pt RTD temperature probe (2-wire or

3-wire) can be connected to the monitor.

3-Wire Probe:

1. Connect PT100 compensate wire to Pin 5 of J10 connector.

2. Connect PT100 sense wire to Pin 6 of J10 connector.

3. Connect PT100 GND wire to Pin 7 of J10 connector.

2-Wire Probe:

1. Short Pin 5 & 6 of J10 connector using a jumper wire.

2. Connect PT100 sense wire to Pin 6 of J10 connector

3. Connect PT100 GND wire to Pin 7 of J10 connector.

7

Page 14

Instruction Manual Alpha-CON 550

2.4 Installation

2.4.1 Mechanical Dimensions

lpha CON550

ESC

CAL

2.4.2 Wall Mount

ENT

Conductivity Monitor

Cover the catch slots at

2

both sides with overlays

Pierce through holes at

11

both sides

8

Page 15

Instruction Manual Alpha-CON 550

2.4.3 Panel Mount

Prepare panel cut-out of

1

1

92.0 mm X 92.0 mm

Remove back cover of

2

conductivity monitor

and slide it through

panel cut-out

Gasket

Panel

Panel

Insert threaded rods through catch

4

until conductivity monitor is held

against panel

Attach catch to both sides

3

of conductivity monitor

9

Page 16

Instruction Manual Alpha-CON 550

2.5 Display & Keypad

2.5.1 Display Overview

The Liquid Crystal Display (LCD) of αlpha CON 550 conductivity monitor has

two alpha-numerical displays (Upper and a Lower).

• Upper display: Measured conductivity value is displayed when the

monitor is in normal operation (measurement) mode.

• Lower display: Measured temperature value is displayed when the

monitor is in normal operation (measurement) mode. In conductivity

calibration mode, measured conductivity values are displayed here.

The two displays indicate function names, options & settings in Setup mode.

Refer ‘Appendix 4 - Abbreviations Used in LCD’ for more details.

The LCD also consists of various mode indicators, status annunciators and

unit of measurement indicators.

Upper Display

Mode Indicators

MEAS

SETUP

CAL

Status Annunciators

READY

HOLD

ATC

Measurement mode (Refer Section 3.1 )

Setup mode (Refer Section 5)

Calibration mode (Refer Section 4)

Appears when the reading is stable

Appears in Setup mode and Calibration mode to indicate that the relay function

is frozen

Appears when Automatic Temperature Compensation (ATC) is enabled.

Not visible when Manual Temperature Compensation (MTC) is enabled.

Flashes if the temperature probe is faulty in its ATC mode.

SETUP ME AS

READY

HOLD

ERR

K=

8.8.8.8

-

-

CAL

.8.8.8

Lower Displ a y

R.

%

mS

µS

°F

°C

ATC

(Refer Section 5.3)

ERR

K

Appears when an error occurs

Electrode annunciator. Blinks during calibration error (Refer Section 4.2)

Buffer annunciator. Appears in calibration mode (Refer Section 4.2)

Cell Constant (Refer Section 4.2)

10

Page 17

Instruction Manual Alpha-CON 550

Units of Measurement Indicators

mS

µS

R.

%

ºC

ºF

Conductivity in Milli Siemens

Conductivity in Micro Siemens

Line Resistance in Ohms (Refer Section 5.5)

Temperature Coefficient (Refer Section 5.2)

Temperature in Celsius (Refer Section 5.3)

Temperature in Fahrenheit (Refer Section 5.3)

2.5.2 Key Functions

lpha CON550

Key Description

CAL

Enter Calibration mode

Enter Setup mode

Access sub screens (parameters) within a group of settings in Setup

ENT

mode

Confirm (save) setup parameters and numerical values

Start/Confirm calibration in Calibration mode.

Select a group of settings in Setup mode.

Select parameters and increment/decrement numerical values in Setup

and Calibration modes.

(When pressed continuously, speed of value increment/decrement

increases)

ESC

CAL

Conductivity Monitor

ENT

Returns to Measurement mode when both keys are pressed

simultaneously.

11

Page 18

Instruction Manual Alpha-CON 550

3. Operation

3.1 Measurement mode

When the conductivity monitor is powered on, the display shows all the LCD

segments briefly, and then automatically enters into the measurement mode.

MEAS

READY

µS

°C

25.0

The mode indicator ‘MEAS’ at the top of the display indicates that the

conductivity monitor is in measurement mode. The upper alpha-numerical

display shows the measured conductivity value, while the lower display

shows the temperature value.

The monitor has five selectable measuring ranges. The unit of measurement

and resolution of the conductivity reading depend on the selected measuring

range. If the monitor reads a conductivity reading beyond the selected

measuring range, the display shows ‘Or’ (over range) error indicator.

NOTE:

From measurement mode you can access:

• Calibration mode (by pressing CAL key)

• Setup mode (by pressing ENT key)

For more details, refer section 4 for Calibration mode and section 5 for Setup

mode.)

To guarantee accurate readings, the measuring system (the

conductivity monitor and the sensor) must be calibrated regularly.

ATC

12

Page 19

Instruction Manual Alpha-CON 550

3.2 Menu Overview

READY

MEAS

ENT

µS

CAL ENT

°C

ATC

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

13

Page 20

Instruction Manual Alpha-CON 550

4. Calibration Mode

4.1 About Calibration

Calibration should be carried out each time a new electrode is attached to the

monitor or when you suspect that the monitor/electrode is out of calibration.

The monitor allows you to perform temperature calibration and conductivity

calibration.

About Temperature Calibration

It is important to ensure that temperature calibration is carried out prior to

conductivity calibration since temperature readings affect the accuracy of

conductivity measurements. It is recommended that temperature calibration

should be carried out only if the temperature value displayed on the monitor

is different from that of a calibrated thermometer. A temperature offset

calibration of ± 10 °C/± 18 °F from the default reading is allowed. Once a

temperature calibration is performed, conductivity calibration should be

carried out to ensure the accuracy of conductivity measurements.

About Measuring Ranges & Conductivity Calibration

The monitor has five selectable conductivity measuring ranges. You can only

calibrate one-point in the measuring range that you have selected for your

process application. You have to recalibrate the monitor every time you

change the measuring range since the calibration data of the monitor will be

reset every time a new measuring range is selected.

About Conductivity Calibration

During conductivity calibration, the monitor allows a calibration window of

± 40% from the measured default reading of the calibration standard. The

minimum allowable calibration point is 10% of the full scale reading of the

measuring range selected.

For best results, select a standard conductivity solution close to the sample

value you are measuring.

14

Page 21

Instruction Manual Alpha-CON 550

A

4.2 Calibration

The monitor requires one-point calibration. Conductivity calibration is always

carried out in the specific measuring range selected for the monitor. Make

sure, the monitor is set to desired measuring range before you enter

calibration mode (Refer Section 5.4 for selecting measuring ranges).

Select a suitable standard conductivity solution so that its conductivity value

is within 10% to 100% of the full scale of the selected measuring range of the

monitor. (For better accuracy, select the calibration standard to be nearly

50% of the full scale of the measuring range selected.) Prepare calibration

standard solution in two beakers – one for rinsing and the other for calibration.

Prepare separate de-ionized water for electrode rinsing.

All new calibration values will automatically override existing calibration data.

If you wish to abort the calibration, press ▲ and ▼ keys simultaneously and

the monitor reverts to measurement mode and the monitor will revert to

previous calibration data.

READY

MEAS

1

µS

CAL

°C

ATC

HOLD

HOLD

From measurement mode press CAL key to enter calibration mode.

11

The display briefly shows the cell type (“2 CELL” or “4 CELL”) to which

2

the monitor is configured (Refer section 5.5 for cell type settings)

Next, the last configured cell constant (k) is displayed in the upper

display. Use ▲ or

constant of the conductivity probe. Adjustable range is 0.10 to 10.0.

Press ENT key to confirm the new cell constant value.

Rinse the electrode in de-ionized water and then rinse with the

calibration standard. Immerse the probe in calibration standard solution

intended for calibration and swirl gently to create a homogenous sample.

Make sure there are no any air-bubbles trapped in the sensor.

OR

2

HOLD

K=

HOLD

K=

CAL

CAL

2

ENT

READY

HOLD

2

READY

HOLD

CAL

CAL

3

µS

3

µS

ENT

READY

HOLD

READY

CAL

MEAS

▼ keys to adjust the cell constant to mach the cell

ENT

4

µS

°C

TC

The upper display shows the currently measured conductivity value of

3

the solution based on last calibration (if any). The lower display shows

uncalibrated (default) reading of the solution. The buffer annunciator

appears in LCD. The ‘READY’ annunciator appears when the reading is

stable.

Once the reading stabilizes press the ▲ or ▼ key to adjust the upper

display value to that of the standard solution. Press the ENT key to

accept the value.

15

Page 22

Instruction Manual Alpha-CON 550

NOTES:

• The acceptable calibration window is ±40% of the

displayed (default) value. For example, if the display is

1000 µS, the values to which it can be adjusted is 600 to

1400 µS.

• If the conductivity reading of the solution is not within 10%

to 100% of the full scale of the selected measuring range,

calibration error occurs; LCD displays “ERR” and flash

electrode annunciator.

• If the conductivity reading of the solution is beyond the

selected measuring range, calibration error occurs; LCD

displays “Or” (over range), “ERR” and flashes electrode

annunciator.

• If calibration error occurs, exit form calibration mode by

pressing ▲ and ▼ keys simultaneously.

Calibration is completed. The display shows the calibration factor (FCt).

4

This serves as an indication of the effectiveness of the sensor which will

degrade with time and usage. An effective sensor should have a

calibration factor of 0.60 to 1.40

Press ENT key to return to measurement mode.

NOTES:

• If you use a 2-cell conductivity sensor, make sure that the pin 1 and 2

are shorted and pin 3 and 4 are shorted on the J10 connector. (Refer

section 2.3.3 for more details)

• When calibrating with manual temperature compensation, the monitor

automatically changes from the preset process temperature to the

calibration temperature. After leaving the Calibration mode, the

monitor switches back to the process temperature (for setting the

calibration temperature and the process temperature, see section 5.3)

WARNING: If you change the measuring range of the monitor after calibration

is done, the monitor will reset back to its factory default calibration.

16

Page 23

Instruction Manual Alpha-CON 550

5. Setup Mode

5.1 Enter Setup mode

The setup mode allows you to customize the settings of the conductivity monitor to

suite your requirements. While in measurement mode, press the ENT key to access

setup mode. LCD shows ‘SETUP’ mode indicator and the first page of setup (rAng –

Range settings). Press ▲ or ▼ key to access other pages of the setup mode.

READY

MEAS

µS

°C

ATC

ENT

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

NOTES:

• To exit setup mode at any time press ▲ and ▼ keys simultaneously

(escape). The monitor returns to the measurement mode

• If you do not press any key for 2.5 minutes, the monitor automatically

exists from the setup mode.

17

Page 24

Instruction Manual Alpha-CON 550

5.2 Temperature Coefficient Settings

Setting the temperature coefficient to match your process/calibration liquids allows

monitor to achieve conductivity readings with higher accuracy.

SETUP

HOLD

From measurement mode press ENT key to enter setup mode as

11

1

ENT

SETUP

HOLD

SETUP

HOLD

2

2

ENT

ENT

SETUP

HOLD

3

%

ENT

SETUP

HOLD

4

%

described in section 5.1. The LCD shows the first screen of setup mode

(rAng). Press ▲ or ▼ key to select temperature coefficient settings

screen (tC).

Press ENT key to access temperature coefficient settings (tC).

Select type of temperature coefficient: The upper display shows the

2

last configured temperature coefficient type (Lin or PUr). Press ▲ or ▼

key to select the desired type based on type of your process liquid.

PUr :

Pure water temperature coefficient: Select this if your process

liquid is pure water or ultra pure water.

ENT

Lin :

Linear temperature coefficient: Select this for all other

process liquids

Press ENT key to confirm your selection.

If PUr was selected:

The monitor reverts back to tC screen

If Lin was selected:

Select temperature coefficient for process liquid: The lower

3

display shows ‘P.tC’. The upper display shows last configured

temperature coefficient for process liquid (if any). The default value

is 2.1%. Press ▲ or ▼ key to select the desired value. Allowable

range: 0 to 10%.

Press ENT key to confirm your value.

Select temperature coefficient for calibration liquid: The lower

4

display shows ‘C.tC’. The upper display shows last configured

temperature coefficient for calibration liquid (if any). The default

value is 2.1%. Press ▲ or ▼ key to select the desired value.

Allowable range: 0 to 10%. Press ENT key to confirm your value.

The monitor reverts to tC screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

18

Page 25

Instruction Manual Alpha-CON 550

A

5.3 Temperature Settings

Automatic Temperature Compensation (ATC):

The conductivity value of a sample is affected by temperature. Use ATC feature of

the monitor to compensate for conductivity changes when the temperature of the

sample or process liquid fluctuates. Connect a separate temperature probe

(Pt100/pt1000) to the monitor if an integrated conductivity/Temperature probe is not

available.

Manual Temperature Compensation (MTC):

Set the monitor to MTC (disable ATC) when the temperature of sample or process

liquid is constant and a temperature probe is not available. If you disable ATC, the

monitor allows you to set your process temperature (P.ºC) and calibration

temperature (C.ºC). This allows calibration at a different temperature other than the

process temperature. Example: Setting calibration temperature of 25°C lets you

calibrate using standard solutions at 25°C, even if your process temperature is

different from 25°C.

SETUP

HOLD

1

ENT

SETUP

HOLD

SETUP

HOLD

2

°C

2

°F

ENT

ENT

SETUP

HOLD

SETUP

HOLD

3

°C

3

°C

ENT

ENT

SETUP

HOLD

SETUP

HOLD

4

°C

TC

6

ENT

SETUP

HOLD

SETUP

HOLD

From measurement mode press ENT key to enter setup mode as

11

described in section 5.1. The LCD shows the first screen of setup mode

(rAng). Press ▲ or ▼ key to select Temperature settings screen (SET

ºCF).

Press ENT key to access temperature settings (SET ºCF).

Selecting unit of measurement for temperature: The upper display

2

shows ‘Unit’ and the lower display shows the last configured unit of

measurement for temperature.

5

ENT

°C

ATC

7

ENT

Press ▲ or ▼ key to select the desired units for temperature (ºC or ºF).

Press ENT key to confirm your selection.

Enable/disable ATC: The lower display shows ‘AtC’ and the upper

3

display shows the last configured ATC selection (‘On’ or ‘OFF’).

Press ▲ or ▼ key to enable (ATC On) or disable (ATC OFF) automatic

temperature compensation. Press ENT key to confirm your selection.

19

Page 26

Instruction Manual Alpha-CON 550

If ATC enabled (ATC On):

Selecting temperature offset: The upper display shows the last

4

configured temperature offset value (if any), otherwise the default is

zero. The lower display shows currently measured temperature

reading (including last configured offset value). LCD shows ‘ATC’

annunciator in lower-right corner.

Place a thermometer, which is known to be accurate, in your

sample or process liquid. Make sure your temperature probe is

placed in the same liquid. Compare the stabilized temperature

reading displayed on the monitor with the thermometer. If there is a

difference between the two readings (offset), you can adjust the

reading of the monitor. Press ▲ or ▼ key to adjust the lower

display to the correct temperature value.

As the lower display value changes, the monitor adjust the upper

55

display reading automatically to suit the new offset value. Up to ± 10

ºC/ ± 18 ºF offset is allowed.

Press ENT key to confirm the value. The monitor reverts to SET

ºCF screen.

If ATC disabled (ATC OFF):

Setting process temperature: The lower display shows ‘P.ºC’ and

6

the upper display shows the last configured process temperature.

Press ▲ or ▼ key to adjust the upper display to desired process

temperature. Allowable range: –10.0 to 125.0°C / 14.0 to 257.0°F.

Press ENT key to confirm the process temperature.

Setting calibration temperature: The lower display shows ‘C.ºC’

7

and the upper display shows the last configured calibration

temperature. Press ▲ or ▼ key to adjust the upper display to

desired calibration temperature. Allowable range: –10.0 to 125.0°C /

14.0 to 257.0°F.

Press ENT key to confirm the calibration temperature. The monitor

reverts to SET ºCF screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

To exit from any intermediate steps, press ▲ and ▼ keys simultaneously

(escape). The monitor returns to the first screen of temperature settings SET

ºCF.

20

Page 27

Instruction Manual Alpha-CON 550

5.4 Measuring Range Settings

The conductivity monitor has 5 different measuring ranges. You need to select a

range which is the most suitable for conductivity reading of your applications/samples.

The factory default is 2000 µS (0 to 2000 µS/cm).

The measuring range you select here will affect the way the monitor behaves in the

measurement mode and calibration mode. In measurement mode, if the conductivity

reading of the monitor is above the selected measuring range, the LCD shows “Or”

(over range) error. In calibration mode, the monitor adjusts calibration tolerance

based on full scale of the selected measuring range. The calibration is carried out

only for the selected measuring range.

WARNING: If you change the measuring range of the monitor after calibration is

done, the monitor will reset back to its factory default calibration.

From measurement mode press

11

ENT key to enter setup mode as

described in section 5.1. The LCD

shows the first screen of setup mode

(rAng). Press ENT key to access

measurement range setting (rAng).

The upper display shows the

2

currently selected measuring range.

The factory default is 2000 µS. The

lower display shows the currently

configured cell constant (k). (Refer

section 4.2 for setting cell constant)

Press ▲ or ▼ key to select the

desired measuring range. Press

ENT key to confirm your selection.

The monitor reverts to rAng screen.

Measuring range Resolution

0.00 to 20.00 µS/cm 0.01 µS/cm

0.0 to 200.0 µS/cm 0.1 µS/cm

0 to 2000 µS/cm 1 µS/cm

0.00 to 20.00 mS/cm 0.01 mS/cm

0.0 to 200.0 mS/cm 0.1 mS/cm

SETUP

HOLD

1

ENT

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

2

µS

ENT

2

µS

ENT

2

µS

ENT

2

mS

ENT

2

mS

ENT

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

21

Page 28

Instruction Manual Alpha-CON 550

5.5 Configuration Settings

Configuration settings let you select between 2-cell & 4-cell and reset the monitor to

factory defaults.

SETUP

HOLD

1

ENT

SETUP

HOLD

SETUP

HOLD

2

2

SETUP

ENT

HOLD

This screen appears only

when 2-cell is selected

and measuring range is set to

0.0 to 200.0 mS/cm

ENT

3

R.

ENT

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

READY

MEAS

ATC

4

ENT

4

ENT

4

ENT

µS

°C

From measurement mode press ENT key to enter setup mode as

11

described in section 5.1. The LCD shows the first screen of setup mode

(rAng). Press ▲ or ▼ key to select configuration settings screen

(Cnfg).

Press ENT key to access configuration settings (Cnfg).

Select cell type of the sensor: The lower display shows ‘CEL’. The

2

upper display shows the last configured cell type (‘2’ or ‘4’).

Press ▲ or ▼ key to select the cell type of your conductivity probe.

Press ENT key to confirm your selection.

NOTE: If you use a 2-cell conductivity sensor, make sure that the pin 1

and 2 are shorted and pin 3 and 4 are shorted on the J10 connector.

(Refer section 2.3.3 for more details)

Setting line resistance: The lower display shows ‘L.Ad’ and the upper

3

display shows the last configured line resistance; otherwise the default is

0.00 R.

NOTE: Line resistance of sensor cable constitutes to an error in

measurement of high conductivity values. The monitor will compensate

this error if you specify line resistance value in this setting. The setting is

available only if the cell type is set to 2-cell (step 3 above) and the

22

Page 29

Instruction Manual Alpha-CON 550

measuring range is selected to ‘0.0 to 200.0 mS/cm’.

Press ▲ or ▼ key to set the line resistance of the sensor cable

connected to the monitor.

Press ENT key to confirm your selection.

Reset to factory defaults: The display shows ‘nO dEF’.

4

Press ▲ or ▼ key to select:

nO dEF : Not default reset of the monitor. User configured values

remain active, when confirmed by pressing ENT key.

FCt dEF: Reset all settings of the monitor to factory defaults, when

confirmed by pressing ENT key.

CAL dEF: Reset all calibration settings of the monitor to factory

defaults, when confirmed by pressing ENT key.

NOTE: Refer section 6 for factory/calibration default settings

Press ENT key to confirm your selection.

- If ‘nO dEF’ was selected, the monitor reverts to Cnfg screen.

Press ▲ or ▼ key to access other setup screens or press ▲

and ▼ key simultaneously (escape) to return to measurement

mode.

- If ‘FCt dEF’ or ‘CAL dEF’ was selected, the monitor performs the

selected reset and returns to measurement mode.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

To exit from any intermediate steps, press ▲ and ▼ keys simultaneously

(escape). The monitor returns to the first screen configuration settings (Cnfg).

23

Page 30

Instruction Manual Alpha-CON 550

5.6 Viewing Electrode Properties

Each time you calibrate the conductivity sensor, the monitor re-calculates the

calibration factor of the sensor and shown in the LCD at the end of calibration. The

setup mode allows you to view the last saved calibration factor and cell constant at

any time.

SETUP

HOLD

1

ENT

SETUP

HOLD

2

ENT

SETUP

HOLD

ENT

From measurement mode press ENT key to enter setup mode as

11

described in section 5.1. The LCD shows the first screen of setup mode

(rAng). Press ▲ or ▼ key to select viewing electrode properties screen

(CdAt).

Press ENT key to view electrode properties (CdAt).

Cell constant: The lower display shows ’CEL’ and the upper display

2

shows the last configured cell constant.

Press ENT key.

Calibration factor: The lower display shows ‘FCt’ and the upper display

3

shows the calibration factor based on the last conductivity calibration.

NOTE: The upper display shows ‘- - - ‘ if the monitor has not been

calibrated yet or the monitor has been reset to factory defaults.

Press ENT key to quit from electrode properties screen. The monitor

reverts to CdAt screen.

Press ▲ or ▼ key to access other setup screens or press ▲ and ▼ key

simultaneously (escape) to return to measurement mode.

24

Page 31

Instruction Manual Alpha-CON 550

6. Technical Specifications

General Specification

Conductivity

Measuring Range: Resolution:

0.00 - 20.00 µS/cm 0.01 µS/cm

0.0 - 200.0 µS/cm 0.1 µS/cm

0- 2000 µS/cm 1 µS/cm

0.00 - 20.00 mS/cm 0.01 mS/cm

0.0 - 200.0 mS/cm 0.1 mS/cm

Relative accuracy ± 1% of full scale reading

System accuracy The effective measuring range and the total system

accuracy depend on the sensor used with the monitor.

Please refer respective sensor documentation.

Temperature

Measuring range -10.0 to +125.0 oC

+14.0 to +257.0 oF

Resolution 0.1

Relative accuracy ±0.5 oC

Sensor 2 wire / 3 wire - Pt100 or Pt1000 (Jumper Selectable)

Compensation Automatic or Manual (reference at 25oC)

o

C

0.1 oF

±1.0 oF

Calibration

Conductivity

Number of calibration points 1 point

Calibration window ±40% of default reading

Calibration standard solution window 10% to 100% of the selected measuring range

Temperature

Offset Adjustment ± 10 ˚C/ ± 18 ˚F

Display

LCD 7 segments display with symbols for status information

Electrical Data and Connections

Conductivity Input Screw Terminal (3.5mm pitch)

Connection terminal 8-pin & 2-pin terminal blocks, DC power connector

EMC Specifications

Emission EN 61 36

Susceptibility EN 61326

Other

Power Input Universal +9 V DC Adaptor and 24V DC Supply

Dimensions (W x H x D) 96mm x 96mm x 66 mm

Weight (Estimated) 210g

Ambient Temp. operating range 0 to 40 oC

Maximum Relative Humidity 80% up to 31 oC decreasing linearly to 50% at 40oC

(1.2mm diameter)

25

Page 32

Instruction Manual Alpha-CON 550

Calibration Default Settings (CAL dEF)

Conductivity

Calibration factor Reset to 1.000

Factory Default Settings (FCt dEF)

Conductivity

Calibration factor Reset to 1.000

Cell constant 1.00

Cell type 2-cell

Measuring range 0 to 2000 µS/cm

Line resistance 0.000 Ω

Temperature

Unit of measurement

o

C

Temperature compensation ATC On

Temperature coefficient 2.1% (Both process & calibration temp. coefficients)

Temperature coefficient type Linear

MTC (ATC Off) 25 oC (Both process & calibration temperature)

26

Page 33

Instruction Manual Alpha-CON 550

7. List of Accessories

Monitor Replacement and Accessories

Item Description Order Code

Alpha CON 550 Monitor EC-PHCP0550

Conductivity cell, Epoxy body, Graphite sensor, w/3-wire Pt100, k = 0.1 EC-CONSEN89X

Conductivity cell, Epoxy body, Graphite sensor, w/3-wire Pt100, k = 1.0 EC-CONSEN88X

Conductivity 2 Cell type probe, 0.1 - 200μS; Cell constant, K=0.1 with

integrated Pt 100, Material SS316 and 25ft cable (open-ended)

Conductivity 2 Cell type probe, up to 200 mS; Cell constant, K=1.0 with

integrated Pt 100, Material SS316 and 25ft cable (open-ended)

NOTE: Please contact your authorised distributor or dealer for the prices of extension

measuring cables and other accessories such as tee joints, electrode assembly, and

calibration solutions.

EC-CS10-0-1S

EC-CS10-1-0S

27

Page 34

Instruction Manual Alpha-CON 550

8. Troubleshooting

Problem

Power on, but no display a) Loose connections

Unstable conductivity

reading

Oscillating temperature

readings

Slow response a) Dirty / Oily probe a) Clean probe

Blinking ATC

Blinking electrode

annunciator

Or (Conductivity)

Or/Ur (Temperature)

Cause

b) Incorrect output voltage of

the power adaptor

c) Cables not in correct polarity

(+ and – position)

a) Air bubbles in the probe

b) Dirty probe

c) Probe not deep enough in

sample

a) Electrical nois e interference

a) No temperature probe

connection during ATC mode

a) Error in calibration

b) Conductiv ity value of the

calibration standard is not

within acceptable range

a) Conductiv ity reading is

above the selected

measuring range

a) Temperature probe is not

connected when ATC

enabled

b) Temperature value exceeds

above/ below the specified

range

Solution

a) Ensure cables make good

contact

b) Use an power adaptor with

specified output voltage

c) Re-wire loop cables with correct

polarity

a) Tap probe to remove air bubbles

b) Clean probe and recalibrate

c) Ensure that the sample entirely

covers the sensor of the probe

a) Ensure shield wire is properly

connected to pin 7

a) Ensure temperature sensing

cable makes good contact

a) Ensure calibration standard

solution is not contaminated.

Ensure electrode is clean

b) Ensure calibration standard is

within 10 to 100% of full-scale of

the selected measuring range

a) Ensure correct conductivity

measurement range is selected

a) Ensure electrode makes good

contact with monitor

b) Ensure temperature calibration is

done properly. Ensure process

temperature is within the

specified range

28

Page 35

Instruction Manual Alpha-CON 550

9. General Information

9.1 Warranty

Eutech Instruments warrants this product to be free from significant

deviations in material and workmanship for a period of one year from the date

of purchase. If repair is necessary and not the result of abuse or misuse

within the warranty period, please return by freight pre-paid and amendment

will be made without any charge. Eutech Instrument Customer Service Dept.

will determine if the product problem is due to deviations or customer abuse.

Out-of-warranty products will be repaired on an exchange basis at cost.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

• Improper or inadequate maintenance by customer

• Unauthorized modification or misuse

• Operation outside of the environment specifications of the products

9.2 Return of Goods

Before returning goods for any reason whatsoever, the Customer Service

Dept. has to be informed in advance. Items must be carefully packed to

prevent damage during shipment, and insured against possible damage or

loss. Eutech Instruments will not be responsible for any damage resulting

from careless or insufficient packing.

Warning: Shipping damage as a result of inadequate packaging is the

user's/distributor’s responsibility. Please follow the guidelines below before

shipment.

9.3 Guidelines for Returning Unit for Repair

Use the original packaging material if possible when shipping the unit for

repair. Otherwise wrap it with bubble pack and use a corrugated box for

additional protection. Include a brief description of any faults suspected for

the convenience of Customer Service Dept., if possible.

29

Page 36

Instruction Manual Alpha-CON 550

10. Appendices

10.1 Appendix 2 Conductivity of various aqueous solutions

At Temperature 25 oC /77 oF

Solution Conductivity Resistivity

Ultra-pure Water 0.055 µS/cm 18.18 MΩ-cm

Power Plant Boiler Water 0.05 - 1 µS/cm 1 - 18 MΩ-cm

Distilled Water 0.5 µS/cm 2 MΩ-cm

De-ionized Water 0.1 - 10 µS/cm 0.1 - 10 MΩ-cm

De-mineralized Water 1 - 80 µS/cm 0.01 - 1 MΩ-cm

Mountain Water 10 µS/cm 0.1 MΩ-cm

Drinking Water 0.5 - 1 mS/cm 1 - 2 kΩ-cm

Waste-water 0.9 - 9 mS/cm 0.1 - 1 kΩ-cm

Potable Water Maximum 1.5 mS/cm 0.7 kΩ-cm

Brackish Water 1 - 80 mS/cm 0.01 - 1 kΩ-cm

Industrial Process Water 7 - 140 mS/cm Rarely stated

Ocean Water 53 mS/cm Rarely stated

30

Page 37

Instruction Manual Alpha-CON 550

10.2 Appendix 4 - Abbreviations Used in LCD

Abbreviation Description

AtC Automatic Temperature Compensation CAL Calibration mode C.ºC Calibr ation temperature CdAt Electrode properties CEL Cell CnFg Configuration C.tC Temperature coefficient for calibration liquid dEF Default values FCt Factory (defaults) HOLD Relay functions are hold K Cell constant L.Ad Linear resistance Lin Linear MEAS Measurement mode Or Reading is over range P.ºC Process temperature P.tC Temperature coefficient for process liquid PUr Pure water rAng Range Set Setting SETUP Setup mode tC Temperature Coefficient tyP Type Ur Reading is under range

31

Page 38

NOTES

Page 39

Page 40

Water Analysis Instruments

North America

166 Cummings Center

Beverly, MA 01915 USA

Toll Free: 1-800-225-1480

Tel: 1-978-232-6000

Dom. Fax: 1-978-232-6015

Int’l Fax: 978-232-6031

Europe

P.O. Box 254, 3860 AG Nijkerk

Wallerstraat 125K, 3862 CN Nijkerk,

Netherlands

Tel: (31) 033-2463887

Fax: (31) 033-2460832

Asia Pacific

Blk 55, Ayer Rajah Crescent

#04-16/24, Singapore 139949

Tel: 65-6778-6876

Fax: 65-6773-0836

www.thermo.com/process

© 2009 Thermo Fisher Scientific Inc.

All rights reserved. Thermo Fisher Scientific Inc.

68X216870 Rev 4

Loading...

Loading...