Page 1

Inductive

Read/Write Identsystem

CIS3

System - Manual

for

Read-Only Head CIT3PL..

Read/Write Head CIT3SX..

Ident. Nr. 071652

EUCHNER GmbH + Co.

Industrie-Elektrik und -Elektronik

Kohlhammerstraße 16

D-70771 Leinfelden-Echterdingen

Telefon: 07 11 / 75 97-0

Telefax: 07 11 / 75 33 16

www.euchner.de

info@euchner.de

Page 2

EUCHNER Identsystem CIS3

Contents

1. Overview................................................................................................................. 3

1.1. Cable- and terminal assignment................................................................................. 3

1.1.1 Read-Only Head CIT3PL........................................................................................ 3

1.1.2 Read/Write Head CIT3SX... ................................................................................... 4

1.2 Connection example for read/write head CIT3SX........................................................ 4

2. Notes on installation ............................................................................................... 4

3. Pulse Timing Diagram for the Read-Only Head CIT3PL... ..................................... 5

4. Basic telegram structure without response telegram .............................................. 6

4.1 Basic command structure............................................................................................ 6

4.2 Special features of the 3964-R data transfer protocol /1/ ............................................ 7

4.2.1 Basic information on data transfer procedures with protocol /1/ ............................. 7

4.2.2 The 3964-R transfer protocol /1/ ............................................................................ 7

4.2.2.1 Control sends /1/ ................................................................................................ 8

4.2.2.2 Control receives /1/ ............................................................................................ 8

4.2.3 Summary of the most important points................................................................... 9

5. Commands for writing and reading the data carrier.............................................. 10

5.1 Write operation ......................................................................................................... 10

5.2 Read operation ......................................................................................................... 11

5.3. Command overview:................................................................................................. 13

6. Error messages .................................................................................................... 13

7. Example of a PC-Program in Q-BASIC under MS-DOS....................................... 14

8. Maximum permitted centre offset of the CIT3PL... read only head ...................... 19

9. Maximum relative speed with the CIT3PL... read only head................................. 20

10. Installation instructions for CIS3 data carriers .................................................... 21

11. Technical data .................................................................................................... 22

Bibliography:............................................................................................................. 23

071652-01-8/99 Subject to technical modifications page 2 / 23

Page 3

EUCHNER Identsystem CIS3

1. Overview

This Manual describes on the whole the communication between PLC resp. CNC control and

the CIT3SX... read/write head.

The Protocol R transfer procedure serves to connect the CIT3SX1 read/write head to

PLC or NC controls.

The transfer telegrams for the commands

- Program (write) data carrier

- Read data carrier

are based on the 3964-R transfer procedure /1/

1.1. Cable- and terminal assignment

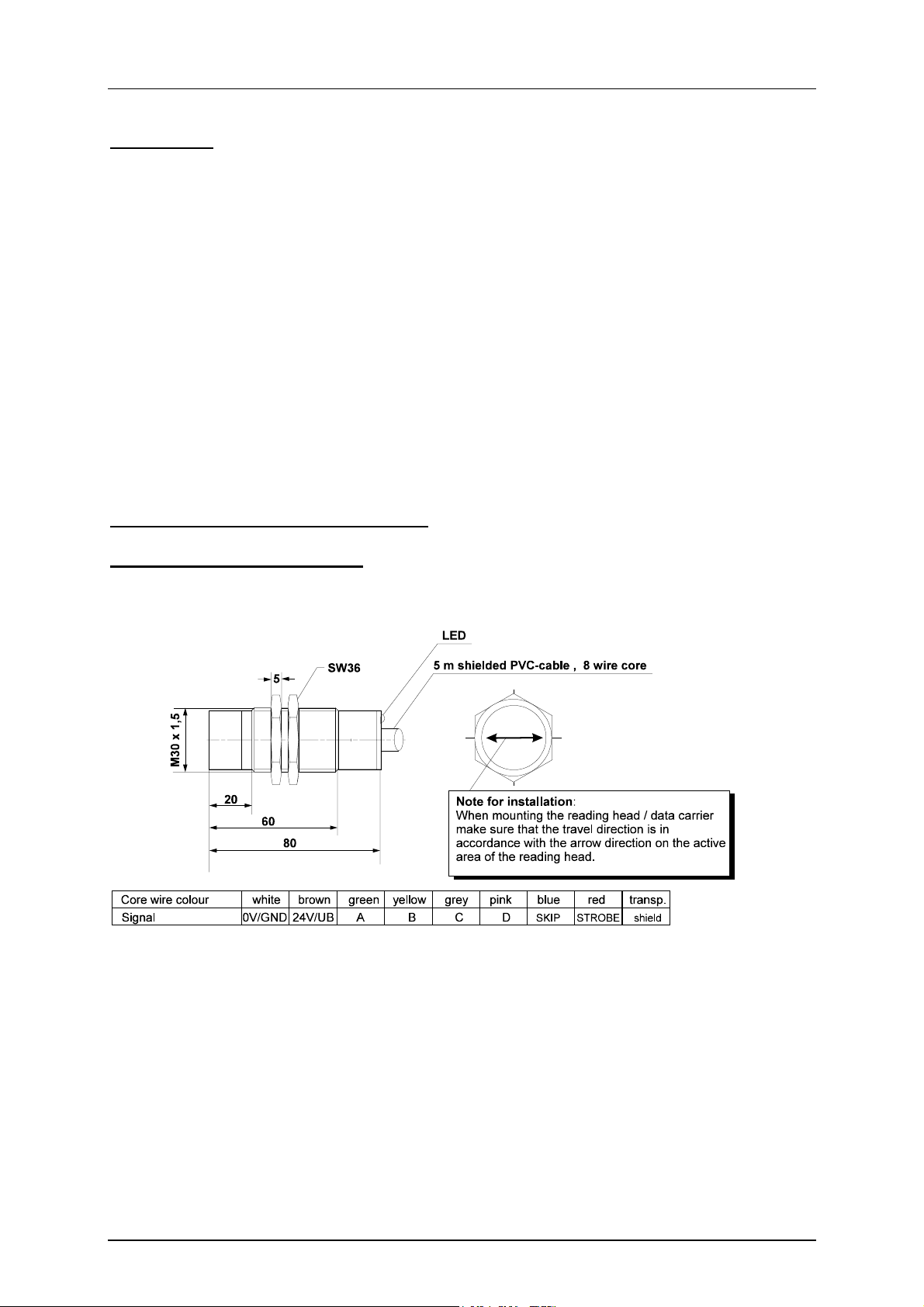

1.1.1 Read-Only Head CIT3PL...

Figure 1: Wiring diagram of the read-only head CIT3PL...

071652-01-8/99 Subject to technical modifications page 3 / 23

Page 4

EUCHNER Identsystem CIS3

K

4

3

2

1

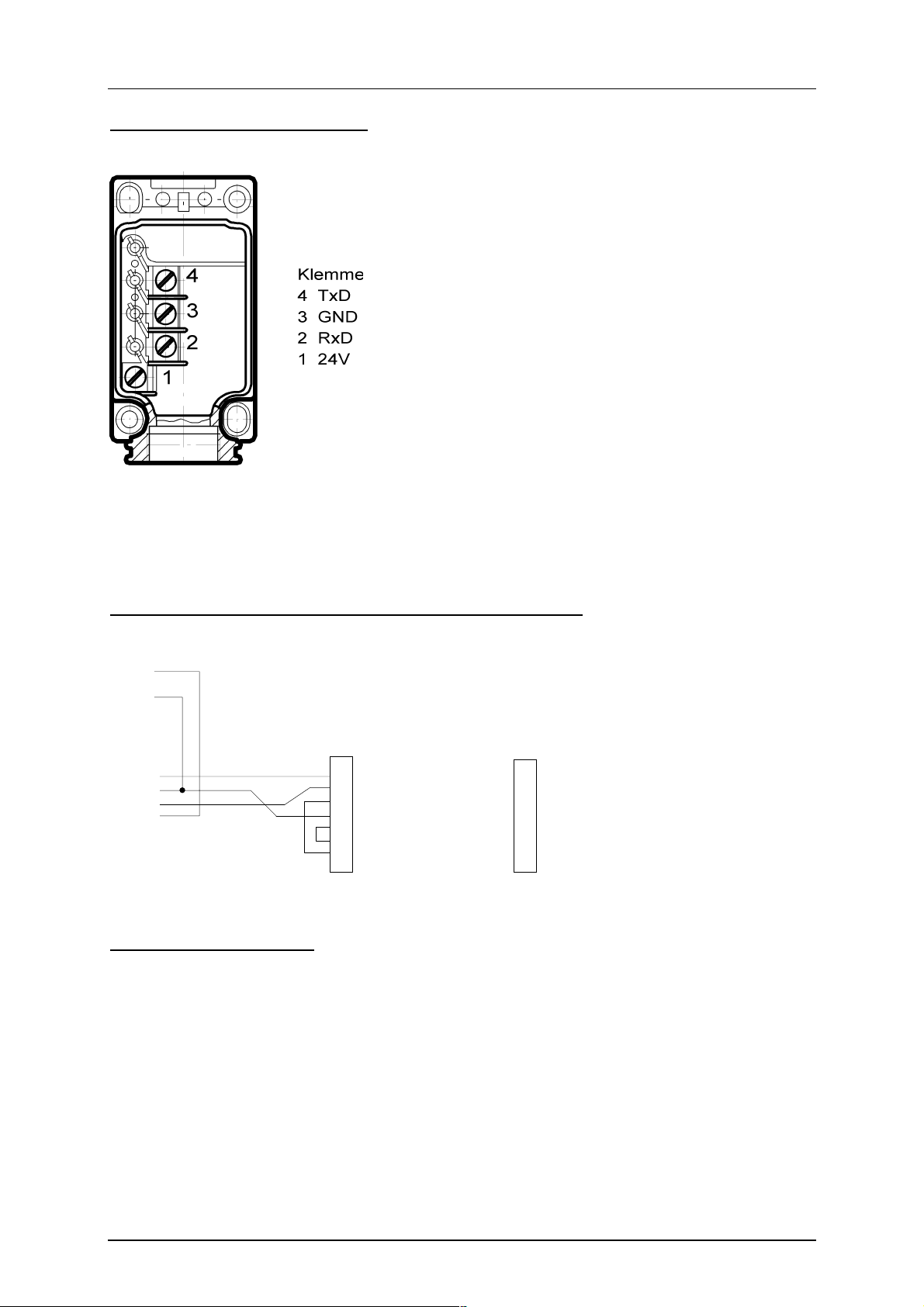

1.1.2 Read/Write Head CIT3SX...

Figure 2: Terminal assignment read/write head CIT3SX1R1G05...

( basic unit with terminal cover open )

1.2 Connection example for read/write head CIT3SX...

24V

GND

PC oder SPS

9-pin

lemme

TxD

GND

RxD

24V

2 Receive Data

3 Transmit Data

4 Data Term Ready

5 Signal Ground

7 Request to Send

8 Clear to Send

6 Data Set Ready

Figure 3

2. Notes on installation

• Do not connect the read/write head CIT3SX... as well as the read-only head CIT3PL... if it

is still connected to the electrical power supply.

• The Read-Only head CIT3PL... should be mounted isolated, to avoid any interference’s

• When mounting the facilities make sure that the travel direction is in accordance with the

arrow direction on the active area of the reading head.

25-pin

3

2

20

7

4

5

6

071652-01-8/99 Subject to technical modifications page 4 / 23

Page 5

EUCHNER Identsystem CIS3

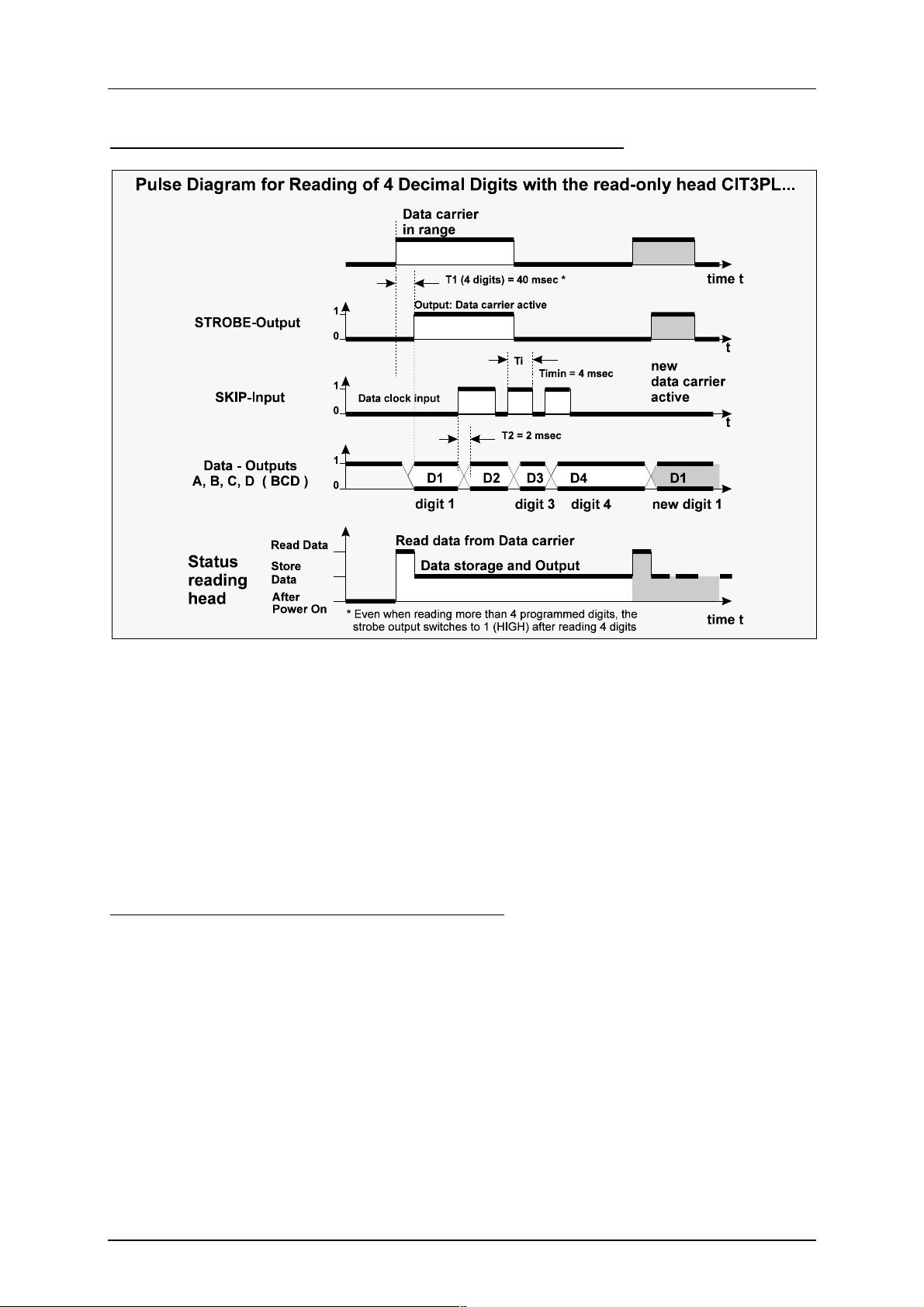

3. Pulse Timing Diagram for the Read-Only Head CIT3PL...

The above pulse timing diagram shows the time response of the input and output signals of

the read-only head with respect to the PLC.

As soon as a data carrier is read in, the first digit is disposed at the data outputs of the readonly head. To switch the following digits to the data outputs, you have to give a HIGH-pulse

to the Skip-input.

With every HIGH-pulse to the Skip-input, the digits are switched on.

The read-only head stores the coded information read from one data carrier until another

data carrier has been read.

The storage function offers the following advantage:

At high relative speeds between Read head and data carrier, the dwell time of a data carrier

in the read-only head’s response range may, under certain circumstances, be shorter than

the scan time of the PLC control. Owing to the storage characteristics of the Read head, the

code can nevertheless be read by the PLC in the next scan time cycle.

The additional STROBE output, when at HIGH level, indicates that a data carrier is located in

the read head’s response range.

This output is set to HIGH as soon as the Read head has been able to read 4 decimal digits.

If more than 4 digits are required, it is not possible to check with the STROBE output

whether all required digits have been read in.

If any error should occur during reading, an error message F

is given at the point in the

hex

data string. All preceding data is valid.

071652-01-8/99 Subject to technical modifications page 5 / 23

Page 6

EUCHNER Identsystem CIS3

p

4. Basic telegram structure without response telegram

Each command and any related data blocks are transferred within the telegram frame in

accordance with Procedure 3964-R from and to the read/write head (Figure 4).

With Protocol 3964-R, the relevant receiver acknowledges the received telegram by

returning an acknowledgement character (DLE). In the case of negative acknowledgement

(NAK), the entire protocol is repeated. If it is not possible to transfer the protocol error-free

after a total of six attempts, the operation is aborted.

4.1 Basic command structure

Connection set-u

Telegram data

max. 128 Bytes

(telegram core)

Connection

cleardown

Figure 4 : Basic command structure

Description Byte No. C O N T E N T S

ASCII

3964-R procedure start

STX

Number of telegram Bytes 0

Command

identification

Header address *) 3 01h

User data description 4

User data 7

3964-R Procedure

end

5

6

to n

1

2

T or R

command

Start address

Start address

Number of data

items

DLE

ETX

BCC

Acknowledgement

of the receiver

+ -

DLE NAK

DLE NAK

*) For downward compatibility with the CIS2 identification system.

The content of the header address must always be 1 in the case

of CIS3.

071652-01-8/99 Subject to technical modifications page 6 / 23

Page 7

EUCHNER Identsystem CIS3

4.2 Special features of the 3964-R data transfer protocol /1/

The 3964-R data transfer protocol is a comparatively reliable program for electronic data

interchange between a control and a connected peripheral since data transfer is handled with

a standardised protocol.

On controls with integrated 3964-R driver (see /1/ for instance), it is not necessary for the

user to bother with the details of connection set-up and cleardown resp. data integrity.

It suffices to transfer the telegram core to the 3964-R driver via the program.

On controls without 3964-R driver or if a read/write head is connected to PC’s, the user must,

however, also program the connection set-up and cleardown and the retry attempts.

4.2.1 Basic information on data transfer procedures with protocol /1/

Numerous conventions must be agreed for a data transfer procedure: codes, operating

modes, transfer speeds and the algorithmic transfer sequence. The stipulation of the

algorithmic sequence is referred to as transfer protocol (protocol for short). A transfer

protocol generally defines the following phases of data transfer:

• Request from A to B for data interchange

• Data interchange

• End of data interchange

The transfer protocol is essentially a matter of the control. This means that it handles data

transfer independently on the basis of this protocol.

4.2.2 The 3964-R transfer protocol /1/

Unlike non-protocol-based data transfer procedures, 3964-R is a data transfer procedure

with protocol. This means that the actual data to be transferred is enclosed in specific control

characters. The 3964-R driver allows comparatively reliable data transfer by virtue of the fact

that the receiver must first signal to the transmitter that it is ready to receive (connection

set-up) and, after data interchange, must acknowledge correct reception. Data integrity is

enhanced by an additional block check character with the 3964-R transfer protocol.

The 3964-R driver interprets the following control characters:

• DLE (10

• STX (02

• NAK (15

• ETX (03

) Data Link Escape

hex

) Start of Text

hex

) Negative Acknowledgement

hex

) End of Text

hex

With the 3964-R transfer protocol, a block check character (BCC for short) is transmitted

for data integrity at the end of each data block. The block check character BCC is the even

longitudinal parity (EXORing of all data Bytes) of a transmitted or received block.

Generation starts with the first user data Byte (first Byte of the telegram) after connection

set-up and ends after characters DLE and ETX on connection cleardown.

071652-01-8/99 Subject to technical modifications page 7 / 23

Page 8

EUCHNER Identsystem CIS3

4.2.2.1 Control sends /1/

The control sends the control character STX in order to set up the connection. If the

peripheral responds before expiry of the acknowledgement delay time (QVZ, typically:

2 seconds) with control character DLE, the transfer protocol reverts to Transmit mode. If the

peripheral responds with control character NAK or any other character (apart from DLE) or if

the acknowledgement delay time elapses with no response, this means that connection

set-up has failed. The procedure is aborted after a total of 6 unsuccessful attempts

(specification of the 3964-R protocol).

If connection set-up is successful, the user information characters contained in the control's

transmit buffer are transmitted to the peripheral at the selected transfer speed. The

peripheral monitors the interval between the incoming characters. The interval between two

characters may not exceed the character delay time (ZVZ, typically: 100 ms).

Each control character DLE (10

) contained in the user information must be transmitted

hex

twice so that the communication partner recognises that the data is user data and not the

control character DLE. (DLE doubling).

After transmission of the user data, the control appends the following characters as end

identifier: DLE, ETX, BCC

The control then waits for an acknowledgement character from the peripheral. If the

peripheral sends control character DLE within the acknowledgement delay time (QVZ,

typically: 2 seconds), the data block has been accepted error-free.

By contrast, if the peripheral responds with control character NAK or any other character or if

the acknowledgement delay time elapses with no response, the control starts transmission

again with connection set-up STX. The procedure is aborted and the control sends the

control character NAK to the peripheral after a total of 6 unsuccessful attempts (specification

of the 3964-R protocol).

If the peripheral sends control character NAK during a running transmission, the control

aborts the block and repeats it in the manner described above. In the case of any other

character, the control initially waits for the character delay time (ZVZ) to elapse and then

sends control character NAK in order to set the peripheral to idle state. The control then

starts transmission again with connection set-up STX.

4.2.2.2 Control receives /1/

If the control receives control character STX from the peripheral in idle state, it responds with

DLE. If the control receives another character (apart from STX) in idle state, it waits for the

character delay type (ZVZ, typically: 100 ms) to elapse and then sends the control character

NAK. After each character, the next character is awaited during the character delay time

(ZVZ). If the character delay time elapses without reception, control character NAK is sent to

the peripheral.

If the control detects character string DLE ETX BCC, it terminates reception. It compares

the received block check character BCC with the internally generated longitudinal parity. If

the block check character is correct and no other reception error has occurred, the control

sends control character DLE. If the BCC is errored, control character NAK is sent to the

peripheral. A retry is then awaited. If it is not possible to receive the block error-free even

after a total of 6 attempts (specification of the 3964-R protocol), or if the retry is not started

by the peripheral within the block waiting time of 4 seconds, the control aborts reception.

If transmission errors (lost character, frame error, parity error) occur during reception,

reception continues through to connection cleardown and control character NAK is then sent

to the peripheral. A retry in the manner described above is then awaited.

071652-01-8/99 Subject to technical modifications page 8 / 23

Page 9

EUCHNER Identsystem CIS3

4.2.3 Summary of the most important points

• DLE doubling:

In order for the control to be able to distinguish between control character DLE and any

randomly occurring DLE as user information character, a further DLE must be sent in

the case of a DLE as user information character. This means that if a byte with ASCII

value DLE ( 10

) occurs within the telegram core, this character must be transmitted

HEX

again so that it is not interpreted by the distant station as a control character for

connection cleardown.

• Block check character (BCC):

A block check character is sent at the end of each data block for data integrity. The block

check character BCC is the even longitudinal parity (EXORing of all data Bytes) of a

transmitted or received block. Generation starts with the first user data Byte (first Byte

of the telegram) after connection set-up and ends after characters DLE and ETX on

connection cleardown.

• Retry attempts in the case of errors:

If an error occurs for any reason during data transfer, a total of 6 attempts are made to

transfer the data correctly.

Please refer to the program example in the Annex of this Manual for further details.

071652-01-8/99 Subject to technical modifications page 9 / 23

Page 10

EUCHNER Identsystem CIS3

5. Commands for writing and reading the data carrier

Read and write operations are always initiated by the higher-level control

(NC, PLC) with a "command telegram".

The read/write head then sends a response telegram to the control.

Control Read/write head CIT3SX...

Command telegram

→

Response telegram

←

5.1 Write operation

The data carrier must be in front of the read/write head in the case of this command and

may be removed from the active area only after reception of the response telegram.

Command telegram (telegram core, PLC → CIT3SX , see also Figure 5):

TP (read/write head address) (start address) (number of Bytes user data) (user data)

Response telegram (telegram core, CIT3SX → PLC, see also Figure 6):

RF (read/write head address) (0.0) (Error No.)

Content or possible value range

Byte

No.

0

1

2

3 Read/write head address *)

4

5

6

7 ... 22

Figure 5: Command telegram "Write data carrier" (telegram core)

Description

ASCII

Number of telegram Bytes 8 ... 23

Command

identification

Start address of the

user data

Number of Bytes of the

user data 1 ... 10h 1 ... 16

User data

T

P

ASCII or HEX resp. BCD (code-transparent) **)

C O N T E N T S

HEX Decimal

54

50

01 01

00

0 ... 5Fh

84

80

00

0 ... 95

*) For downward compatibility with the CIS2 identification system.

The content of the header address must always be 1 in the case of CIS3.

**) If read/write head CIT3SX.. is used in conjunction with read head

CIT3PL, please note that a Byte comprises 2 BCD digits (0 ... 9) when

programming the user data.

071652-01-8/99 Subject to technical modifications page 10 / 23

Page 11

EUCHNER Identsystem CIS3

Byte

No.

0 Number of telegram Bytes 7

1

2

3 Read/write head address * 01 01

4

5

6 Error number

Figure 6: Response telegram "Write data carrier" (telegram core)

Description

ASCII

Command

identification

Padding data 00

*) For downward compatibility with the CIS2 identification system.

The content of the header address must always be 1 in the case of CIS3.

**) Error number f = 00: No error

R

F

02: Data carrier not in active area

03: Read operation aborted

05: Write operation aborted, move data carrier

C O N T E N T S

HEX Decimal

52

46

00

Error No. **

out of active area

82

70

00

00

5.2 Read operation

Command telegram (telegram core, PLC → CIT3SX , see also Figure 7):

TL (read/write head address) (start address) (number of Bytes user data)

Response telegram (telegram core, CIT3SX → PLC, see also Figure 8 or Figure 9):

There are two different possible responses for this command

1. RL (read/write head address) (start address) (number of Bytes user data) (user data)

or

2. RF (read/write head address) (0.0)(error No.)

The response telegram RL (see also Figure 8) means error-free reception of the data.

If it is not possible to read a data carrier, an RF response telegram is received

(see also Figure 9). The error number then indicates the cause of the error.

Content or possible value range

Byte

No.

0

1

2

3

4

5

6

Description

ASCII

Number of telegram Bytes 7

Command

identification

Read/write head address *) 01 01

Start address of

user data

Number of Bytes of

user data 1 ... 10h 1 ... 16

T

L

C O N T E N T S

HEX Decimal

54

4C

00

0 ... Fh

84

76

00

0 ... 15

Figure 7: Command telegram "Read data carrier" (telegram core)

071652-01-8/99 Subject to technical modifications page 11 / 23

Page 12

EUCHNER Identsystem CIS3

Byte

No.

0

1

2

3

4

5

Description

ASCII

C O N T E N T S

HEX Decimal

Number of telegram Bytes 8 ... 23

Command

identification

R

L

52

4C

Read/write head address *) 01 01

Start address of

user data

00

0 ... Fh

Number of Bytes of

6

7 ... 22

user data 1 ... 10h 1 ... 16

User data ASCII or HEX resp. BCD (code-transparent)

Figure 8: Response telegram "Read data carrier" (telegram core)

Byte

No.

0

1

2

3

4

5

6

Description

ASCII

C O N T E N T S

HEX Decimal

Number of telegram Bytes 7

Command

identification

R

F

52

46

Read/write head address *) 01 01

Padding data 00

00

Error number Error No.

82

76

00

0 ... 15

82

70

00

00

Error number f = 02: Data carrier not in active area

Figure 9: Response telegram "Read data carrier" (telegram core)

*) For downward compatibility with the CIS2 identification system.

The content of the header address must always by 1 in the case of CIS3.

071652-01-8/99 Subject to technical modifications page 12 / 23

Page 13

EUCHNER Identsystem CIS3

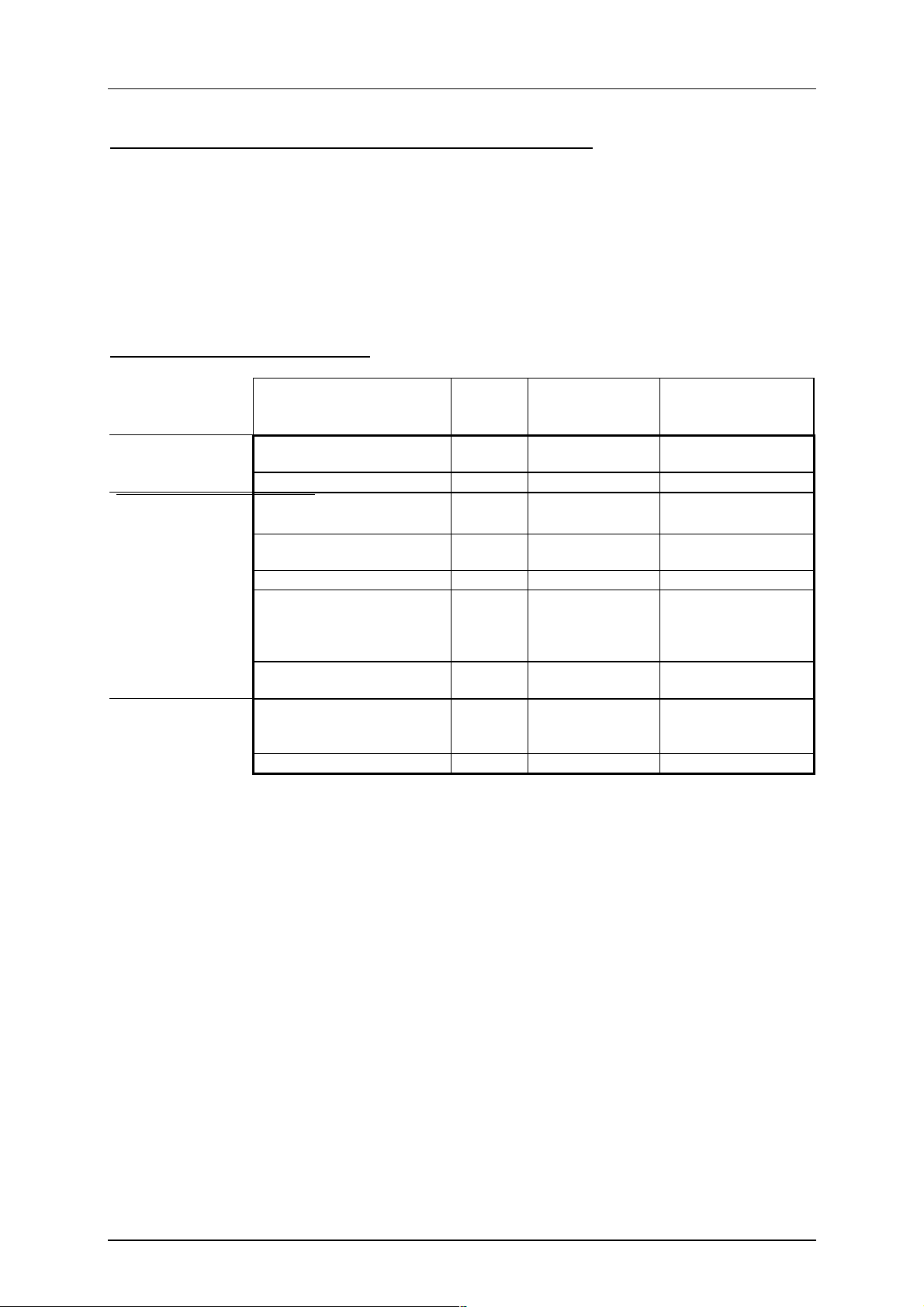

5.3. Command overview:

Description Command telegram Response telegram

Program data (Num. Tele-Bytes)

TP

(Read/write head address *)

(Start address)

(Number of Bytes user data)

(User data.....)

Read data carrier

in active area

*) For downward compatibility with the CIS2 identification system.

The content of the header address must always by 1 in the case of CIS3.

(Num. Tele-Bytes)

TL

(Read/write head address *)

(Start address)

(Number of Bytes user data)

(Num. Tele-Bytes)

RF

(read/write head address *)

(Error No.)

(Num. Tele-Bytes)

RL

(read/write head address *)

(Start address)

(Number of Bytes user data

(User data)

or

(Num. Tele-Bytes)

RF

(read/write head address *)

(Error No.)

6. Error messages

02h Data carrier not in active area

03h Read operation aborted

04h Error while programming or while check-reading the data carrier

05h Write operation aborted, remove data carrier from active area

16h Data length greater than 16 Bytes

071652-01-8/99 Subject to technical modifications page 13 / 23

Page 14

EUCHNER Identsystem CIS3

7. Example of a PC-Program in Q-BASIC under MS-DOS

' ******* Demoprogramm für EUCHNER S/L System *******************************'

DECLARE FUNCTION Lesebefehl$ (Start!, Anzahl%, Kopfnr%)

DECLARE FUNCTION Schreibbefehl! (Start!, Anzahl%, Kopfnr%, Daten$)

DECLARE FUNCTION Telegrammsenden! (Telegramm$, AnVersu!)

DECLARE FUNCTION Antworttelegramm$ (AnVersu!)

DECLARE FUNCTION BCCErmittlung$ (Telegramm$)

DECLARE FUNCTION Datenauswerten$ (A$)

DECLARE SUB Fehleranzeigen (A$)

REM ***** Einstellung fuer COM1 *****

REM OPEN "COM1:9600,N,8,1,CD,CS,DS,OP0,RS,TB0,RB0" FOR RANDOM AS #1

REM OUT &H3FB, &H1B '8 Datenbit 1 Stopbit Even Parity für COM1

REM ***** Einstellung fuer COM2 *****

OPEN "COM2:9600,N,8,1,CD,CS,DS,OP0,RS,TB0,RB0" FOR RANDOM AS #1

OUT &H2FB, &H1B '8 Datenbit 1 Stopbit Even Parity für COM2

REM ***** Verbindungsabbau **********

END$ = CHR$(&H10) + CHR$(&H3)

DO

CLS

PRINT "Datenträger lesen :1"

PRINT "Datenträger schreiben :2"

PRINT "Daten ausdrucken :3"

PRINT "Beenden :4"

PRINT " "

PRINT " "

INPUT "Auswahl :?", A

SELECT CASE A

REM ********* Datentraeger lesen *************

CASE 1

INPUT "Datenträger Startadresse :", A!

INPUT "Anzahl der Daten 0 bis 16 :", B%

INPUT "Kopfadresse :", C%

INPUT "Schleife J/N :", D$

SCHLEIFE:

Returnwert$ = Lesebefehl(A!, B%, C%)

IF Returnwert$ = "0" THEN

PRINT "Keine gültigen Daten eingelesen"

ELSE

PRINT Returnwert$

END IF

FOR i = 0 TO 10

NEXT i

IF D$ = "J" THEN GOTO SCHLEIFE

INPUT H

071652-01-8/99 Subject to technical modifications page 14 / 23

Page 15

EUCHNER Identsystem CIS3

CASE 2

REM ********* Datentraeger schreiben *************

INPUT "Datenträger Startadresse :", A!

INPUT "Daten max. 16 Bytes :", D$

INPUT "Kopfadresse :", C%

B% = 16

REM B% = LEN(D$)

Returnwert = Schreibbefehl(A!, B%, C%, D$)

REM ** Datentraegerinhalt nach lesen ausdrucken **

CASE 3

IF Returnwert$ = "0" THEN

PRINT "Keine gültigen Daten eingelesen"

ELSE

OPEN "LPT1:" FOR OUTPUT AS #2

PRINT #2, Returnwert$

INPUT H

CLOSE #2

END IF

CASE 4

REM ******* Programmende ************************

END

CASE ELSE

INPUT "Fehlerhafte Eingabe", H

END SELECT

LOOP UNTIL 0

CLOSE #1

END

'*

'******************** 3964R Antworttelegramm einlesen **********************

'*

FUNCTION Antworttelegramm$ (AnVersu)

END$ = CHR$(&H10) + CHR$(&H3)

STX$ = CHR$(2)

DLE$ = CHR$(&H10)

NAK$ = CHR$(&H15)

Wiederholzaehler = 0

Startantworttelegr:

A$ = INPUT$(1, #1) 'STX von Bussystem einlesen

PRINT #1, DLE$; 'DLE senden

Wiederholzaehler = Wiederholzaehler + 1

A$ = INPUT$(1, #1) 'Telegrammlänge einlesen

B = ASC(A$) - 1

BCCWE = ASC(A$)

IF A$ = DLE$ THEN 'DLE Vedopplung nach 3964R

D$ = INPUT$(1, #1)

BCCWE = BCCWE XOR ASC(D$)

END IF

FOR i = 1 TO B 'Telegramm einlesen

C$ = INPUT$(1, #1)

071652-01-8/99 Subject to technical modifications page 15 / 23

Page 16

EUCHNER Identsystem CIS3

BCCWE = BCCWE XOR ASC(C$)

IF C$ = DLE$ THEN 'DLE Vedopplung nach 3964R

D$ = INPUT$(1, #1)

BCCWE = BCCWE XOR ASC(D$)

END IF

A$ = A$ + C$

NEXT i

C$ = INPUT$(1, #1) 'DLE einlesen

BCCWE = BCCWE XOR ASC(C$)

C$ = INPUT$(1, #1) 'ETX einlesen

BCCWE = BCCWE XOR ASC(C$)

C$ = INPUT$(1, #1) 'BCC einlesen

IF Wiederholzaehler = AnVersu THEN 'nach mehrmaligen ungültigen Versuch, Verbindung abbrechen

PRINT "Kein gültiges Antworttelegramm"

PRINT #1, NAK$

GOTO Abbruch

END IF

IF BCCWE <> ASC(C$) THEN 'Vergleich ob Telegramm-BCC richtig ist

PRINT "BCC-Fehler", BCCWE, ASC(C$)

PRINT #1, NAK$

GOTO Startantworttelegr 'Erwartet Protokollwiederholung

END IF

PRINT #1, DLE$; 'positiv quittieren

Antworttelegramm$ = A$

Abbruch:

END FUNCTION

'*

'************************ Ermittlung des BCC *******************************

'*

FUNCTION BCCErmittlung$ (Telegramm$) STATIC

BCC = 0

FOR i = 1 TO LEN(Telegramm$)

BCC = BCC XOR ASC(MID$(Telegramm$, i, 1))

NEXT i

BCCErmittlung$ = CHR$(BCC)

END FUNCTION

'*

'**************** Daten aus dem Antworttelegramm ausfiltern ****************

'*

FUNCTION Datenauswerten$ (A$)

IF MID$(A$, 3, 1) = "K" THEN PRINT "Daten korrigiert"

Z = ASC(MID$(A$, 7, 1))

B$ = MID$(A$, 8, Z)

Datenauswerten$ = B$

END FUNCTION

'*

'********************* Fehler oder Statusermittlung ************************

'*

SUB Fehleranzeigen (A$)

PRINT "Fehler Nr. : ";

B$ = MID$(A$, 7, 1)

PRINT ASC(B$)

INPUT X

END SUB

071652-01-8/99 Subject to technical modifications page 16 / 23

Page 17

EUCHNER Identsystem CIS3

'

*

'*************************** Datenträger lesen *****************************

'*

FUNCTION Lesebefehl$ (Start!, Anzahl%, Kopfnr%)

Starthi% = Start \ 256 'Startadresse in high und low Teil aufteilen

Startlo% = Start MOD 256

Telegramm$ = CHR$(7) + "TL" + CHR$(Kopfnr%) + CHR$(Starthi%) + CHR$(Startlo%) + CHR$(Anzahl%)

IF Telegrammsenden(Telegramm$, 6) <> 0 THEN GOTO ende1

A$ = Antworttelegramm(6) 'Antworttelegramm einlesen

PRINT "Antworttelegramm auswerten"

'Antworttelegramm auswerten

IF MID$(A$, 3, 1) = "F" THEN Fehleranzeigen (A$): Lesebefehl$ = "0"

IF MID$(A$, 3, 1) = "L" THEN Lesebefehl$ = Datenauswerten(A$)

IF MID$(A$, 3, 1) = "K" THEN Lesebefehl$ = Datenauswerten(A$)

ende1:

END FUNCTION

'*

'****************** Daten auf Datenträger schreiben ************************

'*

FUNCTION Schreibbefehl (Start!, Anzahl%, Kopfnr%, Daten$)

Starthi% = Start \ 256 'Startadresse in high und low Teil aufteilen

Startlo% = Start MOD 256

Telegramm$ = CHR$(LEN(Daten$) + 7) + "TP" + CHR$(Kopfnr%) + CHR$(Starthi%) + CHR$(Startlo%) +

CHR$(Anzahl%) + Daten$

A = Telegrammsenden(Telegramm$, 6)

IF A <> 0 THEN GOTO ende

PRINT "Programmiertelegramm gesendet"

A$ = Antworttelegramm(6) 'Antworttelegramm einlesen

PRINT "Antworttelegramm auswerten"

'Antworttelegramm auswerten

IF MID$(A$, 3, 1) = "F" THEN Fehleranzeigen (A$)

Schreibbefehl = 0

ende:

END FUNCTION

'*

'********************* 3964R Telegramm senden ******************************

'*

FUNCTION Telegrammsenden (Telegramm$, AnVersu!)

END$ = CHR$(&H10) + CHR$(&H3)

STX$ = CHR$(2)

DLE$ = CHR$(&H10)

071652-01-8/99 Subject to technical modifications page 17 / 23

Page 18

EUCHNER Identsystem CIS3

Wiederholzaehler = 0

Protokolstart:

PRINT #1, STX$; 'STX ausgeben

A$ = INPUT$(1, #1) 'DLE einlesen

IF Wiederholzaehler = AnVersu! THEN

PRINT "Kein Verbindungsaufbau": INPUT " ", Q

Telegrammsenden = -1

GOTO ENDE2

END IF

IF A$ <> DLE$ THEN

Wiederholzaehler = Wiederholzaehler + 1

GOTO Protokolstart

END IF

telegraus$ = ""

FOR i = 1 TO LEN(Telegramm$)

C$ = MID$(Telegramm$, i, 1)

IF C$ = DLE$ THEN telegraus$ = telegraus$ + C$ 'DLE Verdopplung nach 3964R

telegraus$ = telegraus$ + C$

NEXT i

' Kommandotelegramm senden

PRINT #1, telegraus$ + END$ + BCCErmittlung$(telegraus$ + END$);

A$ = INPUT$(1, #1) 'DLE von Bussystem einlesen

IF Wiederholzaehler = AnVersu! THEN PRINT "negative Quittierung": INPUT " ", Q: Telegrammsenden = -1:

GOTO ENDE2

IF A$ <> DLE$ THEN Wiederholzaehler = Wiederholzaehler + 1: GOTO Protokolstart

PRINT "Anforderung gesendet"

Telesenden = 0:

ENDE2:

END FUNCTION

071652-01-8/99 Subject to technical modifications page 18 / 23

Page 19

071652-01-8/99 Subject to technical modifications page 19 / 23

Units used: Read-only head CIT3PL1N30-5000 (Order No. 040085)

Data carrier CIS3P35X16SH01KH (Order No. 040045)

Test conditions: Ambient temperature: 25 °C

8. Maximum permitted centre offset of the CIT3PL... read only head

EUCHNER Identsystem CIS3

Read distance (in mm)

0

1

2

3

4

5

6

7

-20 -15 -10 -5 0 5 10 15 20

8

10

11

9

12

permitted centre offset (in mm)

Page 20

071652-01-8/99 Subject to technical modifications page 20 / 23

Note: Since at least 4 decimal digits must be read, the diagram also only starts at the 4th decimal digit

9. Maximum relative speed with the CIT3PL... read only head

EUCHNER Identsystem CIS3

101112131415161718192021222324252627282930

Relative speed in m/min.

4567891011121314151617181920212223242526272829303132

Number of Decimal Digits

as a function of number of digits

max. relative read speed

Page 21

EUCHNER Identsystem CIS3

10. Installation instructions for CIS3 data carriers

Please comply with the following points when installing the data carrier in order to comply

with the technical specifications contained in the data sheets for the CIS3 ident system even

in the case of flush installation in metal:

• On data carrier, Type CIS3P35X16SH01KH (Order No. 040045 or 071745), there must

be a minimum clearance of 5 mm per side with respect to the surrounding metal on the

long side (35 mm side). The short side (16 mm side) may directly adjoin the surrounding

metal.

• Data carrier, Type CIS3P35X16SH01KV (Order No. 040046 or 071746) can be installed

flush in metal with no problems.

No minimum clearance with respect to the surrounding metal needs to be complied with

on any side.

071652-01-8/99 Subject to technical modifications page 21 / 23

Page 22

EUCHNER Identsystem CIS3

11. Technical data

CIT3PL1N30-5000

Operating voltage: 15 - 28 V

Current consumption: 100 mA (max.)

Load current per output: 30 mA (max.)

Storage temperature 0 - 80°C

Ambient temperature 0 - 50°C

Read distance: 0 - 12 mm (see also page 18)

Centre offset: nominal ±10 mm (see also page 18)

Response time

(for 4 decimal digits): 40 msec. (max.)

Relative speed: max. 30m/min. (see also page 19)

CIT3SX1R1G05KS:

Operating voltage: 15 - 25 V

Current consumption: 140 mA (max.)

Storage temperature 0 - 80°C

Ambient temperature 0 - 50°C

Type of connection: Screw terminals

Line length (RS232): 5 m (max.)

Read distance: 0 - 12 mm

Write distance

(Static writing): 0 - 6 mm

Write time

4 decimal digits: 230 ms (max.)

32 decimal digits: 420 ms (max.)

The following values are set for the serial interface (V24, RS 232):

1 Start Bit

8 Data Bits

1 Parity Bit (even parity)

1 Stop Bit

Baud rate: 9600 baud

071652-01-8/99 Subject to technical modifications page 22 / 23

Page 23

EUCHNER Identsystem CIS3

Bibliography:

/1/ SIEMENS Manuals :

Connection components for S5 controls:

Communication processor CP 521 SI

Designation : SIEMENS Order No.

Device Manual CP 521 SI GES5 998 - 1 UD 11

Communication processor CP 523

Designation : SIEMENS Order No.

Device Manual CP 523(d/e/f/s/i) GES5 998 - 0 DD d 1

Communication processor CP 544

Designation : SIEMENS Order No.

Device Manual CP 544(d/e/f) GES5 998 - 2 DB d 1

/2/ Link, W. Coding and code integrity on programmable data carrier

IDENT´88 , Sindelfingen

071652-01-8/99 Subject to technical modifications page 23 / 23

Loading...

Loading...