Page 1

SMART™ Chamber

(Statistical Mode Averaging Reverberation Test Site)

Installation, Operation,

& Maintenance Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 2004–2009 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo and SMART are

trademarks of ETS-Lindgren L.P; Scotch-Brite is a registered trademark for 3M.

Revision Record | MANUAL,SMART CHAMBER | Part #399275, Rev. E

Revision Description Date

A Initial Release March, 2004

B Updates/edits August, 2005

C Updated tuner Installation

Procedure; rebrand

D Added EC Declaration of

Conformity

E Updated Warranty July, 2009

ii |

July, 2008

November, 2008

Page 3

Table of Contents

Notes, Cautions, and Warnings ................................................ v

ETS-Lindgren Product Information Bulletin ............................ v

1.0 Good Shielding Practices ................................................... 7

2.0 Maintenance ......................................................................... 9

Optional Maintenance Program ..................................................................... 9

Tuners .......................................................................................................... 10

Cleaning ............................................................................................... 11

Doors ........................................................................................................... 11

Monthly Maintenance ........................................................................... 12

Annual Maintenance ............................................................................ 13

Replacing Finger Stock and Vinyl Seal ............................................... 13

Finger Stock Repair ............................................................................. 14

Service Procedures ..................................................................................... 15

3.0 Tuners ................................................................................. 17

General Precautions .................................................................................... 17

Installation Procedure for SMART 200 and Larger Chambers .................... 18

Electrical .............................................................................................. 25

Vertical Tuner Installation .................................................................... 25

Tuner Control – SMART 1000 ..................................................................... 25

RS-232 Port Settings ........................................................................... 26

Operation ............................................................................................. 26

Command Syntax ................................................................................ 27

Tuner Control – SMART 80 and SMART 200 .............................................. 27

4.0 Shielding ............................................................................. 29

Series 81 Modular Shielding ........................................................................ 29

Pan-Type Shielding ..................................................................................... 30

5.0 Power Line Filters .............................................................. 31

6.0 Vents ................................................................................... 33

7.0 Penetrations ....................................................................... 35

8.0 Doors ................................................................................... 37

General Precautions .................................................................................... 37

| iii

Page 4

Door Types .................................................................................................. 38

Door Operation for Types A, B, C, D, E, and F ............................................ 38

Type A Door Latch ............................................................................... 39

Type B Door Latch ............................................................................... 39

Door Operation for Type G .......................................................................... 40

Adjusting RCM 1 Hinges .............................................................................. 40

Up-and-Down Adjustment.................................................................... 40

Side-to-Side Adjustment ...................................................................... 40

Appendix A: Warranty ............................................................. 43

Appendix B: EC Declaration of Conformity .......................... 45

iv |

Page 5

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

| v

Page 6

This page intentionally left blank.

vi |

Page 7

1.0 Good Shielding Practices

To retain the RF shielding integrity of the chamber, follow these good shielding

practices:

• Periodically clean and lubricate doors.

• When mounting screw-retaining items within the enclosure, do not

penetrate through both shields of a modular panel system. Screws

must not penetrate any portion of the screen system.

• Do not use framing screws to fasten items within the enclosure.

• When a hole is bored for a new penetration, remove all burrs. Clean

the perimeter of the hole and the penetration with a cleaning agent

before installing the new penetration.

• Nothing must penetrate the enclosure wall, floor, or ceiling without use

of a proper ETS-Lindgren designated penetration.

• Bolts fitted to the modular and pan-type rooms must be fitted to

correctly-sized holes, correctly de-burred, and cleaned.

• Use flat washers on both sides of the shield penetration.

Good Shielding Practices | 7

Page 8

This page intentionally left blank.

8 | Good Shielding Practices

Page 9

2.0 Maintenance

Before performing any maintenance, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

If you have any questions concerning maintenance, contact ETS-Lindgren

Customer Service.

Optional Maintenance Program

ETS-Lindgren offers an optional maintenance program that consists of a

complete package of services for continued RF integrity in the shielded

enclosures. The services may be performed on a three-month or six-month cycle.

The program consists of the following:

• Inspection of doors and access panels. Extreme care will be taken

to repair, clean, and lubricate the RF seals (fingers and vinyl seals). If

necessary, they will be replaced.

• Inspection of hinges. Hinges will be checked for alignment and

adjusted as needed.

• Inspection of door and access panel latching mechanisms.

Latching mechanism of doors and access panels will be inspected.

Any defective or worn components which cannot be repaired will be

replaced. Adjustment will be performed as needed. Extra material used

to replace damaged parts due to abuse or failure to comply with

recommended maintenance procedures will be charged to the

customer.

• Inspection of tuners. Tuner operation will be checked, lubricated, and

adjusted as necessary.

Maintenance | 9

Page 10

Tuners

The SMART™ (Statistical Mode Averaging Reverberation Test Site) chamber

tuners are manufactured from rigid structure of gatorboard covered with copper

sheet on the Z-fold section to provide the necessary reflective surface, or of an

aluminum frame with aluminum reinforced sheet reflectors.

No maintenance of the box structure is required in normal use. However, the

surfaces may be dusted or vacuumed periodically to maintain their appearance.

The tuners are supported at their ends only with coupling clamps. These should

be inspected monthly for signs of wear, loose screws, or distortion.

The motors mounted external to the chamber are fixed to the chamber

wall and additionally supported either on a separate frame or the

chamber supports. The motor shaft passes into the chamber through

a shielded penetration fitted to the chamber wall. The horizontal

penetration also ensures that the axial load is not transmitted to the

motor from the tuner.

The RF feed through bearing assembly on the motor side and a self-aligning (on

large chambers) idler bearing on the non-driven end supports the horizontal

tuner. The self-aligning bearing assemblies have a grease nipple that should be

topped off every six months using standard bearing grease. They should also be

checked periodically to ensure free movement and that fixings remain secure.

The tuner body needs only periodic cleaning to remove any accumulated dust.

On all chambers the RF feed-through assembly on the motor side of the tuner

contains a large number of ball bearings. These provide the RF shielding of the

gear shaft as it passes through the shield and should not be removed.

On the SMART 1000 model the tuners are much smaller and subject to less

wear. The tuners should be inspected every six months for signs of excessive

noise or motor overheating. The tuners are lubricated at the factory, so additional

lubrication should not be required.

10 | Maintenance

Page 11

CLEANING

Removal of the tuner assembly must be

performed by qualified ETS-Lindgren

personnel.

• Remove excess dust from the tuner and bearing assembly with a dry

cloth or vacuum.

• Check the fixings to the shielded room and the tuner assemblies.

Doors

Periodically clean the brass or steel door frame and beryllium copper finger stock

with Channel Master® 9101 lubricant. See the decal applied to the door for more

detailed instructions. If staining or corrosion is present on the brass frame or

finger stock, polish lightly with 3M Scotch-Brite® pads. If extreme staining or

corrosion persists, call ETS-Lindgren for assistance.

Periodically inspect the roller cams and cam blocks to verify that a thin film of

lubricant is present. If additional lubricant is required, apply a very thin film of

silicone grease. The door maintenance kit included with each door contains the

necessary lubricants, cleaning material, and replacement finger stock.

Maintenance | 11

Page 12

Do not polish the brass or beryllium copper

finger stock with steel wool, electric sanders,

wire brushes, medium or fine sandpaper, or any

abrasive materials or devices other than those

specified in Maintenance on page 40.

Do not polish any of the brass striking surfaces

with any type of brass polish.

Do not apply a floor wax to the door sill of door

types D and E (flush sills). Use caution when

waxing the floors inside and outside the

enclosure to make sure that wax is not applied

to the flush door saddle.

Do not apply wax to the metal surfaces of the

chamber.

Do not attempt to oil hinges or door handles.

They are permanently lubricated.

MONTHLY MAINTENANCE

To catch excess fluids, place absorbent material (cloth, sponge, and so on)

beneath the entire length of the door sill prior to cleaning and lubricating. Do not

wipe finger stock.

Perform proper cleaning and lubrication of the contact finger

mechanism every month.

Use the cleaning agent Channel Master 9101; lubricate only in accordance with

the manufacturer instructions.

1. Use a generous amount of the cleaning agent to flush the entire finger

recess on the door frame. Start across the top of the door frame and

work down both sides. Flush bottom last. This process will wash off all

visible residues on fingers.

2. Wipe brass door frame with a clean cloth.

12 | Maintenance

Page 13

3. Inspect finger stock; install new finger stock where necessary.

4. Wipe knob edge on door leaf with a clean cloth wetted with cleaning

agent.

ANNUAL MAINTENANCE

1. Perform maintenance as described in Monthly Maintenance (see

previous section).

2. During inspection of finger stock, count the number of patches that

have been replaced. If more than five patches have been replaced,

remove all finger stock (part# 81D-6L) and vinyl seal shield

(part# VS-100) from the channel. Install new finger stock and new seal.

3. Lubricate tuner bearing grease nipples using standard bearing grease.

4. Check motor supply and signal cable condition external to the

chamber.

5. Remove excess dust from motor (and amplifier, if fitted).

REPLACING FINGER STOCK AND VINYL SEAL

1. Remove old finger stock and vinyl seal using needle-nose pliers.

2. Clean channel.

Use the cleaning agent as described in the manufacturer instructions.

3. Cut exact lengths of finger stock for each of the four sides of the frame.

4. Cut exact length of vinyl seal.

5. Starting in upper left corner, install first row of finger stock down the

entire side of the frame.

6. Lubricate fingers and channel again.

7. Again starting in the upper left corner, insert second row of finger stock

down the entire side of the frame. Fingers should be gently pressed

into position one at a time until they are locked in place.

8. Repeat steps 5, 6, and 7 for each of the remaining three sides of the

frame.

Maintenance | 13

Page 14

9. Re-lubricate all finger stock and channel.

10. Beginning in the middle of the side of the frame, start installing the

vinyl seal by inserting it by hand into the channel opening. Go around

the door frame so that the vinyl seal covers the finger stock completely.

11. Using the right angle corner of a rectangular piece of sheet metal

(about 4 in x 8 in x 16 ga.) or a wide putty knife, gently push the vinyl

seal between the two rows of finger stock to the final position at the

base of the channel. Use caution at the corners to insert the vinyl seal

behind one finger at a time.

12. If fingers are broken during insertion of the vinyl seal, a patch section

must be inserted.

FINGER STOCK REPAIR

For All Doors

You can replace recessed finger stock without removing the door.

Finger stock 81D-6L can be replaced in sections if a maximum of 10 inches is

damaged.

1. Remove broken or loose pieces with needle-nose pliers.

2. Select an overlapping piece not less than four inches longer than the

missing section and insert new finger stock.

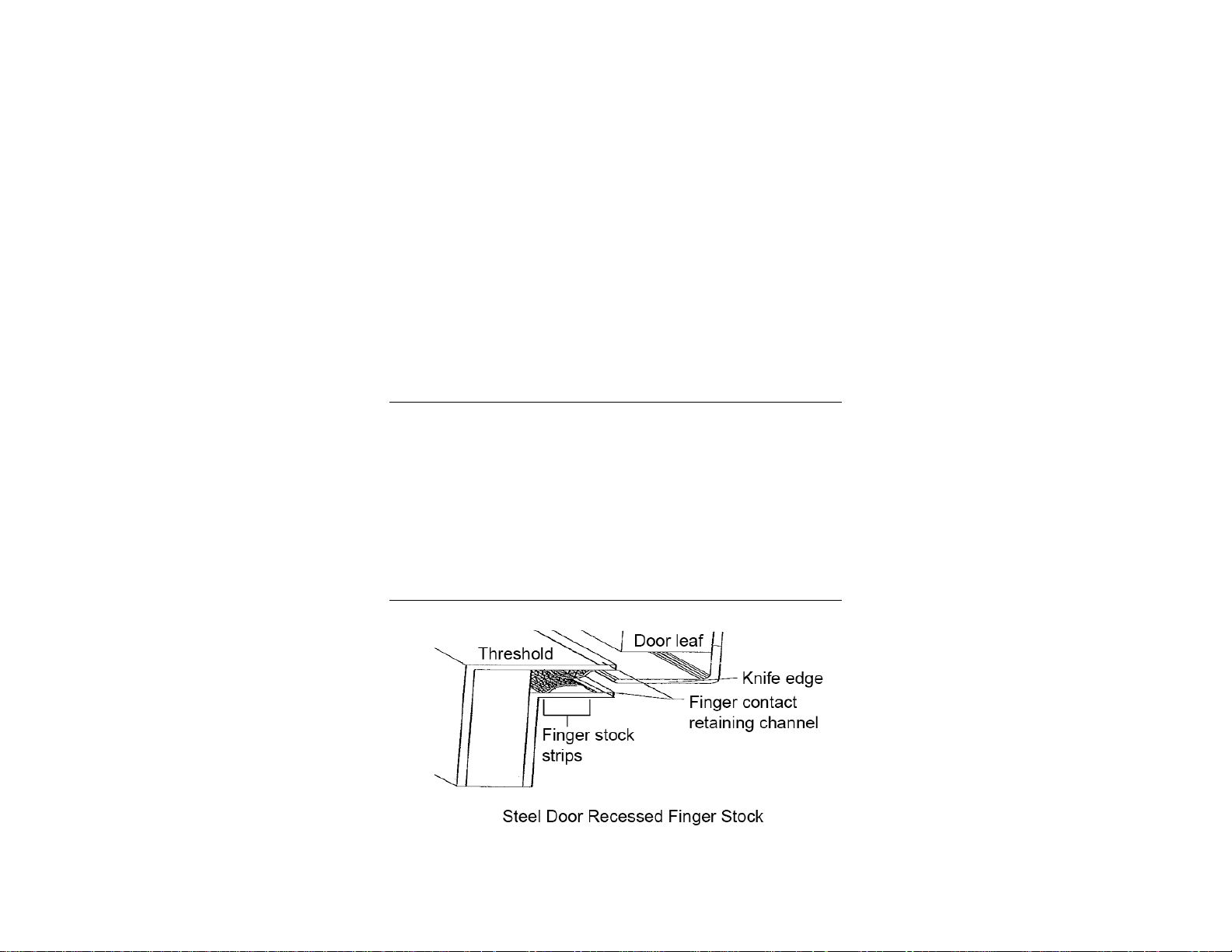

For Door Type D and Type E

14 | Maintenance

Page 15

1. Follow the finger stock repair instructions in For All Doors (see

previous section) for door types D and E.

The flush sill requires the following additional instructions.

2. Type D door—Remove all screws at the bottom edge of the type D

door that permit removal of the finger stock angle.

Finger stock is soldered onto this removable brass angle at the bottom

of the door. As with replacement of recessed fingers, it is not

necessary to remove the door to replace the finger stock at the sill.

Use a sharp instrument (such as a penknife) to remove the section of

broken fingers.

Install new finger stock 81D-6L by overlapping one finger at each end

of old finger stock; solder the perforated area of a new finger to the

brass plate.

Make sure that the solder does not flow to the fingers; this anneals the

temper of the fingers and will cause them to break during use.

3. Type E door—The type E double flat sill door uses a different finger

support arrangement. The 16-in finger strips are retained by an

aluminum strip that must be removed to access the fingers. A

removable steel strip retains the fingers on the center carrier.

Additional parts are included in the Steel Door Maintenance Kit,

part# UM144.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

Maintenance | 15

Page 16

This page intentionally left blank.

16 | Maintenance

Page 17

3.0 Tuners

General Precautions

Do not stand beneath the horizontal tuner or in

the path of the vertical tuner while they are

under remote control or moving. It is

recommended that a warning indication or

barrier be placed in the chamber to reduce the

risk of damage or injury during operation.

Do not use abrasives on the tuner assembly.

Clean only with vacuum or by dusting.

The tuners must never be turned manually by

pushing the tuners (except SMART 1000

tuners). This could result in damage to the

support shaft or motor/gear box assembly.

Do not fit any additional loads to the tuner

assemblies. The motor acceleration and

deceleration profiles have been set to account

for the inertia of the tuners; changing the loads

could overstress the couplings or gear box

assembly. Manually running the tuners at

speeds in excess of the preset limits could also

result in damage and should not be performed.

Do not cover any surface of the tuners. This

could affect the performance of the chamber.

For the SMART 1000 tuners, the zero or home

position is indicated with a mark in the

chamber; see the following illustration.

See Maintenance on page 9 for information on recommended tuner

maintenance and cleaning.

Tuners | 17

Page 18

Zero/home position

Installation Procedure for SMART 200 and

Larger Chambers

Before installing any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

Tuner installation steps are provided for both the S81 sandwich-type and

pan-type shields. The installation is similar with differences in the mounting

bracket assembly. The tuners may be installed during or after the completion of

the chamber installation. Access will be required on both the inner and outer

sides of the wall panels for the installation of the horizontal tuner.

Review the entire installation procedure before beginning.

18 | Tuners

Page 19

1. Determine the orientation of the motor, and then place the motor on a

clear surface to check plug locations. Locate the oil plug behind the

mounting flange. Locate the vent and drain plugs and verify that they

are positioned so that the vent and filler plugs are uppermost on the

gear box with the drain at the lowest position. If necessary, move to

another position on the gear box.

2. Mark the location on the chamber wall where the tuner motor is to be

mounted. Using the mounting plates as a template, mark the motor

and fixing holes in the shield.

Tuners | 19

Page 20

3. Verify that the idler mounting plate can be mounted at the opposite end

without obstruction, and that the motor(s) can be mounted in horizontal

or vertical orientation without obstruction, and with suitable fixing.

4. Cut the holes in the panel as required for the shaft and the

four mounting screws.

20 | Tuners

Page 21

5. Mount the motor and fix securely to the chamber wall with the outer

plate, inner plate, and bearing cup.

• Using an axial laser level, locate and mark the position for the tuner

idler bearing on the opposite wall. This must be directly aligned with

the motor shaft.

Tuners | 21

Page 22

• Mount bearing inner and outer plate.

• Using a lift, raise the tuner into position and align the shaft ends. Fix

the couplers without the key to the motor shaft end and bearing end if

a separate shaft is used. Alternatively, insert the tuner end shaft into

the idler bearing and secure with the fixing (set/grub) screws.

• For the vertical tuner, locate the tuner shaft in the ceiling clamp to

temporarily support the weight of the tuner.

• Locate and fix the idler bearing to the floor using wood screws supplied

for modular panels (S81) or bolts to the inner floor of the pan-type

room.

• Secure the tuner shaft in the idler bearing with at lease 1/2-in (12-mm)

gap between the shaft and chamber surface. Secure the set screw so

that tuner weight can be taken by the bearing.

• Release the motor coupling and insert the key into the keyway. Tighten

coupling.

22 | Tuners

Page 23

• Fill the bearing housing with the supplied shot.

Tuners | 23

Page 24

• Remove grease cap next to shot filler hole and fill with the conductive

grease supplied, then replace. Do not overfill to the point where

excessive grease is visible on the shaft.

• Mount the motor control panel in a convenient position on the outer

wall of the chamber, within easy reach for operation of the emergency

stop.

• Route and secure cables and fibers as necessary to the motor

controller and power supply.

• Check installation before powering on. Confirm that the bearing

housing cap is secure and check all fixings.

• Rotate tuner using the controller and verify free operation.

6. For the pan-type chamber, mark the location of the motor angle

bracket. Fix the motor to the bracket and the bracket to the chamber

support so that the motor plate is perpendicular to the shield wall. The

motor should be supported by the chamber support structure.

24 | Tuners

Page 25

ELECTRICAL

The tuner motor is connected to the control unit at the factory and supplied with a

length of conduit appropriate to the chamber. The control unit should be mounted

on the wall of the chamber within easy reach to operate the emergency switch.

Each tuner motor is a three-phase unit with a variable speed drive control. Each

motor uses less than eight amps under normal load.

The unit should be connected to a protected 208–230 volt, 15A supply, with the

wires connected as follows:

Brown: Phase 1

Blue: Phase 2

Green / Yellow: Earth

For chambers with two tuners, the motor controllers can be connected to a single

20-amp supply.

VERTICAL TUNER INSTALLATION

1. Install the motor end of the tuner as described in the installation

procedures beginning on page 18.

2. Using on the inner mounting plate, mount the idler bearing as

described in the installation procedures beginning on page 18.

3. Fix the plate to the inner shield surface using adhesive or wood screws

penetrating only the inner surface of the panel.

Tuner Control – SMART 1000

The SMART™ (Statistical Mode Averaging Reverberation Test Site)

1000 chambers are fitted with a dedicated motor drive control unit mounted onto

the back of the chamber. This unit controls the motors for both the vertical and

horizontal tuners. The motors are linked to 10:1 gear box and use half-stepping,

providing 400 steps per revolution. The motor controller is set so that the

required angular position of the motor is defined by θ/4.5, which means that the

angular position used in the seek command must be divided by 4.5.

Tuners | 25

Page 26

The current position (CP) read from the controller returns the corrected value.

The tuners can be operated in either a stepped (tuned) mode with step size from

two-degree increments, or a stirred mode with one of three available speed

settings using the Sx command. The stepper motors can provide position

feedback while switched on and when queried will reply with the current tuner

position relative to the zero position set at switch on.

Stored tuner positions do not exist; therefore, the tuners default to a setting of

zero degrees when powered on, regardless of actual position. The home position

for the tuners should always be set prior to performing measurements using the

indications provided on the inside of the chamber. This also represents the

home position used for the factory calibration.

Communication is through an RS-232 interface. Two ports are required for the

two tuners. Following are the required computer settings.

RS-232 PORT SETTINGS

Baud Rate: 9600

Bits: 8

Parity: None

Stop Bit: One

Flow Control: None

OPERATION

The antennas fitted to the SMART 1000 can be used for either transmit or

receive depending if the chamber is being used for immunity or emission

measurements. In either case, calibration data can be used to provide

corrections for the measured quantities.

SMART 1000 chambers are provided either with two antennas covering the

entire frequency range of 1 to 40 GHz or with two identical antennas from

1 to 18 GHz (one transmit and one receive). The chamber is calibrated at the

factory and supplied with the chamber calibration factors based on the

IEC61000-4-21 method.

26 | Tuners

Page 27

COMMAND SYNTAX

Use a program that allows direct communication with the COM ports to verify

satisfactory operation of the tuners; for example, ETS-Lindgren SMARTImm

Immunity Control Software.

Command Parameters Function Example

Sx 0/1/2/3/ ? Set tuner speed/Query S1

CR NA Continuous rotation

NCR NA Non-continuous rotation

ST NA Stop

CPnnn.n 000.0-999.9/ ? Current Position/Query CP180.0

CC NA Move CCW

CW NA Move CW

ULnnn.n 000.0 – 999.9 / ? Set CW Limit/Query UL360.0

LLnnn.n 000.0 – 999.9 / ? Set CCW Limit/Query LL000.0

DIR? NA Query Direction

SKnn.n* nn.n – 80* Seek Position SK75

* Angle required divided by 4.5; for example, 300/4.5 = 75

Tuner Control – SMART 80 and SMART 200

The SMART 80, SMART 200, and other large chambers are operated using the

ETS-Lindgren Model 2090 Multi-Device Controller (or next generation

ETS-Lindgren controller, if applicable). The command set for the controller is

described in detail in the controller manual. Go to www.ets-lindgren.com

download the controller manual.

Operation of all SMART chambers is described in detail in the SMARTImm

Immunity Control Software and SMARTEmi Emission Control Software manuals.

These programs are used to control the chamber and contain the necessary

drivers for all available tuner control options.

Tuners | 27

to

Page 28

This page intentionally left blank.

28 | Tuners

Page 29

4.0 Shielding

Series 81 Modular Shielding

DESCRIPTION: Two layers of sheet steel laminated to a wood core.

OPERATION:

The RF shield must be installed by or the

installation supervised by a qualified individual.

TYPE: Modular Systems—Series 81 (28 ga. steel)

Modular panels joined with 11 ga. ETS-Lindgren

framing system using 1/4 in screws on 4-in centers.

After the enclosure is installed, the interior finishes should not be

changed. It is important that:

1. Liquids are not spilled on the shielding.

2. Only ETS-Lindgren RF penetration be used through the walls,

floors, and ceiling.

3. Framing screws are not used to secure any item to the wall.

4. All screws are tightened to 90-in lb torque. If screws are

removed, they must be reinstalled with the use of a calibrated

torque wrench or screw gun.

Shielding | 29

Page 30

Pan-Type Shielding

TYPE: Pan-Type Systems—Euroshield (18 ga. steel or

aluminum)

DESCRIPTION: One layer of sheet steel or aluminum, joined with

M8 screws and double-row gasket in all mating joints.

OPERATION:

After the enclosure has been installed, the interior finishes should

not be changed. It is important that:

1. Liquids are not spilled on the shielding.

2. Only ETS-Lindgren RF penetration be used through the

walls, floors, and ceiling.

3. All screws are tightened to 90-in lb torque. If screws are

removed, they must be reinstalled with the use of a

calibrated torque wrench or screw gun.

4. Suspended floors are earthed with bonded contact to the

shield walls. Changing this bonding could affect the

chamber performance.

30 | Shielding

Page 31

5.0 Power Line Filters

An electrician generally installs power line filters at the time of the enclosure

installation. After the filters are put into service, they rarely require maintenance.

Should a problem occur, only a qualified electrician should troubleshoot the

problem.

Most power line filters have a built-in voltage

discharge system. However, it is possible for

the discharge system to be inoperative in

certain conditions; therefore, all filters must be

discharged prior to being handled. To

discharge filters a resistance greater than

100,000 ohms must be used in the discharge

probe.

Power Line Filters | 31

Page 32

This page intentionally left blank.

32 | Power Line Filters

Page 33

6.0 Vents

Honeycomb vents are used for the ventilation system of the enclosure and

normally do not require maintenance. The honeycomb vents work as a

waveguide beyond cut-off and are sized depending on the upper frequency of

operation of the chamber. High frequency rooms, therefore, use small bore

vents. Conductors of any kind must not be passed through the vents or the

performance of the vent will be drastically reduced.

Should the accumulation of lint or dust require that the honeycomb be cleaned,

the duct system on both sides of the honeycomb must be opened so that the

honeycomb vent may be vacuum-cleaned from both sides. The duct system

should then be reinstalled per the original construction.

Vents | 33

Page 34

This page intentionally left blank.

34 | Vents

Page 35

7.0 Penetrations

Penetrations must be provided for any services which pass through the walls,

floor, or ceiling of the enclosure. These penetrations are normally put in place at

the time the enclosure is installed and rarely require maintenance.

Exceptions are for active penetrations such as cable feed-throughs,

tuner penetrations, and coaxial fittings, which must be re-tightened occasionally.

Installation of a new penetration can be performed by the customer but must be

done in accordance with ETS-Lindgren shielding practices. For more information,

see Good Shielding Practices on page 7.

Penetrations | 35

Page 36

This page intentionally left blank.

36 | Penetrations

Page 37

8.0 Doors

ETS-Lindgren manufactures RF shielding doors. Doors are one of the most

active and, therefore, the most vulnerable components of any reverb chamber.

The instructions in this section must be followed to retain the RF integrity of the

enclosure.

General Precautions

Do not slam the door to start engaging the

fingers. This is not necessary with the

ETS-Lindgren latching mechanism and could

result in damage to the latch roller assembly.

Do not shove or kick the door when opening.

The contact finger pressure release is

performed entirely by the ETS-Lindgren

latching mechanism.

Do not attempt to close the door with the

handle rotated in the full stop or closed

position. This may break off the latching roller

pins.

Do not exert excess pressure on the door

handle. A nominal force of 25 lb is all that is

required until full stop or full open positions are

reached. Excessive forces could result in

broken latch pins.

If the closing or opening forces become

excessive, the door should be serviced.

See Maintenance on page 9 for information on recommended door

maintenance, including steps to replace and repair finger stock.

Doors | 37

Page 38

Door Types

• Type A—RCM Light Weight

• Type B—RCM Single

• Type C—RCM Double

• Type D—RCM Flush Sill, Single

• Type E—RCM Flush Sill, Double

• Type F—RCM Access Panel

• Type G—Sliding Doors, Manual and Automatic

Door Operation for Types A, B, C, D, E, and F

In the operation of the door, the ETS-Lindgren cam-actuated latching mechanism

brings the door to a completely closed condition with the handle rotated to the full

stop position. Conversely, when the handle is rotated in the opposite direction to

the alternate position, the door knife edge is removed from the finger contacts,

allowing the door to fully open. In this position the door will swing freely with little

opposition.

When closing the door, normal door pressure should be applied until the

cam actuators are engaged in the cam blocks. At this point no further inward

pressure on the door is required. Rotate the door handle until the handle has

reached the full stop position. The cam action of the door latching mechanism

provides all the pressure required to separate and correctly contact the fingers.

On large double-leaf swing doors, the surface area of the contact fingers is larger

so the latching effort required is slightly greater. At no time should more than

hand pressure be required or applied to the latch mechanism.

Flush sill doors have a double or triple row of contact fingers fitted to the bottom

edge. These are exposed and should be checked periodically for damage.

38 | Doors

Page 39

TYPE A DOOR LATCH

TYPE B DOOR LATCH

Doors | 39

Page 40

Door Operation for Type G

This door is most often installed on large chambers for large equipment access.

Operating and maintenance instructions differ quite significantly from the

standard swing doors; therefore, individual operation and maintenance manuals

are issued with each door fitted to a chamber.

Adjusting RCM 1 Hinges

Adjustment is the same for left and right hinges. All hinges must be aligned

together.

UP-AND-DOWN ADJUSTMENT

1. Open the door.

2. Place a hex key in the top of the hinge pin.

3. Turn the hinge pin clockwise to move the door leaf up; turn the hinge

pin counterclockwise to move the door down. Approximately three to

four turns are typically required to set the correct spacing between

door and the jamb; for example, 1/8 in (3 mm) to 5/32 in (4 mm).

4. Close the door.

5. Repeat as required.

SIDE-TO-SIDE ADJUSTMENT

1. Adjust each hinge as required to move either the top or bottom of the

door leaf.

2. Close the door. Do not loosen the dome head nuts on the frame side of

the hinge.

3. Loosen the M5 x 10 mm grub screw on the side of the hinge fitted to

the door leaf.

4. Loosen the three dome nuts on the hinge (3/8-in diameter).

5. Move the door leaf to set the correct spacing between door and the

jamb. Tighten dome nuts and torque to 12 ft lb.

40 | Doors

Page 41

6. Insert and tighten the grub screw until it touches the middle bolt of the

hinge to stop the door from moving.

7. Open and close the door. Check the spacing at the door and jam.

Adjust as required.

8. Tighten all bolts to correct torque setting.

Doors | 41

Page 42

This page intentionally left blank.

42 | Doors

Page 43

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty.

DURATION OF WARRANTIES

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to the warranty period indicated in the following table.

Product Warranted Duration of Warranty Period

Anechoic Chamber Performance 5 Years

Antennas 2 Years

Positioning Equipment 2 Years

Field Probes 3 Years

Doors & Accessories 1 Year

Filters 1 Year

Telescoping Sprinkler Assemblies 1 Year

Custom Equipment 1 Year

Cables & Connectors 1 Year

CCTV 2 Years

Warranty | 43

Page 44

This page intentionally left blank.

44 | Warranty

Page 45

Appendix B: EC Declaration of Conformity

EC Declaration of Conformity | 45

Loading...

Loading...