Page 1

EMC Field Probes

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 2006–2013 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo, ProbeView,

LaserPro, and ProbeView II are trademarks of ETS-Lindgren L.P; Microsoft and

Windows are registered trademarks of Microsoft Corporation in the United States

and/or other countries.

ii |

Page 3

Revision Record

Revision

Description

Date A Initial Release

December, 2006

B

Added EC Declaration of Conformity; updated

descriptions of I and r commands in Operating

Protocols; consistency/quality edits

January, 2007

C

Added FM5004 Field Monitor to Introduction;

added new sections, Typical Configurations

and HI-6153 Electric Field Probe; updated

photos, specifications, battery replacement in

HI-6053 Field Probe; added HI-6153 to Probe

Stand; updated service procedures, safety

notices

April, 2007

D

Updated H-491269 Probe Stand

November, 2007

E

Added information for HI-6022 and HI-6122

probes

March, 2008

F

Updated HI-6153 fiber optic connectors;

branding updates

May, 2008

G

Added HI-4413USB content

Added ETSProbe DLL User Guide

October, 2009

H

Removed HI-4422 content; removed

FM5004 content

October, 2010

I

Added General Safety Considerations

March, 2011

J

Updated About Probe Operation

June, 2011

MANUAL,EMC PROBES | Part #H-600100, Rev. K

| iii

Page 4

Revision

Description

Date

K

Updated Specifications: All probes

Added Typical Isotropic Response charts:

HI-6105, HI-6005, HI-6153, HI-6053

Updated Frequency Response charts:

All probes

Updated Additional Parts: All probes

Added laser shutoff information to

Laser-Powered Field Probes

February, 2013

iv |

Page 5

Table of Contents

Notes, Cautions, and Warnings ............................................... ix

General Safety Considerations ................................................ x

ETS-Lindgren Product Information Bulletin ............................ x

1.0 Introduction ........................................................................ 11

Readout Options ....................................................................................... 12

HI-6100 Field Monitor ....................................................................... 12

HI-6113 Laser Data Interface ............................................................ 12

HI-4413P Fiber Optic Modem ............................................................ 13

HI-4413USB Fiber Optic to USB Converter ....................................... 13

Optional Tripod ......................................................................................... 14

Optional Probe Stand................................................................................ 15

About Probe Operation ............................................................................. 16

2.0 Typical Configurations ...................................................... 17

HI-6100 Field Monitor Configuration.......................................................... 18

HI-6113 Laser Data Interface Configuration .............................................. 19

HI-4413P / HI-4413USB Configuration ...................................................... 20

3.0 Maintenance ....................................................................... 21

Annual Calibration .................................................................................... 21

Laser Probes and Maintenance of Fiber Optics ......................................... 22

Upgrade Policies ....................................................................................... 22

Service Procedures .................................................................................. 22

4.0 Laser-Powered Field Probes ............................................ 23

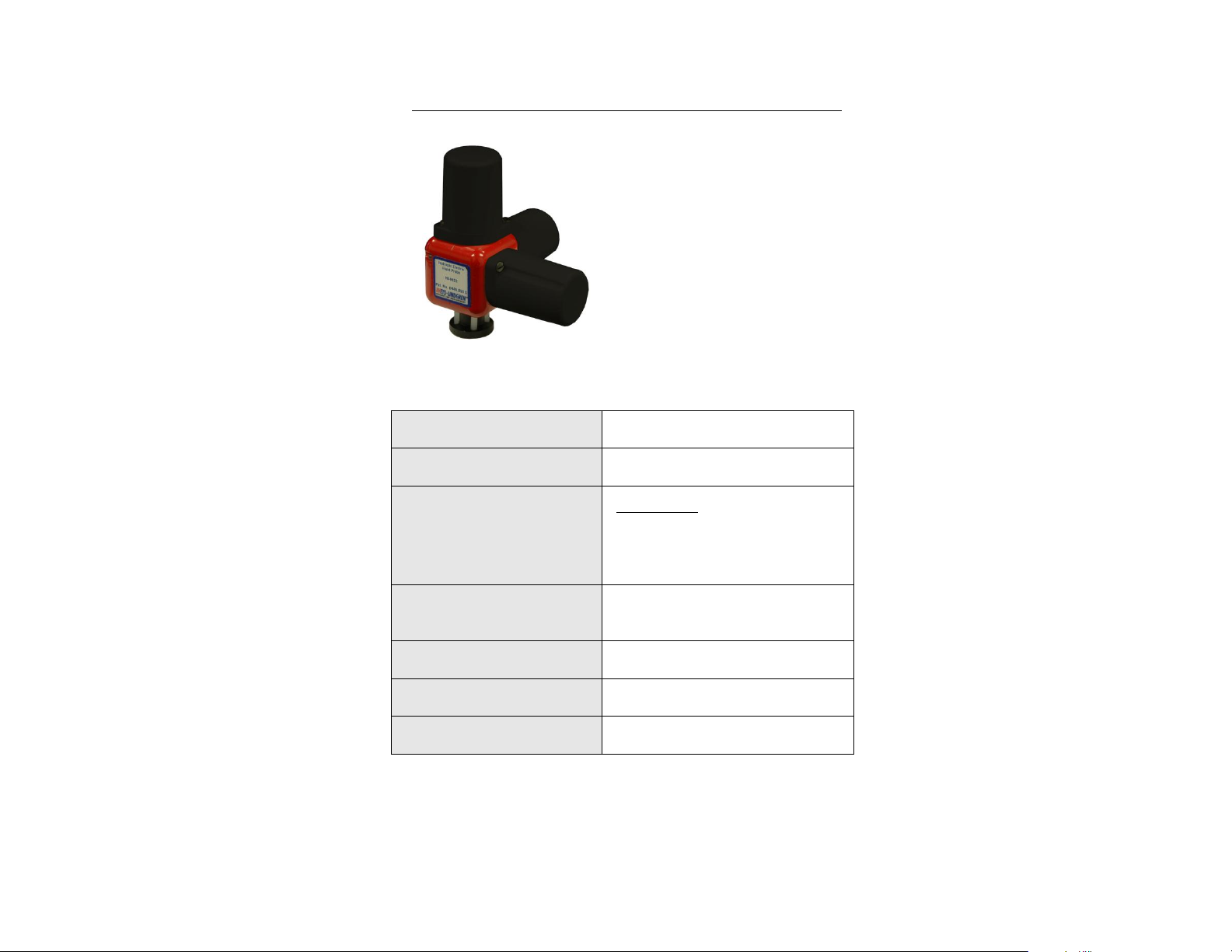

HI-6122 Electric Field Probe ..................................................................... 24

HI-6122 Specifications ...................................................................... 24

HI-6122 Operation ............................................................................ 25

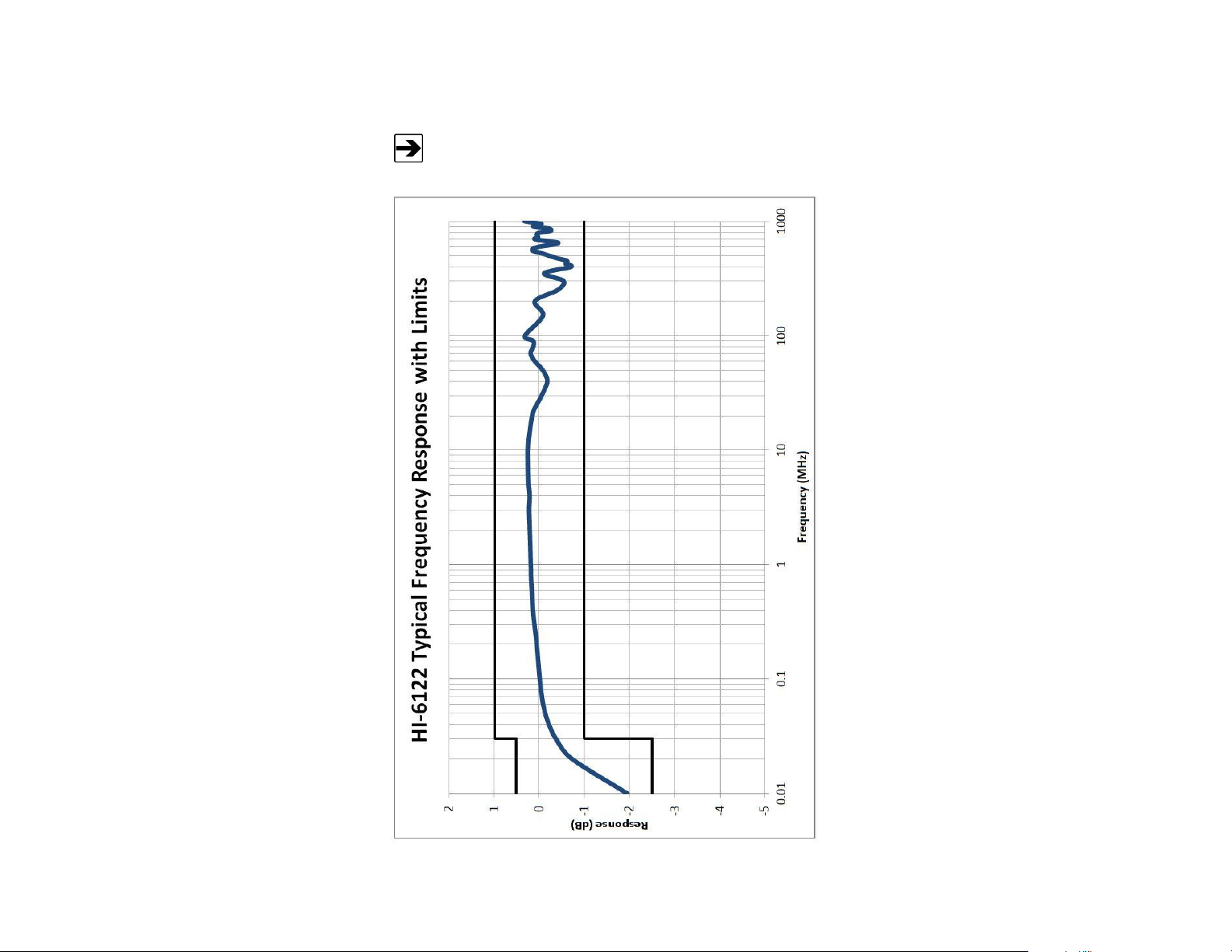

HI-6122 Typical Frequency Response .............................................. 26

HI-6122 Typical Isotropic Response .................................................. 27

HI-6122 Additional Maintenance ....................................................... 28

HI-6122 Additional Parts ................................................................... 28

HI-6153 Electric Field Probe ..................................................................... 30

HI-6153 Specifications ...................................................................... 30

HI-6153 Operation ............................................................................ 32

HI-6153 Typical Frequency Response .............................................. 33

| v

Page 6

HI-6153 Typical Isotropic Response .................................................. 34

HI-6153 Additional Maintenance ....................................................... 37

HI-6153 Additional Parts ................................................................... 37

HI-6105 Electric Field Probe ..................................................................... 39

HI-6105 Specifications ...................................................................... 39

HI-6105 Operation ............................................................................ 40

HI-6105 Typical Frequency Response .............................................. 41

HI-6105 Typical Isotropic Response .................................................. 42

HI-6105 Additional Maintenance ....................................................... 43

HI-6105 Additional Parts ................................................................... 43

5.0 Battery-Operated Field Probes ......................................... 45

HI-6022 Field Probe .................................................................................. 46

HI-6022 Specifications ...................................................................... 46

HI-6022 Operation ............................................................................ 47

HI-6022 Power Switch ...................................................................... 48

HI-6022 Typical Frequency Response .............................................. 49

HI-6022 Typical Isotropic Response .................................................. 50

HI-6022 Additional Maintenance ....................................................... 51

HI-6022 Additional Parts ................................................................... 51

HI-6053 Field Probe .................................................................................. 53

HI-6053 Specifications ...................................................................... 53

HI-6053 Operation ............................................................................ 55

HI-6053 Power Switch ...................................................................... 56

HI-6053 Controls ............................................................................... 57

HI-6053 Typical Frequency Response .............................................. 58

HI-6053 Typical Isotropic Response .................................................. 59

HI-6053 Additional Maintenance ....................................................... 62

HI-6053 Battery Replacement ........................................................... 62

HI-6053 Additional Parts ................................................................... 64

HI-6005 Field Probe .................................................................................. 66

HI-6005 Specifications ...................................................................... 66

HI-6005 Operation ............................................................................ 67

HI-6005 Power Switch ...................................................................... 68

HI-6005 Typical Frequency Response .............................................. 69

HI-6005 Typical Isotropic Response .................................................. 70

HI-6005 Additional Maintenance ....................................................... 71

vi |

Page 7

HI-6005 Additional Parts ................................................................... 71

6.0 H-491269 Probe Stand ....................................................... 73

Probe Stand Dimensions .................................................................. 73

Probe Stand Assembly ............................................................................. 74

Parts to Assemble ............................................................................. 74

Steps to Assemble ............................................................................ 75

Probe Stand Operation ............................................................................. 78

7.0 Probe Shield Care and Replacement ............................... 81

Appendix A: Warranty ............................................................. 83

Appendix B: Series H-491198-01 Battery Charger

for NiMH Batteries .................................................................... 85

Appendix C: Series H-491198-48 Battery Charger

for NiMH Batteries .................................................................... 93

Appendix D: Operating Protocols ........................................ 101

Appendix E: ETSProbe DLL User Guide ............................. 111

About Redistribution.................................................................................111

Getting Started.........................................................................................111

DLL Function Calling Conventions ...........................................................112

Supported Probes and Communications Protocols ..................................112

Probe Family HI-Any (Auto Probe Detector) .....................................116

Probe Family FP-Any (Auto Probe Detector FP) ..............................116

Probe Family Virtual .........................................................................116

Probe Family HI-44xx MS ................................................................117

Probe Family HI-6005 MS (Medium Speed) .....................................117

Probe Family HI-6005 HS (High Speed) ...........................................118

Probe Family Laser HS (High Speed) ..............................................118

Probe Types Not Supported .............................................................118

Quick Start Function Reference ...............................................................119

ETS_CreateProbe() .........................................................................119

ETS_ReadFieldSynchronous() .........................................................122

ETS_RemoveProbe() .......................................................................123

Advanced Function Reference .................................................................124

ETS_Battery() ..................................................................................124

ETS_CalibrationDate() .....................................................................125

| vii

Page 8

ETS_CombinedField() .....................................................................126

ETS_Field() .....................................................................................127

ETS_Firmware() ..............................................................................128

ETS_GetErrorDescription() ..............................................................129

ETS_GetUnitsString() ......................................................................130

ETS_InitiateReadBattery() ...............................................................131

ETS_InitiateReadField() ...................................................................132

ETS_InitiateReadTemperature() ......................................................133

ETS_IsOperationComplete() ............................................................134

ETS_Model()....................................................................................135

ETS_ProbeName() ..........................................................................136

ETS_ReadBatterySynchronous() .....................................................137

ETS_ReadTemperatureSynchronous() ............................................138

ETS_SerialNumber() ........................................................................139

ETS_SetRange() .............................................................................140

ETS_SetUnits() ................................................................................141

ETS_TemperatureC() ......................................................................142

ETS_LaserCurrent() .........................................................................143

ETS_Version() .................................................................................144

ETS_SupplyVoltage() ......................................................................145

ETS_LaserTemperature() ................................................................146

ETS_ZeroProbe().............................................................................147

Status Codes ...........................................................................................148

Appendix F: EC Declaration of Conformity ......................... 151

viii |

Page 9

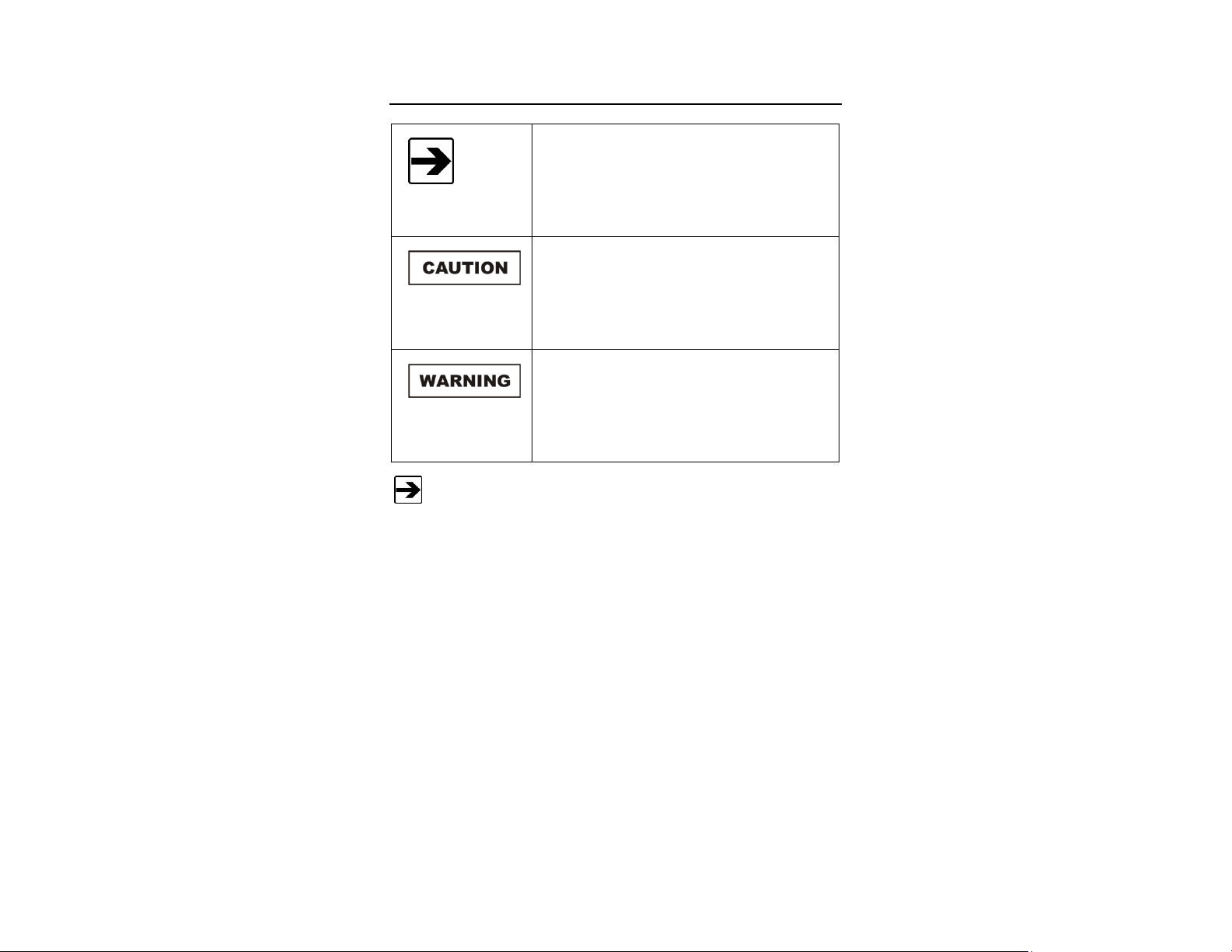

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

| ix

Page 10

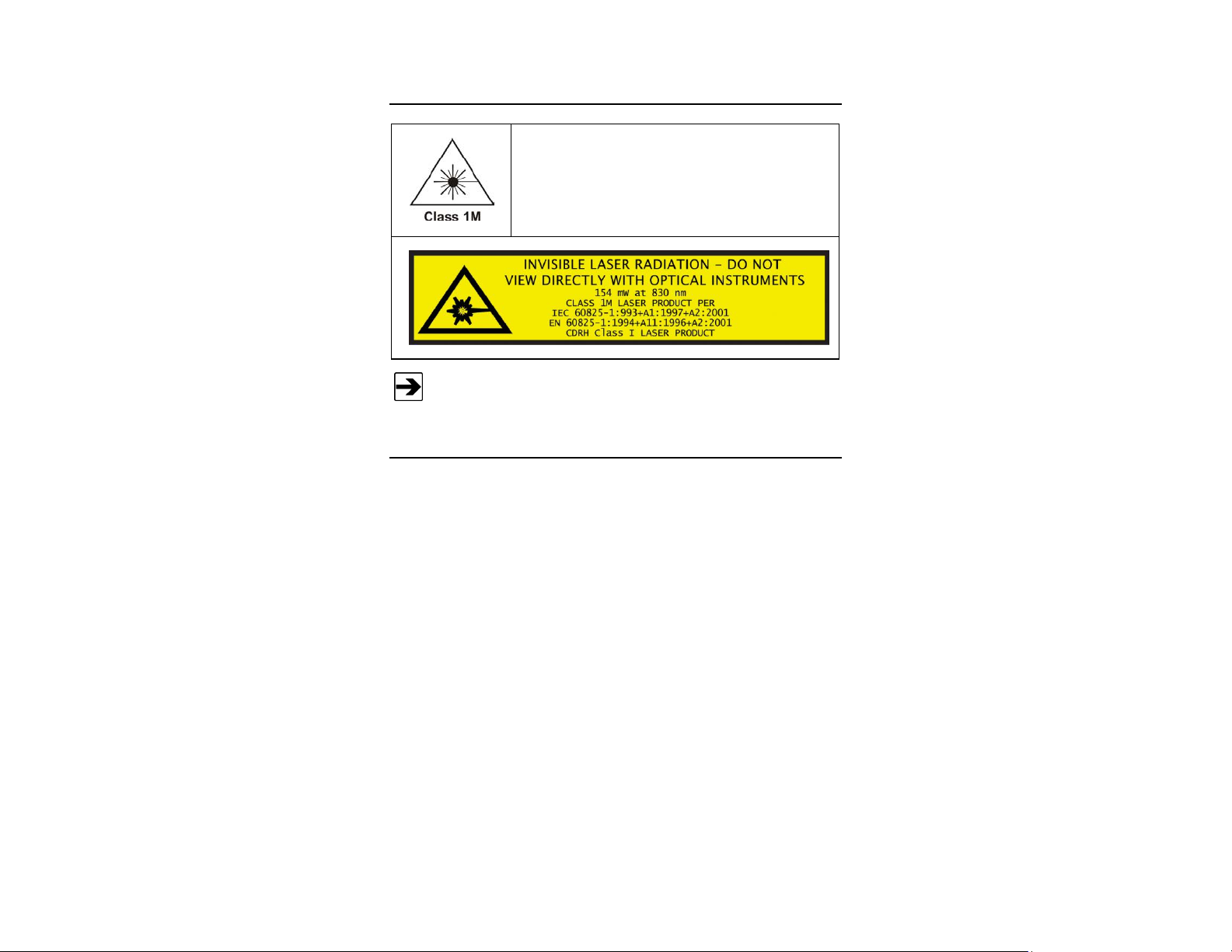

General Safety Considerations

LASER HAZARD. Laser power up to 150 mW at

830 nm may be accessible at the fiber connector of the

laser. However, the laser beam itself is not hazardous

as the interlock ensures that the exposure time will be

less than 30 ms.

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

Warranty information

Safety, regulatory, and other product marking information

Steps to receive your shipment

Steps to return a component for service

ETS-Lindgren calibration service

ETS-Lindgren contact information

x |

Page 11

Laser-Powered

HI-6122

HI-6153

HI-6105

Battery-Operated

HI-6022

HI-6053

HI-6005

ETS-Lindgren may substitute a similar part or new part number with

the same functionality for another part/part number. Contact

ETS-Lindgren for questions about part numbers and ordering parts.

1.0 Introduction

The ETS-Lindgren EMC Field Probes embody the latest innovations in isotropic

sensor design and low-noise, miniaturized electronics. Each probe is a fully

intelligent sensor enabling fast and accurate EMF measurements with

industry-leading performance specifications. Optical coupling to a variety of

readout options makes these probes ideally suited for a wide range of field

monitoring applications.

The EMC field probes include laser-powered (laser) probes and battery-operated

probes. This manual includes operating information and specifications for these

probe models:

Introduction | 11

Page 12

The HI-6100 may be used in

conjunction with both the laser

and battery-operated probes.

HI-6100 Field Monitor

The laser probes and the

HI-6113 Laser Data

Interface together

communicate with

ProbeView™ Laser

software through a USB

port on the computer.

HI-6113 Laser Data Interface

Readout Options

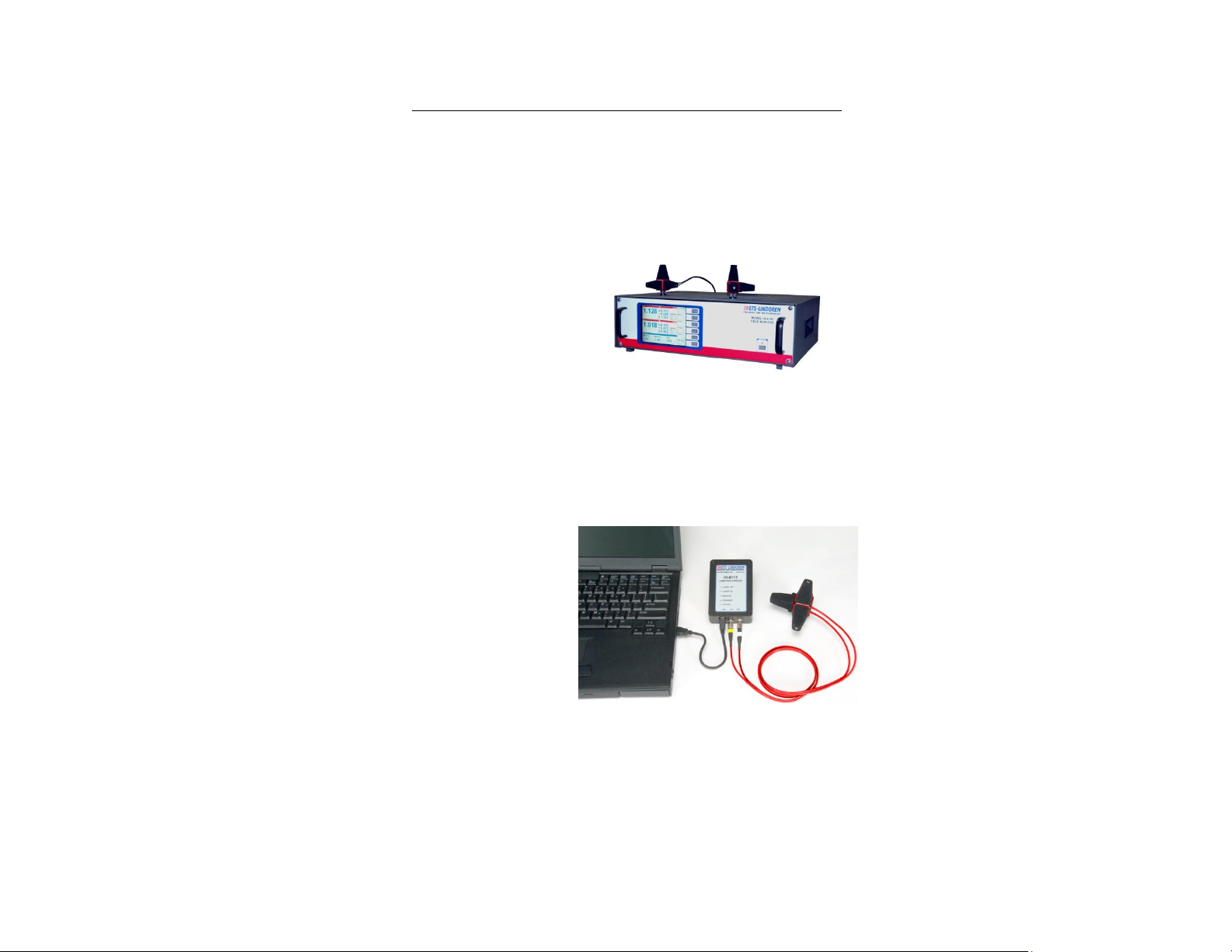

HI-6100 FIELD MONITOR

The HI-6100 Field Monitor accepts inputs from up to any four probes, and

analyzes and displays information on a user-configurable LCD.

For information on using the HI-6100 with ETS-Lindgren probes, see HI-6100

Field Monitor Configuration on page 18.

HI-6113 LASER DATA INTERFACE

For information on using the HI-6113 with ETS-Lindgren probes, see HI-6113

Laser Data Interface Configuration on page 19.

12 | Introduction

Page 13

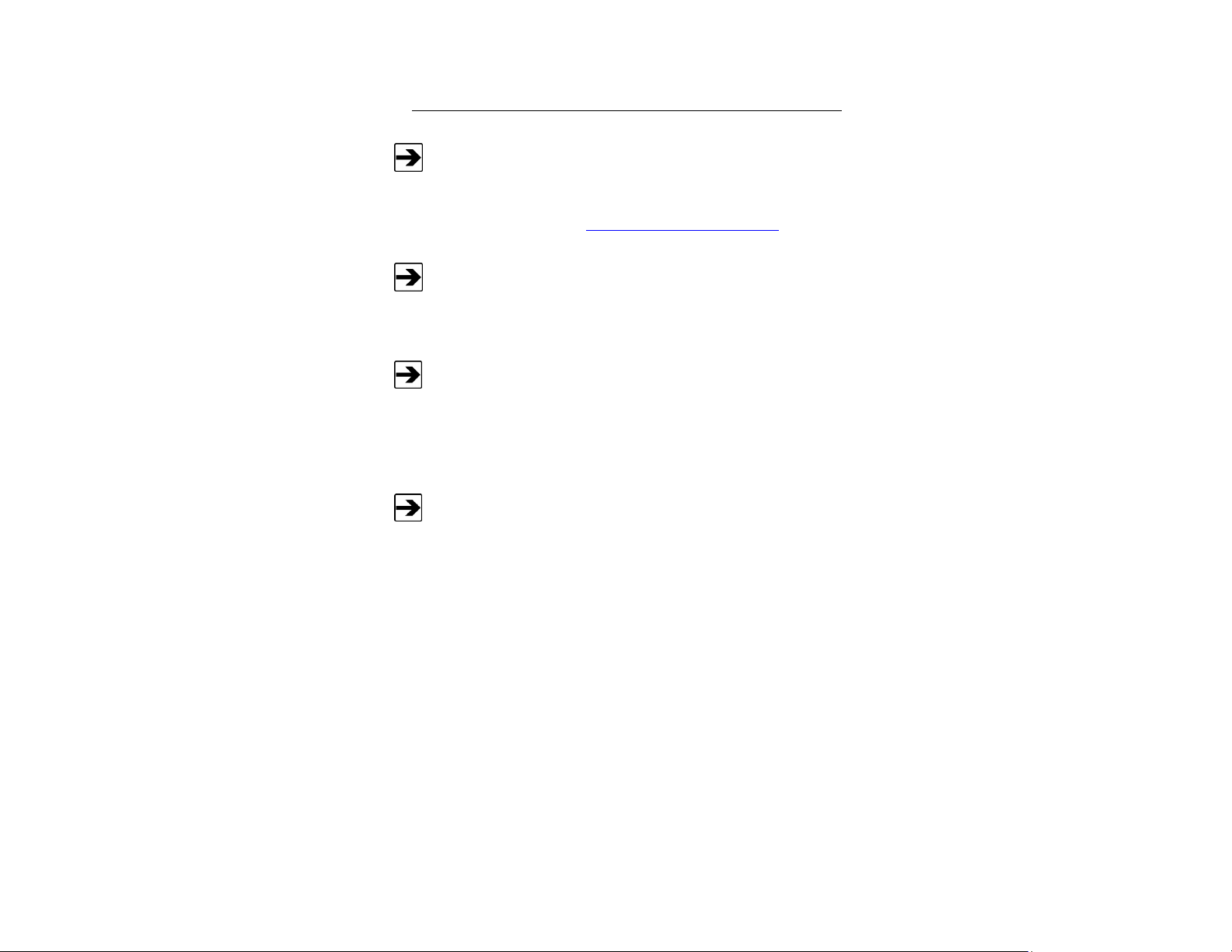

The battery-powered probes use the

HI-4413P Fiber Optic Modem to

communicate with ProbeView II™

software through a serial port on the

computer.

HI-4413P Fiber Optic Modem

The battery-powered

probes use the

HI-4413USB Fiber Optic to

USB Converter to

communicate with

ProbeView II™ software

through a USB port on the

computer.

HI-4413USB Fiber Optic to USB Converter

HI-4413P FIBER OPTIC MODEM

For information on using the HI-4413P with ETS-Lindgren probes, see

HI-4413P / HI-4413USB Configuration on page 20.

HI-4413USB FIBER OPTIC TO USB CONVERTER

For information on using the HI-4413USB with ETS-Lindgren probes, see

HI-4413P / HI-4413USB Configuration on page 20.

Introduction | 13

Page 14

The H-491009 Dielectric Tripod is the

preferred method for mounting field probes

for making unperturbed field

measurements. It provides stable

placement for one probe, and includes a

1/4–20 UNC threaded stud for mounting

any ETS-Lindgren probe with a tripod

mount. It is designed with an adjustable

center post and a rotating mount.

Optional Tripod

14 | Introduction

Page 15

The ETS-Lindgren Probe Stand

may also be used in testing

configurations. The probe stand

supports up to two probes. For

complete information on probe

stand assembly and operation, see

H-491269 Probe Stand on page 73.

Optional Probe Stand

Introduction | 15

Page 16

For information on reducing measurement uncertainties and selecting

the best field probe for your application see the white paper Practical

Considerations for Radiated Immunities Measurement using

ETS-Lindgren EMC Field Probes. This document is located on the

ETS-Lindgren website at: www.ets-lindgren.com/whitepapers.

For complete information on setting up and operating the field monitor,

software, and other devices available for the laser and

battery-operated field probes, please see the documentation provided

with those products.

Field probes are nominally rated for operation within a specific

frequency range, but may also respond to signals above and below

those frequencies. A probe may exhibit response to frequencies below

the lower end of the range, and may also respond to frequencies

above the upper end of the range, though not consistently or

predictably.

Keep all conductive objects away from laser-powered and

battery-operated probes. Conductive objects in the proximity of the

probe can distort the near field and compromise measurement

accuracy. If the application requires measurements from a fixed

position, always mount the probe on a non-metallic platform, using

non-metallic screws.

About Probe Operation

16 | Introduction

Page 17

2.0 Typical Configurations

A variety of configurations are available with the field monitors, probes, and other

devices. Following are typical examples of how the components can be

assembled to accommodate most testing environments.

Typical Configurations | 17

Page 18

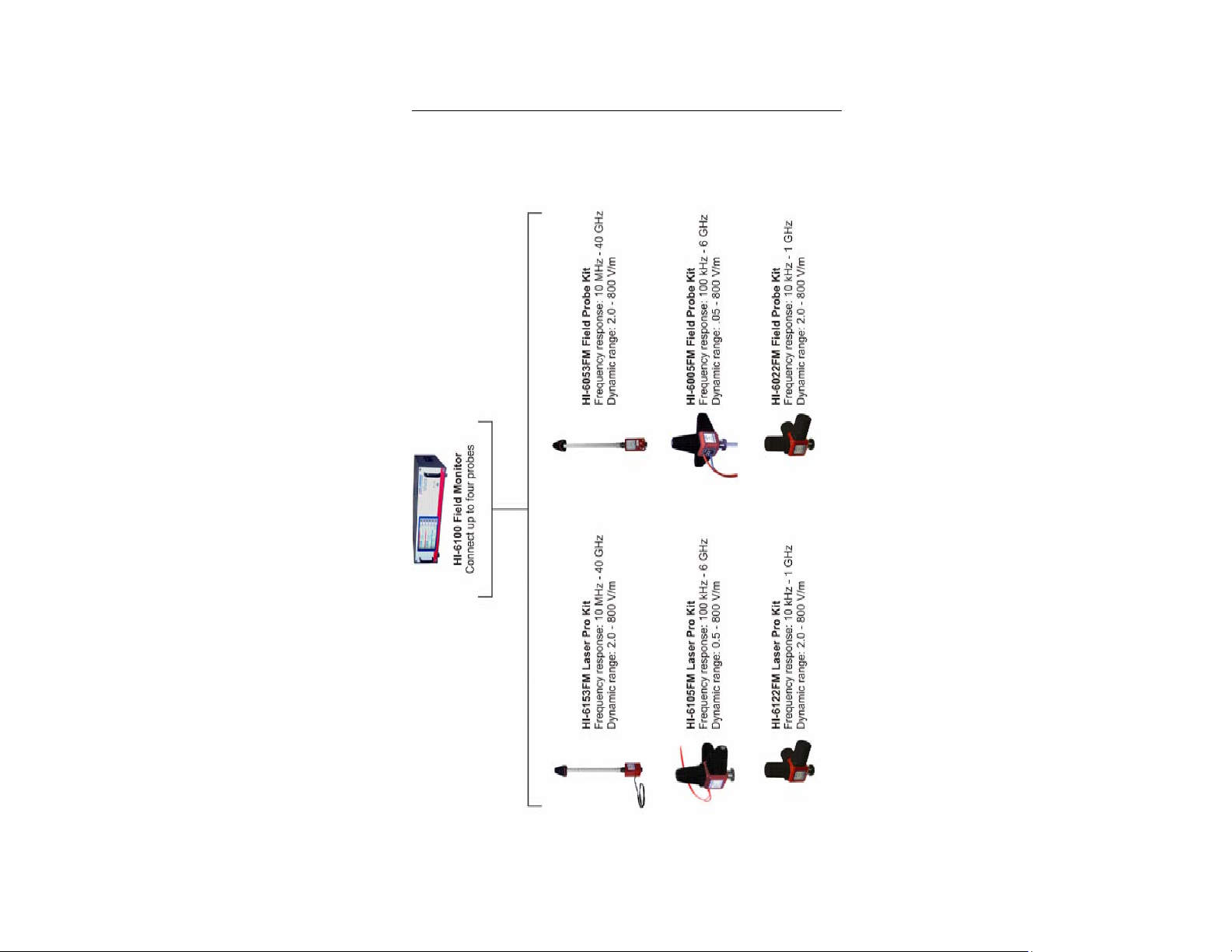

HI-6100 Field Monitor Configuration

The following diagram illustrates the ETS-Lindgren probes that may be used with

the HI-6100 Field Monitor. In the diagram, the FM in HI-6153FM, for example,

refers to Field Monitor Kit. As a kit, the probe includes an interface card.

18 | Typical Configurations

Page 19

HI-6113 Laser Data Interface Configuration

The following diagram illustrates the ETS-Lindgren probes that may be used with

the HI-6113 Laser Data Interface (LDI). In the diagram, the USB in HI-6153USB,

for example, refers to USB Kit. As a kit, the probe includes all components

required to operate the probe with the HI-6113.

Typical Configurations | 19

Page 20

HI-4413P / HI-4413USB Configuration

The following diagram illustrates the ETS-Lindgren probes that may be used with

the HI-4413P Fiber Optic Modem or the HI-4413USB Fiber Optic to USB

Converter.

20 | Typical Configurations

Page 21

Before performing any maintenance,

follow the safety information in the

ETS-Lindgren Product Information

Bulletin included with your shipment.

Maintenance of probes is limited to

external components such as cables or

connectors.

Warranty may be void if the housing is

opened.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

WARRANTY

3.0 Maintenance

If you have one of the following probes, see Probe Shield Care and Replacement

on page 81: HI-6122, HI-6022, HI-6105, or HI-6005 Field Probe.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Maintenance | 21

Page 22

Before performing any maintenance, disconnect

the fiber optic cables from the unit and turn off

power.

When disconnecting fiber optic cables, apply the

included dust caps to the ends to maintain their

integrity.

Before connecting fiber optic cables, clean the

connector tips and in-line connectors.

Before attaching in-line connectors, clean them

with moisture-free compressed air.

Failure to perform these tasks may result in

damage to the fiber optic connectors or cables.

Laser Probes and Maintenance of Fiber Optics

The fiber optic connectors and cables used with laser-powered probes can be

damaged from airborne particles, humidity and moisture, oils from the human

body, and debris from the connectors they plug into. Always handle connectors

and cables with care, using the following guidelines.

Upgrade Policies

Periodically, probes are upgraded to enhance functionality. Contact

ETS-Lindgren Customer Service for the upgrade status of your probe.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

22 | Maintenance

Page 23

The laser driver in the HI-6100 Field Monitor also incorporates this

safety interlock mechanism, and operates in the same manner.

4.0 Laser-Powered Field Probes

The HI-61XX Series LaserPro™ Field Probe is a laser-powered probe, an

excellent tool for electric field mapping, industrial monitoring, and EMC field

measurements.

The HI-61XX Series probes contain a photo-voltaic converter that provides power

to the probe circuitry when sufficient light power is received by the converter. The

light power is generated by a laser in the HI-6113 Laser Data Interface, and is

transmitted to the converter through an optical fiber in the duplex fiber optic

cable. The probe communicates with the HI-6113 through this fiber optic cable.

Receiving power from the HI-6113 allows for unlimited test times.

The probe system incorporates a safety interlock mechanism that turns off the

laser if the HI-6113 does not receive data from the probe within a specified time

frame. The safety mechanism is intended to prevent injury from the laser if the

HI-6113 issues a command to turn on the laser while the fiber optic cables are

disconnected, improperly connected, cut, or damaged.

The HI-6100 Field Monitor may also be used with the HI-61XX Series for

RFI/EMC testing. For more information on readout options, see page 12.

Laser-Powered Field Probes | 23

Page 24

The ETS-Lindgren HI-6122 Field Probe

provides broadband frequency coverage

and wide dynamic range that satisfies the

demands of most test requirements.

The frequency response of the HI-6122 is

10 kHz to 1 GHz, and the dynamic range is

2 to 800 Volts per meter (V/m).

Dynamic Range:

2.0 – 800 Volts per meter (V/m)

Ranges:

Single

Typical Frequency Response:

10 kHz–1 GHz

10 kHz–30 kHz: +0.5 dB, -2.5 dB

30 kHz–1 GHz: ±1 dB

Typical Frequency Response

with Correction:

10 kHz–1 GHz: ±0.9 dB

Linearity:

±0.5 dB @ 27 MHz

Isotropicity:

±0.5 dB @ 400 MHz

Overload Withstand:

> 1,500 V/m CW

HI-6122 Electric Field Probe

HI-6122 SPECIFICATIONS

24 | Laser-Powered Field Probes: HI-6122 Electric Field Probe

Page 25

Physical Interface:

Duplex optical fiber

(62.5 micron multimode)

FC connectors for laser cable,

integral 1-m optical cable

ST connector for transmitter cable,

integral 1-m optical cable

Probe Mount:

1/4–20 UNC tapped hole (internal thread)

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

Dimensions

Housing:

32 mm x 32 mm x 32 mm

1.26 in x 1.26 in x 1.26 in

Probe Shields:

36 mm (1.42 in)

Weight:

80 g (2.82 oz)

HI-6122 OPERATION

The HI-6122 can be used with the HI-6100 Field Monitor. It can also be

connected to a personal computer using an optional HI-6113 Laser Data

Interface and ProbeView™ Laser software.

The HI-6122 is a true 3-axis probe. When requested, X, Y, Z, and total field data

can be reported.

For a list and description of communication and information transfer protocols,

including command structure, probe commands, and HI-6113 commands, see

Appendix D: Operating Protocols on page 101.

Laser-Powered Field Probes: HI-6122 Electric Field Probe | 25

Page 26

TEM Cell and GTEM! – Field Level 20 V/m

HI-6122 TYPICAL FREQUENCY RESPONSE

26 | Laser-Powered Field Probes: HI-6122 Electric Field Probe

Page 27

Isotropic response measured in a 20 V/m field at 400 MHz.

HI-6122 TYPICAL ISOTROPIC RESPONSE

Laser-Powered Field Probes: HI-6122 Electric Field Probe | 27

Page 28

Any maintenance or calibration task requires probe disassembly,

which may void your warranty. Only ETS-Lindgren service personnel

should perform these tasks. To avoid problems with your warranty,

contact ETS-Lindgren Customer Service before performing any

maintenance.

Part Description

Part Number

Probe shield replacement Kit

includes:

Three probe shields (cones)

One each X, Y, and Z label

Six screws

112955

Cable Assembly, Fiber, FC-FC,

ST-ST

H-491263-xx

(xx=length in meters)

FC to FC Inline Connector

H-23861521000

ST to ST Inline Connector

708027

Carrying Case

H-491291

HI-6100 Field Monitor

HI-6100

HI-6122 ADDITIONAL MAINTENANCE

Maintenance of the HI-6122 is limited to external components such as cables,

connectors, and probe shields. For information on fiber optic cable and connector

maintenance, see Laser Probes and Maintenance of Fiber Optics on page 22. To

replace the probe shields, see Probe Shield Care and Replacement on page 81.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6122 ADDITIONAL PARTS

Use the following table to order replacement or optional parts for the HI-6122.

28 | Laser-Powered Field Probes: HI-6122 Electric Field Probe

Page 29

Part Description

Part Number

Laser Data Interface

HI-6113

Tripod, Dielectric

H-491009

Probe Stand

H-491269

Fiber Optic Cleaning System

H-34FO1

Laser System Fiber Optic

Maintenance Kit

112333

Probe Carrier for H-491269

Probe Stand

H-491276

Laser-Powered Field Probes: HI-6122 Electric Field Probe | 29

Page 30

The ETS-Lindgren HI-6153 Field Probe

provides broadband frequency coverage

and wide dynamic range that satisfies the

demands of most test requirements.

The frequency response of the HI-6153 is

10 MHz to 40 GHz, and the dynamic range

is 2 to 800 Volts per meter (V/m).

Dynamic Range:

2.0–800 Volts per meter (V/m)

Ranges:

Single

Typical Frequency Response:

10 MHz–40 GHz

10 MHz–100 MHz: +3 dB, -4 dB

100 MHz–1 GHz: +3 dB, -0.5 dB

1 GHz–18 GHz: +4 dB, -2 dB

18 GHz–40 GHz: +3.5 dB, -4.5 dB

Typical Frequency Response

with Correction:

10 MHz–18 GHz: ± 0.9 dB

18 GHz–40 GHz: ± 1.1 dB

Linearity:

±0.5 dB @ 1 GHz

Isotropicity:

±1.0 dB < 18 GHz

HI-6153 Electric Field Probe

HI-6153 SPECIFICATIONS

30 | Laser-Powered Field Probes: HI-6153 Electric Field Probe

Page 31

Overload Withstand:

1,500 V/m

Physical Interface:

Duplex optical fiber

(62.5 micron multimode)

FC connectors for laser cable,

integral 1-m optical cable

ST connector for transmitter cable,

integral 1-m optical cable

Probe Mount:

1/4–20 UNC tapped hole (internal thread)

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

Dimensions

Probe Length:

438 mm (17.24 in)

(includes electronics housing)

Probe Diameter:

57 mm (2.24 in)

Weight:

0.36 kg (12.64 oz)

Laser-Powered Field Probes: HI-6153 Electric Field Probe | 31

Page 32

The HI-6153 assembly consists

of a pyramidal casing containing

the sensor, which is mounted on

one end of a shaft. The other

end of the shaft is attached to

an extrusion that houses the

electronics. The sensor and

electronics housing operate and

are calibrated as a unit.

The HI-6153 is a true 3-axis

probe. When requested, X, Y, Z,

and total field data can be

reported.

The HI-6153 can be used with

the HI-6100 Field Monitor. It can

also be connected to a personal

computer using an optional

HI-6113 Laser Data Interface

and ProbeView™ Laser

software.

HI-6153 OPERATION

For a list and description of communication and information transfer protocols,

including command structure, probe commands, and HI-6113 commands, see

Appendix D: Operating Protocols on page 101.

32 | Laser-Powered Field Probes: HI-6153 Electric Field Probe

Page 33

Field Level 20 V/m

HI-6153 TYPICAL FREQUENCY RESPONSE

Laser-Powered Field Probes: HI-6153 Electric Field Probe | 33

Page 34

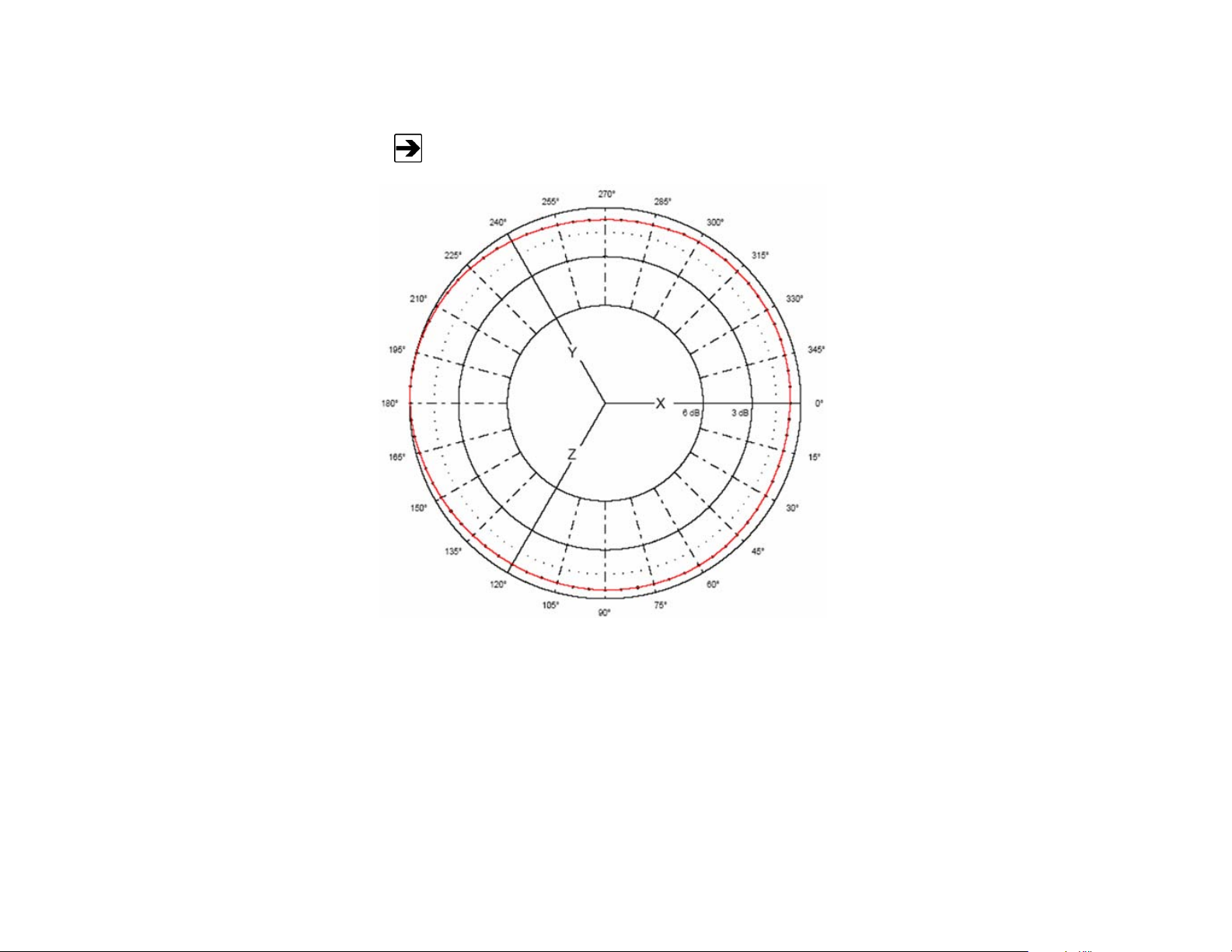

HI-6153 TYPICAL ISOTROPIC RESPONSE

Typical Isotropic Response in dB at 1 GHz

34 | Laser-Powered Field Probes: HI-6153 Electric Field Probe

Page 35

Typical Isotropic Response in dB at 10 GHz

Laser-Powered Field Probes: HI-6153 Electric Field Probe | 35

Page 36

Typical Isotropic Response in dB at 18 GHz

36 | Laser-Powered Field Probes: HI-6153 Electric Field Probe

Page 37

Any maintenance or calibration task requires probe disassembly, which may

void your warranty. Only ETS-Lindgren service personnel should perform

these tasks. To avoid problems with your warranty, contact ETS-Lindgren

Customer Service before performing any maintenance.

Part Description

Part Number

Cable Assembly, Fiber, FC-FC,

ST-ST

H-491263-xx

(xx=length in meters)

FC to FC Inline Connector

H-23861521000

ST to ST Inline Connector

708027

Carrying Case

H-491291

HI-6100 Field Monitor

HI-6100

HI-6113 Laser Data Interface

HI-6113

H-491009 Tripod, Dielectric,

Field Probe

H-491009

H-491269 Probe Stand

H-491269

Fiber Optic Cleaning System

H-34FO1

HI-6153 ADDITIONAL MAINTENANCE

Maintenance of the HI-6153 is limited to external components such as cables

and connectors. For information on fiber optic cable and connector maintenance,

see Laser Probes and Maintenance of Fiber Optics on page 22.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6153 ADDITIONAL PARTS

Use the following table to order replacement or optional parts for the HI-6153.

Laser-Powered Field Probes: HI-6153 Electric Field Probe | 37

Page 38

Part Description

Part Number

Laser System Fiber Optic

Maintenance Kit

112333

Probe Carrier for H-491269

Probe Stand

H-491276

38 | Laser-Powered Field Probes: HI-6153 Electric Field Probe

Page 39

The ETS-Lindgren HI-6105 Electric

Field Probe is a fully intelligent sensor

enabling fast and accurate

EMF measurements with industry-

leading performance specifications.

Optical coupling to a variety of readout

options makes this probe ideally suited

for a wide range of field monitoring

applications.

Dynamic Range:

0.5–800 Volts per meter (V/m)

Single Range (64 dB)

Typical Frequency Response:

100 kHz–6 GHz

500 kHz–2 GHz: +1 dB, -2.5 dB

2 GHz–5.5 GHz: +3.5 dB, -4 dB

5.5 GHz–6 GHz: +2 dB, -6 dB

Typical Frequency Response

with Correction:

100 kHz–6 GHz: ±0.9 dB

Linearity:

±0.5 dB @ 27 MHz

Isotropicity:

±0.5 dB @ 400 MHz

Overload Withstand:

1,500 V/m

HI-6105 Electric Field Probe

HI-6105 SPECIFICATIONS

Laser-Powered Field Probes: HI-6105 Electric Field Probe | 39

Page 40

Physical Interface:

Duplex optical fiber

(62.5 micron multimode)

FC connectors for laser cable,

integral 1-m optical cable

ST connector for transmitter cable,

integral 1-m optical cable

Probe Mount:

1/4–20 UNC (internal thread)

Dimensions

Housing:

32 mm x 32 mm x 32 mm

1.26 in x 1.26 in x 1.26 in

Probe Shields:

43 mm (1.69 in)

Weight:

0.08 kg (2.6 oz.)

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

HI-6105 OPERATION

The HI-6105 can be used with the HI-6100 Field Monitor. It can also be

connected to a personal computer using an optional HI-6113 Laser Data

Interface (LDI) and ProbeView™ Laser software.

For a list and description of communication and information transfer protocols,

including command structure, probe commands, and HI-6113 commands, see

Appendix D: Operating Protocols on page 101.

40 | Laser-Powered Field Probes: HI-6105 Electric Field Probe

Page 41

Anechoic Room and TEM Cell – Field Level 20 V/m

HI-6105 TYPICAL FREQUENCY RESPONSE

Laser-Powered Field Probes: HI-6105 Electric Field Probe | 41

Page 42

Actual data taken at 400 MHz, field level 20 V/m, maximum variation

0.54 dB.

HI-6105 TYPICAL ISOTROPIC RESPONSE

42 | Laser-Powered Field Probes: HI-6105 Electric Field Probe

Page 43

Any maintenance or calibration task requires probe disassembly, which may

void your warranty. Only ETS-Lindgren service personnel should perform

these tasks. To avoid problems with your warranty, contact ETS-Lindgren

Customer Service before performing any maintenance.

Part Description

Part Number

Probe shield replacement Kit

includes:

Three probe shields (cones)

One each X, Y, and Z label

Six screws

H-491237

Cable Assembly, Fiber, FC-FC,

ST-ST

H-491263-xx

(xx=length in meters)

FC to FC Inline Connector

H-23861521000

ST to ST Inline Connector

708027

HI-6105 ADDITIONAL MAINTENANCE

Maintenance of the HI-6105 is limited to external components such as cables,

connectors, and probe shields. For information on fiber optic cable and connector

maintenance, see Laser Probes and Maintenance of Fiber Optics on page 22. To

replace the probe shields, see Probe Shield Care and Replacement on page 81.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6105 ADDITIONAL PARTS

Use the following tables to order replacement or optional parts for the HI-6105.

Laser-Powered Field Probes: HI-6105 Electric Field Probe | 43

Page 44

Part Description

Part Number

Tripod, Dielectric

H-491009

HI-6100 Field Monitor

HI-6100

Laser Data Interface

HI-6113

Probe Stand

H-491269

Fiber Optic Cleaning System

H-34FO1

Laser System Fiber Optic

Maintenance Kit

112333

Probe Carrier for H-491269

Probe Stand

H-491276

44 | Laser-Powered Field Probes: HI-6105 Electric Field Probe

Page 45

Before using your battery-operated probe, read the following:

HI-6053 Field Probe: Appendix B: Series H-491198-01 Battery

Charger on page 85.

HI-6022 and HI-6005 Field Probe: Appendix C: Series H-491198-48

Battery Charger on page 93.

To calibrate the probe prior to shipment, ETS-Lindgren also charges

the internal battery at the factory. Every effort is made to make sure

that the probe arrives ready to use, but you should verify the condition

of the battery prior to making any measurements.

5.0 Battery-Operated Field Probes

The HI-60XX Series Field Probe is a battery-operated probe that utilizes

three orthogonal sensors to provide an isotropic reading of the electric field.

When requested, X, Y, Z, and total field data can be reported, making the

HI-60XX Series true 3-axis probes.

The HI-60XX Series uses either the HI-4413P Fiber Optic Modem or the

HI-4413USB Fiber Optic to USB Converter to communicate with ProbeView II™

software through a port on the computer. The HI-6100 Field Monitor may also be

used with the HI-60XX Series. For more information on readout options, see

page 12.

Battery-Operated Field Probes | 45

Page 46

The ETS-Lindgren HI-6022 Field Probe

provides broadband frequency coverage

and wide dynamic range that satisfies the

demands of most test requirements.

The frequency response of the HI-6022 is

10 kHz to 1 GHz, and the dynamic range is

2 to 800 Volts per meter (V/m).

Dynamic Range:

2.0–800 Volts per meter (V/m)

Ranges:

Single

Typical Frequency Response:

10 kHz–1 GHz

10 kHz–30 kHz: +0.5 dB, -2.5 dB

30 kHz–1 GHz: ±1 dB

Typical Frequency Response

with Correction:

10 kHz–1 GHz: ±0.9 dB

Linearity:

±0.5 dB @ 27 MHz

Isotropicity:

±0.5 dB @ 400 MHz

Overload Withstand:

> 1,500 V/m CW

Fiber Optic Cable Connector:

Standard FSMA

Probe Mount:

1/4–20 UNC tapped hole (internal thread)

HI-6022 Field Probe

HI-6022 SPECIFICATIONS

46 | Battery-Operated Field Probes: HI-6022 Field Probe

Page 47

Battery:

Rechargeable Nickel-Metal Hydride

(NiMH)

Battery Life:

Up to 8 hours

Battery Charger:

100–240 VAC universal input

3-hour charge from full depletion

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

Dimensions

Housing:

32 mm x 32 mm x 32 mm

1.26 in x 1.26 in x 1.26 in

Probe Shields:

36 mm (1.42 in)

Weight:

80 g (2.82 oz)

HI-6022 OPERATION

The HI-6022 can be used with the HI-6100 Field Monitor. It can also be

connected to a personal computer using an optional HI-4413P Fiber Optic

Modem or HI-4413USB Fiber Optic to USB Converter and

ProbeView II™ software.

The HI-6022 is a true 3-axis probe. When requested, X, Y, Z, and total field data

can be reported.

For a list and description of communication and information transfer protocols,

including command structure and probe commands, see Appendix D: Operating

Protocols on page 101.

Battery-Operated Field Probes: HI-6022 Field Probe | 47

Page 48

HI-6022 POWER SWITCH

The power switch activates and deactivates the HI-6022:

ON (I)—When the power switch is in the I position, an internal 4.8 VDC

Nickel-Metal Hydride (NiMH) battery provides power to the probe, and

the power indicator LED blinks.

OFF (0)—When the power switch is in the O position, the probe is

inactive. To prolong battery life, set the switch to OFF when the probe

is not in use.

48 | Battery-Operated Field Probes: HI-6022 Field Probe

Page 49

TEM Cell and GTEM! – Field Level 20 V/m

HI-6022 TYPICAL FREQUENCY RESPONSE

Battery-Operated Field Probes: HI-6022 Field Probe | 49

Page 50

Isotropic response measured in a 20 V/m field at 400 MHz.

HI-6022 TYPICAL ISOTROPIC RESPONSE

50 | Battery-Operated Field Probes: HI-6022 Field Probe

Page 51

Any maintenance or calibration task requires probe disassembly,

which may void your warranty. Only ETS-Lindgren service personnel

should perform these tasks. To avoid problems with your warranty,

contact ETS-Lindgren Customer Service before performing any

maintenance.

Optional Part Description

Part Number

Probe shield replacement Kit

includes:

Three probe shields (cones)

One each X, Y, and Z label

Six screws

112955

Cable, Fiber Optic, Glass

H-491106-xx

(xx=length in meters)

Connector Set, two required

(Bulkhead Feedthrough)

H-231205000

Fiber Optic Modem, RS-232

Interface

HI-4413P

Fiber Optic to USB Converter, USB

Interface

HI-4413USB

HI-6022 ADDITIONAL MAINTENANCE

Maintenance of the HI-6022 is limited to external components such as cables,

connectors, and probe shields. To replace the probe shields, see Probe Shield

Care and Replacement on page 81.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6022 ADDITIONAL PARTS

Use the following table to order replacement or optional parts for the HI-6022.

Battery-Operated Field Probes: HI-6022 Field Probe | 51

Page 52

Optional Part Description

Part Number

Battery Charger

H-491198-48

Carrying Case

H-491291

Tripod, Dielectric

H-491009

HI-6100 Field Monitor

HI-6100

Probe Stand

H-491269

Probe Carrier for H-491269

Probe Stand

H-491276

52 | Battery-Operated Field Probes: HI-6022 Field Probe

Page 53

The ETS-Lindgren HI-6053 Field Probe provides broadband

frequency coverage and wide dynamic range that satisfies the

demands of most test requirements.

The frequency response of the HI-6053 is 10 MHz to 40 GHz,

and the dynamic range is 2 to 800 Volts per meter (V/m).

Dynamic Range:

2.0–800 Volts per meter (V/m)

Ranges:

Single

Typical Frequency Response:

10 MHz–40 GHz

10 MHz–100 MHz: +3 dB, -4 dB

100 MHz–1 GHz: +3 dB, -0.5 dB

1 GHz–18 GHz: +4 dB, -2 dB

18 GHz–40 GHz: +3.5 dB, -4.5 dB

Typical Frequency Response

with Correction:

10 MHz–18 GHz: ±0.9 dB

18 GHz–40 GHz: ±1.1 dB

Linearity:

±0.5 dB @ 1 GHz

Isotropicity:

±1.0 dB < 18 GHz

HI-6053 Field Probe

HI-6053 SPECIFICATIONS

Battery-Operated Field Probes: HI-6053 Field Probe | 53

Page 54

Overload Withstand:

1,500 V/m

Fiber Optic Cable Connector:

Standard FSMA

Probe Mount:

1/4–20 UNC tapped hole (internal thread)

Battery:

Four AAA batteries, rechargeable

Nickel-Metal Hydride (NiMH)

Battery Charger:

100–240 VAC

Approximately three hours

Battery Life:

> 30 hours continuous (at full charge)

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

Dimensions

Probe Length:

438 mm (17.24 in)

(includes electronics housing)

Probe Diameter:

57 mm (2.24 in)

Weight:

0.36 kg (12.64 oz)

54 | Battery-Operated Field Probes: HI-6053 Field Probe

Page 55

The HI-6053 assembly consists of a

pyramidal casing containing the

sensor, which is mounted on one

end of a shaft. The other end of the

shaft is attached to an extrusion

that houses the electronics. The

sensor and electronics housing

operate and are calibrated as a

unit.

The HI-6053 is a true 3-axis probe.

When requested, X, Y, Z, and total

field data can be reported.

The HI-6053 can be used with the

HI-6100 Field Monitor. It can also

be connected to a personal

computer using an optional

HI-4413P Fiber Optic Modem or

HI-4413USB Fiber Optic to USB

Converter and ProbeView II™

software.

HI-6053 OPERATION

For a list and description of communication and information transfer protocols,

including command structure and probe commands, see Appendix D: Operating

Protocols on page 101.

Battery-Operated Field Probes: HI-6053 Field Probe | 55

Page 56

HI-6053 POWER SWITCH

The power button that activates and deactivates the HI-6053 is located on the

bottom of the electronic housing. A green indicator light in the power button

flashes when the probe is on.

On—To turn the HI-6053 on, push in the power button, and then

release. The power button flashes a green indicator light when the

probe is on, and four AAA Nickel-Metal Hydride (NiMH) batteries

supply power.

Off—To turn the HI-6053 off, push in the power button, and then

release. The green indicator light stops flashing, indicating the probe is

off. When not in use, turn the probe off to prolong battery life.

56 | Battery-Operated Field Probes: HI-6053 Field Probe

Page 57

HI-6053 CONTROLS

Two fiber optic connectors and a battery charger connector are mounted on the

HI-6053 housing.

Battery-Operated Field Probes: HI-6053 Field Probe | 57

Page 58

Field Level 20 V/m

HI-6053 TYPICAL FREQUENCY RESPONSE

58 | Battery-Operated Field Probes: HI-6053 Field Probe

Page 59

HI-6053 TYPICAL ISOTROPIC RESPONSE

Typical Isotropic Response in dB at 1 GHz

Battery-Operated Field Probes: HI-6053 Field Probe | 59

Page 60

Typical Isotropic Response in dB at 10 GHz

60 | Battery-Operated Field Probes: HI-6053 Field Probe

Page 61

Typical Isotropic Response in dB at 18 GHz

Battery-Operated Field Probes: HI-6053 Field Probe | 61

Page 62

Any other maintenance or calibration task requires probe disassembly, which

may void your warranty. Only ETS-Lindgren service personnel should

perform these tasks. To avoid problems with your warranty, contact

ETS-Lindgren Customer Service before performing any maintenance.

If you are not qualified to perform this procedure, please consult

ETS-Lindgren Customer Service. ETS-Lindgren is not responsible for

damage to the probe as a result of replacing the batteries.

See the Product Information Bulletin included with your shipment for

information on ETS-Lindgren calibration services.

HI-6053 ADDITIONAL MAINTENANCE

Maintenance of the HI-6053 is limited to external components such as cables or

connectors, and replacing the batteries. For complete information on replacing

the batteries, see the next section, HI-6053 Battery Replacement.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6053 BATTERY REPLACEMENT

During the annual calibration of your HI-6053 at the ETS-Lindgren factory, the

batteries are tested to verify continued operability. If required, the batteries are

replaced at that time. It is rare that you should need to replace the batteries

between calibration checks, but in that event, follow these steps.

1. Turn the HI-6053 off. Verify that the green indicator light is not flashing.

2. Carefully disconnect the fiber optic cables from the Transmit and

3. Remove the two nuts; one on each fiber optic connector.

4. Remove the four screws from the bottom of the electronics housing.

5. Lift the bottom away from the housing. Wires from the power button

62 | Battery-Operated Field Probes: HI-6053 Field Probe

Receive connectors.

are connected to the internal circuitry, so carefully turn the bottom over

and place it to the side, avoiding placing stress on the wires.

Page 63

6. A single connector attaches the two boards together. Withdraw the two

boards from the housing at the same time. The boards should easily

slide out of the tracks.

7. Detach the two boards by carefully separating them at the connector,

avoiding damage to the pins.

8. Replace the four AAA rechargeable NiMH batteries, orienting the

+/- ends as indicated.

Battery-Operated Field Probes: HI-6053 Field Probe | 63

Page 64

Recycle the used batteries, or dispose of them safely and properly.

Many cities collect used batteries for recycling or disposal. You may

contact your local waste disposal agency for information on battery

recycling and disposal.

Optional Part Description

Part Number

Cable, Fiber Optic, Glass

H-491106-xx

(xx=length in meters)

Connector Set, two required

(Bulkhead Feedthrough)

H-231205000

Fiber Optic / RS232 Interface

HI-4413P

Fiber Optic to USB Converter, USB

Interface

HI-4413USB

Battery Charger

H-491198-01

Carrying Case

H-491291

Tripod, Dielectric

H-491009

9. Reattach the two boards at the connector.

10. Slide the two boards into the correct tracks inside the housing, and

carefully push them until they are completely recessed.

11. Replace the bottom of the housing, avoiding damage to the power

button wires.

12. Replace and tighten the four screws into the bottom of the housing.

13. Replace the two nuts removed in step 3; one on each fiber optic

connector.

HI-6053 ADDITIONAL PARTS

Use the following table to order replacement or optional parts for the HI-6053.

64 | Battery-Operated Field Probes: HI-6053 Field Probe

Page 65

Optional Part Description

Part Number

HI-6100 Field Monitor

HI-6100

Probe Stand

H-491269

Probe Carrier for H-491269

Probe Stand

H-491276

Battery-Operated Field Probes: HI-6053 Field Probe | 65

Page 66

The ETS-Lindgren HI-6005 Field Probe

is a fully intelligent sensor enabling fast

and accurate EMF measurements with

industry-leading performance

specifications. Optical coupling to a

variety of readout options makes this

probe ideally suited for a wide range of

field monitoring applications.

Dynamic Range:

0.5–800 Volts per meter (V/m)

Single Range (64 dB)

Typical Frequency Response:

100 kHz–6 GHz

500 kHz–2 GHz: +1 dB, -2.5 dB

2 GHz–5.5 GHz: +3.5 dB, -4 dB

5.5 GHz–6 GHz: +2 dB, -6 dB

Typical Frequency Response

with Correction:

100 kHz–6 GHz: ±0.9 dB

Linearity:

±0.5 dB @ 27 MHz

Isotropicity:

±0.5 dB @ 400 MHz

Overload Withstand:

1,500 V/m maximum

Continuous field

Fiber Optic Cable Connectors:

Standard FSMA

HI-6005 Field Probe

HI-6005 SPECIFICATIONS

66 | Battery-Operated Field Probes: HI-6005 Field Probe

Page 67

Probe Mount:

1/4–20 UNC (internal thread)

Battery:

Rechargeable Nickel-Metal Hydride

(NiMH)

Battery Charger:

100–240 VAC

Approximately three hours

Dimensions

Housing:

32 mm x 32 mm x 32 mm

1.26 in x 1.26 in x 1.26 in

Probe Shields:

43 mm (1.69 in)

Weight:

0.08 kg (2.6 oz)

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

HI-6005 OPERATION

The HI-6005 can be used with the HI-6100 Field Monitor. It can also be

connected to a personal computer using an optional HI-4413P Fiber Optic

Modem or HI-4413USB Fiber Optic to USB Converter and

ProbeView II™ software.

The HI-6005 is a true 3-axis probe. When requested, X, Y, Z, and total field data

can be reported.

For a list and description of communication and information transfer protocols,

including command structure and probe commands, see Appendix D: Operating

Protocols on page 101.

Battery-Operated Field Probes: HI-6005 Field Probe | 67

Page 68

HI-6005 POWER SWITCH

The power switch activates and deactivates the HI-6005:

ON (I)—When the power switch is in the I position, an internal 4.8 VDC

Nickel-Metal Hydride (NiMH) battery provides power to the probe, and

the power indicator LED blinks.

OFF (0) —When the power switch is in the O position, the probe is

inactive. When not in use, turn the probe off to prolong battery life.

68 | Battery-Operated Field Probes: HI-6005 Field Probe

Page 69

Anechoic Room and TEM Cell – Field Level 20 V/m

HI-6005 TYPICAL FREQUENCY RESPONSE

Battery-Operated Field Probes: HI-6005 Field Probe | 69

Page 70

Actual data taken at 400 MHz, field level 20 V/m, maximum variation

0.54 dB.

HI-6005 TYPICAL ISOTROPIC RESPONSE

70 | Battery-Operated Field Probes: HI-6005 Field Probe

Page 71

Any maintenance or calibration task requires probe disassembly, which may

void your warranty. Only ETS-Lindgren service personnel should perform

these tasks. To avoid problems with your warranty, contact ETS-Lindgren

Customer Service before performing any maintenance.

Part Description

Part Number

Cone replacement Kit includes:

Three cones

One each X, Y, and Z label

Six screws

H-651016

Battery Charger

H-491198-48

Carrying Case

H-491207

Cable, Fiber Optic, Glass

H-491106-xx

(xx=length in meters)

Connector Set, two

(Bulkhead Feedthrough)

H-231205000

Fiber Optic/RS232 Interface

HI-4413P

Fiber Optic to USB Converter, USB

Interface

HI-4413USB

HI-6005 ADDITIONAL MAINTENANCE

Maintenance of the HI-6005 is limited to external components such as cables,

connectors, and probe shields. To replace the probe shields, see Probe Shield

Care and Replacement on page 81.

For complete information on maintenance and calibration, see Maintenance on

page 21.

HI-6005 ADDITIONAL PARTS

Use the following tables to order replacement or optional parts for the HI-6005.

Battery-Operated Field Probes: HI-6005 Field Probe | 71

Page 72

Part Description

Part Number

Tripod, Dielectric

H-491009

HI-6100 Field Monitor

HI-6100

Probe Stand

H-491269

Probe Carrier for H-491269

Probe Stand

H-491276

72 | Battery-Operated Field Probes: HI-6005 Field Probe

Page 73

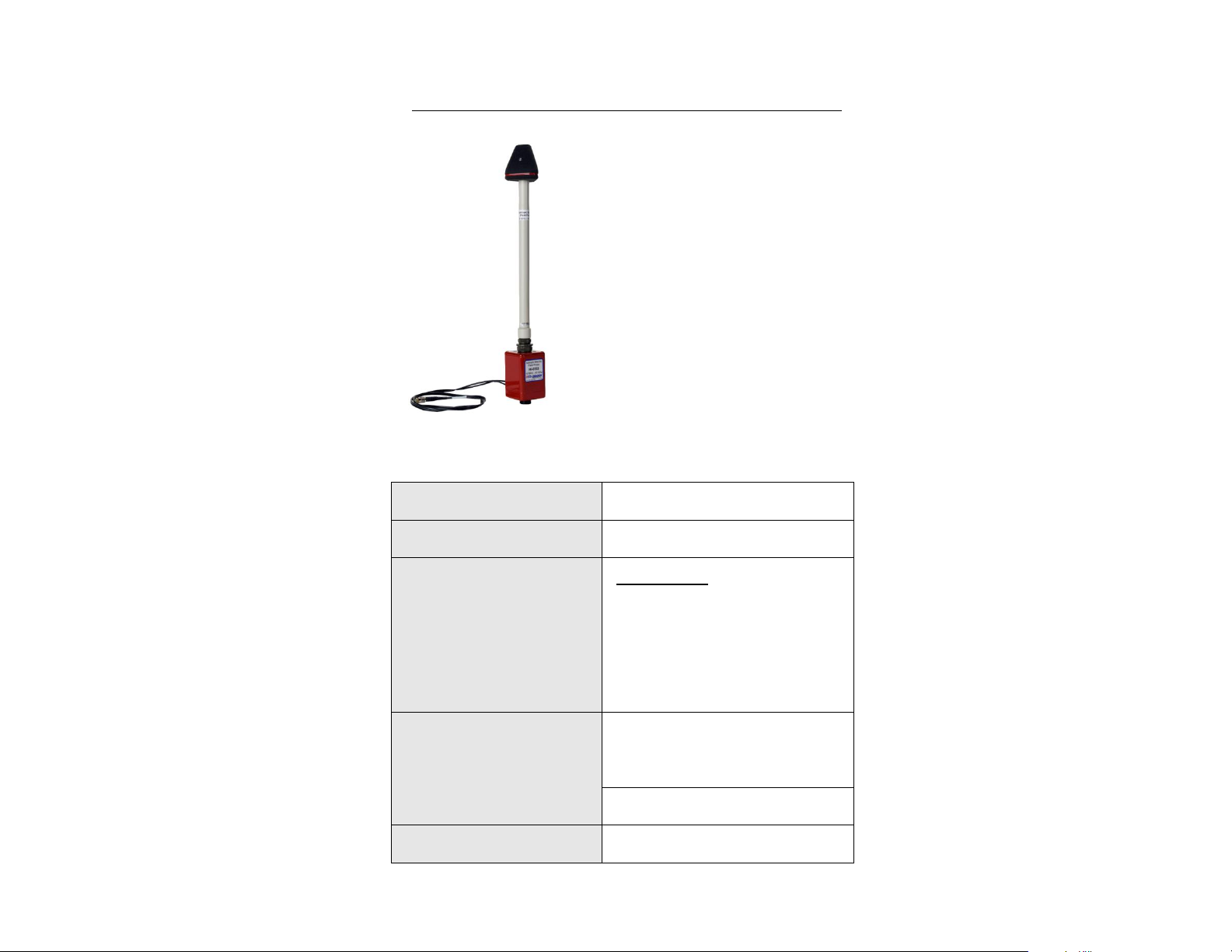

The ETS-Lindgren Probe Stand is

designed for EMC testing in anechoic

chambers and shielded enclosures. The

probe stand provides stable placement for

up to two probes.

PROBE STAND DIMENSIONS

Base Plate and

Tube Height:

2438 mm

96 in

Tube Height:

2248 mm

88.50 in

Base Width:

406 mm

16 in

Tube Width:

51 mm

2 in

6.0 H-491269 Probe Stand

H-491269 Probe Stand | 73

Page 74

In addition to these

parts, the probe stand

includes the following

assembly hardware:

Locking knobs (4)

1/4–20 x 3/4-inch

thumbscrews (2)

10–32 x 5/8-inch

set screw

8–32 x 3/8-inch

thumbscrew

Probe Stand Assembly

PARTS TO ASSEMBLE

74 | H-491269 Probe Stand

Page 75

For accurate measurements, make sure to completely insert the

probe stand tube into the base plate. When fully inserted, the

bottom of the tube should rest evenly on the floor or surface.

On the bottom of the base plate are rubber feet. Make sure all feet

rest evenly on the floor or surface.

Incorrect tube placement or an uneven base can cause inaccurate

measurements.

STEPS TO ASSEMBLE

1. Insert the probe stand tube into the base plate.

H-491269 Probe Stand | 75

Page 76

Testing can be performed using two probes simultaneously. If you

ordered an optional second probe carrier, attach the additional probe

carrier by repeating step 3.

2. To stabilize the tube, insert and tighten the two locking knobs into their

locations.

3. Attach the probe carrier to the tube. Insert one 1/4–20 x 3/4

thumbscrew into the end closer to the tube, and a second one at the

center of the tube. Tighten the thumbscrews.

76 | H-491269 Probe Stand

Page 77

4. Attach the scale pointer to the tube with the 10–32 x 5/8 set screw.

5. Attach the support rod to the tube with the 8–32 x 3/8 thumbscrew.

H-491269 Probe Stand | 77

Page 78

The base plate includes:

Handholds (2)—To

easily move

the probe stand

Floor grid

finders (2)—To align

probe to floor grid

Probe Stand Operation

The support rod is marked with sensor positions that correspond to each probe,

and the probe stand tube is graduated to easily measure the distance to the floor.

1. Attach the probe to the probe carrier using the probe thumbscrew.

78 | H-491269 Probe Stand

Page 79

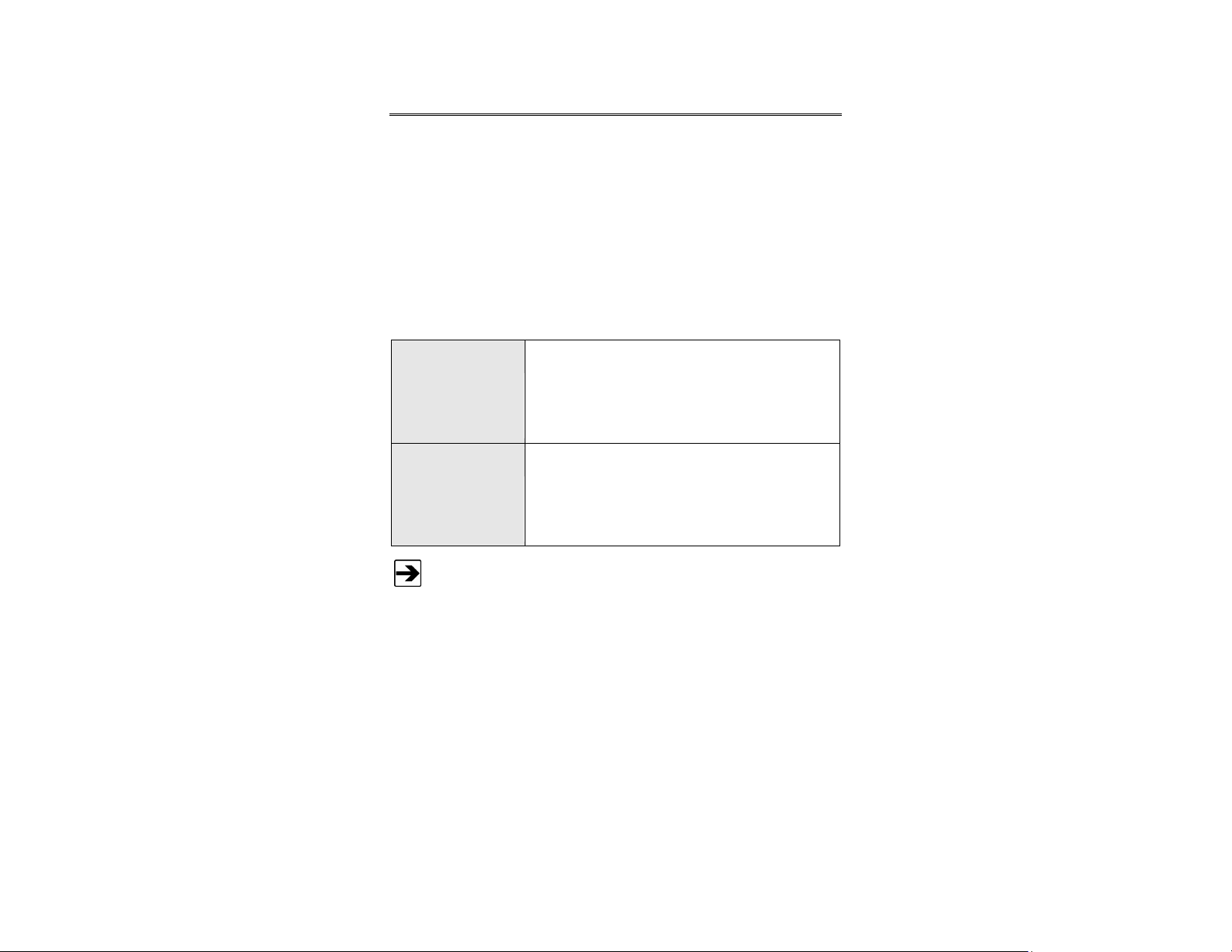

Field Probe

Minimum

Maximum

HI-4433

800 mm

(31.5 in)

2438 mm

(96 in)

HI-6153

HI-6053

HI-4453

HI-4450

673 mm

(26.5 in)

2438 mm

(96 in)

HI-4422

317.5 mm

(12.5 in)

2438 mm

(96 in)

HI-6122

HI-6022

HI-6105

HI-6005

292 mm

(11.5 in)

2438 mm

(96 in)

2. Align the scale pointer to the mark for the probe you are using, and

confirm the distance is between the estimated minimum and maximum

provided in the following Estimated Distance from Element to Floor

chart.

Estimated Distance from Element to Floor

H-491269 Probe Stand | 79

Page 80

This page intentionally left blank.

80 | H-491269 Probe Stand

Page 81

If you have an HI-6122,

HI-6022, HI-6105, or

HI-6005 Field Probe, over

time the probe shields

(the cone-shaped

structures with axis

labels) may accumulate

foreign materials that

could become embedded

in the shield surface.

Probe shields must be

kept clean to maintain

proper operation.

Lift the shield high enough to clear the internal antenna assembly, or

you may damage the assembly. Never touch the antenna assembly.

You may transfer a static charge to the assembly that may distort or

disable the measuring capability in that axis.

Make sure to clear the internal antenna assembly when lowering the

shield or you may damage the assembly.

7.0 Probe Shield Care and Replacement

If the probe shields need to be replaced, you may order them from

ETS-Lindgren. Follow these steps to replace the probe shields:

1. Remove the nylon screws from the probe shield.

2. Lift the shield straight up and away from the housing.

3. With the probe in a protective, supportive position, carefully replace the

probe shield by lowering it straight down onto the housing.

Probe Shield Care and Replacement | 81

Page 82

Over-tightening the screws may damage the screw heads. If you

require additional nylon screws, you may order them from

ETS-Lindgren or obtain them locally. Non-conductive screws must be

used for this application. Never use metal screws.

4. Replace the screws snugly without over-tightening them.

5. Repeat this procedure for the other shields, if necessary.

82 | Probe Shield Care and Replacement

Page 83

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your EMC Field Probe.

Product Warranted

Duration of Warranty Period

HI-6005

3 Years

HI-6022

3 Years

HI-6053

3 Years

HI-6105

3 Years

HI-6122

3 Years

HI-6153

3 Years

Appendix A: Warranty

DURATION OF WARRANTIES

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to three years.

Warranty | 83

Page 84

This page intentionally left blank.

84 | Warranty

Page 85

The HI-6053 Field Probe contains four AAA Nickel-Metal Hydride

(NiMH) batteries, and uses the Series H-491198-01 Battery Charger.

Before operating the Series H-491198-01 Battery

Charger, see General Safety Considerations on

page ix.

The H-491198-01 Nickel-Metal

Hydride (NiMH) Battery Charger is

a dual power source battery charger.

It charges 4.8 volt 220 mA NiMH

batteries and is powered by

85-264 VAC line power or

12.5 VDC. The H-491198-01 Battery

Charger uses a -(dV)/(dT) negative

delta V technique to determine when

the battery is fully charged, which is

typically two hours. With this

technique, the charge state of the

battery has no effect other than

shortening the charge time.

Appendix B: Series H-491198-01 Battery Charger

for NiMH Batteries

SAFETY PRECAUTIONS

INTRODUCTION

Housed in a rugged enclosure, power enters the battery charger through a power

entry module, which contains the fuses, or an optional cigarette lighter plug

adapter. The front face of the battery charger displays LEDs that provide the

operating status. The battery charger connects to the device being charged

through a short cord terminated with a power jack.

An integrated circuit within the battery charger monitors the battery voltage and

controls the charging functions according to the charge state of the battery.

Series H-491198-01 Battery Charger for NiMH Batteries | 85

Page 86

BATTERY LIFE

The NiMH batteries powering the battery-operated probe have high energy

density for maximum operating time between charges, but also have a significant

self-discharge characteristic. When the probe is stored for longer than a week or

two, the batteries will discharge even though not in use. Leaving the batteries in

a discharged condition for long periods of time may result in reduced battery life.

For optimum testing time, charge the batteries before use.

The battery charger is microprocessor controlled to charge the batteries in the

fastest possible manner. When the charger senses that the batteries are fully

charged, the charging current drops to a maintenance level. This level is

sufficient to maintain the full charged without causing battery damage. It is

acceptable to leave the probe connected to the battery charger for extended

periods of time.

With proper care, the batteries should last two to three years. Follow these

recommendations to ensure maximum battery life and optimum testing

performance:

Turn the probe off when the probe is not in use. Leaving the probe on

for extended periods of time will damage the batteries. When the

batteries are discharged, the flashing power ON indicator will not

function.

When possible, leave the robe connected to the battery charger, and

the battery charger connected to the mains electrical supply (charger

operating). The battery charger status indicators will show CHARGER

ON and COMPLETE when the batteries are on a maintenance charge.

Operate the robe only within the optimum operating temperature range

of +20ºC to +30ºC (+68ºF to +86ºF). Although NiMH batteries are

rated for operation in temperatures from -20ºC to +65ºC

(-4ºF to +140ºF), operating the probe at temperature extremes

reduces the operating time of the batteries.

Make sure the batteries are fully charged before resuming operation.

The batteries do not require periodic deep discharges to reverse the

effect caused by repeated shallow discharges, but undercharging can

reduce battery capacity.

86 | Series H-491198-01 Battery Charger for NiMH Batteries

Page 87

Never attempt to recharge a non-rechargeable

battery.

Fully charged batteries (nominal output voltage of 4.8 VDC) provide up to

30 hours of operation. When the batteries have discharged to 4.4 VDC, the probe

will operate, but the batteries need to be charged. When the voltage drops below

4.0 VDC, measurement accuracy may be compromised by continued operation.

When the battery voltage indication is less than 4 volts, a low battery indication is

attached to the output data string warning of the problem. ETS-Lindgren software

applications provide a warning indication on the display screen of the readout

device. It is recommended that custom software packages using data from the

probe monitor the data output for this condition.

If the batteries exhibit low terminal voltages during charging, or if they appear

unable to acquire or maintain a charge, the batteries may be shorted or

damaged. To replace the batteries, see HI-6053 Battery Replacement on

page 62.

CHARGING THE BATTERIES

For maximum battery life, fully charge the batteries before placing the probe into

service. Failing to fully charge the batteries may result in reduced battery life and

cause premature battery failure.

To charge a battery:

1. Make sure the probe is off or the batteries will not charge.

2. Connect the battery charger to the electrical mains, and then plug the

charger output into the battery charger connector on the probe.

Series H-491198-01 Battery Charger for NiMH Batteries | 87

Page 88

CHARGING INDICATORS

The following LEDs are located on the front of the battery charger:

POWER ON (green)—Indicates the battery charger is connected to the

AC power source.

NO BATTERY (amber)—Indicates the battery charger does not detect

a battery.

PENDING (amber)—Indicates the battery charger detects a battery.

Before fast charging can begin, the battery voltage must fall within

predetermined acceptable limits. A pulse-trickle charge is provided to

bring a depleted battery to a valid charge prior to fast charge.

CHARGING (amber)—Indicates the voltage pre-qualification condition

has been met, and fast charge has started.

Fast charging continues until termination by a peak voltage detect or a

maximum charge time. For peak voltage detect, the fast charge is

terminated when the battery voltage is lower than the previously

measured values by 24mV. If a peak voltage is not detected, then the

fast charge is terminated when the maximum time limit of 180 minutes

is reached.

COMPLETE (green)—Indicates a fast charging peak voltage is

detected.

If the probe is turned on during the fast charge period of the charge

cycle, the current surge that the batteries provide to the electronics in

the probe will cause a momentary voltage drop on the batteries,

causing the charger to terminate the fast charge based on a peak

voltage detect condition.

The battery charger switches to top-off charge mode that provides a charge

current one-eighth of the fast charge rate. This charge continues from the time

when a peak voltage detect terminates the fast charge, until the maximum time of

180 minutes is reached. If the probe is disconnected from the charger at this

point in the charge cycle, the batteries will operate properly.

88 | Series H-491198-01 Battery Charger for NiMH Batteries

Page 89

Following the maximum time of 180 minutes, a pulse-trickle charge mode is used

to compensate for the self-discharge of the batteries while idle in the charger.

The fast charge current is low enough that there is not always enough heating of

the battery cells to cause the voltage to drop. With no voltage drop there is no

peak voltage detection, and the fast charge will terminate after the maximum time

of 180 minutes is reached.

SYNCHRONIZING THE BATTERY CHARGE INDICATOR

The probe has internal circuitry to track the charge condition of the batteries.

NiMH batteries have a sharp discharge-curve knee, which means there is little

indication that the batteries are nearly discharged prior to a low battery condition.

The internal circuitry tracks the charging and discharging currents of the batteries

and displays the calculated battery condition.

It is possible that the battery charge indication may lose synchronization with the

actual battery condition. A loss of synchronization may be indicated by a low

battery charge alert after the batteries were recently fully charged. Loss of

synchronization may also be indicated by short battery life and premature low

battery alert.

To synchronize the battery charge indicator:

1. Make sure the probe is off or the batteries will not charge.

2. Connect the battery charger to the electrical mains, and then plug the

charger output into the battery charger connector on the probe.

3. Press the DISCHARGE button on the battery charger. The batteries

will fully discharge, and then fully recharge. The total time required to

discharge and recharge is approximately seven hours.

4. For best results, repeat the process once. However, it may be

necessary to repeat the process three times for proper

synchronization. The synchronization process may take up to 12

hours.

When completely charged, the battery indicator for the probe should indicate a

charge level of more than 90%.

Series H-491198-01 Battery Charger for NiMH Batteries | 89

Page 90

NiMH Battery:

4 AAA batteries, rechargeable

NiMH (rapid charge cells,

1.2 volts/cell)

ETS-Lindgren Part #400038

(quantity required = 4)

Power

Main:

IEC filtered AC power input module

110-240 VAC, 500 mA max,

50-100 Hz

Alternate:

Automobile cigarette lighter to 2 mm

power plug adapter cord, 12.5 Vdc,

100 mA

Fuses:

250 volt, 1.0 Amp, Type T

(5 mm x 20 mm)

DISCHARGING A BATTERY

To discharge the batteries:

1. Make sure the probe is off or the batteries will not charge.

2. Connect the battery charger to the electrical mains, and then plug the

charger output into the battery charger connector on the probe.

3. Press the DISCHARGE button on the battery charger. The batteries

will fully discharge, and then fully recharge. The total time required to

discharge and recharge is approximately seven hours.

SPECIFICATIONS

BATTERY CHARGER SPECIFICATIONS

The battery charger may be powered by standard line voltage (110–240 VAC,

50–60 Hz) or by an optional automobile cigarette lighter plug (12.5 VDC).

90 | Series H-491198-01 Battery Charger for NiMH Batteries

Page 91

Output

Open Circuit Voltage:

12 Vdc

Fast Charge Pending Current:

2.0 mA

Fast Charge Current:

220 mA

Pulsed Trickle Charge Current:

2.0 mA

Output Voltage (During Fast

Charge):

4–8 Vdc

Environmental

Operating Temperature:

10°C to 40°C

50°F to 104°F

Humidity:

5% to 95% relative humidity,

non-condensing

MAINTENANCE RECOMMENDATIONS

Operate the battery charger with care.

There are no user serviceable parts inside the battery charger.

Opening the battery charger housing may void your warranty.

Series H-491198-01 Battery Charger for NiMH Batteries | 91

Page 92

Disconnect the battery charger from power

before replacing a fuse.

REPLACING THE FUSE

If the battery charger fails to operate, check for a blown fuse inside the power

entry module. A blown fuse must be replaced with the same value and type of

fuse, or an unsafe condition may result. Use only 250 Volt, 1.0 Amp, Type T

(5 mm x 20 mm) fuses.

To replace a fuse:

1. Two fuses are located in the fuse drawer in the power input module.

Use a screwdriver to open the drawer.

2. The fuse towards the outside of the drawer is the spare. Remove the

spare fuse from the module.

3. Replace the blown fuse with the spare fuse.

4. Slide the fuse drawer back into the module. Make sure that the drawer

snaps securely into its locked position.

92 | Series H-491198-01 Battery Charger for NiMH Batteries

Page 93

The HI-6022 and HI-6005 probes contain a Nickel-Metal Hydride

(NiMH) battery, and use the Series H-491198-48 Battery Charger.

Before operating the Series H-491198-48 Battery

Charger, see General Safety Considerations on

page ix.

The H-491198-48 Nickel-Metal Hydride

(NiMH) Battery Charger is a dual power

source battery charger. It charges 4.8 volt

25 mA NiMH batteries and is powered by

85-264 VAC line power or 12.5 VDC. The

H-491198-48 Battery Charger uses a

-(dV)/(dT) negative delta V technique to

determine when the battery is fully charged,

which is typically two hours. With this

technique, the charge state of the battery

has no effect other than shortening the

charge time.

Appendix C: Series H-491198-48 Battery Charger

for NiMH Batteries

SAFETY PRECAUTIONS

INTRODUCTION

Housed in a rugged enclosure, power enters the battery charger through a power

entry module, which contains the fuses, or an optional cigarette lighter plug

adapter. The front face of the battery charger displays LEDs that provide the

operating status. The battery charger connects to the device being charged

through a short cord terminated with a power jack.

An integrated circuit within the battery charger monitors the battery voltage and

controls the charging functions according to the charge state of the battery.

Series H-491198-48 Battery Charger for NiMH Batteries | 93

Page 94

BATTERY LIFE

The NiMH battery powering the battery-operated probe has high energy density

for maximum operating time between charges, but also has a significant self-