Page 1

Model HI-3702

Clamp-On Induced

Current Meter

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 1995–2009 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren L.P.

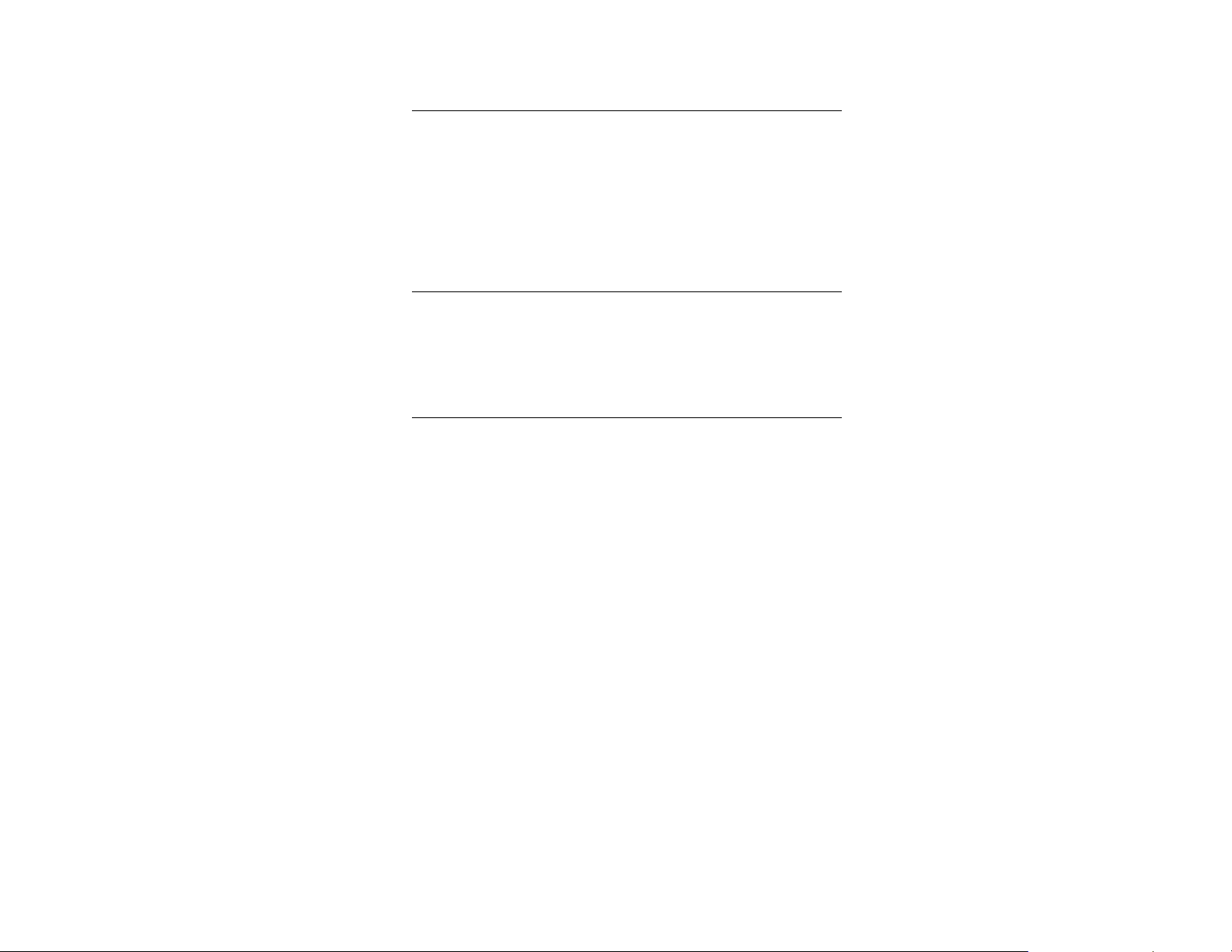

Revision Record | HI-3702 MANUAL | Part #H-600070, Rev. G

Revision Description Date

Initial Release November, 1995

A Updates May, 1996

B Update battery charger June, 1997

C Add CE label June, 1997

D Add Appendix A January, 1998

E Update battery charger specifications August, 1999

F Update contact information; reformat February, 2006

G Update frequency range; rebrand February, 2009

ii |

Page 3

Table of Contents

Notes, Cautions, and Warnings ................................................ v

General Safety Considerations ................................................ v

1.0 Introduction .......................................................................... 7

Standard Configuration .................................................................................. 8

Optional Items ................................................................................................ 8

ETS-Lindgren Product Information Bulletin ................................................... 8

2.0 Maintenance ......................................................................... 9

Battery Maintenance .................................................................................... 10

Annual Calibration ....................................................................................... 10

Maintenance of Fiber Optics ........................................................................ 10

Replacement and Optional Parts ................................................................. 11

Service Procedures ..................................................................................... 12

3.0 Ranges and Specifications ............................................... 13

Ranges ........................................................................................................ 13

Specifications ............................................................................................... 13

HI-3702 Typical Frequency Response ........................................................ 15

4.0 Operation ............................................................................ 17

Computer Controlled Data Logging ............................................................. 20

Battery Charging .......................................................................................... 20

Error Codes ................................................................................................. 21

5.0 Functional Theory of Operation ....................................... 23

Appendix A: Warranty ............................................................. 25

Appendix B: Series H-491198-36 Battery Charger ............... 27

Safety Precautions ....................................................................................... 27

Introduction .................................................................................................. 27

Charging a Battery ....................................................................................... 28

Charging Indicators ...................................................................................... 28

Specifications ............................................................................................... 29

Maintenance Recommendations ................................................................. 30

Replacing the Fuse ...................................................................................... 30

| iii

Page 4

Appendix C: EC Declaration of Conformity .......................... 33

HI-3702 Clamp-On Induced Current Meter .................................................. 33

Series H-491198-36 Battery Charger .......................................................... 34

iv |

Page 5

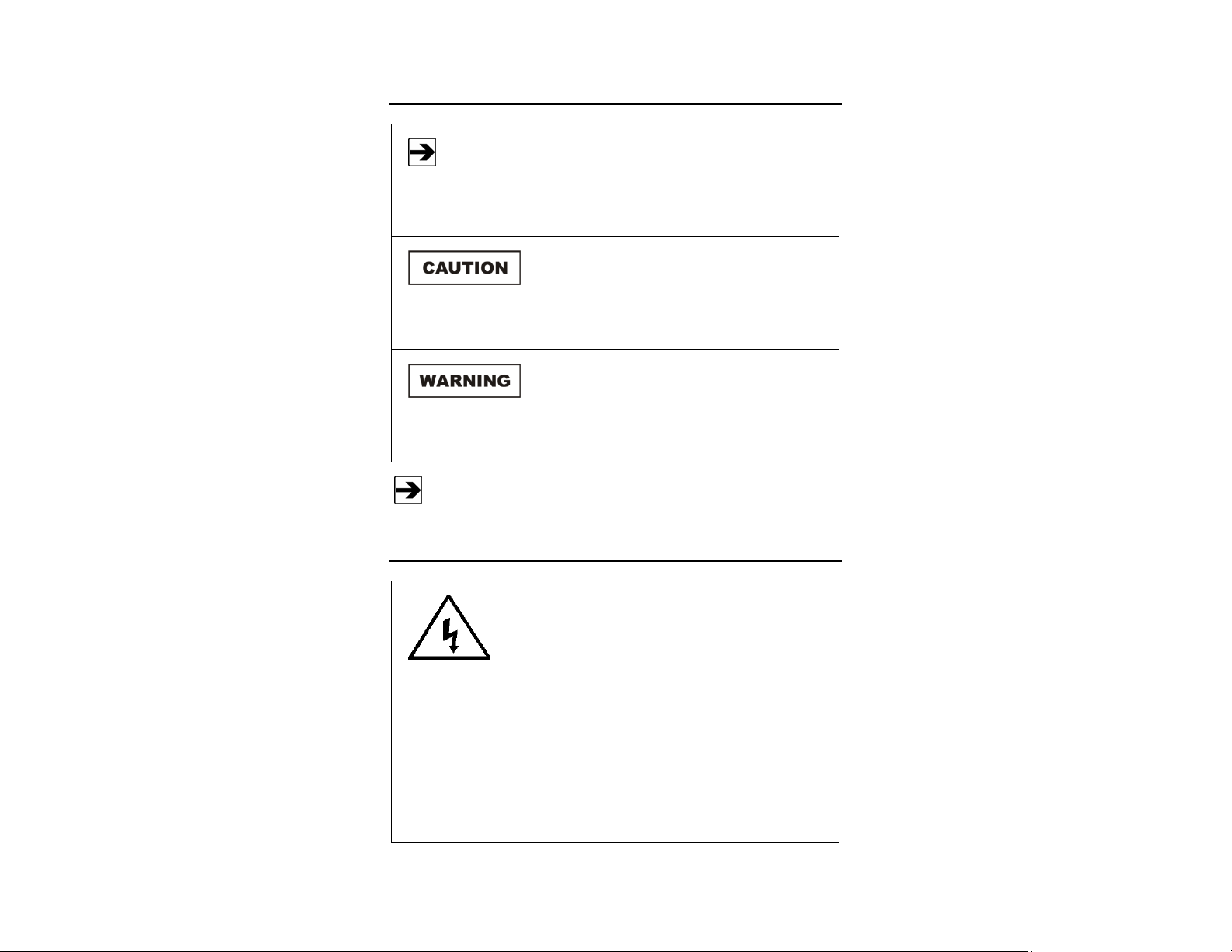

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

General Safety Considerations

Warning: This is a Safety Class I product

(provided with a protective earthing ground

incorporated in the power cord). The mains

plus shall only be inserted in a socket outlet

provided with a protective earth contact. Any

interruption of the protective conductor,

inside or outside the instrument, is likely to

make the instrument dangerous. Intentional

interruption is prohibited. DO NOT defeat the

earth grounding protection by using an

extension cable, power cable, or

autotransformer without a protective ground

conductor.

| v

Page 6

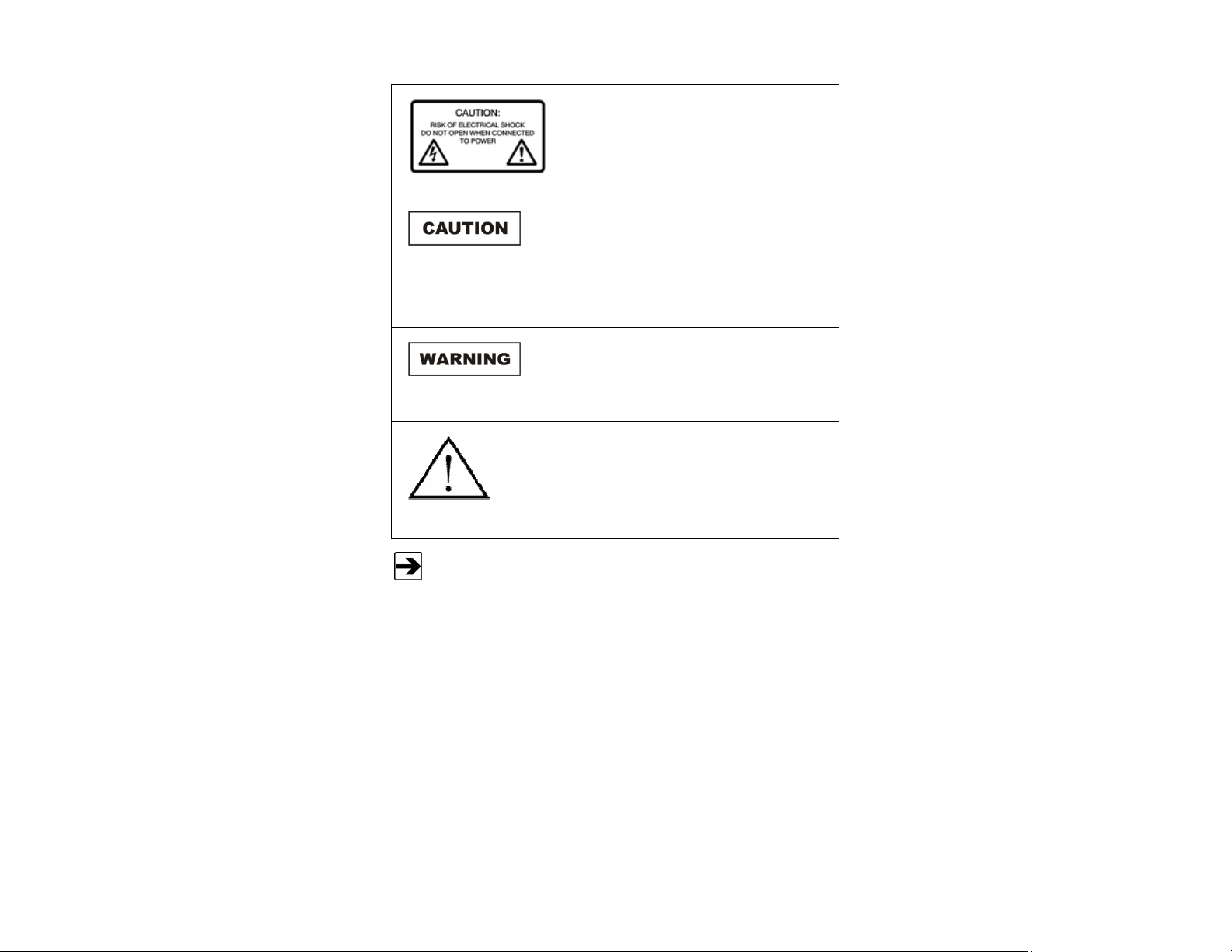

Caution: Uninsulated voltage within the unit

may have sufficient magnitude to cause

electric shock. Therefore, it is dangerous to

make any kind of contact with any parts

inside this unit.

Caution: This instrument is shipped with a

three-wire power cable, in accordance with

international safety standards. When

connected to an appropriate power line

outlet, this cable grounds the instrument

cabinet.

Warning: No operator serviceable parts

exist inside. Refer servicing to qualified

personnel. To prevent electrical shock, do

not remove covers.

Warning: The battery charger incorporates

parts, such as a switch and relay that

potentially could produce sparks or arcs.

Warning: For indoor use only, do not

expose to rain.

vi |

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

Page 7

1.0 Introduction

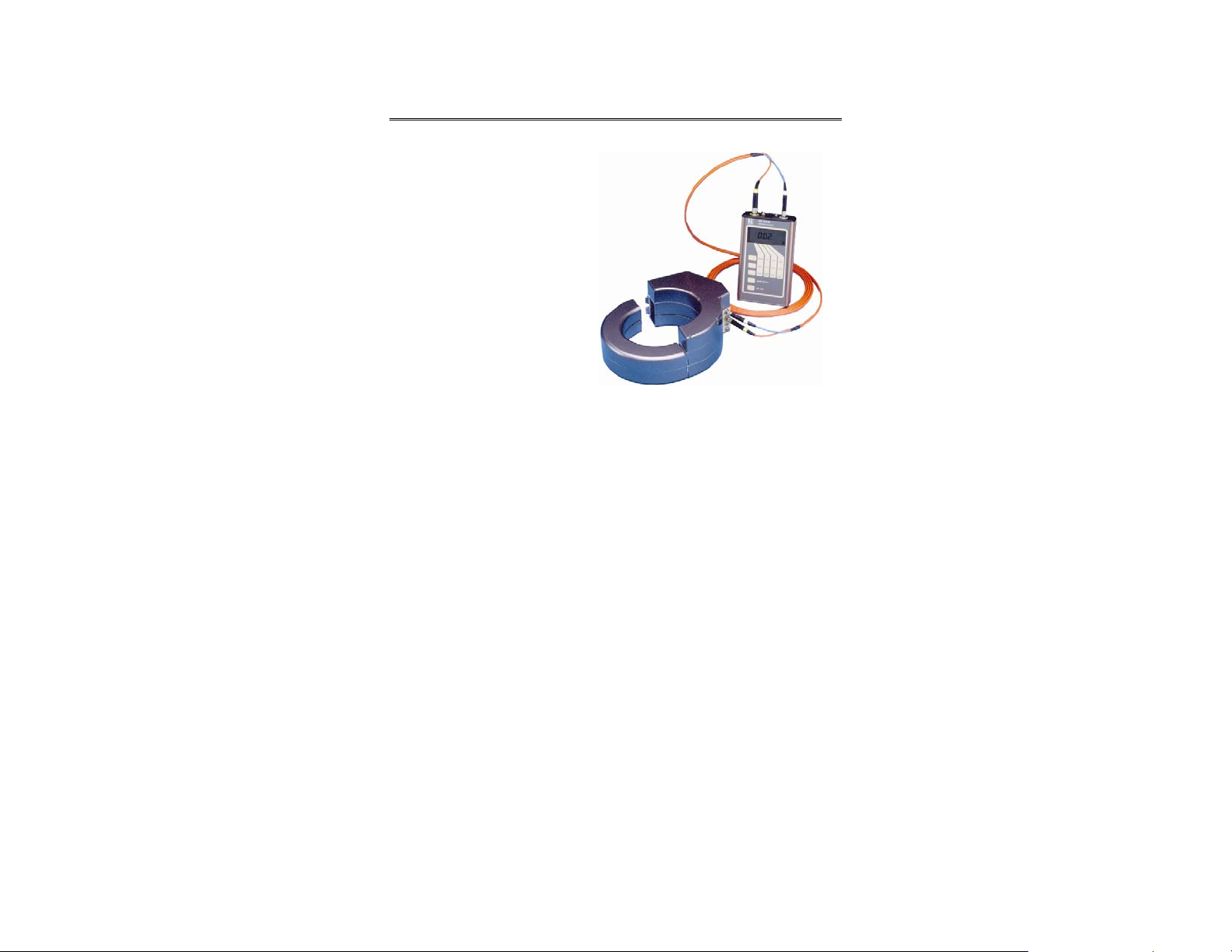

The ETS-Lindgren HI-3702

Clamp-on Induced Current

Meter measures the induced

body current of individuals

working in environments where

radio frequency (RF)

electromagnetic fields are

present. The HI-3702 is designed

to meet the requirements of

IEEE C95.1-1991 Standard for

Safety Levels with Respect to

Human Exposure to Radio

Frequency Electromagnetic

Fields, 3 kHz to 300 GHz.

HI-3702 Clamp-On Current Sensor

HI-4416 Digital Readout/Control Unit

IEEE C95.1-1991 defines the acceptable levels of RF-induced body current for

the frequency range of 3 kHz to 100 MHz. The acceptable levels range from

3 mA for uncontrolled exposures at 3 kHz, to 200 mA for controlled exposures

between 100 kHz and 100 MHz.

Shown:

The accuracy of the HI-3702 provides a means for determining compliance. The

unit is completely portable and self-contained, and is simple to set up and easy to

operate. The rugged design can be used for measurements in environments

such as:

• Induction heating facilities

• Industrial welding applications

• Broadcast transmitting and antenna locations

Introduction | 7

Page 8

Standard Configuration

• HI-3702 Clamp-On Current Sensor with cushioned case

• HI-4416 Digital Readout/Control Unit with fiber optic cable

• Series H-491198-36 Battery Charger

• Carrying Case

Optional Items

• Belt-Pac Readout/Control Unit Case

• HI-4413P Fiber Optic Modem

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

8 | Introduction

Page 9

2.0 Maintenance

Before performing any maintenance,

follow the safety information in the

ETS-Lindgren Product Information

Bulletin included with your shipment.

WARRANTY

Take care to keep dirt and moisture from getting inside the housing of the

HI-3702 Clamp-on Induced Current Meter and on the coplanar surfaces of the

ferrite core that are exposed when the clamp-on sensor is open. The cushioned

case provides only minimal protection to the clamp-on sensor in keeping dirt or

other particulate matter from entering the gap on the inner side of the housing.

Do not use high-pressure sprays, and under no circumstance should the unit be

immersed in water or other liquid; the HI-3702 is not waterproof. Such actions

void the warranty.

Maintenance of the HI-3702 is limited to

external components such as cables or

connectors.

Do not open the HI-3702 housing.

Warranty may be void if the housing is

opened.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

Maintenance | 9

Page 10

Battery Maintenance

Under normal operating conditions, recharging the battery is the only

HI-3702 maintenance performed by the user.

Maintaining the HI-3702 requires that the nickel-cadmium (NiCd) battery be

properly charged and the battery condition monitored. The normal operational life

of the battery (approximately 1000 charge/discharge cycles) is such that by the

time the battery needs replacement; the HI-3702 will need recalibration; these

tasks are performed by ETS-Lindgren. For information on calibration services,

see Annual Calibration on page 10.

For the steps to charge the battery, see page 20.

In case of damage to the battery that causes premature failure, the HI-3702 must

be sent to ETS-Lindgren for battery replacement; replacement in the field is not

possible. See Service Procedures on page 11 for information on returning the

HI-3702 to ETS-Lindgren for service.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Maintenance of Fiber Optics

Fiber optic connectors and cables can be damaged from airborne particles,

humidity and moisture, oils from the human body, and debris from the connectors

they plug into. Always handle connectors and cables with care, using the

following guidelines.

10 | Maintenance

Page 11

Before performing any maintenance, disconnect

the fiber optic cables from the unit and turn off

Replacement and Optional Parts

Following are the part numbers for ordering replacement or optional parts for the

HI-3702.

power.

When disconnecting fiber optic cables, apply the

included dust caps to the ends to maintain their

integrity.

Before connecting fiber optic cables, clean the

connector tips and in-line connectors.

Before attaching in-line connectors, clean them

with moisture-free compressed air.

Failure to perform these tasks may result in

damage to the fiber optic connectors or cables.

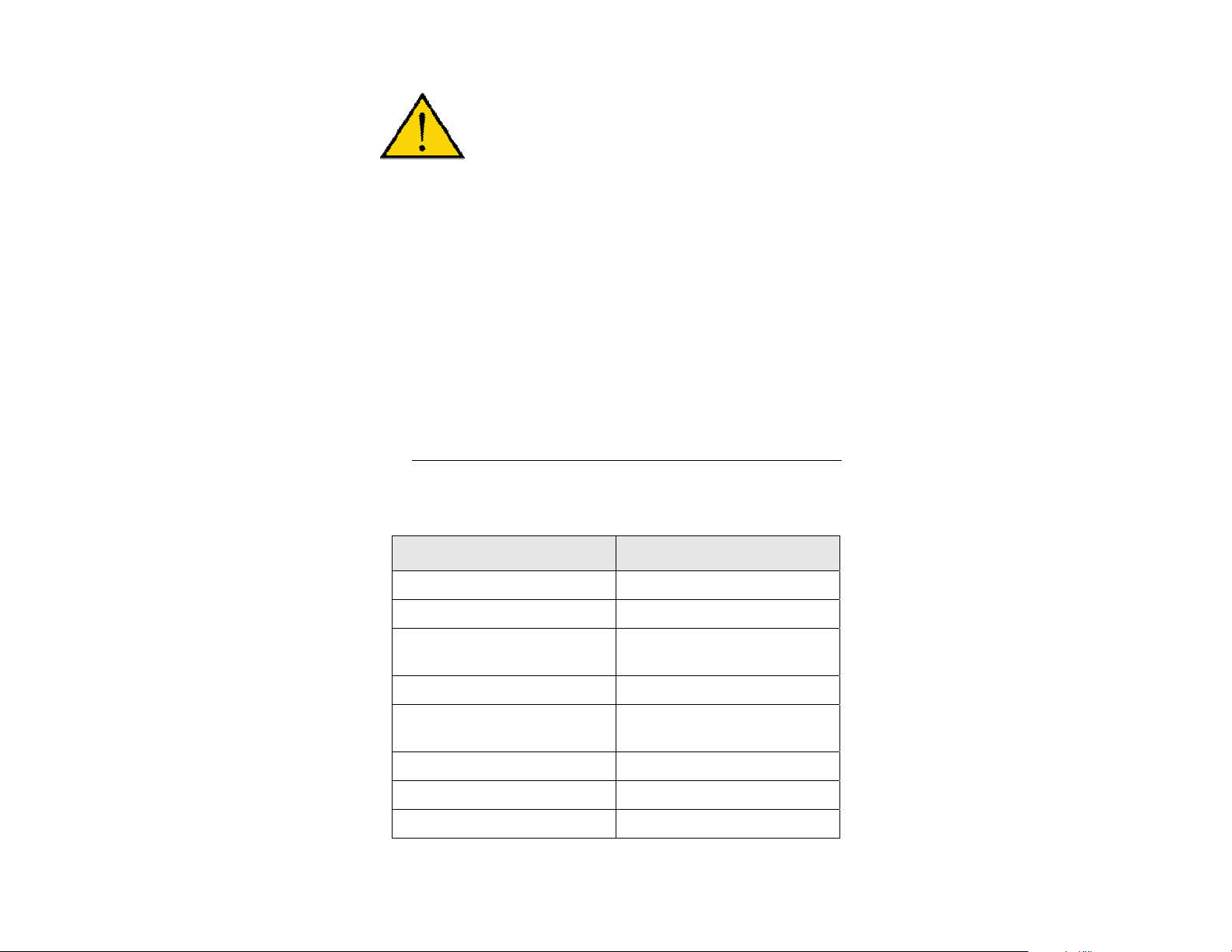

Part Description Part Number

HI-3702 Cushioned Case H-51560044

HI-3702 Fitted Carrying Case H-491132

HI-4416 Digital Readout/Control

Unit

Fiber Optic Cable, 2-meter H-491106-02

Series H-491198-36

Battery Charger

Belt-Pac Readout/Control Unit Case H-51560045

HI-4413P Fiber Optic Modem HI-4413P

12V Auto Lighter Power Cord H-22270-1534D

HI-4416

H-491198-36

Maintenance | 11

Page 12

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

12 | Maintenance

Page 13

3.0 Ranges and Specifications

Ranges

Autorange: 1.00 mA–1.000 A

Range 1: 1.00 mA–10.0 mA

Range 2: 3.1 mA–31.6 mA

Range 3: 10.0 mA–100.0 mA

Range 4: 0.031 A–0.316 A

Range 5: 0.100 A–1.000 A

Specifications

Typical Frequency Response: 9 kHz–70 MHz ±2.0 dB

Linearity: ±0.5 dB

At lower levels, the linearity for

Range 1 deviates within ±0.5 dB

due to noise. The remaining ranges

follow the ideal curve as shown for

Range 2 in Typical Frequency

Response on page 15.

Fiber Optic Connectors: Standard FSMA

Fiber Optic Cable: 200 micron, Graded Index,

Multimode, Max Length 1 Km

Readout: HI-4416 Digital Readout/Control

Unit

Ranges and Specifications | 13

Page 14

Physical Specifications

HI-3702 Inner Diameter: 105.4 mm (4.15 in)

HI-3702 Outer Diameter: 171.4 mm (6.75 in)

HI-3702 Height: 72.6 mm (2.86 in)

HI-3702 Weight: 1.7 kg ( 3 lb 13 oz)

HI-4416 Digital Readout/Control

Unit:

Cushioned Case: 0.085 kg (3.0 oz)

Fiber Optic Cable: 0.071 kg (2.5 oz)

Battery / Battery Charger

Battery: 3.6 VDC, 1400 mAH rechargeable

Battery Charger: 115/230 VAC, approximately

Battery Life: Approximately 5 hours of continuous

Environmental

Humidity: 5% to 95% relative humidity,

Operating Temperature: 10°C–40°C (50°F–104° F)

0.42 kg (14.8 oz)

nickel-cadmium (NiCd)

one hour

operation per full charge

non-condensing

14 | Ranges and Specifications

Page 15

HI-3702 Typical Frequency Response

Ranges and Specifications | 15

Page 16

This page intentionally left blank.

16 | Ranges and Specifications

Page 17

4.0 Operation

1. Charge the battery.

Before taking any

measurements, charge

the battery to maximum

capacity. For the steps to

charge the battery, see

page 20.

The nickel-cadmium

(NiCd) battery installed in

the HI-3702 Clamp-on

Induced Current Meter

was charged prior to

shipment; however, NiCd

batteries can

self-discharge to nearly

zero capacity after

two months.

Before connecting any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

If you use this equipment in a manner not

specified by ETS-Lindgren, the protection

provided by the equipment may be impaired.

Do not position the equipment so that it is

difficult to connect cables to or disconnect

cables from the back of the unit.

The battery charger requires approximately one hour to charge the battery to

maximum capacity. Under normal operation, a fully-charged battery should

provide five hours of operation. If the battery fails to hold a charge or if a

significant degradation in operational time occurs, you may need to replace the

battery.

Operation | 17

Page 18

2. Connect the fiber optic cables.

Connect the fiber optic cable to the HI-3702 and to the HI-4416 Digital

Readout/Control Unit. Follow the color coding on the fiber optic cable, the

HI-3702, and the HI-4416.

3. Power on the HI-3702.

Turn on the HI-3702. The HI-3702 is equipped with a locking lever on/off

switch. Pull the switch lever out before toggling it to the appropriate position.

4. Power on the HI-4416.

Turn on the HI-4416. See the HI-4416 manual for more complete operating

information.

5. Select the range.

Use the HI-4416 to select the range that is appropriate for the expected

current levels to be measured. To select auto range, scroll through the ranges

until Range A appears on the screen.

When auto range is enabled, the probe will scroll up to the next higher range

when the reading displayed exceeds full scale. The probe will scroll down to

the next lower range when the reading displayed is -14 dB (20%) of the full

scale reading for the current range. This will put the reading at approximately

2/3 of full scale of the next lower range. See the following Auto Range

Readings Table and Auto Range Flow Diagram.

Range -20dB of

full scale

1 1 mA 7.2 mA 10 mA 10 mA

2 3.16 mA 20 mA 7.2 mA 31.6 mA 10 mA 31.6 mA

3 10 mA 72 mA 20 mA 100 mA 31.6 mA 100 mA

4 31.6 mA 200 mA 72 mA 316 mA 100 mA 316 mA

5 100 mA 200 mA 316 mA 1000 mA

Reading

after scroll

down

-14dB of

full scale;

scroll down

point

Full scale

scroll up

point

Reading

after scroll

up

18 | Operation

Full scale

reading

Page 19

Auto Range Readings Table

Auto Range Flow Diagram

6. Select averaging.

Use the HI-4416 to select Instantaneous Readings or One-Second

Averaging. The HI-3702 collects a measurement approximately seven times

per second. When the X-axis is selected, each measurement is sent to the

display. When the Y-axis is selected, the one-second average of the

measurements is displayed. The averaging algorithm stores the seven most

recent measurements. Each time a measurement is taken, the algorithm drops

the oldest value, adds in the new value, and then recalculates the average and

sends the new average value to the display.

7. Attach the clamp-on curre nt sensor.

Place the clamp-on current sensor on the arm or leg of the body under test

and close the buckle. For accurate measurements, verify that nothing

interferes with complete closure of the clamp-on current sensor. Make sure no

clothing is caught between the coplanar surfaces of the ferrite core material or

the aluminum housing.

Displayed readings that are less than 10% of the full scale reading for the

selected range are not valid. When Range 1 or Autorange is selected and there

is no current passing through the current meter, a noise floor reading will display.

This is a normal operating condition.

Operation | 19

Page 20

Computer Controlled Data Logging

The HI-3702 is

connected for data

logging as shown.

Software is available for the personal computer that simulates the HI-4416. For

information on using the HI-4416 for data logging, see the HI-4416 manual.

Use the optional RS-232 cable assembly (part #H-2239615) to connect the

HI-3702 to the HI-4413P Fiber Optic Modem. This provides direct input of

HI-3702 data into a personal computer or other data logging device.

Battery Charging

Never attempt to recharge a non-rechargeable

battery.

If the battery has been through its normal life span of approximately

1000 charge/discharge cycles, return the HI-3702 to ETS-Lindgren for

battery replacement and recalibration. For more information, see

Battery Maintenance on page 10.

1. Turn off the HI-3702.

2. Connect the battery charger to an AC outlet.

20 | Operation

Page 21

3. Plug the charger jack completely into the CHARGE connector on the

clamp-on current sensor.

Allow approximately one hour for a full charge cycle. When charging is

complete, the battery charger automatically goes into a trickle charge.

It will remain in trickle charge mode until disconnected from the

HI-3702.

4. When the charge cycle is complete, remove the charger jack from the

CHARGE connector on the clamp-on current sensor.

5. Unplug the battery charger from the AC outlet.

6. Use the HI-4416 to verify that the battery is charged to approximately

3.8 VDC.

See Series H-491198-36 Battery Charger on page 27 for complete information

on the battery charger.

Error Codes

If an error occurs, the probe will respond with one of the following strings. These

strings begin with a colon and end with a carriage return.

E01 Communication error (for example, overflow)

E02 Buffer full error; too many characters contained between the

start character and carriage return sequence

E03 Received command is invalid

E04 Received parameter is invalid

E05 Hardware error (for example, EEPROM failure)

E06 Parity error

E9 Received command is invalid

Operation | 21

Page 22

This page intentionally left blank.

22 | Operation

Page 23

5.0 Functional Theory of Operation

Following is a functional theory of operation for the HI-3702 Clamp-on Induced

Current Meter. The objective is to enhance user understanding of the theory

behind the design to aid with the operation and maintenance of the HI-3702.

The HI-3702 is designed to measure RF induced current flowing through the

ankles or arms of the body under test, even while walking or climbing. The fiber

optically coupled readout/control unit does not perturb the measured RF field or

the current distributions. The sensor is a ferrite split core current transformer. The

signal generated by the sensor is amplified by 10 dB to 50 dB depending on the

range that is selected. There is 20 dB of linearity for each range. This signal is

applied to a True RMS Thermal RMS to DC Converter. The DC voltage output of

the True RMS Thermal RMS to DC Converter is applied to a 12 bit

A/D converter. This digital representation of the DC voltage is read by the

microprocessor, converted to a number that is representative of current being

sensed, and transmitted through the fiber optic interface to the HI-4416 Digital

Readout/Control Unit.

Functional Theory of Operation | 23

Page 24

This page intentionally left blank.

24 | Functional Theory of Operation

Page 25

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your HI-3702.

DURATION OF WARRANTIES FOR HI-3702

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to one year.

Product Warranted Duration of Warranty Period

HI-3702 Clamp-on Induced

Current Meter

Series H-491198-36

Battery Charger

1 Year

1 Year

Warranty | 25

Page 26

This page intentionally left blank.

26 | Warranty

Page 27

Appendix B: Series H-491198-36 Battery Charger

The HI-3702 Clamp-on Induced Current Meter contains a

nickel-cadmium (NiCd) battery, and uses the Series H-491198-36

Battery Charger.

SAFETY PRECAUTIONS

Before operating the Series H-491198-36 Battery

Charger, see General Safety Considerations on

page v.

INTRODUCTION

The Series H-491198-36 Battery Charger

is a dual power source battery charger. It

charges 3.6 Volt 1400 mAH NiCd batteries

and is powered by 120-240 VAC line power

or 12.5 VDC. The H-491198-36 charger

uses a -(dV)/(dT) negative delta

V technique to determine when the battery

is fully charged, which is typically one hour.

With this technique, the charge state of the

battery has no effect other than shortening

the charge time.

Housed in a rugged enclosure, power enters the battery charger through a power

entry module, which contains the fuses, or an optional cigarette lighter plug

adapter. The front face of the battery charger displays LEDs that provide the

operating status. The battery charger connects to the device being charged

through a short cord terminated with a power jack.

An integrated circuit within the battery charger monitors the battery voltage and

controls the charging functions according to the charge state of the battery.

Series H-491198-36 Battery Charger | 27

Page 28

CHARGING A BATTERY

Never attempt to recharge a non-rechargeable

battery.

For the steps to charge a battery, see page 20.

CHARGING INDICATORS

The following LEDs are located on the front of the battery charger:

• POWER ON (green)—Indicates the battery charger is connected to the

AC power source.

• NO BATTERY (amber)—Indicates the battery charger does not detect

a battery.

• PENDING (amber)—Indicates the battery charger detects a battery.

Before fast charging can begin, the battery voltage must fall within

predetermined acceptable limits. A pulse-trickle charge is provided to

bring a depleted battery to a valid charge prior to fast charge.

• CHARGING (amber)—Indicates the voltage pre-qualification condition

has been met, and fast charge has started.

• COMPLETE (green)—Indicates a fast charging peak voltage is

detected. The Field Probe can remain connected to the battery charger

indefinitely while in this maintenance mode.

28 | Series H-491198-36 Battery Charger

Page 29

SPECIFICATIONS

Power

Main: IEC filtered AC power input module

110-240 VAC, 500 mA max,

50-100 Hz

Alternate: Automobile cigarette lighter to 2 mm

power plug adapter cord, 12.5 Vdc,

100 mA

Fuses: 250 Volt, 1.0 Amp,

Type T (5 mm x 20 mm)

Output

Open Circuit Voltage: 15 Vdc

Fast Charge Pending Current: 60 mA

Fast Charge Current: 1400 mA

Pulsed Trickle Charge Current: 50 mA

Output Voltage (During Fast

Charge):

NiCd Battery:

Series H-491198-36 Battery Charger | 29

3–6 Vdc

Battery

• 3.6 Volt 3 Cell NiCd Battery,

1400 mAH (rapid charge cells,

1.2 Volts/cell)

• ETS-Lindgren Part #491038

Page 30

Environmental

Operating Temperature: 10°C–40°C (50°F–104°F)

Humidity: 5% to 95% relative humidity,

non-condensing

MAINTENANCE RECOMMENDATIONS

• Operate the battery charger with care.

• There are no user serviceable parts inside the battery charger.

Opening the battery charger housing may void your warranty.

REPLACING THE FUSE

Disconnect the battery charger from power

before replacing a fuse.

If the battery charger fails to operate, check for a blown fuse inside the power

entry module. A blown fuse must be replaced with the same value and type of

fuse, or an unsafe condition may result. Use only 250 Volt, 1.0 Amp, Type T

(5 mm x 20 mm) fuses.

To replace a fuse:

1. Two fuses are located in the fuse drawer in the power input module.

Use a screwdriver to open the drawer.

2. The fuse towards the outside of the dra wer is the spare. Remove the

spare fuse from the module.

30 | Series H-491198-36 Battery Charger

Page 31

3. Replace the blown fuse with the spare fuse.

4. Slide the fuse drawer back into the module. Make sure that the drawer

snaps securely into its locked position.

Series H-491198-36 Battery Charger | 31

Page 32

This page intentionally left blank.

32 | Series H-491198-36 Battery Charger

Page 33

Appendix C: EC Declaration of Conformity

HI-3702 CLAMP-ON INDUCED CURRENT METER

EC Declaration of Conformity | 33

Page 34

SERIES H-491198-36 BATTERY CHARGER

34 | EC Declaration of Conformity

Loading...

Loading...