Page 1

Model HI-3624A

ELF Magnetic Field Meter

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 1991–2009 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren L.P.

Revision Record | HI-3624A ELF Magnetic Field Meter, MANUAL

Part #H-600044, Rev. B

Revision Description Date

Initial Release April, 1991

A Added CE, updated January, 2000

B Updated branding: Revised to

meet Style Guide specifications;

reformatted to half-size; PIB

included with release; Remove HI3624 reference. Remove VDT

reference.

ii |

July, 2009

Page 3

Table of Contents

Notes, Cautions, and Warnings ................................................ v

1.0 Introduction .......................................................................... 7

Standard Configuration .................................................................................. 8

ETS-Lindgren Product Information Bulletin ................................................... 8

2.0 Maintenance ......................................................................... 9

Battery Replacement ..................................................................................... 9

Annual Calibration ......................................................................................... 9

Service Procedures ....................................................................................... 9

3.0 Specifications ..................................................................... 11

Electrical Specifications ............................................................................... 11

Physical Specifications ................................................................................ 11

4.0 Practical Application and Use .......................................... 13

Example Application .................................................................................... 13

5.0 Operation ............................................................................ 17

Appendix A: Warranty ............................................................. 19

Appendix B: EC Declaration of Conformity .......................... 21

| iii

Page 4

This page intentionally left blank.

iv |

Page 5

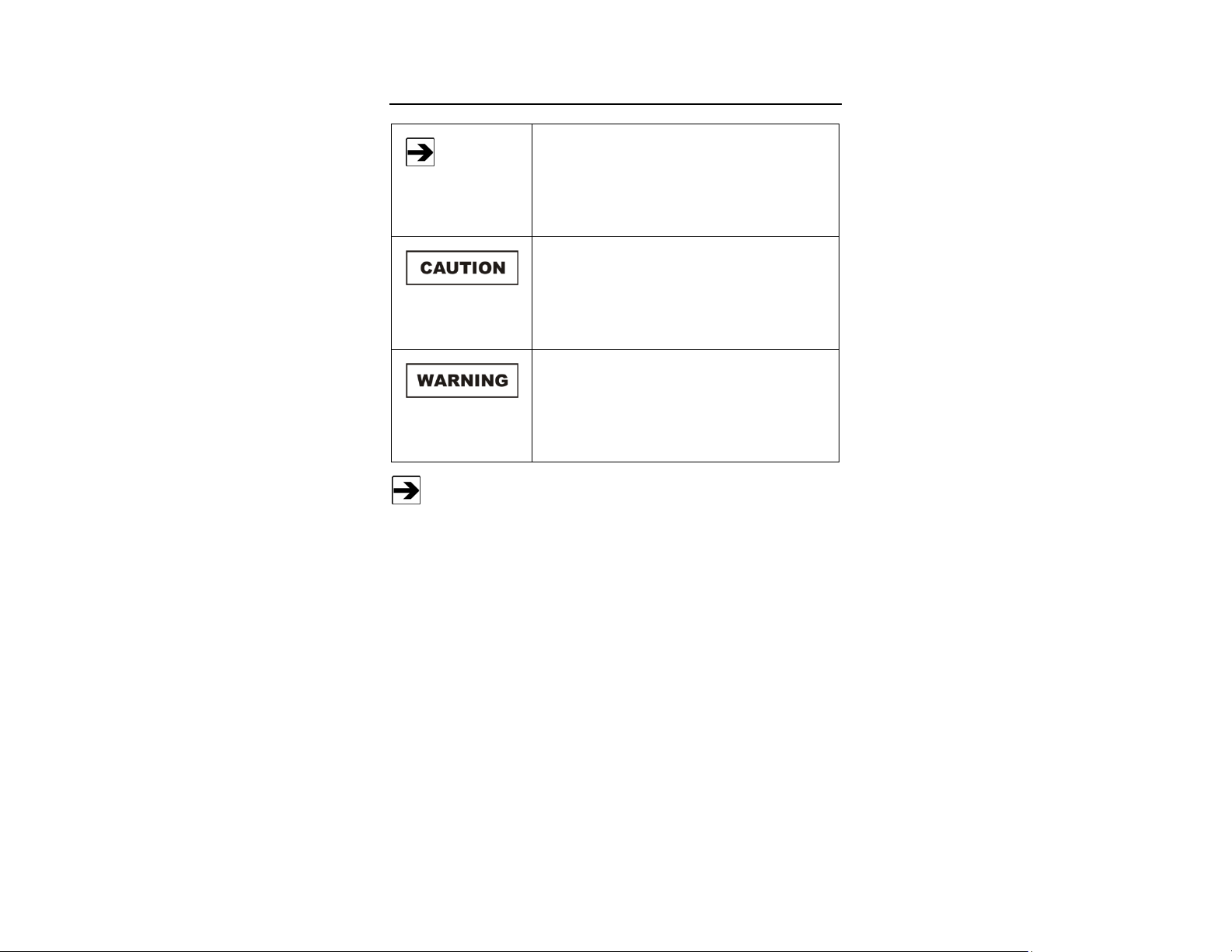

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

| v

Page 6

This page intentionally left blank.

vi |

Page 7

1.0 Introduction

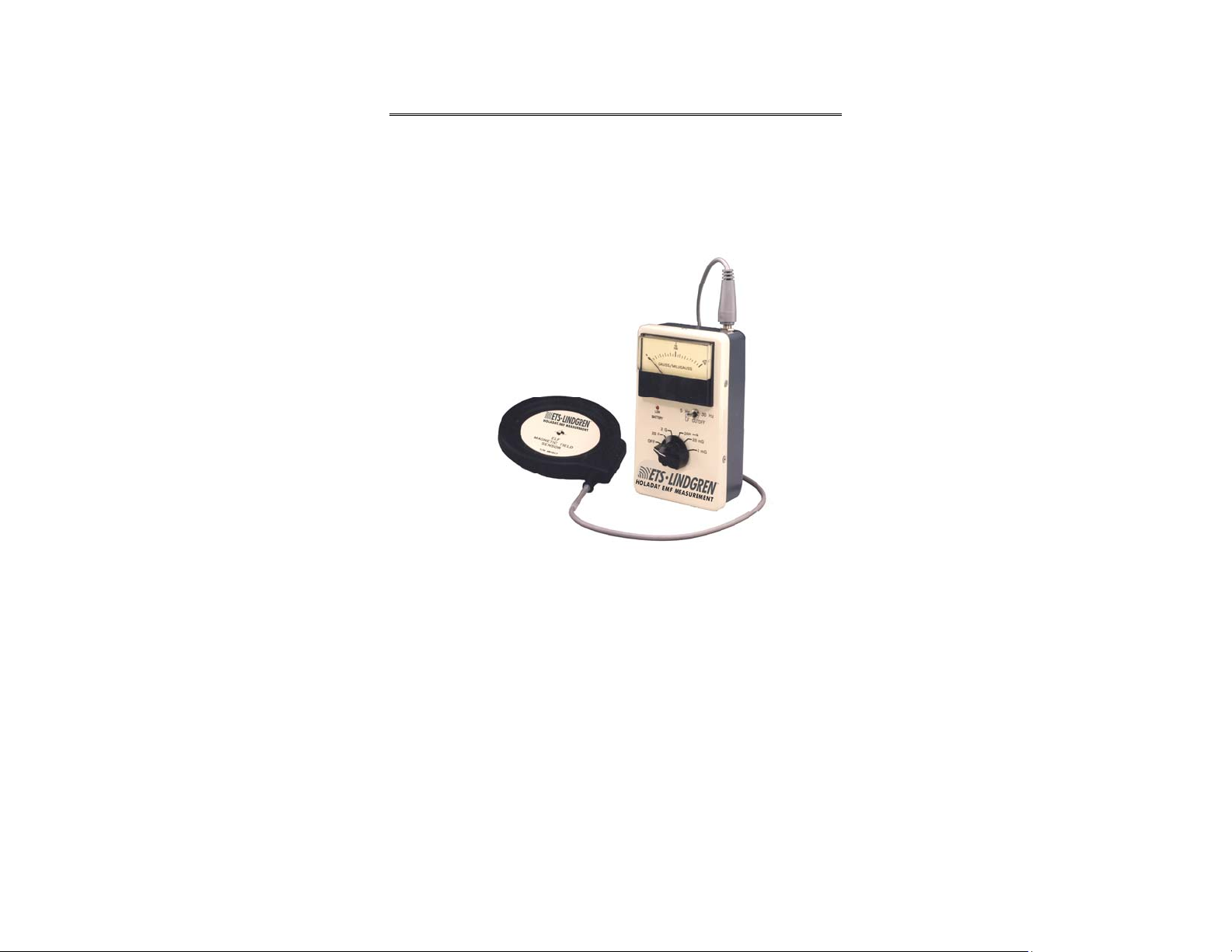

The HI-3624A ELF Magnetic Field Meter is designed to measure the flux density

of magnetic fields in the frequency range of 30 Hz to 2 kHz. The Model

HI-3624A provides for a switch selectable measurement range from 5 Hz to 2

kHz. It finds application in the measurement of magnetic fields associated with

electric power lines and electrically operated appliances.

The HI-3624A is a single axis flux density meter designed to be responsive to

either sinusoidal or complex magnetic fields. It directly displays the root-meansquare (rms) value of magnetic flux density on an analog meter. The sensor

consists of a multi-turn loop connected to the instrumentation readout package

via a one meter long cable.

The separate loop sensor provides for orientation of the sensor relative to the

various magnetic field polarization components. This allows quick assessment of

the greatest flux density value while conveniently holding the instrument for easy

meter reading. This feature makes the HI-3624A especially useful for rapid,

large area surveys of magnetic fields.

The field sensor loop is electrically shielded; consequently the response of the

HI-3624A is solely due to magnetic fields. No interference is caused by ambient

strong electric fields like those found beneath high voltage, overhead electric

power lines or nearby radio or television stations.

Introduction | 7

Page 8

The HI-3624A has a wide dynamic measurement range. The range provides for

full scale ranges of as small as 2 milligauss to as great as 20 gauss. This large

dynamic range makes the HI 3624A convenient for measurement of ambient

residential magnetic fields as well as high level fields found near high current

carrying conductors or electrical machinery.

Standard Configuration

• Meter

• Probe

• Manual

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

8 | Introduction

Page 9

2.0 Maintenance

Before performing any maintenance, follow

the safety information in the ETS-Lindgren

Product Information Bulletin included with

your shipment.

WARRANT Y

Maintenance of the HI-3624A is limited to

external components such as cables or

connectors.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

Battery Replacement

Two 9 volt alkaline batteries power the HI-3624A ELF Magnetic Field Meter. To

replace the batteries, remove the eight screws located on the back of the meter,

pull the panel away from the chassis and unplug the battery connectors. Install

the new batteries and reverse the proceeding steps to reassemble the meter.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

Maintenance | 9

Page 10

This page intentionally left blank.

10 | Maintenance

Page 11

3.0 Specifications

Electrical Specifications

Frequency Response 5 to 2000 Hz Flat

5 Hz -3 dB

2000 Hz -3 dB

<5 Hz Falling 80 dB/decade

>2000 Hz Falling 80 dB/decade

Detector Response

Sensitivity

Accuracy Within ±5% at calibration frequencies of 50,

Linearity 2%

True rms field indication for accurate

measurement of non-sinusoidal waveforms.

Full scale ranges of:

2 mG, 20 mG, 200 mG, 2 G, 20 G

±5% at calibration frequencies of 50, 100, 500

and 1000 Hz

100, 500 and 1000Hz

Physical Specifications

Power Two, 9 volt alkaline batteries

Battery Life Up to 120 hours intermittent use

Inside diameter = 110 mm

External Multi-Turn

Loop Sensor

Cable Length 1.2 m

Outside diameter =116 mm

Area = 0.010 m2

Specifications | 11

Page 12

Instrument accuracy is derived from a field calibration using a one meter

diameter pair of Helmholtz coils for establishing an accurately known magnetic

field flux density. A precisely controlled and measured sinusoidal current is driven

through the Helmholtz coils and, based on the dimensions of the coils; the

magnetic field flux density between the coils in milligauss (mG) is calculated.

While the HI-3624A indicates magnetic flux density (B) in units of milligauss, the

flux density in microtesla or magnetic field strength (H) in milliamperes per meter

may be obtained via the following relations:

1 microTesla = 10 mG

1 mG = 80 milliamperes per meter (mA/m)

12 | Specifications

Page 13

4.0 Practical Application and Use

Before operating any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

Example Application

Power Lines

Magnetic fields near overhead power lines can be easily measured with the

HI-3624A. An approach commonly used to characterize power line fields is to

measure the flux density along a straight line which passes perpendicular to the

power line. Generally, readings are first taken along the length of a span of the

power line to identify the point at which the greatest flux density exists. Then at

this point take the readings perpendicular to the power line. Take readings every

five to ten feet and orient the sensor for maximum reading. A magnetic field flux

density profile can then be developed. This method is outlined by the Institute of

Electrical and Electronics Engineers (IEEE) in the American National Standards

Institute (ANSI) standard 644 1987

A similar approach may be used for measuring the flux density produced by

buried lines. In this case, the area must be explored by walking about with the

meter, simultaneously moving the sensor in various orientations, until the region

of maximum flux density is found.

Practical Application and Use | 13

Page 14

Residential Measurements

Magnetic fields found in home environments are highly variable, depending on

location within the home. This variability is strongly related to the distribution of

the wiring in the home, the location of electrical appliances and occasionally, the

location of plumbing lines or other metallic structures within the ground which

may form low resistance paths for electrical ground return currents. Establishing

what the ambient magnetic field environment is in a home usually requires

numerous measurements throughout the home, with at least one measurement

within each room. Normal practice would include at least one field measurement

taken near the center of each room. A more thorough approach would include

five measurements in each room, one at the center and one near each corner of

the room. A reasonable technique is to position the sensor at a point

approximately one meter from each room corner for the flux density

measurement. This avoids, to an extent, placing the sensor immediately next to

wiring which may be hidden within the walls of the room and which may yield

unrealistically high values of flux density compared to what most individuals

within the room might be exposed.

Surveys of the areas near electrical appliances will usually reveal higher values

of flux density due to the currents flowing within motors or heating elements.

Logical choices would include the location of beds, for example, since this is a

location of extended occupancy. In characterizing the magnetic fields near

obvious sources, such as appliances, it is often helpful to measure and record

the flux density value at intervals of a few inches (or centimeters) beginning near

the surface of the device. These data will help provide a perspective on the

spatial extent of the elevated field levels and the significance of the levels relative

to other values determined elsewhere within the home. Field measurements

should take into account the likelihood that individuals may have access to areas

where measurements are contemplated.

Because 60-Hz magnetic fields produced by the use of electricity within the home

are dependent on the magnitude of current flowing within wires or the operation

of appliances, flux densities will be seen to vary with time, being greater when

more electrical power is being used. For example, when heating or air

conditioning systems turn on or the compressor within a refrigerator cycles on,

the flux density will increase. Measurements must take this condition into

account and it is recommended that, when taking measurements in a room, the

meter be watched for a period of time to observe for fluctuations in the indicated

value of flux density. After some experience, it may be possible to relate the

observed fluctuations to various uses of electricity within the home.

14 | Practical Application and Use

Page 15

A phenomenon which has recently received some attention in regard to

residential magnetic fields is the flow of earth currents via plumbing lines or

telephone cables buried beneath the home. In some cases, it has been noted

that 60-Hz magnetic fields exist within a home, even when the home is not using

any electrical power (the circuit breakers have all been turned off at the main

electrical service box of the home). This observation has, in some cases, been

related to the flow of currents beneath the home on pipes or cables. It is not

unusual for currents, related to other neighbors' use of electricity, to flow back to

the electrical supply via low resistance paths formed by metal plumbing pipes or

wires used for telephones as opposed to the electrical system neutral wire. In

such cases, it is possible to measure magnetic flux densities within the home

without any apparent reason if the power to the home has been shut off.

Practical Application and Use | 15

Page 16

This page intentionally left blank.

16 | Practical Application and Use

Page 17

5.0 Operation

Before placing into operation, follow the safety

information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

The ELF magnetic field sensor must be plugged into the HI-3624A meter case for

proper operation; it makes no difference whether the sensor is plugged in before

or after the meter is turned on.

The main switch turns on the instrument and selects one of five ranges for

measurement. A second switch controls the desired low frequency cutoff. A

"Low Battery" LED glows when the batteries are low. If the "low Battery" indicator

remains on replace both of the batteries which are accessible from the back side

of the meter case (instructions for replacing batteries may be found in the

Maintenance section of this manual). It is normal for the LED battery indicator to

briefly blink while turning the switch to various ranges and when turning the

instrument off.

When beginning field measurements, successively turn the range switch to the

right, increasing the instrument's sensitivity until an upscale reading on the meter

is obtained. Most accuracy is achieved when the meter reads approximately

midscale. At each range setting, while holding the meter in one hand, rotate the

sensor with the other hand so as to obtain a maximum indication on the meter.

Because the sensor is capable of measuring only one polarization component of

the magnetic field at any specific time, there are two methods that can be used

for measurements. In the majority of cases, it is sufficient to orient the sensor so

that a maximum indication on the meter is observed. In many instances this will

be a measurement of the resultant magnetic flux density. The sensor must be

rotated about three axes which are each perpendicular to one another. This can

be quickly accomplished with a little practice.

Operation | 17

Page 18

In other cases, the root-sum-squared resultant value of flux density may be

obtained by taking three orthogonal measurements of the field; in this case, the

sensor is successively oriented in three mutually perpendicular directions around

a fixed point and the individual readings recorded. The mutually perpendicular

directions will be denoted as X, Y, and Z. The resultant flux density is then found

by forming the root-sum-squared value from the individual readings as follows:

2

+ By2 + Bz2)

B = (Bx

B = resultant flux density; B

= Reading in the y direction; Bz = Reading in the Z direction.

B

y

1/2

= Reading in the X direction;

x

It does not matter which orientation of the field sensor is used for the X

orientation but the Y and Z orientations must be perpendicular to one another

and the X orientation.

The user may select the lower frequency of the band pass for the instrument as

either 30 Hz or 5 Hz. It should be noted that when the instrument is switched to

the 5 Hz lower frequency cutoff, the unit will be very sensitive to motion of the

sensor since movement within the earth's constant field will appear as a signal to

the instrument. When the sensor is accelerated or rotated within a constant field,

there will be an output from the sensor at a frequency corresponding to the

movement and this will usually include frequency components greater than 5 Hz.

Consequently, during such movement, the meter will typically show significant

upscale indications. The 5 Hz frequency cutoff setting is primarily useful for

measurements at fixed coil positions. For area surveys of ELF fields, the 30 Hz

cutoff will be more useful.

18 | Operation

Page 19

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your HI-3624A ELF Magnetic

Field Meter.

DURATION OF WARRANTIES FOR HI-3624A ELF MAGNETIC FIELD

METER

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to one year.

Product Warranted Duration of Warranty Period

HI-3624A ELF Magnetic Field Meter 1 Year

Warranty | 19

Page 20

This page intentionally left blank.

20 | Warranty

Page 21

Appendix B: EC Declaration of Conformity

EC Declaration of Conformity | 21

Page 22

This page intentionally left blank.

22 | EC Declaration of Conformity

Loading...

Loading...