Page 1

HI-3520

Archived 4/2/10

Microwave Monitor

User's Manual

Copyright © 1993 Holaday Ind. Inc.

Manual #600052 10/97 $12.50

Page 2

Revision Record

Archived 4/2/10

Manual # 600052

HI-3520

Microwave Monitor

Revision Description Date

--- Preliminary Release 4/93

A Added CE Label 10/97

Page 3

TABLE OF CONTENTS

Archived 4/2/10

1.0 PRODUCT OVERVIEW ................ 1

1.1 Introduction ................... 1

2.0 SPECIFICATIONS .................... 3

3.0 OPERATION ........................ 5

3.1 General Information ............... 5

3.2 Safety Precautions ............... 5

3.3 Operating Controls and Indicators .... 6

3.4 Operating Procedure .............. 6

3.5 Set-up Mode ................... 7

3.6 Setting Alarm Warning Level ........ 8

3.7 Enabling/Disabling Audible Alarm ..... 8

3.8 Measurement Modes .............. 8

3.9 "Average" Measurement Mode ....... 8

3.10 "Instantaneous" Measurement Mode .. 9

3.11 Latched Alarm ................. 9

3.12 Built-In Test Functions ........... 10

4.0 THEORY OF OPERATION .............. 11

4.1 RF Circuit .................... 11

4.2 DC Circuit .................... 11

4.3 RF Shielding ................... 12

5.0 MAINTENANCE ..................... 13

5.1 General ...................... 13

5.2 Battery Replacement ............. 13

5.3 Trouble Shooting ............... 14

6.0 CALIBRATION ...................... 17

6.1 General ...................... 17

6.2 Calibration Procedure ............. 17

6.3 Test Data Sheet Model HI-3520 ..... 20

Page 4

LIMITED WARRANTY

Archived 4/2/10

Holaday Industries, Inc. warrants each Model HI-3520

Microwave Monitor to be free from defects in material and

workmanship for a period of one year from date of shipment to

the purchaser. This warranty extends to the original purchaser

only and does not apply to batteries or any product or parts

subject to misuse, neglect, accident, unauthorized service or

abnormal conditions of operations.

In the event of instrument failure covered by this warranty,

Holaday Industries, Inc. will, without charge, repair and

recalibrate the instrument if returned to their factory within one

year of the original purchase, provided that Holaday Industries'

examination discloses to its satisfaction that the product was

defective. Holaday Industries, Inc may, at its option, replace the

product in lieu of repair. If the defect was caused by misuse,

neglect, accident, unauthorized service or abnormal conditions

of operations, repairs will be billed at a nominal cost. In such

case, an estimate will be provided before work is started if

requested by the purchaser.

For warranty service, contact Holaday Industries, Inc., giving full

details of the failure and the serial number of the instrument.

You will then be given service information or shipping

instructions. Return the instrument to the factory, transportation

prepaid. Repairs will be made at the factory and the instrument

returned to you, transportation paid. Holaday Industries, Inc.

assumes no responsibility for loss of, or damage to, products in

transit.

!! WARNING !!

Special caution is advised when working in environments where

contact with high voltage or high current circuits or apparatus is

possible. This is particularly true when attempting to obtain

induced body current measurements near electrically-powered

equipment, such as heat sealers, or in areas marked with

warnings about the presence of high voltages, currents, or RF

fields. Accidental contact with objects, circuits, or fields

operated at high voltages or high current can be lethal! Holaday

Industries, Inc. assumes no liability for damages or personal

injury which may result from accidents arising out of the use of

this equipment.

Page 5

HI-3520 Manual Page 1

Archived 4/2/10

1.0 PRODUCT OVERVIEW

1.1 Introduction

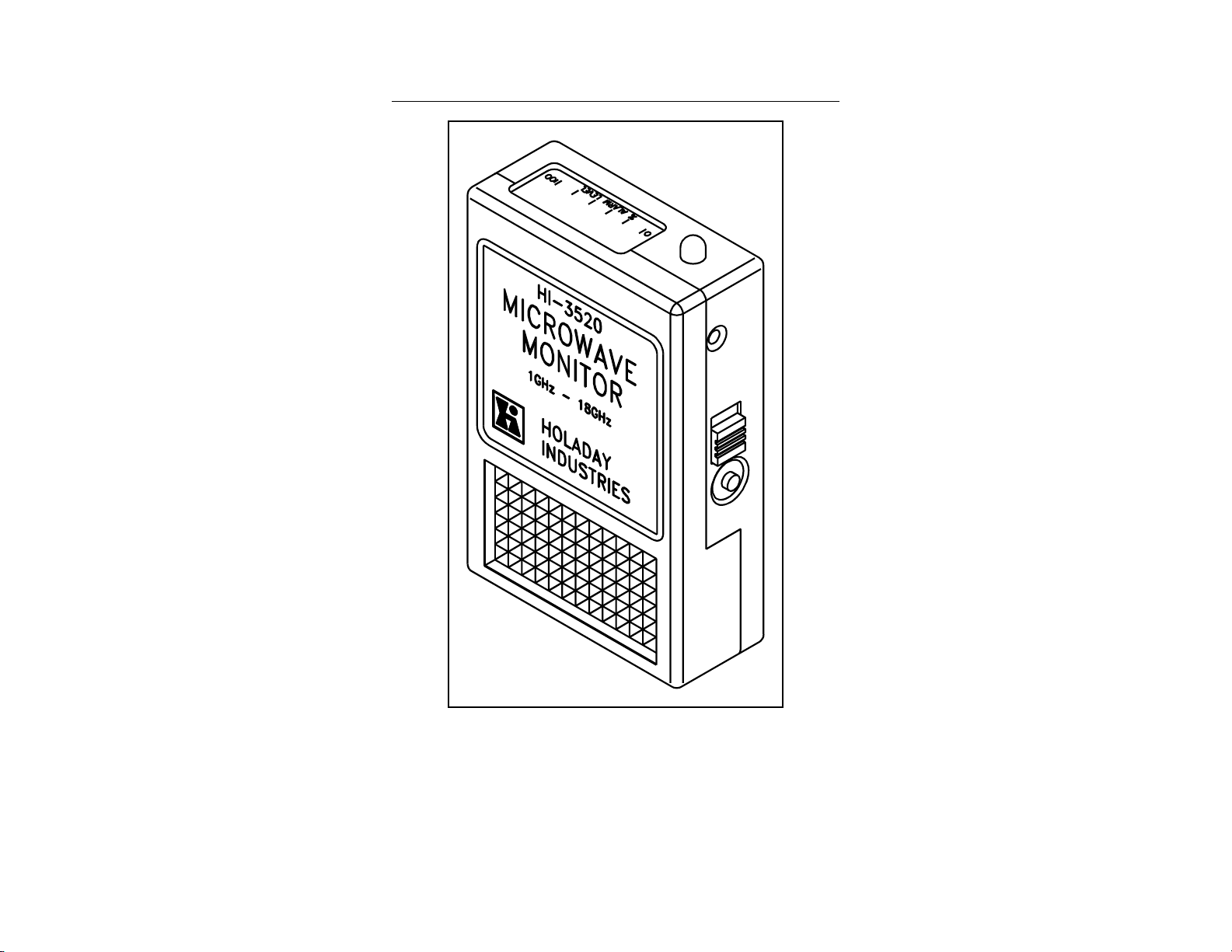

The Model HI-3520 RF Radiation Badge (see Figure 1) is

a portable, battery operated, non-ionizing radiation hazard

detector intended for personal use. It detects

electromagnetic radiation from RF and microwave sources

in the frequency range from 1 to 18 GHz and alerts the

user to potentially hazardous fields. The Model HI-3520

enables the user to set the alarm warning level anywhere

in the range from 0.2 to 20 mW/cm2. In addition, the

user can choose either of two measurement modes:

instantaneous exposure level or a six minute average

measurement. Both modes are displayed on a three digit

LCD panel along with a ten segment bar graph normalized

to the selected alarm warning level. Electrical,

mechanical and performance characteristics are described

in section 2.0.

The Model HI-3520 is intended for use by personnel who

work with or service RF and microwave equipment such

as:

! Microwave Ovens

! Medical Equipment

! Radar Installations

! Microwave Heaters and Dryers

! Communication Systems

! Electronic Warfare Systems

Page 6

Page 2 HI-3520 Manual

Archived 4/2/10

HI-3520 Microwave Monitor

Figure 2

Page 7

HI-3520 Manual Page 3

Archived 4/2/10

2.0 SPECIFICATIONS

HI-3520 Technical Specifications

SPECIFICATION DESCRIPTIVE

DATA

Frequency Range: 1 to 18 GHz

Power Density Range: 0.01 to 20

mW/cm

Alarm Accuracy: ± 2dB

Half Power Beam Width:

Horizontally Polarized

Vertically Polarized

Average Power

Overload:

Peak Power Overload: 100 W/cm

Pulse Energy

Density Overload: 150 W-:sec/cm

Temperature Range:

Operating

Non-Operating

Battery:

Type

Life

Size:

inches

mm

Weight:

oz

gm

90°

120°

0.5 W/cm

-10° C to +50° C

-40° C to +65° C

DL2450B, Lithium

1000 hours

2.40 x 3.75 x 1.00

61.0 x 95.3 x 25.4

4.8

136

2

2

2

2

Page 8

Page 4 HI-3520 Manual

Archived 4/2/10

Page 9

HI-3520 Manual Page 5

Archived 4/2/10

3.0 OPERATION

3.1 General Information

The Model HI-3520 can be carried inside outer garments

or fastened to a shirt or jacket pocket or to a belt using

the clip provided on the instrument. Metallic objects such

as belt buckle, pen, pencil, etc.,could affect the accuracy

of the Model HI-3520. Do not locate the unit near any

metallic object.

NOTE:

The side of the unit containing the clip

should always face towards the

wearer's body.

3.2 Safety Precautions

The following precautions should be observed when

entering an area where unsafe radiation levels may be

expected.

1. Turn on the Model HI-3520. Set it to the

"Instantaneous" Measurement Mode as

described in section 3.10.

2. Enter the area and do a "walkaround". Should

the Model HI-3520 indicate that an alarm

condition exists, take corrective action by

turning off the source of RF power or leaving the

area immediately.

3. Keep the Model HI-3520 turned on and continue

to wear it as long as you are in the area.

Page 10

Page 6 HI-3520 Manual

Archived 4/2/10

3.3 Operating Controls and Indicators

The operating controls on the Model HI-3520 are the ONOFF switch and the Mode switch, both of which are

located on the side of the unit. In addition, the Model HI3520 has three alarm indicators: Two visual indicators

consisting of an LCD display panel and a red LED warning

light, both located on the top of the unit (see figure 2),

and an audible alarm produced by a beeper located within

the unit. Unless programmed off, the audible alarm

operates synchronously with the visual alarm. In

addition, there is an audio output jack to which the

furnished acoustical earpiece can be connected.

3.4 Operating Procedure

To turn the unit ON, place the ON-OFF switch in the ON

position. The unit will respond with a three second beep

and its red LED will glow to confirm that the unit is

operational. In addition, all segments of the LCD display

will be on during this three second interval. The LCD

display will then indicate the preset alarm warning level

for about seven seconds. The unit will then respond with

a short beep and red LED flash. At this time, the unit is

operational and will indicate the power density in the area

as well as the ratio of the power density in the area to

the preset alarm warning level (% ALARM LEVEL bar

graph). This display is normalized to the programmed

alarm level so that the alarm indicates when the bar

graph reaches 100%. Using this display, the wearer can

tell how closes he or she is to the alarm without being

exposed to an alarm power level. (If you are working in

a noisy environment, connect the acoustical earpiece to

ensure hearing the audible alarm). When there are no RF

fields present higher that the preset alarm warning level,

there will be no further alarm indications from the unit.

Should the unit detect a field that exceeds the preset

alarm warning level, the unit will start to beep and flash.

Page 11

HI-3520 Manual Page 7

Archived 4/2/10

The beep and the flash rate are directly proportional to

the RF field strength. Note that once the alarm starts, it

will latch at the minimum flash rate, continuing to warn

of an over-exposure even if the RF field that caused the

alarm is no longer present. In order to reset the alarm

function, the unit must be turned OFF and back ON using

the ON-OFF switch. For information concerning disabling

the latch function, refer to section 3.11. For information

concerning "Instantaneous" vs "Average" measurement

modes, refer to section 3.8.

HI-3520 Display

Figure 3

3.5 Set-up Mode

The "Set-up" mode is used to set the alarm warning level

and to enable/disable the audible alarm. To enter this

mode, set the "ON-OFF" switch to ON. Then depress the

MODE switch after the initial three second period

referenced in section 3.4. The LCD display will indicate

"S.U.". At this point, the alarm warning level can be

changed (section 3.10) or the audible alarm indicator can

be enabled or disabled (section 3.7).

3.6 Setting Alarm Warning Level

Page 12

Page 8 HI-3520 Manual

Archived 4/2/10

In the "Set-Up" mode (section 3.5), depress and hold the

MODE switch. After three seconds, the preset alarm

warning level will be displayed. Release the MODE

switch. Depressing and holding the MODE switch again

at this point will result in a rapidly increasing alarm

warning level indication. Continue to depress the MODE

switch until the desired alarm level is approached. Then

release the MODE switch and pulse it at a convenient

rate until the desired alarm warning level is reached.

Once it is reached, set the ON-OFF switch to OFF and

then to ON again. The alarm warning level that has just

been set will remain in memory until changed again as

described above.

3.7 Enabling/Disabling Audible Alarm

In the "Set-Up" mode (section 3.5), continue to depress

and release the MODE switch and observe that the

audible alarm indicator (a small bell in the upper left area

of the LCD display) appears and disappears. If an audible

alarm is desired, allow the audible alarm indicator to

remain visible; if an audible alarm is not required,

continued to depress and release the MODE switch until

the audible alarm indicator disappears. Using the ON-OFF

switch, turn the unit OFF and then ON again.

3.8 Measurement Modes

The Model HI-3520 Measurement Mode can be set to

either "Instantaneous" or "Average" by depressing and

releasing the MODE switch while the unit is in its normal

operating mode. See sections 3.9 and 3.10.

3.9 "Average" Measurement Mode

When the AVG annunciator on the left side of the display

area is visible, a six-minute running average is maintained

by the unit. Power density is sampled every 3.6

seconds. During the first six minutes (i.e.-360 seconds

Page 13

HI-3520 Manual Page 9

Archived 4/2/10

or 100 measurements), the running average of all

measurements taken will be displayed. After six minutes,

each "new" measurement will replace the measurement

taken 363.3 seconds prior to the "new" measurement.

Therefore, the average of the most recent 100

measurements will always be displayed.

The average of the latest 100 measurements is also

compares by the unit to the alarm warning level set by

the operator (section 3.6) to determine the % ALARM

LEVEL ratio. (During the first six minutes of operation,

the running average of all measurements taken will be

compared by the unit to the alarm warning level set by

the operator to determine the % ALARM LEVEL ratio.) If

the % ALARM LEVEL ratio reaches 100%, the unit's

alarm circuitry will be activated, the red LED and the

ALARM annunciator on the LCD will flash every 3.6

seconds, and the audible alarm will sound every 3.6

seconds.

3.10 "Instantaneous" Measurement Mode

When the INST annunciator on the left side of the LCD

display area is visible, the measured power density is

sampled and displayed every 1.8 seconds. (Note that the

Model HI-3520 saves data for six minutes regardless of

the display selected. Switching between "Average" and

"Instantaneous" does affect the data being stored.)

3.11 Latched Alarm

A feature of the unit's alarm system is that the beeps and

flashes are progressive. Once the alarm level has been

reached, the unit will indicate a single beep and flash

each 1.8 second with the "INST" annunciator displayed

or 3.6 seconds with the "AVG" annunciator displayed.

Should the unit detect a field that exceeds the preset

alarm level, the unit will start to beep and flash. The

Page 14

Page 10 HI-3520 Manual

Archived 4/2/10

beep and the flash rate are directly proportional to the RF

field strength. Note that once the alarms start, they latch

at the minimum flash rate, continuing to warn of an over

exposure situation even it the RF field that initially caused

the alarm is no longer present. In order to reset the alarm

function, it is necessary to turn the unit OFF and back ON

using the ON-OFF switch. If it is desired to disable the

latch function, follow the turn-on procedure described in

section 3.4 except depress and hold the MODE switch

before placing the ON-OFF switch to the ON position.

3.12 Built-In Test Functions

The unit generates a beep and flash at turn on to verify

that the alarm indicators are functioning. At this time, all

segments of the LCD display are enabled to indicate that

the display is operating properly. Ten seconds after turn

on. the unit will generate a second beep and flash which

indicated that it is operational. A low battery condition

is indicated if the unit beeps and flashes two times after

the ten second period. To verify, check the LCD display

for a "BAT" indication. In addition, the battery condition

is tested automatically every minute. Should the battery

measure low, the "BAT" indicator will flash and the unit

will beep and flash once a minute. Refer to Section 5.0

for battery replacement procedures.

The unit also contains continuous fault detection circuitry

to alert the user to a RF detector failure. In that event,

the beeper and light will start to beep and flash at a

constant tone and light, and the LCD display will indicate

"FAIL". The unit is no longer usable in this condition and

should be turned off and serviced.

Page 15

HI-3520 Manual Page 11

Archived 4/2/10

4.0 THEORY OF OPERATION

4.1 RF Circuit

The Model HI-3520 RF circuit consists of two orthogonal

tft

1 (thin-film thermoelectric) arrays, each containing a

number of series connecter thermoelectric junctions.

These are mounted between a pair of thermally

conductive dielectric wafers to enhance the detector

sensitivity. When placed in an RF field, the dipoles

absorb power which gives rise to thermal gradients

across the thermocouple junctions. By keeping the

temperature differential small, the detector acts as a true

rms device producing a dc output voltage directly

proportional to the absorbed power.

The tft elements, acting as resistive screens, operate over

the frequency range 1 to 18 GHZ.

1

tft registered trademark of General Microwave

Corporation.

4.2 DC Circuit

The DC output produced by the RF circuit is amplifies by

a differential chopper-stabilized amplifier. This circuit has

high common mode rejection and low DC drift. The high

level output of this circuit is connected to a

microcontroller which has a built in A/D converter. The

amplifier has two gain ranges that are controlled by the

microcontroller.

A self-contained test signal is constantly applied to the

RF detector. Should a fault occur in this circuit, a fault

signal is generated through the DC amplifier which then

generated a fault bit to the microcontroller.

Page 16

Page 12 HI-3520 Manual

Archived 4/2/10

The analog output from the DC amplifier is digitized by

the microcontroller's A/D converter. The reference

voltage for the A/D converter is generated from a bandgap reference diode which provides excellent long term

stability. The microcontroller then controls the

measurement rate for instantaneous or average

measurements, amplifier ranges. LCD display, fault

indications and low battery signals. It store and

computes the data for the six minute average readout and

stores the alarm warning level trip point.

4.3 RF Shielding

To enable accurate operation of the sensitive circuits

within the RF Radiation Badge in the presence of RF

fields, an array of shielded and absorbers is used. The

circuits are contained within a Faraday shielded area

which is then covered by a graded absorber to minimize

field disturbances. To prevent reflections from behind the

unit giving distorted measurements results, the antenna

section is protected by an absorber. The net result is

that the sensitivity to any reflection from the rear of the

unit is minimized relative to its performance in free space.

Page 17

HI-3520 Manual Page 13

Archived 4/2/10

5.0 MAINTENANCE

5.1 General

The unit has been designed for rugged field use. Normal

maintenance for this unit consists only of battery

replacement and calibration.

5.2 Battery Replacement

The unit furnished with a DL2450B lithium cell. Normal

operating life is 1000 hours. With the alarm in its latched

mode, the battery life is about 80 hours. The shelf-life of

the battery is about ten years when stored in a cool

environment.

The unit has a built in battery monitoring circuit that

generates a single beep and flash at one minute intervals

under low battery conditions. To replace the battery,

proceed as follows:

1. Turn the unit off. THIS IS IMPORTANT.

2. Loosen the screw that secures the battery cover

and remove the cover.

3. To remove the battery, pry it up with a small

screwdriver to clear the lip of the battery holder

before sliding it out.

4. Insert the new battery, making sure to observe

the correct battery polarity as indicated on the

retaining clip (i.e., +toward the clip).

5. Turn the unit on. The instrument should now be

operational and the one minute beep and flash

warning indicators should cease.

Page 18

Page 14 HI-3520 Manual

Archived 4/2/10

NOTE:

Should the unit exhibit any form of

unusual or erratic performance, or

doesn't turn on at all, proceed as

follows:

1. Turn the unit off.

2. Slide an insulator such as a piece of paper

between the plus battery clip and the battery.

3. Turn the unit on for five minutes.

4. Turn the unit off and then quickly slide out the

insulator.

5. Turn the unit on. The instrument should now

operate normally.

Once the unit is operating properly, replace the cover and

tighten the cover screw.

The instrument should now be operational and the one

minute beep and flash warning indicators should cease.

5.3 Trouble Shooting

NOTE:

In general, except for normal battery

replacement, trouble shooting and repair of this

instrument by the user is not recommended.

As a part of its self-test capability, the unit will produce

a tone and flash when it is turned on. In the event it fails

to do so, check the condition of the battery by replacing

it in accordance with the procedure described in section

Page 19

HI-3520 Manual Page 15

Archived 4/2/10

5.2 above.

Should the unit continue to malfunction, return it to

Holaday Industries Inc. for repair.

Page 20

Page 16 HI-3520 Manual

Archived 4/2/10

Page 21

HI-3520 Manual Page 17

Archived 4/2/10

6.0 CALIBRATION

NOTE

The following is applicable only to units with

serial numbers higher than 220104. Please

contact the Holaday Industries Inc. for calibration

instructions for units with serial numbers of

220104 and lower.

6.1 General

The Model HI-3520 Radiation Badge should be calibrated

at 12 month intervals. To do so requires the use of

highly specialized test equipment and facilities, such as a

radio-frequency anechoic chamber and test cells, wherein

fields of known power density can be accurately

established. It should also be noted that to establish the

required power densities will require CW sources of 10W

or greater together with accurately calibrated test

antennae and power monitoring equipment. If facilities of

this type are not available, the unit should be returned to

General Microwave or to another qualified calibration

facility for this service.

6.2 Calibration Procedure

Set the alarm warning level to 0.2 mW/cm2 as described

in section 3.6.

Disable the latch function as described in section 3.11.

1.0 Position the unit in an anechoic chamber. The

preferred orientation of the E-field is parallel to

the vertical axis of the unit.

2.0 At 1.4 GHz, raise the power density level at the

unit until an alarm is indicated. Record this

Page 22

Page 18 HI-3520 Manual

Archived 4/2/10

power density level on the test data sheet in

mW/cm

2.

3.0 Repeat step 2.0 at 2.45, 3.8, 8.0, 12.0 and

18.0 GHz.

4.0 From the data in step 2.0 and 3.0, calculate the

average power density measured over the band

by taking the square root of the product of the

highest and lowest readings recorded. Record

the resultant on the data sheet for P

cal

.

5.0 Divide 0.2 mW/cm2 by the power density level

recorded on the data sheet for P

. This

cal

determines the correction multiplier, M.

6.0 Alignment can now be performed at any one of

the calibration frequencies specified in steps 2.0

and 3.0. Select a convenient calibration

frequency.

7.0 At the selected calibration frequency, multiply by

M the indicated power density from the data

recorded in step 2.0 and 3.0 above. Record this

as P

REF

.

8.0 Remove the battery compartment cover and

located the calibration potentiometer behind the

hole adjacent to the battery cover screw hole.

NOTE:

It is necessary to remove the battery cover door

to adjust the calibration potentiometer but the

cover must be replaced for the RF test.

9.0 Apply the P

power at the calibration

REF

frequency. Adjust this potentiometer such that

Page 23

HI-3520 Manual Page 19

Archived 4/2/10

the alarm just starts to indicate. Repeat this

adjustment as required.

10.0 This completes the RF calibration. Replace the

battery compartment cover. Attach a new

calibration sticker with the current calibration

date.

NOTE:

Do not place any stickers or labels that contain

metal on the bottom surface of the unit or the

lower portions (i.e., approximately 1 ½ inches

up from the bottom surface) of the front and

both sides of the unit. This could seriously

affect the accuracy of the unit. Paper or plastic

stickers are acceptable.

Page 24

Page 20 HI-3520 Manual

Archived 4/2/10

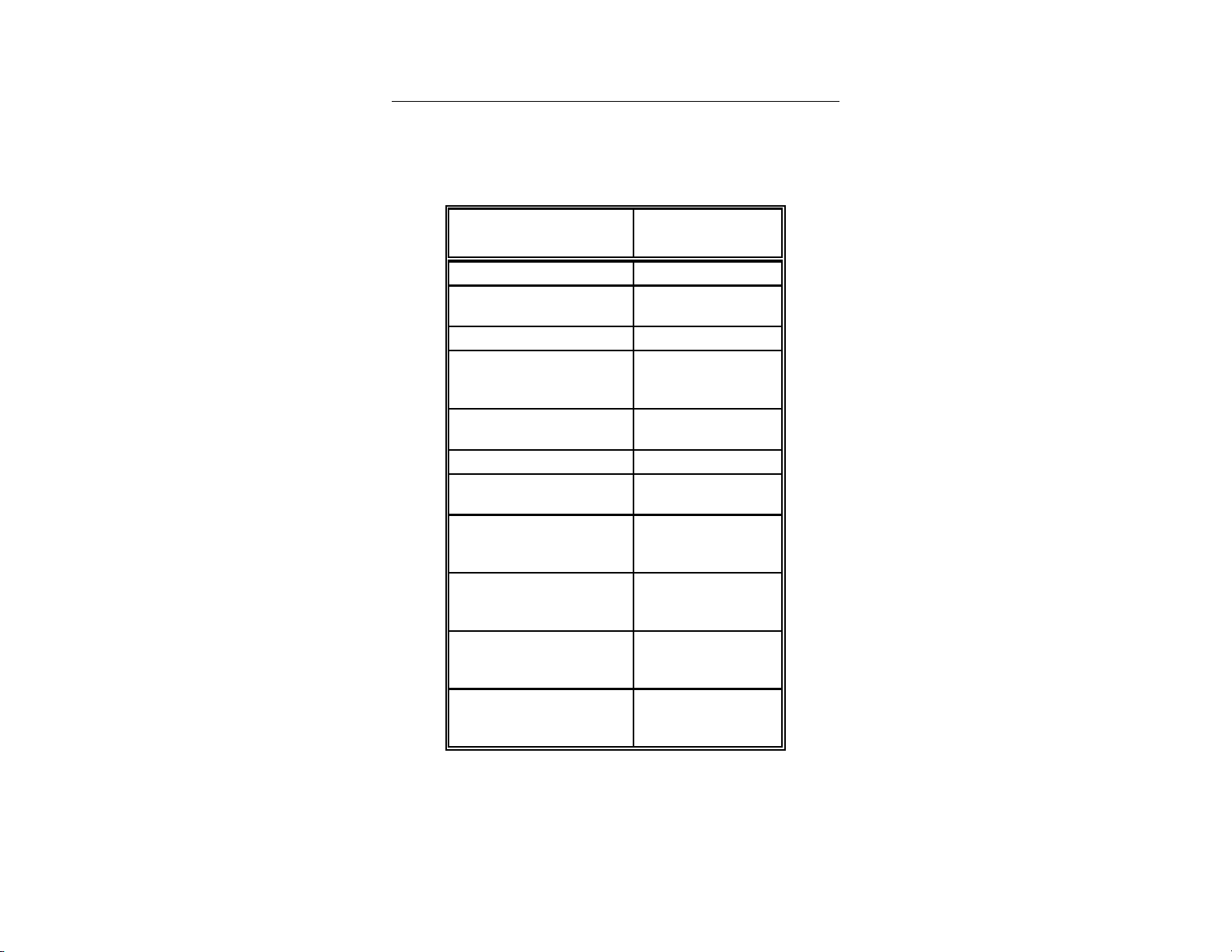

6.3 Test Data Sheet Model HI-3520

DATE SERIAL NUMBER TESTED BY

STEPS 2.0 AND 3.0

FREQUENCY (GHz) POWER DENSITY LEVEL (mW/cm

1.4

2.45

3.8

8.0

12.0

18.0

STEP 4.0 P

= (PHI X PLO)

CAL

STEP 5.0 M =

0.2

=

P

CAL

1/2

=

STEP 6.0 CAL FREQ =

2

STEP 7.0 P

= M (POWER DENSITY AT CAL FREQ)

REF

=

STEP 9.0 ALARM SET FOR P

CHECK

REF

Page 25

HI-3520 Manual Page 21

Archived 4/2/10

-- NOTES --

Page 26

Page 22 HI-3520 Manual

Archived 4/2/10

-- NOTES --

Loading...

Loading...