Page 1

HI-1710A

Microwave Measurement

System

User Manual

Page 2

ii

www.ets-lindgren.com

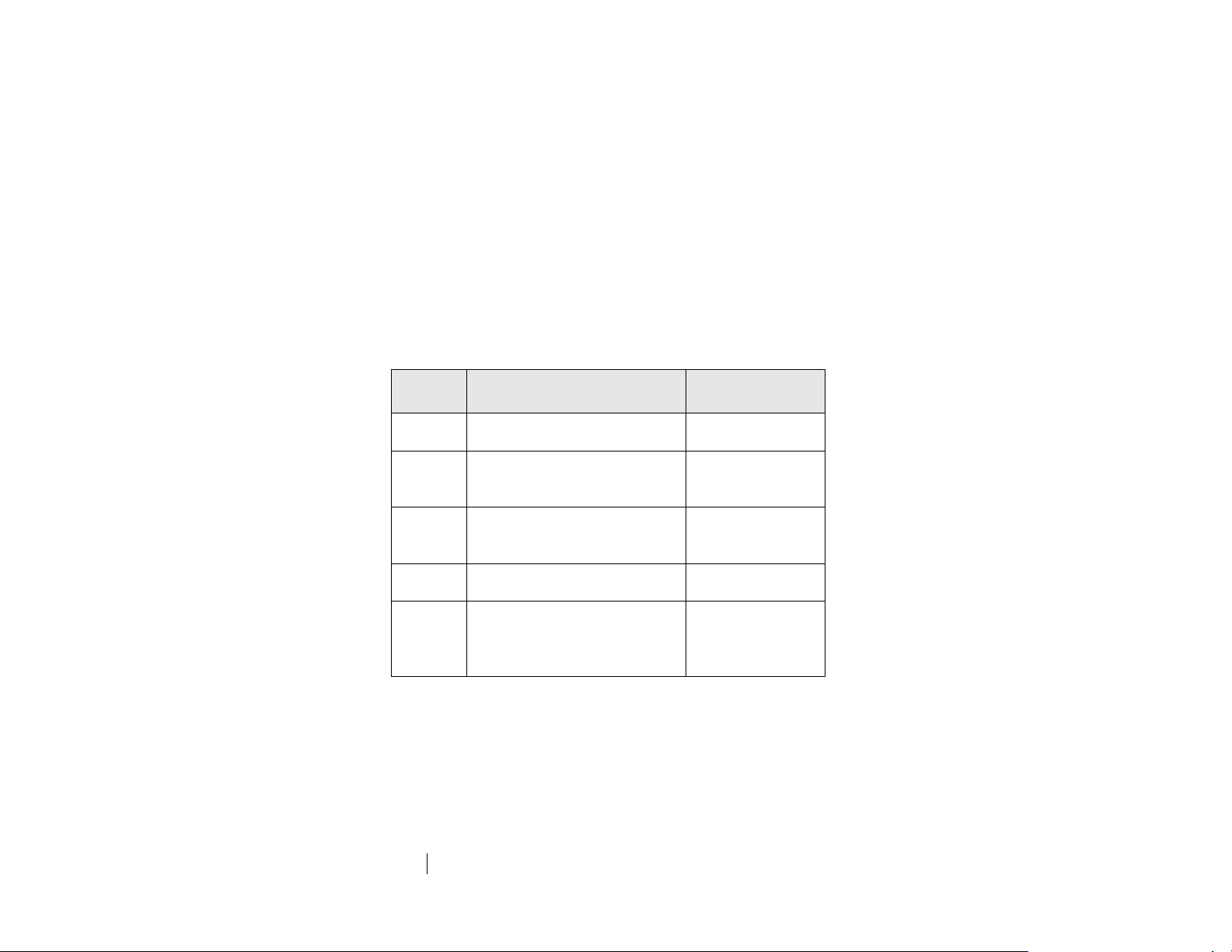

ETS-Lindgren Inc. reserves the right to make changes to any product described herein in

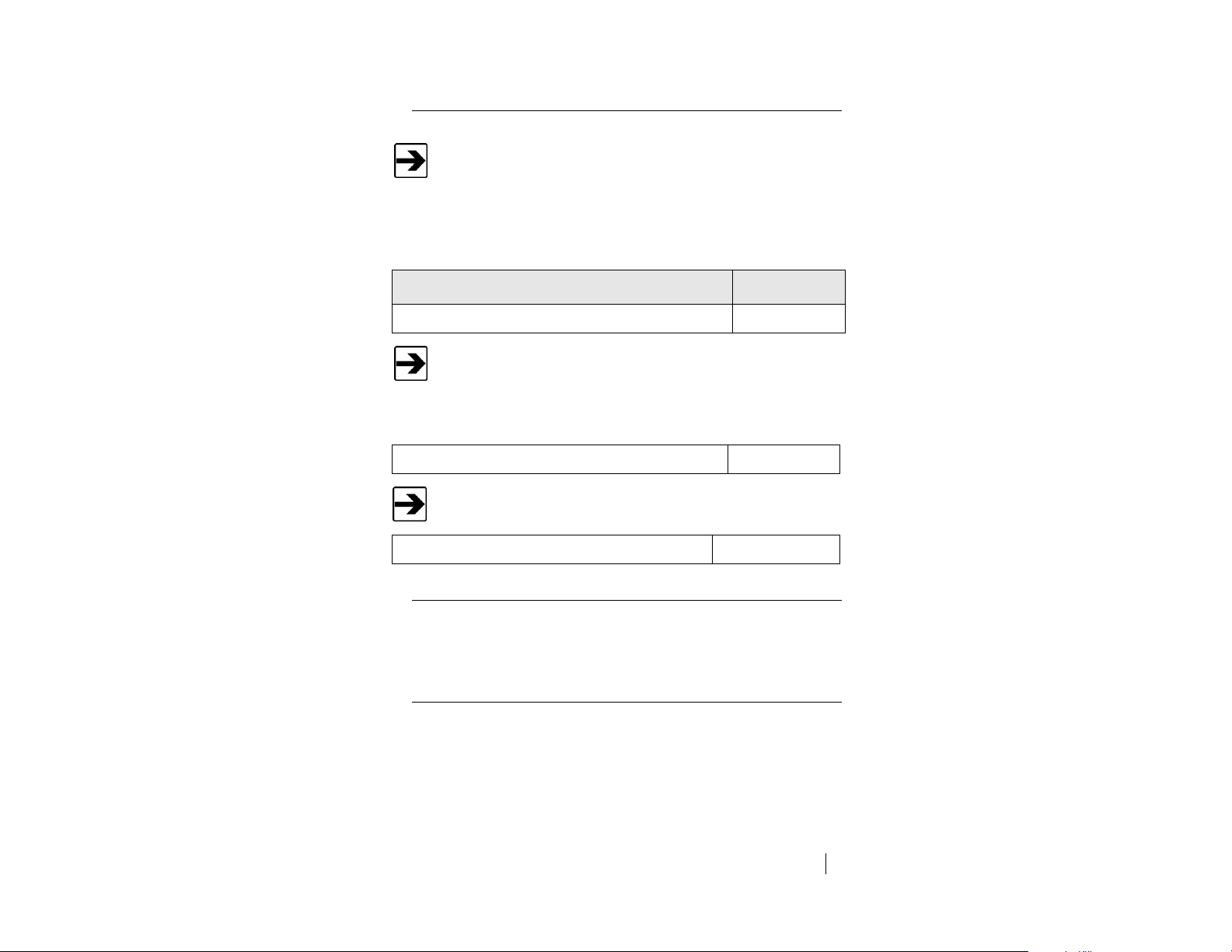

Revision

Description

Date

A

Initial Release

May, 2001

B

Added Alarm Out pin definitions;

rebranding

June, 2008

C

Updated Error Analysis table in

Specifications

June, 2009

D

Updated for v3.0 firmware release

May, 2012

E

Updated Menu Option Settings

table in Filter (Response)

command

August, 2014

order to improve function, design, or for any other reason. Nothing contained herein shall

constitute ETS-Lindgren Inc. assuming any liability whatsoever arising out of the application

or use of any product or circuit described herein. ETS-Lindgren Inc. does not convey any

license under its patent rights or the rights of others.

© Copyright 2001–2014 by ETS-Lindgren Inc. All Rights Reserved. No part of this

document may be copied by any means without written permission from

ETS-Lindgren Inc.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren Inc.; Avery is a registered trademark of Avery Dennison Corporation.

Revision Record

MANUAL,HI-1710A | Part #H-600094, Rev. E

Page 3

www.ets-lindgren.com

iii

This page intentionally left blank.

Page 4

iv

www.ets-lindgren.com

Table of Contents

Notes, Cautions, and Warnings .............................................. vii

General Safety Considerations ............................................. viii

1.0 Introduction .......................................................................... 9

HI-1710A Features ..................................................................................... 9

Standard Configuration ............................................................................. 10

Optional External Zero Receptacle ........................................................... 11

ETS-Lindgren Product Information Bulletin ............................................... 11

2.0 Maintenance ....................................................................... 13

Software/Firmware Updates (Version 3.XX Only) ...................................... 13

Replacing the Fuse ................................................................................... 14

Replacement and Optional Parts .............................................................. 15

Annual Calibration .................................................................................... 15

Service Procedures .................................................................................. 15

3.0 Specifications ..................................................................... 17

Electrical Specifications ............................................................................ 17

Physical Specifications ............................................................................. 18

RS-232 Specifications ............................................................................... 18

Calibration ................................................................................................ 19

Power Cable ............................................................................................. 19

Error Analysis ........................................................................................... 20

4.0 Operation ............................................................................ 21

About Zeroing ........................................................................................... 21

Menu Navigation ....................................................................................... 22

Back Panel Controls and Connectors........................................................ 23

ZERO ............................................................................................... 23

ANALOG OUT .................................................................................. 23

ALARM OUT ..................................................................................... 24

RS-232 (Digital Input/Output) ............................................................ 24

Starting the HI-1710A ............................................................................... 25

Using the HI-1710A .................................................................................. 25

Connecting and Using the Zero Receptacle .............................................. 26

Page 5

www.ets-lindgren.com

v

5.0 Menu Options, Settings, Command Set .......................... 27

Menu Options ........................................................................................... 27

Menu Option Settings and Command Set ................................................. 28

3 OR 4 DIGITS ................................................................................. 28

ABOUT (Version 3.XX Only) ............................................................. 29

ALARM SETPOINT ........................................................................... 30

AUDIO .............................................................................................. 31

AUTO-RANGE .................................................................................. 31

BAUD RATE ................................................................ ..................... 32

CONTRAST ...................................................................................... 33

ECHO ............................................................................................... 33

FILTER (RESPONSE) ...................................................................... 34

PARAMETER SCREEN .................................................................... 35

PEAK HOLD ................................................................ ..................... 36

PRINT MODE ................................................................................... 37

RANGE ............................................................................................. 39

SELF TEST ...................................................................................... 40

STATUS ........................................................................................... 41

STIM ................................................................................................. 44

RESET.............................................................................................. 44

TEST ALARM ................................................................................... 45

VERSION (Firmware) – Version 3.XX Only ....................................... 45

ZERO ............................................................................................... 45

Factory Default Settings ............................................................................ 46

6.0 Theory of Operation ........................................................... 47

Appendix A: Warranty ............................................................. 49

Appendix B: Error Messages .................................................. 51

Self-Test Error Messages ......................................................................... 51

Startup Error Messages ............................................................................ 52

REF C – OUTSIDE LIMIT ................................................................. 52

+5SUP C – OUTSIDE LIMIT ............................................................. 52

+8SUP C – OUTSIDE LIMIT ............................................................. 52

-8SUP C – OUTSIDE LIMIT .............................................................. 52

BIAS C – OUTSIDE LIMIT ................................................................ 53

STIM C – OUTSIDE LIMIT ................................................................ 53

Page 6

vi

www.ets-lindgren.com

Appendix C: Summary of RS-232 Command Set ................. 55

Appendix D: EC Declaration of Conformity .......................... 57

Page 7

www.ets-lindgren.com

vii

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

Page 8

viii

www.ets-lindgren.com

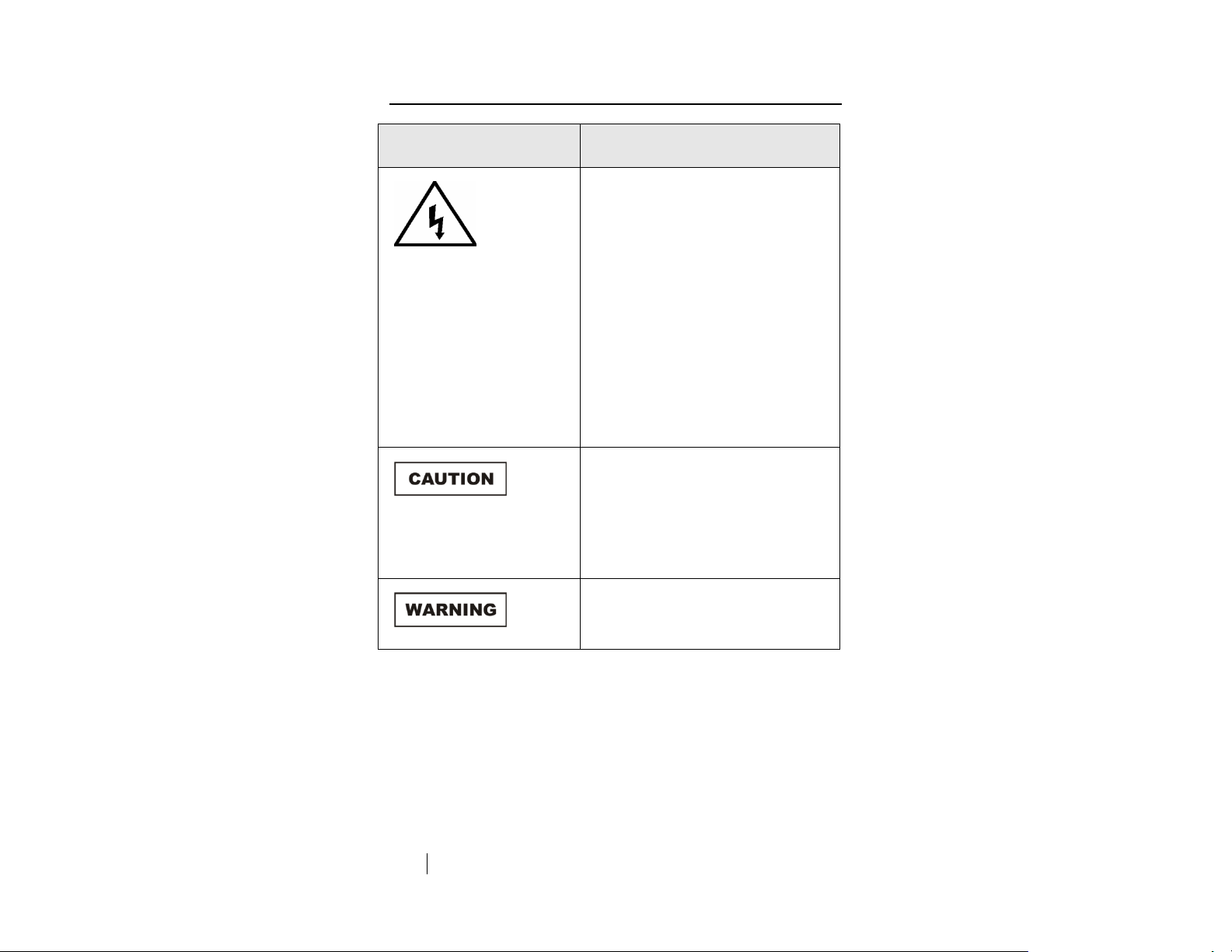

General Safety Considerations

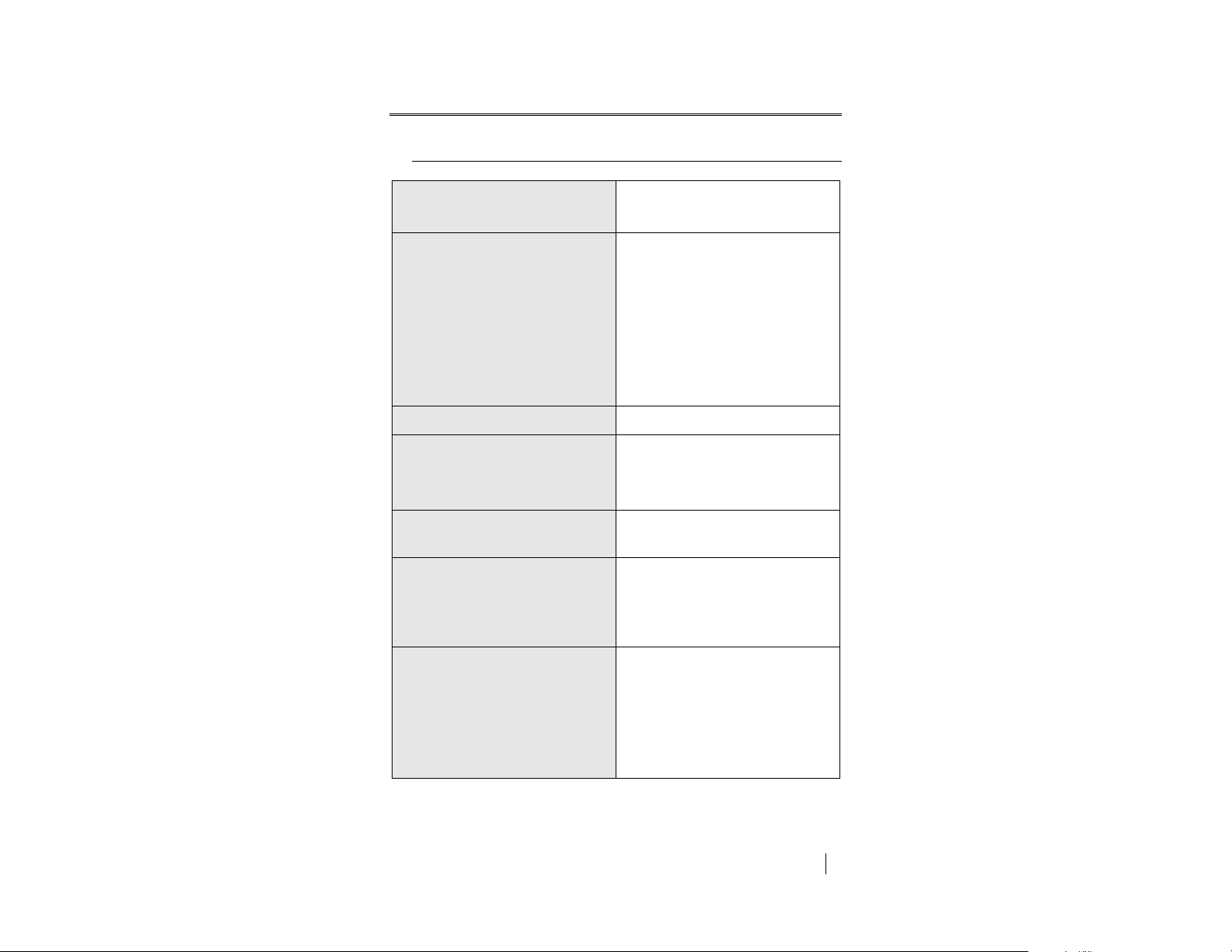

Safety Symbol

Definition

Warning: This is a Safety Class I product

(provided with a protective earthing

ground incorporated in the power cord).

The mains plus shall only be inserted in a

socket outlet provided with a protective

earth contact. Any interruption of the

protective conductor, inside or outside the

instrument, is likely to make the instrument

dangerous. Intentional interruption is

prohibited. DO NOT defeat the earthgrounding protection by using an

extension cable, power cable, or

autotransformer without a protective

ground conductor.

Caution: This instrument is shipped with a

three-wire power cable, in accordance

with international safety standards. When

connected to an appropriate power line

outlet, this cable grounds the instrument

cabinet.

Warning: For indoor use only, do not

expose to rain.

Page 9

www.ets-lindgren.com

Introduction

9

The ETS-Lindgren

Holaday HI-1710A

Microwave Measurement

System combines the

proven and reliable diode

sensing technology of the

ETS-Lindgren Holaday

Microwave Survey Meters

with the digital processing

techniques developed for

automatic oven scanning.

HI-1710A with

HI-2623 Microwave Oven Probe

1.0 Introduction

HI-1710A Features

HI-1710A Front Panel

Provides time response characteristics, or filters:

raw (Version 3.XX only), fast, and slow. These allow standard

hand scan measurements, as well as the potential for faster scanning

similar to that of automated scanning systems.

The unit is shielded with the necessary isolating and attenuating

devices to provide immunity to stray leakage of microwave energy.

The circuitry is powered by a regulated supply with normal industrial

transient protection devices.

Page 10

10

Introduction

www.ets-lindgren.com

The diode detection array of eight hot carrier diodes is housed in the

large end of the plastic probe assembly. This antenna array has the

unique feature of being able to sum microwave electric fields of any

plane perpendicular to the axis of the probe. The antenna lobe is also

very broad, making it easy to use when measuring leakage around an

oven door.

The cone spacer is designed to provide 5-cm spacing (as required by

the CDRH performance standard) from the tip of the probe cone to the

center of the array. The shape of the cone provides minimum

perturbation of the electric field impinging on the diode array.

The probe is attached permanently to the preamplifier assembly by a

9-ft shielded cable. Each detection probe and amplifier assembly is

calibrated as a unit and can be used interchangeably with any

HI-1710A readout. The digital indicator reads to two or three decimal

places from 0 to 9.999 mW/cm2. Temporary over exposure to

microwave fields up to 2000 mW/cm2 will not cause probe burnout or

damage the instrument or the calibration.

Either auto-range or four ranges with full-scale indications of 1, 2, 5,

and 10 mW/cm2 can be selected from the front panel or with a remote

serial port command. Selecting the range determines the full-scale

setting of the bar graph display located below the digital readout for a

continuous analog indication of the measured leakage level.

The audio alarm circuit can be set to any level up to 9.99 mW/cm2.

When the level of the microwave leakage exceeds the pre-selected

value the audio alarm will sound if the audio is enabled, alerting the

operator that the chosen level has been exceeded. For more

information about the alarm, see page 30.

Standard Configuration

HI-1710A Microwave Measurement System

HI-2623 Microwave Oven Probe

Power cable

Page 11

www.ets-lindgren.com

Introduction

11

Optional External Zero Receptacle

The external zero receptacle will help shield the probe from stray RF fields while

being zeroed. Additionally, in high-volume testing situations, the zero receptacle

can reduce wear on the ZERO button located on the HI-1710A front panel.

The zero receptacle ships with a 10-foot cable.

For ordering information, see Replacement and Optional Parts on page 15. For

information on using the zero receptacle, see Connecting and Using the Zero

Receptacle on page 26.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

Warranty information

Safety, regulatory, and other product marking information

Steps to receive your shipment

Steps to return a component for service

ETS-Lindgren calibration service

ETS-Lindgren contact information

Page 12

12

Introduction

www.ets-lindgren.com

This page intentionally left blank.

Page 13

www.ets-lindgren.com

Maintenance

13

Before performing any maintenance,

follow the safety information in the

ETS-Lindgren Product Information

Bulletin included with your shipment.

Maintenance of the HI-1710A is limited to

external components such as cables or

connectors.

Clean the exterior of the cabinet using a

damp cloth and mild cleaner. Always

unplug the unit before cleaning.

To prevent electrical shock, do not

remove cover.

Warranty may be void if the housing is

opened.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

WARRANTY

2.0 Maintenance

Software/Firmware Updates (Version 3.XX Only)

Periodically you should check for updates to the software/firmware for your

HI-1710A Microwave Measurement System.

Go to www.ets-lindgren.com.

On the Resources menu, click Software/Firmware.

In the Software/Firmware column, look for HI-1710A files. Save the

zip file to the desired location on your computer.

In the same section where the zip file is located, click the link to

download the installation instructions. Follow those instructions to

install the new software/firmware.

Page 14

14

Maintenance

www.ets-lindgren.com

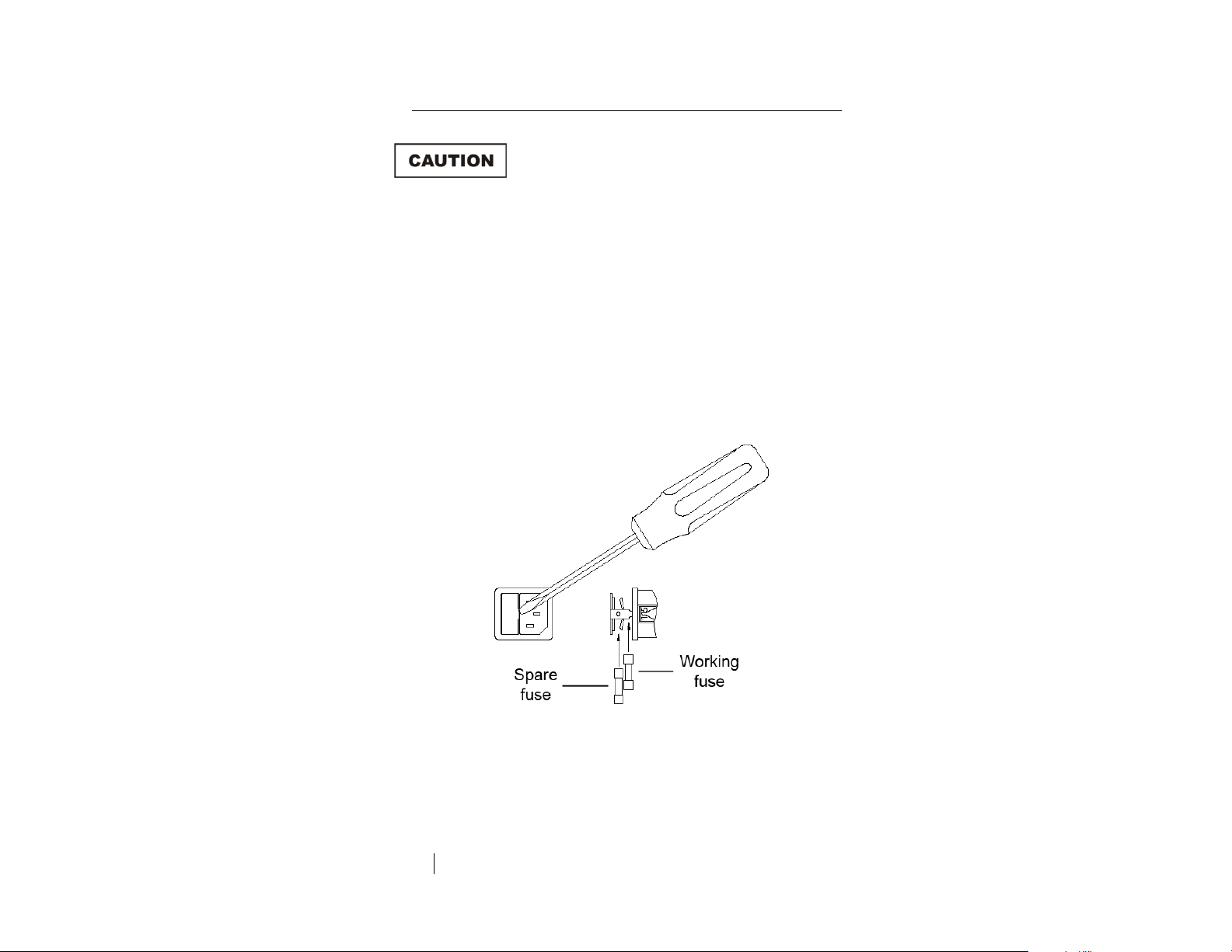

Disconnect the HI-1710A from power before

replacing a fuse.

Replacing the Fuse

If the HI-1710A fails to operate, check for a blown fuse inside the power entry

module. A blown fuse must be replaced with the same value and type of fuse, or

an unsafe condition may result. Use only 250 Volt, 1.0 Amp, Type T

(5 mm x 20 mm) fuses.

To replace a fuse:

1. Two fuses are located in the fuse drawer in the power input module.

Use a screwdriver to open the drawer.

2. The fuse towards the outside of the drawer is the spare. Remove the

spare fuse from the module.

3. Replace the blown fuse with the spare fuse.

4. Slide the fuse drawer back into the module. Make sure that the drawer

snaps securely into its locked position.

Page 15

www.ets-lindgren.com

Maintenance

15

ETS-Lindgren may substitute a similar part or new part number with

the same functionality for another part/part number. Contact

ETS-Lindgren for questions about part numbers and ordering parts.

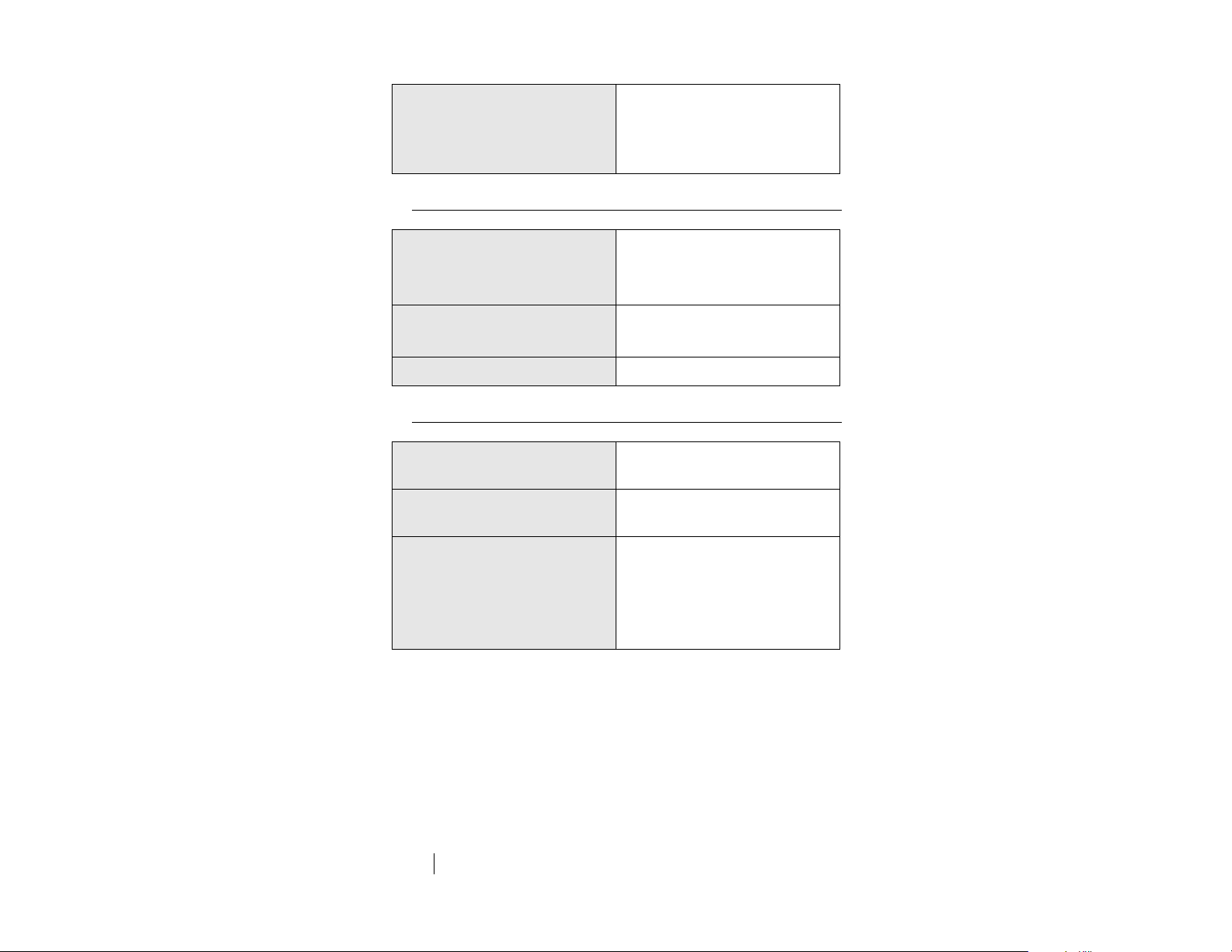

Part Description

Part Number

Microwave Oven Probe

HI-2623

The HI-2623 Microwave Oven Probe may be used interchangeably

with the HI-1710A. A calibrated assembly may be used to replace the

existing probe, eliminating downtime. Many service problems are

related to probe or cable damage and can be corrected without

sending the HI-1710A for service.

Spacer Cone Kit—Includes 10 cones and 20 shields.

H-540013

To maintain stated accuracy, use only ETS-Lindgren replacement

cones.

Zero Receptacle

H-490930

Replacement and Optional Parts

Following are the part numbers for ordering replacement or optional parts for the

HI-1710A.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Service Procedures

The inner case of the HI-1710A is sealed to maintain calibration. Normally, user

repair operations are limited to verification of proper input voltage and

replacement of the probe/preamplifier assembly.

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

Page 16

16

Maintenance

www.ets-lindgren.com

This page intentionally left blank.

Page 17

www.ets-lindgren.com

Specifications

17

Ranges:

Four ranges:

0–1, 0–2, 0–5, and 0–10 mW/cm2

Response Characteristics:

0 to 90% of final value for step

input:

F0, Raw (Version 3.XX only)—

unfiltered

F1, Slow—less than three

seconds

F2, Fast—less than one second

Maximum Power Density:

2.0 Watts/cm2 (2000 mW/cm2)

Power Input:

100–240 VAC

0.8–0.4 A max

50/60 Hz

Fuses:

250 Volt, 1.0 Amp, Type T

(5 mm x 20 mm)

Control Inputs:

Zero—Dry switch closure to zero

the HI-1710A

RS-232—Standard 9-pin, 2-way

communications input

Control Outputs:

Alarm Output—Form C contact;

24 V 1 Amp

Analog Output—4 VDC max;

1 mA max

RS-232— Standard 9-pin, 2-way

communications output

3.0 Specifications

Electrical Specifications

Page 18

18

Specifications

www.ets-lindgren.com

Environmental:

Operating Temperature:

15°C–40°C

Humidity: 5% to 95% relative

humidity, non-condensing

Dimensions:

Height: 127 mm (5.0 in)

Width: 311 mm (12.25 in)

Depth: 254 mm (10.0 in)

Probe:

Probe Length: 305 mm (12 in)

Cable Length: 2.74 m (9 ft)

Weight:

3.6 kg (8 lb)

Connector:

Standard 9-pin, 2-way

communications input/output

Communications Protocol:

8 data bits, 1 stop bit, no parity, no

flow control, 9600 baud (default)

Pin Designations:

Pin 2: Data received by HI-1710A

from computer

Pin 3: Data transmitted from

HI-1710A to computer

Pin 5: Ground

Physical Specifications

RS-232 Specifications

Page 19

www.ets-lindgren.com

Specifications

19

Calibration:

Calibrated at 2450 MHz for use in

the ISM band

Calibration

Calibration is performed at a standard temperature of 75°F in an

anechoic chamber, utilizing a slot radiator.

A CW field is generated using a crystal-controlled solid state source.

The power monitoring system is the HI-2795 Calibration Comparison

System.

The calibration field level is established using a reference survey meter

with CDRH calibration correction factors.

All ranges are calibrated at mid-scale.

Power Cable

The HI-1710A Microwave Measurement System is shipped with a three-wire

power cable. When the cable is connected to an appropriate AC power source, it

connects the chassis to earth ground. The type of power cable shipped with each

HI-1710A depends on the country of destination.

Page 20

20

Specifications

www.ets-lindgren.com

1.0 mW/cm2

Absolute Calibration

+0.30 dB

Precision

±0.13

Linearity and AM response

±0.15

Frequency Response*

±0.04

Near field response

±0.29

Polarization*

±0.21

Pattern

+0 / -0.11

Temperature

+0.46 / -0.15

Supply Voltage

±0.01

RFI*

±0.01

Overload

±0.01

Drift*

±0.04

-1.068 / +1.568 dB

* Values are combined in an RMS manner.

Error Analysis

Page 21

www.ets-lindgren.com

Operation

21

Before connecting any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

Do not use without spacer cone in place.

RF must not be present in the vicinity of the probe when the zero

switch is activated, or it will result in an inaccurate zero.

4.0 Operation

About Zeroing

Zeroing determines the offset value that will be subtracted from all subsequent

measurements.

There are three ways to zero a probe connected to the HI-1710A Microwave

Measurement System:

Press the ZERO button on the front panel.

Send the serial port command Z.

Attach an external device to the ZERO connector on the back panel.

The zero will drift as the electronic circuitry and diodes warm up to normal

operating temperature. There will also be small variations as the ambient

temperature changes during the day. For these reasons, the zero point must be

reset periodically.

In addition, the bias and offset readings are checked against preset internal limits

each time the zero switch is activated. If the limits are exceeded, an error

message is displayed. Zeroing in a sufficiently high RF field or zeroing with the

probe removed will also cause an error. These tests measure the performance

characteristics of the probe and serve as failure indicators.

Page 22

22

Operation

www.ets-lindgren.com

See Menu Options, Settings, and Command Set on page 27.

(Version 3.XX only) Press the ZERO button once on the front of the

HI-1710A to go back one level in the menu. Do not to press the

button more than once or you will zero the probe.

Menu Navigation

HI-1710A Front Panel

1. To display the menu, press any arrow button on the front of the

HI-1710A.

2. Press the down arrow button to move the highlighted selection down

one item at a time, and press the up arrow button to move the

highlighted selection up one item at a time.

3. With the item you want to change highlighted, press the left/right arrow

button to move to the settings for that item.

4. Press the up or down arrow buttons to scroll through the available

settings for the highlighted item.

5. Highlight the desired setting and then release the buttons. After

approximately three to four seconds the display will return to the main

screen with the new/highlighted settings in effect.

Page 23

www.ets-lindgren.com

Operation

23

The resistance of the external load connected to the analog output

receptacle should not be less than 5000 ohms.

Back Panel Controls and Connectors

HI-1710A Back Panel

ZERO

Can be used to attach an external device to the ZERO connector. See

About Zeroing on page 21 for more information on the zero function.

ANALOG OUT

This analog output BNC connector is a DC voltage varying from 0 to 4 volts

proportional to the full scale range setting. For example, with the instrument on

range 2 (0–2 mW/cm2), a leakage value of 2 mW/cm2 will have an analog signal

of 4 VDC and a 1 mW/cm2 value will have a signal of 2 VDC. On range 4

(0–10 mW/cm2), the 4 VDC analog output signal will indicate 10 mW/cm2.

Page 24

24

Operation

www.ets-lindgren.com

Pin

Definition

1

NC 2 NC 3 Normal

4

Common

5

Alarm

ALARM OUT

RS-232 (DIGITAL INPUT/OUTPUT)

This two-way, standard 9-pin RS-232 serial data port is used to connect external

devices. These external devices can monitor and/or control the HI-1710A.

All functions normally accessed by the touch switch inputs can be controlled

externally and all data normally displayed can be transmitted through the serial

port. This is accomplished using a simple command structure of ASCII character

codes and a controller such as a personal computer or a video display terminal

(VDT). See Appendix C on page 55 for a summary of commands.

The default mode of the HI-1710A generates a formatted test summary. When

on, the default conditions are 8 data bits, 1 stop bit, no parity, and no flow control.

The HI-1710A is set up at the factory for 9600 baud. This makes it possible to

connect a monitoring device such as a VDT or printer.

The baud rate of the serial port can be changed either through the HI-1710A

menu options or by an external command through the RS-232 serial port.

Page 25

www.ets-lindgren.com

Operation

25

Check the probe spacer cone for damage, discoloration, or

contamination. Accuracy may be affected by cone wear or damage or

by contamination by metallic particles which may become imbedded in

the cone. If necessary, replace the cone. See Replacement and

Optional Parts on page 15 for part numbers.

Starting the HI-1710A

1. With the power off, attach the HI-2623 Microwave Oven Probe to the

probe connector on the front of the HI-1710A. Insert the connector so

that the locating screw is facing upward.

2. Connect the HI-1710A to AC power.

3. Turn on the power switch on the front of the HI-1710A.

The screen will display the firmware version and additional

ETS-Lindgren information. During this time a series of self-tests are

performed; when the self-tests are complete, the probe is ready to be

zeroed.

4. Place the probe in a zero field environment, and then press ZERO on

the front of the HI-1710A.

When zeroing is complete, the HI-1710A is ready for operation.

Using the HI-1710A

1. Allow the HI-1710A to warm up for at least 10 minutes.

2. Select the operating settings for the test needs. For normal tests or a

beginning point, use the default conditions. To select settings, see

Menu Options, Settings, and Command Set on page 27.

3. Zero the probe before beginning the test. With the oven operating with

a suitable load, move the probe across the oven surfaces, keeping the

probe axis (handle) perpendicular to the potential leak area.

Hold the probe by the red handle to avoid potential interference. Keep

other parts of the body and the probe cord away from the immediate

vicinity of the probe head.

Page 26

26

Operation

www.ets-lindgren.com

The zero receptacle should be located in an area that is relatively free

of significant RF fields. The fields near the zero receptacle should be

checked periodically to confirm that no significant stray fields are

present.

The analog bar graph display may be used to determine areas of highest

leakage. In the normal mode (not Peak Hold) the bar graph display will track the

displayed digital value and respond to the filtered RF signal. When the instrument

is operated in the Peak Hold mode, the bar graph display is not filtered and

responds very rapidly to changes in RF intensity. The Peak Hold mode may be

used while scanning to capture the area of highest leakage, while the bar graph

will continuously display instantaneous variations in leakage.

Changing the filter selection to FAST will decrease the response time of the

system. This will more effectively show the effect of rapid variations in RF levels

due to mode stirrers or other modulating devices. In both the SLOW and FAST

filter positions, the response time meets the CDRH requirement for RF

measuring instrument response times while the SLOW response characteristic

provides maximum smoothing of RF variations.

After the test is completed and the RF reading recorded, zero the HI-1710A

again before the next test. The zero point may gradually drift over long periods.

Re-zero before beginning a test.

Connecting and Using the Zero Receptacle

1. Attach the cable to the ZERO BNC connector located on the back of

the HI-1710A.

2. Attach the other end of the cable to the connector on the side of the

zero receptacle.

The zero receptacle is most often used with Peak Hold mode. When scanning an

oven in Peak Hold, the highest reading is displayed on the HI-1710A. When the

probe is inserted into the zero receptacle, the RF reading is sent to the RS-232

serial port for automatic data collection and the probe is zeroed.

For manual data recording, the RF reading must be recorded before the probe is

inserted into the zero receptacle.

Page 27

www.ets-lindgren.com

Menu Options, Settings, Command Set

27

Use the arrow buttons on the front of the HI-1710A to navigate the

menu. See Menu Navigation on page 22 for a description of the

arrow buttons.

Menu Option & Serial Port Command

Serial Port Command Only

3 OR 4 DIGITS—see page 28

AUTO-RANGE—see page 31 **

ABOUT—see page 29

** Auto-Range is also a setting

ALARM SETPOINT—see page 30

in the RANGE menu option;

AUDIO—see page 31

see page 39.

BAUD RATE—see page 32

ECHO—see page 33

CONTRAST—see page 33

STATUS—see page 41

FILTER (RESPONSE)—see page 34

VERSION (firmware)—see page 45

PARAMETER SCREEN—see page 35

ZERO—see page 45

PEAK HOLD—see page 36

PRINT MODE—see page 37

RANGE—see page 39

RESET—see page 44

SELF TEST—see page 40

STIM—see page 44

TEST ALARM—see page 45

5.0 Menu Options, Settings, Command Set

Menu Options

Following are the menu options and command set for the HI-1710A Microwave

Measurement System; each is described in the following pages.

Page 28

28

Menu Options, Settings, Command Set

www.ets-lindgren.com

All serial port commands must be completed with a carriage return

(CR).

Menu Option

Setting

Serial Port

Command

3

D3 4 D4 — D?

Menu Option Settings and Command Set

Following is a description of each menu option and the available settings. The

majority of the menu options have an equivalent serial port command that can be

used to set or retrieve a status; in a few cases, there is no menu option, and only

the serial port command can be used.

3 OR 4 DIGITS

Specifies whether 3 or 4 digits will display; includes digit to the left of

the decimal point and either 2 or 3 digits to the right of the decimal

point.

All numeric commands return a total of 3 or 4 digits.

In 3-digit mode, the fourth digit is rounded and not displayed.

In 4-digit mode, some least significant bit noise will be seen, resulting

in the least significant digit changing.

Page 29

www.ets-lindgren.com

Menu Options, Settings, Command Set

29

Menu Option

Setting

Serial Port

Command

OFF — ON — —

*IDN?

ABOUT (VERSION 3.XX ONLY)

Displays/returns the installed firmware version and other ETS-Lindgren

and system information. When ON is selected, the information will

display for approximately 10 seconds.

Page 30

30

Menu Options, Settings, Command Set

www.ets-lindgren.com

The alarm will sound only if the audio is turned on. To turn

on the alarm, see Audio on page 31.

Menu Option

Setting

Serial Port

Command

XX.XX

T#### — T?

Where #### is a value from 0 to 9999 in mW/cm2. For

example, 5000 is 5.0 mW/cm2, 5 is 0.005 mW/cm2, and so

on.

ALARM SETPOINT

Sets a level after which an alarm will sound to indicate that the

measured leakage has exceeded the level.

Each press of the up/down arrow button will raise/lower the setting

Any time a change in direction is made up or down, the change

by 0.01 for the first ten presses (9.99, 9.98, 9.97, and so on), by 0.10

for the next ten presses (9.89, 9.79, 9.69, and so on), and by 1.00 for

the remaining presses (8.89, 7.89, 6.89, and so on).

increment begins at 0.01.

The alarm will sound only when the displayed RF value exceeds the

alarm set point. For example, if the alarm is set at 4.99 mW/cm2, the

alarm will only sound when the displayed RF level is 5.00 or greater.

Once the RF level decreases below the alarm set point, the alarm will

turn off.

Page 31

www.ets-lindgren.com

Menu Options, Settings, Command Set

31

Although the alarm set point may be specified, the alarm will

not sound unless the audio is turned on. For set point

information, see page 30.

Menu Option

Setting

Serial Port

Command

OFF

Q0

ON

Q1 — Q?

Menu Option

Setting

Serial Port

Command

Function

—

A0

OFF — A1

ON — A?

Retrieve status

The auto-range setting only affects the bar graph display

and the analog output.

When in Peak Hold with the range set to AUTO, the range

will change as the field strength increases; it will remain in

the range that shows the highest peak value until the ZERO

button is pressed. This is so the peak value can be

displayed on the bar graph. When the ZERO button is

pressed with no field present, the range will revert back to

the lowest (1 mW/cm2).

AUDIO

AUTO-RANGE

Turns on the audible alarm indicator, which will sound to indicate that

the measured leakage has exceeded a preset level (alarm set point).

When set to auto-range, the best range for each measuring condition

will automatically be selected.

Page 32

32

Menu Options, Settings, Command Set

www.ets-lindgren.com

Menu Option

Setting

Serial Port

Command

57600

B57

19200

B19

9600

B96

4800

B48

2400

B24

1200

B12

600

B60

300

B30 — B?

BAUD RATE

Sets the communication rate between the HI-1710A and an

external device.

After the baud rate is changed on the HI-1710A, it also must be

changed on the external device. When baud rates are incorrectly set, a

video display terminal (VDT) may display nonsense or non-printing

characters.

The baud rate is changed immediately when a B command is sent.

The baud rate setting is saved in memory when the power is turned off.

Page 33

www.ets-lindgren.com

Menu Options, Settings, Command Set

33

Menu Option

Setting

Serial Port

Command

0–8

C0–8 — C?

Menu Option

Setting

Serial Port

Command

OFF

E0

ON

E1 — E?

CONTRAST

ECHO

Increase the value to darken the display or decrease it to lighten the

display.

When echo is on, keyboard entries on the VDT will also be displayed

on the VDT screen.

The echo mode can be used when marginal transmission conditions

exist or when the HI-1710A is connected to a full duplex terminal that

requires the characters be re-transmitted.

Page 34

34

Menu Options, Settings, Command Set

www.ets-lindgren.com

Menu Option

Setting

Serial Port

Command

RAW (Version 3.XX only)

F0

SLOW

F1

FAST

F2 — F?

FILTER (RESPONSE)

Digital filtering, or response times, changes the response to

rapidly-changing RF or leakage levels; see Theory of Operation on

page 47 for more information.

RAW (Version 3.XX only)—Unfiltered.

SLOW—Equivalent to slow response mode on analog meters. SLOW

is the default setting, and is used for most hand-scanning of microwave

ovens. It responds more slowly to rapidly-changing RF or leakage

levels and tends to average the response to peak levels caused by

oven mode stirring devices. This is designed to meet the

CDRH requirement that an instrument respond to a step CW

microwave input to 90% of its steady state reading within a maximum

of three seconds, while still providing maximum smoothing of

RF peaks.

FAST—Equivalent to fast response mode on analog meters. It is used

to observe rapid variations in RF leakage and to evaluate the effect of

stirrer modulation on leakage.

Page 35

www.ets-lindgren.com

Menu Options, Settings, Command Set

35

Change the setting to ON, and exit the menu to display the

parameter screen. Press the ZERO button to escape the

parameter screen.

Menu Option

Setting

Serial Port

Command

OFF — ON

—

PARAMETER SCREEN

Displays system board voltages and probe voltages and offsets.

Sample Parameter Screen

RF—Probe RF level currently detected.

BIAS—Probe bias reading; value should be between 0.30 and

0.40 volts.

REF—Power supply reference voltage; value should be between 1.22

and 1.26 volts.

+5SUP—Power supply +5 voltage; value should be between 4.75 and

5.25 volts.

+8SUP—Power supply +8 voltage; value should be between 7.60 and

8.40 volts.

-8SUP—Power supply -8 voltage; value should be between -7.92 and

-8.08 volts.

OFST—Probe offset reading; value should be between 0.02 and

0.40 mW (0.005 and 0.100 volts).

Page 36

36

Menu Options, Settings, Command Set

www.ets-lindgren.com

If an error occurs in any of the parameter readings, the

parameter screen displays and the erroneous reading

flashes. Turn the HI-1710A off, correct the problem, and

then turn it on again.

Menu Option

Setting

Serial Port

Command

ON

P1

OFF

P0 — P?

PEAK HOLD

STIM—Applies and displays a DC voltage to the input of the RF signal

circuitry; value should be between 2.44 and 4.88. Readings outside

this range indicate a fault in the HI-2623 probe/preamplifier.

TEST—Voltage at the analog output jack; value should be between

3.80 and 4.20 volts.

Captures and holds the highest leakage reading displayed.

While in Peak Hold the bar graph on the display shows the current

instantaneous RF reading, without filtering. A bar graph segment

remains lit to indicate the relative location of the peak reading. The

bar graph display responds very rapidly and will show stirrer/turntable

modulation as well as minima and maxima of leakage around the

microwave oven periphery.

Because of the fast, unfiltered, response of the bar graph display, the

digital peak reading may lag behind the bar graph indication,

depending on the filter factor chosen. When the instantaneous RF

indication on the bar graph display is greater than the reading on the

digital display, the bar graph segment proportional to the digital reading

is unlit. In this way the Peak Hold mode of the meter can be used to

observe the effects of the various digital filters on fast changing RF

inputs.

In the normal mode (not Peak Hold), the bar graph display follows the

filtered display reading.

Page 37

www.ets-lindgren.com

Menu Options, Settings, Command Set

37

See page 42 for the status message formats for modes

0, 1, and 2, and page 43 for mode 3.

Menu Option

Setting

Serial Port

Command

0

M0 1 M1 2 M2 3 M3 — M?

PRINT MODE

There are four modes that specify the content and length of the

information provided during testing.

Mode 0—Print mode off. Select this mode when no automatic output

from the HI-1710A is needed; for example, when all output is

specifically requested by the controller. This mode might be chosen in

a fully-automatic test system where the external device requests the

measurement, data gathering, and the zeroing of the meter.

Status messages are transmitted in the same form as in mode 2,

but no message is transmitted by the HI-1710A when the zero

command is received.

Mode 1—Prints continuous reading. In this mode the HI-1710A

continually sends the RF reading through the RS-232 serial port. Data

is transmitted at a high rate and can only be used at baud rates of

4800 and above; data is sent at a rate of 45 Hz, the same rate at which

the probe is sampled. The controlling device must be able to receive a

serially-transmitted 4-digit number 45 times a second.

This mode might be used in the laboratory to investigate the

effects of different filter constants and scan rates. The output from

the HI-1710A is a three- or four-digit ASCII string in the format

X.XX or X.XXX.

Page 38

38

Menu Options, Settings, Command Set

www.ets-lindgren.com

Mode 2—Prints summary ticket. This is the default mode. The

HI-1710A sends a pre-formatted summary report through the RS-232

serial port each time the probe is zeroed. This is most useful when

using Peak Hold mode. With this configuration, a serial input printer set

up to print adhesive-backed labels can be connected to the RS-232

serial port. After scanning an oven, the meter is zeroed. On zeroing, a

ticket is printed with the maximum leakage observed as well as several

system test parameters.

The output is formatted for a standard 3 1/2-in x 15/16-in label

(for example, Avery® label 4013). Line feed characters are

transmitted following the formatted data to advance one additional

label space with each formatted output. By printing the report on

every other label, the labels can be removed from the backing

more conveniently.

Mode 3—Does not print summary ticket when zeroed. Changes the

output format of the status messages S0–S8. The transmitted

summary messages are shortened for easier adaptation to a computer

interface program.

The zero command does not transmit a formatted report as in

mode 2. In mode 3 the transmitted status messages end with only

a carriage return terminator (CR). In modes 0, 1, and 2, the

messages end with a carriage return and a line feed (CR/LF).

Page 39

www.ets-lindgren.com

Menu Options, Settings, Command Set

39

For more information on auto-range, see page 31.

Menu Option

Setting

Serial Port

Command

AUTO

A1

0-1mW

R1

0-2mW

R2

0-5mW

R3

0-10mw

R4

—

R?

RANGE

The range determines the full-scale setting of the bar graph display

located on the front panel digital readout for a continuous analog

indication of the measured leakage level. The four ranges have

full-scale indications of 1, 2, 5, and 10 mW/cm2; the digital display will

always indicate any value between 0 and 9.999 mW/cm2. When set to

auto-range, the best range for each measuring condition will

automatically be selected.

With no RF input, the instrument will shift to the 0–1 mW/cm2 scale.

When the displayed value exceeds 95% of full scale, the next higher

scale is automatically selected.

While the digital reading will always indicate any value up to

9.999 mW/cm2, the bar graph display will change to reflect the correct

percentage of the newly-selected range. When the displayed value

drops below 30% of full scale, the next lower range is selected.

If the unfiltered RF signal from the probe exceeds 20 mW/cm2 or the

filtered RF signal exceeds 10 mW/cm2, the HI-1710A will indicate an

over range condition by sounding a continuous beep. The over range

condition will remain until the filtered RF signal drops below

10 mW/cm2.

Page 40

40

Menu Options, Settings, Command Set

www.ets-lindgren.com

Menu Option

Setting

Serial Port

Command

SELF TEST

ST

SELF TEST

Performs a series of self-tests; when the self-tests are complete, the

probe is ready to be zeroed.

After successful completion of the self-test, the HI-1710A sends

SELF TEST PASSED message, plus three blank lines.

If the self-test fails, the parameter screen displays. Press the

ZERO button to initiate another self-test.

If an error occurs, turn off the HI-1710A, correct the error, and then

turn on the HI-1710A.

Page 41

www.ets-lindgren.com

Menu Options, Settings, Command Set

41

Menu

Option

Serial Port

Command

Function

—

S0

Send System Status

—

S1

Send Alarm Set Point

—

S2

Send Range Number

—

S3

Send Filter Number

—

S4

Send Bias Voltage

—

S5

Send Offset — S6

Send STIM Value

—

S7

Send Power Supply Voltages

—

S8

Send RF Reading*

—

S9

(Version 3.XX only)

Send Non-Filtered RF

Reading*

*(Version 3.XX only) In Peak Hold mode S8 will return peak

RF value. For the current RF reading, use S9.

The format of information returned depends on the current

print mode. See page 42 for the status message formats for

print modes 0, 1, and 2, and page 43 for print mode 3.

For more information on print modes, see page 37.

STATUS

Checks status for the following:

Page 42

42

Menu Options, Settings, Command Set

www.ets-lindgren.com

S0

DIGITS=V/AUTO RNG WWW/PEAK HOLD XXX/YY

RNG/PRINT MODE Z

Where:

V is 3 or 4

WWW is ON or OFF

XXX is ON or OFF

YY is IN or OUT

Z is 0,1, or 2

S1

ALARM --- X.XX or X.XXX

S2

SCALE --- X

S3

FILTER --- XXXX

Where XXXX is RAW (Version 3.XX only), FAST,

or SLOW

S4

BIAS --- X.XX or X.XXX

S5

OFFSET --- X.XX or X.XXX

S6

STIM --- X.XX or X.XXX

S7

REFERENCE --- X.XXX

5 VOLTS --- X.XXX

8 VOLTS --- X.XXX

-8 VOLTS --- X.XXX

S8

RDNG OK --- X.XX or X.XXX

The RF value depends on the filter setting.

S9

(Version 3.XX only)

RDNG OK --- X.XX or X.XXX

The RF value is raw/unfiltered.

Print Modes 0, 1, 2

Page 43

www.ets-lindgren.com

Menu Options, Settings, Command Set

43

S0:

XXXXX

First digit—3 or 4 for number of digits

displayed and transmitted

Second digit—0 or 1 for auto-range off

or on

Third digit—0 or 1 for Peak Hold off or

on

Fourth digit—0 or 1 for in range or

over range

Fifth digit—0, 1, 2, or 3 for operating

mode

S1:

X.XX

Alarm trigger point (X.XXX in four-digit

mode)

S2: X Range number 1–4

S3: X 1 = F1 (Slow)

S4:

X.XXX

Bias voltage (X.XXX in four-digit mode)

S5:

X.XXX

Offset; milliwatts (X.XXX in four-digit

mode)

S6:

X.XX

STIM test value (X.XXX in four-digit

mode)

S7:

X.XXX

Reference voltage level

X.XXX

5 volt power supply level

X.XXX

8 volt power supply level

X.XXX

-8 volt power supply level

S8:

X.XX

RF reading (X.XXX in four-digit mode)

S9:

X.XX

(Version 3.XX only)

Raw/unfiltered RF value (X.XXX in

four-digit mode)

Print Mode 3

Page 44

44

Menu Options, Settings, Command Set

www.ets-lindgren.com

Menu Option

Setting

Serial Port

Command

NO — YES

S6

Menu Option

Setting

Serial Port

Command

NO — YES

I

STIM

Performs a stimulus routine to verify that the probe is operational.

When activated, the HI-1710A will apply a DC voltage to the input of

the RF signal.

The STIM value should be between 2.44 and 4.88. Readings outside

this range indicate a fault in the HI-2623 probe/preamplifier.

RESET

This will reset the HI-1710A to factory settings and overwrite any

settings you changed. See Factory Default Settings on page 46 for

more information.

In addition to resetting the system to factory defaults, RESET performs

the self-test sequence.

Page 45

www.ets-lindgren.com

Menu Options, Settings, Command Set

45

Menu Option

Setting

Serial Port

Command

ON — OFF

—

Menu Option

Setting

Serial Port

Command

—

VER?

Menu Option

Setting

Serial Port

Command

—

Z

When the zero command is received and the RS-232 output

is in mode 2 (default mode), a formatted output message is

sent through the serial port and the probe is zeroed. The

formatted message transmits the RF reading only when the

front panel Peak Hold mode is ON.

TEST ALARM

Sets or resets the alarm relay located on the back panel of the

HI-1710A.

VERSION (FIRMWARE) – VERSION 3.XX ONLY

Returns the version of installed firmware.

Format: X.XX

ZERO

Zeros the probe; performs the same function as pressing the ZERO button on the

front panel.

Page 46

46

Menu Options, Settings, Command Set

www.ets-lindgren.com

All settings are stored in memory. The last settings used will be

restored each time the HI-1710A is turned off.

RESET returns the HI-1710 to factory default settings. For more

information on RESET, see page 44.

3 or 4 Digits:

3 (two places to the right of the decimal)

Alarm Set Point:

5.0

Audio Alarm:

OFF

Baud Rate:

9600

Display Contrast:

7

Filter (Response):

Slow

Peak Hold:

OFF

Print Mode:

2

Range:

0–1 mW/cm2

Factory Default Settings

When you receive the HI-1710A, it is configured with the following settings; these

default settings can be used for normal production line testing.

Page 47

www.ets-lindgren.com

Theory of Operation

47

6.0 Theory of Operation

The HI-1710A Microwave Measurement System uses a unique diode/dipole

antenna sensor that is coupled with digital filtering techniques developed for

Automatic Microwave Oven Scanner Systems. A radial array of eight antennas is

located perpendicular to the axis of the probe handle. The electric field is

detected by hot carrier diodes operating in the square law region. A negative

voltage is applied to the cathode connection of the diodes to bias them in an

optimum operating region. The bias is adjusted individually for each

probe/preamplifier assembly. The diode signals are summed and input to

two stages of amplification. The amplifying stages perform analog filtering to

minimize external interference at 60 Hz.

The analog output of the preamplifier is connected to one input of a

seven channel analog-to-digital converter. The bias input is connected to another

channel. Scaled values of the various power supply voltages are connected to

the remaining inputs. The digital equivalent of the RF signal is input to the

microprocessor. A software-implemented filter is used to condition the RF signal

for most effective RF measurement. The filtering in the HI-1710A is

accomplished by an integrating software filter. Sets of fixed filter parameters can

be selected from the front panel of the HI-1710A.

Selecting filter 1 (F1 / SLOW) results in a digital filter characteristic with a rise

time 90% of less than three seconds. This response is equivalent to the SLOW

response of the common analog microwave survey meter.

Filter 2 (F2 / FAST) results in a digital filter characteristic with a rise time 90% of

less than one second. The response of this filter is much faster and is equivalent

to the FAST response of an analog survey meter.

After filtering, the final leakage value is displayed as a 3- or 4-digit value. The

microprocessor also performs the peak hold and alarm functions. In the

Peak Hold mode, the bar graph display is driven without any digital filtering to

display the real time variations in the RF level. In the Peak Hold mode, the

highest reading sent to the digital display by the processor is held and

continuously displayed until either a higher reading is transmitted or until the

probe is zeroed. The peak value displayed is the value obtained after all filtering

is accomplished.

Page 48

48

Theory of Operation

www.ets-lindgren.com

When not in the Peak Hold mode, the bar graph display responds to the filtered

signal as displayed.

The system performs a series of self-tests at startup and each time the probe is

zeroed. The bias voltage is measured to check for defective diodes and for a

proper bias supply, and then the offset voltage of the array is measured. The

offset voltage is the signal at the preamp output with the probe in a zero RF field.

Limits on the offset voltage check for proper probe/preamplifier operation. A zero

chamber option is available to minimize the RF present at the probe head during

zeroing; see Zero Receptacle Option on page 11. A stimulus voltage is applied to

the input of the first operational amplifier stage in the preamp. This signal is used

to test the integrity of the RF signal path. The level of each of the four power

supply outputs is tested on startup. If an error is detected, the parameter screen

will be displayed with the erroneous value flashing. Upon zeroing, the self-test is

repeated until all errors are corrected.

Page 49

www.ets-lindgren.com

Warranty

49

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your HI-1710A Microwave

Measurement System.

Product Warranted

Duration of Warranty Period

HI-1710A Microwave

Measurement System

1 Year

Appendix A: Warranty

DURATION OF WARRANTIES FOR HI-1710A

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to one year.

Page 50

50

Warranty

www.ets-lindgren.com

This page intentionally left blank.

Page 51

www.ets-lindgren.com

Error Messages

51

BIAS

OUTSIDE LIMIT

REF

OUTSIDE LIMIT

+5SUP

OUTSIDE LIMIT

+8SUP

OUTSIDE LIMIT

-8SUP

OUTSIDE LIMIT

STIM

OUTSIDE LIMIT

Appendix B: Error Messages

In any mode, an invalid command will produce the error message

ENTRY ERROR -- PLEASE RETRY.

Self-Test Error Messages

The following error messages will be transmitted if during the self-test an out of

specification condition is detected.

Page 52

52

Error Messages

www.ets-lindgren.com

Startup Error Messages

As part of the self-test performed on startup, a number of error messages can be

displayed indicating operating problems. In addition, the offset and bias values of

the probe are measured each time the probe is zeroed. If an erroneous reading

is detected, the HI-1710A Microwave Measurement System will display the

parameter screen and the erroneous reading will flash. A message will also be

sent to the RS-232 port. Following is the action to be taken for each error.

REF C – OUTSIDE LIMIT

1.24-volt supply low

1.24-volt supply high: The 1.24 volt reference to the A/D converter is

beyond specification. Return for service if error message persists.

+5SUP C – OUTSIDE LIMIT

5-volt supply low

5-volt supply high: The 5-volt logic supply is beyond specification.

Voltage is not user-adjustable; return for repair.

+8SUP C – OUTSIDE LIMIT

8-volt supply low

8-volt supply high: The 8-volt supply to the analog circuitry is beyond

specification. Voltage is not user-adjustable; return for repair.

-8SUP C – OUTSIDE LIMIT

-8-volt supply low

-8-volt supply high: The negative 8-volt supply to the analog circuitry is

beyond specification. Voltage is not user-adjustable; return for repair.

Page 53

www.ets-lindgren.com

Error Messages

53

BIAS C – OUTSIDE LIMIT

Bias voltage low

Bias voltage high: The probe bias voltage is beyond specification.

Check the negative 8-volt supply level. If the supply voltage is within

specification, the probe/preamplifier assembly should be replaced. If

the bias voltage is still beyond specification, return for service.

STIM C – OUTSIDE LIMIT

STIM test low

STIM test high: A fault exists in the RF signal processing path. Replace

the probe/preamplifier assembly; if the error persists, return for service.

Page 54

54

Error Messages

www.ets-lindgren.com

This page intentionally left blank.

Page 55

www.ets-lindgren.com

Summary of RS-232 Command Set

55

For a list of factory settings, see page 46.

Function

Command

Range

Default

3 or 4 digit display

D#

3–4

3

Alarm trigger point

T####

0–9999

5000

Audio mode (1=ON)

Q#

0–1

0

Auto-range (1=ON)

A#

0–1

0

Baud rate

B##

12–96

96

Echo (1=ON)

E#

0–1

0

Filter (Response) number

(0 is available only in

Version 3.XX)

F#

0–2 1

Re-initialize system (Reset)

I — —

Peak Hold (1=ON)

P#

0–1

0

Print mode

M#

0–3

2

Range

R#

1–4

1

Self-test

ST — —

Zero meter

Z — —

Appendix C: Summary of RS-232 Command Set

Page 56

56

Summary of RS-232 Command Set

www.ets-lindgren.com

This page intentionally left blank.

Page 57

www.ets-lindgren.com

EC Declaration of Conformity

57

Appendix D: EC Declaration of Conformity

Loading...

Loading...