Page 1

Archived 4/2/10

HI-4422/FP2000/

FP4000/FP5000

Isotropic Electric Field Probe

User's Manual

Declaration of Conformity

ETS-Lindgren, L.P.

1301 Arrow Point Drive

Cedar Park, TX 78613

USA

Declares that the HOLADAY product described in this

instruction manual is in compliance with: EN EMC Directive

86/336/EEC, EN50082-1, EN55011

ETS-Lindgren, L.P.

(Formerly Holaday Industries, Inc.)

© ETS-LINDGREN L.P. – July, 2005

Revision G – Part # H-600054

Page 2

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

ETS-Lindgren L.P., reserves the right to make changes to any

product described herein in order to improve function, design, or

for any other reason. Nothing contained herein shall constitute

ETS-Lindgren L.P. assuming any liability whatsoever arising out

of the application or use of any product or circuit described

herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 2005 by ETS-Lindgren L.P. All Rights Reserved.

No part of this document may be copied by any means without

written permission from ETS-Lindgren L.P.

EMAIL & INTERNET ADDRESSES

support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Dr., Cedar Park TX 78613 USA

P.O. Box 80589, Austin, TX 78708-0589 USA

Tel 512.531.6400

Fax 512.531.6500

FINLAND

Mekaanikontie 1, 27510, Eura, Finland

Tel 358.2.838.3300

Fax 358.2.865.1233

JAPAN

4-2-6, Kohinata

Bunkyo-ku

Tokyo 112-0006 JAPAN

Phone + 81 3 3813 7100

Fax + 81 3 3813 8068

CHINA

1917-1918 Xue Zhixuan Building

No 16 Xue Qing Road

Haidian District

Beijing Postcode: 100083 CHINA

Phone + 86 010 82755304

Fax + 86 010 82755307

2

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 3

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

REVISION RECORD

HI-4422/FP2000/FP4000/FP5000, Manual, Part #600054

Revision Description Date

Initial Release July, 1993

A Revised August, 1994

B Changed Battery Charger June, 1997

C Added CE Label June, 1997

D Revised January, 1998

E Changed Charger Specs August, 1999

F Changed Area Code February, 2000

G Revised July, 2005

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

3

Page 4

This page intentionally left blank.

Archived 4/2/10

Isotropic Electric Field Probe

HI-4422/FP2000/FP4000/FP5000

4

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 5

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Table of Contents

1.0 Introduction .............................................................. 7

Specifications ........................................................................... 8

2.0 Getting Started ........................................................ 9

Acceptance and Controls ......................................................... 9

Probe ........................................................................................ 9

CHARGER ............................................................................. 10

Battery .................................................................................... 11

Battery Charging .................................................................... 11

3.0 Operation ............................................................... 13

System Theory ....................................................................... 13

Application Considerations ..................................................... 17

4.0 Maintenance .......................................................... 19

Maintenance Recommendations ............................................ 19

Upgrade Policies .................................................................... 20

Return Procedures ................................................................. 21

Periodic/Preventive Maintenance ........................................... 21

Parts Information .................................................................... 22

5.0 Warranty Policy for Electromagnetic Isotropic

Field Monitoring Components ...................................... 23

Scope and Duration of Warranties ......................................... 23

Warranty Exclusions ............................................................... 24

Buyer’s Remedies .................................................................. 25

6.0 Appendix A: Error Codes ................................... 27

Probe Error Output ................................................................. 27

7.0 Appendix B: Operating Protocols ..................... 29

Communication Protocol ........................................................ 29

Information Transfer Protocol ................................................. 29

Command Structure ............................................................... 30

8.0 Appendix C: Battery Charger Manual .............. 33

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

5

Page 6

This page intentionally left blank.

Archived 4/2/10

Isotropic Electric Field Probe

HI-4422/FP2000/FP4000/FP5000

6

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 7

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

1.0 INTRODUCTION

The HI-4422/FP2000/FP4000/FP5000 is a battery-operated

broadband radio frequency (RF) isotropic electric field probe

designed for a variety of applications including broadcast

facilities, industrial RF source and electro magnetic compliance

(EMC) testing.

The HI-4422/FP2000/FP4000/FP5000 probes are fully intelligent

sensor enabling fast and accurate EMF measurements with

industry-leading performance specifications. Optical coupling to

a variety of readout options makes this probe ideally suited for a

wide range of field monitoring applications. The

HI-4422/FP2000/FP4000/FP5000 probes are excellent tools for

electric field mapping, RADHAZ measurements and EMC field

monitoring.

Figure 1:

The basic HI-4422/FP2000/FP4000/FP5000 probes are shipped

complete with a 10 meter fiber extension cable, a carrying case,

battery charger and connectors for extending the optic cable.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

HI-4422/FP2000/FP4000/FP5000

Electric Field Probe

7

Page 8

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

The HI-4422/FP2000/FP4000/FP5000 probe measures field

strength in each of three axes. It performs a vector addition

calculation on the readings and sends the result to the receiver

via a fiber optic cable. Data from each axis can be viewed

individually, or can be combined. Frequency response of the

HI-4422/FP2000/FP4000/FP5000 is 10 kHz to 1 GHz; dynamic

range is 1 to 300 Volts/meter (V/m).

SPECIFICATIONS

Dynamic Range

Ranges

Frequency

Response

Linearity

Isotropicity

Overload Withstand

Environmental

Operating Temp

Environmental

Humidity

Fiber Optic Cable

Connector

Battery

Battery Charger

Probes

Probe Mount

Weight

Optional Equipment

1 to 300 Volts/meter (V/m)

10, 30, 100, 300 Volts/meter full scale

10 kHz to 250 MHz ± 0.5 dB

250 MHz to 1.0 GHz ± 1.0 dB

± 0.5 dB full scale (F.S.): ± 2 least

significant bits (LSBs) of A/D converter

± 0.5 dB

1000 Volts/meter maximum, all ranges

10 °C to 40 °C

(+50 °F to +104 °F)

5% to 95% relative humidity, noncondensing

Standard FSMA

3.6 VDC, 1400 mA-h rechargeable

Nickel-Cadmium (NiCd)

115/230 VAC, approximately 1 hour

64 mm (2.5 in) cube with probe shields

on three sides

¼ - 20 UNC tapped hole (internal

thread) in base of probe

0.4 Kg (14 oz.)

See Table 2

8

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 9

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

2.0 GETTING STARTED

ACCEPTANCE AND CONTROLS

UNPACKING AND ACCEPTANCE

Step 1. Upon delivery of your order, inspect the shipping

container(s) for evidence of damage. Record any damage on

the delivery receipt before

damage or loss, retain the packing materials for inspection by

the carrier.

Step 2. Remove the probe from its shipping containers. Save

the boxes and any protective packing materials for future use.

Step 3. Check all materials against the packing list to verify that

the equipment received matches that, which was ordered. If you

find any discrepancies, note them and call ETS-Lindgren

Customer Service for further instructions.

Be sure that you are satisfied with the contents of your order and

the condition of your equipment before

PROBE

signing. In case of concealed

installing the probe.

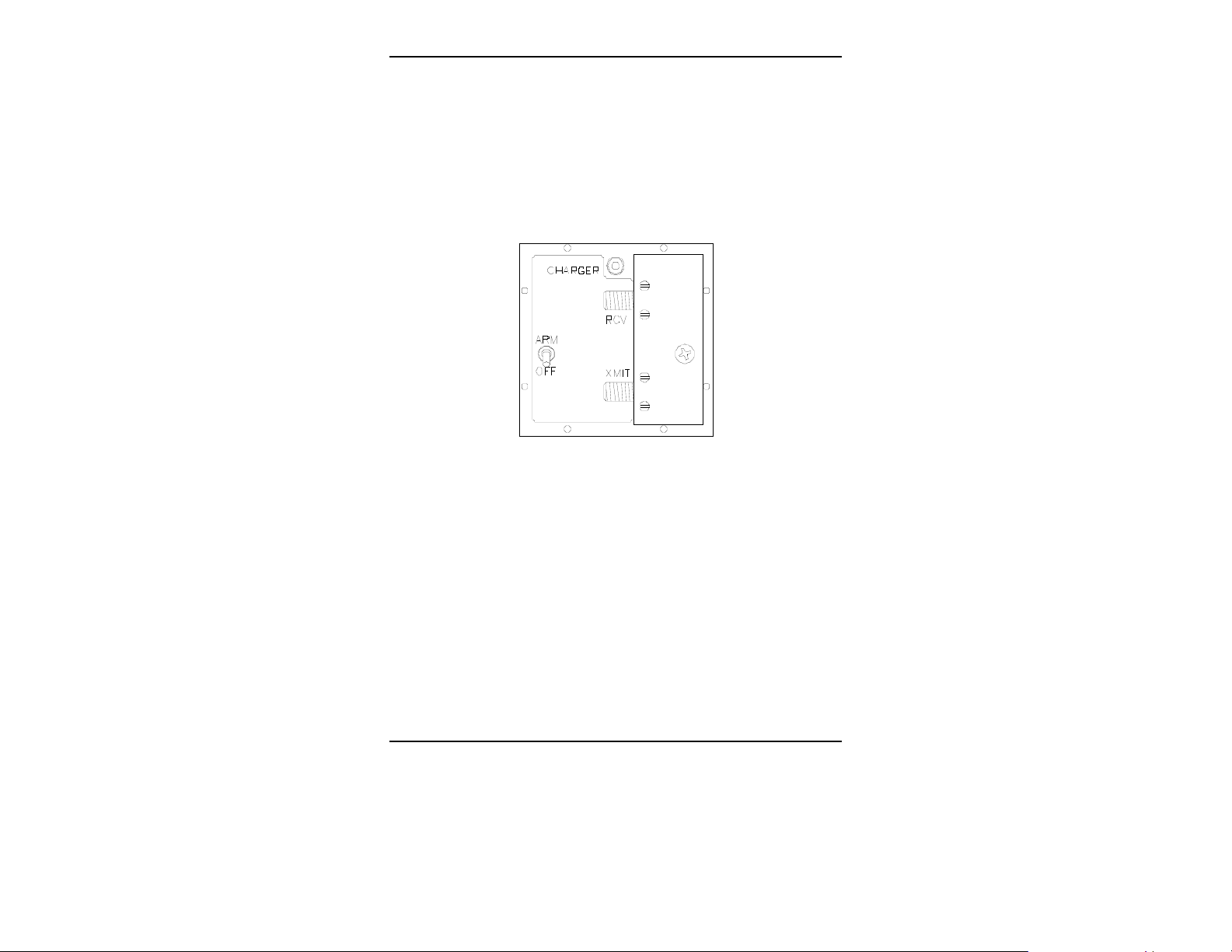

A switch, two fiber optic connectors and a battery charger

connector are mounted on the HI-4422/FP2000/FP4000/FP5000

probe housing (Figure 3-1).

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

9

Page 10

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

XMIT/RCV

The fiber optic cable assembly from the receiver is attached to

the probe via two connectors. The cable ends are color-coded—

white for XMIT, yellow for RCV. Identically colored dots are

located on the probe housing adjacent to these connectors. Be

sure that each cable is attached to the proper probe connector.

Figure 2: Switch and Connectors

When the cables are not attached, always cover the probe

connectors with the protective plastic covers supplied with the

unit, or with similar material. This prevents dirt and other

contaminants from entering the connector, causing

communication problems.

ARM/OFF

The ARM/OFF switch activates and deactivates the probe. In

the ARM position, its internal 3.6 VDC NiCd battery powers the

probe: in the OFF position, the probe is inactive. To prolong

battery life, set this switch to OFF when the probe is not in use.

CHARGER

A standard fast charger is supplied with the

HI-4422/FP2000/FP4000/FP5000. When charging is complete,

the fast charger acts as a trickle charger. Battery performance

will not degrade, regardless of how long it is on the trickle

charger.

10

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 11

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

BATTERY

The NiCd battery provides up to 40 hours of probe operation

when fully charged.

BATTERY CHARGING

Each HI-4422/FP2000/FP4000/FP5000 probe contains a

rechargeable nickel-cadmium (NiCd) battery. A fully-charged

battery (nominal output voltage of 3.6 VDC) provides up to

4m,asghjkl89asghjkl890 hours of operation. When the battery

has discharged to 3.3 VDC, the probe is still operational, but its

battery needs charging: when the voltage drops below 3.18

VDC, measurement accuracy will be compromised by further

operation.

NOTE: ETS-Lindgren charges the internal NiCd battery

of the HI-4422/FP2000/FP4000/FP5000 at the factory in

order to calibrate the probe prior to shipment. While

every effort is made to ensure that your probe arrives

ready to use, we cannot guarantee that this will be the

case. Always check the condition of the probe's battery

prior to making any measurements. To check probe

battery voltage, refer to the operation of the BAT keypad

in Section 8.0 of the HI-4416 User's Manual.

CHARGING PROCEDURE

Step 1. Plug the charger into a suitable AC source.

Step 2. Set the probe switch to OFF. Insert the plug on

the charger cable into the probe's CHARGER jack.

Step 3. The battery is now charging. This may take

approximately 1 hour, depending on how deeply the batteries are

discharged. When charging is complete, the charger

automatically goes into a trickle charge and will continue to do so

until the probe is disconnected.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

11

Page 12

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

BATTERY TIPS

NiCd batteries have several characteristics that can affect both

their performance and operating life. The following tips advise

you how to take advantage of these characteristics to get the

most out of your probe's battery.

• Although NiCd batteries are rated for operation in

temperatures from -20°C to +65°C (-4°F to +140°F),

operating the probe in extreme temperatures will reduce

operating time significantly. The optimum operating

temperature range for these batteries is +20°C to +30°C

(+68°F to +86°F).

• The battery in the HI-4422/FP2000/FP4000/FP5000

does not require periodic "deep discharges" to reverse

the capacity-depleting "memory effect" caused by

repeated shallow discharges; however, undercharging

can reduce battery capacity. Therefore, after the

charging procedure is complete, be sure that the battery

is fully charged before resuming field operation.

• If the battery exhibits low terminal voltage during

charging, or if it appears unable to acquire or maintain

an appreciable charge, individual cells in the battery may

be shorted or damaged. If, for any reason, your battery

needs replacement, contact ETS-Lindgren Customer

Service for assistance.

12

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 13

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

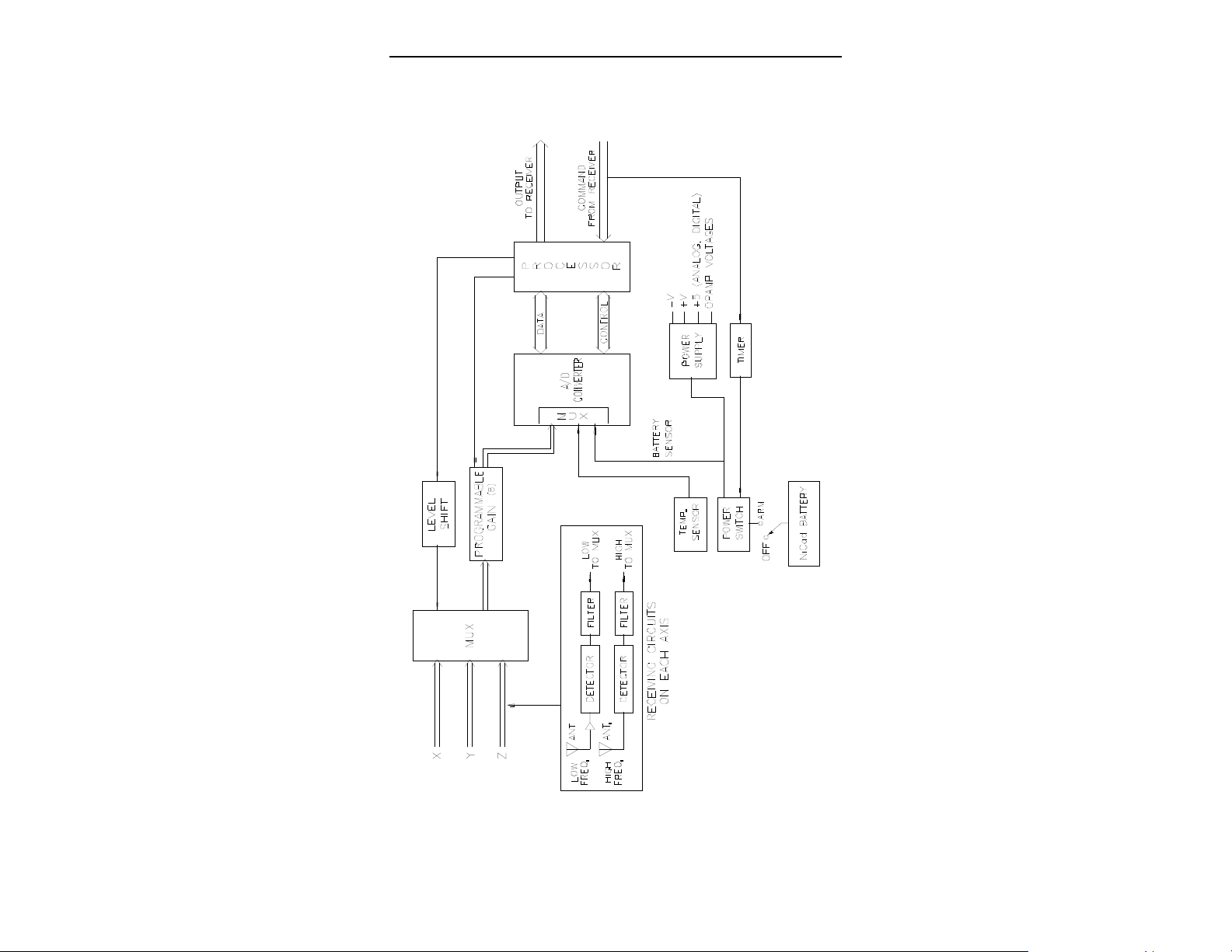

3.0 OPERATION

This section discusses the theory of operation and the functions

of the HI-4422/FP2000/FP4000/FP5000 Isotropic Electric Field

Probe. A high-level block diagram (Figure 4) is included to aid

the discussion. The objective is to provide information that

enhances the user's understanding of the design of this probe.

SYSTEM THEORY

The HI-4422/FP2000/FP4000/FP5000 Isotropic Electric Field

Probe utilizes a microprocessor for intelligent operation and

control. The probe's self-contained power supply employs a 3.6

VDC NiCd battery, which provides up to 40 hours of continuous

operation.

For each axis, the probe measures the radio frequency signal

level and generates a linearized reading of the measurement. A

vector addition is performed on these three readings: the

resultant is transmitted to the receiver over glass fiber optic

cables. The probe provides data to the readout via either a short

form or long form output word. See Appendix B for details on

both output word formats.

PROBE OPERATION

Receiver commands to the probe consist of the following:

! Send reading

! Read battery voltage

! Zero

! Set sleep timer

! Change range

! Read temperature

!Enable/disable axis

The signal flow within the probe is shown in the block diagram.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

13

Page 14

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

14

Figure 4: Probe Block Diagram

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 15

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

To measure field strength, three sets of mutually orthogonal

monopole antennas are used to provide an isotropic response to

the ambient field. The probe uses two antennas per axis—one

each for high and low frequencies—to receive RF signals. The

signals are fed to a Schottky diode detector (low frequency

signals are pre-amplified first). After filtering and amplification,

the high and low frequency signals generated by each axis (a

total of six signals) are fed into the multiplexer.

The microprocessor instructs the multiplexer to look at each of

the six axis signals sequentially. A time-division output signal

from the multiplexer is fed into the programmable gain stage.

The programmable gain stage provides the required

amplification factors for the high and low frequency signals on

each range. The system uses four ranges (10, 30, 100, and 300

V/m): each range requires both a high and low frequency gain

setting—eight amplification factors in all.

For example, assume the probe is making measurements using

the 100 V/m range. When the multiplexer selects the low

frequency X axis signal, the microprocessor directs the

programmable gain stage to use the appropriate amplification

factor for this signal. This process is repeated for the next signal

sample (X high) as well as for the four remaining axis signals.

The output of the gain stage feeds the multiplexed front end of

the analog-to-digital (A/D) converter.

After stepping through all six axis signals, the microprocessor

commands the multiplexed A/D front end to read the battery

voltage and temperature sensing lines. An entire A/D cycle,

therefore, consists of eight readings.

The eight readings from the A/D converter are input to the

microprocessor, which performs a vector sum calculation on the

X, Y and Z channels. This data is transmitted to the receiver.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

15

Page 16

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

PROBE POWER SUPPLY

A sealed rechargeable 3.6 VDC NiCd battery, which drives both

the analog and digital power supplies, powers the probe; the

HI-4422/FP2000/FP4000/FP5000 employs separate power

sources to provide isolation between the analog and digital

circuitry. With the probe switch in the ARM position, voltage

from the battery is applied to the power switch. This switch

routes the battery voltage to the power supply, enabling the

microprocessor. A timer circuit controls the power switch. The

timer monitors the fiber optic connector input line to determine

whether the probe has received a command during a specified

period (several seconds). If no command is received during this

period, the timer signals the power switch to disable the power

supply and the microprocessor. In essence, the probe goes

dormant to conserve battery power: only the fiber optic input

circuitry remains active in order to detect new commands. When

the next command from the receiver reaches the probe, power is

reapplied automatically and the processor is reactivated, "waking

up" the probe.

NOTE: The probe uses volatile random access

memory (RAM). If, for any reason, power to the

probe is lost, the probe must be re-zeroed.

ZEROING

When the receiver sends a zero command, the probe must be in

a zero field environment. This is because the zero command

causes the multiplexer (via the processor) to perform a normal

read cycle on all axis signals. This procedure is executed for all

24 ranges (four ranges, three axes per range, two antennas per

axis). When the processor receives all the zero-field signal

values, it stores them in a special register; these values are

subtracted from all subsequent measurements. Therefore, a

probe that is zeroed while it is not in a zero field environment will

give erroneous readings.

16

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 17

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

APPLICATION CONSIDERATIONS

OUT-OF-BAND CONSIDERATIONS

Although the specified operating range of the

HI-4422/FP2000/FP4000/FP5000 is from 10 kHz to 1 GHz, it

responds to signals both above and below these frequencies.

Such responses must be taken into account when performing

certain operations, such as zeroing.

On the low frequency end, the HI-4422/FP2000/FP4000/FP5000

is specified to operate down to 10 kHz; however, the probe can

exhibit some response to frequencies as low as 50/60 Hz. Such

an out-of-band response poses a problem when zeroing the unit,

since this operation obviously assumes a zero field condition.

Therefore, when zeroing, the user must compensate accordingly

for any low frequency out-of-band response.

At the upper end, similar problems can occur. The specified

upper operating limit is 1 GHz. Above this frequency, the

dimensions of the probe body itself become appreciable in

relation to wavelength: this makes the behavior of the

HI-4422/FP2000/FP4000/FP5000 unpredictable above 1 GHz.

Responses to frequencies up to 6 GHz must be compensated for

when zeroing the probe.

RESOLUTION LIMITATIONS

Limitations in system resolution may result in a non-zero reading

when the receiver is zeroed. If this occurs, it does not

necessarily mean either that there is a problem with the receiver

or that your readings are inaccurate. Probe linearity is specified

0.5 dB full scale: in addition, the variance of the probe's A/D

as +

converter is +

sensitive range (10 V/m), these specifications create the

possibility that, under zero field conditions, the receiver may

display a non-zero value.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

2 least significant bits. When using the most

17

Page 18

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

PROBE SUPPORT STRUCTURES

It is very important to keep conductive objects away from the

HI-4422/FP2000/FP4000/FP5000. Any such objects in the

proximity of the probe may distort the near field and compromise

measurement accuracy. If your application requires

measurements from a fixed position, always mount the probe on

a non-metallic platform, using non-metallic screws.

18

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 19

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

4.0 MAINTENANCE

This section explains which maintenance tasks can be

performed by the user. It also provides information regarding

replacement and optional parts. If you have any questions

concerning probe maintenance, consult ETS-Lindgren Customer

Service.

MAINTENANCE RECOMMENDATIONS

Maintenance of the HI-4422/FP2000/FP4000/FP5000 is limited

to external components such as cables or connectors.

Any calibration or maintenance task that requires probe

disassembly should be performed at the factory. Check with

ETS-Lindgren Customer Service (+1-512-531-6400) before

opening the unit to avoid problems with your probe's warranty.

NOTE: Opening the probe enclosure may void your

warranty. If your system is under warranty, contact ETSLindgren Customer Service before performing any

maintenance inside the probe.

PROBE SHIELDS

Over time, the probe shields (the white, cone-shaped structures

with the axis labels) accumulate foreign materials; in particular,

bits of dirt or metal may become embedded in the shield surface.

Shields must be kept clean to maintain proper probe operation.

NOTE: NEVER attempt to clean the shields while they

are mounted on the probe housing.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

19

Page 20

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

To clean the shields, use the following procedure:

Step 1. Remove the four nylon screws from the faceplate of the

probe shield.

Step 2. Lift the faceplate straight up and away from the

HI-4422/FP2000/FP4000/FP5000 housing. BE SURE THAT

YOU LIFT THE FACEPLATE HIGH ENOUGH TO CLEAR THE

INTERNAL ANTENNA ASSEMBLY, OR YOU MAY DAMAGE IT.

Place the probe in a protected location while performing the next

step.

NOTE: NEVER touch the antenna assembly. You may

transfer a static charge to the assembly that may distort

or disable the measuring capability in that axis.

Step 3. Clean the shield's exterior surface using a mild soap and

water solution. Rubbing alcohol is also effective, provided care

is taken to keep it away from the axis label. Wait for exterior

surface to dry completely. DO NOT clean the interior surface of

the shield.

Step 4. CAREFULLY replace the faceplate by lowering it straight

down onto the housing: again, be sure to clear the antenna

assembly when doing so.

Step 5. Replace the screws holding the faceplate. Snug them

up only: DO NOT OVERTIGHTEN THE SCREWS, OR YOU

MAY DAMAGE THE HEADS.

NOTE: If you require additional nylon faceplate screws,

you may order them from ETS-Lindgren or you may

obtain them locally. Non-conductive screws must be

used for this application. NEVER use metal screws.

The probe is now ready to be put back into operation. Repeat

this procedure for the other shields, if necessary.

UPGRADE POLICIES

Periodically, probes are upgraded to enhance functionality.

Contact ETS-Lindgren Customer Service to check on the

upgrade status of your probe(s).

20

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 21

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

RETURN PROCEDURES

To return a probe to ETS-Lindgren, use the following procedure:

Step 1. Briefly describe the problem in writing. Give details

regarding the observed symptom(s), and whether the problem is

constant or intermittent in nature. If you have talked previously

to ETS-Lindgren Customer Service about the problem, provide

the date(s), the name of the service representative you spoke

with, and the nature of the conversation. Include the serial

number of the item being returned.

Step 2. Package the probe carefully. Use the original boxes and

packing materials, if possible. If not, use the Parts List in Table 1

to order new boxes and foam packing from ETS-Lindgren.

If the probe is still under warranty, refer to the Limited Warranty

at the front of this manual for additional information about your

return.

PERIODIC/PREVENTIVE MAINTENANCE

ETS-Lindgren recommends an annual calibration check of the

HI-4422/FP2000/FP4000/FP5000 probe to verify that it is

performing within specifications. ETS-Lindgren Service

Personnel at the factory may perform this calibration check.

Return your probe(s), using the original packing materials (if

possible), to:

ETS-Lindgren

1301 Arrow Point Drive

Cedar Park, TX, USA 78613

Tel: +1 512-531-6400

Fax: +1 512-531-6500

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

21

Page 22

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

PARTS INFORMATION

Use the following tables for ordering replacement (Table 1) or

optional (Table 2) parts for the HI-4422/FP2000/

FP4000/FP5000.

Part Description (Replacement Parts) Part Number

Battery Pack, 3.6 VDC, Rechargeable H-491038

Box, Foam Insert,

4422/FP2000/FP4000/FP5000 Body H-470442

Box, Foam Insert,

4422/FP2000/FP4000/FP5000 H-470450

Box, Shipping, 4422/FP2000/FP4000/FP5000 H-390053

Standard Fast Charger (115/230 Volt) H-491198-36

Element Cover Kit H-651021

HI-4422/FP2000/FP4000/FP5000 User's

Manual H-600054

Table 1. Replacement Parts List

Part Description (Optional Parts) Part Number

Cable, Fiber Optic, Glass, 10 Meter H-490994-10

Probe Support,

HI-4422/FP2000/FP4000/FP5000 H-490984

Tripod, Dielectric,

HI-4422/FP2000/FP4000/FP5000 H-491000

Probe Stand H-491269

Graphical EMF Readout HI-4460

Numeric EMF Readout HI-4416

Field Monitor FM5004

Fiber Optic / RS232 Interface HI-4413P

Table 2: Optional Parts List

22

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 23

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

5.0 WARRANTY POLICY FOR

ELECTROMAGNETIC ISOTROPIC FIELD

MONITORING COMPONENTS

SCOPE AND DURATION OF WARRANTIES

Seller warrants to Buyer that the Holaday Brand Products to be

delivered hereunder will be (1) free from defects in material,

manufacturing workmanship, and title, and (2) conform to the

Seller’s applicable product descriptions and specifications, if any,

contained in or attached to Seller’s quotation. If no product

descriptions or specifications are contained in or attached to the

quotation, Seller’s applicable product descriptions and

specifications in effect on the date of shipment shall apply. The

criteria for all testing shall be Seller’s applicable product

specifications utilizing factory-specified calibration and test

procedures and instruments.

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited in time as shown in the table below.

Any product or part furnished to Buyer during the warranty period

to correct a warranty failure shall be warranted to the extent of

the unexpired term of the warranty applicable to the repaired or

replaced product.

The warranty period shall commence on the date the product is

delivered to Buyer; however, if Seller as sembles the product, or

provides technical direction of such assembly, the warranty

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Product Warranted

FM5004 3 Years

HI-6005 3 Years

FP-6001 3 Years

HI-4450 3 Years

FP-4080 3 Years

FP-5000 3 Years

FP-2080 3 Years

HI-4453 3 Years

FP-4083 3 Years

FP-5083 3 Years

FP-2083 3 Years

FP-5080 3 Years

FP-4000 3 Years

FP-2000 3 Years

HI-4422 3 Years

Duration of Warranty Period

23

Page 24

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

period for such product shall commence on the date the

assembly of the product is complete. Notwithstanding the

foregoing, in the event that the assembly is delayed for a total of

thirty (30) days or more from the date of delivery for any reason

or reasons for which Seller is not responsible, the warranty

period for such product may, at Seller’s options, commence on

the thirtieth (30th) day from the date such product is delivered to

Buyer. Buyer shall promptly inspect all products upon delivery.

No claims for shortages will be allowed unless shortages are

reported to Seller in writing within ten (10) days after delivery. No

other claims against Seller will be allowed unless asserted in

writing within thirty (30) days after delivery (or assembly if the

products are to be assembled by Seller) or, in the case of

alleged breach of warranty, within the applicable warranty period.

WARRANTY EXCLUSIONS

Except as set forth in any applicable patent indemnity, the

foregoing warranties are exclusive and in lieu of all other

warranties, whether written, oral, express, implied, or statutory.

EXCEPT AS EXPRESSLY STATED ABOVE, SELLER MAKES

NO WARRANTY, EXPRESS OR IMPLIED, BY STATUTE OR

OTHERWISE, WHETHER OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE OR USE OR

OTHERWISE ON THE PRODUCTS, OR ON ANY PARTS OR

LABOR FURNISHED DURING THE SALE, DELIVERY OR

SERVICING OF THE PRODUCTS. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF.

Warranty coverage does not include any defect or performanc e

deficiency (including failure to conform to product descriptions or

specifications) which results, in whole or in part, from (1)

negligent storage or handling of the product by Buyer, its

employees, agents, or contractors, (2) failure of Buyer to prepare

the site or provide an operating environmental condition in

compliance with any applicable instructions or recommendations

of Seller, (3) absence of any product, component, or accessory

recommended by Seller but omitted at Buyer’s direction, (4) any

design, specification, or instruction furnished by Buyer, its

employees, agents or contractors, (5) any alteration of the

product by persons other than Seller, (6) combining Seller’s

product with any product furnished by others, (7) combining

24

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 25

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

incompatible products of Seller, (8) interference with the radio

frequency fields due to conditions or causes outside the product

as furnished by Seller, (9) improper or extraordinary use of the

product, or failure to comply with any applicable instructions or

recommendations of Seller, or (10) acts of God, acts of civil or

military authority, fires, floods, strikes or other labor

disturbances, war, riot, or any other causes beyond the

reasonable control of Seller. This warranty does not cover

batteries or any item that is designed to be consumable. Seller

does not warranty products of others, which are not included in

Seller’s published price lists.

BUYER’S REMEDIES

If Seller determines that any product fails to meet any warranty

during the applicable warranty period, Seller shall correct any

such failure by either, at its option, repairing, adjusting, or

replacing without charge to Buyer any defective or

nonconforming product, or part or parts of the product. Seller

shall have the option to furnish either new or exchange

replacement parts or assemblies.

Warranty service during the applicable warranty period will be

performed without charge to Buyer within the contiguous 48

United States during Seller’s normal business hours. After the

warranty period, service will be performed at Seller’s prevailing

service rates. Subject to the availability of personnel, after-hours

service is available upon request at an additional charge. For

service outside the contiguous 48 United States, travel and per

diem expenses, when required, shall be the responsibility of the

Buyer, or End User, whichever is applicable.

The remedies set forth herein are conditioned upon Buyer

promptly notifying Seller within the applicable warranty period of

any defect or nonconformance and making the product available

for correction.

The preceding paragraphs set forth Buyer’s exclusive remedies

and Seller’s sole liability for claims based on failure of the

products to meet any warranty, whether the claim is in contract,

warranty, tort (including negligence and strict liability) or

otherwise, and however instituted, and, upon the expiration of

the applicable warranty period, all such liability shall terminate.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

25

Page 26

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

IN NO EVENT SHALL SELLER BE LIABLE TO BUYER FOR

ANY SPECIAL INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY KIND ARISING OUT OF, OR AS A

RESULT OF, THE SALE, DELIVERY, NON-DELIVERY,

SERVICING, ASSEMBLING, USE OR LOSS OF USE OF THE

PRODUCTS OR ANY PART THEREOF, OR FOR ANY

CHARGES OR EXPENSES OF ANY NATURE INCURRED

WITHOUT SELLER’S WRITTEN CONSENT DESPITE ANY

NEGLIGENCE ON BEHALF OF THE SELLER. IN NO EVENT

SHALL SELLER’S LIABILITIES UNDER ANY CLAIM MADE BY

BUYER EXCEED THE PURCHASE PRICE OF THE PRODUCT

IN RESPECT OF WHICH DAMAGES ARE CLAIMED. This

agreement shall be construed in accordance with laws of the

State of Illinois. In the event that any provision hereof shall

violate any applicable statute, ordinance, or rule of law, such

provision shall be ineffective to the extent of such violation

without invalidating any other provision hereof.

Any controversy or claim arising out of or relating to the sale,

delivery, nondelivery, servicing, assembling, use or loss of use of

the products or any part thereof or for any charges or expenses

in connection therewith shall be settled in Austin, Texas by

arbitration in accordance with the Rules of the American

Arbitration Association, and judgment upon the award rendered

by the Arbitrator may be entered in either the Federal District

Court for the Western District of Texas or the State District Court

in Austin, Texas, all of the parties hereto consenting to personal

jurisdiction of the venue of such court and hereby waive the right

to demand a jury trial under any of these actions.

26

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 27

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

6.0 APPENDIX A: ERROR CODES

PROBE ERROR OUTPUT

If an error occurs, the probe will respond with one of the

following strings. These strings begin with a colon and end with

a carriage return.

Code Explanation

E1 Communication error (e.g., overflow)

E2 Buffer full error. Too many characters contained

between the Start Character/ Carriage Return

sequence

E3 The received command is not valid

E4 The received parameter is not valid

E5 Hardware error (e.g., EEPROM failure)

E6 Parity error

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

27

Page 28

This page intentionally left blank.

Archived 4/2/10

Isotropic Electric Field Probe

HI-4422/FP2000/FP4000/FP5000

28

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 29

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

7.0 APPENDIX B: OPERATING

PROTOCOLS

The information in this appendix assumes that you have

purchased the optional HI-4413P Fiber Optic/RS232 Interface,

and are capable of communicating directly with the

HI-4422/FP4000/FP5000 probe.

NOTE: The FP2000 is excluded from this

section. The FP2000 Firmware is designed to

operate with the FM2000 and FM5000 only.

The following protocol information does not

apply to this product. If further information is

required, please contact ETS-Lindgren

Customer Service at +1.512.531.6400.

COMMUNICATION PROTOCOL

Data Type: RS-232 Serial

Data Mode: Asynchronous

Word Length: 7 bit

Parity: Odd

Stop Bits: 1

Data Rate: 9600 baud

INFORMATION TRANSFER PROTOCOL

The HI-4422/FP4000/FP5000 responds to commands from

another device; it transmits no data without first receiving

instructions to do so.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

29

Page 30

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

COMMAND STRUCTURE

A command to an HI-4422/FP4000/FP5000 probe consists of 1)

a command letter, followed by 2) possible parameters, 3)

terminated with a carriage return. When it completes the

command, the HI-4422/FP4000/FP5000 responds with a string

consisting of 1) a start character (":"), 2) the command letter,

followed by 3) data, if required, and terminated with 4) a carriage

return. If the command does not require the probe to return any

data, the probe simply responds with the command letter and a

carriage return. If an error occurs, the probe responds with an

error code, as detailed in Appendix A.

Command Description

Axxx

B Read battery voltage.

Cx Set baud rate.

x = 1 sets rate to 2400 baud

x = 2 sets rate to 9600 baud

Note: The baud rate does not change until the HI-4422/

FP4000/FP5000 has been powered down (turned off), let sit for at

least 10 seconds, and then powered up (turned on) again.

Dx Read probe data.

x = 1 enables short form output

x = 2 enables long form output

Rx

Sx

Axis enable/disable. x = "E" means

enable, x = "D" means disable, xxx order is

X axis, Y axis, Z axis

Set range. x = 1, 2, 3, 4 or N (next range)

Sleep timer. x = number of seconds to wait

for a command before putting the probe into

the sleep mode. In the sleep mode, the

HI-4422/FP4000/FP5000 changes to a low

power mode that increases battery life. In

the sleep mode, the probe can only

recognize the receipt of a command; it

cannot recognize a command. The first

command sent when the probe could be in a

sleep mode may be an ASCII null character

or any command. Following the receipt of

this "wakeup" character, a command can be

sent to which the probe will respond.

30

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 31

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Command Description

Tx

Ux

1 = V/m

2 = mW/cm²

3 = [V/m]²

Z Zero.

Null

NOTE: When remotely operating the probe using commands

manually entered from a computer keyboard, the HI-4422/

FP4000/FP5000 may "go to sleep" between commands. This

may be noted when the Sleep Timer is set to a short interval

such as one or two seconds. When this happens, the probe may

seem to be unresponsive to commands or may seem to skip

commands. If this condition is observed, send an S0 command

and keep sending the command as fast as possible until the

probe responds (:S) and the sleep timer is turned off. Now the

probe will respond in the proper manner.

Read Temperature. x = C or F

Set unit type. x = 1, 2, 3, or N (next unit)

Send the ASCII null character. This is a

special command that can be used as the

initial command to the probe after it is turned

on. The probe responds with "N".

PROBE OUTPUT

Command HI-4422/FP4000/FP5000/ Response

B

D1

xx.xx is the reading. The position of the

uuu = units

_V_ = V/m, mW2 = mW/cm², _V2 = [V/m]²

(underscore indicates a space character).

D2

xx.xx = the reading, as described for D1.

uuu = units, as describe for D1.

rrr = recorder out value (A 3-digit ASCII

o = over range indicator ("N" = ok, "O" =

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Bxx.xx, where xx.xx is the battery voltage.

Dxx.xxuuu, the short form output.

decimal point depends upon the range

setting of the HI-4422/FP4000/FP5000.

Dxx.xxuuurrrobaaat, the long for output

number from 0 to 255).

over range).

31

Page 32

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Command HI-4422/FP4000/FP5000/ Response

D2 (cont’d)

aaa = axis enable ("E" = enabled, "D" =

t = terminating carriage return.

Rx Rx, where x is the range.

x = "" returns the range currently in use

x = 1, 2, 3, 4 enables the selected range

x = N sets the probe to the next (higher)

TF Txxx, where xxx is temperature in E

TC Txxx, where xxx is temperature in E

b = battery status ("N"= safe operating

level, "W"= warning level, "F" = fail level).

disabled). Axis order is X, Y, Z.

range.

Fahrenheit.

Centigrade.

32

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 33

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

8.0 APPENDIX C: BATTERY CHARGER

MANUAL

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

33

Page 34

This page intentionally left blank.

Archived 4/2/10

Isotropic Electric Field Probe

HI-4422/FP2000/FP4000/FP5000

34

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 35

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Series 491198-36

NiCd Battery Fast Charger

User's Manual

Declaration of Conformity

ETS-Lindgren, L.P.

1301 Arrow Point Drive

Cedar Park, TX 78613

USA

Declares that the HOLADAY product described in this

instruction manual is in compliance with: EN EMC Directive

86/336/EEC, EN50082-1, EN55011

ETS-Lindgren, L.P.

(Formerly Holaday Industries, Inc.)

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

35

Page 36

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

36

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 37

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

ETS-Lindgren L.P. reserves the right to make changes to any

product described herein in order to improve function, design or

for any other reason. Nothing contained herein shall constitute

ETS-Lindgren L.P. assuming any liability whatsoever arising out

of the application or use of any product or circuit described

herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 2004 by ETS-Lindgren L.P. All Rights Reserved.

No part of this document may be copied by any means

without written permission from ETS-Lindgren L.P.

EMAIL & INTERNET

support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Dr., Cedar Park TX 78613 USA

P.O. Box 80589, Austin, TX 78708-0589 USA

Tel 512.531.6400

Fax 512.531.6500

FINLAND

Mekaanikontie 1, 27510, Eura, Finland

Tel 358.2.838.3300

Fax 358.2.865.1233

JAPAN

4-2-6, Kohinata

Bunkyo-ku

Tokyo 112-0006 JAPAN

Tel: +81 3 3813 7100 358.2.838.3300

Fax + 81 3 3813 8068

CHINA

1917-1918 Xue Zhixuan Building

No 16 Xue Qing Road

Haidian District

Beijing Postcode: 100083 CHINA

Tel: + 86 10 82755304

Fax: + 86 10 82755307

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

37

Page 38

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Table of Contents

8.0 Appendix C: Battery Charger Manual .......................... 33

Introduction .......................................................................................... 43

Power .................................................................................................. 45

Output .................................................................................................. 45

NiCd Battery: ....................................................................................... 45

Environmental ..................................................................................... 45

Power Cable ........................................................................................ 45

Power Cable Set Information .............................................................. 46

Input Power Requirements .................................................................. 48

Fuse Replacement .............................................................................. 48

Charging a Battery .............................................................................. 49

Charging Indicators ............................................................................. 50

38

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 39

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Revision Record

Manual #600086, Series 491198-36 NiCd Battery Fast Charger

Revision Description Date

Release 4/99

A Changed Area Code 2/00

B Updates 12/04

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

39

Page 40

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

1. General Safety Considerations

This symbol alerts the user that important

literature concerning the operation and

maintenance of this unit has been included.

Therefore, it should be read carefully in

order to avoid any problems.

This is a Safety Class I product (provided

with a protective earthing ground

incorporated in the power cord). The

mains plug shall only be inserted in a

socket outlet provided with a protective

earth contact. Any interruption of the

protective conductor, inside or outside the

instrument, is likely to make the instrument

dangerous. Intentional interruption is

prohibited. DO NOT defeat the earthgrounding protection by using an extension

cable, power cable, or autotransformer

without a protective ground conductor.

This instrument is to be used with a threewire power cord set which meets or

exceeds the requirements of EN60799.

The power cord set used must be rated for

a minimum of 250V/10A. When connected

to an appropriate power line outlet, this

cable grounds the instrument cabinet.

No operator serviceable parts exist inside

the device. Refer servicing to qualified

personnel. To prevent electrical shock, do

not remove cover.

If this instrument is used in a manner not

specified by ETS-Lindgren, the protection

provided by the instrument may be

impaired.

This battery charger incorporates parts,

such as a switch and relay that potentially

could produce sparks or arcs.

For indoor use only, do not expose to rain.

40

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 41

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

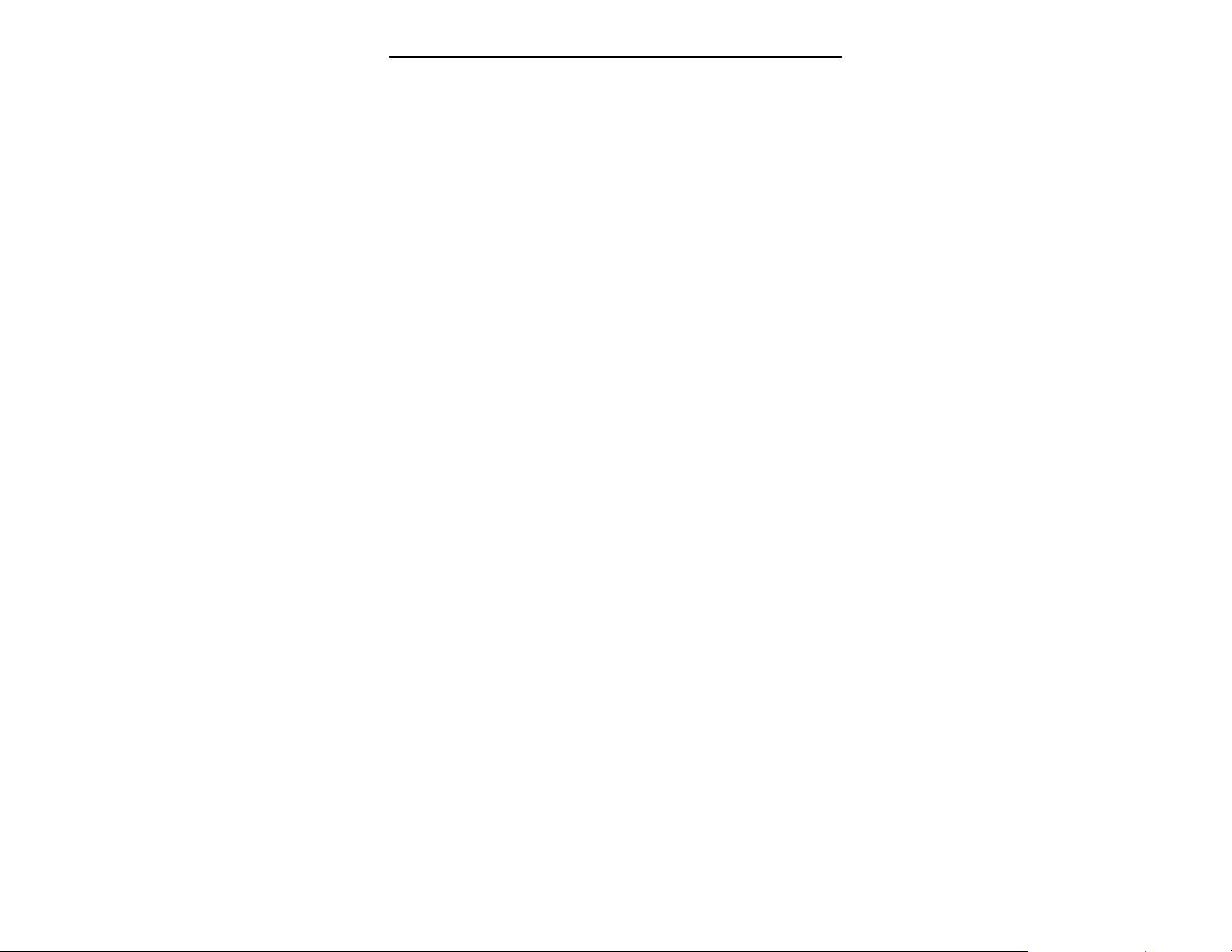

2. Description

The 491198-36 NiCd Battery Fast Charger is a dual power

source battery charger. It charges 3.6 volt 1400 mAH NiCd

batteries and is powered by 120-240 Vac line power or 12.5 Vdc.

The 491198-36 uses a -(dV)/(dT) (negative delta V) technique to

determine when the battery is fully charged, typically one hour.

With this technique, the charge state of the battery has no effect

other than shortening the charge time.

Housed in a rugged enclosure, power enters the battery charger

through a power entry module, which contains the fuses, or an

optional cigarette lighter plug adapter. LEDs and the label on the

front face of the unit provide operating status. The battery

charger connects to the device being charged through a short

cord terminated with a power jack.

An integrated circuit within the charger monitors the battery

voltage and controls the charging functions according to the

charge state of the battery.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

41

Page 42

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

42

Figure 1: 3.6V Battery Charger

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 43

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

3. Unpacking and Acceptance

Introduction

This section contains information on unpacking and acceptance

of the 491198-36 NiCd Battery Fast Charger.

Step 1. Upon delivery of your order, inspect the shipping

container(s) for evidence of damage. Record any damage on

the delivery receipt before signing. In case of concealed

damage or loss, retain the packing materials for inspection by

the carrier.

Step 2. Remove the product from its shipping container. Save

boxes and any protective packing materials for future use.

Step 3. Check all materials against the packing list to verify that

the equipment received matches that which was ordered. If you

find any discrepancies, note them and call ETS-Lindgren

Customer Service for further instructions.

Be sure that you are satisfied with the contents of your order and

the condition of your equipment before

using it.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

43

Page 44

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

44

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 45

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

4. Specifications

Power

Main: IEC filtered AC power input module

110 - 240 Vac, 500 mA MAX., 50 - 100 Hz

Alternate: Automobile cigarette lighter to 2mm power plug

adapter cord., 12.5 Vdc, 100 mA

Fuses: 250 Volt, 1.0 Amp, Type T (5 mm x 20 mm)

Output

Open Circuit Voltage: 15 Vdc

Fast Charge Pending Current: 60 mA

Fast Charge Current: 1400 mA

Pulsed Trickle Charge Current: 50 mA

Output Voltage (During Fast Charge): 3 - 6 Vdc

NiCd Battery:

3.6 Volt 3 Cell NiCd Battery, 1400 mAH (Rapid charge cells, 1.2

volts/cell); ETS-Lindgren Part #491038

Environmental

Operating temperature 10 to 40{ C

Humidity: 5% to 95% relative humidity,

non-condensing

Power Cable

This charger is shipped with a three-wire power cable. When

this cable is connected to an appropriate AC power source, it

connects the chassis to earth ground. The type of power cable

shipped with each battery charger depends on the country of

destination.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

45

Page 46

HI-4422/FP2000/FP4000/FP5000

Archived 4/2/10

Power Cable Set Information

Isotropic Electric Field Probe

ETS-

Lindgren

Part No.

2217500 Volex #17500

Type SVT, Foil shielded, PVC Jacketed, 60°C

Molded PVC Grounding Plug NEMA 5-15P UC-004

Molded PVC Receptacle IEC320/C13 UC-005

18 Ga. 3 Cond. 10A-125V

2217506C Volex #17506

Type SVT, Foil shielded, PVC Jacketed, 60°C

Molded PVC Grounding Plug NEMA 5-15P UC-004

Molded PVC Right-Angle Receptacle

IEC320/C13 UC-006

18 Ga. 3 Cond. 10A-125V

Countries: Canada, Japan, Puerto Rico, Taiwan,

Venezuela, Hong Kong, United States

221100 Kobiconn #173-7001

Type H05VV-F, PVC Jacketed, 70°C

Molded PVC Right-Angle Grounding Plug CEE 7/7 UC814

Molded PVC Receptacle IEC320/C13 UC-051

1.0mm2 3 Cond. 10A-250V

Countries: Argentina, Austria, Brazil, Finland, France,

Germany, Israel, Italy, Holland, Korea, Netherlands,

Norway, Sweden, Turkey

222600 QualTek #370001-E01

Type H05VV-F, PVC Jacketed, 70°C, Harmonized

Molded PVC Grounding Plug BS 1363, Fused UC-851

Molded PVC Receptacle IEC320/C13 UC-852

1.0mm2 3 Cond. 10A-250V

Countries: England, Ireland, Malaysia, Scotland,

Singapore, South Africa, Wales

221600 Leeds Electronic Components #FFBS-1310

Type SAA, Ordinary Duty, PVC Jacketed, 75°C

Molded Grounding Plug AS3112 UC-822

Molded PVC Receptacle IEC320/C13 UC-051

1.0mm2 3 Cond. 10A-250V

Countries: Australia, China

46

Manufacturer, Part No. and Information

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 47

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

ETS-

Lindgren

Part No.

221500

Volex #2102H-C3-10

Type H05VV-F, PVC Jacketed, 70°C

Molded PVC Grounding Plug SEV 1011 UC-841

Molded PVC Receptacle IEC320/C13 UC-051

1.0mm2 3 Cond. 10A-250V

Country: Switzerland

Manufacturer, Part No. and Information

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

47

Page 48

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

5. OPERATING INSTRUCTIONS

The 491198-36 battery charger is intended to charge the 3.6 volt

NiCd batteries, either in the lab or in the field.

Input Power Requirements

The 491198-36 charger may be powered by standard line

voltage (110 - 240 Vac, 50 - 60 Hz) or by an optional automobile

cigarette lighter plug (12.5 Vdc), see specifications. The AC

power entry module contains a fuse.

Fuse Replacement

If a fuse has blown, it must be replaced with the same type and

value or an unsafe condition may result. Refer to Figure 2 for

fuse replacement.

The fuse is contained in the fuse drawer in the power input

module. To access the fuse, use a screwdriver to pry the drawer

open and remove it from the module. The drawer holds two

fuses; the fuse towards the outside of the drawer is a spare.

After the fuse has been replaced, slide the fuse drawer back into

the module. Make sure that it snaps securely into its locked

position.

NEVER attempt to change the fuse with

the battery charger plugged in.

48

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 49

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Figure 2: Fuse Replacement

Charging a Battery

After connecting the battery charger to a proper power source,

the battery charger simply plugs into the charger jack on the HI-

6005. The HI-6005 must be turned off or the battery will not

charge.

NEVER attempt to recharge a non-

rechargeable battery.

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

49

Page 50

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

Charging Indicators

There are five LEDs located on the front of the charger that

provide operating information to the user.

The “POWER ON” LED (green) will remain illuminated as long

as the charger is plugged into the AC power source.

If the charger does not detect a battery, the “NO BATTERY” LED

(amber) light will illuminate.

When the charger does detect the unit’s battery, the “PENDING”

LED (amber) light illuminates while the charger qualifies the

battery for fast charge. If the voltage is below the safe fast

charge level, the battery is charged in the pulse trickle mode.

When the voltage is at a safe level the charger will switch to the

fast charge mode and the “CHARGING” LED (amber) light

illuminates.

When charging is complete, the charger switches back to the

pulse trickle mode and the “COMPLETE” LED (green) light will

illuminate. The device can be left on the charger in this

maintenance mode indefinitely.

50

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Page 51

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

51

Page 52

Isotropic Electric Field Probe

Archived 4/2/10

HI-4422/FP2000/FP4000/FP5000

6. MAINTENANCE

Electronic instruments are delicate. Operate the battery charger

with care.

User serviceable parts do not exist inside the battery charger.

Warranty may be void if the battery charger housing is opened.

If the battery charger fails to operate, check for a blown fuse

inside the power entry module (refer to figure 2).

NEVER attempt to change the fuse with

the battery charger plugged in.

If a fuse is blown it must be replaced. Be sure to use only 250

Volt, 1.0 Amp, Type T (5 mm x 20 mm).

If the battery charger still fails to operate, or if you have any

questions concerning charging your products, contact ETSLindgren Customer Service.

52

© ETS-LINDGREN L.P. – July, 2005

Revision G- Part # H-600054

Loading...

Loading...