Page 1

Archived 10/19/10

FM5004

Field Monitor

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

Archived 10/19/10

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 1994–2009 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren L.P.

Revision Record | FM5004 MANUAL | Part #H-600069, Rev. B

Revision Description Date

Initial Release January, 1994

A Updates / edits April, 2005

B Rebrand April, 2009

ii |

Page 3

Table of Contents

Archived 10/19/10

Notes, Cautions, and Warnings ............................................... ix

General Safety Considerations ................................................ x

1.0 Introduction ........................................................................ 11

Theory of Operation ..................................................................................... 12

System Theory ..................................................................................... 12

System Block Diagram ................................................................ 13

Receiver Theory .................................................................................. 14

Receiver Block Diagram .............................................................. 15

Zeroing ................................................................................................. 16

ETS-Lindgren Product Information Bulletin ................................................. 16

2.0 Maintenance ....................................................................... 17

Maintenance Recommendations ................................................................. 17

Weekly ................................................................................................. 17

Monthly ................................................................................................ 17

Annual Calibration ....................................................................................... 18

Maintenance of Fiber Optics ........................................................................ 18

Service Procedures ..................................................................................... 18

3.0 Before You Begin ............................................................... 19

Verify FM5004 Operation ............................................................................. 19

Verify Optional Connections ........................................................................ 20

Remote Operation ............................................................................... 20

Analog Output ...................................................................................... 21

4.0 Quick Start .......................................................................... 23

5.0 Front Panel Controls and Indicators ................................ 25

Power Switch ............................................................................................... 25

Input Selection Matrix .................................................................................. 26

Base Mode Switches ........................................................................... 26

Channel Select Switches ..................................................................... 27

Channel Mode Indicators ..................................................................... 28

System Status .............................................................................................. 29

Range (Alt Disp) .................................................................................. 29

Battery (Temp) ..................................................................................... 30

| iii

Page 4

Local (Reset) ....................................................................................... 31

Archived 10/19/10

(Shift) ................................................................................................... 31

Display ......................................................................................................... 31

Menu Select ................................................................................................. 32

Using the Menu Keys ........................................................................... 32

Navigating the Menu System ............................................................... 32

Changing Settings ............................................................................... 33

Exiting the Menu System ..................................................................... 33

6.0 Menu System ...................................................................... 35

MAIN MENU ................................................................................................ 35

DISPLAY SETUP ......................................................................................... 36

DISPLAY FORMAT / ALT DISPLAY FORMAT ................................... 37

4-PROBE ..................................................................................... 38

2-LINE ......................................................................................... 38

3-AXIS ......................................................................................... 40

DISPLAY UPDATE RATE ................................................................... 41

LCD CONTRAST ................................................................................. 41

LCD BRIGHTNESS ............................................................................. 41

ANALOG OUT SETUP ................................................................................ 42

FULL SCALE RANGE ......................................................................... 43

MIN/MAX/AVG ..................................................................................... 44

FILTER SIZE ....................................................................................... 45

LOG SCALE OUTPUT ......................................................................... 45

REMOTE OPER SETUP ............................................................................. 46

ALARM SETUP ........................................................................................... 47

4-PROBE / 3-AXIS ALARM SETUP .................................................... 48

LINE 1 ALARM / LINE 2 ALARM ......................................................... 49

TEMP ALARM SETUP ........................................................................ 50

SYSTEM ALARM ................................................................................. 52

SETUP SAVE/RECALL ............................................................................... 53

ZERO PROBES ........................................................................................... 54

MAINTENANCE ........................................................................................... 54

LAST ERRORS ................................................................................... 54

SYSTEM STATUS ............................................................................... 55

SAMPLES/SEC ................................................................................... 55

KEY CLICK .......................................................................................... 55

iv |

Page 5

ALARM SILENCE ................................................................................ 55

Archived 10/19/10

7.0 Remote Operation .............................................................. 57

Command Set Format ................................................................................. 57

IEEE-488 ..................................................................................................... 57

IEEE-488 Requirements ...................................................................... 57

IEEE-488 (GPIB) Communications...................................................... 58

RS-232 ......................................................................................................... 58

RS-232 Communications ..................................................................... 58

RS-232 Settings ................................................................................... 59

RS-232 Pin Detail ................................................................................ 59

Remote Commands ..................................................................................... 60

Alarm Latch .......................................................................................... 62

Alarm Silence ....................................................................................... 63

Alternate Display Format ..................................................................... 64

Alarm Lower Enable ............................................................................ 66

Alarm Lower Value .............................................................................. 67

Alarm Upper Enable ............................................................................ 68

Alarm Upper Value .............................................................................. 69

Analog Output Mode ............................................................................ 70

Analog Output Range .......................................................................... 71

Baud Rate ............................................................................................ 72

Buss Voltage ........................................................................................ 73

Change Range ..................................................................................... 74

Display Format ..................................................................................... 75

Display Update Rate ............................................................................ 77

Error Register Query ............................................................................ 78

Filter Size ............................................................................................. 79

GPIB Address ...................................................................................... 80

Key Click .............................................................................................. 80

Last Errors ........................................................................................... 81

LCD Brightness .................................................................................... 81

LCD Contrast ....................................................................................... 82

LED Setup ........................................................................................... 83

Local Mode .......................................................................................... 84

Log Scale ............................................................................................. 84

Read Display ....................................................................................... 85

| v

Page 6

Read Battery Voltages ......................................................................... 86

Archived 10/19/10

Read Temperatures ............................................................................. 87

Remote Mode ...................................................................................... 88

Sample Rate ........................................................................................ 89

Setup Recall ........................................................................................ 90

Setup Save .......................................................................................... 91

System Alarm, Hard Probe Failure ...................................................... 92

System Alarm, Momentary Probe Failure ............................................ 93

Software Date ...................................................................................... 93

Software Revision ................................................................................ 94

Verbose Mode ..................................................................................... 94

Zero Probes ......................................................................................... 95

System Level Commands for IEEE-488.2 Compliance ............................... 96

Clear Status ......................................................................................... 96

Define Device Trigger .......................................................................... 97

Event Status Enable ............................................................................ 98

Error Status Register Query ................................................................ 98

Identification Query .............................................................................. 99

Operation Complete ........................................................................... 100

Reset ................................................................................................. 101

Self-Test ............................................................................................ 101

Service Request Enable .................................................................... 102

Status Byte Query .............................................................................. 103

Trigger ............................................................................................... 104

8.0 Troubleshooting and Error Handling ............................. 105

Troubleshooting ......................................................................................... 105

Error Handling ............................................................................................ 106

Error Code A: Alarm L1 Up Line 1 Upper Alarm ................................ 106

Error Code B: Alarm L1 Line 1 Lower Alarm ..................................... 106

Error Code C: Alarm L2 Up—Line 2 Upper Alarm ............................. 106

Error Code D: Alarm L2 Lo—Line 2 Lower Alarm ............................. 106

Error Code E: Probe Err Probe Returned Error ................................. 106

Error Code F: Batt Fail At Fail Level .................................................. 107

Error Code G: Double Flt–Receive–Probe Reset .............................. 107

Error Code H: Probe Fail–Probe Did Not Recover ............................ 107

Error Code L: Temp Lower–Temp Under Lower Limits ..................... 107

vi |

Page 7

Error Code N: Non Support–Probe Not Supported ........................... 107

Archived 10/19/10

Error Code O: Over Range Error ....................................................... 107

Error Code P: Process Err No Time to Process Data ........................ 107

Error Code Q: Sample/s–1 Process Err–Rate Too High ................... 108

Error Code R: Receive Err Data Not Rec From Probe ...................... 108

Error Code S: Send Error Probe Not Ready to Send ........................ 108

Error Code U: Temp Upper Temp Over Upper Limits ....................... 108

Error Code W: Batt Warn At Warning Level ...................................... 108

Error Code Y: Alarm Upper 4/3 Display Alarm .................................. 108

Error Code Z: Alarm Lower 4/3 Display Alarm................................... 108

Appendix A: Warranty ........................................................... 109

Appendix B: Summary List of Commands .......................... 111

IEEE-488.2 Commands ............................................................................. 111

No Parameter Commands ......................................................................... 112

One Parameter Commands ....................................................................... 113

Two Parameter Commands ....................................................................... 114

Three Parameter Commands .................................................................... 114

Appendix C: EC Declaration of Conformity ........................ 115

| vii

Page 8

This page intentionally left blank.

Archived 10/19/10

viii |

Page 9

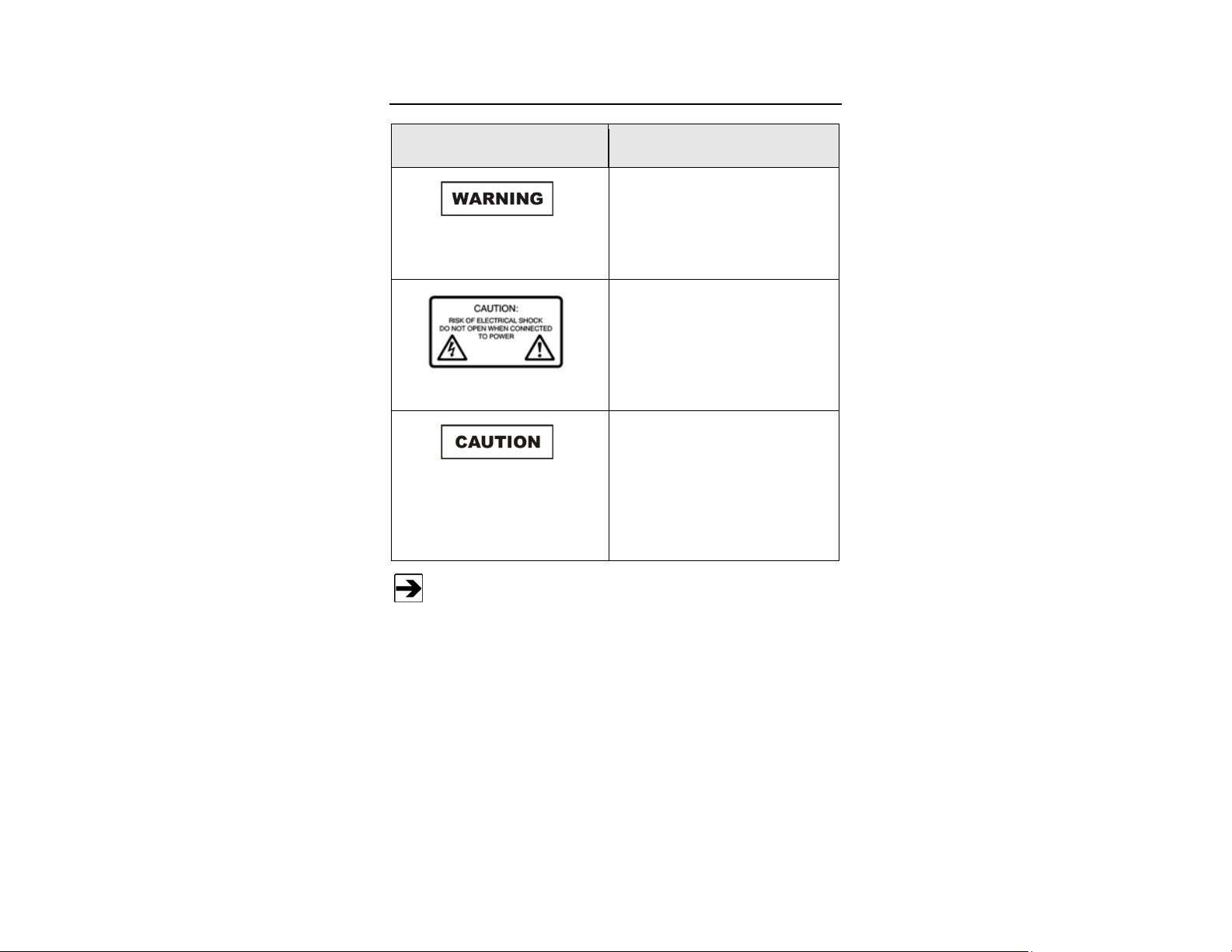

Notes, Cautions, and Warnings

Archived 10/19/10

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

| ix

Page 10

General Safety Considerations

Archived 10/19/10

Safety Symbol Definition

Warning: No operator serviceable

parts exist inside. Refer servicing to

qualified personnel. To prevent

electrical shock, do not remove

covers.

Caution: Uninsulated voltage within

the unit may have sufficient

magnitude to cause electric shock.

Therefore, it is dangerous to make

any kind of contact with any parts

inside this unit.

Caution: This instrument is shipped

with a three-wire power cable, in

accordance with international safety

standards. When connected to an

appropriate power line outlet, this

cable grounds the instrument

cabinet.

x |

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

Page 11

Archived 10/19/10

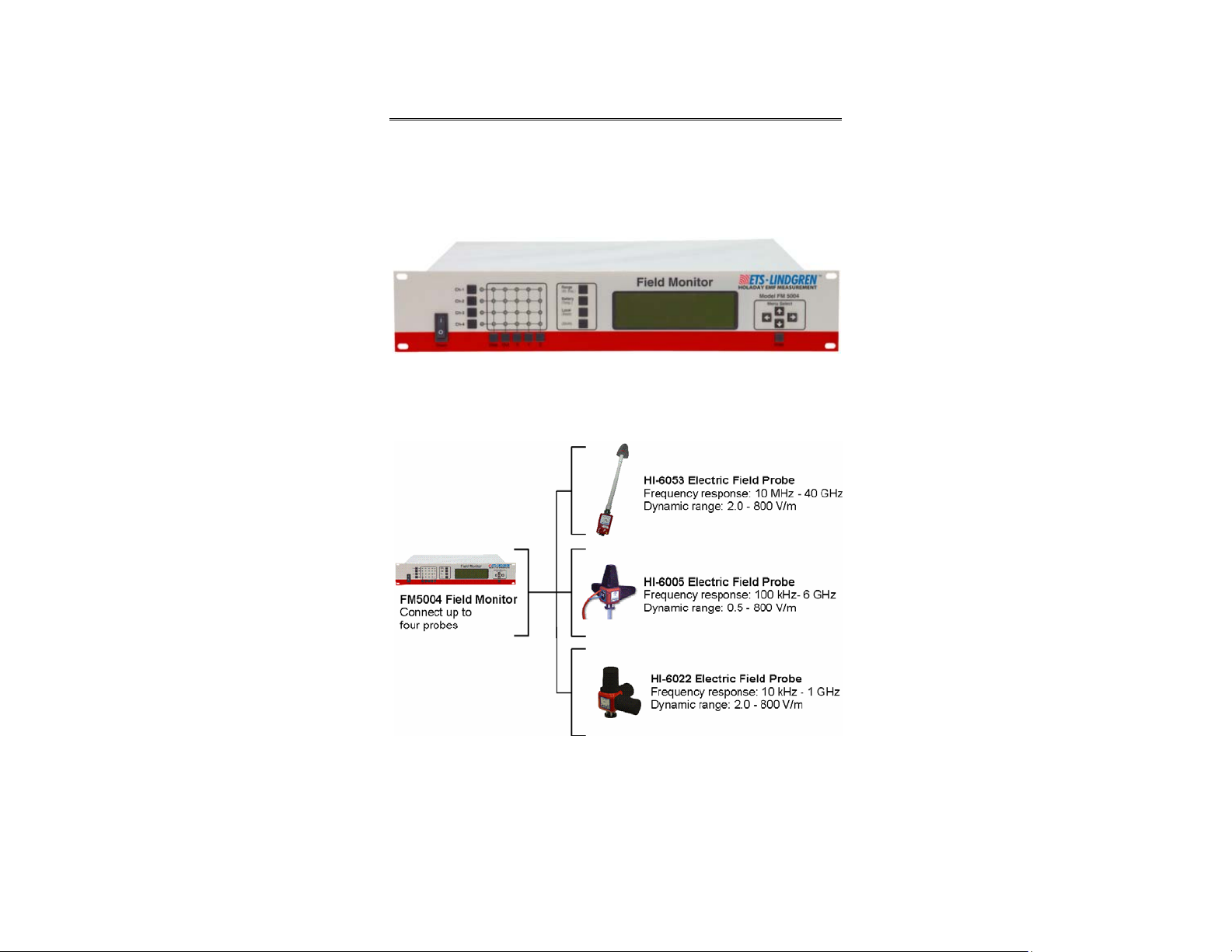

1.0 Introduction

The ETS-Lindgren FM5004 Field Monitor is a broadband electric and magnetic

field monitor designed for use in radio frequency interference and

electromagnetic compatibility (RFI/EMC) test system applications.

The FM5004 is compatible with the following ETS-Lindgren E (electric) field or

H (magnetic) battery-operated field probes.

The FM5004 accepts inputs from up to any four probes, and analyzes and

displays information on a user configurable LCD display.

Introduction | 11

Page 12

Archived 10/19/10

The FM5004 provides two digital interfaces (IEEE-488 and RS-232), a switch

selectable 0–5 VDC analog output, and audible user selected field strength,

temperature, and low probe battery alarms. It has a probe dependent frequency

response of 10 kHz–40 GHz and a sensitivity of 0.5 V/m–3000 V/m,

15.0 mA/m–30 A/m (probe dependent).

Theory of Operation

For information about a specific probe, see the probe manual.

SYSTEM THEORY

A complete FM5004 system consists of one to four field measurement probes

coupled to the FM5004 through fiber optic cables, and optional external devices.

The FM5004 contains fiber optic I/O cards to communicate with the probes, a

main processor board, an LCD to display data and system status, a keypad for

operator control, and an audible alarm to indicate field strengths above or below

a user-defined value. RS-232 and IEEE-488 ports are provided for remote

system operation and data collection, and an analog output port is provided for

leveling purposes.

The probes and I/O cards use microprocessors to provide intelligent control and

operation of the system. Each has a self-contained power supply: a universal

input 110–230 VAC supply for the FM5004, and rechargeable battery packs for

the probes.

When a field strength reading is requested by the FM5004, the I/O card for that

probe sends the appropriate command to the probe through the fiber optic cable.

The probe measures the signal level for each enabled axis, a vector addition is

performed on these readings, and then the result is transmitted to the I/O card

through the fiber optic cables. The I/O card formats the data from the probe and

routes it to the main FM5004 processor for interpretation, display, and

transmission to a remote recorder (if desired).

12 | Introduction

Page 13

Archived 10/19/10

SYSTEM BLOCK DIAGRAM

Introduction | 13

Page 14

Archived 10/19/10

Following are other commands performed by the probes; depending on the

specific probe, additional commands may be available.

• Zero

• Switch range

• Enable/disable axis

• Send temperature/battery voltage

When a probe receives a command from the I/O card it performs the requested

function and sends a response back to the FM5004.

RECEIVER THEORY

The FM5004 issues commands to the I/O cards, then the I/O card issues control

signals to the probe processor. It also receives the data from the probe, formats

it, and relays it to the FM5004 main processor.

The sampling rate, range settings, autorange enable/disable, display format, and

other setup parameters are stored in Electrically Erasable Programmable

Read-Only Memory (EEPROM). The setups are automatically restored each time

the FM5004 is powered on. Flash EEPROM memory is used to store the main

program. Random Access Memory (RAM) is used to temporarily store

measurements and settings.

Inputs to the FM5004 come from the keypad switches on the front panel or from

a remote control device connected through the IEEE-488 or RS-232 ports.

Information from the probes is communicated through the front panel LEDs and

display. Optional receiver outputs include:

• Output to a remote receiver through the IEEE-488 or RS-232 ports

• Analog output (with 12-bit resolution) to recorders or leveling circuitry

• Programmable alarm values for driving a relay that controls a remote

alarm

The FM5004 power supply operates from a 115–230 VAC power source. The

supply provides outputs of +5 VDC, -12 VDC, and +12 VDC.

14 | Introduction

Page 15

Archived 10/19/10

RECEIVER BLOCK DIAGRAM

Introduction | 15

Page 16

Archived 10/19/10

ZEROING

Not all probes have a zero function. For information on zeroing a

probe, see the probe manual.

When a probe receives a zero command from the FM5004, the probe must be in

a zero field. The processor directs the multiplexer to perform a normal read cycle

on all axis signals; this procedure is executed for all 24 settings (four ranges,

three axes per range, two antennas per axis). When the processor receives

these readings, it stores them in a special register, and then these values are

subtracted from all subsequent measurements. Therefore, a probe that is zeroed

when it is not in a zero field environment will give erroneous readings.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

16 | Introduction

Page 17

Archived 10/19/10

2.0 Maintenance

Before performing any maintenance, follow

the safety information in the ETS-Lindgren

Product Information Bulletin included with

your shipment.

WARRANTY

Maintenance of the FM5004 is limited to

external components such as cables or

connectors.

Warranty may be void if the housing is

opened.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

Maintenance Recommendations

W

EEKLY

• Check battery status using front panel switch or remote command.

M

ONTHLY

• Clean contaminants from the front panel with a damp cloth. Always

unplug the unit before cleaning.

• Disconnect fiber optic cables and verify they are clean. See

Maintenance of Fiber Optics on page 18 for cleaning guidelines.

• Inspect cables for kinks, breaks, cracks, and loose connectors.

Maintenance | 17

Page 18

Archived 10/19/10

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Maintenance of Fiber Optics

Fiber optic connectors and cables can be damaged from airborne particles,

humidity and moisture, oils from the human body, and debris from the connectors

they plug into. Always handle connectors and cables with care, using the

following guidelines.

Before performing any maintenance, disconnect

the fiber optic cables from the unit and turn off

power.

When disconnecting fiber optic cables, apply the

included dust caps to the ends to maintain their

integrity.

Before connecting fiber optic cables, clean the

connector tips and in-line connectors.

Before attaching in-line connectors, clean them

with moisture-free compressed air.

Failure to perform these tasks may result in

damage to the fiber optic connectors or cables.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

18 | Maintenance

Page 19

Archived 10/19/10

3.0 Before You Begin

Before connecting any components or placing

into operation, follow the safety information in

the ETS-Lindgren Product Information Bulletin

included with your shipment.

Perform all steps in this section before powering on the FM5004 Field Monitor or

installing it in a test environment.

Verify FM5004 Operation

1. Make sure the probes are fully charged. See the probe manual for

charging information.

2. Remove the protective covers from the fiber optic cable. Inspect the

tips of the cable to verify they are free from dirt and other

contaminants.

Save all protective caps and covers for re-use.

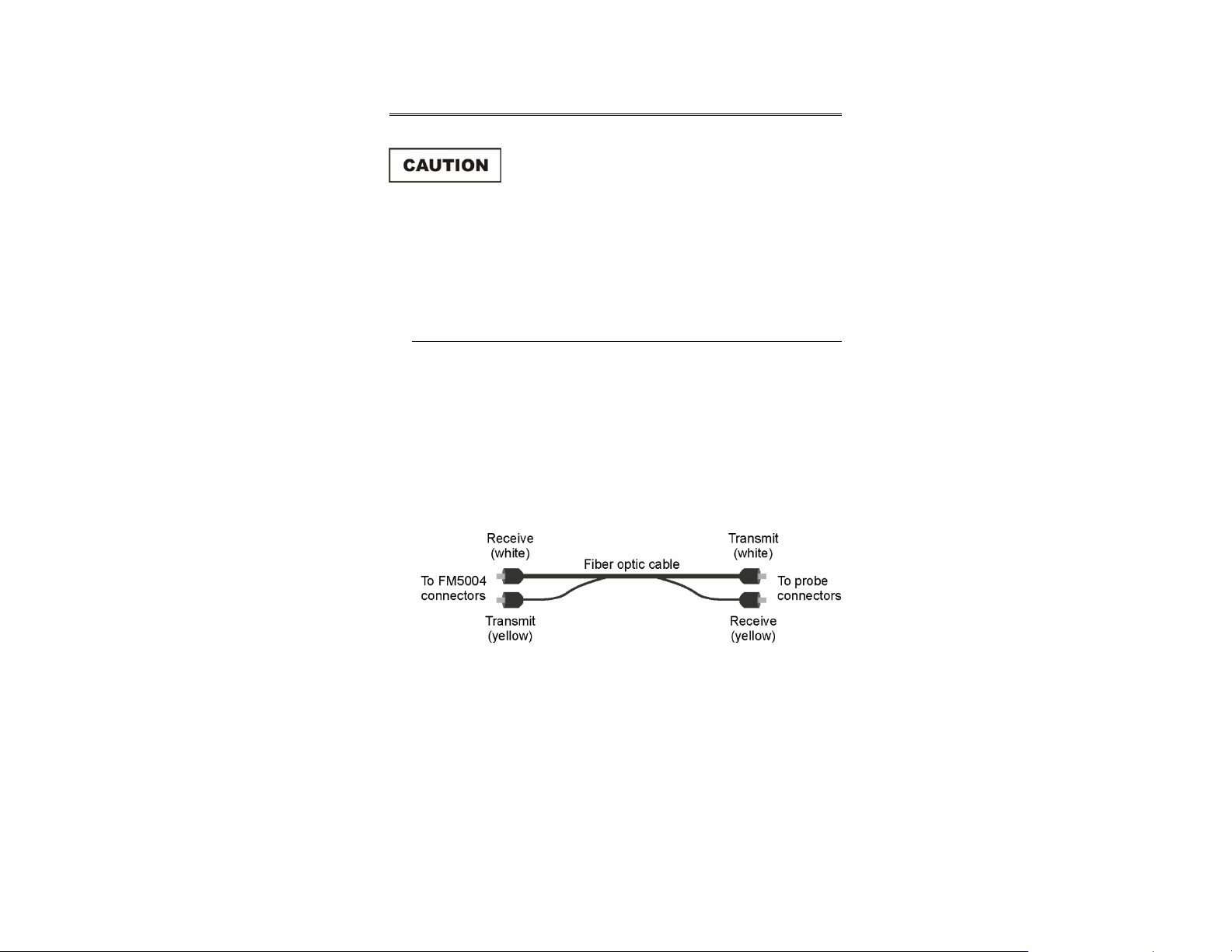

3. Attach the fiber optic cable to the transmit and receive connectors on

the back of the FM5004, matching yellow to transmit and white to

receive.

4. Attach the other end of the fiber optic cable to the probe connectors,

matching white to transmit and yellow to receive.

5. Plug the power cord into the power connector on the back of the

FM5004.

6. Plug the other end of the power cord into an electrical outlet.

Before You Begin | 19

Page 20

Archived 10/19/10

7. Set the ARM/OFF switch on all probes to ARM.

8. Power on the FM5004. A tone will sound, and it will perform a self-test.

If an error occurs, see Troubleshooting and Error Handling on

page 105.

Verify Optional Connections

If optional connections are part of your system configuration, perform a

bench test prior to installing the FM5004.

REMOTE OPERATION

1. Connect the RS-232 or IEEE-488 cable to the appropriate connector.

• If RS-232 remote control is used—See Baud Rate on page 72 for

information on setting the device baud rate.

• If IEEE-488 remote control is used—Set the DEVICE ADDRESS to

the appropriate bus address for your installation. See IEEE-488

Requirements on page 57 for more information.

2. Send an identification query (*IDN?<LF>) from the remote controller;

verify that the FM5004 returns the proper response. See Identification

Query on page 99 for more information.

20 | Before You Begin

Page 21

Archived 10/19/10

ANALOG OUTPUT

1. Connect the appropriate cable to the Analog Out connector on the

back of the FM5004.

2. Enable the analog output system and verify proper operation. See

ANALOG OUT SETUP on page 42 for information on setting up the

analog output system.

Before You Begin | 21

Page 22

Archived 10/19/10

This page intentionally left blank.

22 | Before You Begin

Page 23

Archived 10/19/10

4.0 Quick Start

Before placing into operation, follow the safety

information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

Before operating the FM5004, complete the steps in Before You Begin

on page 25.

Following are the basic steps to configure and operate the FM5004 Field Monitor.

To save time and improve accuracy during configuration, before you start the

following steps identify the modes and configurations you want for each channel

See Front Panel Controls and Indicators on page 25 for complete

information on using the switches, buttons, and other controls located

on the front of the FM5004.

1. Set the ARM/OFF switch on all probes to ARM.

2. Press on the FM5004.

3. Verify no error codes appear on the FM5004 display and that there are

no fault indications. If an error code appears or a fault is indicated, see

Troubleshooting and Error Handling on page 105.

4. Select the channel to which a probe is connected by pressing the

channel select switch for that channel, and then press Disp.

Select the desired axes and whether the data is for display or for

analog output.

5. If more than one probe is attached, repeat step 4 for each channel.

The configuration is saved in non-volatile memory. It will remain stored unless

altered, regardless of whether the FM5004 is powered on.

Quick Start | 23

Page 24

Archived 10/19/10

This page intentionally left blank.

24 | Quick Start

Page 25

Archived 10/19/10

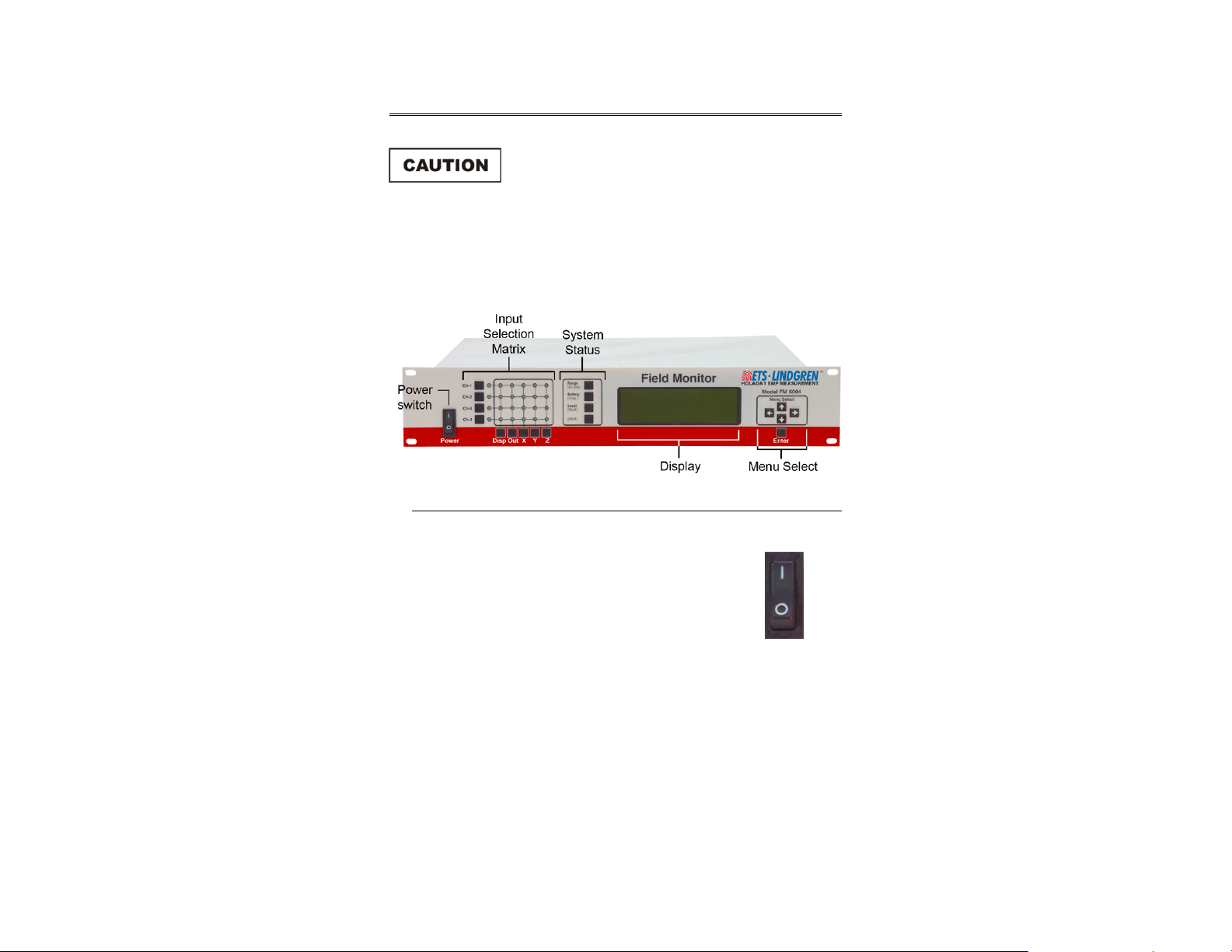

5.0 Front Panel Controls and Indicators

Before connecting any components or placing

into operation, follow the safety information in

the ETS-Lindgren Product Information Bulletin

included with your shipment.

The front panel of the FM5004 Field Monitor is divided into five sections:

Power switch, Input Selection Matrix, System Status, Display, and Menu Select.

Power Switch

When power is turned on to the FM5004, it initiates a

self-test.

The power switch controls power only to the FM5004, and

does not affect power to the probes.

Front Panel Controls and Indicators | 25

Page 26

Archived 10/19/10

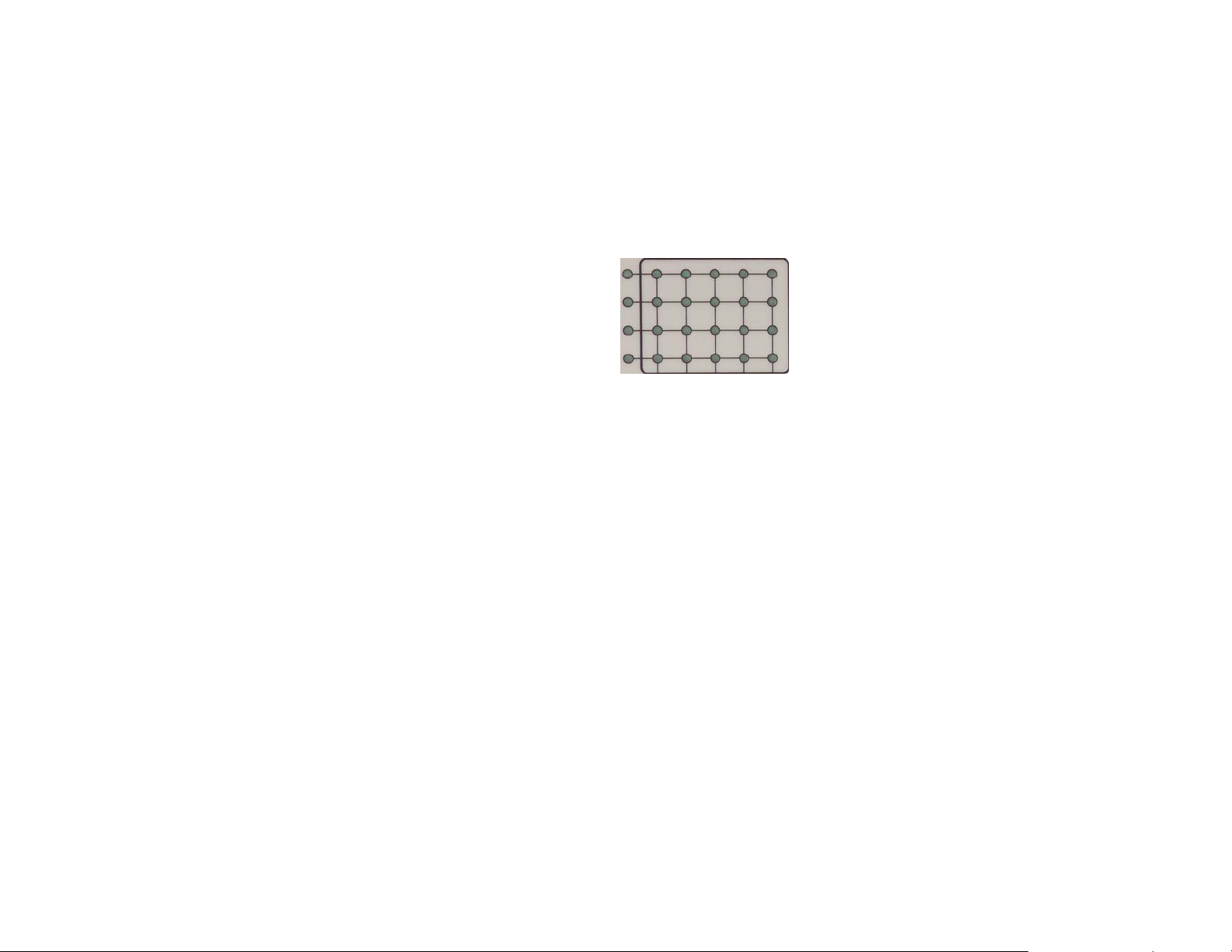

Input Selection Matrix

The Input Selection Matrix

includes Channel Select

Switches, Base Mode

Switches, and Channel Mode

Indicators.

BASE MODE SWITCHES

The Base Mode Switches

include Disp, Out, X, Y,

and Z.

These switches are used to

define the FM5004 base

operating mode for the

selected channel.

The base mode switches select a probe axis (or axes) for display and/or analog

output. The input data for the assigned channel may be displayed on the

Channel Mode Indicators and/or may be routed to analog output. The base mode

selections for a given channel remain active until readjusted.

26 | Front Panel Controls and Indicators

Page 27

Archived 10/19/10

Switch Description

Disp When this LED is illuminated for a selected channel, that channel

is display selected, meaning that the readings from this probe will

be routed to the display. The FM5004 displays the channel input

as a numeric value. To set display mode parameters, use

Menu Select. See Menu Select on page 32 for more information.

Out When this LED is illuminated for a selected channel, that channel

is analog output selected; meaning that the readings from this

probe will be routed to the analog output system. See ANALOG

OUT SETUP on page 42.

X, Y, Z This activates a particular axis on selected channel(s) for display

or analog output. Any combination of axes may be chosen;

isotropic response requires selecting all three axes. When multiple

axes are selected, individual axes are combined vectorially.

Some probes do not allow an individual axis to be disabled.

CHANNEL SELECT SWITCHES

The Channel Select Switches

include Ch-1, Ch-2, Ch-3,

and Ch-4.

These switches are used to

select the input channel.

These switches determine the channel for which the base mode settings apply. A

different base mode may be set up for each channel.

Front Panel Controls and Indicators | 27

Page 28

Archived 10/19/10

When a channel select switch is pressed, the FM5004 establishes

communication with the probe. During this process the base mode (Disp or Out)

LED for that channel will flash. When the connection is established, the LED

lights continuously. If the FM5004 fails to make connection with the probe, the

LED will go dark.

CHANNEL MODE INDICATORS

These 24 LEDs form a matrix

that signify the current

channel and base mode

selections. Following are

examples that illustrate the

correspondence between the

LEDs and the base mode

selections.

Example 1–Single Probe Configuration

1. Press channel select switch Ch-1 to select the probe attached to

channel 1.

2. Press base mode switches X ,Y, and Z to provide isotropic response.

3. Press Disp to display the numeric value of the vectorially-combined

axis values.

4. All LEDs in the top row of the matrix are illuminated, except for the

second from the left.

All other LEDs are dark.

Example 2–Dual Probe Configuration

1. Press channel select switch Ch-1 to select the probe attached to

channel 1.

2. Press Ch-2 to select the probe attached to channel 2.

3. Press base mode switches X and Y to gather the data from only those

two axes.

4. Press Out to provide the vectorially-combined value of X and Y

reading as an analog output.

28 | Front Panel Controls and Indicators

Page 29

Archived 10/19/10

5. For channel 1, all LEDs in the top row are illuminated, except for the

second from the left.

For channel 2, the middle three LEDs in the second row from the top

are illuminated.

All other LEDs are dark.

System Status

The System Status selections

provide one-button access to

all selected probes for range

and battery as well as

enabling local control.

These buttons use Shift for

additional functionality:

alternate display,

temperature, and reset.

To perform a function on a selected probe, press the channel select switch for

the probe. The function will be performed only on the selected probe with the

blinking LED. When no channels are selected, the function will be performed for

all display or analog output selected channels.

RANGE (ALT DISP)

ANGE

R

Some probes do not respond to the range button due to the presence

of an internal auto range function.

Press Range to determine the sensitivity of the probe. With each press of the

button all selected probes will increment one range.

If the measured signal exceeds the full-scale value for the selected range, an

over-range message will display. If the selected measured signal is too low, then

an under-range indication will display.

Front Panel Controls and Indicators | 29

Page 30

Archived 10/19/10

Range Description

Auto Sets the selected channels to autorange.

1 to 4 Sets the selected channels to the desired range. See the probe

manual for a description of the units of measure and range levels.

5 Some probes may use five or more ranges; this is supported by

the FM5004.

(ALT DISP)

To change to the alternate display mode, press Shift. Set up alternate display by

selecting ALT DISPLAY FORMAT in the Main Menu. The FM5004 supports

two display formats. See Display Format on page 36 for more information.

BATTERY (TEMP)

ATTERY

B

Press Battery to display a percentage that represents where in the discharge

curve the battery voltage is for each selected probe. This number is derived by

taking the actual voltage of the battery pack, subtracting it from the minimum

voltage level for the battery (3.18 Volts for a three-cell battery pack), and dividing

the result by the full range of the battery (maximum charge voltage minus fully

discharged voltage; 4.10–3.18 Volts for a three-cell battery pack).

Due to the non-linear discharge curve of nickel-cadmium (NiCd)

batteries, the percentage displayed does not reflect the actual

operation time left for a probe. It is recommended that for each probe,

the approximate battery life left for a given battery voltage percent be

noted. In addition, as a battery ages, the overall voltage decreases.

When the battery level drops below approximately 13% (3.3 Volts for a

three-cell battery pack), a low battery warning will display. When this

occurs, the battery should be charged as soon as possible.

When the battery voltage drops to the fully discharged level, a battery

fail indication will display. When this occurs, measurement accuracy

will be compromised by further operation.

30 | Front Panel Controls and Indicators

Page 31

Archived 10/19/10

(TEMP)

Press Shift and then Battery/(Temp) to display all selected probe temperatures

in Fahrenheit and in Celsius.

LOCAL (RESET)

OCAL

L

Press Local to transfer control of the FM5004 to a remote device. The remote

device can be an RS-232 serial device or an IEEE-488 device. When the

FM5004 is in remote operation, REM appears in the upper left corner of the

display. Press Local again to return the FM5004 to local operation.

(RESET)

Press and hold Shift and then press Reset to redraw the display and re-establish

communication with the probes. This is useful if the display malfunctions or

communication with a probe is lost. It will also reset the running minimum,

maximum, and average readings if they are active.

Press Reset while pressing Shift to cause a hard reset. This is equivalent to

cycling the power on the FM5004.

(SHIFT)

When Shift is pressed, the functions in parentheses become active. When

active, Shift displays. Press Shift again to turn it off.

Display

The display is 240x64 with an adjustable LED back light. The display is used to

indicate probe and status information as well as to display the menu windows for

system setup.

Front Panel Controls and Indicators | 31

Page 32

Archived 10/19/10

Menu Select

The FM5004 menus appear on the

display, and five keys control the

movement through the

menu system and changing the

settings.

The setup parameters are saved in

non-volatile memory (EEPROM)

and are loaded each time the

FM5004 is powered on.

USING THE MENU KEYS

Five keys control menu navigation and data entry:

• Navigate the menu system—The four arrow keys are used to enter

the menu system, move between selections in the menus, open

submenus, change settings, and exit the menu system.

The UP ARROW and DOWN ARROW are used to increment and

decrement a number when in a numeric entry menu.

• Select settings—Enter is used to select settings from a list and to

save numeric entries.

NAVIGATING THE MENU SYSTEM

For a complete description of the menu system, Main Menu, and

submenus, see Menu System on page 35.

• To display the Main Menu, press any arrow key. A cursor appears to

the left of the first item in the Main Menu.

• The UP ARROW and DOWN ARROW move the cursor through the

menu items.

32 | Front Panel Controls and Indicators

Page 33

Archived 10/19/10

• When the bottom of a column is reached, press the DOWN ARROW to

go to the top of the next column or to the top of the same column if the

menu contains only one column of selections. The UP ARROW works

in reverse.

• With the cursor next to a submenu icon, press the RIGHT ARROW to

open that submenu.

• Press the LEFT ARROW to back up to the previous menu.

CHANGING SETTINGS

1. Press the arrow keys to move the cursor through the menu items.

When the menu that contains the item to be changed is reached, place

the cursor to the left of that item.

2. To save the value, press Enter. This will return the display to the

previous menu.

If you press the LEFT ARROW before Enter, the value will return to

the last value saved and the previous menu will display.

If the item icon is a checkmark, press Enter to toggle

the function on or off.

A solid checkmark indicates that the function is

selected, and a hollow checkmark indicates it is not

selected. If several checkmarks appear, only one of

the options may be enabled at one time.

If the item icon is a set of arrow keys, the numeric

entry screen will appear. The name of the selected

item will display at the top of the menu and the current

value for that item will display in large type.

Press the arrow keys to increment or decrement the

number.

EXITING THE MENU SYSTEM

Press the LEFT ARROW until the menu system closes.

Front Panel Controls and Indicators | 33

Page 34

Archived 10/19/10

This page intentionally left blank.

34 | Front Panel Controls and Indicators

Page 35

Archived 10/19/10

6.0 Menu System

For information on navigating the menu system, see Menu Select

on page 32.

The menus are organized into a tree format. For example, the Main Menu

contains a list of submenus that will call another submenu, and that menu may

call additional submenus.

Other menu types include:

• Numeric entry—Calls up a data entry screen.

• Item selection—Allows you to select a setting from a list of options.

• Advanced setup—Allows you to perform diagnostics and upgrade

software.

MAIN MENU

Menu System | 35

Page 36

Archived 10/19/10

DISPLAY SETUP

36 | Menu System

Page 37

Archived 10/19/10

Sets the format of

the data on the

display, display

brightness, and

display contrast.

DISPLAY FORMAT / ALT DISPLAY FORMAT

Contains items

associated with

the presentation of

data on the

display when in

normal and

alternate display

mode.

For each saved setup, two display configurations are saved. This

allows you to quickly switch between two commonly used formats.

To toggle between normal and alternate display format, on the front

panel press Shift and then Range (Alt Disp).

Menu System | 37

Page 38

Archived 10/19/10

4-PROBE

When selected, the display is divided into four sections, one for each channel.

The reading from each probe is displayed in these sections. If the display is

disabled for a given channel, that section of the display will be empty.

2-LINE

Allows you to

view two

readings on the

display at

one time.

Only one selection at a time may be made from the Line 1 column and

Line 2 column.

The display is divided into two sections, line 1 on top, and line 2 on bottom. The

minimum, maximum, or average of the display-enabled probes appear on each

line, and the reading is sent to the analog output system; see Analog Out Setup

on page 42 for information on setting up the analog output system. Different

channels may be selected for routing to the analog output and display systems,

displaying readings from different probes on each line.

For example, you may display the maximum reading from channel 1 and

channel 2 on line 1, and the maximum of the readings from channel 3 and

channel 4 on line 2. Selecting channel 1 and channel 2 for the display system

and channel 3 and channel 4 for the analog output system will achieve this

set up.

Unless indicated, calculations for the following readings are based on

the number of previous samples, which is determined from the display

update rate. See Display Update Rate on page 41 for information on

setting the display update rate.

38 | Menu System

Page 39

Archived 10/19/10

LINE 1

• MIN OF PROBE

• MAX OF PROBE

• AVERAGE OF PROBE

• ANALOG OUT • The readings sent to the analog output

The minimum of the current reading and the

previous samples for the display-selected

probes will display on line 1.

The maximum of the current reading and the

previous samples for the display-selected

probes will display on line 1.

The average of the current reading and the

previous samples for the display-selected

probes will display on line 1.

system will display on line 1. The number

will be an average of the current reading

and previous readings.

• The number of previous readings is

determined from the filter size setting in

the Analog Out Setup menu.

• For example, if filter size is set to 10, the

number displayed is an average of the

current reading plus the nine previous

readings. This number will be updated at

the display update rate.

LINE 2

• MIN OF PROBE

The minimum of the current reading of all

probes attached and the previous samples

for the display-selected probes will display

on line 2.

Menu System | 39

Page 40

Archived 10/19/10

LINE 2

• MAX OF PROBE

• AVERAGE OF PROBE

• ANALOG OUT • The readings sent to the analog output

The maximum of the current reading of all

probes attached and the previous samples

for the display-selected probes will display

on line 2.

The average of the current reading and the

previous samples for the display-selected

probes will display on line 2.

system will display on line 2. The number

displayed will be an average of the

current reading and previous readings.

• The number of previous readings is

determined from the filter size setting in

the Analog Out Setup menu.

• For example, if filter size is set to 10, the

number displayed is an average of the

current reading plus the nine previous

readings.

3-AXIS

The readings for all enabled axes and the combined reading (square root of the

sum of squares) is displayed for the selected probe. Only one probe at a time

may be selected for 3-axis display. If an axis is disabled, only readings for the

enabled axes are displayed, and the combined reading includes only the enabled

axes.

40 | Menu System

Page 41

Archived 10/19/10

DISPLAY UPDATE RATE

Sets the display

update rates, which

is the number of

times per second

that the display will

update with new

readings.

If the samples per second setting in the Main Menu is greater than the display

update rate, then all samples taken after the last display update will be included

in the new update. The displayed reading will be an average of the previous

samples.

In 2-line display mode, with minimum or maximum of probe selected, the

displayed reading will be the minimum or maximum of the previous samples. If

the display update rate is set greater than samples per second, the display will

update only when new samples are taken.

LCD CONTRAST

Adjusts the display contrast. This can make the display more readable under

different lighting conditions and viewing angles.

Improper adjustment of the contrast may make the display

unreadable. If the display is blank, the contrast may be set too low. If

the display is completely dark, the contrast may be set too high.

LCD BRIGHTNESS

Adjusts the brightness of the display. This can make the display more readable

under different lighting conditions and viewing angles.

Menu System | 41

Page 42

Archived 10/19/10

ANALOG OUT SETUP

42 | Menu System

Page 43

Archived 10/19/10

Contains the

items associated

with the analog

output functions

of the FM5004.

To select a probe for the analog output system, press the channel select switch

for the desired probe, and then press Out. The Out LED for that channel will

illuminate. More than one channel may be selected at one time.

FULL SCALE RANGE

This only applies

to operation in

auto-range

mode.

When operating

in a fixed range,

the analog output

full scale range

will be the upper

limit of the

highest range of

analog output

selected probes.

Contains the allowable full scale range settings for the analog output system. The

field level that corresponds to a full scale output of five volts is the upper limit of

the range selected. A zero field will create an analog output of zero volts.

Menu System | 43

Page 44

Archived 10/19/10

If the output reading is larger than the upper range, the output voltage

will be five volts and an analog output over range condition will display

on the front panel.

MIN/MAX/AVG

Contains the

allowable functions to

be used on the

analog output data.

• Minimum: The minimum sample in the sample window is sent to the

analog output system.

• Maximum: The maximum sample in the sample window is sent to the

analog output system.

• Average: The average of all samples in the sample window is

calculated and sent to the analog output system.

For more information, see the next section, Filter Size.

44 | Menu System

Page 45

Archived 10/19/10

FILTER SIZE

Calls up the numeric entry screen to select the number of samples to use for

each analog output update. The saved sample represents a sliding window and

serves as a smoothing function for the analog output signal. The analog output

level is updated every sample according to the samples per second setting in the

Main Menu.

• If the filter size is greater than one, the sample window contains the

current sample plus the most recent samples.

• If the filter size is set to one, only the current sample is used by the

analog output system.

The minimum/maximum/average setting affects how the data is processed. See

Min/Max/Avg on page 44.

LOG SCALE OUTPUT

Selects either linear or log scale for the analog output voltage.

• When selected, the output will track a logarithmic curve with a zero

field level being zero volts out and a full scale field level being five volts

out.

• When deselected, the endpoints will be the same but the analog

voltage out to field level ratio will be linear.

Menu System | 45

Page 46

Archived 10/19/10

REMOTE OPER SETUP

Contains items

associated with

setting up the

FM5004 for remote

operation.

• RS-232: Settings for the communications rate between the FM5004

and the remote controller.

• GPIB: Calls the numeric entry screen to select the GPIB address

(0 to 31) for the FM5004.

46 | Menu System

Page 47

Archived 10/19/10

ALARM SETUP

Menu System | 47

Page 48

Archived 10/19/10

Contains the items

associated with

setting up the alarms

for the FM5004.

4-PROBE / 3-AXIS ALARM SETUP

Contains the items

associated with the

following functions:

• Enabling the upper and

lower alarms.

• Setting the levels that

will cause an alarm.

• The pulse type of the

alarm.

• Upper Enable: The alarm will activate when the measured field is

greater than the upper alarm value.

• Upper Value: Calls the numeric entry screen to enter the upper

measured field value above which the alarm will

activate.

• Lower Enable: The alarm will activate when the measured field falls

below the lower alarm value.

48 | Menu System

Page 49

Archived 10/19/10

• Lower Value: Calls the numeric entry screen to enter the lower

measured field value below which the alarm will

activate.

• Latched: The alarm will sound continuously when an enabled

upper or lower value is crossed, even if the measured

field returns to within the normal field level.

To temporarily disable the alarm, select Alarm Silence

from the Main Menu or power the FM5004 on and off.

LINE 1 ALARM / LINE 2 ALARM

Contains the items associated with setting up the alarm for use while in 2-line

display mode. There are separate alarm setup menus for each line in 2-line

display mode.

Using the alarms while in 2-line display mode allows the use of two

different upper and lower alarm values for different probes.

• Upper Enable: The alarm will activate when the measured field is

greater than the upper alarm value.

• Upper Value: Calls the numeric entry screen to enter the upper

measured field value above which the alarm will

activate.

Menu System | 49

Page 50

Archived 10/19/10

• Lower Enable: The alarm will activate when the measured field falls

below the lower alarm value.

• Lower Value: Calls the numeric entry screen to enter the lower

measured field value below which the alarm will

activate.

• Latched: The alarm will sound continuously when an enabled

upper or lower value is crossed, even if the measured

field returns to within the normal field level.

To temporarily disable the alarm, select Alarm Silence

from the Main Menu or power the FM5004 on and off.

TEMP ALARM SETUP

Contains the items

associated with

setting up the alarm

for an out of range

temperature

condition.

The temperature alarm will become inactive when the sample rate is set above

10 samples per second. However, taking a temperature measurement from

either the front panel or by a remote temperature measurement command will

cause an alarm if the alarm is enabled and the measurement causes an alarm

condition.

50 | Menu System

Page 51

Archived 10/19/10

• Upper Enable: The alarm will activate when temperature of any active

probe rises above the upper alarm value.

• Upper Value: Calls the numeric entry screen to enter the upper

temperature level above which the alarm will activate.

• Lower Enable: The alarm will activate when a probe temperature falls

below the lower alarm value.

• Lower Value: Calls the numeric entry screen to enter the lower

temperature level below which the alarm will activate.

• Latched: The alarm will sound continuously when an enabled

upper or lower temperature level is crossed, even if the

measured temperature returns to within the normal

field level.

To temporarily disable the alarm, select Alarm Silence

from the Main Menu or power the FM5004 on and off.

Menu System | 51

Page 52

Archived 10/19/10

SYSTEM ALARM

Contains the items

associated with

setting up the alarm

for probe failures or

system errors.

• Momentary Probe Fail: The alarm will activate when a momentary error

occurs in a probe or if an error occurs during

communication with a probe.

• Hard Probe Fail: The alarm will activate when an error condition

occurs repeatably.

• Battery Enable: The alarm will activate when the voltage on an active

probe falls below the level at which normal probe

operation is guaranteed.

The battery alarm will become inactive when the

sample rate is set above 10 samples per second.

However, taking a battery measurement from either

the front panel or by a remote battery measurement

command will cause an alarm if the alarm is enabled

and the measurement causes an alarm condition.

52 | Menu System

Page 53

Archived 10/19/10

SETUP SAVE/RECALL

Contains the items

associated with

saving and recalling

up to four different

setup configurations.

Each setup may

contain a separate

primary display and

an alternate display.

To switch between primary and alternate displays, on the front panel press and

release Shift and then press and release Alt Disp.

When the FM5004 is powered up it will be configured as it was before it was

previously powered down; any changes made to a setup will not be saved

permanently until it is saved in this menu.

The recall default setting will configure the FM5004 as it was shipped from the

factory.

Menu System | 53

Page 54

Archived 10/19/10

ZERO PROBES

Contains the items

associated with

zeroing the probes

connected to the

FM5004.

To zero a probe, it

must be enabled for

either display or

analog output

functions.

The actual zero function will not occur until the menu system is exited. ZERO will

display after a zero operation is performed.

MAINTENANCE

Contains the items

associated with

updating the FM5004

software and

checking the system

voltage levels.

LAST ERRORS

Displays detailed descriptions of any errors that occurred since the last system

reset or power up. Each error includes a time stamp, in seconds, identifying

when it occurred since the last system reset or power up. Press the UP ARROW

and DOWN ARROW to scroll through the errors.

54 | Menu System

Page 55

Archived 10/19/10

SYSTEM STATUS

Displays the following information:

• Software Revision

• Software Date

• +5V Buss Voltage

• +12V Buss Voltage

• -12V Buss Voltage

The acceptable values for the buss voltages are +/-10% of nominal. If the

measured voltages are outside of this range, contact ETS-Lindgren.

SAMPLES/SEC

Calls the numeric entry screen to select the field measurement sample rate in

samples per second. The minimum sample rate is one sample per second. The

maximum sample rate is determined by the FM5004 and is based on the speed

of the connected probes. The maximum rate is limited to the slowest probe that is

communicating with the FM5004.

When the FM5004 is in 3-axis mode, the actual sample rate for a

complete measurement of the probe field is 1/6 of the selected

sample rate.

KEY CLICK

If selected, the FM5004 alarm will emit a short pulse each time a key is pressed.

ALARM SILENCE

To silence the alarm temporarily when in latched mode, position the arrow to the

left of this item and press Enter. However, if the parameter that caused the alarm

to occur is still outside of the alarm limits, the alarm will still latch on when the

menu system is exited.

To silence the alarm permanently, the alarm must be disabled in the alarm setup

section or the probe must be disconnected or turned off.

Menu System | 55

Page 56

Archived 10/19/10

This page intentionally left blank.

56 | Menu System

Page 57

Archived 10/19/10

7.0 Remote Operation

The FM5004 Field Monitor may be operated remotely by connecting the

IEEE-488 parallel port or the RS-232 serial port to a remote device, such as an

IEEE-488 bus or a personal computer.

The IEEE-488 port is IEEE-488.2 compatible.

Command Set Format

See Remote Commands on page 60 for a detailed description of

remote commands.

Each command code is composed of two or three alpha characters and an

optional numeric parameter; commands can be entered in upper or lower case.

If a command is sent without the optional numeric parameter, the instrument

assumes the command is a status request. When the command is a status

request, the instrument returns a string consisting of the command followed by

the current setup for that command.

All commands are terminated by a line feed <LF>. To include several commands

in a single command string, separate each command by a semicolon (delimiter).

Do not include spaces between a command and the associated numeric

parameter. Data returned from the instrument will be terminated with a

<CR><LF>.

IEEE-488

IEEE-488 REQUIREMENTS

For IEEE-488 operation, the device address is set using the menu system. At the

factory the device address is set to 4. If your IEEE-488 device uses address 4,

reset the switch to a vacant address.

Remote Operation | 57

Page 58

Archived 10/19/10

Specific IEEE-488 bus commands depend on the software package

you use. To send commands, be sure that the receiver address is set

properly and that the controller also has correctly identified the

receiver as a listening device.

IEEE-488 (GPIB) COMMUNICATIONS

For General Purpose Interface Bus (GPIB) communications, the End or Identify

(EOI) control line may also be used for command termination. When sending

commands to the receiver through the GPIB, terminate the command with

a <LF>, an EOI, or both. No characters are permitted after the <LF> or EOI; the

system interprets characters following <LF> or EOI as the start of another

command.

When an error condition is present at the receiver, the Service Request (SRQ)

signal is asserted. The operator can then perform a serial poll operation. The

receiver error code (in binary) is contained in the lower bits of the serial poll

status byte. If the receiver is addressed as a listener and the GPIB remote line is

asserted, the receiver will switch to remote mode.

RS-232

RS-232 COMMUNICATIONS

During initialization, the receiver will test for a properly connected RS-232

interface. For the receiver to recognize an RS-232 device, the Data Carrier

Detect (DCD) line must be asserted. This line is sampled continuously to

determine if the RS-232 connection is broken; therefore, it must remain asserted

for the RS-232 interface to function.

The Clear To Send (CTS) line is also used to gate information from the receiver;

this line must be asserted for information to be transferred from the receiver. The

CTS line can be used as a handshake line to inform the receiver when it is

permissible to send information (there is a five second timeout error built into the

receiver, resulting in an error if the timeout occurs). If the CTS line is de-asserted

in the middle of a transmission, a character in the process of being transmitted

will be completed, and then transmission will halt until the CTS line is

re-asserted.

58 | Remote Operation

Page 59

Archived 10/19/10

The receiver asserts two lines: Data Terminal Ready (DTR) and Request To

Send (RTS). These lines are asserted continuously and do not perform a

handshake function; they can simply be connected to the CTS and DCD lines at

the connector. This will allow the receiver to transmit with a minimum of wires

and with no handshaking. See RS-232 Pin Detail on page 59 for pinout

information.

Once the RS-232 interface is established, commands are processed in a manner

similar to the IEEE interface. The command structure is identical, except there is

no EOI line; therefore, all commands must be terminated by a <LF>.

When a valid command is received, it is processed and the result is immediately

transmitted back over the RS-232 interface. The CTS line can be used to control

the flow of information from the receiver, as described on page 58. The output

format is identical to that of the IEEE format except there is no EOI line.

RS-232 SETTINGS

Word Length: 8 bits

Stop Bits: 1

Baud Rate: 1200–19200 (menu selectable)

Parity: None

RS-232 PIN DETAIL

• Connector: DB-9S

• Mating connector:

DB-9PS

Remote Operation | 59

Page 60

Archived 10/19/10

Pin Signal Data Direction Description

1 DCD Input to FM5004 Device Carrier Detect

2 RD Input to FM5004 Receive Data

3 TD Output from FM5004 Transmit Data

4 DTR Output from FM5004 Data Terminal Ready

5 GND NA Ground

6 NC NA No Connection

7 RTS Output from FM5004 Ready to Send

8 CTS Input to FM5004 Clear to Send

9 NC NA No Connection

A null modem cable or adapter is required to interface the FM5004 to

a standard serial port on a personal computer.

Remote Commands

For system level commands required for IEEE-488.2 compliance, see

page 96.

The following conventions are used in the remote commands and returned data

syntax:

• x—A lowercase x represents a numeric value, which may be a voltage

value or a numeral associated with a functional selection.

• n—A lowercase n represents a channel number (1 through 4)

associated with a system probe.

• m—A lowercase m represents a mode selection.

60 | Remote Operation

Page 61

Archived 10/19/10

When a numeric input is sent to the FM5004, the base of the numbers can be

decimal, binary, octal, or hexadecimal. For data sent back from the FM5004, the

base is always base 10. For example, all of the following are equivalent:

• AUPV,1,100

• AUPV,1,#h64

• AUPV,1,#b1100100

• AUPV,1,#q144

• AUPV,1,1e2

Remote Operation | 61

Page 62

Archived 10/19/10

ALARM LATCH

Description: Sets or clears the FM5004 alarm latches.

There is a separate alarm latch for each of the three

alarms: line 1 alarm, line 2 alarm, and 4-probe/3-axis

alarm

Syntax: ALAT,m,x

Parameters: Alarm mode (m):

• 0 = 4-probe/3-axis alarm latch

• 1 = line 1 alarm latch

• 2 = line 2 alarm latch

Numeric value (x):

• 0 = latch disabled (clear)

• 1 = latch enabled (set)

Example:

62 | Remote Operation

• To set the line 1 alarm latch:

ALAT,1,1<LF>

• To verify the latch status:

ALAT,1?<LF>

• If the latch is set, the FM5004 will return:

ALAT,1,1<CR><LF>

Page 63

Archived 10/19/10

ALARM SILENCE

Description: Temporarily silences the FM5004 alarm when it is

Syntax: ALSR

Parameters: None

Example: If the alarm is latched on, to silence it:

latched.

The alarm will silence temporarily, and will become

active again if the reading that caused the alarm to

occur does not return to the normal range before the

next measurement.

ALSR<LF>

Remote Operation | 63

Page 64

Archived 10/19/10

ALTERNATE DISPLAY FORMAT

Description: Sets the alternate display format for the

Syntax: ADFM,m,n,x

Parameters: Display format (m):

FM5004 display.

When a command is sent to enable a display format,

the previous format will become disabled. If all modes

are turned off, the alternate display will become

inactive (blank).

In the case of the 4-probe display mode, only the

m and x parameters are required.

When setting the alternate display to 2-line mode, a

separate command is required to define each line.

• 1 = 2-line, line 1 display

• 2 = 2-line, line 2 display

• 3 = 3-axis display

• 4 = 4-probe display (n parameter not used)

Display mode (n):

• 1 = probe 1 (3-axis format) or minimum of probes

(2-line format)

• 2 = probe 2 (3-axis format) or maximum of probes

(2-line format)

• 3 = probe 3 (3-axis format) or average of probes

(2-line format)

• 4 = probe 4 (3-axis format) or analog output

(2-line format)

Numeric value (x):

• 0 = mode disabled

• 1 = mode enabled

64 | Remote Operation

Page 65

Archived 10/19/10

ALTERNATE DISPLAY FORMAT

Example:

• To set the alternate display mode to 2-line format,

line 1 to average of display enabled probes, and

line 2 to the analog output reading:

ADFM,1,3,1<LF>, ADFM,2,4,1<LF>

• To verify that the line 1 display is set to average of

display selected probes:

ADFM,1,3?<LF>

If it is enabled, the FM5004 will return:

ADFM,1,3,1<CR><LF>

• To set the alternate display mode to 4-probe display

format:

ADFM,4,1<LF>

Remote Operation | 65

Page 66

Archived 10/19/10

ALARM LOWER ENABLE

Description: Enables the line 1, line 2, 4-probe/3-axis, battery, or

Syntax: ALOE,m,x

Parameters: Alarm Type (m):

temperature lower limit alarms. Each of these alarms

must be enabled and disabled separately.

In the case of the low battery alarm, the level is not

adjustable. See the Battery on page 30 for a

description of the low battery alarm operation. See

Alarm Lower Value on page 67 to set the alarm lower

values.

• 0 = low temperature alarm enable

• 1 = line 1 lower alarm enable

• 2 = line 2 lower alarm enable

• 4 = 4-probe/3-axis lower alarm enable

• 5 = low battery alarm enable

Numeric value (x):

• 0 = lower alarm disabled

• 1 = lower alarm enabled

Example:

66 | Remote Operation

• To enable the line 1 lower alarm:

ALOE,1,1<LF>

• To verify the line 1 lower alarm status:

ALOE,1?<LF>

The FM5004 will return:

ALOE,1,1<CR><LF>

Page 67

Archived 10/19/10

ALARM LOWER VALUE

Description: Sets the lower levels for the line 1, line 2,

Syntax: ALOV,m,xxxxxx

Parameters: Alarm Type (m):

4-probe/3-axis, and high temperature alarms. Each of

the alarm levels must be set using individual

commands.

For an alarm to operate, that alarm must be enabled.

The data entered can contain up to five numbers and a

decimal point.

See the description for each alarm type for the

permissible range. See Alarm Lower Enable on

page 66 to enable an alarm.

• 0 = low temperature alarm,

range: 32

• 1 = line 1 alarm,

range: 0—max of probe

• 2 = line 2 alarm,

range: 0—max of probe

°F–211°F

Example:

• 4 = 4-probe/3-axis alarm,

range: 0—max of lowest range probe

Alarm level (xxxxxx)

• xxxxxx = alarm value: 0–1999.9

• To set the line 1 lower alarm value to 150.5:

ALOV,1,150.5<LF>

• To verify the line 1 lower alarm value:

ALOV,1?<LF>

The FM5004 will return:

ALOV,1,150.5<CR><LF>

Remote Operation | 67

Page 68

Archived 10/19/10

ALARM UPPER ENABLE

Description: Enables the line 1, line 2, 4-probe/3-axis, battery, or

Syntax: AUPE,m,x

Parameters: Alarm Type (m):

temperature upper limit alarms. Each of these alarms

must be enabled and disabled separately.

See Alarm Upper Value on page 69 to set the alarm

upper values.

• 0 = high temperature alarm enable

• 1 = line 1 upper alarm enable

• 2 = line 2 upper alarm enable

• 4 = 4-probe/3-axis upper alarm enable

Numeric value (x):

• 0 = upper alarm disabled

• 1 = upper alarm enabled

Example:

68 | Remote Operation

• To enable the line 1 upper alarm:

AUPE,1,1<LF >

• To verify the line 1 upper alarm status:

AUPE,1?<LF >

The FM5004 will return:

AUPE,1,1<CR><LF >

Page 69

Archived 10/19/10

ALARM UPPER VALUE

Description: Sets the upper levels for the line 1, line 2,

Syntax: AUPV,m,xxxxxx

Parameters: Alarm Type (m):

4-probe/3-axis, and high temperature alarms. Each of

the alarm levels must be set using individual

commands.

For an alarm to operate, that alarm must be enabled.

The data entered can contain up to five numbers and a

decimal point.

See the description for each alarm type for the

permissible range. See Alarm Upper Enable on

page 68 to enable an alarm.

• 0 = high temperature alarm,

range: 32

• 1 = line 1 alarm,

range: 0—max of probe

• 2 = line 2 alarm,

range: 0—max of probe

°F–211°F

Example:

• 4 = 4-probe/3-axis alarm,

range: 0—max of lowest range probe

Alarm level (xxxxxx)

• xxxxxx = alarm value: 0–1999.9

• To set the line 1 upper alarm value to 150.5:

AUPV,1,150.5<LF >

• To verify the line 1 upper alarm value:

AUPV,1?<LF >

The FM5004 will return:

AUPV,1,150.5<CR><LF >

Remote Operation | 69

Page 70

Archived 10/19/10

ANALOG OUTPUT MODE

Description: Sets the analog output mode to output the minimum,

Syntax: ANAO,m

Parameters: Mode (m):

maximum, or average of the analog output selected

probes.

Selecting an analog output mode will disable the

previously selected mode.

• 1 = minimum of analog output selected probes

• 2 = maximum of analog output selected probes

• 3 = average of analog output selected probes

Example:

• To set the analog output to average mode:

ANAO,3<LF>

• To verify the analog output mode is average of

probes:

ANAO?<LF>

The FM5004 will return:

ANAO,3<CR><LF>

70 | Remote Operation

Page 71

Archived 10/19/10

ANALOG OUTPUT RANGE

Description: Sets the analog output full scale range to correspond to

Syntax: ANAR,x

Parameters: Range value (x):

the maximum of range 1 through range 4 of the analog

output selected probes.

All analog output selected probes must use the same

units of measurement and have the same ranges.

• 1 = range 1 upper limit corresponds to full scale

analog output voltage

• 2 = range 2 upper limit corresponds to full scale

analog output voltage

• 3 = range 3 upper limit corresponds to full scale

analog output voltage

• 4 = range 4 upper limit corresponds to full scale

analog output voltage

Example:

• To set the analog output full scale voltage to

correspond to range 2 of the analog output selected

probes:

ANAR,2<LF>

• To verify the analog output full scale voltage

corresponds to range 2 of the analog output

selected probes:

ANAR?<LF>

The FM5004 will return:

ANAR,2<CR><LF>

Remote Operation | 71

Page 72

Archived 10/19/10

BAUD RATE

Description: Sets the baud rate used for remote communication

between the FM5004 and a controller.

Syntax: BAUD,xxxxx

Parameters: Baud rate (xxxxx):

• 1200 = 1200 Baud

• 2400 = 2400 Baud

• 4800 = 4800 Baud

• 9600 = 9600 Baud

• 19200 = 19200 Baud

Example:

• To set the baud rate to 9600:

BAUD,9600<LF>

• To verify the baud rate is set at 9600:

BAUD?<LF>

The FM5004 will return:

BAUD,9600<CR><LF>

72 | Remote Operation

Page 73

Archived 10/19/10

BUSS VOLTAGE

Description: Measures and returns the FM5004 buss voltages.

Syntax: BUSV?

Parameters: None

Example: To check the buss voltages:

BUSV?

The FM 5004 will measure the buss voltages and

return:

+12 - +12.00<CR><LF>

+5V - +5.00<CR><LF>

-12 - -12.00<CR><LF>

Remote Operation | 73

Page 74

Archived 10/19/10

CHANGE RANGE

Description: Change the range of a probe.

Syntax: CHRA,c,r

Parameters: Channel (c):

Example: • If command is entered with no parameters, all probe

• 1–4

Range (r):

• 1–4 (or highest range) or A (autorange)

ranges will be returned.

• If no probe is on that channel, range = 0

• If command is entered with one parameter, the