Page 1

Model 3140

™

BiConiLog

MANUAL

Antenna

© EMC TEST SYSTEMS, L.P. – MARCH 2002 REV C – PN 399258

Page 2

MODEL 3140 BICONILOG ™ ANTENNA

EMC Test Systems, L.P. reserves the right to make changes to any product described herein in order to

improve function, design or for any other reason. Nothing contained herein shall constitute EMC Test

Systems, L.P. assuming any liability whatsoever arising out of the application or use of any product or

circuit described herein. EMC Test Systems, L.P. does not convey any license under its patent rights or the

rights of others.

© Copyright 2002 by EMC Test Systems, L.P. All Rights Reserved.

No part of this document may be copied by any means

without written permission from EMC Test Systems, L.P.

E-MAIL & INTERNET

Support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Dr., Cedar Park, TX 78613

P.O. Box 80589, Austin, TX 78708-0589

Tel 512.531.6400 Fax 512.531.6500

FINLAND

Euroshield OY

Mekannikontie 1

27510, Eura, Finland

Tel 358.2.838.3300

Fax 358.2.865.1233

SINGAPORE

Lindgren RF Enclosures Asia-Pacific

87 Beach Road

#06-02 Chye Sing Building

Singapore 189695

Tel 65.536.7078 Fax 65.536.7093

© EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 3

MODEL 3140 BICONILOG™ ANTENNA

INTRODUCTION............................................................................................................ 1

ASSEMBLY INSTRUCTIONS ......................................................................................4

MOUNTING INSTRUCTIONS ..................................................................................... 8

APPLICATION.............................................................................................................. 12

TYPICAL DATA ...........................................................................................................14

SPECIFICATIONS........................................................................................................ 18

MAINTENANCE........................................................................................................... 19

WARRANTY STATEMENT........................................................................................ 20

Table of Contents

© EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 4

MODEL 3140 BICONILOG ™ ANTENNA

© EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 5

MODEL 3140 BICONILOG™ ANTENNA Introduction

INTRODUCTION

The ETS-Lindgren EMCO brand Model 3140 is a highfield addition to the popular bow-tie/log periodic

combination BiConiLogTM family, providing the highest

field-to-power ratio at low frequencies of any of the

BiConiLog™ antennas. The Model 3140 is designed

specifically to generate the field levels required for

immunity/susceptibility tests required by standards such as

IEC/EN 61000-4-3 using the lowest amount of input power

possible.

A BiConiLog™ antenna combines a broadband biconicallike bow-tie antenna with a standard LPDA (log periodic

dipole array) to replace the traditional use of two antennas

in the 26-1000 MHz EMC test frequency range. Many

EMC antennas are variations of a standard tuned dipole,

which must be nearly half a wavelength long to transmit or

receive energy most efficiently. Thus, at 26 MHz, a tuned

dipole would have to be approximately 5.3 meters long,

about 4.6 meters long at 30 MHz, and 2.8 meters long at 50

MHz. Unfortunately, this is too unwieldy for many

anechoic chambers and test sites. The end plates of the

Model 3140 T bow-ties make the bow-tie antenna segment

look like an antenna twice as long as its 1.6 meter length.

The result is about a 10-dB improvement in low frequency

transmit gain compared to a same-length regular bow-tie.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 1

REV C – PN 399258

Although bow-ties have been used for all of the elements

on some log-periodic antenna designs in the past, in EMC

applications the advantage gained is an extension of the

Page 6

Introduction MODEL 3140 BICONILOG™ ANTENNA

useful low frequency range of the typical LPDA's from

100 MHz down to 26 MHz. At 26 MHz, an efficient single

dipole type antenna must be over 5 meters long, whereas

suitable performance is obtained here with a 1.6 meter long

bow-tie. A simple wire outline bow-tie antenna is

narrowband compared to a sheet bow-tie or biconical, thus

struts are added to the Model 3140 bow-ties to better

simulate the broadband sheet bow-tie.

The unique feature of the Model 3140 is the T bow-tie

elements. A T bow-tie increases the equivalent dipole

electrical length, thereby decreasing resonant frequency

and increasing efficiency in the 20-60 MHz range.

Similarly, a regular bow-tie has a lower resonant frequency

than an equal length single-wire dipole. The T bow-tie has

its first resonance at a frequency where its length is about

0.22λ, a regular bow-tie at a length of 0.3λ, and a tuned

dipole at about a length of 0.48λ. Thus at 50 MHz the 1.4

m long T bow-tie of the Model 3140 behaves like a 2.8 m

tuned dipole. Cross-polar radiation is minimized because

current flow on one of the T end frames is almost exactly

cancelled by the oppositely-phased current on the other T

end.

The standard "self-balun" feed of the log-periodic also

provides a matched balanced feed to the bow-tie elements.

To prevent cable pickup below 100 MHz, and to improve

2 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

matching to the bow-tie elements, the Model 3140 contains

a "balun" transformer which acts as a common-mode choke

to keep unbalanced current off the coaxial feed cable outer

shield, as well as adding some additional inductance to

Page 7

MODEL 3140 BICONILOG™ ANTENNA Introduction

improve impedance matching to the bow-ties. Even though

the Model 3140 is highly balanced (symmetry +/- 0.5 dB),

in vertically polarized measurements cable position can

effect results, so it is recommended that the cable be

suspended horizontally back from the antenna at least 1

meter before any vertical drop. Below 150 MHz, bow-tie

radiation dominates with a dipole-like pattern, while above

150 MHz the radiation in the plane of the elements is

directional.

The antenna has dual mounting bracket and 1/4x20 UNC

knob for attaching to ETS-Lindgren tripod and tower

adapters. The brackets are spaced to align with the

mounting holes on the Model 7-TR tripod and the ETSLindgren towers. Typical antenna factor data is included in

Figure 11.

Note: The Model 3140 is designed only for immunity

testing. The large size of the antenna makes it impractical

for emissions testing where height scanning is required,

and the bow-tie end plates increase the measurement

uncertainty when the antenna is polarized vertically. Thus,

individual calibrations are not provided for the Model

3140.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 3

REV C – PN 399258

Page 8

Assembly Instructions MODEL 3140 BICONILOG™ ANTENNA

ASSEMBLY INSTRUCTIONS

The Model 3140 Antenna consists of the following

(shipped unassembled):

1 ea. Boom Assembly

2 ea. Bow-tie Elements

2 ea. Long T leg Elements

2 ea. V Elements

4 ea. Diagonal Struts

2 ea. Boom adapters for ETS booms with 7/8” mount holes

2 ea. Thread inserts 7/8” to ¼”

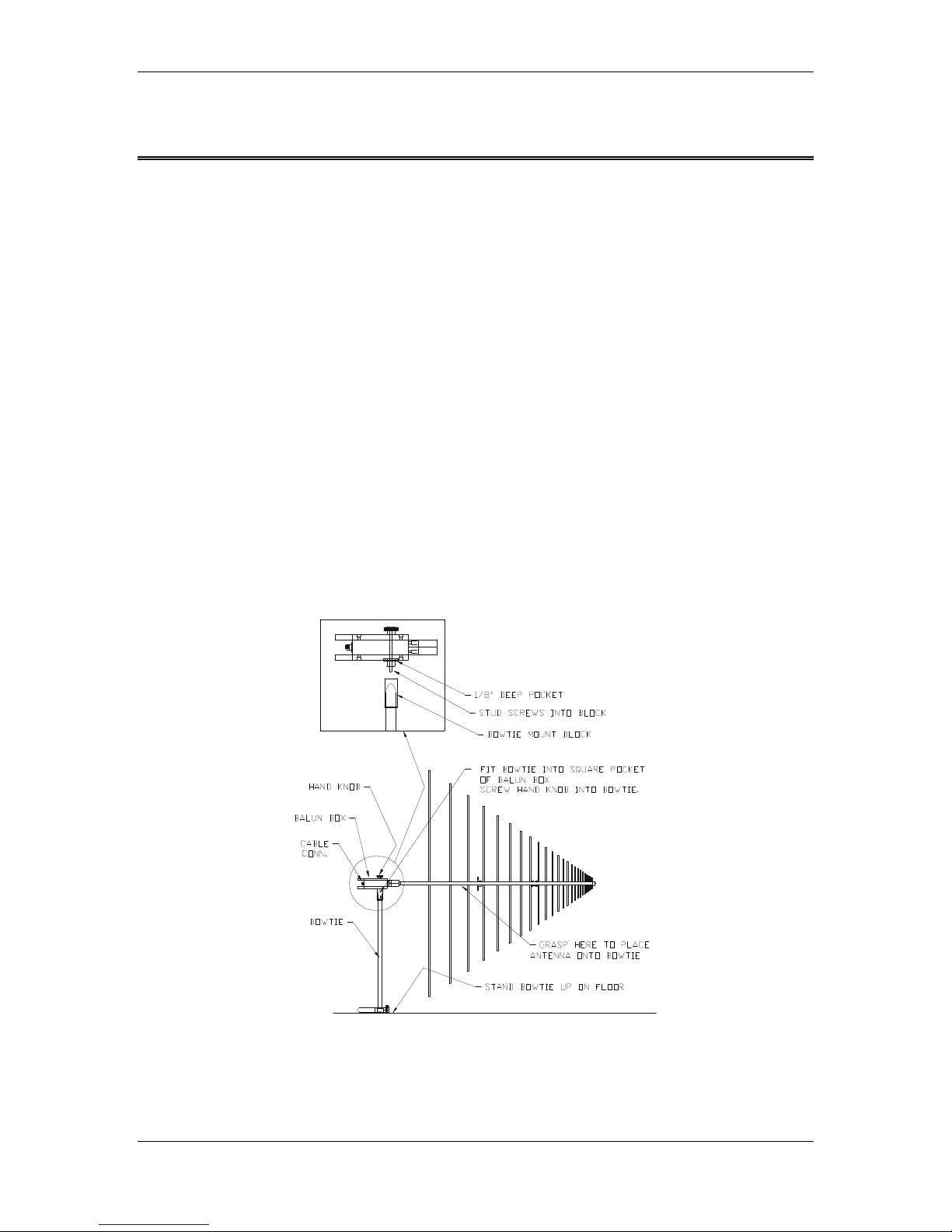

Step 1. Attach a bow-tie element to the antenna balun box (see

Figure 1). The bow-tie should be standing vertical and the

antenna held horizontal and attached to it using the hand

screw knob. Supporting the antenna during the assembly

process will eliminate stress at the connection of the balun

box and prevent damage to the connection.

4 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

FIGURE 1 – Assembly Step 1

Page 9

MODEL 3140 BICONILOG™ ANTENNA Assembly Instructions

Step 2. Once you have attached both bow-tie elements; with both

hands, rotate the antenna and bow-tie into a vertical

position resting on a flat surface (see Figure 2). The

antenna can now rest by itself on the feet of the balun box,

and the bottom edge of the bow-tie elements.

FIGURE 2 - Assembly Steps 2 through 4

Step 3. Attach the other bow-tie element to the antenna balun box

(see Figure 2). The antenna should rest on the balun end

and stand vertically to attach the 2nd bow-tie with the

opposite hand knob.

Step 4. The long T leg elements are installed and clamped to the

bow-ties (Figure 2) with the antenna standing vertical.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 5

REV C – PN 399258

Page 10

Assembly Instructions MODEL 3140 BICONILOG™ ANTENNA

Step 5. The four diagonal struts should be installed. Loosen the

thumbscrews at the mount on the T legs and at the boom

mounts to install the strut ends. Place the pocket of the

straight end facing the raised face of each mount and

tighten the thumbscrew to lock in place (see Figure 3).

FIGURE 3 – Assembly Step 5

6 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 11

MODEL 3140 BICONILOG™ ANTENNA Assembly Instructions

Step 6. The V elements should be installed and tightened using the

thumbscrews through the boom (see Figure 4).

FIGURE 4 – Assembly Step 6

The antenna is now ready for mounting on a boom of a

stand such as the ETS-Lindgren 7-TR or mast such as the

ETS-Lindgren 2070 series. See the next section “Mounting

Instructions” for more details.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 7

REV C – PN 399258

Page 12

Mounting Instructions MODEL 3140 BICONILOG™ ANTENNA

MOUNTING INSTRUCTIONS

The Model 3140 boom has dual mounting brackets that are

spaced 8” on center. The dual mounts make the Model

3140 very stable on a boom when polarizing and moving

up and down a mast.

Step 1. Install the antenna adapters onto the two mount brackets on

the antenna boom (see Figure 5). These have a 7/8”

threaded hole for an ETS-Lindgren mount knob. Install the

threaded insert adapter into the 7/8” hole if a ¼” thread is

required on the mounting stand or mast.

FIGURE 5 – Attachment of antenna mount adapters to Model 3140

8 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 13

MODEL 3140 BICONILOG™ ANTENNA Mounting Instructions

Step 2. The antenna can be mounted on standard ETS-Lindgren

perforated cross booms using two 7/8” mount knobs

through the 2” square boom (see Figure 6).

FIGURE 6 – Attachment of Model 3140 to perforated offset boom.

The antenna can be mounted to the 2” square booms of the

following ETS-Lindgren products:

Model 7-TR tripod stand (see Figure 7),

Model 2075 MiniMast tower (see Figure 8),

and Model 2070/2071 towers (see Figure 9).

For other 2” square booms, two slip-on boom brackets that

do not require through holes in the boom can be used to

mount the antenna.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 9

REV C – PN 399258

Page 14

Mounting Instructions MODEL 3140 BICONILOG™ ANTENNA

FIGURE 7 – Attachment of Model 3140 to Model 7-TR

heavy duty antenna stand

FIGURE 8 – Attachment of Model 3140 to Model 2075 MiniMast

10 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 15

MODEL 3140 BICONILOG™ ANTENNA Mounting Instructions

FIGURE 9 – Attachment of Model 3140 to Model 2070 or 2071 Tower

© EMC TEST SYSTEMS, L.P. – MARCH 2002 11

REV C – PN 399258

Page 16

Application MODEL 3140 BICONILOG™ ANTENNA

d

APPLICATION

Assemble and mount the Model 3140 per the instructions in

the previous sections. Connect an N-type coaxial cable

from the antenna connector to a signal generator or

amplifier. Contact with any metal or non-metallic structure

can capacitively load the antenna, which may cause

unrepeatable results. Therefore, care must be taken to

ensure that no part of the dipole elements or bow-ties are in

contact with the tripod or tower, particularly in verticallypolarized tests. Where possible, run the feed cable straight

back at least 1 meter or more from the Model 3140 before

dropping vertically.

Both horizontal and vertical polarization is easily

accomplished when the Model 3140 is mounted on an

ETS-Lindgren tower. The Model 7-TR tripod is designed

specifically for the T bow-tie BiConiLog™ antennas to

allow easy polarization changes, and with the air

polarization option can provide automated polarization

using a Model 2090 controller. The previous section

“Mounting Instructions” shows the mounting scheme for

both ETS-Lindgren towers and the 7-TR tripod.

For immunity testing, the electric field strength generated

at a distance d can be approximated by the formula

Pg

E

V / m =

( )

30

12 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

where d is in meters, g is the numeric gain (10

see attached calibration data), and P is antenna net input

power in Watts. An estimate of the power required for any

G[dB]/10

,

Page 17

MODEL 3140 BICONILOG™ ANTENNA Application

()(

)

field strength E can be obtained from Figure 12 or 13 in the

Typical Data section below, which shows forward power

required in Watts to generate 1 V/m. Note that while the

formula provided above is based on the net power (forward

minus reflected) transmitted by the antenna, the gain

determined from the antenna factor already contains effects

due to mismatch, so the formula then predicts the required

forward power rather than net power. To determine the

power (in Watts) required for any other field strength not

shown, multiply the power required for 1 V/m by the

desired E-field squared, or

P E E PV / m V / m=

2

1

To determine the additional amplifier overhead required to

handle 80% amplitude modulation, multiply the result by

3.24 (1.82). Actual transmitted field strength should be

verified using an ETS-Lindgren Model 7200 series electric

field probe or equivalent. Figures 14 and 15 show power

requirements for the lower frequencies at 3 meters based on

measurements using a field probe on an OATS over both

conducting ground and a (2.4m)2 ferrite absorber field over

conducting ground. For IEC 1000-4-3 type testing, the

antenna tip can be placed at any distance between 1 and 3

meters from the EUT as long as the front face plane is

illuminated according to the -0, +6 dB uniform field

specification. In general, closer distances require less

© EMC TEST SYSTEMS, L.P. – MARCH 2002 13

REV C – PN 399258

power to create a given field strength.

Page 18

Typical Data MODEL 3140 BICONILOG™ ANTENNA

TYPICAL DATA

Figure 10 shows the typical VSWR for the Model 3140 in

the frequency range from 26-2000 MHz. Figure 11 shows

the typical horizontal antenna factors for the 3140 in the

same range. The separation distance for the ANSI C63.5 3

and 10 meter calibrations is measured from the antenna

midpoint, while for SAE/ARP-958 1 meter calibrations the

distance is measured from the antenna tip. Midpoint is

defined as half the distance between the small elements and

the bow-ties, which is about 65 cm from the small end tip.

Figure 12 shows the typical forward power required for 1,

3, and 10 V/m (with and without 80% amplitude

modulation) at 1 meter from the tip of the antenna, while

Figure 13 is for 3 meters from the antenna tip. Figures 14

and 15 show power requirements for the lower frequencies

at 3 meters based on measurements using a field probe on

an OATS over both conducting ground and a (2.4m)2 ferrite

absorber field over conducting ground. The power shown

was measured with 1.5 meter transmit antenna and probe

height and horizontal polarization. Horizontal polarization

represents the worst-case power requirement; typically less

power is required for vertical polarization. In practice,

many users place ferrite tiles on the ground between the

antenna and probe to reduce reflected-ray interference. For

any other field strength E, multiply the power in Watts for

1 V/m by E2.

14 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 19

MODEL 3140 BICONILOG™ ANTENNA Typical Data

100

10

VSWR

1

10 100 1000 2000

Frequency (MHz)

FIGURE 10 - Model 3140 typical VSWR.

35

30

1 m

25

20

15

AF (dB (1/m))

10

5

0

20 100 1000 2000

3 m

10 m

Frequency (MHz)

FIGURE 11 – Model 3140 typical antenna factors.

© EMC TEST SYSTEMS, L.P. – MARCH 2002 15

REV C – PN 399258

Page 20

Typical Data MODEL 3140 BICONILOG™ ANTENNA

100

10 V/m 80% AM

10 V/m

1 V/m 80% AM

3 V/m

10

1

0.1

Forward Power (W)

0.01

0.005

20 100 1000 2000

1 V/m 80% AM

1 V/m

Frequency (MHz)

FIGURE 12 – Model 3140 typical 1 meter forward power

based on 1 meter antenna factor.

500

100

10

1

Forward Power (W)

0.1

0.01

20 100 1000 2000

10 V/m 80% AM

10 V/m

1 V/m 80% AM

3 V/m

1 V/m 80% AM

1 V/m

Frequency (MHz)

FIGURE 13– Model 3140 typical 3 meter forward power

based on 3 meter antenna factor.

16 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 21

MODEL 3140 BICONILOG™ ANTENNA Typical Data

1000

100

10

1

Forward Power (W)

0.1

0.01

20 26 100 300

10 V/m 80% AM

10 V/m

1 V/m 80% AM

3 V/m

1 V/m 80% AM

1 V/m

Frequency (MHz)

FIGURE 14 – Model 3140 typical 3 meter forward power

measured over ferrite tile.

1000

100

10

1

Forward Power (W)

0.1

0.01

20 100 300

10 V/m 80% AM

10 V/m

1 V/m 80% AM

3 V/m

1 V/m 80% AM

1 V/m

FIGURE 15 – Model 3140 typical 3 meter forward power

© EMC TEST SYSTEMS, L.P. – MARCH 2002 17

REV C – PN 399258

Frequency (MHz)

measured over conducting ground.

Page 22

Specifications MODEL 3140 BICONILOG™ ANTENNA

SPECIFICATIONS

Electrical (nominal)

Frequency range

Input impedance

VSWR

CW power

Symmetry

Connector Type N female

Physical

Height (T bow-tie) 76.65 cm

Width (T bow-tie) 161.5 cm

Depth (length) 149.3 cm

Weight 10 kg

26 - 2000 MHz

50 Ω

2:1 average

750 W

+/- 0.5 dB

30.18 in

63.60 in

58.78 in

22 lbs

18 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Page 23

MODEL 3140 BICONILOG™ ANTENNA Maintenance

MAINTENANCE

The ETS-Lindgren EMCO brand Model 3140 was designed

to be used for Immunity testing. Because the testing is for

immunity, the generated field is measured with a calibrated

field probe, not the Model 3140. Thus it is not required that

the Model 3140 be recalibrated regularly. If you would like

to have your Model 3140 antenna verified or serviced

please contact our Calibration Department.

For more information about our calibration services or to

place an order for antenna calibration, visit our calibration

website at http://antennacalibration.com/

© EMC TEST SYSTEMS, L.P. – MARCH 2002 19

REV C – PN 399258

Page 24

Warranty Statement MODEL 3140 BICONILOG™ ANTENNA

WARRANTY STATEMENT

EMC Test Systems, L.P., hereinafter referred to as the Seller, warrants that standard EMCO

products are free from defect in materials and workmanship for a period of two (2) years from

date of shipment. Standard EMCO Products include the following:

v Antennas, Loops, Horns

v GTEM cells, TEM cells, Helmholtz Coils

v LISNs, PLISNs, Rejection cavities & Networks

v Towers, Turntables, Tripods & Controllers

v Field Probes, Current Probes, Injection Probes

If the Buyer notifies the Seller of a defect within the warranty period, the Seller will, at the Seller’s

option, either repair and/or replace those products that prove to be defective.

There will be no charge for warranty services performed at the location the Seller designates.

The Buyer must, however, prepay inbound shipping costs and any duties or taxes. The Seller will

pay outbound shipping cost for a carrier of the Seller’s choice, exclusive of any duties or taxes. If

the Seller determines that warranty service can only be performed at the Buyer’s location, the

Buyer will not be charged for the Seller’s travel related costs.

This warranty does not apply to:

v Normal wear and tear of materials

v Consumable items such as fuses, batteries, etc.

v Products that have been improperly installed, maintained or used

v Products which have been operated outside the specifications

v Products which have been modified without authorization

v Calibration of products, unless necessitated by defects

THIS WARRANTY IS EXCLUSIVE. NO OTHER WARRANTY, WRITTEN OR ORAL, IS

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE REMEDIES

PROVIDED BY THIS WARRANTY ARE THE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

IN NO EVENT IS THE SELLER LIABLE FOR ANY DAMAGES WHATSOEVER, INCLUDING

BUT NOT LIMITED TO, DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Note: Please contact the Seller’s sales department for a Return Materials Authorization (RMA)

number before shipping equipment to us.

20 © EMC TEST SYSTEMS, L.P. – MARCH 2002

REV C – PN 399258

Loading...

Loading...