Page 1

Model 95236-1 / Model 95242-1

Bulk Current

Injection Probes

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 2001–2010 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren L.P.

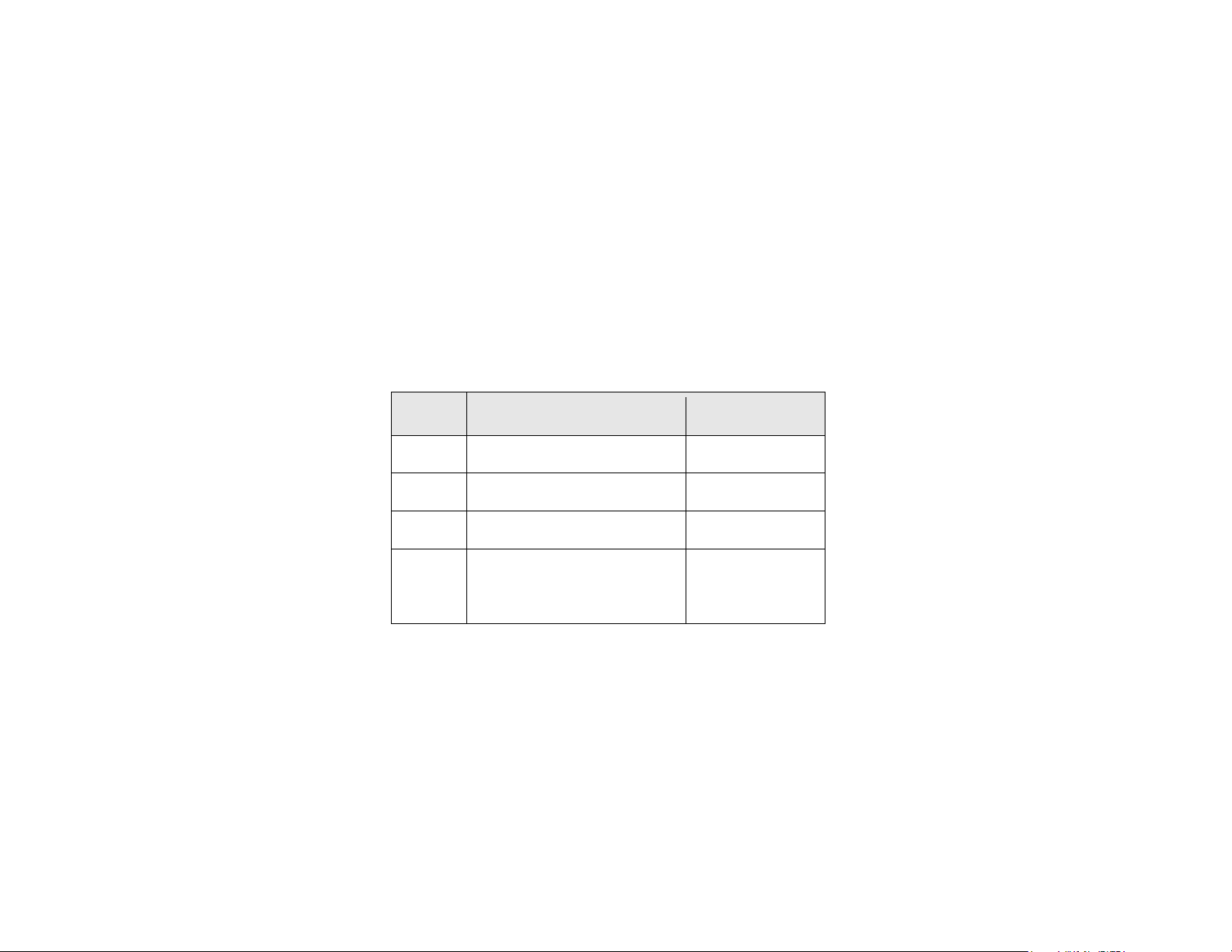

Revision Record

MANUAL, CURRENT PROBE, 95236,95242 | Part #399263, Rev. D

Revision Description Date

A Initial Release October, 2001

B Updates/edits March, 2002

C Updates/edits February, 2005

D Remove Model 95252-1; update

frequency range specifications;

rebrand

ii |

June, 2010

Page 3

Table of Contents

Notes, Cautions, and Warnings ................................................ v

1.0 Introduction .......................................................................... 7

Supporting Equipment ................................................................................... 8

Optional Injection Probe ........................................................................ 8

Model 95241-1 Calibration Jig ............................................................... 8

Current Monitoring probes ..................................................................... 8

Operation: Precautionary Measures .............................................................. 9

ETS-Lindgren Product Information Bulletin ................................................. 10

2.0 Maintenance ....................................................................... 11

Annual Calibration ....................................................................................... 11

Service Procedures ..................................................................................... 11

3.0 Specifications ..................................................................... 13

Physical Specifications ................................................................................ 13

Electrical Specifications ............................................................................... 14

4.0 Application ......................................................................... 17

Conducted Susceptibility ............................................................................. 17

Typical Test Setup ............................................................................... 17

Test Setup Equipment ................................................................................. 18

Sample Conducted Susceptibility Calibration Setup Diagrams ................... 19

Diagram 1 ............................................................................................ 19

Diagram 2 ............................................................................................ 20

5.0 Conducted Emission: Transfer Impedance .................... 21

Model 95236-1 ............................................................................................. 22

Model 95242-1 ............................................................................................. 23

6.0 Insertion Loss .................................................................... 25

Equipment .................................................................................................... 25

Typical Reference Calibration Setup ........................................................... 25

Procedure .................................................................................................... 26

Appendix A: Warranty ............................................................. 27

| iii

Page 4

This page intentionally left blank.

iv |

Page 5

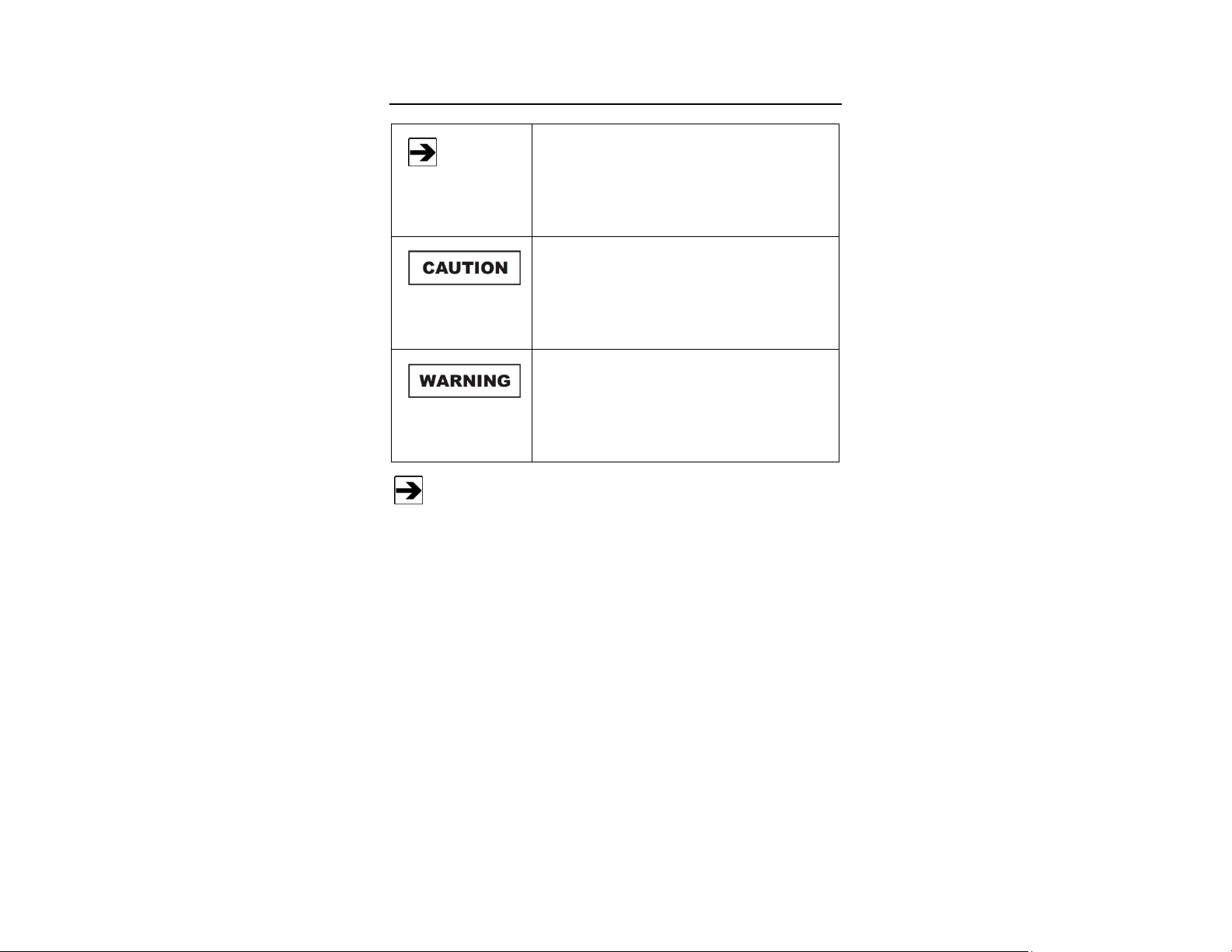

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

| v

Page 6

This page intentionally left blank.

vi |

Page 7

1.0 Introduction

The ETS-Lindgren Bulk Current Injection Probe (BCIP) Series is used to

inject RF current into conductors and cables of electrical and electronic

equipment undergoing susceptibility testing. This manual includes information for

these BCIP models:

• Model 95236-1

• Model 95242-1

The BCIP provides a means of applying a controlled RF stress level to an

instrument under test through interconnecting cables or power cables without

requiring a direct connection to the conductor(s) of interest. The models in this

series are simply clamped around the test conductor which then becomes a

one turn secondary winding, with the current probe forming the core and primary

winding of an RF transformer. RF energy can be injected onto single and

multi-conductor cables, grounding and bonding straps, outer conductors of

shielding conduits and coaxial cables, and so on.

Because of the high efficiency design, the probes can also be used as sensors.

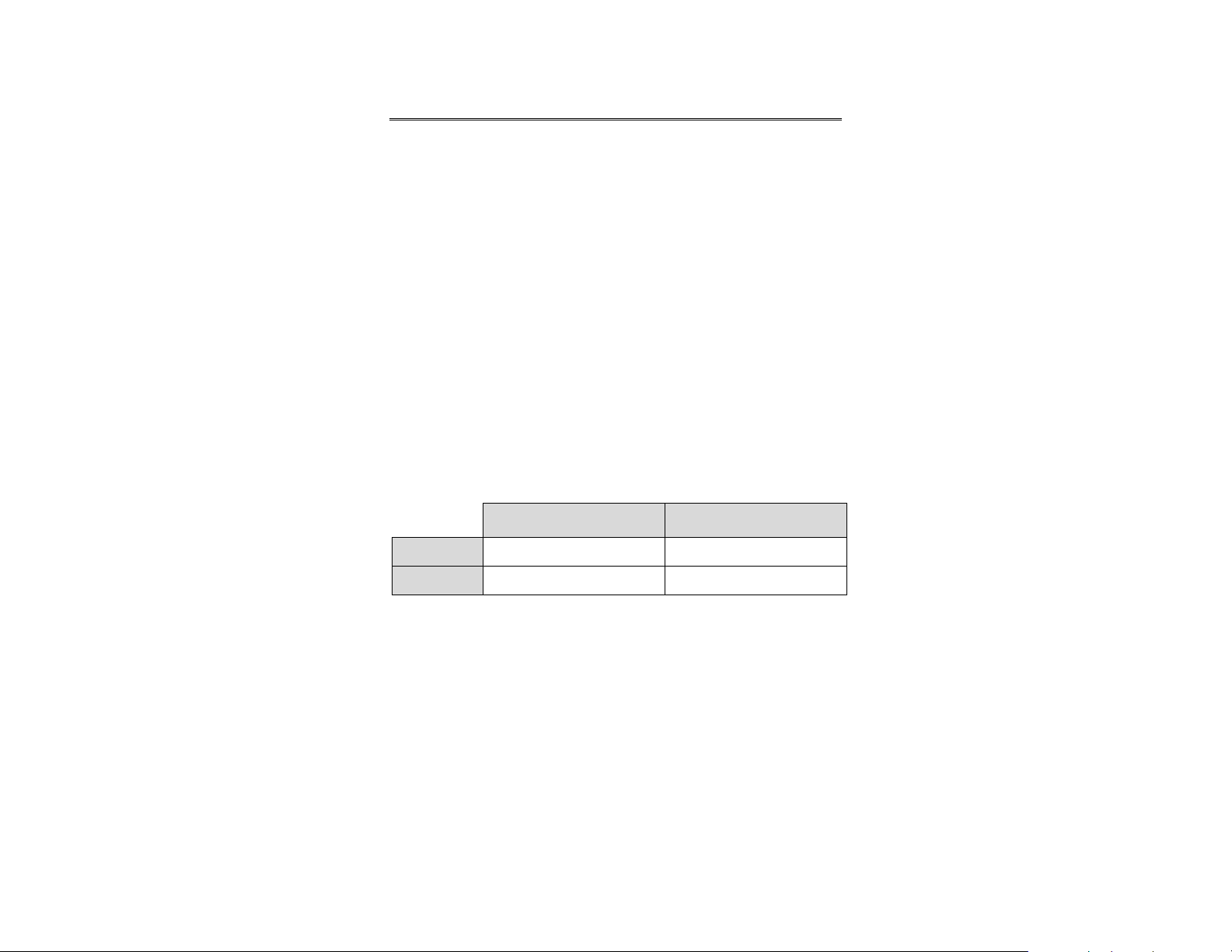

95236-1 1 MHz–100 MHz 10 kHz–100 MHz

95242-1 10 MHz–400 MHz 2 MHz–400 MHz

The BCIP Series is especially designed to provide minimum insertion loss

*

over these frequency ranges.

Frequency Range* Useful Range

Introduction | 7

Page 8

Supporting Equipment

Contact ETS-Lindgren for sizes and sensitivities of other current

probes.

When using the Model 95242-1 to perform susceptibility tests, the following

equipment may be required.

OPTIONAL INJECTION PROBE

The Model 93686-1 Current Probe with a 6.6 cm window diameter may be used

as a bulk current injection probe over the frequency range 50 kHz to 2 MHz.

MODEL 95241-1 CALIBRATION JIG

The Model 95241-1 Calibration Jig is used in equipment setup for measuring

insertion loss of the current probe and is essential to set up equipment for some

susceptibility test procedures.

CURRENT MONITORING PROBES

Suggested current monitoring probes are Model 91550-1 (10 kHz to 100 MHz)

and Model 94111-1 (1 MHz to 1 GHz). These probes have a 1.25-inch (3.2-cm)

window size and a transfer impedance of 1 ohm to 6 ohms over the 50 kHz to

400 MHz frequency range.

8 | Introduction

Page 9

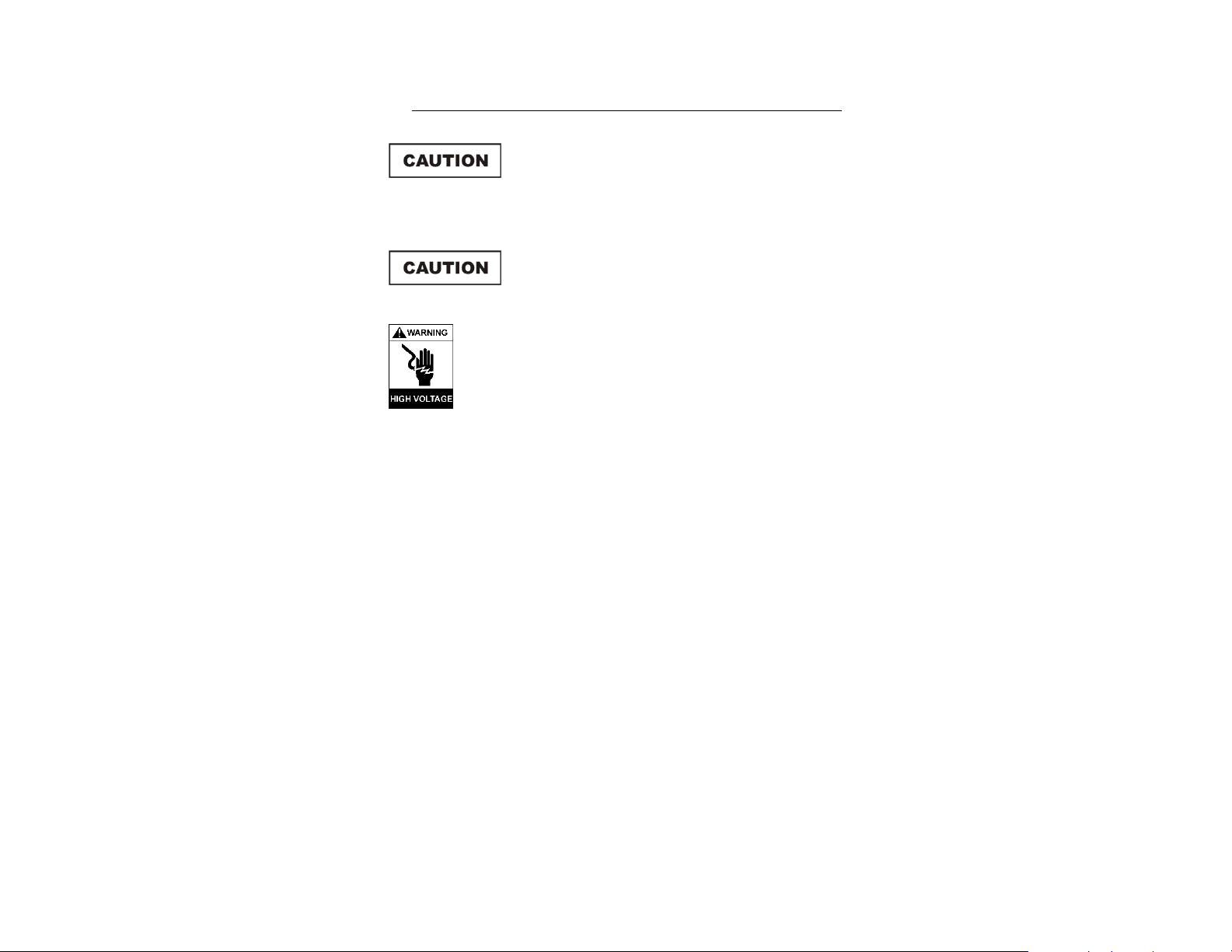

Operation: Precautionary Measures

Before connecting any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

RF fields can be hazardous. Observe

appropriate RF exposure limits.

When measuring conductors that are not

insulated, use extreme care when installing the

current probe and taking measurements. If

possible, de-energize the test sample during

assembly and disassembly of the setup. Also,

arrange to center the test conductor in the

current probe window for additional voltage

breakdown protection.

Do not permit the uninsulated current probe

connector and cable connectors to come in

contact with the ground plane or other nearby

conductors. This will prevent possible

measurement error due to ground loops, and

will avoid danger from high voltages.

Ensure that the 50-ohm load is capable of safely

dissipating the incurred power. Should the load

become disconnected, the developed voltage

will be come much greater and may be very

dangerous.

Introduction | 9

Page 10

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

10 | Introduction

Page 11

2.0 Maintenance

Before performing any maintenance,

follow the safety information in the

ETS-Lindgren Product Information

Bulletin included with your shipment.

WARRANTY

Maintenance of the Bulk Current Injection

Probe is limited to external components

such as cables or connectors.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

Maintenance | 11

Page 12

This page intentionally left blank.

12 | Maintenance

Page 13

3.0 Specifications

Physical Specifications

Window Diameter: 4.0 cm (1.57 in)

Outside Diameter: 13.0 cm (5.11 in)

At Widest Point: 10.2 cm (4.01 in)

Height: 6.0 cm (2.36 in)

Weight: 1.60 kg (3.52 lb)

Output Connector: Type N

Input Impedance: 50 Ω

Specifications | 13

Page 14

Electrical Specifications

Frequency Range: 1 MHz–100 MHz 10 MHz–400 MHz

Maximum Input

Power:

Maximum Input

Current:

Maximum Core

Temperature:

Recommended

Maximum

Temperature Rise:

Maximum Time for

Continuous Rating at

Full Power:

Turns Ratio: 1:2 1:1

Inductance: 47 μH, ±20% 0.8 μH, ±20%

95236-1: The power limit of the 95236-1 is 100 W. Powers in excess of

*

75 W should be used with care to avoid excessive temperature in the

equipment under test. Prolonged testing should be avoided, particularly if

unattended.

95236-1 95242-1

100 W

* 200 W**

20 Amperes 60 Amperes

80

°C 80°C

35

°C 35°C

30 minutes 30 minutes

95242-1: The power limit of the 95242-1 is 200 W. Powers in excess of

**

100 W should be used with care to avoid excessive temperature in the

equipment under test. Prolonged testing should be avoided, particularly if

unattended.

14 | Specifications

Page 15

Useful Range

dB Range

95236-1 10 kHz–100 MHz

95242-1 2 MHz–400 MHz < 15 dB 10 MHz–400 MHz

Insertion Loss (Typical)

< 15 dB

-35 db ± 3 dB

1 MHz–100 MHz

@ 10 kHz

Specifications | 15

Page 16

This page intentionally left blank.

16 | Specifications

Page 17

4.0 Application

The principal use of the Bulk Current Injection Probe (BCIP) is for inducing

relatively large RF currents into the signal and power circuits of equipment under

test for conducted susceptibility. A secondary application would be to use the

same probe in a more familiar role as a sensor for measuring weak conducted

RF currents.

Conducted Susceptibility

Conducted susceptibility testing is intended to ensure that RF signals, when

coupled on to interconnecting cables and power supply lines of a device under

test (DUT), will not cause malfunction or degradation of performance. In addition,

this testing can provide an amplitude vs. frequency malfunction signature for the

system which, when compared with the levels of current on the cables in a typical

operating environment, can assist in the determination of adequate safety

margins.

TYPICAL TEST SETUP

Typical conducted susceptibility tests require that all power and interconnecting

cables be tested by subjecting them to the required current or voltage levels,

while monitoring the applied current using a current probe. Usually, a reference

level calibration is performed using a calibration jig with a specified impedance.

This reference curve is then replayed to expose the DUT to a controlled stress

level, while a current probe is used to ensure that a low impedance DUT is not

overstressed.

Some tests may allow the reference calibration to be performed at a

lower level and then scaled up to the required power level when

applied to the DUT.

Entire cables or cable bundles may be tested, or each line may be broken out

and tested individually. Some standards may also require simultaneous injection

onto multiple cable bundles using several injection probes. Absorbing clamps

may be required to isolate peripheral equipment from the DUT, and ensure that

only the DUT is exposed to the required stress level. See the pertinent test

standard for more details.

Application | 17

Page 18

Test Setup Equipment

The following equipment may be needed to set up the test environment.

• Current Injection Probes: 95236-1

95242-1

• Calibration Jig 95241-1

• Current Monitoring Probes

• Signal Source/Generator

• Power Amplifier(s): The power amplifier should be capable of

supplying the full rated power into the current

injection probes (which have a high VSWR)

with a low harmonic content.

• Spectrum Analyzer or Measuring Receivers

• Directional Coupler

• RF Voltmeter(s)

• RF Absorbing Clamp

• RF Attenuator

• RF Loads

18 | Application

Page 19

DIAGRAM 1

Sample Conducted Susceptibility Calibration

Setup Diagrams

Application | 19

Page 20

DIAGRAM 2

20 | Application

Page 21

5.0 Conducted Emission: Transfer Impedance

The Bulk Current Injection Probe (BCIP) may also be used as a sensor for

I

measuring conducted emission. The RF current

conductor under test is determined from the measuring receiver reading of the

E

probe output

(in ohms).

(in microvolts) divided by the probe transfer impedance ZT

S

IP = ES / ZT

Or, in dB:

IP(dBµA) = ES(dBµV) – ZT(dB)

The transfer impedance is determined by passing a known RF current IP through

the primary test conductor and noting the voltage

load on the probe output.

(in microamperes) in the

P

E

developed across a 50 ohm

S

ZT = ES / I

Calibration gig 95241-1 may be used for this determination. Following are the

typical transfer impedance values when the BCIP is used as a sensor.

High sensitivity and minimal core gap indicate that the current probe

should be used only on signal lines where heavy currents are not

encountered. Heavy currents may affect measurement accuracy

should current probe core saturation occur.

Conducted Emission: Transfer Impedance | 21

P

Page 22

Model 95236-1

Frequency (MHz) ZT (Ω)

1 16

2 20

3 19

4 19

5 19

6 19

7 19

8 19

9 19

10 19

20 18

30 18

40 17

50 16

60 15

70 14

80 13

90 12

100 11

22 | Conducted Emission: Transfer Impedance

Page 23

Model 95242-1

Frequency (MHz) ZT (Ω)

2 7

4 13

6 19

8 22

10 27

20 25

30 27

40 30

50 32

60 32

70 32

80 30

90 30

100 30

200 33

300 32

400 30

Conducted Emission: Transfer Impedance | 23

Page 24

This page intentionally left blank.

24 | Conducted Emission: Transfer Impedance

Page 25

6.0 Insertion Loss

Insertion loss of the Bulk Current Injection Probe (BCIP) may be measured at low

signal levels. ETS-Lindgren offers this measurement as a calibration service. See

the Product Information Bulletin included with your shipment for information on

ETS-Lindgren calibration services.

Equipment

Signal Generator (50 Ohms): 10 kHz to 400 MHz

RF Voltmeter (50 Ohms): 10 kHz to 400 MHz

Calibration Jig: 95241-1

50 Ohm Termination: VSWR <1.2

Bulk Injection Current Probe: 95236-1 or 95242-1

Typical Reference Calibration Setup

Insertion Loss | 25

Page 26

Procedure

1. Connect the signal generator output directly to the RF voltmeter input

as show in Typical Reference Calibration Setup on page 25, indicated

by the dashed line. Use the same cables which connected the

calibration jig and the injection probe under test. Tune to the test

frequency and adjust the signal level for a reference of 0 dBm

indication on the RF voltmeter.

2. Without changing control settings, connect the signal generator output

to the bulk current injection probe input and connect the calibration jig

connector to the RF voltmeter input.

3. Note the RF voltmeter output in dB. The difference between this

reading and 0 dB is the insertion loss. In this measurement, the loss

cannot be less than 3 dB since half the injected power is absorbed by

the 50 ohm termination that is particularly loading (50%) the

calibration jig.

26 | Insertion Loss

Page 27

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your Bulk Current

Injection Probe.

DURATION OF WARRANTIES FOR BULK CURRENT INJECTION PROBE

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to two years.

Product Warranted

Model 95236-1 Bulk Current Injection Probe 2 Years

Model 95242-1 Bulk Current Injection Probe 2 Years

Duration of

Warranty Period

Warranty | 27

Loading...

Loading...