ETS 5502 Operating Manual

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B - 20190722

Mini Environmental Chambers for Instron

Single Column 3300, 5500, and 5900

ETS Model 5502 Operating Manual

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 2

Table of Contents

I. Important Safety Information

II. Description of contents

III. Setup Guide

IV. Quick Start Guide

V. Operation Guide

VI. Maintenance/Calibration

VII. Warranty

VIII. Liquid Nitrogen Safety Addendum

IX. Liquid Nitrogen Cooling System Set-Up Addendum

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 3

I. Important Safety Information

SAFETY INSTRUCTIONS

The equipment described in this Manual is designed and manufactured to operate within defined design

limits. Any misuse may result in electric shock or fire. To prevent the equipment from being damaged,

the following rules should be observed for installation, use and maintenance. Read the following

safety instructions before operating the instrument.

POWER

POWER CORD: Use only the power cord specified for this equipment and certified for the country of use. If the

power (mains) plug is replaced, follow the wiring connections specified for the country of use. When installing or

removing the power plug, hold the plug, not the cord.

The power cord provided is equipped with a 3-prong grounded plug (a plug with a third grounding pin). This

is both a safety feature to avoid electrical shock and a requirement for correct equipment operation. If the outlet

to be used does not accommodate the 3-prong plug, either change the outlet or use a grounding adapter.

FUSES: Replace fuses only with those having the required current rating, voltage and specified type such as

normal blow, time delay, etc. DO NOT use makeshift fuses or short the fuse holder. This could cause a shock or

fire hazard or severely damage the instrument.

OPERATION

CAUTION

DO NOT OPERATE WITH COVERS OR PANELS REMOVED. Voltages inside the equipment

consist of line (mains) that can be anywhere from 100-240VAC.

DO NOT OPERATE WITH SUSPECTED EQUIPMENT FAILURES. If any odor or smoke becomes apparent

turn off the equipment and unplug it immediately. Failure to do so may result in electrical shock, fire or permanent

damage to the equipment. Contact the factory for further instructions.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE: Operating the equipment in the presence of flammable

gases or fumes constitutes a definite safety hazard. For equipment designed to operate in such environments

the proper safety devices must be used such as dry air or inert gas purge, intrinsic safe barriers and/or explosionproof enclosures.

DO NOT IMPEDE THE CHAMBER FROM VENTING EXCESS PRESSURE. The humidification and

dehumidification systems are open loop systems that pump external air into the chamber. If the chamber is not

allowed to vent, pressure could build up and cause serious damage to the chamber.

USE DISTILLED OR DEIONIZED WATER SOURCE FOR HUMIDIFICATION. Build-up of contaminates on the

transducer will cause stress to the transducer and electronics and resulting in premature failure and invalidate

the warranty.

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 4

IF YOUR UNIT INCLUDES OPTIONAL LIQUID NITROGEN COOLING CAPABILITES, REVIEW ALL SAFETY

INFORMATION IN THE LIQUID NITROGEN SAFETY ADDENDUM.

DO NOT USE IN ANY MANNER NOT SPECIFIED OR APPROVED BY THE MANUFACTURER:

Unapproved use may result in damage to the equipment or present an electrical shock or fire

hazard.

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 5

II. Description of Contents

Included:

Item

Qty.

Description

Control Unit

1

Control unit houses the primary control and operating systems to

support heating, cooling, humidification, and dehumidification.

Control Unit Base

1

Base provides support for the control unit and adjustability to align the

control unit with the chamber which will mounted to the Instron unit.

Chamber

1

The Model 5502 includes one chamber as standard. However, chambers are

frequently customized to the application and quantity and size may vary.

Water tank

1

One 2.5-gallon water tank is included as standard. Optionally, the

humidification system can be connected directly to a DI water supply.

Tubing

1

One 10-foot length of tubing is provided to be used for connecting the

water supply, air supply, and water drainage.

Power Cord

1

AC line cord for connecting the control unit to power.

Chamber Support

Bracket and Hardware

1

1 bag containing the vertical support bracket and hardware.

Chamber Base Mounting

Hardware

1

1 bag containing standoffs and hex bolts for mounting chamber to base

of Instron unit.

Cleaning Brush

1

Cleaning brush for preventative maintenance cleaning of the

humidification system ultrasonic transducers.

Optional LN2 cooling:

DC Power Cable

1

Over pressure safety DC power cable

Optional: LN2 cooling:

High pressure hose

1

LN2 High Pressure Hose

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 6

III. Setup Guide

Part 1: Mount the Environmental Chamber onto the Instron unit

Tools Needed:

□ Adjustable wrench

□ 4mm Allen wrench

□ Phillips screwdriver

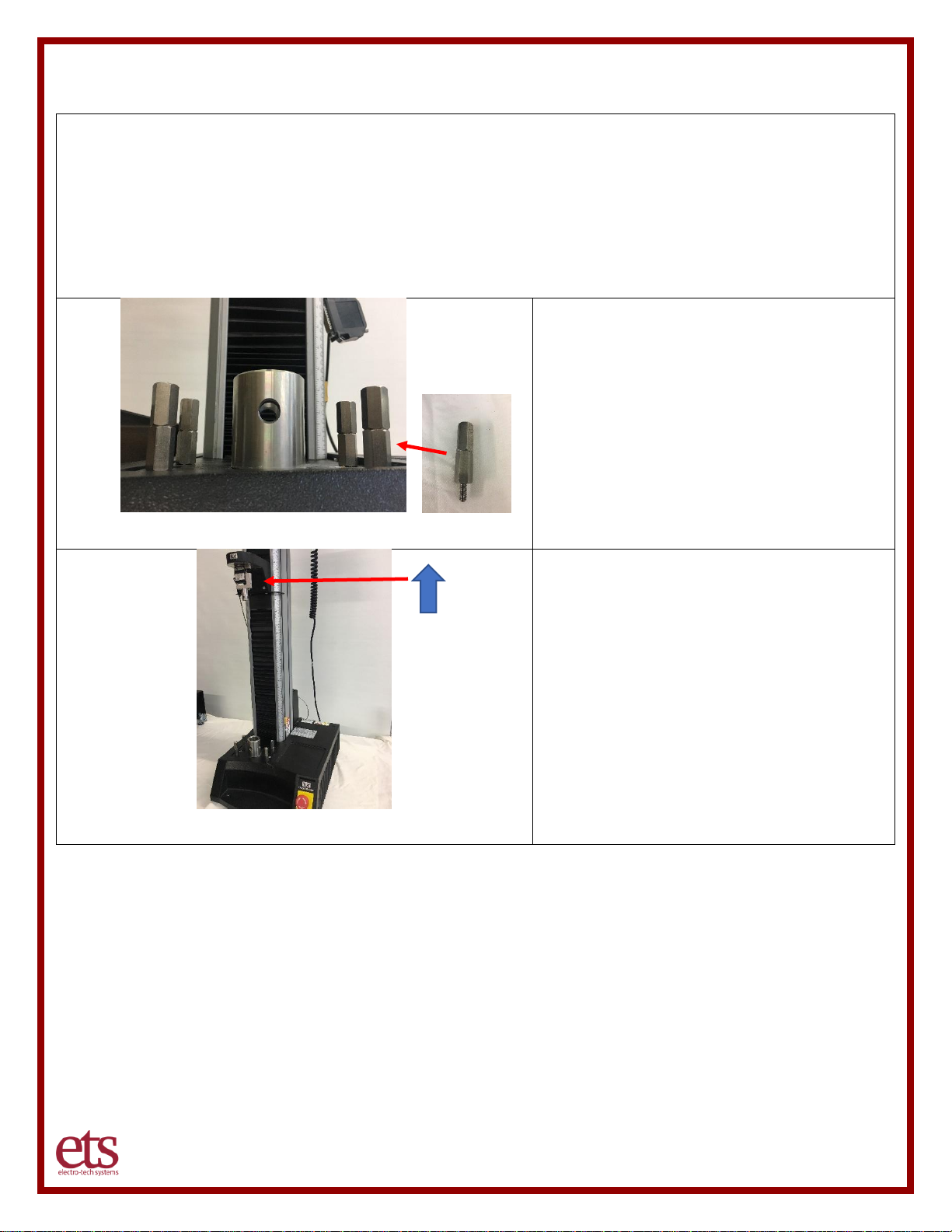

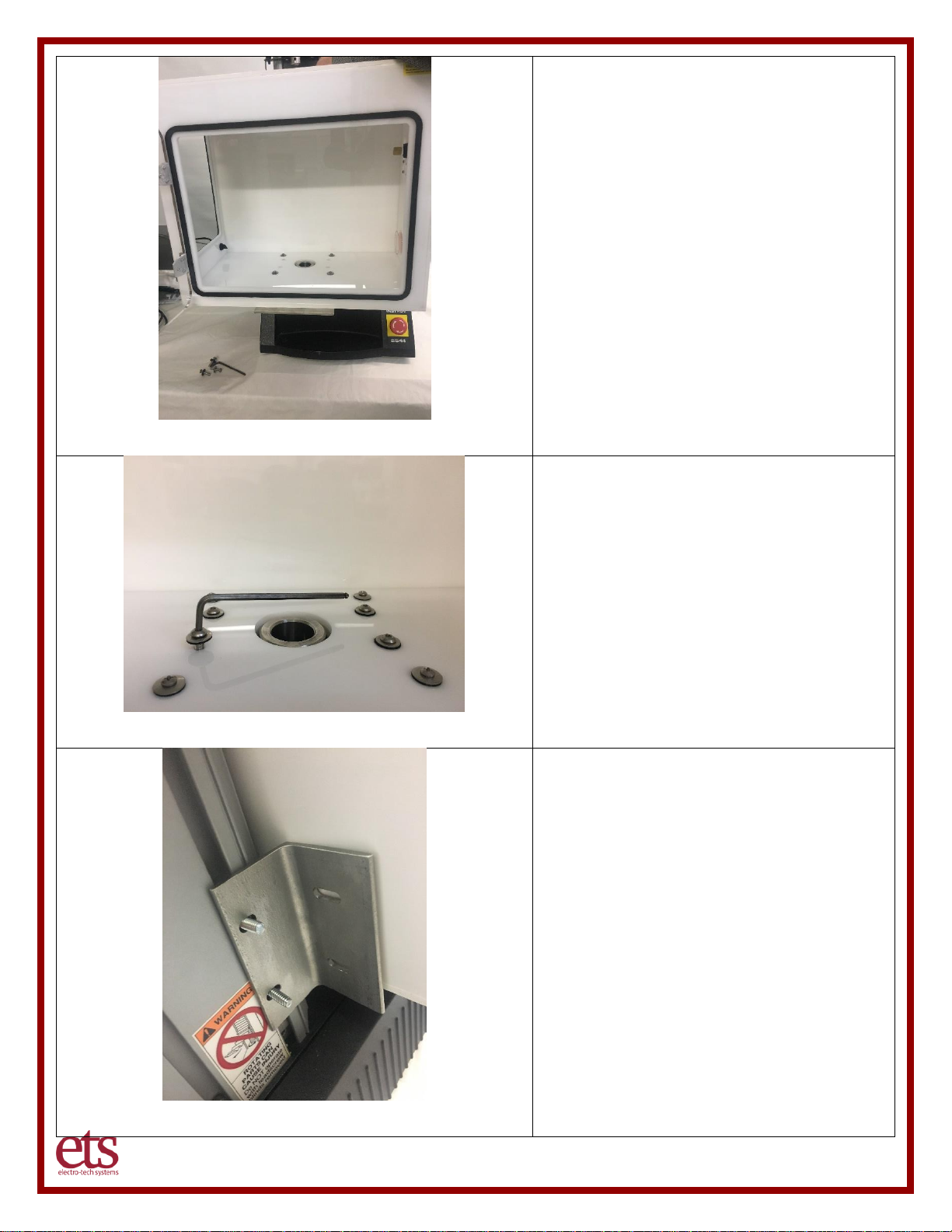

Step 1 – Attach Chamber Standoffs

Insert and tighten the four 2” inch tall standoff

assemblies into the 4 threaded holes in the

Instron platform as shown. An adjustable

wrench can be used to tighten the standoffs.

Step 2 – Raise the Instron armature

Make sure the armature of the Instron unit is

fully raised to ensure it is not in the way of

mounting the environmental chamber.

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 7

Step 2 – Set the chamber in place

With 2 people, carefully place the chamber

centered from left to right) onto the standoffs

and slide the chamber back into place until

the hex standoffs and center Instron post

align with the holes of the bottom metal

support plate. Once in place, have one

person hold the chamber steady in place,

while the other person completes the next

step of attaching using screws.

Step 3 – Insert and tighten screws

Once the chamber is in place and the

mounting holes are aligned, utilize the four

M6x25mm screws and shock mount washers

(rubber side down) to attach the chamber to

the standoffs. Use a 4mm Allen wrench to

tighten the screws.

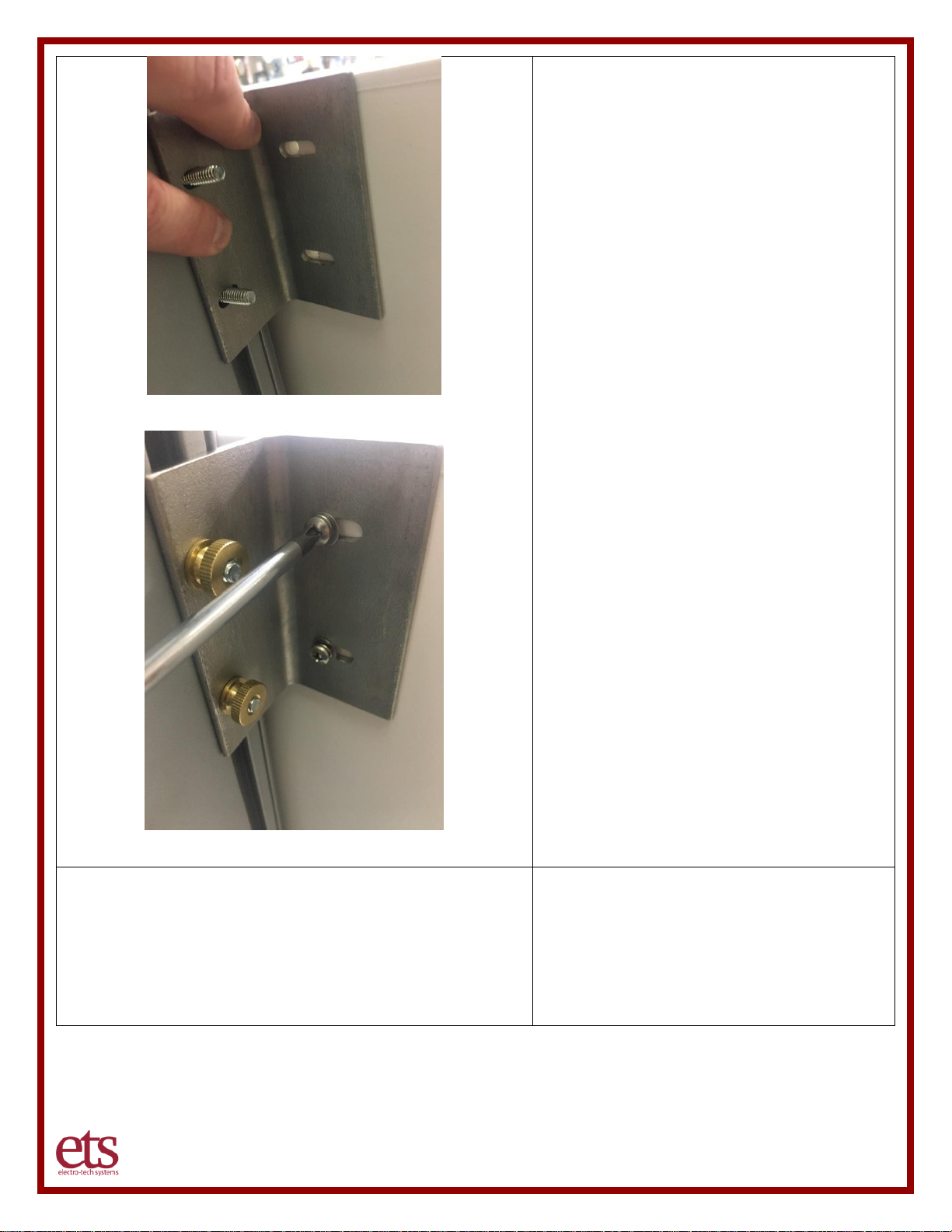

Step 4 – Attach rear support bracket

Attach rear support bracket to the Instron

Column utilizing the T-slot nuts.

Start by placing the T-slot nuts into the

channel on the Instron column and let them

fall to the bottom of the channel. Thread the

¼”-20 1-inch studs loosely into the T-slot

nuts. Do not tighten; the t-slot nuts still need

to be able to slide in the channel.

Slide the top stud up and place the bracket

onto the studs with one stud in each of the

slots in the bracket. The bracket should be

oriented with the side having the shorter slots

placed against the column [and the side with

the longer slots placed against the chamber].

www.electrotechsytems.com 833-ENV-GURU (833) 368-4878 D00804 Revision B – 20190722 - Page 8

Next, slide the entire bracket upward until the

long slots on the bracket align with the holes

in the chamber. Loosely attach the bracket

to the ETS chamber using the 10-24x3/4”

pan head screws, #10 split washer, and #10

washer. Do not tighten pan head screws.

You can now finger tighten the studs on the

Instron column to lock the T-slot nuts into

place.

Next thread the ¼”-20 thumb nuts loosely

onto the studs on the Instron column. Do not

tighten.

With the bracket in place flush against both

the Instron column and ETS chamber,

proceed to tighten the screws and

thumbnuts. Utilize a Phillips screwdriver to

tighten the 10-24x3/4” pan head screws.

Be careful to avoid placing any strain on the

chamber that could cause stress/cracking. If

necessary, STOP, and loosen the hardware

and readjust the position of the bracket to

eliminate any physical stress and then

tighten.

Refer to documentation from Instron for your

model of single column Instron unit.

Step 5 – Set limits on Instron column

To avoid the Instron unit armature from

destroying the chamber accidently, set your

lower physical stop limit on your Instron

armature to a safe level to avoid physical

contact with the chamber.

Loading...

Loading...