HARMONIC™

Generator 300 System

Service Manual

GEN04

1

GEN04

Table of Contents

Introduction – Harmonic Generator 300 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1 – Warnings, Precautions and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Chapter 2 – General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3 – Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 4 – System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 5 – Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Controls, Indicators, and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Screen Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 6 – Cleaning and Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Generator and Cart Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Foot Switch Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 7 – Safety and Function Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Safety Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Chapter 8 – Generator Output Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Procedure for Checking the Output of GEN300 Generators . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chapter 9 – High-Level System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Audible Indicators and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error Codes and Displays in Normal Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 10 – Hand Piece Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Procedure for Checkout/Screening of HP054 Hand Pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2

GEN04

Service Manual

Chapter 11 – Advanced Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Error Code Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Estimating Hand Piece Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Generator Error Log Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Hand Piece Error Log Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Chapter 12 – Hardware Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Common Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Chapter 13 – Generator Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Required Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Calibration One . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Calibration Two . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Chapter 14 – System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Chapter 15 – Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Power Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Audible Activation Tone Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Chapter 16 – Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Available Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Service and Repair Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 17 – Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 18 – Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix A – Mains Power Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Appendix B – GEN04 Assembly Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Appendix C – GEN04 Top Level Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

3

GEN04

Introduction

Scope

This manual and the equipment it describes are for use only by qualified Biomedical Service Personnel. It is

intended only as a guide for technical maintenance of the HARMONIC™ Generator 300 System.

This manual is intended to be a companion to the HARMONIC™ Generator 300 System Operator’s Manual. A

thorough understanding of the Operator’s Manual is required to properly understand and use the information

in this service manual.

Installation Guidelines

The person installing the device shall ensure that the installation, inspection, and any required testing are

performed in accordance with the instructions in this and the HARMONIC™ Generator 300 System Operator’s

Manual. The inspection shall be documented along with any test results to demonstrate proper installation.

Ethicon Endo-Surgery reserves the right to change the electrical/electronic or mechanical configurations and

components without notice. Schematic revisions may not match PCB revisions in the unit being

maintained; consult Ethicon Endo-Surgery before making any changes. When necessary, amendments to this

manual will be made available by request only.

Product Information

Product Name: H

ARMONIC™ Generator 300 System (formerly known as ULTRACISION

®

HARMONIC SCALPEL

®

Generator 300 System)

Model Number/Product Code: GEN300/GEN04

Voltage: 100 – 240 VAC

This manual is subject to revision. When referring to this manual please include the following:

Document Type: Service Manual

Document Number: P40401P0X (on back cover of manual)

Manufactured by:

Ethicon Endo-Surgery, LLC

Guaynabo, Puerto Rico 00969 USA

1-800-USE-ENDO (U.S.Customers)

http://www.harmonicscalpel.com

Service

1-800-USE-ENDO (U.S. Customers)

Customers outside the U.S. should contact their Ethicon Endo-Surgery representative for assistance.

4

GEN04

Service Manual

5

GEN04

Chapter 1 - Warnings, Precautions and Notes

Warnings and Precautions

• This equipment, in conjunction with the accessories, is intended to produce high-frequency

mechanical energy which enables hemostatic cutting and/or coagulation of soft tissue.

• Safe and effective ultrasonic surgery is dependent not only upon equipment design, but also, to a

large extent, upon factors under control of the operator. It is important that the instructions supplied

with this equipment be read, understood, and followed in order to enhance safety and effectiveness.

• The HARMONIC™ Generator 300 System, including the hand piece, is not Magnetic Resonance safe

and is not Magnetic Resonance compatible.

• Equipment is not suitable for use in the presence of a flammable anesthetic mixture with air or with

oxygen or nitrous oxide. It is possible to create sparks by hitting other metal instruments. Sparks

may ignite flammable gases such as bowel gas.

• The HARMONIC™ Generator 300 System must be operated within the required ambient operating

conditions. Refer to Chapter 14 – System Specifications.

• The HARMONIC™ Generator 300 System should be tested on a periodic basis by qualified biomedical

maintenance personnel to ensure proper and safe operation.

• Refer all servicing to qualified biomedical personnel. Your Ethicon Endo-Surgery

representatives are available to assist in having your equipment serviced.

• Removing the top cover of the generator unit may expose the user to parts within the generator unit

which may have high surface temperatures and high voltage. These surfaces are potentially

dangerous and should be treated with extreme caution.

• Always unplug the generator from the wall outlet prior to opening the cover for servicing. This poses

a potential electric shock hazard.

• After removing the cover, inspect the internal components for obvious damage or foreign debris.

Never power ON a suspected problem unit.

• Never remove or install any parts with power on.

• To avoid user or patient injury in the event that accidental activation occurs, the The HARMONIC™

Generator 300 System instrument blades should not be in contact with the patient, drapes, or

flammable materials while not in use. During prolonged activation in tissue, the instrument blade,

clamp arm and distal end of the shaft may become hot. Avoid unintended blade contact with tissue,

drapes, surgical gowns, or other unintended sites after activation.

• The user should verify that the power receptacle with which this unit is used is properly grounded

and is correctly polarized. Do not use ground cheater plugs or extension cords. Do not connect the

The HARMONIC™ Generator 300 System to an ungrounded outlet. Grounding reliability can only be

achieved when this equipment is connected to a hospital-grade receptacle. (Refer to

Chapter 14 – System Specifications.)

• Verify that the outlet voltage correctly corresponds to the generator’s requirements. (Refer to

Chapter 14 – System Specifications.) Connection to an improper power supply may result in damage

to the generator and risk of shock or fire hazard.

6

GEN04

Service Manual

• Do not connect the The HARMONIC™ Generator 300 System to an ungrounded outlet. Grounding

reliability can only be achieved when this equipment is connected to a hospital-grade receptacle.

• Spilling or spraying fluids on or into the generator or immersing the generator may result in damage

to the generator and risk of shock or fire hazard.

• Do not place liquid containers on top of the unit. Wipe spilled liquids off the unit immediately. To

avoid inadvertent penetration of liquids, do not operate this unit in a tilted position.

• Locate the The HARMONIC™ Generator 300 System, including the hand piece cable, at least 3 ft.

(approximately 1 m) from electrosurgical systems and their hand piece (e.g., pencil) cables. The

generator should not be on the same circuit as other equipment and machines. Please note that

different outlets may not necessarily mean different circuits.

• To prevent overheating during use, ensure that the air vents found on the generator’s bottom and

back panels are not blocked and that they allow adequate clearance from obstructions to allow air to

flow freely through the generator enclosure. Avoid placing the generator on a soft surface.

• Use proper electrical safety and hospital procedures when working on the generator unit.

• The AC mains voltage presents a shock hazard and is accessible when the generator cover is

removed. Caution must be used near internal system components, which attach directly to the AC

mains such as the power entry module, mains fuses, power switch, and open-frame 48V power

supply.

• It is hazardous to connect non-isolated probes to specific isolated sections of the generator. Doing

so may introduce a high voltage from the hand piece to earth ground and produce a shock hazard.

• Refer to all other HARMONIC™ System documentation to review operating procedures.

Notes

• Use only Ethicon Endo-Surgery approved replacement parts. Contact the

Ethicon Endo-Surgery representative for assistance in obtaining replacement parts by calling

1-800-USE-ENDO for customers in the United States. Customers outside the U.S. should contact

their Ethicon Endo-Surgery representative for assistance.

• Minimizing operating temperature and extreme thermal cycles will extend the life of the equipment.

• Throughout this manual “instrument(s)” refers to The HARMONIC™ Generator 300 System blades,

ball coagulators, or coagulating shears.

7

GEN04

Chapter 2 - General Description

System Description

The HARMONIC™ Generator 300 System utilizes ultrasonic energy to enable hemostatic cutting and/or

coagulation of soft tissue. The system consists of an ultrasonic generator, a foot switch, an optional hand

switching adaptor, a hand piece, and a variety of open and minimally invasive instruments.

Note: Throughout this manual “instrument(s)” refers to The HARMONIC™ Generator 300 System blades, ball

coagulators, or coagulating shears.

The HARMONIC™ instruments vibrate longitudinally at 55.5 kilohertz. This ultrasonic vibration at the blade

enhances its cutting ability. The same vibration seals small vessels with coagulated blood and tissue proteins.

Hemostasis occurs when tissue couples with the instrument. This coupling causes collagen molecules within

the tissue to vibrate and become denatured, forming a coagulum.

Indications

The H

ARMONIC™ Generator 300 System is indicated for soft tissue incisions when bleeding control and

minimal thermal injury are desired. The HARMONIC™ Generator 300 System instruments can be used as an

adjunct to or substitute for electrosurgery, lasers, and steel scalpels.

Contraindications

• The instruments are not indicated for incising bone.

• The instruments are not intended for contraceptive tubal occlusion.

System Components

Generator 300

The generator supplies the hand piece with electrical energy and facilitates selection of power levels, system

monitoring, and system diagnostics.

Power is delivered by activating the foot switch or hand switching adaptor.

Hand Piece

The hand piece contains an acoustic transducer that converts the electrical energy supplied by the generator to

mechanical motion. The transducer is connected to an ultrasonic wave guide/amplifier which amplifies the

motion produced by the transducer and relays it to the instrument.

Instrument

The mechanical motion from the hand piece advances to the instrument, transmitting ultrasonic energy which

enables hemostatic cutting and/or coagulation of tissue.

Power Levels

The generator delivers two power levels: minimum (MIN) and maximum (MAX). The minimum power level

may be adjusted by the user from Level 1 to 5. The maximum power level is always Level 5. With all

instruments except the ball coagulator, use a higher generator power level for greater tissue cutting speed and

a lower generator power level for greater coagulation. For the ball coagulator, higher generator power levels

will provide greater coagulation. The amount of energy delivered to the tissue and resultant tissue effects are

a function of many factors including the power level selected, instrument characteristics, grip force (when

applicable), tissue tension, tissue type, pathology, and surgical technique.

Note: Refer to the instruments’ package inserts for additional power level information.

8

GEN04

Service Manual

9

GEN04

Chapter 3 - Theory of Operation

The HARMONIC™ Generator 300 System consists of the following components: Generator (GEN04),

hand piece, instruments, foot switch, and hand switching adaptor (if used). The generator produces an electric

signal, which is transmitted via a coaxial cable to the hand piece, which then converts the electrical signal

into ultrasonic, mechanical motion.

Hand Piece

The hand piece houses several major components that generate, amplify, and deliver ultrasonic energy to the

instrument end-effector. When each component is attached to the other and tuned, an acoustic drive train is

formed. Two key parts of the acoustic system or acoustic drive are:

Acoustic Transducer: Converts the electrical energy into motion. When an AC waveform is applied to the

transducer, the piezoelectric material expands and contracts to produce longitudinal motion.

Instrument: Couples the ultrasonic energy to the tissue and amplifies motion. In a laparoscopic configuration,

the instrument is elongated by means of a "Laparoscopic Extension." This extension allows the ultrasonic

energy to propagate from the hand piece to the instrument with minimal loss.

Generator

The generator converts the AC line voltage to a controlled DC level. The DC level is then modulated at the

resonant frequency of the hand piece. The modulated signal is then filtered and delivered to the hand piece,

where it resonates the acoustic drive train. A more detailed description follows.

Power Entry Module: Accepts a standard, hospital grade utility cord. Refer to Chapter 14 – System

Specifications for details. Provides susceptibility filtering from the external environment as well as

suppressing electromagnetic emissions produced by the generator that could be conducted back through the

power cord.

Power Supply: Provides 48 VDC to DC/DC Converter and Current/Power Regulation Circuit.

Current and Power Regulation Circuit: Provides Current/Power regulation. Current limit circuits protect these

assemblies and others from overload conditions.

Patient Isolation Circuit: Provides a safety isolation barrier to patient and/or user. The voltage generated on

the secondary of the transformer is isolated from the primary and thereby not referenced to earth ground.

Microprocessor: The microprocessor contains the software program that drives the HARMONIC™ Generator

300 System. The software provides the user interface, frequency drive signal, as well as drive signals to the

Liquid Crystal Display, front panel indicators, and generator audio circuit.

Liquid Crystal Display and Front Panel: The Liquid Crystal Display and front panel indicators report the

operating mode of the HARMONIC™ Generator 300 System. They are driven by the microprocessor.

Foot Switch and Hand Switching Adaptor

Foot Switch(es): The foot switch(es) allow(s) the user to activate the system in either the minimum (MIN) or

maximum (MAX) modes based on which foot pedal is being pressed. Pedal activations are communicated to

the microprocessor.

Hand Activation Circuit: The hand switching adaptor allows the user to activate the system in either the

minimum (MIN) or maximum (MAX) modes based on which button is being pressed. Hand activations are

communicated to the microprocessor.

10

GEN04

Service Manual

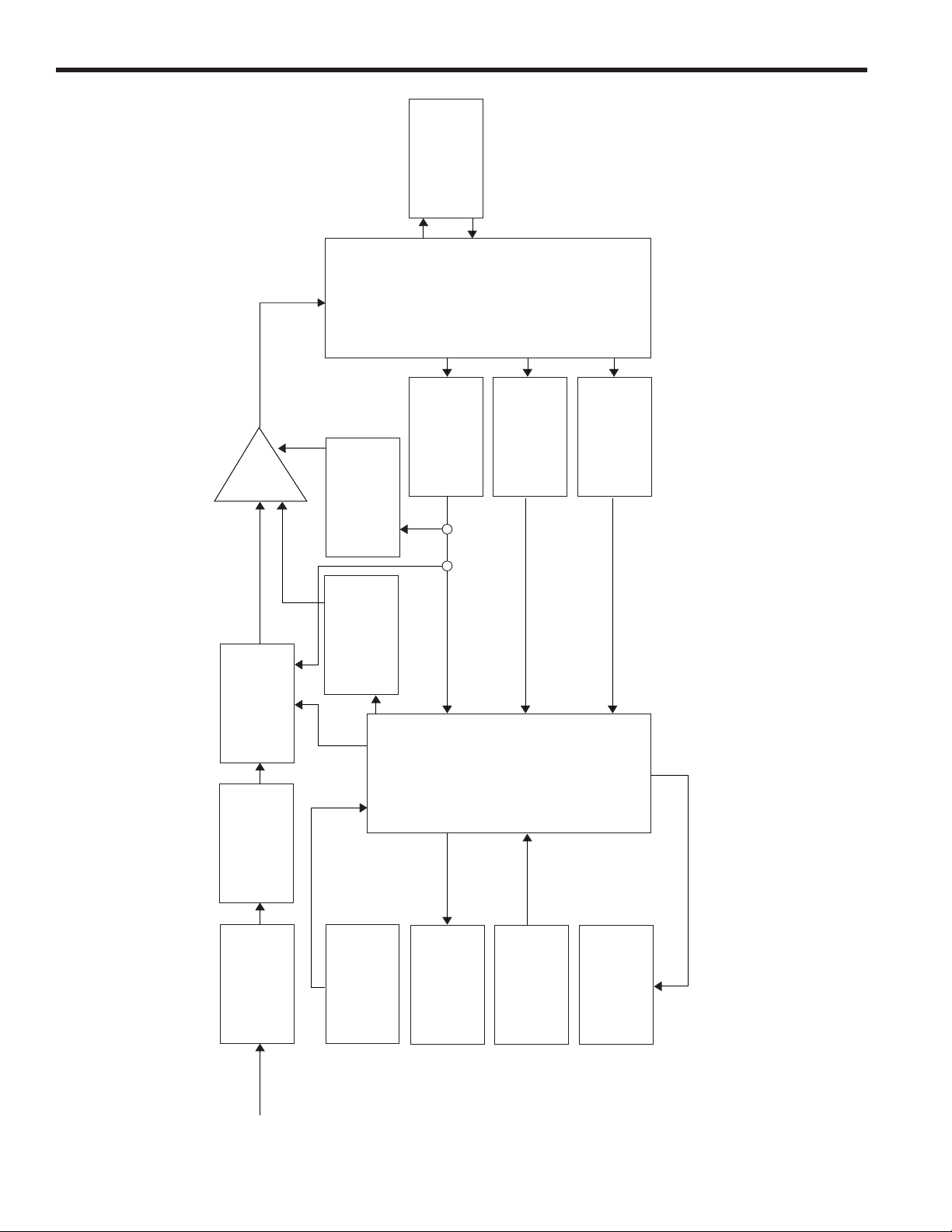

Fig. 3-1 Block Diagram

Power Entry

Module

Foot Switch

Assembly (x2)

Liquid Crystal

Display and Front

Panel Indicators

Front Panel

Switches

Audio

Power Supply

Microprocessor

Current and Power

Regulation Circuit

Drive Frequency

Circuit

Power

Amplifier

Current Limit

Circuit

Current Feedback

Circuit

Voltage Feedback

Circuit

Hand Activation

Circuit

Patient Isolation

Circuit

Hand Piece and

Hand Switching

Adaptor

11

GEN04

Chapter 4 - System Setup

Unpacking Instructions

The HARMONIC™ Generator 300 System includes several components that are purchased separately. Upon

receiving the ordered components, check for visible shipping damage. Do not attempt to use any component

if it appears damaged. If damage is seen, contact your Ethicon Endo-Surgery representative.

Note: The original packaging should be saved for future storing and/or transporting of the device. Warranty

may be voided if the unit is not returned to the service center in the original packaging or equivalent

packaging which will protect the unit from damage during shipment.

System components may include the following parts (for product codes, see Chapter 14 – System

Specifications):

Generator 300 - includes the generator, power cord, user manual, and service manual.

Note: The Operator’s Manual includes a troubleshooting guide (see back pocket of manual binder). Remove

the self-adhesive guide’s backing and adhere the guide to the top panel of the generator. Placement guides for

the Troubleshooting Guide are found on the generator’s top panel.

Foot Switch - includes the foot switch and detachable cable assembly.

Note: The foot switch is required if the system will be used with coagulating shears or instruments that are

not compatible with the hand switching adaptor. Since the generator has receptacles for two foot switches,

two foot switches may have been shipped.

Cart - the cart is optional. It is designed to hold one HARMONIC™ Generator 300 unit. The cart requires

assembly; instructions are included with the cart.

Initial Setup

1 Confirm that the generator power switch is OFF during setup.

Caution: To avoid injury, in the event that accidental activation occurs, the HARMONIC™ Generator

300 System instrument blades should not be in contact with drapes or flammable materials while not

in use. During prolonged activation, the instrument blades may become hot. Avoid unintended blade

contact with drapes, surgical gowns, or other unintended sites after activation.

2 Secure the generator on its cart or on another suitable fixture. To secure the generator on its cart,

place the generator’s rubber feet into the corresponding holes on the cart. Push down on the

generator’s top panel.

Caution: To prevent overheating during use, ensure that the air vents found on the generator’s

bottom and back panels are not blocked and that they allow adequate clearance from obstructions to

allow air to flow freely through the generator enclosure. Avoid placing the generator on a soft

surface.

Warning: The HARMONIC™ Generator 300 System must be operated within the required ambient

operating conditions. (Refer to Chapter 14 – System Specifications for requirements.)

12

GEN04

Service Manual

3 Connect the line cord into the AC inlet located on the generator’s rear panel and into an

appropriately-grounded outlet. If the power cord is wrapped around the cart handle, it must be

completely removed from the cart handle prior to plugging it into the power outlet.

Warning: Verify that the outlet voltage correctly corresponds to the generator’s requirements (Refer

to Chapter 14 – System Specifications). Connection to an improper power supply may result in

damage to the generator and risk of shock or fire hazard.

Caution: Do not connect the HARMONIC™ Generator 300 System to an ungrounded outlet.

Grounding reliability can only be achieved when this equipment is connected to a hospital-grade

receptacle.

4a.Attach the foot switch cable to the foot switch:

Note: Although installation of the foot switch is optional when using the hand switching adaptor,

installing the foot switch is recommended in case its use is needed during the procedure.

• Confirm that the connector and receptacle are dry and clean.

• Orient the slot on the foot switch cable’s larger connector at 12 o’clock.

• Seat the connector in the foot switch receptacle.

• Turn the connector collar clockwise until tight. Ensure the collar is finger-tight to prevent

inadvertent activation that may result from fluid ingress.

b. Connect the foot switch cable’s smaller connector to the foot switch receptacle on the rear panel

of the generator.

• Confirm that the connector and receptacle are dry and clean.

• Align the red dot on the foot switch 4-pin connector with the red dot on the 4-pin receptacle

on the generator back panel.

Note: The generator has two identical foot switch receptacles. If one foot switch is used, either

receptacle may be used.

Repeat steps 4a and 4b if a second foot switch will be used.

5 Connect the instrument and adaptor (or hand switching adaptor), if required, to the hand piece

following instructions in their package inserts.

Note: The hand switching adaptor must be at room temperature to function properly. Do not

immerse in water to cool rapidly. After steam sterilization, allow hand switching adaptor to air cool

for at least 15 minutes prior to use.

6 Connect the hand piece connector to the receptacle on the front panel. Align the white dot on the

connector with the white dot on the generator. Ensure the hand piece connector is clean and dry

before connecting the hand piece to the generator. Fully insert the hand piece connector to assure

complete, proper connection to the generator. (To disconnect the hand piece, firmly grasp the

connector and pull the connector away from the generator.)

13

GEN04

Chapter 4 - System Setup

7 Turn the generator power switch on and observe the power-up sequence. During power-up, the

following indicators on the front panel will briefly illuminate:

• READY, STANDBY, MIN, MAX, TEST, ATTENTION, HAND ACTIVATION

The system will run its start-up sequence and display the software version. An audible tone will

sound during the initiation sequence.

Note: The entire power-up initiation sequence should not exceed ten seconds.

If the start-up sequence deviates from the description above, contact qualified service personnel following

hospital protocol.

When the initiation sequence is complete, the system will go to Standby. If the system senses a generator,

hand piece, or instrument fault during use, an audible alarm (tone with long pulses) will sound and a visual

alarm indicator will appear on the control panel. (Refer to Chapter 9 – High-Level System Troubleshooting or

the Troubleshooting Guide located on top of the generator unit to resolve the problem.)

14

GEN04

Service Manual

15

GEN04

Chapter 5 - Operation

Controls, Indicators, and Connections

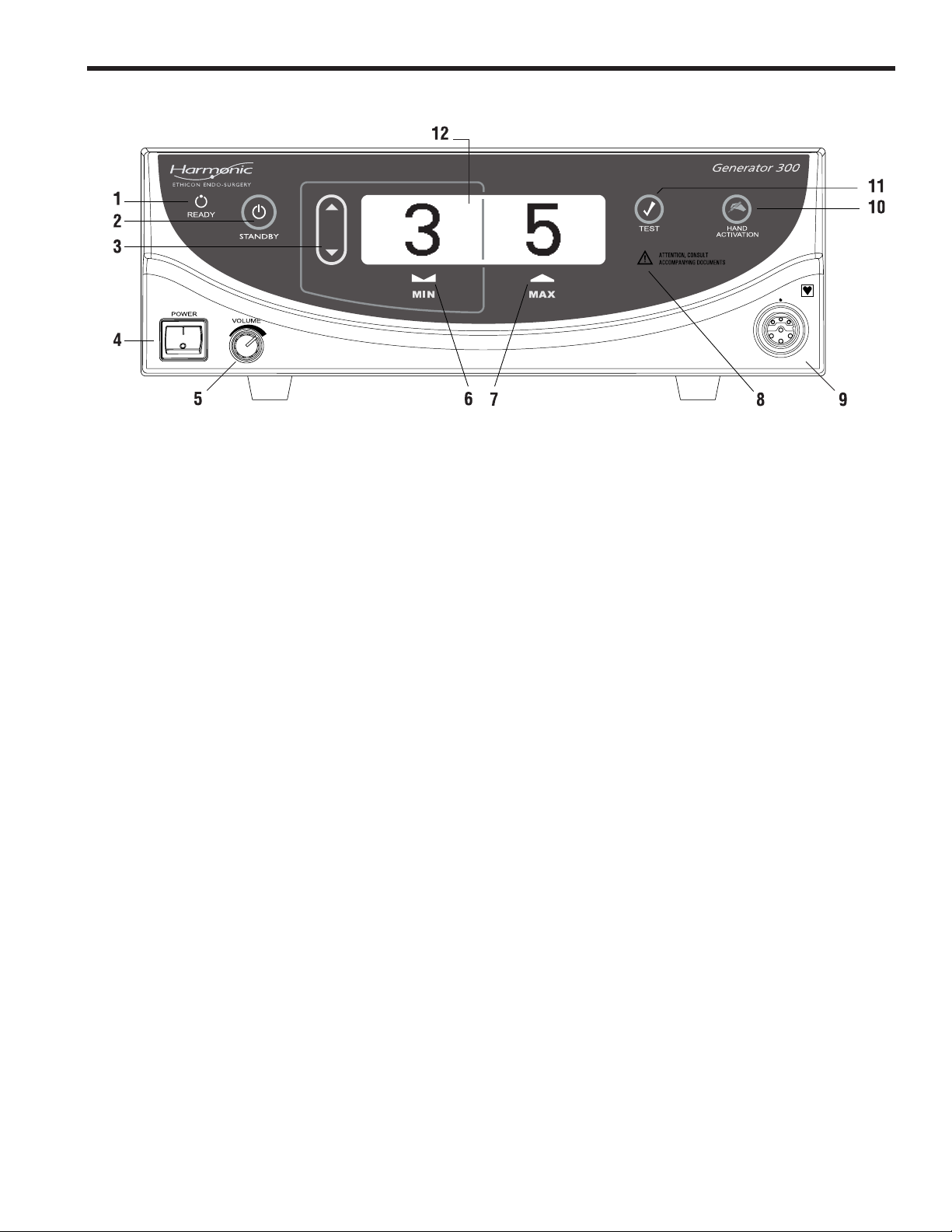

Fig. 5-1 Front Panel

1 READY When this indicator is green, the system is ready for activation.

Note: In the Ready mode, for self-diagnostic purposes, the system sends a

low-amplitude signal to the blade, causing the blade to vibrate slightly. This

vibration does not pose a risk to the user.

2 STANDBY Push this button to toggle between Standby and Ready modes. In Standby mode,

this button, and the STANDBY icon, light up and all power is removed from the

hand piece. Both the foot switch and hand switch are disabled. Upon power-up, the

system defaults to Standby mode enabled.

3 INCREASE/ Push this button to increase or decrease the minimum (MIN) power

DECREASE POWER setting to the desired level (from 1 to 5). The level chosen will be shown

LEVEL on the graphic display. The power level may be adjusted when the generator is in

Ready or Standby mode.

4POWER This switch controls the main electrical power to the generator.

5 VOLUME Turn this knob to adjust the volume of the activation tones. A tone will sound

indicating the volume level selected.

6MIN Indicates the user-settable MIN power level setting. When this power level is

activated (by foot switch or hand switch), the MIN indicator will flash. On

power-up the system defaults to MIN power level 3. Refer to the instruments’

package inserts for the recommended MIN power level.

7 MAX Indicates the maximum power level setting. This setting is always “5”. When this

power level is activated (by foot switch or hand switch), the MAX indicator will

flash.

8 ALARM INDICATOR This red indicator appears only if a system alarm occurs in response to a

component or generator problem.

16

GEN04

Service Manual

9 HAND PIECE This receptacle is used to connect the hand piece to the generator.

RECEPTACLE

10 HAND ACTIVATION When the indicator is green, hand activation on the hand switching adaptor is

enabled. To disable the Hand Activation mode, depress the button. Upon power-up,

the system defaults to Hand Activation mode disabled.

Note: If the foot switch is installed, the foot switch is always enabled.

11 TEST Depressing this button initiates the Test mode. This mode is used during

troubleshooting. The generator will emit a tone when the Test mode is active and

“TEST IN PROGRESS” will appear on the display.

12 GRAPHIC DISPLAY In Ready or Standby modes, this display indicates the minimum (user-settable

level 1 to 5) and maximum (level 5) power levels. If a system or component

problem exists, error codes will appear on this display.

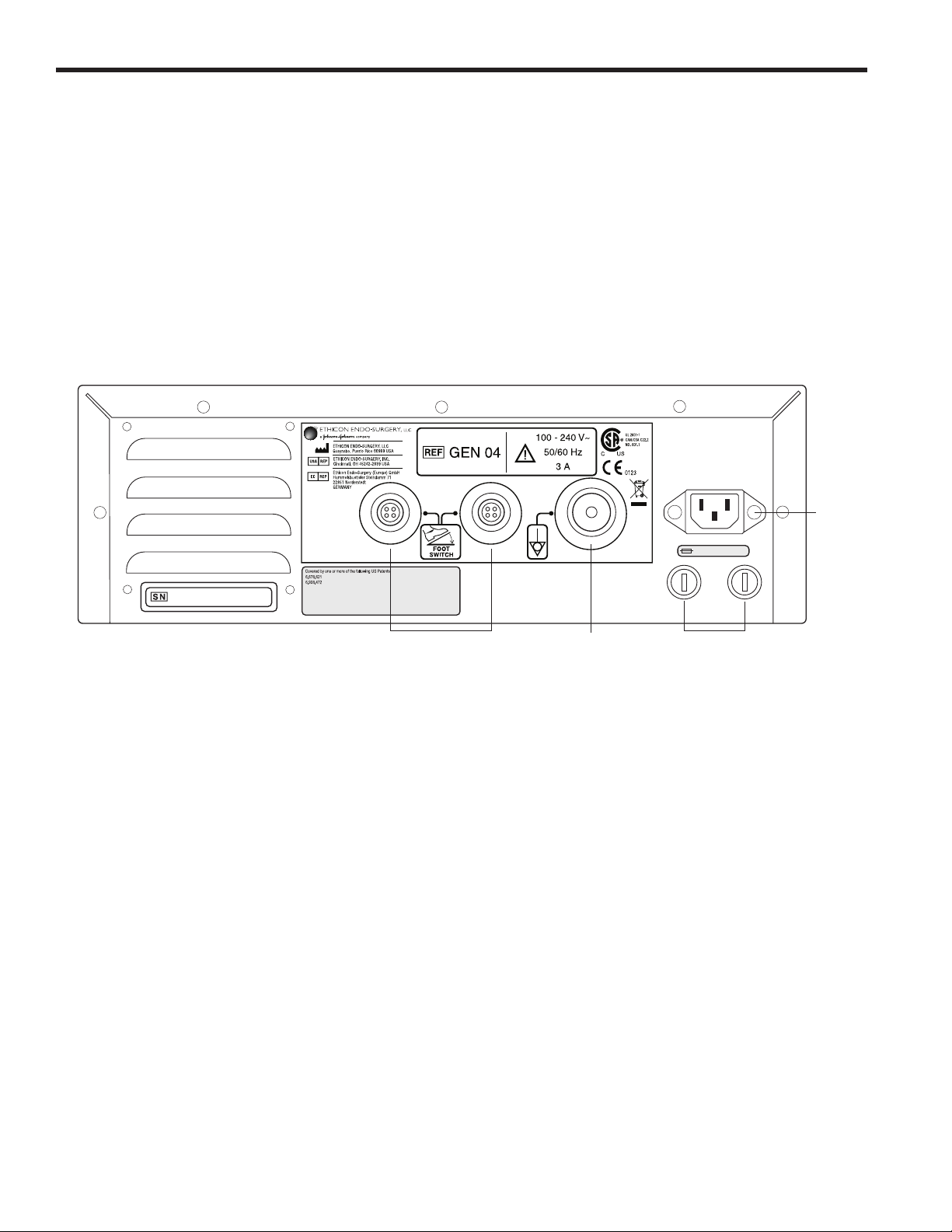

Fig. 5-2 Back Panel

13 FOOT SWITCH Identical receptacles allow connection of up to two foot switch

RECEPTACLES assemblies for user convenience. If only one foot switch is used, connect to either

receptacle.

14 POTENTIAL This terminal provides a means for connection to a Potential Equalization

EQUALIZATION Conductor.

TERMINAL

15 FUSES Refer to the Replacement Parts drawings in the back of this manual for additional

fuse locations and fuse type.

16 POWER CORD This receptacle is used to attach the power cord to the generator. For

RECEPTACLE power cord requirements, refer to Chapter 14 – System Specifications.

AUDIBLE SIGNALS The generator delivers audible tones to signal activation, test, and alarm states. The

user may choose from three activation tone pitches. Refer to

Chapter 15 – Adjustments for tone selection information. Upon power-up, the

system defaults to the last tone chosen (the mid-pitch tone is factory-set).

16

T3.15H 250V

13 14 15

17

GEN04

Chapter 5 - Operation

Screen Descriptions

Power-Up Screen

Below is an example of the Software Version displayed during power-up.

Fig. 5-3 Power-Up Screen

Tone Selection Screen

Refer to Chapter 15 – Adjustments for descriptions of the Tone Selection Screens.

User-Initiated and Pre-Activation Test Screens

The generator will cycle between the following two screens, displaying each screen briefly, for the duration

of the time that the system is in the User-Initiated Test state and Pre-Activation Test state. Refer to

Chapter 7 – Safety and Function Testing for details.

Fig. 5-4 Test in Progress Screens

Standby, Ready and Run Screens

The Standby, Ready, and Run screen appearances depend on the mode in which the system is running. In

Normal mode, the Standby, Ready, and Run screens are the same and indicate the MAX power level of 5 on

the right, and the user selected MIN power level on the left (1 to 5). In Developer/Biomed mode, the Standby

screen indicates the user selected MIN power level on the left, and a subset of system parameters on the right.

In Developer/Biomed mode, the Ready screen displays the user selected MIN Power level on the left (1 to 5)

and the system run time parameters on the right. Developer/Biomed Run screen is identical to the

Developer/Biomed Ready screen.

18

GEN04

Service Manual

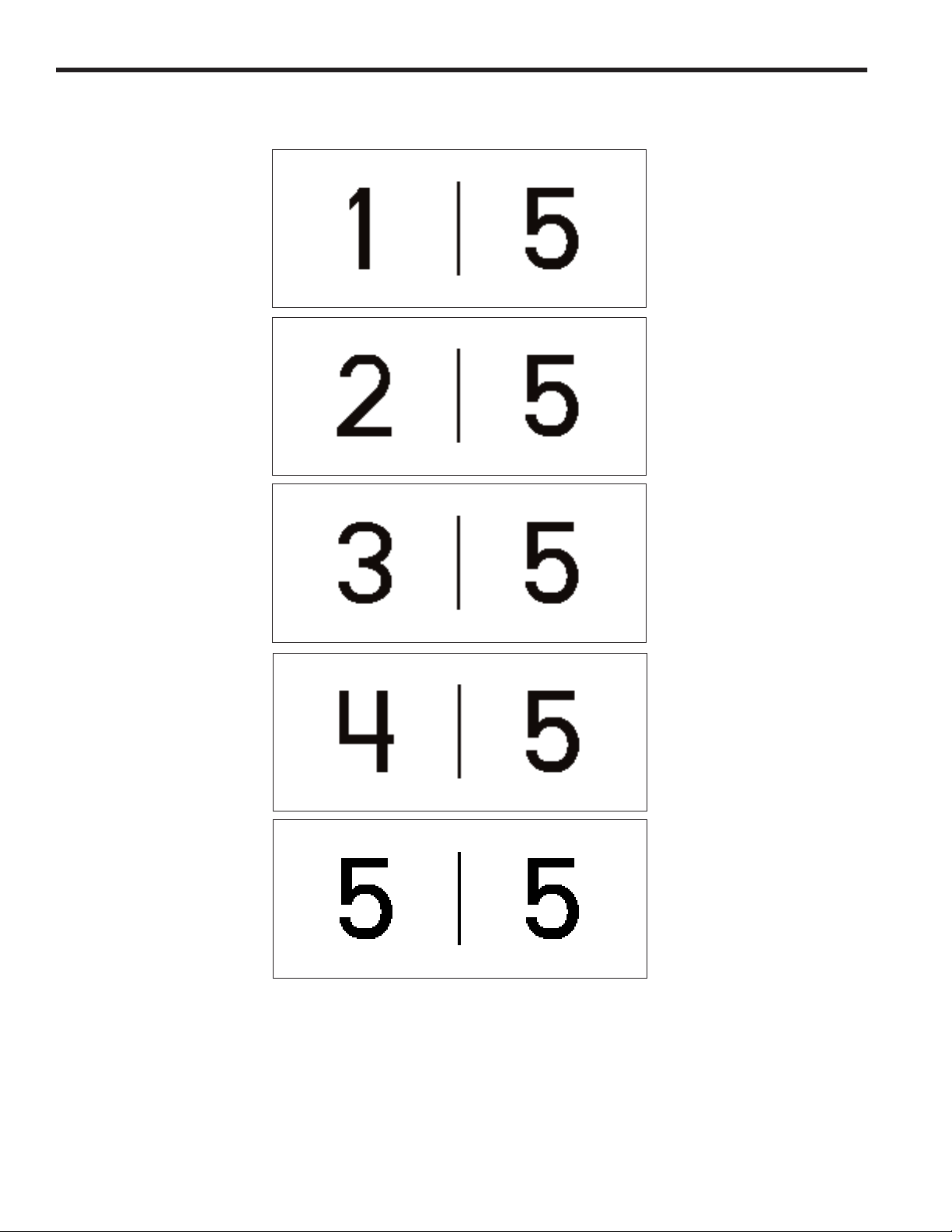

The following are all possible screens for the Standby, Ready, and Run states in Normal mode. The number

on the left indicates the power level for MIN activation (1 to 5), and the number on the right is the power

level for MAX activation.

Fig. 5-5 Standby, Ready and Run Screens in Normal Mode

Error Screens

Refer to Chapter 9 – High-Level System Troubleshooting for examples of each of these screens.

19

GEN04

Chapter 5 - Operation

System Operation

For an understanding of system operation, refer to the HARMONIC™ Generator 300 System Operator’s

Manual for instructions and specifications for use of the HARMONIC™ Generator 300 System, Foot Switch,

and Cart. Refer to package inserts provided separately for information about the Hand Piece, Hand Switching

Adaptor, Adaptors, Test Tip and Instruments prior to using the system. This manual is not a reference to

surgical techniques.

After completing system setup, the system may be operated.

1 Place the generator in Ready mode by depressing the STANDBY button.

Note: In the Ready mode, for self-diagnostic purposes, the system sends a low-amplitude signal to

the blade, causing the blade to vibrate slightly. This vibration does not pose a risk to the user.

2 System check and activation:

Each time the generator is activated after exiting Standby, hold the instrument in the air (if

coagulating shears are used, open the clamp arm) and depress the MIN or MAX power level on the

foot switch or hand switching adaptor. “TEST IN PROGRESS” will appear on the graphic display

and a rapid two-tone pulse will sound while the test is occurring. During this five-second period, a

system check is being performed.

• If the system is operating properly, the activation tone corresponding to the power level activated

will be heard when the check is complete. Stop activation, position the instrument on tissue, and

resume activation.

• If the system is not operating properly, an error code will appear (refer to Chapter 9 – High-Level

System Troubleshooting or the Troubleshooting Guide located on top of the generator unit).

Warning: To avoid user or patient injury, ensure that the instrument is clear of other instruments,

drapes, the patient or other objects during the system check. Safety measures (in accordance with

hospital protocol) taken in the presence of aerosols should be in effect during the system check.

Note: The foot switch or hand switch must be depressed until the system check is complete. If the

switch is released prematurely, the check will reinitiate at the next activation.

Note: The HAND ACTIVATION button on the generator control panel must be illuminated for the

hand switch to be active. To deactivate the hand switch, depress the HAND ACTIVATION button (if

the HAND ACTIVATION button is not illuminated, hand switch will be inactive).

Note: If the hand switch will not turn off during operation, depress the button corresponding to the

power level opposite that being activated to turn it off - an alarm will sound. Press the HAND

ACTIVATION button to disable the hand switching adaptor. Place the generator in Standby, and

replace the hand switch; or, continue using the foot switch after deactivating the hand switch.

3 If the system senses a generator, hand piece, or instrument fault during use, an audible alarm (tone

with long pulses) will sound and a visual alarm indicator will appear on the control panel. (Refer to

Chapter 9 – High-Level System Troubleshooting or the Troubleshooting Guide on top of the

generator unit to resolve the problem.)

Warning: Place the generator in Standby before removing or replacing an instrument, hand

switching adaptor or hand piece or when the system is not in use.

20

GEN04

Service Manual

System Shutdown

1 Turn the generator power switch off and remove power cord from outlet.

2 Disconnect the hand piece, instrument, and adaptor or hand switching adaptor (if used) and process

them as indicated in their respective package inserts.

3 Clean the generator and cart and disinfect the foot switch(es) following hospital protocol (for

recommendations, refer to Chapter 6 – Cleaning and Disinfection).

4 Store foot switch(es) on the cart shelves provided. Each shelf will hold one foot switch.

5 Wrap foot switch cable(s) and the power cord on the cart’s back handle for storage.

21

GEN04

Chapter 6 - Cleaning and Disinfection

Generator and Cart Cleaning

Clean generator and cart following hospital protocol. Before cleaning, turn the generator main power off and

unplug the power cord from the grounded electrical outlet.

Warning: Spilling or spraying fluids on or into the generator or immersing the generator may result in

damage to the generator and risk of shock or fire hazard.

Proceed with cleaning as follows:

1 Prepare a neutral pH detergent or neutral pH enzymatic detergent according to the detergent

manufacturer’s directions.

2 Use a soft, clean cloth lightly moistened with the cleaning solution to manually clean all surfaces

(including the generator’s display).

3 Rinse thoroughly using a soft, clean cloth lightly moistened with warm tap water.

4 Dry with a clean, soft cloth.

Foot Switch Cleaning

The foot switch and cable should be cleaned after each use as follows:

1 Disconnect the foot switch from the generator.

2 Prepare a neutral pH enzymatic detergent according to the detergent manufacturer’s directions.

3 With the cable securely attached to the foot switch, soak the foot switch and cable in the detergent

solution for two minutes.

Note: Keep the foot switch cable connector that connects to the generator dry at all times to prevent

inadvertent activation.

4 After soaking, use a soft-bristled brush to manually clean the foot switch and cable keeping them

immersed in the detergent solution.

5 Thoroughly rinse the foot switch and cable – with the cable securely attached to the foot switch – with

warm, running tap water for at least one minute.

6 Dry all surfaces with a clean, soft cloth.

22

GEN04

Service Manual

Loading...

Loading...