Page 1

Lighting Playback Controller

QuickGuide

Version 3.1

Page 2

ii

Page 3

Contents

Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

IntroductionIntroduction

Getting started

Getting started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Getting startedGetting started

Mounting the LPC

Mounting the LPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Mounting the LPCMounting the LPC

Rack mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mount on a horizontal or along a vertical surface . . . . . . . . . . . . . . . . . . . . . .4

Mounting beneath a horizontal surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Dimmers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Express

Lighting Playback Controller

QuickGuide

Version 3.1

Front panel

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Front panelFront panel

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Producing shows for the Express LPC

Producing shows for the Express LPC . . . . . . . . . . . . . . . . . . . . . . . . . .6

Producing shows for the Express LPCProducing shows for the Express LPC

LPC operation

LPC operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

LPC operationLPC operation

Reading a showfile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Macro control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Autocontrols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Interfacing with external devices

Interfacing with external devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Interfacing with external devicesInterfacing with external devices

ETCNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Remote Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

MIDI Show Control / ETC MIDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

MIDI time code programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Setting the clock

Setting the clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Setting the clockSetting the clock

Using an RFU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Using autocontrols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Expression Off-Line

Expression Off-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Expression Off-LineExpression Off-Line

Upgrading software

Upgrading software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Upgrading softwareUpgrading software

Upgrading the LPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Upgrading remote interface devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Express LPC QuickGuide, v.3.1 iii

Page 4

Appendix A

Appendix A

Appendix A Appendix A

Specifications

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SpecificationsSpecifications

Appendix B

Appendix B

Appendix B Appendix B

Limited Warranty

Limited Warranty

Limited WarrantyLimited Warranty

Appendix C

Appendix C

Appendix CAppendix C

Declaration of Conformity

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Declaration of ConformityDeclaration of Conformity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

iv

Page 5

Introduction

The ETC Express Lighting Playback Controller (LPC) is a playback system

that provides complete, hands-off control of area lighting. It is ideal for

environments where simplified control of lighting sequences and effects

is needed. If more control capability is needed, the power of the Express

LPC can be expanded by using it in a network or connecting it to external

devices. For example:

• MIDI Show Control (MSC) ~ Send and receive show control

information using the MIDI Show Control protocol.

• ETC MIDI ~ Control shows using this subset of MIDI.

• MIDI Time Code (MTC) ~ Synchronize your show with external

devices using the MIDI time code protocol.

• ETCNet ~ Connect the LPC to an ETC network so that you can control

or view remotely using remote interface devices.

• Remote Macros ~ Start, stop and control shows with up to four

external switches, for example on a door frame or operated by hand.

• Remote Trigger ~ Provide switched control to an external device

during LPC show operation.

The LPC uses the proven design of the Express lighting console, a fullfeatured lighting controller used in thousands of educational and live

performance centers. Working for you is the same complex show

technology that made Express so popular, but in a simplified package. In

fact, a show created for any console in the Expression line of consoles will

run on the Express LPC. What you surrender in show creation, editing and

control capabilities, you gain in ease of operation and simplicity.

Express LPC QuickGuide, v.3.1 1

Page 6

Getting started

To use your Express LPC successfully, please follow the installation and

operation instructions contained in this QuickGuide. In many places, these

instructions rely upon additional information in the Express User Manual,

which is supplied with the LPC. Shows to run in the Express LPC may be

created in the console or in Expression Off-Line, a software program that

emulates the programming capabilities of Expression-family consoles

Following are the items contained in an LPC shipping package. The items

marked with an asterisk (*) are not needed for all mounting positions. If

anything is missing, or if you have questions about the installation or

operation of the Express LPC, please call your dealer or ETC Technical

Services at one of the offices listed on the back page of this document.

• The LPC unit

• LPC power supply and separate power cord

• Two convertible front mounting brackets *

• Two sliders and rear mounting brackets for a 19” rack *

• Four rubber feet *

• Mounting fasteners

• This Express LPC QuickGuide, version 3.1

• Express User Manual, version 3.1

Mounting the LPC

The LPC may be used without brackets securing it if the surface is

sufficiently level and steady. All you need to do is attach the four rubber

feet with the 4-40 x 3/8” screws, all provided with the LPC.

Do not locate the LPC closer than six feet to dimmers or high-current AC

lines to avoid electromagnetic interference.

If you need to mount the LPC for stability or for operating convenience,

hardware is supplied for each of the four mounting orientations listed

below. The procedure to use for each mounting orientation is given next.

• In a 19” rack

• Secured below a horizontal surface, such as a desk or shelf

• Secured to the top of a horizontal surface

• Secured to a vertical surface

2 Getting started

Page 7

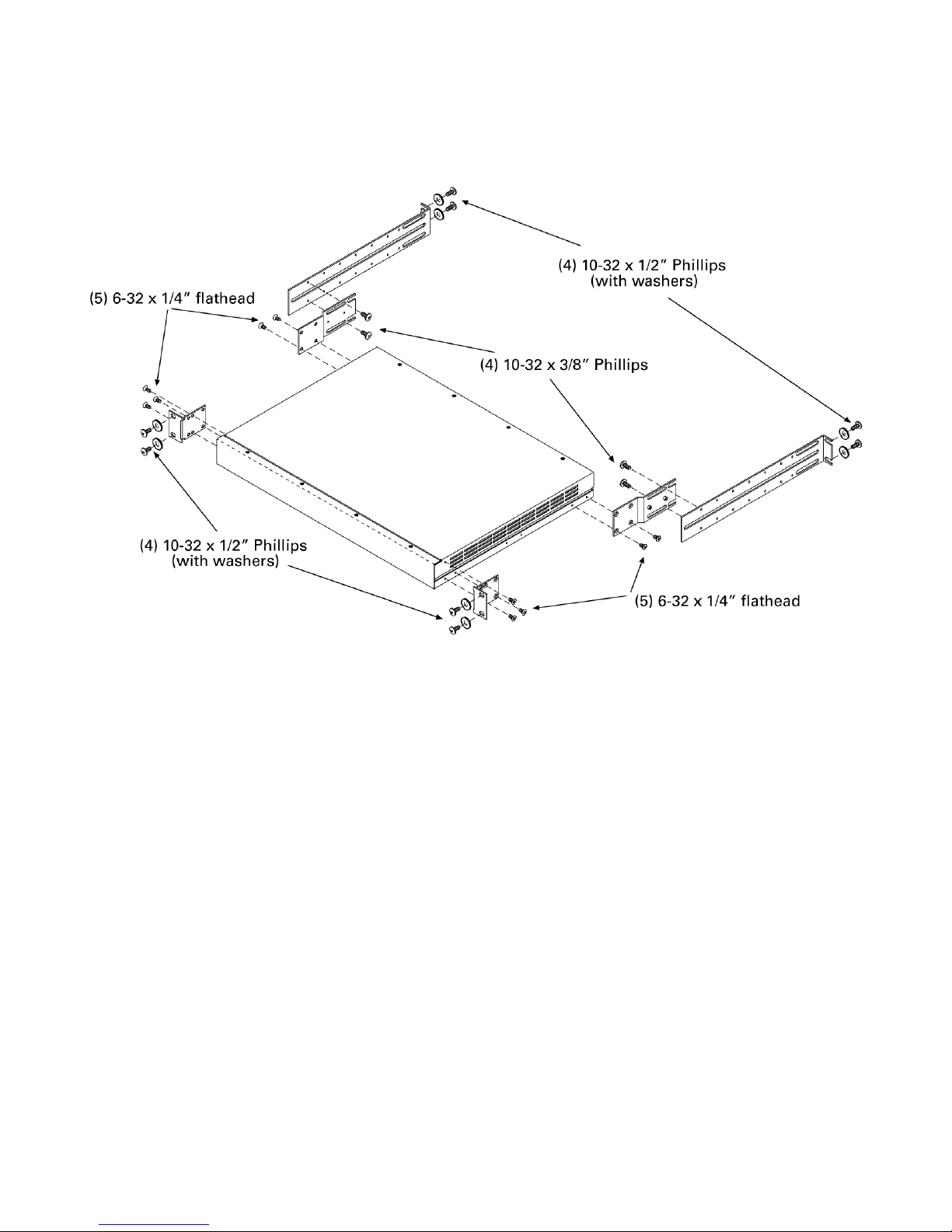

Rack mounting

To mount the LPC in a 19” rack, follow the illustrated procedure below:

1. Remove all mounting hardware from the plastic bag.

2. Place one black washer on each of the eight 10-32 x 1/2” screws.

3. Attach the two L-brackets to the side panels of the LPC using three

6-32 x 1/4” flathead screws each. Choose the bracket holes that

position the bracket flush with the front panel.

4. Secure the two rear brackets to the side panels of the LPC using two

6-32 x 1/4” flathead screws each, orienting the brackets as shown.

5. Fit the LPC through the front of the rack and position over the

mounting holes. The L-brackets should be on the outside of the rack.

6. Secure the LPC to the front of the rack using four 10-32 x 1/2” screws

and washers as shown. If the rack holes are not threaded, small black

clips are provided for that purpose. Slide the black clips over the rack

mounting holes and thread the screws into them. Caution: Keep the

rear of the LPC supported to avoid bending the front brackets.

7. Using four 10-32 x 1/2” bolts (and threaded clips if necessary), attach

the two slider brackets to rear holes in the rack that are opposite those

holes used to mount the front of the LPC. Do not secure yet.

8. Line up the slider brackets with the rear brackets on each side of the

LPC. The threaded studs on the rear bracket should fit into slider

bracket slots. Attach each rear bracket to a slider using two 10-32 x

3/8” screws each. The screws go through slots in the brackets and

into threaded slider bracket holes.

9. Secure all bolts so that the assembly is level and tight.

Express LPC QuickGuide, v.3.1 3

Page 8

Mount on a horizontal or along a vertical surface

To mount the LPC either to the top of a horizontal surface or along a

vertical surface, follow the illustrated procedure below:

1. Remove all mounting hardware from the plastic bag.

2. Securely attach the four rubber bumpers to threaded holes in the

bottom of the LPC using 4-40 x 3/8” screws.

3. Securely attach the two L-brackets to the side panels of the LPC as

shown, using two 6-32 x 1/4” flathead screws each. Choose the

bracket holes closest to its bend.

4. Place the LPC on the surface where you want it. Mark the surface

through the mounting holes in each bracket. Remove the LPC.

5. Drill holes at the marks. You will be providing the mounting screws

(and anchors if necessary), so choose a drill bit accordingly.

6. Securely attach the LPC to the mounting surface.

Mounting beneath a horizontal surface

To mount the LPC to the bottom of a horizontal surface, follow the

procedure below, with general reference to the illustration for top and

vertical mounting above:

1. Remove all mounting hardware from the plastic bag.

2. Fasten the four rubber bumpers to the top surface of the LPC with

double-sided tape (not included with LPC).

3. Securely attach the two L-brackets to the side panels of the LPC. The

brackets should be flipped 180

the illustration above, with the mounting flange facing the top. Choose

the bracket holes farthest from its bend.

4. Place the LPC on the surface where you want it. Mark the surface

through the mounting holes in each bracket. Remove the LPC.

5. Drill holes at the marks. You will be providing the mounting screws

(and anchors if necessary), so choose a drill bit accordingly.

6. Securely attach the LPC to the mounting surface.

4 Mounting the LPC

o

from the bracket position shown in

Page 9

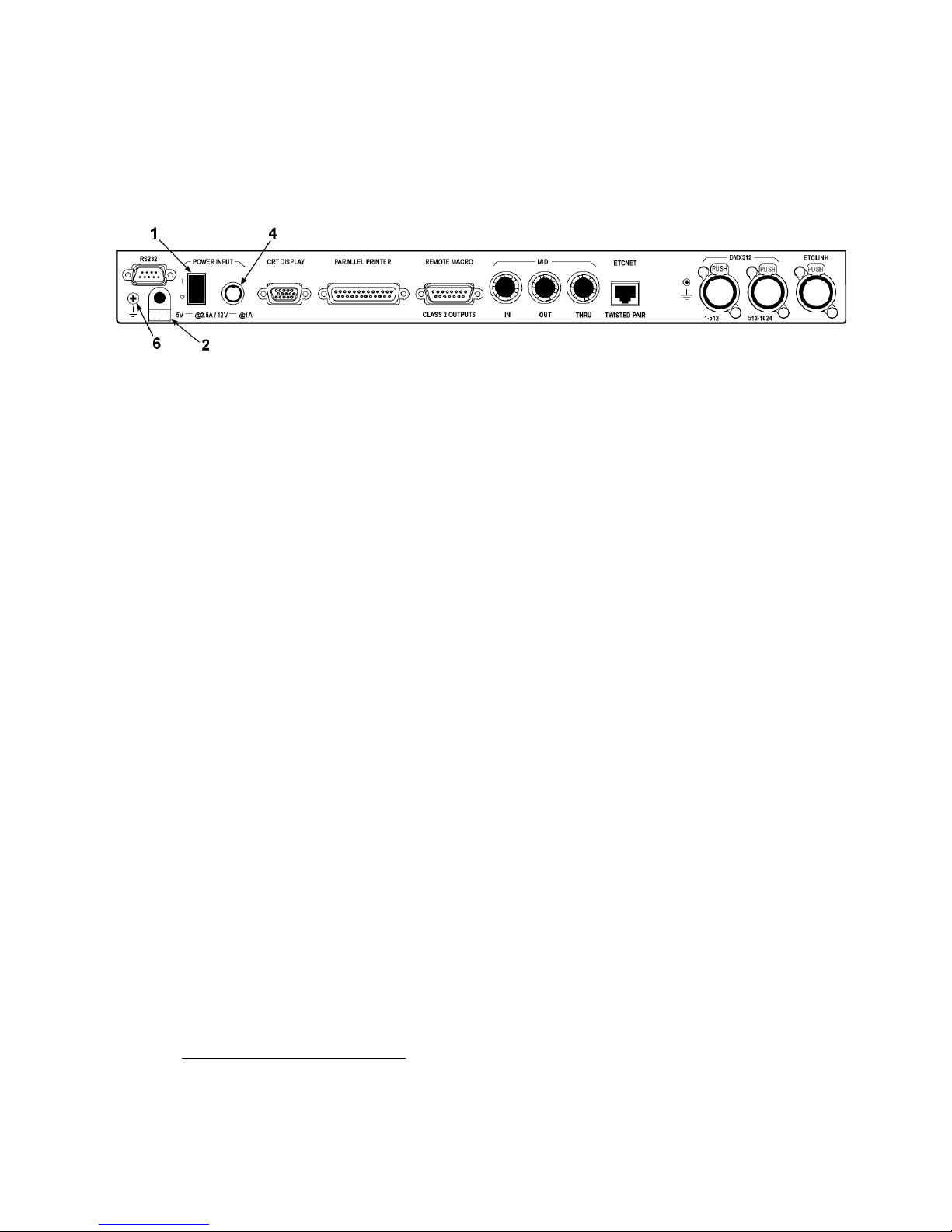

Cabling

All connections to the LPC, except for the optional RFU, are made to the

LPC’s rear panel. The numbers in the figure refer to items under Power

Supply, below.

Power supply

1. Push the LPC’s power switch to the off position (“O” symbol).

2. Remove the thumb screw to free the cable clamp from the rear panel.

3. The power supply has a cable attached to it. Clip the cable clamp over

the cable near the 8-pin male connector.

4. Plug the connector into the LPC rear panel receptacle.

5. Adjust the cable clamp so that you can re-attach it to the LPC.

6. Plug one end of the furnished power cord into the power supply and

the other end into a grounded power outlet.

1

Dimmers

Connect the dimmers as explained in the installation sections of your

Express User Manual (Appendix A).

Accessories

If you are using a monitor, a Remote Focus Unit, a printer, ETCNet, MIDI

or remote macros with your LPC, or if your show performs remote

triggering, connect and install as explained in the installation sections of

your Express User Manual (Appendix A).

1.

The chassis may also be grounded, if needed, by placing a ground wire under this

Phillips-head screw.

Express LPC QuickGuide, v.3.1 5

Page 10

Front panel

The LPC’s front panel is shown in the illustration below. The numbers are

keyed to the explanations of features below.

Features

The features of the LPC front panel are, from left to right:

1. The power-on indicator glows when the LPC is powered on.

2. Seven macro control buttons. Use these to control the LPC and the

show.

3. Read From Disk button. Use this to read the show into the LPC.

4. Disk drive.

5. The fuse holder protects the LPC from an excessive power drain by

the RFU, if attached.

6. RFU connector.

Producing shows for the Express LPC

Shows that run in the Express LPC may be produced in a couple of ways.

One way is to develop the show in an ETC console that runs the same

version of software as the LPC, such as an Express, Expression or Insight

console. If the show is created in a console that has features not available

in the LPC, such as a higher channel or dimmer count, the LPC responds

only within the limits of its capabilities and ignores everything else.

Another way to create a show for an Express LPC with ETC’s console

emulator, Expression Off-Line, which runs on a pc-type computer. With

Expression Off-Line you can produce a complete show that is tailored

exactly for your particular LPC model.

2.

See Expression Off-Line, page 13, for information about using Off-Line to create

or edit LPC showfiles.

2

6 Front panel

Page 11

LPC operation

You need two things to run a show in an Express LPC: a diskette

containing the show in console-ready form, and instructions about which

macros available to the LPC were programmed into the show. The LPC

clock may also be used in addition to macros to control the show, but

clock control is not required.

Reading a showfile

Read showfiles by inserting a diskette in the LPC disk drive and pressing

the Read From Disk button on the LPC’s front panel. If the showfile was

prepared using system software older than version 3.03, everything in the

showfile will be transferred at once to the LPC memory. If, however, the

showfile was prepared with version 3.03 or later software, only the show

components of the showfile will be transferred into memory. For those

later showfiles, if you want to transfer the system configuration

components into the LPC memory, press M7 on the LPC’s front panel

while pressing the Read From Disk button.

See the Showfile appendix in your Express User Manual for a breakdown

of showfiles into show and system configuration components.

Macro control

Macros can control the LPC in three ways. Push button switches M1

through M7 on the LPC’s front panel can be used to activate macros 1 - 7.

Up to four switches can be wired to a rear panel connector and used to

activate macros 1901 - 1904. Used that way, those macros are known as

Remote Macros. Finally, the LPC may be set to respond automatically to

what is known as a Powerup Macro when the LPC is turned on. Any of

the 2,000 macros possible can function as the Powerup Macro.

3

For information about programming macros, including the Powerup

macro, see the Macros chapter of your Express User Manual.

about programming remote macros in the Remote Interfaces chapter of

your Express User Manual. For information about wiring the rear panel

Remote Macro connector, see the Installation appendix of your Express

User Manual.

3.

See Setting the clock, page 11, for information about preparing the LPC for real

time programs by setting the real time clock.

4.

See your user manual for information about programming and setup operations.

Express LPC QuickGuide, v.3.1 7

4

Learn

Page 12

Autocontrols

The front panel buttons, M1–M7 have programmable as well as fixed

functions. Each can operate a macro in your show, as explained under

Macro control, page 7. They may also be used in combinations to give you

access to software displays and to make settings.

When panel buttons, including the Read From Disk button, are used in

non-programmable combinations, they are called autocontrols. Execute an

autocontrol using the following 4-step procedure.

1. Press M7 and hold.

2. Press the additional button or buttons and hold.

3. Release M7.

4. Release the additional button or buttons.

An Express LPC with version 3.1 system software contains the following

autocontrols.

Autocontrol buttons Function

M7 / M1 Stage display

M7 / (M1 and M2) Plus

M7 / M3 Patch display

M7 / (M1 and M3) Enter

M7 / (M2 and M3) Minus

M7 / (M1 and M2 and M3) Clear

M7 / M4 Setup display

M7 / (M1 and M5) Reboot

M7 / (M5 and M6) Nothing

M7 / (M1 and M6) Softkey [S1]

M7 / (M2 and M6) Softkey [S2]

M7 / (M3 and M6) Softkey [S3]

M7 / (M4 and M6) Softkey [S4]

M7 / (M1 and M5 and M6) Softkey [S5]

M7 / (M2 and M5 and M6) Softkey [S6]

M7 / (M3 and M5 and M6) Softkey [S7]

M7 / (M4 and M5 and M6) Softkey [S8]

M7 / (M1 and M2 and M3 and

M7 / Read From Disk

M4 and M5 and M6)

a

b

Record

Read system

configuration

8 LPC operation

a) Use this autocontrol to back out of an autocontrol

operation without changing anything.

b) The softkeys apply to the existing display, as viewed

on your video monitor.

Page 13

Interfacing with external devices

You can do more with your LPC if you use it to control or be controlled by

external devices. Following are the ways you can operate the LPC with

external devices and how you would go about implementing them.

ETCNet

The Express LPC supports ETCNet, a proprietary ETC network operating

with Ethernet protocols, that allows you to operate a wide variety of ETC

devices together. These devices can include ETC’s Remote Interface

Units (RIU) or Remote Video Interface (RVI) devices. You can also use

ETC’s newer interface devices, such as the ETCNet2 DMX Node or the

ETCNet2 Video Node. Network interface devices can provide DMX512

outputs that mirror those of the LPC. They can also support remote

monitors and alphanumeric keyboards that mimic those at the console

and Remote Focus Units (RFUs) for remote control.

Information about installing an RIU or RVI is available in the Reference

appendix of your Express User Manual. Information about installing the

newer ETCNet2 devices is given in their respective QuickGuides. To use

ETCNet2 interface devices with an Express LPC, you must set the device

to operate on ETCNet. See the Upgrade Software section in the Appendix

of your Express User Manual for that procedure. Use unshielded twisted

pair wiring (UTP) when making network connections between any

interface device or network hub and the Express LPC.

5

Remote Trigger

If you are operating an external device that may be controlled by a switch

closure, you can control that device with the LPC Remote Trigger feature.

See the Installation appendix of your Express User Manual for an

explanation about how to wire the LPC’s Remote Macro port for this

purpose. Information about programming the Remote Trigger is found in

the Control Interfaces chapter of your Express User Manual.

MIDI Show Control / ETC MIDI

See Chapter 24 Interfaces of your Express User Manual for information

about using MSC and ETC MIDI.

Connect the external MIDI device, such as a MIDI Sequencer, to the

LPC’s MIDI “In” port. If any other device should receive the MIDI signal,

connect the LPC’s MIDI “Thru” port to the “In” port of the second

receiving device. If MIDI information will be generated within the LPC,

such as to control the external MIDI device, run a cable from the LPC’s

“Out” port to the “In” port of the external MIDI device.

5.

Older Express LPC models also supported thinnet wiring, which is compatible only

with RIU and RVI interface devices. If using an older Express LPC and thinnet, see

the Installation Appendix of your Express User Manual for special information and

information.

Express LPC QuickGuide, v.3.1 9

Page 14

MIDI time code programs

The LPC can run programs that are timed according to the Musical

Instrument Digital Interface protocol (MIDI). MIDI shows consist of a

series of events containing cues, submasters or macros that play back at

times determined by an external or an internal clock. To run a time code

program in the LPC, load it in, connect a time code source and start the

time code running.

Refer to the Control interfaces chapter of your console user manual for

detailed instructions about how to create and edit time code programs.

The chapter also includes information about changing program loop time,

frame rate and playing back a program by various means. To connect an

external MIDI source, see Appendix A of your console user manual.

Printer

See Appendix A of your console user manual for information about

attaching a printer to your LPC. Connect the printer to the LPC port labeled

Parallel Printer. Information about printouts available from the Express

LPC can be found in the Printing chapter of the Express User Manual.

Serial interface

On the rear panel of your LPC is a RS232 connector. This is reserved for a

serial interface function that may be implemented later. It is not

operational at this time. Please disregard option 13, Serial Protocol Baud

Rate, on the Options Settings menu as well as the associated softkey,

[S2], ESP Baud Rate, in that menu. The Options Settings menu is a choice

on the Setup menu, which you may reach with autocontrol M7 / M4.

10 Interfacing with external devices

Page 15

Setting the clock

If you plan to run real time programs from your LPC, you must first set the

time and date configuration of its real time clock. If your real time program

references sunrise or sunset, you must also set the astronomic functions

of your real time clock (the astronomic clock). Latitude, longitude and time

zone values for cities located around the globe are given in the Time and

location appendix of the Express User Manual.

You can set the time and date configuration of the LPC’s real time clock

in either of two ways, both of which require you to attach a video monitor

to the LPC. One way is to attach a Remote Focus Unit to the LPC. The

second way is to take advantage of the LPC autocontrols. You can also set

the astronomic clock when using an RFU, but not when using the LPC

autocontrols. Astronomic clock settings, however, are needed only if your

real time programs reference sunrise or sunset.

If you need to set the LPC astronomic clock, you can perform those

settings in either an Express console or in Expression Off-Line. They

become part of the system configuration components which can then be

read into the LPC from a showfile. See Reading a showfile, page 7, for

information about reading a showfile’s system configuration components.

: Clock settings are retained in LPC memory even if the power is

NOTE

temporarily removed. Once set, you should not need to reset the clock,

but you may need to revise the setup later if, for example, power is

removed for a long time or you need to set the astronomic clock.

Express LPC QuickGuide, v.3.1 11

Page 16

Using an RFU

If attaching an RFU to your LPC to set the real time clock, follow the

procedure below.

1. Connect the RFU and a video monitor to the respective ports on the

LPC.

2. Use the M7/M4 autocontrol to go to the Setup display.

3. Follow the procedure called Setting the Clock in the System settings

chapter of your console user manual.

Using autocontrols

6

The LPC’s autocontrols allow you to perform all the configuration settings

for the real time clock except provide data for the astronomical clock.

general, follow the procedures given under Setting the Clock in the

System settings chapter of your console user manual except where

required to choose from the Clock Functions menu. To make that choice,

in the Express LPC, use the Plus or Minus autocontrols to move through

menu selections. Use the Enter autocontrol to confirm your selection.

For example, set the time and date in your LPC as follows:

1. Connect a video monitor to the LPC.

2. Use the M7/M4 autocontrol to go to the Setup display.

3. Press M7/M1 and M2 to step to selection #2 on the Clock Functions

menu. You will see the following Time/Date display.

: For any operations requiring the Plus or Minus autocontrol, you can

NOTE

repeat the function after first activating it by tapping the M7 key as many

times as needed.

6

In

4. The time will be highlighted when you enter the display. To change it,

press the Plus or Minus autocontrols to increment or decrement the

time. When the minutes move past 60 or before 0, the hours

increment or decrement, respectively.

5. Press the Enter autocontrol to move to the AM/PM field. Change by

using the Plus or Minus autocontrols.

6. Continue with the rest of the settings in the Time/Date display using

the Enter, Plus and Minus autocontrols as above.

7. When you are satisfied with the settings, press the Record

autocontrol to start the clock.

6.

For a list of autocontrols, see Autocontrols, page 8.

12 Setting the clock

Page 17

Expression Off-Line

Shows for the Express LPC are often created in the same type of console

for which the LPC is designed as a playback device. But you can also use

ETC’s console emulator, Expression Off-Line, which runs on an IBMequivalent personal computer. Expression Off-Line reproduces virtually all

of the functions of the LPC software using simulations of the same keys,

controls and displays that you find on the console itself.

When you create shows in Expression Off-Line, you are not constrained

by the lack of a label key and alphanumeric keyboard as is true for an

Express console. Not only can you create shows in Off-Line but you can

also use Off-Line to label things, such as real time programs, cues, groups

and channels. Labels attached in Off-Line stay with the show when

transferred to the Express LPC, where you can view them with an

attached video monitor. Instructions for labeling in Expression Off-Line are

given in the Expression Off-Line QuickGuide.

Off-Line and its QuickGuide may be obtained without charge from your

dealer, from the ETC website at www.etcconnect.com or from ETC

Technical Services. Information about reaching ETC Technical Services at

several sites around the world is given on the back page of this document.

Upgrading software

Upgrading software in your Express LPC is analogous to upgrading

software in an Express console. You can also use the LPC to upgrade the

software of any remote interface devices connected to the LPC and set

its network configuration.

The procedure for upgrading software in your LPC is the same procedure

given under Upgrading software in Appendix A of your console user

manual, with a few exceptions. These are noted below.

Upgrading the LPC

• Setup display ~ Step 5 of the procedure recommends that you verify

the upgrade in the Setup display. In the LPC, execute the autocontrol

for the Setup display (M7 / M4).

• Reset System ~ Step 6 requires you to reset the system after the

upgrade. To reset the system in the LPC, follow the procedure below.

1. Go to the LPC Setup display if you’re not already there (see

above).

2. Activate the Plus autocontrol (M7 / (M1 and M2)). Tap M7 three

more times to get to the Clear Functions choice on the Setup

menu.

3. In the Clear Functions display, execute the autocontrol for softkey

S1 (M7 / (M1 and M6)).

4. Confirm the reset by executing the autocontrol for Enter (M7 /

(M1 and M3)).

Express LPC QuickGuide, v.3.1 13

Page 18

Upgrading remote interface devices

• Crossed wiring ~ Sometimes when you’re using twisted pair wiring,

a remote interface device does not appear on the Remote Units list.

The cause could be crossed wiring. This problem is covered in the

Upgrade software section of the console user manual under Devices

missing from the list. To swap the wiring in the LPC, execute the

autocontrol for softkey S6 (M7 / (M2 and M5 and M6)).

• Setting the configuration ~ You may be unable to communicate

with one or more ETCNet 2 remote interface devices because they

are configured for an ETCNet2 network. This problem is covered in

the Upgrade software section of the console user manual under

Devices missing from the Remote Units list. To set the network

configuration in all ETCNet2 remote interface devices to ETCNet,

execute the autocontrol for softkey S5 (M7 / (M1 and M5 and M6)).

• Upgrade all units ~ To upgrade all remote interface devices at once,

execute the autocontrol for softkey S1 (M7 / (M1 and M6)).

• Upgrade some units ~ To upgrade some units, follow the procedure

below:

1. Use the Plus or Minus autocontrols to move forward or backward

through the Remote Units list.

2. While highlighting a unit you wish to upgrade, execute the

autocontrol for softkey S8 (M7 / (M1 and M6)) to mark the unit.

3. Repeat step 2 to mark as many units as you wish.

4. After marking, execute the autocontrol for softkey S2 (M7 / (M2

and M6)) to upgrade the marked units.

• Upgrade only one unit ~ Follow the procedure below:

1. Use the Plus or Minus autocontrols to move forward or backward

through the Remote Units list.

2. While highlighting the unit you wish to upgrade, execute the

autocontrol for softkey S3 (M7 / (M3 and M6)) to upgrade the unit.

14 Upgrading software

Page 19

Appendix A

Specifications

Electrical

• Voltage input 100-240 VAC, 50-60 Hz

• Maximum current 0.8 amps

Built-in interfaces

• 1,024 DMX512 outputs

• Parallel printer

• RS-232C serial port

• Remote Focus Unit

• Supports CE dimming systems

• Remote Macro control

• Remote Trigger option

• MIDI time code control

• ETCLink

System capacity

• 600 cues per show

• 96, 192 or 250 control channels

• Proportional patching of up to 1,024 DMX512 dimmers

• Eight-part multipart cues

• Thirty-three dimmer profiles, all but one of which are editable

• 500 groups

• 99 focus points

• 2,000 macros

• 24 overlapping submasters

• Ten pages of submaster memory

Playback controls

• Seven front panel push-buttons

Timed control

• Internal or external clock

• 12-hour or 24-hour timing

• References sunrise and sunset with astronomical clock

• Up to 500 user-created, Real Time Programs

Display functions

• VGA video output

•Stage

•Blind

• Fader

•Effects

• Spreadsheets: Cues, Submasters, Groups and Focus Points

•Patch

•Park

• Setup

• Flexichannel (displays only recorded channels)

• Channel attributes

Express LPC QuickGuide, v.3.1 15

Page 20

Submaster functions

• Ten pages of 24 recorded submasters each

• Fully overlapping channel assignments

• Proportional channel levels

• Programmable fade and wait times

• Live and programmed rate control

• Submasters either overlapping pile-on or inhibitive

• All submasters programmable with effects

• Update function

• Control keypad features

• Spreadsheet editing

• Submaster list

Channel functions

• 8-bit and 16-bit data types

• Both highest level (Highest Takes Precedence) and last action (Latest

Takes Precedence) channel types

• Group function to allow channels to be manipulated as proportionally

balanced groups

• [And], [Except], [Only], and [Thru] functions to select

• [Full] function

• [Level] sets a channel to a user-selectable default value

• Independent channels

• Flip channel

Moving light functions

• Fixture personalities load from diskette

• Patch fixtures by assigning personalities, starting channels, starting

DMX512 address, remote dimmer, swap focus, pan or tilt flip

• Five attribute categories

• Fixture box level adjustment

• Fixture focus with Solo

Cue functions

• Up to 600 cues in the range 0.1 to 999.9

• Discrete upfade and downfade times (00:00-99:59) for each cue

• Linked cue sequences

• Effect cues

• Split wait times

• Follow time

• Link to cue or macro

• Eight-part multipart cues

• Selective cue recording

• Update cue command

• Attribute range editing

• Subroutines, with cue or style steps

• Spreadsheet editing

•Cue list

Group functions

• Up to 500 groups

• Any cue or submaster may be accessed as a group

• Spreadsheet editing

• Group list

16 Appendix A Specifications

Page 21

Focus point functions

• up to 99 preset focus points

• Update cues and submasters when focus point changes

• Record level of focus point without link

• Available in effects

• Printout available

• Spreadsheet editing

• Focus point list

Diskette functions

• 3.5-inch high-density diskette drive for show storage

• One show per disk

• Software updates installed through diskette drive

• Retrieve show and configuration contents separately or together

Macro functions

• Seven front panel push-button macro controls

• Up to 2,000 macro selections for programming

• Macros may activate any control sequence

• Live Learn mode

• Macro editing

• Macros programmable for Macro wait

• Can include in real time programs

• Can include in time code events

• Four macros operated by remote switches

• Powerup macro

• Remote Trigger function

Effects functions

• Effects may be recorded as cues or submasters

• Up to 100 steps each

• Live effects recording

• Spreadsheet editing

• 8-bit and 16-bit data types

• Variability of rate during playback

•Step times

• In/Dwell/Out Step fade times

• High/Low Levels

• In/Dwell/Out Effect fade times

• Range editing of effect attributes and step values

Profile functions

• Profiles may be assigned to dimmers

• Ten preset profiles, nine of which are editable

• Twenty-three additional profiles that may be programmed

Options

• Parallel printer

• Remote Focus Unit

• Remote Macro controls

• Remote interface devices

Express LPC QuickGuide, v.3.1 17

Page 22

18 Appendix A Specifications

Page 23

Appendix B

Limited Warranty

Electronic Theatre Controls, Inc. (ETC™)

warrants to the original owner or retail

customer (Customer) that during the

warranty period ETC will repair or replace

its products that are defective in materials

or workmanship under normal use and

service, subject to the terms of this limited

warranty. The warranty period shall begin

on the date of delivery of a portable system

or on the date of energization of a

permanently installed system, and shall

continue for the following periods: (a) one

year, for all Irideon products, and (b) two

years, for all other ETC products. Warranty

is limited to (60) days from shipment for

purchase of demo or loaner products.

Warranty does not cover any product or

part of a product subject to accident,

negligence, alteration, abuse or misuse, or

any accessories or parts not supplied by

ETC. Warranty does not cover

“consumable” parts such as fuses, lamps,

color media or components warranted

directly to the owner by the original

manufacturer. ETC’s warranty does not

extend to items not manufactured by us.

Freight terms on warranty repairs are FOB

ETC factory or designated repair facility.

Collect shipments or freight allowances

will not be accepted.

ETC’s sole responsibility under this

warranty shall be to repair or replace at

ETC’s option such parts as shall be

determined to be defective on ETC’s

inspection. ETC will not assume any

responsibility for any labor expended or

materials used to repair any equipment

without ETC’s prior written authorization.

ETC SHALL NOT BE RESPONSIBLE FOR

ANY INCIDENTAL, GENERAL OR

CONSEQUENTIAL DAMAGES, DAMAGES

TO PROPERTY, DAMAGES FOR LOSS OF

USE, TIME, PROFITS OR INCOME, OR

ANY OTHER DAMAGES.

The customer’s obligations during the

warranty period under this warranty are to

notify ETC at ETC’s address within one

week of any suspected defect, and to

return the goods prepaid to ETC at their

factory or authorized service center.

THIS WARRANTY IS CONTINGENT ON

THE CUSTOMER’S FULL AND TIMELY

COMPLIANCE WITH THE TERMS OF

PAYMENT SET FORTH IN THE “TERMS

AND CONDITIONS.” THIS WARRANTY IS

EXPRESSLY IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESSED OR

IMPLIED, INCLUDING THE WARRANTIES

OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE AND OF

OTHER OBLIGATIONS AND LIABILITIES

ON OUR PART. THE CUSTOMER

ACKNOWLEDGES THAT NO OTHER

REPRESENTATIONS WERE MADE TO

HIM OR RELIED UPON BY HIM WITH

RESPECT TO THE QUALITY AND

FUNCTION OF THE GOODS SOLD.

This written warranty is intended as a

complete and exclusive statement of the

terms thereof. Prior dealings or trade

usage shall not be relevant to modify,

explain or vary this warranty. Acceptance

of, or acquiescing in, a course of

performance under this warranty shall not

modify the meaning of this agreement

even though either party has knowledge of

the performance and a chance to object.

Terms and Conditions

The following terms and conditions, and

those on the face hereof, shall control as to

any order accepted by Electronic Theatre

Controls, Inc. (ETC), notwithstanding any

terms and conditions that may be

contained in any purchase order or other

document of Customer, and ETC’s

acceptance of any order is expressly made

conditional on Customer’s assent to such

terms and conditions. Such terms and

conditions will constitute the entire

agreement between the parties as to any

order and will supersede any prior

understandings, agreements,

representations, or warranties. Such terms

and conditions will not be modified, added

to, superseded or otherwise altered except

by written document signed by an

authorized representative of ETC,

notwithstanding any terms and conditions

contained in the purchase order or other

document of Customer. ETC’s

commencement of performance and/or

delivery shall not constitute a waiver of

these terms and conditions or any

acceptance of any terms and conditions

contained in the Customer’s order or other

Express LPC QuickGuide, v.3.1 19

Page 24

documents. Acceptance of any product or

service by the Customer will be construed

as acceptance of ETC’s terms and

conditions. Any dispute or questions of

construction with respect to any order

placed with ETC shall be governed by the

laws of the State of Wisconsin.

All prices are in US Dollars, FOB ETC’s

factory or warehouse. Prices, models and

specifications are subject to change

without notice. Orders must be in writing.

Phone orders will be accepted from

established accounts when followed by

written confirmation. The acceptance of

any order does not imply conformance

with plans and specifications unless the

plans and specifications accompany the

order and are accepted as binding by ETC.

Equipment ordered which differs in any

way from our standard catalog items will

require drawings approved in writing by the

Customer. When drawings are approved,

they shall take precedence over all other

written or verbal instructions. Orders are

effective only when accepted and

acknowledged by the factory. Minimum

order is $25.00 net, exclusive of freight.

Price protection will be given on orders

entered for immediate shipment and for

project orders entered before the effective

date of a price increase. All other orders

will be billed at the current price at time of

shipment. Quotations for custom products

are valid for thirty (30) days.

ETC will attempt to ship goods for delivery

on or about the times stated on the reverse

side hereof, although time shall not be the

essence in this contract. ETC will attempt

to follow customer’s written instructions

as to mode and routing of shipments. In

absence of such instructions, ETC shall

have absolute discretion as to mode and

routing of shipments, including express or

parcel post for small shipments. Where the

customer has requested expedited freight,

the customer will be responsible for the

incurred additional charges.

ETC shall not be liable for late delivery and/

or inability to perform due to unforeseen

circumstances or conditions, including our

ability to obtain supplies and raw materials,

government regulations, labor stoppages,

casualties, fire, and other causes beyond

our control. When such circumstances or

conditions have been remedied, ETC will

make and Customer will accept delivery/

performance. Equipment is shipped at the

Customer’s risk and our obligation to

deliver equipment is discharged upon their

delivery in good condition to the carrier.

Shipments are FOB ETC factory or

warehouse. ETC will prepay and bill freight

on UPS shipments. Freight and air are sent

collect unless specifically quoted

otherwise. Unless specifically prohibited,

partial shipments will be made. Federal,

state and/or local taxes, duties and other

charges are the responsibility of the

purchaser.

Any changes in engineering drawings,

specifications, or in other terms of

manufacture, assembly or shipment,

requested by customer, must be in writing

and approved by ETC. If any such change

by Customer causes an increase in the cost

of, or in the time required for performance

of, any part of the contract, then ETC shall

make a reasonable adjustment to the price

of the goods.

If purchaser cancels any portion of a

Purchase Order prior to shipment,

Purchaser shall be liable to ETC for a

cancellation charge equal to ETC’s actual

costs incurred in connection with that

portion of the Purchase Order that is

cancelled, including, without limitation,

labor and materials. Customer represents

that it is solvent. ETC retains a security

interest in the goods to secure payment of

the purchase price and all other

indebtedness now or hereafter owed by

the customer to ETC. At ETC’s request,

customer will execute a financing

statement or statements evidencing such

security interest and will take any other

action necessary to perfect the same.

Payment terms are net 30 days after date

of invoice. If ETC in good faith doubts

customers ability or willingness to pay,

ETC may in its discretion complete its

performance of this contract upon a cash in

advance basis or make deliveries only upon

a C.O.D. basis or file a UCC filing or

suspend all or part of its performance here

under. All payments are applied to the

oldest outstanding invoice. Accounts over

thirty (30) days are subject to a 1 1/2% (one

and one-half percent) per month late

payment penalty. ETC will have the option

20 Appendix B Limited Warranty

Page 25

of withholding performance under any and

all orders from the Customer if an invoice

remains unpaid after 30 days. All disputes

otherwise unresolved between ETC and

Customer shall be resolved in a court of

competent jurisdiction in the location of

ETC’s offices, Dane County, Wisconsin. If

suit or action is instituted by ETC to enforce

payment or performance by the Customer,

the Customer agrees to pay all costs and

attorney’s fees incurred.

Claims for shortage or damaged goods

must be made within ten (10) days.

Equipment is carefully packed and

delivered in good condition to the carrier.

All claims for loss or damage in transit must

be made by the consignee directly to the

carrier. ETC will render every aid and

assistance in the presentation and

enforcement of such claims without

waiver of our rights to have compliance

with the terms of payment of our invoices.

Equipment returned without ETC’s written

permission will not be accepted.

Equipment returned for credit must be in

accordance with established RMA

procedures. Equipment must be unused, in

original cartons and in saleable condition,

subject to ETC’s quality control and test

inspection. Restocking charges of $25.00

or 25% of invoice (whichever is greater)

plus any repacking or reconditioning costs

will be deducted from the credit. Returns

for warranty work will be via warranty

procedures. In no case will permission be

granted to return specially-modified or

custom equipment, or merchandise

invoiced more than six (6) months prior to

date of Customer’s return request.

No failure of ETC to insist upon or compel

compliance by the customer with any of

these terms and conditions shall be

constructed as a waiver by ETC of its right

to insist upon compliance. No waiver by

ETC of any breach by customer shall be

effective unless in writing signed by ETC,

and no waiver by ETC of any breach by

customer shall be deemed a waiver of any

other breach.

If ETC shall fail to repair or replace

defective goods within a reasonable time

after they are returned to ETC, or if ETC

shall wrongfully fail to make delivery or

shall wrongfully repudiate this contract,

then customer shall be entitled to recover

from ETC such part of the purchase price

as has been paid by customer to ETC. The

remedy stated in the preceding sentence

shall be customer’s exclusive remedy for

any breach, non delivery, or repudiation by

ETC or for any other liability of ETC to

customer. This exclusive remedy shall not

be deemed to have failed its essential

purpose so long as ETC is willing and able

to repair or replace defective parts in the

prescribed manner.

Express LPC QuickGuide, v.3.1 21

Page 26

22 Appendix B Limited Warranty

Page 27

Appendix C

Declaration of Conformity

Express LPC QuickGuide, v.3.1 23

Page 28

Americas Middleton, Wisconsin • USA • Tel: (+1) 608 831 4116 • Fax: (+1) 608 836 1736 • (+1) 800 775 4382 • service@etcconnect.com

Europe London • England • Tel: +44 (0)20 8896 1000 • Fax: +44 (0)20 8896 2000 • service@etceurope.com

Asia Hong Kong • Tel: (+852) 2799 1220 • Fax: (+852) 2799 9325 • service@etcasia.com

International 3030 Laura Lane • Middleton, Wisconsin 53562 • Tel: (+1) 608 831 4116 • Fax: (+1) 608 836 1736 • www.etcconnect.com

4110M1011 • Rev B • Released 6/01

Copyright © 2001 Electronic Theatre Controls, Inc. All Rights Reserved. Product information and specifications subject to change.

Loading...

Loading...