Page 1

User's Manual

SOLDERING STATION

SMD REWOEK

ETC-RW900D

Intelligent lead-free rework station

CBN 019006

2 in 1

THERMO-CONTROL ANTI-STATIC

Page 2

2

3

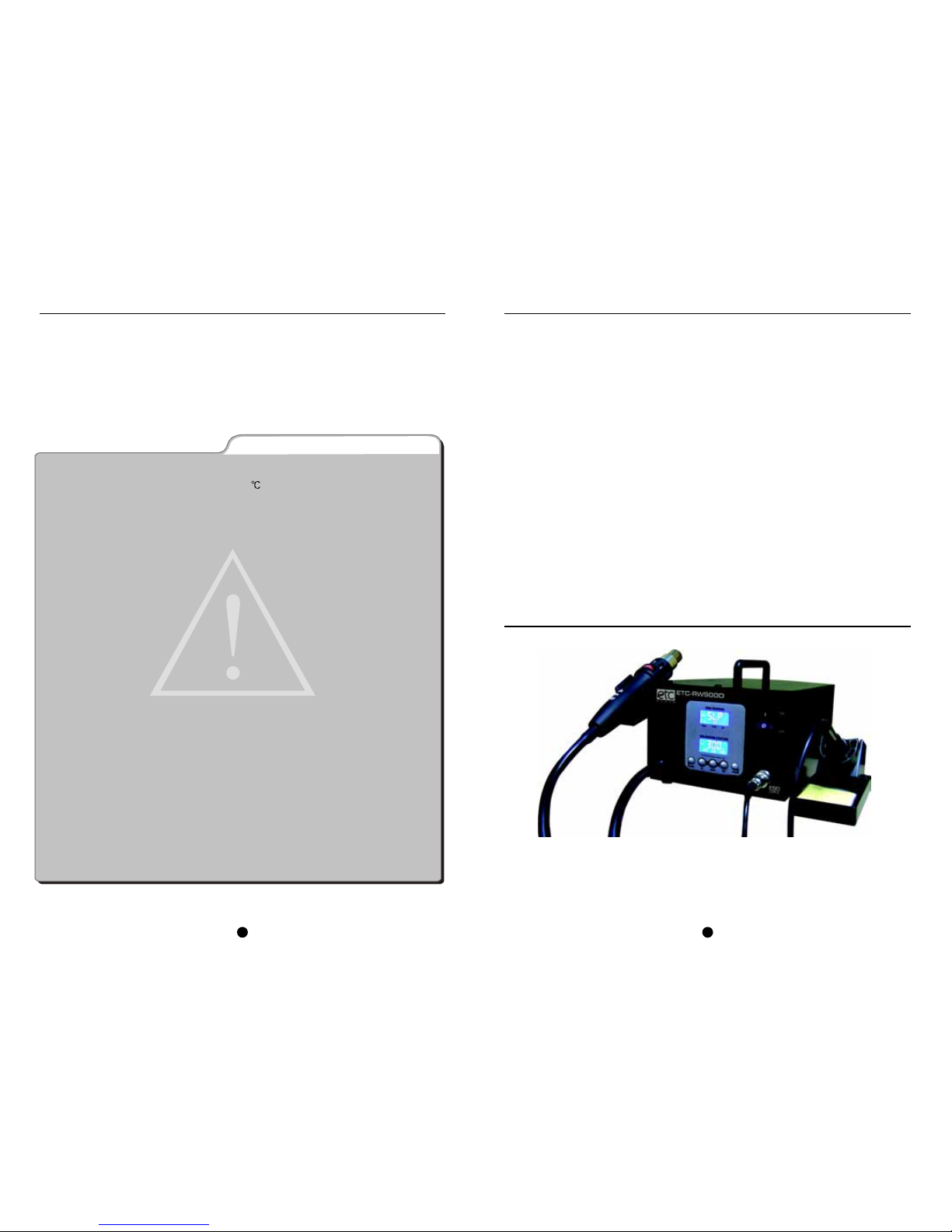

ETC-RW900D is an intelligent lead-free rework station, which combines rework station

and soldering station. It is especially suitable for R&D, production, lab of scientific

research and so on. It is easy to operate, user-friendly and greatly space-saving.

In order to keep machine from damage and insure the safety of operation, please

read through the manual and keep it for required.

Safety and Caution:

The temperature of the hot-air nozzle is 400 so it may lead to injury, fire and other

accident because of improper usage. Please abide the following terms:

1. Don't make the rework station be against people or animals. And never use it

as a hair drier and touch the heating element or blow the skin directly.

2. Never operate it near the flammable gas or substance and put it beside them

after use.

3. After use, the power should be off and it will be automatically off when the

hot air temperature is lowered, (There is fuse inside, so great attention must

be paid to superheat in case of accident.)

4. Please care for using hot-air gun, never make it fall or shake heavily and put

the heavy things on it or press the buttons improperly.

5. Don't operate with wet hands or wet wire in order not to result in short circuit

or electronic shock.

6. Keep away from children.

7. Please use the nozzle offered by manufacture and don't replace

the original nozzle.

8. Temperature will vary from the models of the nozzles, which is normal.

9. Don't touch the iron tip or surrounding metals.

10. Change the components or tip after cutting off power and waiting to cool it.

11. Don't use this device do other work except soldering.

12. Don't rap the handle to remove the doss of tip, which is bad for it.

13. Don't pull the cable but hold tightly the plug when you take out of plug.

14. Please keep good ventilation because there is smoke when solder.

15. Don't play with other people or would be easy to hurt others or yourself.

16. Please pay attention to the specifications of the power supply,

for manufacture offer different specifications, so be careful of selection.

Caution

Characteristics:

1. MCU computer offers PID advanced algorithms industrial control with thermo control and thermo-stability, which makes more exactly control temperature.

2. Dual LCD screen respectively and separately display the working state and

parameter, which is very directly. So customer can understand the output state

at a glance.

3. Temperature rapidly rises with large output power.

4. High flow diaphragm pump suitable for varies of nozzles to desolder

SMD components.

5. Dormancy, automatic shut down and other power-saving features.

6. Shortcut keys on the handle make it more convenient for the user to adjust

temperature and air volume.

7. Three groups of storage functions can bring very fast mode of switching different

groups of temperature and hot-air volume to the customers.

8. All units are equipped with temperature compensation, which ensure stable state

of operation.

9. Indicator for malfunction alert.

Machine diagram:

Page 3

4

5

Technical Specifications:

Rework station nozzle

Hot-air handle button group

B screen to display working

station of soldering stations

Output of soldering station

Sponge for clean iron

Hot-air handle bracket

Rework station handle

Output of hot-air

Function button groups

Iron holder

Iron handle

Function diagram:

Model ETC-RW900D Intelligent lead-free rework station

Total power

Range for temperature

controlling

About 900W (max)

Heating:800W(max), pump (diaphragm):40W Soldering Station:50W

Hot Air Rework Station

Soldering Station

100-500

200-480

Temperature unit

Convertible

Temperature

controlling stability

Static

±2

Temperature

controlling accuracy

Static

±10

Calibration range

Celsius

Fahrenheit

Setting storage

(3 groups)

Rework Station (in the factory)

Soldering Station (in the factory)

1 200 , 40; 2 300 , 60; 3 400 , 80

1 200 2 300 ; 3 400

Range of air volume Rework Station 020 100 level

Dormancy and

standby

Rework Station

Stopping heating, air-blowing delay and then be in the

condition of dormancy and standby.

Cold Air

Rework Station

Air-blowing made by the machine and stopping heating.

Malfunction alert

Heating elements

Sensor

Displaying H-E

Displaying S-E

Shutdown

Shutdown in the

normal condition

Cold air delay shutdown, power off

A screen to display working

station of soldering stations

power switch

12 12

Button instructions:

Position

Knob/Button

First function Second function (short press < 5s) Second function (long press > 5s)

Front Panel Buttons

Hot-air station

handle knob

Work and shutdown

of the rework station

Group Group

Value increasing

Value decreasing

Set temperature

and confirmation

varies of settings

Work and shutdown

of soldering station

Adjustment of

air volume

To increase the Set value of hot-air station

To decrease the Set value of hot-air station

Blowing cold air of

rework station

Awake hot air of

rework station

Group Group

Press with knob and then

select hot-air quick key 1 to set.

Press with knob and

deposit the setting of hot-air

quick knob 1

Press with knob and then

select soldering station quick

key 1 to set.

Press with knob and

deposit the setting of iron

quick knob 1

Press with knob and then

select hot-air quick key 2 to set.

Press with knob and

deposit the setting of hot-air

quick knob 2

Press with knob and then

select soldering station quick

key 2 to set.

Press with knob and

deposit the setting of iron

quick knob 2

Press with knob and then

select hot-air quick key 3 to set.

Press with knob and

deposit the setting of hot-air

quick knob 3

Press with knob and then

select soldering station quick

key 2 to set.

Press with knob and

deposit the setting of iron

quick knob 2

Page 4

7

8

The brackets for the handles must be installed when operating for the first time.

Please see the following illustration:

1. Please fix the bracket by tightening the four screws according to the illustration

and your personal habit.

2. According to your selection, dismantle the two screws on the left or the right,

which fix the bracket of the handle.

3. Place the two installation hole of the bracket to the two fixed screw holes of the

machine, and then tighten the dismantled two screws. Put the components of the

handle on the bracket to check if it is suitable.

Installation:

Introduction for LCD display:

A screen (rework station, same as below) B screen (soldering station, same as below)

Display "- - -" means the device is standby

Screen "A" displays the working state of rework station.

"P_ _" eans rework station is under the normal setting condition.

" P 0 1 " means rework station is under the condition set by memory group 1.

" P 0 2 " means rework station is under the condition set by memory group 2.

" P 0 3"means rework station is under the condition set by memory group 3.

Both screen A and screen B display " OFF" in the memory temperature area 2,

which means the device, is standby.

When the temperature area shines the station is under the condition

available to set.

Description for LCD display

Upon power on the unit, the reworking station and soldering station be standby.

Power:

Standby state of screen A Standby state of screen B

(diagram 1) (diagram 2)

. REWORK STATION

1. Power on: Rework station start to work after press the "POWER" knob at the

left of panel.

2. At that time, if the handle is on the bracket, screen "A" display state standby

(diagram 3), or display the setting temperature and 3 seconds later it display

the actual temperature (diagram 4, diagram 5).

(diagram 3) (diagram 4) (diagram 5)

Screen A: Standby

Screen A:

Setting Temperature

Screen A:

Actual Temperature

3. Temperature Settings

In normal condition, there are two methods to set temperature of hot-air

reworking station.

A. If screen A shines setting temperature through operating the

button of panel. If screen A doesn't shine you must press the

"SET"button to switch to shine of screen A then the station

Display of status

Setting value and display

of real temperature

Temperature unit

Power direction

Working mode

Setting temp.

Air flow display

Display of status

Temperature unit

Power direction

Setting value and display

of temperature

Memory temp. 1 Memory temp. 2 Memory temp. 3

Page 5

9

10

Under the setting condition. Then you can press "SET" button to set hot

-air rework station' s temperature and the main temperature area shines

the setting temperature, you can press UP knob or DOWN knob to adjust

the setting temperature. 4s-no-press or press SET knob, you can keep the

temperature and quit out this setting. (Diagram 6).

A. Setting temperature via handle of rework station. You can press UP knob

or DOWN knob directly to adjust temperature and the main temperature

area indicators setting temperature. 4s-no-press or press SET knob, you

can keep the temperature and quit out this setting, at that time, you can

adjust hot-air volume by pressing " " Whether screen A or screen B

shine as you set, the device is under the setting condition and

shining area for switch to screen "A " automatically.

Notice: continually pressing UP or DOWN knob in long time will quickly adjust

the temperature, at that time, the screen don't shine. (Same as below description)

In normal working condition, there are two methods to set hot-air volume:

A. If screen A shines setting temperature through operating the

button of panel. If screen A doesn't shine you must press the "SET"

button to switch to shine of screen A then the station under the

setting condition. Then you can press "SET" button to set hot-air rework

station' s temperature and the main temperature area shines the setting

temperature, you can press UP knob or DOWN knob to adjust the setting

temperature. 4s-no-press or press SET knob, you can keep the

temperature and quit out this setting (diagram 7).

B. Setting hot-air volume via handle of rework station. You can press UP

knob or DOWN knob to adjust hot-air volume and the main temperature

area indicators setting volume. 4s-no-press or press SET knob, you can

keep the volume and quit out this setting, at that time, you can adjust

hot-air volume by pressing " " When the screen A or screen B shine

as you set, the device is under the setting condition and shining

area for switch to screen"A" automatically.

4.Hot-air volume settings

5. Storing the Temperature values

Under normal working condition, hold down POWER knob at the left of panel,

at the same time long press (>5s) the UP knob or DOWN or SET to adjust

temperature and air volume to the required values separately in term 1 or

term 2 or term 3. But when you hold down POWER knob at the left of panel and

short press (<5s) UP or DOWN or SET knob to use the storage setting

temperature and air volume into current work temperature and air volume

(diagram8, diagram9, diagram10).

(Notice: up, down, set refer to storage term 1, term 2, term 3)

(diagram 6)

(diagram 7)

(diagram 8)

(diagram 9) (diagram 10)

Screen A:

Working state of shortcut 1

Screen A:

Working state of shortcut 2

Screen A:

Working state of shortcut 3

6.Temperature comp temperature and calibration

Under normal working condition, hold down both POWER knob at left of

panel and " " knob on the handle to calibrate. Screen A will display the

character CAL, and temperature value can be calibrated by pressing UP or

DOWN knobs. Pressing the SET knob to confirm storage and quit from this

calibration (diagram 11).

Page 6

11

12

(diagram 11)

Under normal working condition, when the user put the handle on the bracket,

then the equipment will be automatically switch to the dormancy condition and

the heater also stops heating. This happens in the case when the temperature is

higher than 100 , during the hot-air station dormancy period the screen A

display character SLP (diagram 3)

7. Dormancy

(diagram 3)

Screen A: Standby

In normal condition, continually press " "knob twice and then make the

hot-air be in the state of cold-air blow (diagram12). Under the cold-air

condition, press " " knob once, recover the hot-air working condition.

8.Conversation between cold-air and hot-air

(diagram 12)

Under normal working condition, the device keep the current temperature and

air volume and cut down heating to the rework station after pressing POWER

knob at the left of panel (diagram 1A), below 100 , the device is standby

(diagram1). If power is off, the soldering station is off, whole device will be off

after the temperature below 100 .

9.Standby

(diagram 1A) (diagram 1)

Standby state of screen A

1. When "H-E" is displayed on the screen A, there is no hot air in the nozzle

(diagram13), which indicates that the heating element fails.

2. When "S-E" is displayed on the screen A, there is a fault in sensor

(diagram14), which signifies that there is something wrong with the

sensor or the related circuit of the sensor.

10. Error/Fault indication

Screen A: no hot-air fault Screen A: sensor fault

(diagram 13) (diagram 14)

II. SOLDERING STATION

1.Power on

Screen B which displays actual temperature in 3s displays setting temperature

after pressing POWER knob at the right of panel (diagram15, diagram16).

Screen B:

Temperature Settings

Screen B: heating

In normal working condition, if screen B shines or you at first continually

press SET knob twice to switch to shine , then press the UP or DOWN knob

to adjust temperature. Screen B shines"SET" and the main temperature area

shines the setting temperature of soldering station. Stopping pressing knob or

pressing SET knob confirm and keep settings and quit from this operation

(diagram17).

2.Temperature setting

(diagram 15) (diagram 16)

Page 7

13

14

(diagram 17)

Under normal working condition, hold down POWER knob at the left of panel,

at the same time long press (>5s) the UP knob or DOWN or SET to adjust

temperature to the required values separately in term1 or term2 or term3.

When you hold down POWER knob at the left of panel and short press (<5s) UP

or DOWN or SET knob to use the storage setting temperature into current work

temperature and air volume.

(Notice: up, down, set refer to storage term1, term2, term3)

3.Shortcut keys set storage

Under normal working condition, hold down both POWER knob at right of

panel and " " knob on the handle to calibrate soldering station temperature

(diagram18). Temperature value can be calibrated by pressing UP or DOWN

knobs. Pressing the SET knob to confirm storage and quit from this calibration

(diagram 11).

4.Temperature comp temperature and calibration

(diagram 18)

In normal working condition, press POWER key at the right of panel to make

the device be standby (diagram 2). Make the power off, at the same time, the

soldering station is off and the whole station will off when the temperature is

low to 100 .

5.Standby

Standby state of screen B

(diagram 2)

A. When "H-E" is displayed on the screen A, there is no temperature

(diagram19),which indicates that the heating element fails.

B. When "S-E" is displayed on the screen A, there is a fault in sensor

(diagram20), which signifies that there is something wrong with

the sensor or the related circuit of the sensor.

6.Error/Fault indication

Screen B: fault of heating

screen B: fault of sensor

(diagram 19) (diagram 20)

III. Conversion of temperature unit

Under the power off condition, hold down the UP, DOWN and SET knob and

then put power on to switch / .

IV. Replacement of heater

Please follow the following steps for the successful replacement of the heating

element of hot-air rework station:

A. Cut down power, please refer to the following diagram to replace heater

after it is cool.

B. Based on diagram, loosen the three screws of the handle.

C. Dismantle the upper cover of the handle, pull out the ground wire on the

duct and take out the fan.

D. Take out the heating element from PCB board.

Page 8

15

16

E. Insert new heating element in PCB board, pay attention to install properly.

F. Install it as the contrary method of remove.

Please follow the following steps for the successful replacement of heating

element of soldering station:

A. Cut down power; replace the heating element after it is cool.

B. As following diagram, unscrew the nut , take out the stainless steel

cap and iron tip , then unscrew the fixed holder , desoldering the

heating element .

C. Replace the good condition heating element and install it as the contrary

method of remove.

List of accessories:

heating element

Hot air tube

Quartz tube

PCB

Top shell

Lower shell

ETC-RW900D

Power cord

Nozzle

Bracket

handle

iron holder

User manual

1 unit

1 strip

1 set

1 set

1 pc

1 set

1 copy

WARNING: This tool be placed on its stand when not in use

The instructions for heat guns and hand-held paint strippers shall

include the substance of following:

A fire may result if the appliance is not used with care, therefore

be careful when using the appliance in places where there are

combustible materials:

Do not apply to the same place for a long time;

Do not use in presence of an explosive atmosphere;

Be aware that heat may be conducted to combustible materials

that are out of sight ;

Place the appliance on its stand after use and allow it to cool

down before storage;

Do not leave the appliance unattended when it is switched on;

Page 9

17

18

Interchangeable soldering tips of soldering station

Nozzles

Loading...

Loading...