Page 1

2016-04-22

EN

0000000084

V.007

X.36.0

93959-001

Control extension

T2-BT

Operating Instructions

Page 2

ETA Heiztechnik

Gewerbepark 1

A-4716 Hofkirchen an der Trattnach

Tel: +43 (0) 7734 / 22 88 -0

Fax: +43 (0) 7734 / 22 88 -22

info@eta.co.at

www.eta.co.at

Page 3

3

Contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Warranty, guarantee and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Functional description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 ETAtouch control panel BE-P2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 T2-BT control extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Potential equalization and overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Circuit board GM-C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 NT-10VA circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 MK-E1 circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Concluding activities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 4

4 www.eta.co.at

General information General

1 General

1.1 General information

Copyright

All contents of this document are property of ETA

Heiztechnik GmbH and are protected by copyright.

Any reproduction, transfer to third parties or use for

other purposes is prohibited without written permission

from the owner.

Subject to technical alterations

We reserve the right to make technical modifications

without notice. Printing and typesetting errors or

changes of any kind made in the interim are not cause

for claims. Individual configurations depicted or

described here are only optionally available. In the

event of contradictions betwee n individual d ocuments

regarding delivery scope, the information in our current

price list applies.

Explanation of symbols

Instructions and information

Layout of safety instructions

SIGNAL WORD!

Type and source of danger

Possible effects

• Measures for avoiding the danger

Types of safety instruction

CAUTION!

On non-compliance with this safety instruction, there is

a risk of material damage.

WARNING!

On non-compliance with this safety instruction, there is

a risk of physical injury.

DANGER!

On non-compliance with this safety instruction, there is

a risk of major physical injury.

Illustrations

The illustrations in this documentation portray the

wood chip boiler merely as an example which stands

for all ETA boilers.

Electrical connection must only be made by

qualified specialist personnel

The electrical installation must only be performed

by specialist personnel with the corresponding

qualifications.

1.2 Warranty, guarantee and liability

Requirements

We can only accept liability for the function of our

products if they are correctly installed and operated.

This is only possible if the conditions below are

complied with.

Expanding the control system

Only components provided by us may be used for

expanding the control system, unless these are

generally available standard devices, such as thermostats.

Repairs

Repairs are only permitted using spare parts provided

by us. The only exceptions are commonly available

standard parts such as electrical fuses or fastening

materials, provided such parts have the necessary

features and do not compromise the safety of the

system.

Proper installation

The installing contractor is liable for proper installation

according to the corresponding installation instructions

and the relevant rules and safety regulations. If you as

customer have installed the he ating system partly or

entirely without relevant training and in particular

without up-to-date practical experience, without having

the installation checked by a trained and responsible

expert, we exclude defects in our delivery and consequential damages resulting from this cause from our

warranty, guarantee and liability.

Repair of defects

For repairs of defects carried out by the customer or by

a third party, ETA shall only bear the costs or remain

obligated by warranty if this work was approved in

writing in advance by the customer service of ETA

Heiztechnik GmbH.

Page 5

General Safety

5

1.3 Safety

DANGER!

Electric shock

There are live parts on the circuit boards. If

touched, they can cause injury and

property damage.

Before beginning any work, isolate the system

completely from all power sources, ensure that it

cannot be switched back on, and verify that it is

safely isolated from supply.

WARNING!

Configuration errors caused by multiple use of

node numbers with circuit boards and ETAtouch

control panels of the same type

It is impossible to identify circuit boards and ETAtouch

control panels when node numbers are assigned more

than once.

Set the node numbers correctly and conclude by

checking them once again.

CAUTION!

Flexible stranded conductors

If flexible stranded conductors are not used for the

wiring, the contacts in the plug connections will be

subjected to excessive mechanical strain. In this case,

the warranty for the electronics would become null and

void.

Only flexible stranded conductors may be used for

the wiring.

Page 6

6 www.eta.co.at

Functional description

2 Functional description

T2-BT control extension

The T2-BT control extension adds an ETAtouch

control panel and additional interfaces to the existing

ETAtouch controller.

Possible extensions include:

• 2 extra heating circuits with mixing valve

• 1 extra hot water tank

• 1 extra fresh water module

• Solar heating system with 1 or 2 tanks

• Solar heating system with stratified charging

module

A circulation pump, or a light or horn to indicate malfunctions, can be connected with the integrated supplementary relay (potential-free changeover contact).

A USB flash drive is supplied with each cont rol

extension for storing the configuration. We

recommend keeping it in the wall housing.

T4-0 control extension

The T4-0 control extension with the MK-E circuit board

can be optionally added to the control extension's wall

housing.

Extension:

• 2 extra heating circuits with mixing valve

Page 7

Functional description Technical data

7

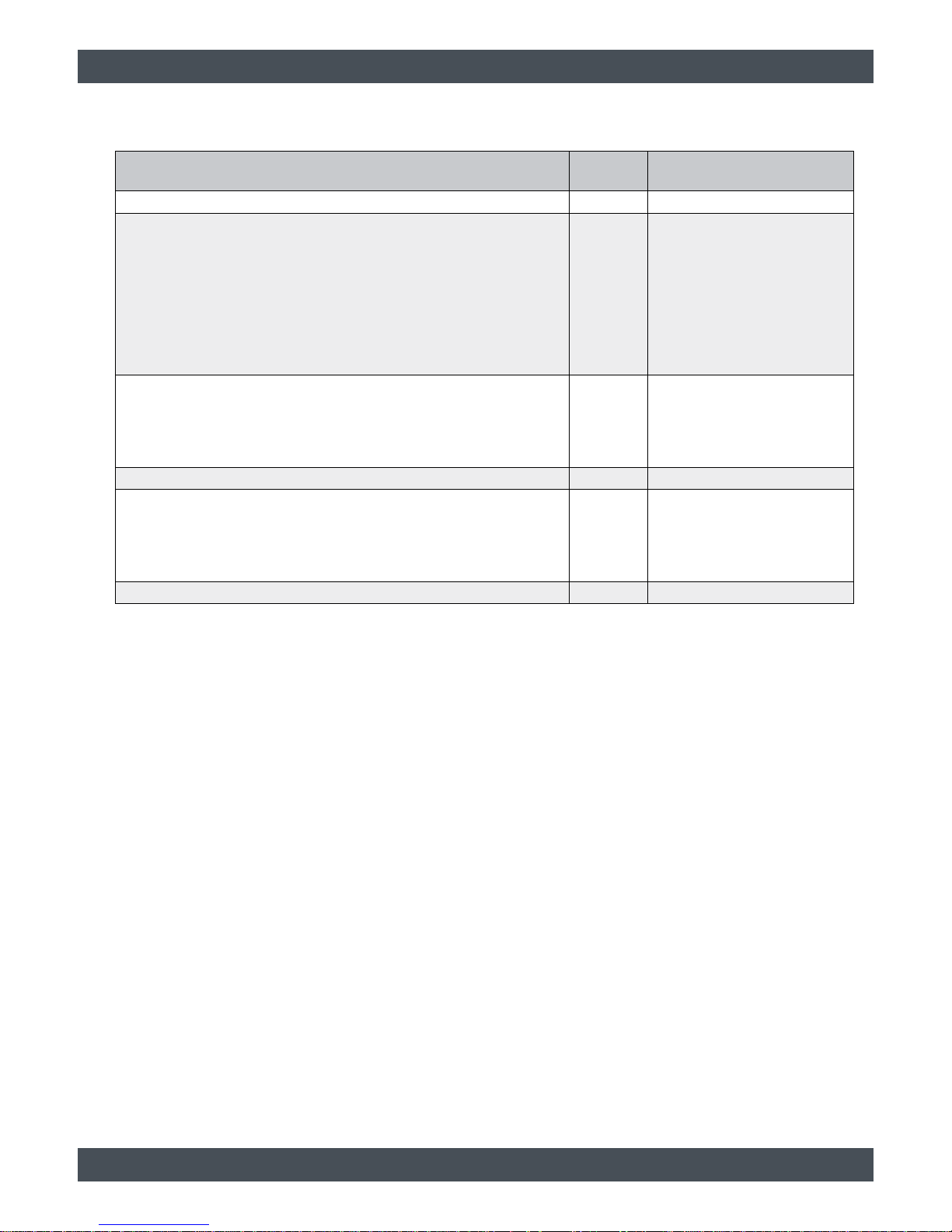

2.1 Technical data

Technical data Unit

Control extension

T2-BT / T2-BTI

Dimensions (WxHxD) mm 291x241x128

Number of inputs/outputs:

Temperature inputs

Analog/digital inputs

230 V outputs

Potential-free outputs

PWM outputs

RS-485 interface

16

2

10

1

4

1

Maximum switching power of the 230 V outputs:

A single 230 V output

Sum of all 230 V outputs

A single potential-free output

W

250

700

500

Supply V / Hz 230 / 50

Energy efficiency calculation factor

Controller class II (no room sensor)

Controller class VI (1-2 room sensors)

Controller class VIII (≥ 3 room sensors)

%

2

4

5

Standby consumption W W 4.4

Page 8

8 www.eta.co.at

Installation

3 Installation

Install T4-0 board in the wall housing

Fasten the T4-0 board onto the spacers on the rear

wall of the wall housing with 4 M3x5 round-headed

screws.

Install T4-0 board

Make the data and power supply connections between

the T4 0-board and the GM-C board.

1 Data line

([GM-C]: [S9],

[MK-E1]: [S15])

2 Power supply

([GM-C]: [S509],

[MK-E1]: [S517])

Fasten wall housing to wall

Fasten the wall housing to the wall using the 4

attachment holes.

1 A = 218.6 mm

2 B = 268.6 mm

Page 9

Specifications Cables

9

4 Specifications

4.1 Cables

CAN bus lines

Install the CAN bus lines according to the provided

specifications and pin assignments.

Use:

• between several circuit boards

• between several ETA boilers

Specifications:

• Total length up to 100 m:

Cable type: 2 x 2 x 0.6 mm STP (shielded twisted

pair) or higher grade

• Total length up to 400 m:

shielded CAT-6 or higher grade

• Maximum total length of all used CAN-bus lines:

400 m

Fig. 4-1: Signal cable (with 2 plugs)

Fig. 4-2: Screw-type terminal block plug

(2 x 0.6 mm STP with single-sided shield)

Fig. 4-3: Screw-type terminal block plug

(2 x 2 x 0.6 mm STP with single-sided shield)

Data cables

Use:

• between base boards and ETAtouch control

panels

Specifications:

• USB type: B

• maximum individual length: 5 m

• maximum total length of all data cables used: 20 m

Fig. 4-4: Data cable (with 2 plugs)

Fig. 4-5: Plug

Fig. 4-6: Socket on the circuit board

Sh Shield

+ Power supply

CH Data line CH

CL Data line CL

GND Earth

Page 10

10 www.eta.co.at

ETAtouch control panel BE-P2 Specifications

4.2 ETAtouch control panel BE-P2

Overview

1 Socket for CAN bus line

2 Terminal for yellow jumper

3 Socket for data line

Set node number on ETAtouch control panel

1. Switch on the entire heating system.

2. On the ETAtouch control panel, increase the authorization level to [Service].

3. Press the [CAN network] button. A window

appears where you can enter the desired node

number.

The values 0 to 7 are permitted for the node

numbers.

4. Restart the entire heating system. The change will

only take effect after the restart.

Page 11

Installation

11

5 Installation

Explanation of symbols

The jumper colours enable visual assignment of

the functions and have no technical relevance.

HACK wood chip boiler

T2-BT control extension with

integrated ETAtouch control panel

ETAtouch control panel BE-P

Node number of the BE-P

Node switch on the circuit board

The circuit board is located at the

end of the CAN bus connection

A yellow jumper must be set.

The circuit board is within the CAN

bus connection.

No yellow jumper may be on the

circuit board.

Page 12

12 www.eta.co.at

T2-BT control extension Installation

5.1 T2-BT control extension

1. Switch off heating system

Isolate the entire heating system from all power

sources, ensure that it cannot be switched back

on, and verify that it is safely isolated from the

power supply.

2. Connect CAN bus lines

Connect the circuit boards with CAN bus lines

using the shortest possible paths.

For details, see page 9

.

Consult the circuit diagrams for details on the

circuit board terminals.

3. Set yellow jumpers

Set one yellow jumper on each of the circuit boards

at the two ends of the CAN bus connection.

The end of the CAN bus connection is the

circuit board on which only one of the CAN

bus sockets is in use.

When both CAN bus sockets are in use, the

circuit board is within the CAN bus

connection and the yellow jumpers must be

removed.

4. Set node numbers

Circuit boards:

Multiple circuit boards of the same design (e.g. 2

GM-C) must have consecutive node numbers.

Set them via the node switch.

ETAtouch control panels:

All ETAtouch control panels must have

consecutive node numbers.

The node number of the ETAtouch cont rol panel

integrated in the ETA boiler is set to the value "0"

at the factory.

Set the node numbers for the external ETAtouch

control panels.

5. Switch on heating system

Switch the entire heating system back on and

check it.

For details, see page 22

.

WARNING!

Maximum length of CAN bus lines

If the maximum length of the CAN bus lines is not

observed, proper operation cannot be ensured!

Ensure that CAN bus-lines do not exceed the

maximum total length of 400 m.

The maximum total length of the CAN bus line is

reduced by 30 m for each overvoltage protection

module.

WARNING!

Configuration errors caused by multiple use of

node numbers with circuit boards and ETAtouch

control panels of the same type

It is impossible to identify circuit boards and ETAtouch

control panels when node numbers are assigned more

than once.

Set the node numbers correctly and conclude by

checking them once again.

Page 13

Installation T2-BT control extension

13

Page 14

14 www.eta.co.at

Electrical connections

6 Electrical connections

Electrical connection must only be made by

qualified specialist personnel

The electrical installation must only be performed

by specialist personnel with the corresponding

qualifications.

Configuration

Switch on the control extension with the main switch

and perform the configuration of the heating system

according to the relevant instructions.

Requirements

Observe the standard and special regulations of local

power supply companies.

For full separation according to the setup require-

ments, a separating device of overvoltage

category III must be installed in the permanent

electrical installation. In most cases, these requirements are fulfilled with a circuit breaker, for example.

For speed-controlled pumps (controled via PWM-

signal), the maximum cable lengths of the pump

manufacturer must be observed.

DANGER!

Electric shock

There are live parts on the circuit boards. If

touched, they can cause injury and

property damage.

Before beginning any work, isolate the system

completely from all power sources, ensure that it

cannot be switched back on, and verify that it is

safely isolated from supply.

CAUTION!

Flexible stranded conductors

If flexible stranded conductors are not used for the

wiring, the contacts in the plug connections will be

subjected to excessive mechanical strain. In this case,

the warranty for the electronics would become null and

void.

Only flexible stranded conductors may be used for

the wiring.

Maximum outputs

Connection diagrams

Fig. 6-1: Mains power input

Fig. 6-2: Analogue input

Fig. 6-3: Digital switch

Mains protection C 13

Mains connection 3 x 1.5²

Type of supply cable H05VV-F 3G 1.5

230 VAC components: 1.0²

Temperature sensors: 0.5² - 1.0²

230 V output

Maximum

power

A single output 250 W

Sum of all outputs 700 W

Potential-free output

(special function)

Maximum

switching

capacity

A single relay output 500 W

Page 15

Electrical connections Potential equalization and overvoltage protection

15

Fig. 6-4: Speed-controlled pump

Fig. 6-5: Special function - pump (with supply extension 230

V)

Fig. 6-6: Special function - changeover valve with three-point

controlling

Fig. 6-7: Special function - burner

Connect system components

Connect the system components according to the

terminal assignment of the configuration.

6.1 Potential equalization and

overvoltage protection

Recommendations for potential equalization and

overvoltage protection

On-site, properly qualified specialist personnel

(electrician) is responsible for a technically

correct earthing concept and proper potential equalization.

In order to avoid electrical potential differentials

between contactable and conductive parts, main

potential equalization will be necessary to protect

against damage caused by electrical shock.

Main potential equalization

All conductive parts within a building (e.g. metal pipes)

must be connected to the foundation ground through

potential equalization bars and potential equalization

cables (minimum diameter for copper: 6 mm²).

Observe national requirements for detailed spec-

ifications and minimum cross-sections of the

lines.

Potential equalization between buildings

Depending on local conditions and the characteristics

of a building's potential equalization, equalization

current may flow between the buildings through the

shielding of the CAN bus connection.

Page 16

16 www.eta.co.at

Potential equalization and overvoltage protection Electrical connections

In order to avoid this, the potential equalization bars of

the buildings should be connected with a thick

potential equalization cable.

Observe national requirements for detailed specifications and minimum cross-sections of the

lines.

Standardized lightning and overvoltage protection

Overvoltage protection that complies with local

conditions, legal requirements and regulations is

recommended for connections between buildings in

addition to potential equalization.

The installation of overvoltage protection may

only be carried out by a specialist.

The overvoltage protection concept must include the

following levels:

• Coarse protection (e.g. lightning rods)

• Medium protection (e.g. integrated distribution

devices)

• Fine protection, if necessary (e.g. power strips with

overvoltage protection)

The protective effects build on each other and are

effective only as a complete overvoltage protection

concept.

WARNING!

Maximum length of CAN bus lines

If the maximum length of the CAN bus lines is not

complied with, the ETAtouch control panel's software

interface may not be displayed correctly.

Ensure that CAN bus-lines do not exceed the

maximum total length of 400 m.

The maximum total length of the CAN bus line is

reduced by 30 m for each overvoltage protection

module.

When using a 4-line control system, an additional

protectively insulated mains adapter is required.

Page 17

Electrical connections Potential equalization and overvoltage protection

17

Page 18

18 www.eta.co.at

Circuit board GM-C2 Electrical connections

6.2 Circuit board GM-C2

Terminal Function Standard assignment

CAN Node CAN-Bus node switch

F1 Fuse T 500 mA (supply 24 V)

S1 230 V supply from circuit board [NT-10VA]: terminal [S51]

S2 230 V output collector pump 2 / secondary pump

S3 230 V output Charging pump for hot water tank

S4 230 V output collector pump 1 / secondary pump

S5 230 V output heating circuit 2: heating circuit pump

S6 230 V output heating circuit 2: heating circuit mixing valve

S7 230 V output heating circuit 1: heating circuit pump

S8 230 V output heating circuit 1: heating circuit mixing valve

S9 Supply extension 230 V to circuit board [MK-E]: terminal [S15]

S10

Potential-free output

(special function)

Diverter valve for solar heating system

S500 T1 Temperature input Solar heating system: secondary flow

S500 T2 Temperature input Solar heating system: primary return

S500 T3 Temperature input Free

S500 T4 Temperature input Free

S500 T5 Temperature input Free

S500 T6 Temperature input Collector

S501 T7 Temperature input Hot water

S501 T8 Temperature input Free

S501 T9 Temperature input Free

S501 T10 Temperature input Free

S501 T11 Temperature input Free

Page 19

Electrical connections Circuit board GM-C2

19

S501 T12 Temperature input Free

S502 T13 Temperature input heating circuit 1: Flow (for buffer operation)

S502 T14 Temperature input Free

S502 LD1 LED output Free

S503 T15 Temperature input heating circuit 2: Flow

S503 T16 Temperature input Primary return (fresh water module 1pump)

S503 LD2 LED output Free

S504 PWM output Speed for pump on terminal [S2]

S505 PWM output Speed for pump on terminal [S3]

S506 PWM output Speed for pump on terminal [S4]

S507 PWM output Speed for pump on terminal [S5]

S508A CAN-Bus Free

S508B CAN-Bus Free

S509 Signal line to circuit board [MK-E]: terminal [S517]

S510 Data line to ETAtouch control panel

S511 RS-485 bus Digital room sensor

S512 Supply 24 V from mains adapter

S513 Analogue or digital input

Flow switch flow rate

(fresh water module 1pump)

S514 Analogue or digital input Free

X2 CAN bus supply GND (for standalone mode)

X3 Boot jumper

X4 CAN-Bus terminal resistor

X5 RS-485 terminator resistor

X24 CAN bus supply +24 V (for standalone mode)

Terminal Function Standard assignment

Terminals marked with this symbol are not pre-wired.

Page 20

20 www.eta.co.at

NT-10VA circuit board Electrical connections

6.3 NT-10VA circuit board

Terminal Function Default assignment

F2 Fuse 230 V, T 6,3 A

X1 Supply 230 V Mains power input

X2 230 V input Mains switch

X3 Supply extension 24 V to circuit board [GM-C]: terminal [S512]

X4 Supply extension 230 V to circuit board [GM-C]: terminal [S1]

Terminals marked with this symbol are not pre-wired.

Page 21

Electrical connections MK-E1 circuit board

21

6.4 MK-E1 circuit board

Terminal Function Default assignment

S15 Supply 230 V from circuit board [GM-C]: terminal [S9]

S16 230 V output heating circuit 3: heating circuit pump

S17 230 V output heating circuit 3: heating circuit mixing valve

S18 230 V output heating circuit 4: heating circuit pump

S19 230 V output heating circuit 4: heating circuit mixing valve

S515 T17 Temperature input heating circuit 3: Flow

S515 T18 Temperature input Free

S515 LD3 LED output Free

S516 T19 Temperature input heating circuit 4: Flow

S516 T20 Temperature input Free

S516 LD4 LED output Free

S517 Signal line to circuit board [GM-C]: terminal [S509]

Terminals marked with this symbol are not pre-wired.

Page 22

22 www.eta.co.at

Concluding activities

7 Concluding activities

Check node numbers

1. On the ETATouch control panel, the system

settings menu is opened by tapping the

symbol (in the lower left of the screen).

2. Press the [Version overview] button. Compare

the node numbers of the circuit boards and the

previously configured ETAtouch control panels

with the numbers that appear in this window.

[Touchscreen(s)]:

Here, all available ETAtouch control panels are

displayed with their assigned node numbers.

[Circuit boards]:

Here, all available circuit boards are displayed with

their assigned node numbers.

If any circuit boards or ETAtouch control panels

are not displayed in this window, the configuration

of the corresponding node numbers needs to be

checked and corrected.

3. Close the window.

Page 23

Page 24

www.eta.co.at

www.eta.co.at/downloads

DOWNLOAD

Loading...

Loading...