Page 1

Rack

Installation Instruction

Page 2

2

Date of issue:

Date of publication: May 2017

This document replaces the following documents:

„ControlPlex

®

Rack I_19BGTCP_d_200916

Editor:

E-T-A Elektrotechnische Apparate GmbH

Industriestraße 2-8 . 90518 ALTDORF

GERMANY

Tel. +49 9187 10-0 . Fax +49 9187 10-397

E-Mail: info@e-t-a.de . www.e-t-a.de

Copyright © 2017 E-T-A GmbH

The contents of this document are the property of E-T-A GmbH. No part of this publication must in any way

be reproduced or distributed without prior written consent of E-T-A GmbH. Any person acting illegally with

regard to this publication can be prosecuted.

Limitation of liability

Although all provisions were taken when creating this document, the editor does not accept any reponsibility

for errors or omissions or for damages caused by using the information contained in this document. The information contained in this document may be revised at any time without pre-advice.

Brands

All references to software and hardware in this document are generally protected by brands or patents.

© E-T-A GmbH 2017. All rights reserved

Page 3

3

About this manual

This manual describes the electrical start-up of the ControlPlex® Rack system in connection with compatible

ControlPlex® Rack components. The ControlPlex® Rack allows artless and reliable protection and monitoring

of minus-supplied systems. Typical applications include telecommunications as well as IT centres, e.g. the

protection and electrical monitoring of server or router cabinets.

Besides this document, more information about the E-T-A ControlPlex

®

Rack can be found in the following

documents.

ControlPlex

®

Rack

Data sheet Here you will find more technical data and figures as well as approval infor-

mation on the various components of the ControlPlex

®

Rack system

ControlPlex

®

Rack

Operation instruction

manual RCI10 Here you will find an instruction for configuration and for integration of the

module Remote Control Interface RCI10 into your network. In addition this

document holds a user description of the web browser and the SSH surface

as well as the SNMP MIB for integration into a management system.

ControlPlex

®

Rack

Release Notes RCI10_SW_V2.0 Here you will find the information of the extended performance features of

the current software for the RCI10 sub-assembly.

ControlPlex

®

Rack

Application examples EAI300 Here you will find further configuration and connection examples for the

EAI300 module

The latest documents can be found on our website under

www.e-t-a.de/controlplex_rack

All documents contain important instructions for connection and safe operation of the ControlPlex

®

Rack

system. Safety instructions have to be observed. All users have to be informed about all safety instructions.

The documents have to be accessible for the user.

Page 4

4

Contents

About this manual ...........................................................................................................................................3

Contents ........................................................................................................................................................... 4

General note ....................................................................................................................................................6

1 Introduction ............................................................................................................................................. 8

2 Minimal requirements of installation.....................................................................................................9

3 General: ControlPlex

®

Rack Power-D-Box® .......................................................................................10

3.1 Use of the Power-D-Box

®

............................................................................................................. 10

3.2 Technical data of the Power-D-Box

®

............................................................................................11

3.3 Scope of delivery of the Power-D-Box

®

........................................................................................12

3.4 Pictures of Power-D-Box

®

versions (front view) ............................................................................12

3.5 Drawings and dimensions of Power-D-Box

®

versions ..................................................................13

3.6 Schematic diagrams of Power-D-Box

®

versions .......................................................................... 15

3.7 Pin assignment of Power-D-Box

®

versions ..................................................................................16

3.8 Installation and start-up of the Power-D-Box

®

.............................................................................18

3.8.1 Recommended installation site for Power-D-Box

®

..........................................................18

3.8.2 Basic notes on cabling for Power-D-Box

®

......................................................................18

3.8.3 Mounting and start-up of Power-D-Box

®

........................................................................19

4 General: ControlPlex

®

Rack, electronic circuit protector ESX300-S ...............................................21

4.1 Application ESX300-S .................................................................................................................... 21

4.2 Technical data of the Power-D-Box

®

............................................................................................21

4.2.1 Current rating, voltage drop and load capacity of ESX300-S ..........................................22

4.2.2 LED status indication ........................................................................................................ 22

4.3 Delivery scope ESX300-S .............................................................................................................. 22

4.4 Picture ESX300-S ...........................................................................................................................23

4.5 Installation and start-up ESX300-S ................................................................................................ 23

4.6 Removal of the electronic circuit protector ESX300-S ..................................................................25

4.7 Trouble-shooting concerning electronic circuit protector ESX300-S .............................................26

5 General: ControlPlex

®

Rack, signalling sub-assembly RSI10 ........................................................... 27

5.1 Application RSI10 ..........................................................................................................................27

5.2 Technical data of RSI10 .................................................................................................................27

5.2.1 Operating conditions and LED indication ......................................................................... 28

5.3 Delivery scope RSI10 ..................................................................................................................... 28

5.4 Picture of RSI10 .............................................................................................................................29

5.5 Installation and start-up RSI10 ......................................................................................................29

Page 5

5

6 General: ControlPlex® Rack, control interface RCI10 .......................................................................30

6.1 Application RCI10 ..........................................................................................................................30

6.2 Technical data of RCI10 ................................................................................................................. 30

6.2.1 Momentary switch function and LED status indication .................................................... 32

6.2.2 Function IP-reset by pressing the reset button with LED display .....................................33

6.3 Delivery scope RCI10 .....................................................................................................................33

6.4 Picture of RCI10 ............................................................................................................................. 33

6.5 Installation and start-up RCI10 ...................................................................................................... 34

6.5.1 Picture of slot for RCI10 or RSI10 ....................................................................................35

6.5.2 Picture of an example for network connection ................................................................. 35

6.6 Configuration and start-up RCI10 .................................................................................................. 35

7 General: ControlPlex

®

Rack, E/A external alarm interface EAI300 .................................................36

7.1 Operating mode and application EAI300 ....................................................................................... 36

7.2 Technical data of EAI300 ................................................................................................................36

7.2.1 Operating conditions LED signalling.................................................................................37

7.3 Delivery scope EAI300 ................................................................................................................... 37

7.4. Picture EAI300 ................................................................................................................................37

7.5 Installation and connection EAI300 ................................................................................................38

7.5.1 Example: EAI300 slot configuration .................................................................................. 39

7.5.2 EAI300 pin assignment and connection example ............................................................39

7.6 Configuration and start-up EAI300 ................................................................................................39

Page 6

6

General note

Qualified personnel

The system must only be installed, connected and configured in connection with this document. Installation

and operation of the device/system must only be carried our by qualified personnel. With regard to the safety

instructions of this documentation, qualified persons are persons authorised to operate devices, systems and

circuits according to the standards and rules of safety engineering.

Safety instructions

Please follow the installation and configuration instructions given in this document carefully. Failure

to complay may lead to serious damages of the product or the system. E-T-A does not accept any

liability for problems caused by improper installation or handling by the customer or a third person.

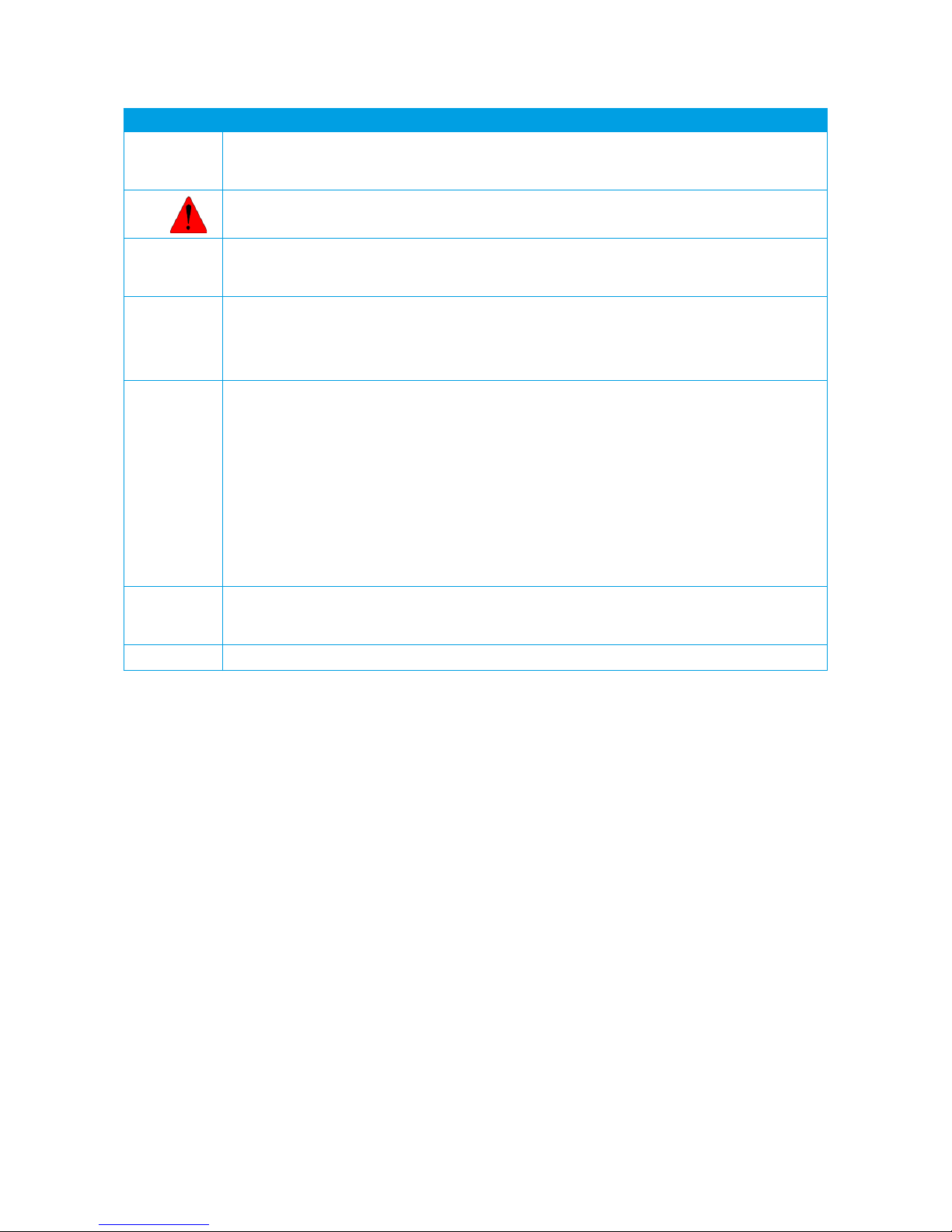

Symbols

You will find the following symbols in the entire manual. Their meaning is as follows:

Danger!

You are in a situation which might cause injury. Before working with one of the devices you have to

be aware of the risks of electrical circuitries and you ought to be familiar with standard procedures of

accident prevention.

Warning

There is a risk in this situation to do something which might cause damage of the devices or data loss.

Note

Here you receive information which might be particularly useful for the application.

Caution:

Electrostatically sensitive devices (ESD). Devices must exclusively be opened by the manufacturer.

Page 7

7

Page 8

8

1 Introduction

You chose ControlPlex® Rack, a comprehensive, future-oriented protection system which combines safety,

user convenience and service friendliness. It is a power distribution and management system which provides

electronic and, in the event of a short circuit, current-limiting protection of various loads. By means of an internal

bus system and an additional, hot-pluggable control interface module (optional), each load can remotely

be controlled and monitored. In addition it allows recording of measuring data of every single load. Besides

providing overcurrent and short circuit protection, it increases system availability by a multiple, because it

disconnects faulty loads quickly, selectively and without voltage dips.

In connection with the control interface module type RCI10 the ControlPlex

®

Rack system can be connected

to a centralised management system (control computer). For this purpose an Ethernet interface is made available with SNMP v1, v2c or v3 protocol. The required private MIB for embedding is part of the delivery scope.

An additional possibility for a centralised or also local monitoring/control is provided by the integral web

server, which can be used without additional software on the control computer by means of the web browser.

Thanks to its system properties the ControlPlex

®

Rack is the perfect solution for smart protection, control

and energy measurement for DC-supplied minus switching system cabinets. Typical applications include:

• System cabinets of any kind in telecommunications with DC -48 V or DC -60 V rated supply

• Server cabinets in IT centres with equipment for DC -48 V or DC -60 V rated supply

• System cabinets for mobile radio and television for DC -40 V to DC -72 V

• Protection and control of illuminated advertising with a power supply of DC -48 V

Further descriptions of the ControlPlex

®

Rack system with information on the configuration and network

connection by means of the module control interface RCI10 are available in the Operation instruction RCI10

manual ControlPlex® Rack.

This document contains the mounting and connection procedures for the hardware of the ControlPlex

®

Rack

system as well as an instruction for the first operation. You will learn more about

• how to mount and connect the different ControlPlex

®

Rack Power-D-Box® versions

• how to start up or exchange the electronic circuit protectors type ESX300-S

• how to identify and remedy failures of the electronic circuit protectors ESX300-S

• how to install and connect the optional control interface RCI10

• how to identify and remedy failures of the control interface RCI10 by means of LED indication

• how to install and connect the E/A external alarm interface EAI300.

• how to identify failures of the EAI300 by means of LED indication.

Page 9

9

2 Minimal requirements of installation

Please check the delivered components upon receipt with regard to completeness. You require the following

hardware components for installation and start-up of the ControlPlex® Rack system:

• One or more Power-D-Box

®

modules type: PDB-N-CP

• Electronic circuit protectors type ESX300-S-x00-xx A (version e.g.: with aux. contact only for PDB-N-

CP-xxx-xx-S, old version) or with bus interface; various current ratings: 2 A…24 A

• Optional: control interface with Ethernet interface type RCI10-000-x. The circuit protector type ESX300-

S-300-xxA is mandatory for use with control interface and signalling sub-assemblies RSI10.

• Optional: Alarm interface EAI300 for including additional “external” alarm contacts. Operation of EAI300

sub-assemblies requires control interface RCI10.

In addition you require different cables for connection of the Power-D-Box

®

, of the supply line, the loads

and the ground. Many manufacturers offer standard cables for this purpose.

2.1 Important information and safety instructions

The following table lists various information and safety instructions for start-up and use of the device.

Danger: Installation and operation of the device

This device has to be installed and operated in compliance with the given instructions.

Failure to comply can lead to injury, damage of loads or of the ControlPlex

®

Rack system.

Danger: Turn off the supply voltage

Before beginning with installation, the system has to be disconnected from the mains.

A cable connection must only be established if the supply voltage is OFF.

Danger: Possible ignition hazard

The device must NOT be used in inflammable surroundings.

Danger: high voltage

The cover must NEVER be opened. Access to the inner components is not allowed unless

indicated otherwise in this manual.

Caution: Work with ESD protection

Electronic modules must only be touched and installed with ESD protection so as to

ensure protection against electrostatic voltage. Failure to comply can cause damages on

the ControlPlex® Rack system or the corresponding components.

Warning: Grounding

The device must be grounded before switching on.

Table 1: Important information

2.12 EMC installation directives

The ControlPlex

®

Rack hardware and accessories comply with the EMC directives. Thus electromagnetic

interferences between the devices are avoided which would otherwise affect the system performance.

A professional installation is mandatory. In order to ensure the best EMC conditions, the widest possible distance between the different electrical devices should be applied.

2.3 Technical Accuracy

All technical data in this manual were correct in all conscience at the time of printing. E-T-A cannot be

held liable for any (inadvertent) errors. Due to continuous product improvements at E-T-A there could be

discrepancies between the actual product and the manual. Product changes or amendments of the technical

specifications will be carried out without prior notification. The latest versions of the ControlPlex

®

Rack

documents are available on our website (www.e-t-a.de).

Page 10

10

3 General: ControlPlex

®

Rack Power-D-Box

®

By using the Power-D-Box® type PDB-N-CPxxx-xx-A you can benefit from the advantages of the ControlPlex®

Rack system to full extent, no matter whether the control interface RCI10 is used from the start or only later.

3.1 Use of the Power-D-Box

®

The ControlPlex® Rack Power-D-Box® has been designed for the quick and easy installation into 19" or

ETSI racks which is ensured by a rotating mounting flange. Depending on the required termination technology

(front or rear) the corresponding Power-D-Box® will be available as a product. The service friendliness has

to be mentioned as a special advantage. The system can be extended with power on and additional circuit

protectors can be plugged into the load terminals. The control interface can also be fitted later with power on

without having to disconnect the loads.

Page 11

11

3.2 Technical data of the Power-D-Box

®

The entire 19" rack features the protection degree IP20. Table 2 summarizes the vital information.

Electrical data PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-NCP18R-RR-A

Operating voltage DC -48 V or

DC -60 V

DC -48 V or

DC -60 V

DC -48 V or

DC -60 V

DC -48 V or

DC -60 V

DC -48 V or

DC -60 V

Max.

supply current:

150 A 150 A 100 A 200 A 2 x 150 A

number of circuit protectors

9 9 9 19 18

Redundant system no no no no yes

Protected pole Negative pole protected electronically, without physical isolation

Suitable for

circuit protector

ESX300-S-3xx (2 A, 5 A, 8 A, 12 A, 16 A, 20 A, 24 A, with BUS)

Ambient temperature -20...+60 °C

Mechanical data PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-NCP18R-RR-A

Dimensions see drawings and dimensions

Mounting method 4 mounting screws M6 x 16 mm (not supplied with product)

tightening torque 5.3...5.7 Nm

Supply PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-NCP18R-RR-A

Terminals on the rear on the rear on the front on the rear on the rear

Screw terminals 16 – 50 mm²

AWG 5 –

AWG 1

16 – 50 mm²

AWG 5 –

AWG 1

4 – 25 mm²

AWG 11 –

AWG 3

16 – 50 mm²

AWG 5 –

AWG 1

16 – 50 mm²

AWG 5 –

AWG 1

Tightening torque 6…8 Nm 6…8 Nm 4 ...4.5 Nm 6…8 Nm 6…8 Nm

Loads PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-NCP18R-RR-A

Max. load current per

load terminal

30 A with

9 ways

30 A with

9 ways

30 A with

9 ways

30 A with

19 ways

30 A with

2 x 9 ways

Terminals on the rear on the front on the front on the rear on the rear

Screw terminals 0.5 – 6 mm²

AWG 20 –

AWG 10

– – 0.5 – 6 mm²

AWG 20 –

AWG 10

0.5 – 6 mm²

AWG 20 –

AWG 10

SUB-D connector – 2.5 – 10 mm²

AWG 13 –

AWG 7

2.5 – 10 mm²

AWG 13 –

AWG 7

– –

Tightening torque 0.5…0.8 Nm – – 0.5…0.8 Nm 0.5…0.8 Nm

Signalling PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-N-

CP18R-RR-A

Terminals on the rear on the front on the front on the rear on the rear

Screw terminals 0.25 – -1.5

mm²

AWG 23 –

AWG 16

– – 0.25 – 1.5

mm²

AWG 23 –

AWG 16

0.25 – 1.5

mm²

AWG 23 –

AWG 16

SUB-D connector – 2.5 – 10 mm²

AWG 13 –

AWG 7

2.5 – 10 mm²

AWG 13 –

AWG 7

– –

Tightening torque 0.22…0.25 Nm– – 0.22…0.25 Nm0.22…0.25

Nm

Grounding PDB-N-

CP09A-RR-A

PDB-NCP09A-RF-A

PDB-NCP09A-FF-A

PDB-NCP19A-RR-A

PDB-N-

CP18R-RR-A

Ground connector M6 ground stud, always on the rear, tightening torque 6 Nm

Table 2: A selection of technical data / *) further information can be found in the data sheet.

Page 12

12

3.3 Scope of delivery of the Power-D-Box

®

The following parts are part of the delivery scope of the Power-D-Box®:

• 19" rack with 19“ / ETSI interchangeable flange (mounted 19“)

• blanking pieces for slots of circuit protectors and control interface (mounted)

• mating plugs in the event of rear screw terminals (plugged on). Versions: PDB-N-CPxxx-xR-Ax

• mating plugs of signalling terminals (screwed on). Versions: PDB-N-CPxxx-xR-Ax

The following accessories can be ordered separately:

• rear cable grip rail (part no. X223 260 01)

• connector set, high current SUB-D for load terminal on the front (part no. X223 189 01)

• marking frame with labels, 0.5U, for customised marking of circuit protectors (part no. X22357501)

• marking frame with labels, 1U with cable gland on the front, for customised marking of circuit protectors

(part no. X22357601)

• circuit protectors, type ESX300-S-3xx-xxA

• signalling sub-assembly RSI10-xxx-x

• control interface type RCI10-xxx-x

• control alarm interface type EAI300-xxx-x

For more information on accessories please see the data sheet of ControlPlex

®

Rack.

3.4 Pictures of Power-D-Box

®

versions (front view)

fig. 1: front view PDB-N-CP18R-RR-A, PDB-N-CP19A-RR-Ax

fig. 2: front view PDB-N-CP09A-RR-Ax

fig. 3: front view PDB-N-CP09A-FF-Ax terminals on the front with high current SUB-D connectors

Page 13

13

3.5 Drawings and dimensions of Power-D-Box® versions

515 (ETS)

465 (19“)

76.2 (19“)

75 (ETS)

88.9 (2HE)

fig. 4: front view PDB-N-CP09A-FF-Ax 1 x 9 slots, terminals on the front with high current SUB-D connectors

fig. 5: rear view PDB-N-CP09A-FF-Ax 1 x 9 slots (with rear cable grip rail)

482.6

88.9

fig. 6: front view PDB-N-CP19A-RR-Ax 1 x 19 slots

fig. 7: rear view DB-N-CP19A-RR-Ax without cable grip

Page 14

14

515 (ETS)

465 (19“)

531.4 (ETS)

482.6 (19“)

76.2 (19“)

75 (ETS)

88.9 (2HE)

fig. 8: front view PDB-N-CP18R-RR-Ax 2 x 9 slots

fig. 9: front view PDB-N-CP18R-RR-Ax 2 x 9 slots

450

171.5

16014

201.5

271.5

cable grip set (optional)

cable guide supply

fig. 10: top view PDB-N-CP18R-RR-Ax 2 x 9 slots (with rear cable grip rail)

Page 15

15

3.6 Schematic diagrams of Power-D-Box® versions

ESX300-S

E-T-A

RCI/RSI

A7 A4

1 11 1 11 1 11 1 11 1 11 1 11 1 11 1 11 1 11 1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 142 12 142 12 142 12 142 12 142 12 142 12 142 12 142 12 142 12 14A9

Status OK FAULT

LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-

LINE-LINE-LINE-LINE-LINE-LINE-LINE-LINE-LINE-

LINE-

EL-BUS

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LINE- LINE-LINE-LINE-LINE-LINE-LINE-LINE-LINE- LINE-

LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-

OK FAULTOK FAULTOK

FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULT OK FAULTOK FA ULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULT

-X0

-A1

-A2

-A3

-A4

-A5

-A6

-A7

-A8

-A9

-A10

-A11

-A12

-A13

-A14

-A15

-A16

-A17

-A18

-A19

pcb X22360401

busbar

busbar

busbar

busbar

A+

A-

A+

A-

ground

enclosure

ground

enclosure

-1.1

+1.3

-X2.1 - + -X2.2 - + -X2.3 - + -X2.4 - +-X2.5 - + -X2.6 - + -X2.7 - +-X2.8 - + -X2.9 - + -X2.10 - +-X2.11 - +

1.9 / Plus

1.9 / LIN

1.9 / ADR

1.9 / GND

1.9 / Line

2.1 / Plus

2.1 / LIN

2.1 / ADR

2.1 / GND

2.1 / Line

-X2.12 - + -X2.13 - +-X2.14 - + -X2.15 - + -X2.16 - + -X2.17 - +-X2.18 - +-X2.19 - +

-1.2

+1.4

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

fig. 11: Schematic diagram PDB-N-CP19A-RR-Ax, 1 x 19 slots with signalling

ESX300-S

E-T-A

RCI/RSI

A7 A4

1 11 1 11 1 11 1 11 1 11 1 11 1 11 1 11 1 11

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

1 11

2 12 14

2 12 142 12 142 12 142 12 142 12 142 12 142 12 142 12 142 12 14A9

Status

LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-

LINE-LINE-LINE-LINE-LINE-LINE-LINE-LINE-

LINE-

EL-BUS

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

LOAD-

LIN

Adresse

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LINE-

GND+

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LIN-BUS

LINE-

LINE-LINE-LINE-LINE-LINE-LINE-LINE-LINE- LINE-

LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-LOAD- LOAD-

OK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK

FAULT

OK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULTOK FAULT

-X0

-A1

-A2

-A3

-A4

-A5

-A6

-A7

-A8

-A9

-B1

-B2

-B3

-B4

-B5

-B6

-B7

-B8

-B9

pcb X22360411

pcb X22360421

busbar busbar

busbar

A

+

ground

enclosure

ground

enclosure

ribbon cable

connection to

pcb B1

ribbon cable

connection to

pcb A1

+A1.2

A- -A1.1

A1

-X2.1 - +-X2.2 - +-X2.3 - + -X2.4 - + -X2.5 - +-X2.6 - + -X2.7 - +-X2.8 - + -X2.9 - +

-X2.11 - +

B+ +B1.2

/ 7.9 / 6.9

B-

B1

-B1.1

-X2.12 - +-X2.13 - +-X2.14 - + -X2.15 - + -X2.16 - + -X2.17 - + -X2.18 - +-X2.19 - +

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

ESX300-S

E-T-A

fig. 12: Schematic diagram PDB-N-CP18R-RR-Ax, 2 x 9 slots with signalling

Page 16

16

3.7 Pin assignment of Power-D-Box® versions

pin assignment PDB-N-CP09A-RR-Ax, PDB-N-CP18R-RR-Ax

• Rear-side supply terminals DC 48 V–DC 60 V / max. 2 x 150 A

• Cable cross section max. 50 mm²

loads B-/B+ loads A-/A+

plus 48 V DC B+ minus 48 V DC A-minus 48 V DC B- plus 48 V DC A+

fig.13 version PDB-N-CP18R-RR-A, pin assignment (cable grip removed)

Pin assignment PDB-N-CP09A-FF-Ax

• Front-side supply terminals DC 48 V–DC 60 V / max. 100 A

• Cable cross section max. 25 mm²

• Front-side supply terminals A1 ... A9 DC 48 V–DC 60 V / max. 30 A

• Cable cross section max. 10 mm²

Page 17

17

minus 48 V DC A-

plus 48 V DC A+

plus 48 V DCminus 48 V DC

protected pole

empty

fig.14 version PDB-N-CP09A-FF-Ax, pin assignment

pin assignment PDB-N-CP09A-RF-Ax

• line entry see PDB-N-CP09A-RR-Ax

• load terminals see PDB-N-CP09A-FF-Ax

pin assignment PDB-N-CP19A-RR-Ax

• Rear-side supply terminals DC 48 V–DC 60 V / max. 200 A with supply via two supply terminals

(internally bridged). Max. 150 A per supply terminal at 50 mm² cable cross section.

• cable cross section max. 50 mm² per supply line

• cable cross section max. 4 mm² with wire end ferrule per load terminal

plus 48 V DC A+

max. 150 A per terminal

plus 48 V DC A+

max. 150 A per terminal

minus 48 V DC Amax. 150 A per terminal

minus 48 V DC Amax. 150 A per terminal

load A19-/19+...A1-/A1+

cable grip

(optional)

fig. 15 version PDB-N-CP19A-RR-A, pin assignment (cable grip installed)

Page 18

18

3.8 Installation and start-up of the Power-D-Box®

The ControlPlex

®

Rack system has been designed for stationary installation in an indoor system cabinet.

For installation in an outdoor cabinet we recommend a fully conditioned cabinet with heating and cooling. In

the event of high humidity the surrounding has to be additionally dried.

3.8.1 Recommended installation site for Power-D-Box

®

Usually the Power-D-Box

®

is installed in the top or bottom area of the sytem rack. We recommend installation

in close proximity to the connected loads so as to reduce wiring and cable management.

Important:

• Leave sufficient space for heat dissipation, min. 0.5U above or below the

Power-D-Box

®

should be free for ventilation.

• Please take care to install the Power-D-Box

®

in enclosed and dry rooms.

• Please observe the required degree of protection.

GENERAL REQUIREMENTS OF INSTALLATION SITE

Various aspects have to be considered when choosing the installation site.

Ventilation

Please ensure sufficient ventilation by leaving enough space at all sides of the device and

ensure that the vent holes are not blocked. Leave enough space between the devices.

Cable management

Ensure installation at a site where the cables can be laid and connected properly. Ensure

ease of access for service and system extensions of all termination versions even after

installation.

Electrical noise pulses

The installation site should provide sufficient distance to any devices that might emit noise

pulses.

Table 3: Power-D-Box® Requirements of installation site

3.8.2 Basic notes on cabling for Power-D-Box®

The selection of the correct cable types regarding temperature resistance and ampacity is important for the

reliable power distribution, control and monitoring by means of a ControlPlex

®

Rack system. Please ensure

to use cables of superior quality with the suitable cross sections so as to avoid voltage drops.

Laying of cables must be carried out carefully. The table 4 gives general hints regarding wiring of a

Power-D-Box

®

, including the connected loads.

Item Note

1 Cables must be protected against damages and heat. Avoid the proximity to moveable or

hot parts and to machines.

2 Ensure a suitable strain relief.

3 Check cables with regard to intact insulation, above all after cable laying.

Table 4: Power-D-Box® wiring hints

Page 19

19

3.8.3 Installation and start-up of the Power-D-Box®

Important notes

Danger: Turn off the supply voltage

Before beginning with installation, the system has to be disconnected from the mains. A

cable connection must only be established if the supply voltage is OFF.

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be carried

out with corresponding ESD protection means. Failure to comply can cause damages on

the ControlPlex® Rack system or the corresponding components.

Warning: Mounting position

The Power-D-Box® must only be installed horizontally in the cabinet, vertical installation

may cause overheating.

Warning: Supply voltage

The voltage of the power supply must be between DC 38 V and DC 72 V to ensure a

smooth operation. In the event of a voltage in excess of DC 75 V the Power-D-Box® may

be damaged.

Table 5: Power-D-Box® Important hints for start-up

Start-up of the Power-D-Box® comprises the following steps:

step action

1 Prepare all necessary devices and tools such as:

• different screw drivers and M6 box wrench (not delivered with product)

• connecting cables for power supply and ground (not delivered with product)

• connecting cables for load terminals (not part of the delivery scope)

• 4 mounting screws M6 x 16mm with plastic sleeve

• 2 x M6 cable lug, not part of the delivery scope (ground connection Power-D-Box

®

)

• load terminal mating plug (can be ordered as accessory for version with front

connection, otherwise it is part of the Power-D-Box

®

delivery scope)

2

If installation shall be in an ETSI rack:

Re-work of the Power-D-Box

®

mounting brackets to ETSI dimensions:

remove, turn bracket by 180°, re-fit with the 2 mounting screws.

3

Important: Please ensure that the system is dead-voltage.

4

Lay all necessary cables for grounding, supply and load terminals of the

Power-D-Box

®

5 Connect the load terminal cables with the corresponding load connectors and mark them

with the corresponding way no. of the Power-D-Box®

Important: Do not yet connect the load connectors

to the Power-D-Box®.

Depending on the version, see chapter 3.7 pin assignment

Depending on the version, tightening torque of supply terminals,

see table 2, "Technical data/supply"

6

Mounting of Power-D-Box® in the system cabinet:

Install the Power-D-Box® horizontally in the system cabinet and

fix it with the 4 supplied mounting screws.

The tightening torque of the mounting screws is 5.3–5.7 Nm.

Page 20

20

7 Connection of the Power-D-Box® grounding cable(s):

The ground connection is on the rear side of the Power-D-Box® (see fig. 15) and is

marked with a grounding symbol. In the event of two separate power supplies

(redundant system) both ground connections have to be connected with one grounding

cable each. The grounding cable can be fixed with an M6 cable lug and the fitted

grounding nut with a tightening torque of 6 Nm.

8 Connection of the Power-D-Box® supply lines:

Depending on the version, see chapter 4.7 pin assignment

Depending on the version, tightening torque of supply terminals,

see table 2, "Technical data/supply"

Important: Do not yet connect any load lines.

9 Switch on the power supply.

Check correct polarity with a voltmeter (plus, minus) and the correct voltage value of

the power supply. terminals. In the event of a failure please remedy before proceeding

with step 10.

10

For installation of circuit protectors, go to chapter 4 "ControlPlex® Rack,

electronic circuit protector ESX300-S"

11

For installation as group alarm indicator (population without circuit protectors, only

with alarm interface EAI300) please go to chapter 7 "ControlPlex® Rack, E/A

external alarm interface EAI300"

End

Table 6: Power-D-Box® steps for start-up

Page 21

21

4 General: ControlPlex® Rack,

electronic circuit protector ESX300-S

The electronic circuit protector ESX300-S has particularly designed for the use in the Power-D-Box® of type

PDB-N-CP. It can be installed and de-installed with the system live without having to disconnect the application

from the mains. Thus you can reduce the installation and service periods to a minimum.

4.1 Application ESX300-S

The electronic circuit protector ESX300-S is suitable for minus supplied systems with voltage ratings from

DC -48 V and DC -60 V. It is capable of disconnecting all faulty loads selectively in the event of overcurrent

and short circuit, i.e. without voltage dip or failure of neighbouring loads. In the event of overcurrent or short

circuit the active current limitation of the ESX300-S prevents a overload-dependent voltage regulation of the

(switched mode) power supply. In the event of a failure the latter prevents a voltage dip of the switch-mode

power supply and thus repercussions on the neighbouring loads. The ESX300-S is available both with BUS

interface and with potential-free signalling: only for PDB-N-CPxxx-xx-S (old version) The version with BUS

interface in connection with the signalling sub-assembly RSI10 (see chapter 5) or with the control interface

RCI10 (see chapter 6) allows failure indication as well as an automatic remote control of the ESX300-S via a

controlling computer.

4.2 Technical data of ESX300-S

Electronic circuit protectors with active current limitation for use in minus-switching equipment.

Technical data of ESX300-S

Current ratings 2 A, 5 A, 8 A, 12 A, 16 A, 20 A, 24 A

Capacitive load max. 7,000 uF (depending on the current rating)

Trip electronically (1-pole), no physical isolation

Threshold for active

current limitation

Typical 1.2 x rated current ESX300-S

Reliability in the event of

faulty electronics

integral fail-safe element (blade fuse)

Protected pole minus pole protected

Operating voltage DC -37 V to DC -72 V

Signalling (optional) potential-free auxiliary contacts

BUS system (optional) EL-BUS

®

for communication with sub-assembly RCI10

Status indication LEDs red and green

Low voltage indication < DC -37 V

Overvoltage indication = / > DC minus 72 V

Trip times typically < 10 ms at short circuit (current limitation active)

typically < 30 sec at overcurrent (I > IN < current limitation threshold)

Approval logos CE to EN 61000-6-3 and EN 61000-6-2, UL 2367

Mechanical data ESX300-S

Ambient temperature -20 °C ... +60 °C *

Cooling convection cooling

Mounting position vertical mounting position

Version rack module with front plate, no separate enclosure, for installation in

Power-D-Boxes

®

Table 7: ESX300-S, technical data

*) major technical data, for further information please see data sheet of ControlPlex® Rack

Page 22

22

4.2 Current ratings, voltage drop and load capacity ESX300-S

Current

rating

range I

N

Typical voltage

drop UON at I

N

active current

limitation typically

trip time

typically at

1.2 x I

N

Fail-safe

element

max. load

current at

100 % ON

duty

Max.

capacitive

load (µF)

T

AMB

= 40

°C

2 A 130 mV 1.20 x I

N

0.2 – 3 s 4 A 2 A 1500

5 A 130 mV 1.20 x I

N

0.2 – 3 s 10 A 5 A 2000

8 A 200 mV 1.20 x I

N

0.2 – 3 s 10 A 8 A 3000

12 A 150 mV 1.20 x I

N

0.2 – 3 s 20 A 12 A 4000

16 A 200 mV 1.20 x I

N

0.2 – 3 s 20 A 16 A 5000

20 A 160 mV 1.20 x I

N

0.2 – 3 s 30 A 20 A 6000

24 A 200 mV 1.20 x I

N

0.2 – 3 s 30 A 24 A 7000

Note: The total current of neighbouring devices must not exceed 44 A.

The derating factor at an ambient temperature of > 40 °C is 0.8 times rated current.

Table 8: ESX300-S, electrical data

4.2.2 LED Status Indication

Operating condition Load output LED green LED red

auxiliary contact

N/C (optional)

no error -> OFF locked flashing slowly OFF open

normal operation connected ON OFF open

error undervoltage with device in

OFF condition (15 V < U < 37 V)

locked OFF ON closed

error undervoltage with device in

OFF condition (U > 72 V)

locked OFF ON closed

overcurrent error detected

(I > IN < 1.2 x IN) overcurrent failure

has to be detected for approx. 30

sec before disconnection is effected

connected ON flashing fast open

error – overcurrent or short circuit

disconnection

locked OFF ON closed

error undervoltage

(U > 15 V < 37 V)

connected ON ON closed

error overvoltage

(72 V, < U < 75 V)

connected ON ON closed

error, no voltage or

internal error

locked

1

OFF OFF closed

error high temperature locked

1

OFF flashing slowly closed

remote disconnection (ordering

option control interface)

locked flashing fast OFF ------

Table 9: ESX300-S operating conditions - LED display

4.3 Delivery scope ESX300-S

The following parts are part of the delivery scope of the ESX300-S:

• Electronic circuit protector, type: ESX300-S-xxx-xxA with front plate

• removeable label in the front plate

Page 23

23

4.4 Picture ESX300-S

fig. 16 ESX300-S electronic circuit protector

4.5 Installation and start-up ESX300-S

Important notes

Note: Power-D-Box

®

installed

Before starting the installation, the Power-D-Box® has to be properly installed first and

supply voltage should be applied. All steps in chapter 3 were carried out properly.

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be

carried out with corresponding ESD protection means. Failure to comply can cause

damages on the ControlPlex® Rack system or the corresponding components.

Warning: Mounting position

The ESX300-S sub-assembly has to be pushed in vertically into the Power-D-Box®.

Warning: load terminal

Load terminal must be open (not connected) when installing the ESX300-S.

Warning: Supply voltage

The voltage of the power supply must be between DC 38 V and DC 72 V to ensure a

smooth operation. In the event of a voltage in excess of DC 75 V the electronic circuit

protector may be damaged.

Table 10: ESX300-S, Important hints for start-up

status LEDs

engagement

nose

ON/OFF

rated current

circuit protector

groove for

label

Page 24

24

Start-up of the ESX300-S comprises the following steps:

step action

1 Prepare all necessary devices and tools such as:

• Electronic circuit protectors ESX300-S (check the ESX300-S with regard to the

required current ratings, see chapter 4.5 fig. 16 "rated current value"

• For use with PDB-N-CPxxx-xx-Ax (new version of Power-D-Box®), use of

bus-capable circuit protectors is mandatory, type ESX300-S-3xx

2

Danger: Please ensure that all steps in chapter 3 for starting up the

Power-D-Box® are carried out correctly.

3

Warning: The total current of neighbouring devices must not exceed 44 A. The

derating factor is 0.8 times rated current of the ESX300-S with ambient temperatures > 40°C.

4

Installation of the circuit protectors ESX300-S into the Power-D-Box

®

:

Push the ESX300-S with the correct current rating carefully into the related and

documented slot (e.g.: slot A1) until it latches on into the front plate in the

Power-D-Box®.

5

Check the LED indication of the installed ESX300-S:

The status LED "OK" must blink green (load output not yet connected). If the green

LED is lighted continuously, push the "On/Off" momentary switch once until it

blinks.

Important: The red status LED "Fault" must be off. If this is not the case, please

go chapter 4.7 ESX300-S trouble-shooting and remedy the failure. Do not continue

with step 6 before the LED status indication (both LEDs) is as described in step 5.

6

Connection load output to the corresponding load channel of the Power-D-Box

®

:

Important: Check correct polarity (plus/minus) before connecting.

Plug in the load terminal connector pertinent to the installed ESX300-S slot.

Example: ESX300-S slot A1 is assigned to load connector A1+ / A1-

7

Switch on the load output of the ESX300-S:

Push the momentary switch "On/Off" of the installed circuit protectors ESX300-S.

LED status indication: Green LED "OK" is lighted continuously, red LED "fault" is

off. If the LED indication is different from the description, please go to chapter 4.7

ESX300-S trouble-shooting.

8 Optional: Individual marking of ESX300-S with a corresponding name.

This can be done either on the small label of the ESX300-S or by means of the

marking bar available as accessory.

9

Repeat step 1–8 for each ESX300-S to be installed.

10

Optional: If additional population with E/A external alarm interfaces EAI300,

please go to chapter 7 "ControlPlex® Rack, E/A external alarm interface EAI300"

END

Table 11: Start-up ESX300-S

Page 25

25

4.6 Removal of the electronic circuit protector ESX300-S

The electronic circuit protectors can be removed as follows:

step action

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be carried

out with corresponding ESD protection means. Failure to comply can cause damages on

the ControlPlex® Rack system or the corresponding components.

1

Important: The ESX300-S has to be in the OFF condition

before being removed.

• Push the momentary switch "On/Off" until the green LED blinks slowly or

• disconnect the Power-D-Box® (dead-voltage, both LEDs off)

2

When removing the electronic circuit protector, the interlock at the bottom of

the front plate of the circuit protector must be pushed down (see fig. 17).

3 Hold down the interlock and remove the circuit protector by pulling simultaneously

at the handles on the top and the bottom of the front plate (see fig. 18).

END

Table 12: Removal of type ESS30-S...

fig. 17: ESX300-S interlock fig. 18: ESX300-S removal

interlock of front

plate ESX300-S

push down interlock and

pull the two handles of

the circuit protector

simultaneously

Page 26

26

4.7 Trouble-shooting concerning electronic circuit protector ESX300-S

The electronic circuit protector ESX300-S has two status LEDs allowing a comprehensive failure analysis in

the event of a failure. Please proceed as follows for trouble-shooting:

Important notes

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be

carried out with corresponding ESD protection means. Failure to comply can cause

damages on the ControlPlex® Rack system or the corresponding components.

Special precautions must be taken in the system or machine which reliably prevent an

automatic re-start of moveable parts of the system (cf. Machinery Directive 98/37/EG and

EN 60204-1, Safety of Machinery).

Note: ESX300-S time after short circuit or overcurrent trip

After tripping due to a short circuit, the circuit protector ESX300-S can only be reset after

a delay time of approx. 20 seconds.

Table 13: Hints for trouble-shooting for ESX300-S

What to do in the event of a failure

step action

1 Check status indication of ESX300-S:

Check the status of the LEDs of the ESX300-S by table 9, chapter 4.2.2

and put down the cause of the failure

2

Depending on the cause of the failure you can establish physical isolation

of the faulty circuit by pulling out the ESX300-S

See chapter 4.6 Removal of the electronic circuit protectors.

3

Remedy the cause of the failure

As described in step 1, e.g. short circuit on load

4

Re-install the ESX300-S after remedy of the failure

See chapter 4.5 Start-up of ESX300-S

END

Table 14: Trouble-shooting ESS300-S

Page 27

27

5 General: ControlPlex® Rack, signalling sub-assembly RSI10

The Remote Signalling Interface RSI10 has particularly been designed for use with the Power-D-Box® type

PDB-N-CPxxx-xx-x in connection with the circuit protector ESX300-S. It can be installed and de-installed

with the system live without having to disconnect the application from the mains. Thus you are able to add

the RSI10 interface sub-assembly later if required, saving costs and avoiding downtimes.

5.1 Application RSI10

The Remote Signalling Interface RSI10 is designed for an operating voltage of DC 20 V to DC 75 V. It communicates with all other ESX300-S circuit protectors installed in the Power-D-Box

®

via an internal bus. Thus

it is possible to realise a potential-free group signalling of alarm messages of the ESX300-S electronic circuit

protectors used in the system (version with bus interface. Per supply group of the Power-D-Box® the RSI10

provides one each potential-free change-over contact. An integral three-coloured LED additionally indicates

failure conditions directly on site. The system can easily be extended at a later date to add the functions

remote control, data logging and extended alarm monitoring by means of replacing the RCI10 sub-assembly

by RSI10 without a failure of the connected loads.

5.2 Technical data of RSI10

Interface card for group alarm signalling of all circuit protectors installed in the ControlPlex

®

Rack.

Technical data of RSI10

Operating voltage DC 20 V…DC 75V

Dielectric strength DC 100 V for 1 ms

Power consumption typical 1.2 W

Internal interfaces ELBus

®

/power, 20-pole pcb connector

External connection two plug-in type 3-pole screw terminals with mating plugs

Cable cross section: 0.25 mm² … 2.5 mm²

Alarm contact potential-free change-over contact

Alarm contact

max. switching voltage

DC 72 V

Alarm contact

Max. switching current

1 A

Alarm contact

Max. rupture capacity

60 W / 62.5 VA

Status indication multicoloured LED (red, green, blue)

Ambient operating tem-

perature

-20° C ... +60° C (without condensation, cf. EN 60204-1)

Storage temperature -30° C ... +70 °C

Cooling convection cooling

Mounting position vertical mounting position

Version rack module with front plate, no separate enclosure, for installation in

Power-D-Box

®

type PDB-N-CP

Degree of protection IP00 DIN 40050

Approval logos CE to EN 61000-6-3 / EN 61000-6-2

Conformity EN 60950-1 / UL 60950-1 compliant (when installed in PDB)

Table 15: RSI10, technical data

*) major technical data, for further information please see data sheet of ControlPlex

®

Rack

Page 28

28

5.2.1 Operating conditions and LED indication

Operating condition

circuit protector

ESX300-S-3xx

Load output

circuit protector

ESX300-S-3xx

LED status RSI10

sub-assembly

Auxiliary contact

RSI10 subassembly group

signal “break

contact”

status RSI10

sub-assembly

no error -> OFF locked green open normal operation

normal operation connected green open normal operation

error undervoltage with

device in OFF condition

(15 V < U < 37 V)

locked green closed normal operation

error undervoltage with

device in OFF condition (U > 72 V)

locked green closed normal operation

Overcurrent error

detected (I > IN < 1.2 x

IN); overcurrent failure

has to be detected for

approx. 30 sec before disconnection is

effected

connected green open normal operation

error – overcurrent or

short circuit disconnection

locked green closed normal operation

error undervoltage

(U > 15 V < 37 V)

connected green closed normal operation

error overvoltage

(72 V < U < 75 V)

connected green closed normal operation

error: no voltage locked OFF (green)1 closed normal duty 1

locked green closed normal operation

green closed no ESX300-S

circuit protector

availabe

check if ESX300-S

bus version

is plugged in

---------- ---------- red closed internal RSI10

error or internal

bus error

---------- ---------- 5 sec blue open one new circuit

protector

ESX300-S was

identified

1

In a redundant system with two supply voltages the green LED lights if only one voltage supply fails, otherwise the RSI10 subassembly is dead-voltage

table 16: RSI10, operating conditions – LED

5.3 Delivery scope RSI10

The following parts are part of the delivery scope of the RSI10:

• Remote control interface, type: RSI10-xxx-A with front plate and label including alarm connection mating plug

Page 29

29

5.4 Picture of RSI10

fig. 19: RSI10 sub-assembly

5.5 Installation and start-up RSI10

Important notes

Information: Power-D-Box® and ESX300-S installed

Before starting the installation, the Power-D-Box® has to be properly installed first and

supply voltage should be applied. All steps in chapter 3.8.3 and chapter 4.5 were carried

out properly.

Caution: work with ESD protectionTo protect electronic components against electrostatic

voltage, any work must only be carried out with corresponding ESD protection means.

Failure to comply can cause damages on the ControlPlex® Rack system or the

corresponding components.

!

Important: Mounting position

The RSI10 sub-assembly has to be pushed in vertically into the Power-D-Box® in slot:. X0.

Table 17: RSI10, Important hints for start-up

status LED

alarm contact terminal

supply group A of the

Power-D-Box

alarm contact terminal

supply group B of the

Power-D-Box

engagement nose

groove for

label

Page 30

30

Start-up of the RSI10 sub-assembly comprises the following steps:

step action

1 Prepare all necessary devices and tools such as:

• Remote Signalling Interface RSI10

• connecting cables for external alarm signalling

2

Important: Please ensure that all steps in chapter 3 for starting up the Power-D-Box®

and in chapter 4 "Start-up ESX300-S" were carried out correctly.

4

Installation of the RSI10 sub-assembly into the Power-D-Box

®

:

Push the RSI10 sub-assembly carefully into slot X0 and push until latch-on in the

front plate in the Power-D-Box®, see fig. 22.

5

Check the LED indication of the RSI10:

The green status LED must be lighted continuously latest after 10 seconds.

If this is not the case,please go chapter 5.2.1 LED operating conditions and remedy the

failure. Do not continue with step 6 before the green LED is lighted continuously.

6

Connection of an external alarm indication

Connect a prepared external alarm indication via the 3-pole alarm contact terminal

to the plug of the corresponding screw terminal ( C = root; NC = break contact; NO

= make contact). An error signal can be indicated via C/NC, an OK signal via C/NO.

Split-up group signal of the Power-D-Box

®

for supply group A = upper 3-pole

terminal on RSI10

Split-up group signal of the Power-D-Box

®

for supply group B = lower 3-pole

terminal on RSI10

Note: If there is only one supply group on the Power-D-Box

®

, the group alarm

signal “A” is emitted at both terminal blocks.

7 In the event of an extension with additional circuit protectors

The RSI10 LED must be lighted in blue for approx. 5 sec. This means that the

newly plugged in circuit protector was identified, see also chapter 5.2.1.

END

Table 18: RSI10, installation and connection

Page 31

31

6 General: ControlPlex® Rack, control interface RCI10

The Remote Control Interface RCI10 has particularly been designed for use with the Power-D-Box® type

PDB-N-CPxxx-xx-A in connection with the circuit protector ESX300-S. It can be installed and de-installed

with the system live without having to disconnect the application from the mains. Thus you are able to add

the interface sub-assembly later if required, saving costs and avoiding downtimes.

6.1 Application RCI10

The Remote Control Interface RCI10 is designed for an operating voltage of DC 20 V to DC 75 V. It communicates with all circuit protectors type ESX300-S-3xx-xxA (version with BUS interface) installed in the

Power-D-Box

®

via an internal BUS. The RCI10 can easily be interconnected with a local LAN network via an

external Ethernet interface. Various integral protocols allow a complete automation and remote control of the

individual circuit protectors, e.g. ON/OFF operation depending on the voltage or current value. In addition

alarm signals and a continuous data recording per query can be forwarded to a connected control computer.

6.2 Technical data of RCI10

Interface card for measuring data recording, automation and remote control of all circuit protectors installed

in the ControlPlex

®

Rack.

5.2 Technical data of RCI10

Operating voltage DC 20 V…DC 75 V

Dielectric strength DC 100 V for 1 ms

Power consumption Typical 2 – 3 W

Internal connection 20-pole pcb connector (EL-BUS, power etc.)

External connection Ethernet 10 / 100 Base-T, RJ45-connection sleeve for standard network cable

of category Cat-5, type "Shielded Twisted Pair"

Status indication RGB LED (red, green, blue)

Momentary switch reset and special functions

Supported protocols SNMP v1, v2c, v3; HTTP, HTTPS, SSH2, DHCP, NTP, IPv4, IPv6

Ambient operating tem-

perature

- 20° C ... +60° C (without condensation, cf. EN 60204-1)

Storage temperature -30° C ... +70 °C

Cooling convection cooling

Mounting position vertical mounting position

Version rack module with front plate, no separate enclosure, for installation in

Power-D-Box

®

Degree of protection IP00 DIN 40050

Approval logos CE to EN 61000-6-3 / EN 61000-6-2

Conformity EN 60950-1 / UL 60950-1 compliant (when installed in PDB)

Table 19: RCI10, technical data

*) major technical data, for further information please see data sheet of ControlPlex

®

Rack

Page 32

32

6.2.1 LED operating conditions, momentary switch "reset" and failure remedy

"reset"

momentary

switch

LED

colour

LED

condition:

importance description / action

- green ON normal operation The green LED is lighted continuously when booting

is completed and the RCI10 is operating faultlessly.

Network connection can be established after another

10 sec.

pushed

down for

35 sec

green blinking reset IP address

to factory

settings

By pushing the reset button for 35 seconds, the IP

settings can be reset For visual control that the reset

button has been pushed down long enough, the

green LED will blink for 5 seconds. Release the

momentary switch while the LED blinks, see fig. 19

- red ON internal failure

RCI10

The red LED indicates a serious internal failure in the

RCI10 sub-assembly. The sub-assembly is no longer

operational.

By means of a cold boot (remove the sub-assembly

- wait for 20 seconds - plug in again) the failure may

be remedied. The RCI10 sub-assembly should be

replaced nevertheless.

- red ON Serious internal

failure BUS

(EL-BUS)

The red LED indicates an EL-BUS failure. The

communication with the circuit protector ESX300-S

and the RCI10 is disrupted.

This problem can be caused by a defective circuit

protector or a defective RCI10 sub-assembly.

- blue ON Ethernet link

available

If a network connection is established in operation

(layer 1), the LED will be lighted blue for some 10

seconds.

- blue ON reset IP address

to factory

settings

The blue LED will be lighted for 10 seconds when

the IP address has successfully been reset to factory

settings, see fig. 19 Automatic booting will follow,

this can last up to 60 seconds.

- - OFF Booting The RCI10 sub-assembly is booting. Booting can

take up to 60 seconds.

- - OFF no supply

voltage

No supply voltage or wrong polarity. 1) The voltage

supply of the Power-D-Box

®

must at least be DC

20 V. 2) Check polarity of the voltage supply at the

Power-D-Box® (plus/minus).

pushed

down for

3 sec

- OFF Warm boot The system can be reset by pushing the reset button

for 3 seconds (warm boot)

- OFF RCI10 sub-as-

sembly defective

If the LED remains unlighted after booting (max. 60

sec), the RCI10 sub-assembly is defective.

The sub-assembly must be replaced.

Table 20: RCI10, operating conditions - LED

Page 33

33

6.2.2 Function IP-reset by pressing the reset button with LED display

fig. 20: RCI10 IP-Reset

6.3 Delivery scope RCI10

The following parts are part of the delivery scope of the RCI10:

• Remote control interface, type: RCI10-xxx-A with front plate

6.4 Picture of RCI10

fig. 21: RCI10 sub-assembly

RGB

Status LED

RJ45 /

Ethernet

engagement nose

momentary switch /

reset

label

Page 34

34

6.5 Installation and start-up RCI10

Important notes

Note: Power-D-Box® and ESX300-S and/or EAI300 installed

Before starting the installation, the Power-D-Box® has to be properly installed first and

supply voltage should be applied. All steps in chapter 3.8.3, chapter 4.5 and (optional)

chapter 7.5 were carried out properly.

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be

carried out with corresponding ESD protection means. Failure to comply can cause

damages on the ControlPlex® Rack system or the corresponding components.

Warning: Mounting position

The RCI10 sub-assembly has to be pushed in vertically into the Power-D-Box® in slot: X0.

Table 21: RCI10, Important hints for start-up

Installation and connection of the RCI10 sub-assembly comprise the following work steps:

step action

1

Prepare all necessary devices and tools such as:

• Remote Control Interface RCI10

• Ethernet cable 10 / 100 Base-T with the correct terminal length

2

Important: Please ensure that all steps in chapter 3 for starting up the

Power-D-Box® and in chapter 4 "Start-up ESX300-S" were carried out

correctly.

3

Important: Please make sure that any connected signalling cables (group

signalling) on the Power-D-Box® are de-installed. Should voltage be

applicable here, parts of the ControlPlex® Rack could be destroyed.

4

Installation of the RCI10 sub-assembly into the Power-D-Box®:

Push the RCI10 sub-assembly carefully into slot X0 and push until latch-on in the

front plate in the Power-D-Box®, see fig. 22.

5

Check the LED indication of the RCI10:

The green status LED must be lighted continuously latest after 60 seconds.

If this is not the case,please go chapter 6.2.1 LED operating conditions and

remedy the failure. Do not continue with step 6 before the green LED is lighted

continuously.

6

Connection of Ethernet cable

Plug the Ethernet cable into the RJ45 connector of the RCI10 sub-assembly, see

fig. 20, and connect it to your internal network or directly with a configuration PC,

see fig. 23.

7

Go to chapter 6.6 and configure the RCI10 sub-assembly according to your

requirements.

END

Table 22: RCI10, installation and connection

Page 35

35

6.5.1 Picture of slot for RCI10 or RSI10

Information: The slot X0 is at the same position with all PDB-N-CPxxx-xx-x versions, first slot on the left side.

fig. 22: PDB slot X0

6.5.2 Picture of an example for network connection

router

PDB-N-CP

Ethernet cable

load-1

load-2

load-3

SNMP v1, v2c, v3

(HTTP(S)/SSH)

configuration PC system cabinet

Power

HTTP(S)/SSH

management system / main computer

intranet

ControlPlex® Rack

RCI10

ESX300-S

EAI300

Fig. 23: connection example network

6.6 Configuration and start-up RCI10

For configuring the RCI10 sub-assembly you need the ControlPlex

®

Rack Operation Instruction RCI10.

In order to establish a logic connection in your LAN network with a configuration PC, the RCI10 sub-assembly

has to be connected with the PC via an Ethernet cable, see fig. 23.

The document ControlPlex

®

Rack Operation instruction RCI10 is available on our website:

www.e-t-a.de/controlplex_rack

Slot RCI10 or RSI10

Page 36

36

7 General: ControlPlex

®

Rack, E/A external alarm interface EAI300

The EAI300 has particularly been designed for use with the Power-D-Box® type PDB-N-CP in connection

with the remote control interface RCI10. It can be installed and de-installed in the Power-D-Box® later with

the system live without having to disconnect the application from the mains. The EAI300 only requires a free

ESX300 slot (slot for circuit protectors) in the Power-D-Box®.

7.1 Operating mode and application EAI300

The EAI300 has been conceived for connection and free text indication of alarm messages from “external”

alarm contacts and sensors in the plant room by means of a control computer. This could include door

contacts, temperature sensors or alarm contacts of the air conditioning system. The EAI300 interface

communicates with the RCI10 Remote Control Interface installed in the Power-D-Box

®

via an internal bus.

The RCI10 sub-assembly communicates with a management system or a control computer by means of an

Ethernet interface. With the help of an integral LED an “external” alarm can also be indicated locally on the

EAI300. An integral 24V voltage output can be used directly for reading the alarm contacts. Equally, there are

two potential-free outputs available for activating e.g. a door lock or for realising an additional group signalling

of the ESX300 circuit protectors. Within a Power-D-Box® you can install up to 20 EAI300 sub-assemblies.

7.2 Technical data of EAI300

Interface card for forwarding additional alarms in the engineering room, so-called “external alarms”.

Technical data of EAI300

Operating voltage

DC 20 V … DC 75 V

Dielectric strength

DC 100 V for 1 ms

Power consumption

Typically 1.9 W

Internal interfaces

EL-Bus

®

and supply via blade terminals

External connection

Two plug-in type 8-pole connection sleeves with

spring-loaded connectors on the front side Cross-section

0.14 mm² … 1.5 mm²

Number of digital inputs:

Eight physically isolated inputs

Current consumption 1 mA at 24 V

Input resistance: 22.1 kOhm

Voltage potential “HIGH” level DC 12 V … DC 72 V

Voltage potential “LOW” level DC 0 V … DC 4 V

Number of analog inputs:

One physically isolated input

Measuring input 4 mA … 20 mA

Number of digital outputs (relay outputs)

Two physically isolated relay outputs (break contacts)

Max. load current of contact 2 A

Voltage range – contact DC 12 V … DC 72 V

Internal supply voltage for I/O connection

Typically DC 24 V

(at Power-D-Box supply voltage ≥ DC 30 V)

Max. load current: 100 mA

Page 37

37

External supply voltage for I/O connection

DC 12 V … DC 72 V

Max. number of EAI300 sub-assemblies per

Power-D-Box® and RCI10 sub-assembly

20 (depending on Power-D-Box

®

type)

Table 23: EAI300, technical data

*) major technical data, for further information please see data sheet of ControlPlex

®

Rack

7.2.1 Operating conditions LED signalling

Operating condition EAI300 LED indication EAI300

EAI300 normal duty green

EAI300 normal duty: digital input has status

“High“

green / cyan blue blinking

EAI300 normal duty: identified new circuit

protector ESX300 (relay output configured as

group signal)

5 seconds blue

EAI300 fault condition: no control interface

RCI10 available

red blinking

EAI300 fault condition: EAI300 internal fault red

EAI300 fault condition: no RCI10 available

and digital input on status “High“

red / cyan blue blinking

Table 24: EAI300, operating conditions – LED

7.3 Delivery scope EAI300

The following parts are standard part of the delivery scope of the EAI300:

• External Alarm Interface, type: EAI300-xxx-A with front plate including spring force mating plugs

• Accessories: 16 labels and coding pin for spring force mating plugs

7.4 Picture EAI300

Page 38

38

7.5 Installation and connection EAI300

Important notes

Note: Power-D-Box® and additional sub-assemblies installed

Before starting the installation, the Power-D-Box® has to be properly installed first and

supply voltage should be applied. All steps in chapter 3 were carried out properly.

Caution: Work with ESD protection

To protect electronic components against electrostatic voltage, any work must only be

carried out with corresponding ESD protection means. Failure to comply can cause

damages on the ControlPlex® Rack system or the corresponding components.

Warning: Mounting position

The EAI300 sub-assembly has to be pushed in vertically into the Power-D-Box®.

Table 25: EAI300, Important hints for start-up

Installation and connection of the EAI300 sub-assembly comprise the following work steps:

step action

1

Prepare all necessary devices and tools such as:

• External Alarm Interface EAI300 and accessories

• connecting cables for external Alarm Interface

• Probably a distribution terminal is required

2

Important: Please ensure that all steps in chapter 3 for starting up the

Power-D-Box® and in chapter 4 "Start-up ESX300-S" were carried out correctly.

3

Important: INSTALLATION POSITION

When using the EAI300 together with ESX300 circuit protectors within one

Power-D-Box®, the EAI300 should always be plugged into the highest slot of the

Power-D-Box®, e.g. with Power-D-Box type: PDB-N-CP19A… into slot 19, the

following EAI300 into slot 18 etc.

4

Installation of the EAI300 sub-assembly into the Power-D-Box®:

Push the EAI300 sub-assembly carefully into the corresponding slot and push until

latch-on in the front plate in the Power-D-Box®, see fig. 7.5.1 "Example EAI300

slot configuration"

5

Check the LED indication of the EAI300:

1. RCI10 sub-assembly already pre-installed: The green status LED must be

lighted continuously.

2. RCI10 sub-assembly not installed: The red status LED must be blinking.

If this is not the case, please go chapter 7.2.1 LED operating conditions and

remedy the failure. Do not continue with the next step before the LED status

indication shows the correct condition.

6

Plug coding and plug numbering