Page 1

OWNERS

MANUAL

MODEL NO.

ECR 3301

ECR 4000

ECR 4500

ECR 5200

ECR 6600

ECR 7200

CAUTION:

Read All Instructions

Carefully Before Starting

The Installation.

ESSICK

CONVERTIBLE

DOWN/FRONT OUTLET

EVAPORATIVE AIR COOLER

ESSICK AIR PRODUCTS

LITTLE ROCK, ARKANSAS 72209

50209-3

Page 2

CONTENTS

INSTALLATION

Tools and Supplies You Need ......................................... 3

Safety Rules ................................................................... 3

Data................................................................................ 3

Locating Your Cooler ...................................................... 4

Converting to Side Outlet ...............................................5

Mounting Cooler .............................................................6

Electrical Connections ................................................... 7

Final Assembly and Adjustment ..................................... 8

Startup Check List .......................................................... 9

COOLER USE

Cooling Your Home....................................................... 10

COOLER CARE

Spring, Summer and Fall Care..................................... 11

Taking Off and Putting on Grilles ................................. 11

Taking Off Pad .............................................................. 12

Cleaning .......................................................................12

Putting On Pad ............................................................. 13

Oiling ............................................................................13

Blower Belt Adjustment ................................................13

REPAIR PARTS...................................................... 38

INTRODUCTION

Your new air cooler uses a new design for evaporating water to cool air. The low energy use of conventional evaporative air coolers is combined with new water handling methods and materials which help overcome most rust problems

of conventional coolers. Your new cooler requires no pad prewetting and is easy to clean. The compact size and modern appearance allow easy installation.

Please read our instructions before you install and use your new cooler. This will help you obtain the full benefits from

your cooler and will also help you avoid any needless service costs that result from causes we cannot control and cannot cover in our warranty.

LIMITED WARRANTY

All products covered by this Instruction Sheet are warranted against defects in workmanship and materials for one year from date of sale.

This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the

nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of this Instruction Sheet. This warranty is valid only

in the fifty states of the United States. No other written or oral warranty applies. No employee, agent, dealer or other person is authorized to

give any warranties on behalf of ESSICK.

The customer shall be responsible for all costs incurred in the removal or reinstallation of the product for repairs. Within the limitations of this

warranty, inoperative parts should be returned freight prepaid to ESSICK service center and we will repair or replace, at our option, at no

charge to you with return freight paid by ESSICK. It is agreed that such repair or replacement is the exclusive remedy available from ESSICK AIR

PRODUCTS and that ESSICK IS NOT RESPONSIBLE FOR DAMAGES OF ANY KIND, INCLUDING INCIDENTAL AND CONSEQUENTIAL

DAMAGE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

No merchandise should be returned to ESSICK AIR PRODUCTS without return authorization. When requesting a return authorization include

model numbers, part numbers, date and place of purchase.

ESSICK AIR PRODUCTS 5800 MURRAY LITTLE ROCK, ARKANSAS 72209

Note: Replacement of filter pads is normal maintenance and is not covered in the warranty.

To function properly, your cooler must be installed correctly. You must know how to use tools and equipment.

2

Page 3

INSTALLATION

TOOLS AND SUPPLIES YOU WILL NEED

• Pliers

• Screwdrivers

• Adjustable Wrenches

• Tubing Cutter

•5/32 Hex Key Wrench

• Electric Drill

• Drill Bits

• Hammer

• Duct Caulking

• #10 Sheet Metal Screws

• Wiring Supplies, as Required by Local Electrical Code

•Level

RULES FOR YOUR SAFETY

1.

WARNING

TO AVOID FIRE, SHOCK, OR

SERIOUS PERSONAL INJURY

FOLLOWING THESE INSTRUCTIONS.

2. The installation must conform to local codes and

utility standards. Use the National Electric Code if

a local code does not exist.

3. Disconnect the electric power EVERY TIME you

work on your cooler. When your hands are inside

the cooler you risk injury if the cooler is accidentally

turned on from inside the home.

• Duct. As Required (a local sheetmetal shop can

supply ducting.)

• Equipment Suitable for installing Duct Through House

Wall or Roof

•1/4" Water Line

• Saddle Valve

• ECR-7 Wall Switch (7 position). Use ECR-5 (5 position) with existing pump type cooler wiring

• Roof Stand Kit (if cooler is roof mounted)

Cooler ECR 3301 - use ECK-30 kit

Cooler ECR 4000 - use ECK-40 kit

Cooler ECR 4500 - use ECK-40 kit

Cooler ECR 5200 - use ECK-50 kit

Cooler ECR 6600/7200 - use ECK-60 kit

4. If you mount the cooler on your home roof remember

these safety tips:

5. Never install or service a cooler during a storm or

high wind conditions. You could be injured or lose or

damage parts.

6. Never wear shoes with slick soles when you work on

a roof. You may slip when you least expect it.

7. Never drain water onto a roof. Water residue may

cause you to slip or may stain your roof. Use a drain

hose to run the drain water to a rain gutter or to a

drain.

8. To avoid injury never use the cooler without connecting it to a house duct system or without a sturdy fine

mesh guard over the outlet.

DATA

Cabinet Dimensions Air Output Opening Operating

Model (inches) (inches) Lbs. Weight

No. Height Width Depth Height Width (with water)

ECR 3301 251/4 251/4 391/8 133/4 133/4 140

ECR 4000 29

ECR 4500 29

ECR 5200 33

ECR 6600 36

ECR 7200 36

ESSICK EVAPORATIVE OUTPUT RATINGS

PAD USAGE (Cubic Feet per Minute)

Model Essick Industry Sizing

No. Pad Number Rating

ECR 3301 EP-30 3300 cfm

ECR 4000 EP-40 4000 cfm

ECR 4500 EP-40 4500 cfm

ECR 5200 EP-50 5200 cfm

ECR 6600 EP-60 6600 cfm

ECR 7200 EP-60 7200 cfm

3

/4 293/4 353/16 173/4 173/4 190

3

/4 293/4 353/16 173/4 173/4 195

3

/4 333/4 371/2 193/4 193/4 235

3

/4 363/4 4213/16 193/4 193/4 285

3

/4 363/4 4213/16 193/4 193/4 290

3

Page 4

INSTALLATION

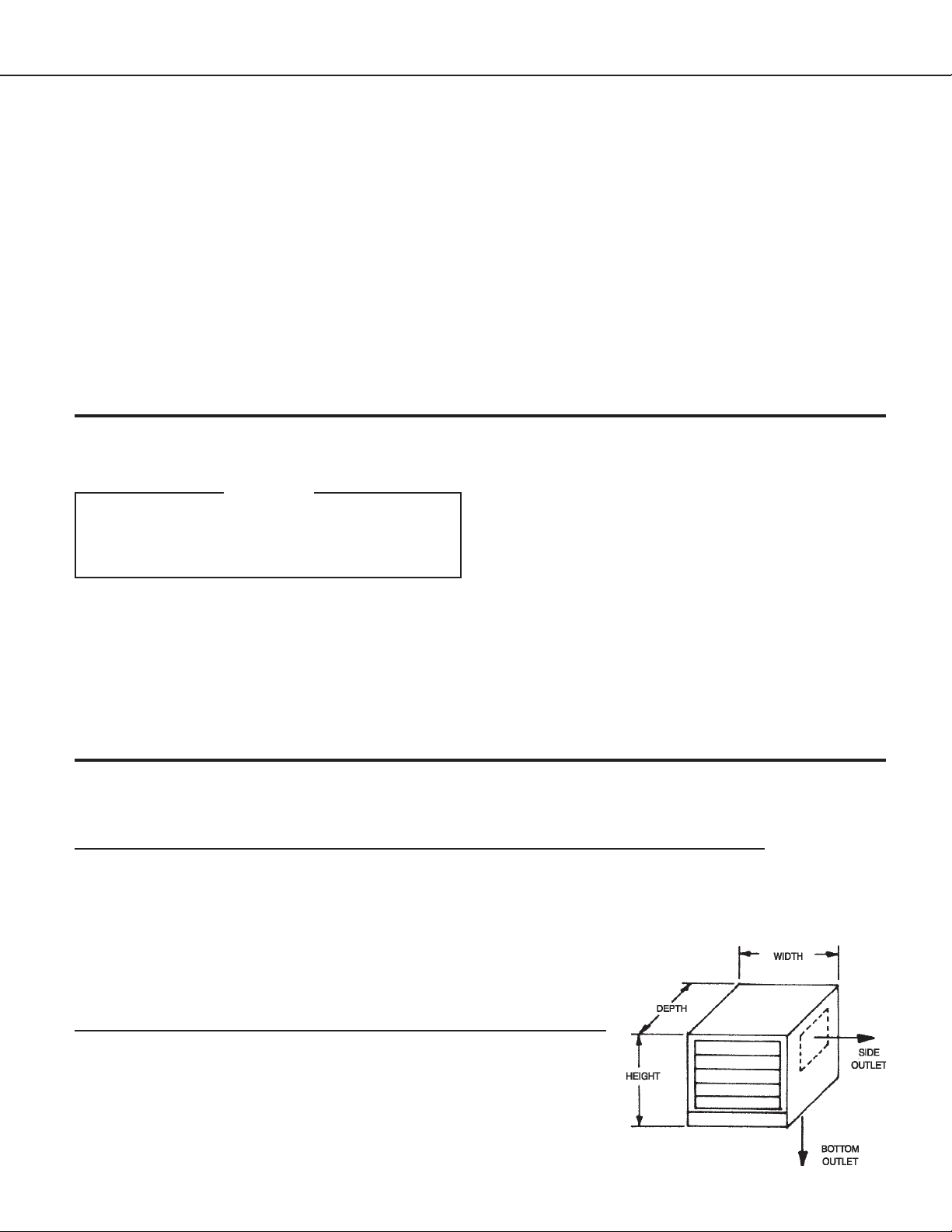

LOCATING YOUR COOLER

This new design Essick cooler may be installed as a bottom or side air outlet cooler. The cooler must be securely

fastened to a frame or pad mount. A roof kit is available

from Essick.

A duct must be attached to the cooler outlet. The duct

must be the same size as the cooler outlet. Sudden duct

size changes will decrease the output of your cooler.

FIGURE 1

The cooler installation must comply with local codes. If

you are not fully qualified to install a cooler, get professional help.

Figure 1 shows some locations for your cooler. Be sure

the intake louvers are clear of obstructions and are

accessible for removal. Do not locate the cooler near vent

pipes, chimneys, or exhausts where odors or fumes

may be drawn into the house. The two drain holes on the

cooler bottom must be clear to allow overflow or drain

access.

WIRING BOX

The wiring box is inside the cooler cabinet. The electrical

supply must be connected to the cooler power leads

inside the box after the cooler is installed. The wiring box

is factory installed for coolers used in the down air outlet

position.

IF YOU INSTALL THE COOLER IN THE SIDE AIR

OUTLET POSITION THE WIRING BOX MUST BE

MOVED. SEE PAGE 5.

FIGURE 2

4

Page 5

INSTALLATION

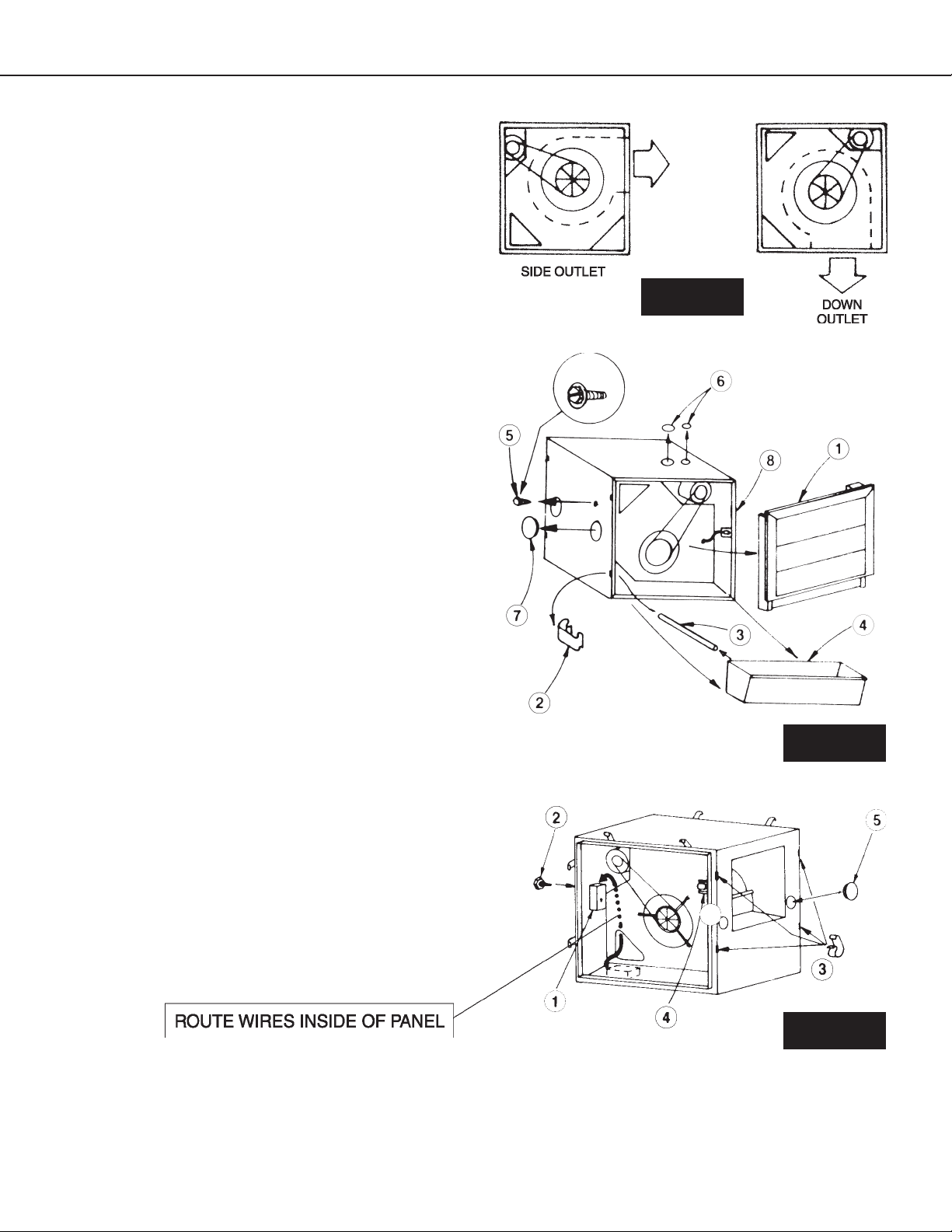

CONVERTING COOLER TO SIDE AIR OUTLET (Fig. 4)

1. Remove both louvers and set them where they will

not fall. See pg. 11.

2. Remove four louver clips on side opposite motor.

3. Remove a reservoir by pushing the water crossover

tube from the grommet and lifting out the reservoir.

4. Remove the second reservoir as above.

5. Remove the screw that holds the wiring box.

6. Remove

knockouts.

7. Remove two plastic plugs.

8. Loosen screw holding pad motor receptacle bracket,

slide bracket up and detach from cabinet flange.

Repeat on other side.

9. Turn cooler to side outlet position.

1

/8 inch diameter and 7/8 inch diameter

REASSEMBLY AS SIDE

OUTLET COOLER (Fig. 5)

1. Move wiring box to new location.

2. Secure wiring box with screw removed at disas-

sembly.

3. Install four louver clips removed at disassembly.

FIGURE 3

FIGURE 4

4. Install two receptacle brackets removed at disas-

sembly.

5. Install two plastic plugs removed at disassembly.

6. Assemble reservoirs, crossover tube and louvers

after

the cooler is installed in location. Use soap or

detergent to lubricate crossover tube before inserting into grommet. DO NOT USE OIL.

FIGURE 5

5

Page 6

INSTALLATION

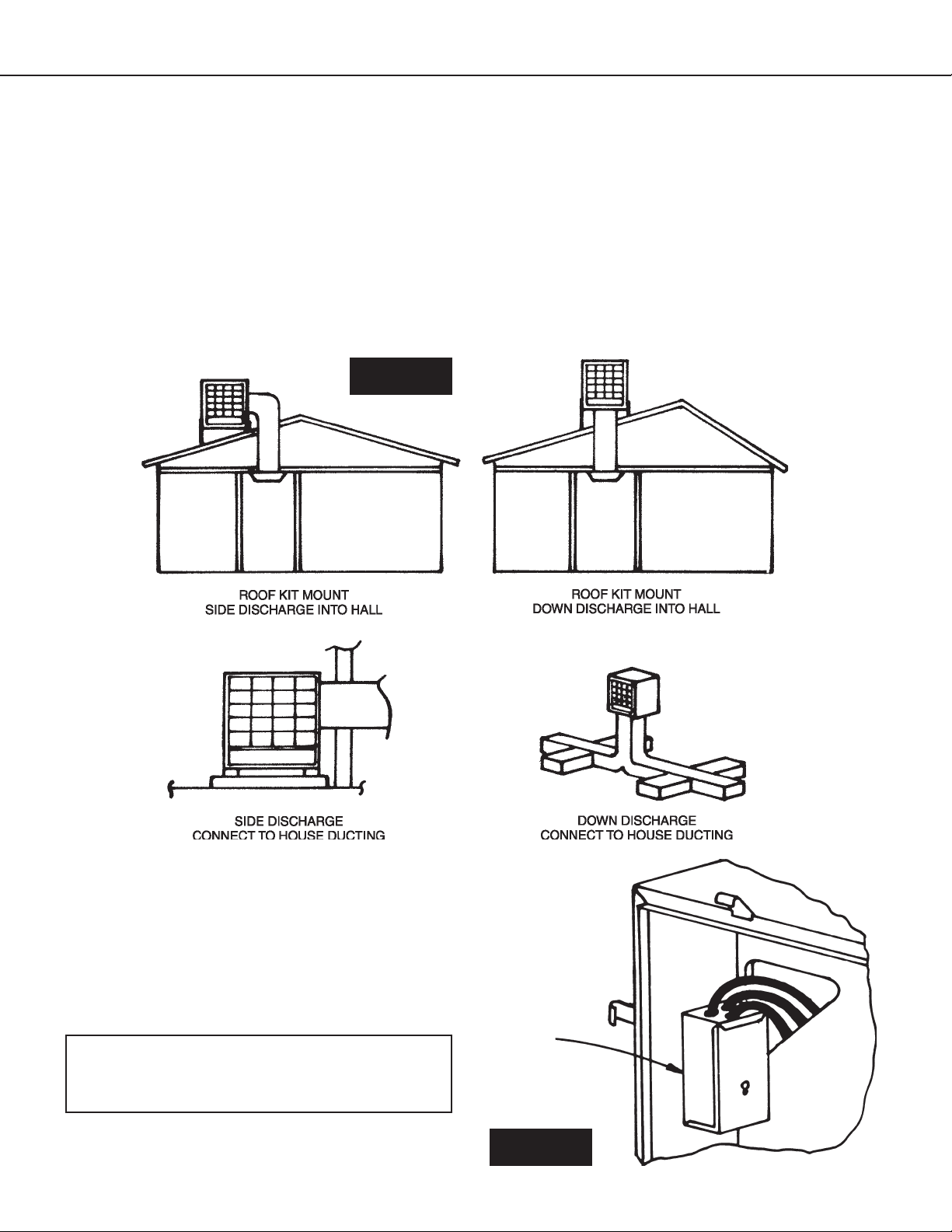

LIFTING COOLER

CAUTION: DO NOT LIFT ON THE LOUVERS.

REMOVE THE LOUVERS BEFORE LIFTING.

DO NOT LIFT ON THE CENTER OF THE

CABINET FLANGES.

MOUNTING COOLER

1. Prepare duct to fit model used. See outlet size specifications on page 3.

2. Cut opening in roof or wall and box in opening.

3. Install duct and secure to boxed-in opening frame.

Allow two inches to fit into cooler outlet. Allow duct

length for cooler bottom to be 4 inches above roof

at closest point. See figure 7.

4. Install flashing on roof or wall to prevent water

entry.

Lift at cabinet corners.

The cooler may be lifted

by putting a bar or strap

through the panel hole

and lifting by means of

the bar or strap.

FIGURE 6

NOTE: THE BOTTOM EDGE NEAREST THE

OUTLET MUST FACE UP THE ROOF.

6. Mount cooler on stand or pad. Cooler must be level

front to back and left to right. Roof stand kits are

available.

7. Be sure to securely fasten four corners of cooler to

stand or pad.

8. Caulk duct to the cooler. Caulk the flashing.

5. Measure cooler and lay out mount location.

FIGURE 7

6

Page 7

INSTALLATION

ELECTRICAL CONNECTIONS

The wiring must comply with local codes. If you are not familiar

with the codes or wiring practices, get professional help.

Use only an Essick ECR-5 or ECR-7 wall mounted switch. This

new cooler does not require prewetting the pads before starting

cooling and does not have a pump.

“pump only” position are not usable.

Existing switches with

NEW INSTALLATIONS

Use the Essick ECR-7 switch which has four

cooling positions and two vent positions:

Maximum Cool - high and low

Minimum Cool - high and low

Vent - high and low

This switch requires six wires to the cooler (including cooler grounding conductor).

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT USE THIS FAN WITH ANY SOLID

STATE SPEED CONTROL DEVICE.

CAUTION: SHUT OFF THE ELECTRIC POWER AT THE

FUSE BOX BEFORE BEGINNING THE WIRING.

FIGURE 8

COOLER CHANGEOUT

INSTALLATIONS

The Essick ECR-5 switch is suitable for existing

installations where five wires go to the cooler (including cooler grounding conductor). There are

two cool positions and two vent positions.

FLOAT VALVE INSTALLATION

INSTRUCTIONS

It is of the Utmost Importance that the Float Valve, Splash Guard

and Splash Guard Cover be installed exactly as described in

the illustration below.

1. The Float Valve - Must be installed with the narrow side

of the float in the vertical position. If not installed this

way the float will hang up and cause the reservoir drain

pipes to overflow.

FIGURE 9

2. The Water Spout and Water Spout Cover are provided

to prevent water from “spurting” and splashing outside

of the reservoirs. Snap in the Splash Guard Cover as

illustrated below.

7

Page 8

INSTALLATION

FINAL ASSEMBLY AND ADJUSTMENT

PUT FLOAT VALVE IN COOLER

Put the float valve through the spout hole and cabinet

hole. Tighten the ring nut. Be sure the float moves

straight up and down.

NARROW SIDE IS UP.

into the Water Spout as shown. The Water Spout and

Splash Guard Cover are provided to prevent water from

“spurting” and splashing outside the Water Reservoir.

CONNECT WATER LINE

Use a saddle valve to connect 1/4 inch water line to

house cold water pipe or use an outdoor faucet adapter.

Put the line into the valve. Tighten the compression

nut over the ferrule.

BEFORE CONNECTING TO COOLER.

float valve. Tighten the compression nut over the ferrule.

PUT IN WATER TRAYS (Fig. 11)

1. Push the drain fitting through the washer and water

tray hole. Tighten the ring nut. Screw the overflow

pipe into the drain fitting. Repeat for the second tray.

TURN THE FLOAT UNTIL A

Snap the Splash Guard Cover

RUN WATER TO CLEAR LINE

Put line into

FIGURE 10

NOTE: INSTALL DRAIN FITTING INVERTED IF

COOLER IS MOUNTED ON A PAD. CUT OFF THE

OVERFLOW PIPE TOP FLUSH WITH THE HEXAGONAL RING.

2. Put in the float valve side tray first. The crossover

tube & grommet MUST be on the float valve side.

(Fig. 12)

3. Push the crossover tube into the grommet. Use soap

or detergent as a lubricant. DO NOT USE OIL.

4. Put the second water tray in place. Push the

crossover tube into the grommet.

5. Turn on the water. Check the water level when the

valve shuts off. If the water level is above the tray

water level mark bend the float rod down. If the level

is too low, bend the rod up. (Fig. 11)

NOTE: CHECK THE CROSSOVER PIPE GROMMETS AND ALL CONNECTIONS FOR LEAKS.

PUT LOUVERS ON COOLER

FIGURE 11

See page 11.

FIGURE 12

8

Page 9

INSTALLATION

MOTOR PULLEY ADJUSTMENT

NOTE: ALL DUCT CONNECTED COOLERS MUST

BE ADJUSTED.

Long or small air ducts have excessive air resistance

which decreases air output and motor amperage. You may

compensate for this by adjusting the motor pulley. Use a

clamp type ampmeter to check the motor amperage.

1. Check amperage at the white lead in the wiring box.

2. If the amperage is less than the motor nameplate

amperage, loosen the pulley pitch adjustment screw,

turn in the pulley 1/2 turn, tighten the screw and

recheck the amperes. Repeat as necessary to bring

the amperage to the nameplate rating.

3. If the amperage is too high, turn out the pulley as

required.

FIGURE 13

4. Adjust the belt tension as required. (See page 13)

STARTUP INSPECTION

Before starting the cooler, make sure all installations and

adjustments are correct. Be sure that:

• Cooler is level and duct is sealed.

• Cabinet is securely fastened to the mount.

• Cooler is grounded. Electrical connections are secure.

• Blower wheel does not rub against housing.

• Water supply is turned on.

STARTUP CHECK LIST

To check out the installation follow this startup procedure. Set the control to each position and check operation per the following chart. Be sure to open windows or

vents.

OPERATION WITH ESSICK SWITCH ECR-5

(Five Position)

Blower Pad

Switch Motor Motors

Off Off Off

Low Vent Low Off

High Vent High Off

Low Cool Low On

High Cool High On

IMPORTANT

NOTE: When checking amperage with the ampmeter,

all louvers must be in place in the cooler,

otherwise incorrect setting of the drive pulley

will occur.

• Water line is connected securely and fittings and

crossover tube grommets do not leak.

• Float is adjusted for proper water level.

• Pulley alignment is OK. Belt tension is OK (See page 13).

• Pads are correctly installed (See page 13).

• Blower and both pad motors are plugged into receptacles.

• All louver clips are snapped tight.

OPERATION WITH ESSICK SWITCH ECR-7

(Seven Position)

Blower Pad

Switch Motor Motors

Off Off Off

Low Vent Low Off

High Vent High Off

Minimum

Cool — Low Low One On

Minimum

Cool — High High One On

Maximum

Cool — Low Low Both On

Maximum

Cool — High High Both On

9

Page 10

HOW TO USE YOUR COOLER

HOW YOUR COOLER WORKS

Your cooler evaporates water to cool air. Evaporative

air cooling is the same natural cooling that happens

when a breeze springs up after a summer shower. You

feel cool because the rain water evaporates and carries

away heat.

Your new cooler has a motor (1) driven blower (2) which

draws outside air through pads (3) which are turned by

drive motors (4). The pads turn through water in trays (5)

filled by the water float valve (6) and water crossover

pipe (7). Air passes through the pads, is cooled by water

evaporation, and is sent into your home.

If the output air is too cool you may switch this cooler

from “Maximum Cool” to “Minimum Cool” (when used

with ESSICK ECR-7 7-position wall switch). Then only

one pad will turn, reducing the cooling effect. You may

also run the cooler in “Vent” when you want fresh air and

no cooling.

COOLING YOUR HOME

Your

cooler and windows or vents

your air cooling system. Outside air is filtered and

cooled, goes through your home, and carries away heat

and household odors. You control the air cooling flow to

your rooms by opening doors, windows, or vents.

are the two parts of

FIGURE 14

You must have window, door, or vent openings to let

air out when the cooler runs. The total opening

areas you need are shown below:

MODEL TOTAL OPENING

AREA

ECR 3301 5 Square feet minimum

ECR 4000 8 Square feet minimum

ECR 4500 9 Square feet minimum

ECR 5200 10 Square feet minimum

ECR 6600 12 Square feet minimum

ECR 7200 14 Square feet minimum

FIGURE 15

10

Page 11

CARE OF YOUR COOLER

CAUTION: ALWAYS SHUT OFF THE ELECTRIC

POWER TO THE COOLER AT THE FUSEBOX

BEFORE WORKING ON THE COOLER. WHEN

YOUR HANDS ARE INSIDE THE COOLER YOU

RISK INJURY IF THE COOLER IS ACCIDENTALLY

TURNED ON INSIDE THE HOUSE.

SPRING CARE:

Clean your cooler. (See page 12)

Oil your cooler. (See page 13)

Put a new pad in if the old pad is plugged with dirt or water

hardness. (See page 13)

Check belt tightness. (See page 13)

See lubrication instructions. (See page 13)

SUMMER CARE:

Drain and clean the cooler every two months if your water

is hard or the air is dusty. (See page 12)

You may prolong pad life in many hard water areas if you

drain the water tray every two to three weeks. (See page

12, steps 1-4).

See lubrication instructions. (See page 13)

NEVER WEAR SHOES WITH SLICK SOLES WHEN

YOU WORK ON A ROOF. YOU MAY SLIP WHEN

YOU LEAST EXPECT IT.

NEVER DRAIN WATER ONTO A ROOF. WATER

RESIDUE MAY CAUSE YOU TO SLIP OR MAY

STAIN YOUR ROOF. USE A DRAIN HOSE TO RUN

WATER TO A RAIN GUTTER OR TO THE GROUND.

FALL CARE:

Drain the cooler and water line to prevent frost damage.

(See page 12)

Clean the cooler. (See page 12)

Cover the cooler.

See lubrication instructions. (See page 13)

PUTTING ON LOUVER (Fig. 17)

1. Be sure the blower motor is plugged in.

2. Put the louver bottom into the water tray.

TAKING OFF LOUVER (Fig. 16)

CAUTION: TO PREVENT ACCIDENTAL INJURY,

SHUT OFF THE ELECTRIC POWER AT THE

FUSEBOX BEFORE WORKING ON THE COOLER.

1. Unsnap the six louver clips. Use a small screwdriver.

2. Tilt out the louver at the top. Unplug the pad motor

plug.

3. Take off the louver. Set it where it will not fall.

3. Plug in the pad motor plug.

4. Close the louver over the cabinet flange. Snap the

six clips onto the louver.

FIGURE 17

FIGURE 16

11

Page 12

CARE OF YOUR COOLER

TAKING OFF PAD (Fig. 18)

1. Lift up the small roller ends to unsnap the two center rollers. Pull out the two small rollers.

2. Pull out and turn the top roller bearing arm to line

up the slot.

3. Pull out the top roll end.

4. Take out the pad and bottom roller which will slide

out of the bottom slots.

CLEANING YOUR COOLER (Fig. 19)

WARNING: NEVER WASH YOUR COOLER INTERIOR WITH A GARDEN HOSE. WATER MAY

HARM THE MOTORS OR GET INTO YOUR

HOUSE.

Clean your cooler as follows:

1. DISCONNECT THE ELECTRIC POWER AT THE

FUSE BOX.

2. Remove the louvers. (See page 11)

3. Connect a garden hose to a water tray drain fitting.

4. Turn out the overflow pipe to drain the tray.

NEVER DRAIN WATER ONTO A ROOF. WATER

RESIDUE MAY CAUSE YOU TO SLIP OR MAY

STAIN YOUR ROOF. USE A DRAIN HOSE TO RUN

WATER TO A RAIN GUTTER OR TO A DRAIN.

5. Drain the other tray.

6. Take off the pads if they are dirty or plugged.

FIGURE 18

FIGURE 19

7. Use a sponge and mild detergent to wash the dirt

and scale from the trays and louvers.

DO NOT GET

WATER ON THE PAD MOTORS.

8. If the pads are plugged with hard water deposits

and dirt, replace the pads. See page 13.

9. Put the overflow pipes and grilles in place. (See

page 11)

Operation of Roto Belt Coolers in “Hardwater” Areas.

1. Clean the cooler frequently.

2. Remove mineral buildup from water troughs and

Roto Belt to prevent clogging.

3. A water analysis will determine: mineral content,

what water treatments can be used, what cleaning

agents should be used.

4. A “bleed-off” kit (Stock No. 8C190) should be installed

to help keep mineral buildup to a minimum.

12

Page 13

CARE OF YOUR COOLER

PUTTING ON NEW PAD (Fig. 20)

THE PADS NEED NO PREWETTING.

1. Put the lower roller in pad.

2. Fit the lower roller into the bottom slots in the frame.

3. Push the top roller through the pad. Fit the roll end

over the pad motor shaft drive block.

4. Push the top roller end into the bearing.

5. Turn the bearing arm to hold the roller.

6. Tuck the pad edges under the 2 guides on each

side.

7. Put the two small center rollers in place. Snap the

ends into the holders. (See greasing instructions

below).

OILING (Fig. 21)

Use electric motor oil available or SAE 20 or 30

nondetergent oil. Oil your cooler once a year.

1. Fill the two blower shaft bearing cups.

2. Put two or three drops in the two oil fill tubes on the

blower motor. Some motors do not need oil. If motor does not have oil tubes, then the motor does not

require oiling.

REPLACEMENT PADS

MODEL NUMBER PAD NUMBER

ECR 3301 EP-30

ECR 4000 EP-40

ECR 4500 EP-40

ECR 5200 EP-50

ECR 6600 EP-60

FIGURE 20

3. Put two or three drops in the end bearing on each

pad motor.

BLOWER BELT ADJUSTMENT (Fig. 22)

CAUTION: DO NOT ADJUST BELT TENSION BY

CHANGING THE DIAMETER OF THE MOTOR

PULLEY. ADJUST BELT TENSION ONLY BY

MOVING THE MOTOR BRACKET.

1. If you can easily move the belt over 1 inch, it needs

adjustment.

2. To adjust belt tension, loosen the three motor mount

bolts.

3. Push the motor to tighten the belt, until it moves

about 1/2 inch with finger force.

4. Tighten the three motor mount bolts.

FIGURE 21

13

FIGURE 22

Page 14

REPAIR PARTS

ESSICK CONVERTIBLE DOWN/FRONT OUTLET EVAPORATIVE AIR COOLER

MODEL NOS. ECR 3301, ECR 4000, ECR 4500, ECR 5200, ECR 6600, ECR 7200

14

Page 15

REPAIR PARTS

ESSICK CONVERTIBLE DOWN/FRONT OUTLET EVAPORATIVE AIR COOLER

MODEL NOS. ECR 3301, ECR 4000, ECR 4500, ECR 5200, ECR 6600, ECR 7200

NOTICE: Order by PART NUMBER, not by Key Number. Refer to the back cover of this manual for parts ordering information.

KEY PART NUMBER

NO. ECR 3301 ECR 4000/4500 ECR 5200 ECR 6600/7200 PART NAME

1 30439 30439 30439 30439 Motor Plug

2 50255 50255 50255 50255 Motor Tail Mount

3 05466-04 05466-04 05466-04 05466-04 Machine Screw 5/16 - 18 x 3/4

4 581189 581188/50310 50310 30491/581191 Motor

5 30315 30315 30315 30315/583054 Pulley - includes Key 6

6 586026 586026 586026 586026 Set Screw 5/16 - 18 x .25 Hex. Socket

7 582004 582010/582030 31720 582088 V-Belt

8 30306 30305-00 30304-00 30304-00 Motor Mount

9 05507 05507 05507 05507 Lock Washer 5/16 Helical Spring

10 05480 05480 05480 05480 Hex Nub 5/16 - 18

11 30105 30105 30105 30105 Clip

12 30311-00 30311-00 30311-00 30311-00 Receptacle Mount

13 50294 50294 50294 50294 Lock Washer - 5/16 internal tooth

13A 30550 30550 30550 30550 Lock Washer

14 30347 30347 30347 30347 Screw #8 - 18 x 3/8 Phillips, Type AB

15 30433 30433 30433 30432 Pad Motor Connector

16 30551 30551 30551 30551 Machine Screw 5/16 - 18 x 3/8

17 30549/08133 30549/08133 30549/08133 30549/08133 Screw 1/4 - 14 x 3/8 Type B

18 30287 30289 30288 30288 Bearing Mount (includes #21, 22)

19 14864 14864 14864 14864 Bushing

20 501244 501241 501241 501241 Thrust Washer

23 30347 30347 30347 30347 Screw #8 - 18 x 1/2, Type B

24 586026 586026 586026 586026 Set Screw 5/16 - 18 Socket

25 31086 31086 31086 31086 Overflow Drain Kit

26 32013-10 32019-10 302025-10 32031-10 Reservoir

27 31984 31984 31984 31984 Grommet

28 583009 30314/583013 30314 30314 Pulley - includes Key 24

29 30241 30238-02 30238-01 30238-01 Shaft

30 502389 502389 502389 502389 Float Valve Assembly

31 30418-01 30418-01 30418-01 30418-01 Water Shield

32 30318 30322 30323 30323 Blower Wheel

33 30208 30177 30148 30167 Baffle

34 30205 30205 30205 30205 Junction Box Cover

35 30202 30202 30202 30202 Junction Box

36 27835 27835 27835 27835 Cupped Washer

37 14982 14982 14982 14982 Lock Washer #8 Star

38 29816 29816 29816 29816 Bushing

39 30585 30585 30585 30585 Screw #8 - 32 x 7/16, Type T, Green

40 32013-20 32019-20 32025-20 32031-20 Reservoir

41 30552 30552 30552 30552 Bushing

42 29996 29996 29996 29996 Plug

43 31985-01 31985-03 31985-02 31985-02 Tube

44 501280 501243 501243 501243 Collar

45 30433 50485 50489 50487 Pad Motor Connector

47 30440 30878 30440 30441 Motor Connector

48 29931-01 30214-01 30254-01 29738-01 Louver

49 31047 31047 31047 31047 Bearing

50 30296-01 30206-01 30250-01 29817-01 Side Support

51 30248 30224-01 30244-01 29861-01 Top Roller

52 30234 30211 30235 30127 Roller

53 30236 30212 30237 30119 Bottom Roller

54 EP-30 EP-40 EP-50 EP-60 Evaporator Pad (2 Req.)

55 30465 30465 30465 30465 Screw #10 - 16 x 7/8

56 30297-01 30233-01 30256-01 29815-01 Motor Side Support

57 30336 30336 30336 30336/00061 Pad Motor

58 29862 29862 29862 29862 Roller Drive

59 586023 586023 586023 586023 Screw #10 - 32 x 3/8

* 50209-3 50209-3 50209-3 50209-3 Owners Manual

60 30339 30338 30337 30332 Louver Assembly includes Keys 48-59

* ECK-30 ECK-40 ECK-50 ECK-60 Roof Stand Kit - Optional

* ECR-5 ECR-5 ECR-5 ECR-5 5 Position Switch (Not Supplied)

* ECR-7 ECR-7 ECR-7 ECR-7 7 Position Switch (Not Supplied)

61 523122 523122 523122 523122 Splash Guard Cover

*Unillustrated items

15

Page 16

ESSICK

CONVERTIBLE

DOWN/FRONT OUTLET

owners

manual

MODEL NO.

ECR 3301

ECR 4000

ECR 4500

ECR 5200

ECR 6600

ECR 7200

HOW TO ORDER

REPAIR PARTS

EVAPORATIVE AIR COOLER

The model number of your cooler will be found on a label fastened

to the housing.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING

INFORMATION:

• PART NUMBER • PART DESCRIPTION

• MODEL NUMBER • NAME OF ITEM

HOW TO ORDER REPAIR PARTS

All parts listed herein may be ordered through our service center by writing:

ESSICK AIR PRODUCTS

5800 MURRY • LITTLE ROCK, ARKANSAS 72209

501-562-1094

Loading...

Loading...