esprit cam NVX NV User Manual

NVX and NV

This manual was prepared with the assumption that the intended reader does have

working knowledge of Esprit and NVX or NV programming experience so that he fully

understands the information it contains.

Contents

1. Introduction ................................................................................................................. 4

2. Defining Work Coordinates ........................................................................................ 4

2.1. Standard Work Coordinate System G54 to G59 ................................................. 4

2.2. Extended Work Coordinate System G54.1 P1-300 ............................................ 5

2.3. Dynamic Fixture Offset Work Coordinate System G54.2 P............................... 6

2.4 Tilted Plane Work Coordinate System G68.2..................................................... 6

2.5 Macro Work Coordinate System G65 P9681 ..................................................... 7

3. Simultaneous 5 Axis Machining Settings ................................................................... 8

3.1 Work Coordinate Setting .................................................................................... 8

3.2 RTCP................................................................................................................... 9

4. Drill Cycles ................................................................................................................. 9

4.2 Peck ......................................................................................................................... 10

4.3 Tap .......................................................................................................................... 10

4.4 Bore ......................................................................................................................... 10

4.5 Peck2 ....................................................................................................................... 10

4.6 Tap2 ........................................................................................................................ 10

4.7 Bore2 ....................................................................................................................... 10

4.8 Bore3 ....................................................................................................................... 10

4.9 Bore4 ....................................................................................................................... 10

4.10 Bore5 ..................................................................................................................... 10

4.11 Bore6 ..................................................................................................................... 10

4.12 Bore7 ..................................................................................................................... 11

5. 4th Axis Wrap Milling Cycles ....................................................................................... 11

5.1 Cylindrical Interpolation ................................................................................... 11

6. Coolant Codes ............................................................................................................... 12

6.1 Primary Coolant Code....................................................................................... 12

6.2 Secondary Coolant Code................................................................................... 13

6.3 Coolant Pressure Code ...................................................................................... 14

7. Custom Codes ............................................................................................................... 14

7.1 Rapid Moves / Tapping Cycles / Boring Cycles ............................................... 15

7.2 Boring Cycles.................................................................................................... 17

7.3 Rigid Tapping ................................................................................................... 18

7.4 Cutting Mode (G332) ........................................................................................ 18

7.5 M Codes at the Beginning and End of an Operation ........................................ 19

7.6 AI Contour Control ........................................................................................... 20

8. Post Output Configuration ........................................................................................ 21

8.1. F15 Format Switch ............................................................................................ 22

8.1. TCP TYPE ........................................................................................................ 22

8.2. Program End Code ............................................................................................ 22

8.3. Additional Rotary Axis (NV)............................................................................ 22

8.4. Axis Roll Over (NV) ......................................................................................... 22

8.5. Position of Sequence Numbers (N)................................................................... 23

8.6. Custom String 10 .............................................................................................. 23

8.7. ESPRIT Version................................................................................................ 23

9. Machine Setup Custom Settings ............................................................................... 23

9.1. Fanuc Output Style ........................................................................................... 24

9.2. RTCP Output .................................................................................................... 24

9.3. Rollover for Rotary Axis .................................................................................. 24

9.4. Machine Name .................................................................................................. 24

9.5. Machine Model Number ................................................................................... 25

9.6. Tool Holder Type .............................................................................................. 25

9.7. TOOLTABLE ................................................................................................... 25

9.8. StopTcOnly ....................................................................................................... 25

9.9. NTCOnly........................................................................................................... 25

10. Rotary Retract Movement Setup ........................................................................... 26

10.1. Clearance........................................................................................................... 26

10.2. Tool Change ...................................................................................................... 27

11. Custom Settings Reference List ............................................................................ 28

11.1. Machine Setup .................................................................................................. 28

11.2. Operation Page .................................................................................................. 29

11.1. Tool Page .......................................................................................................... 29

1. Introduction

This manual documents the Esprit NVX and NV post processors. The

E12MSP_NVX_2012-03-15 post supports the NVX machine tool. The

E12MSP_NVD_2012-03-16 post supports the NV machine tool.

These post processors require ESPRIT 2012 or higher.

2. Defining Work Coordinates

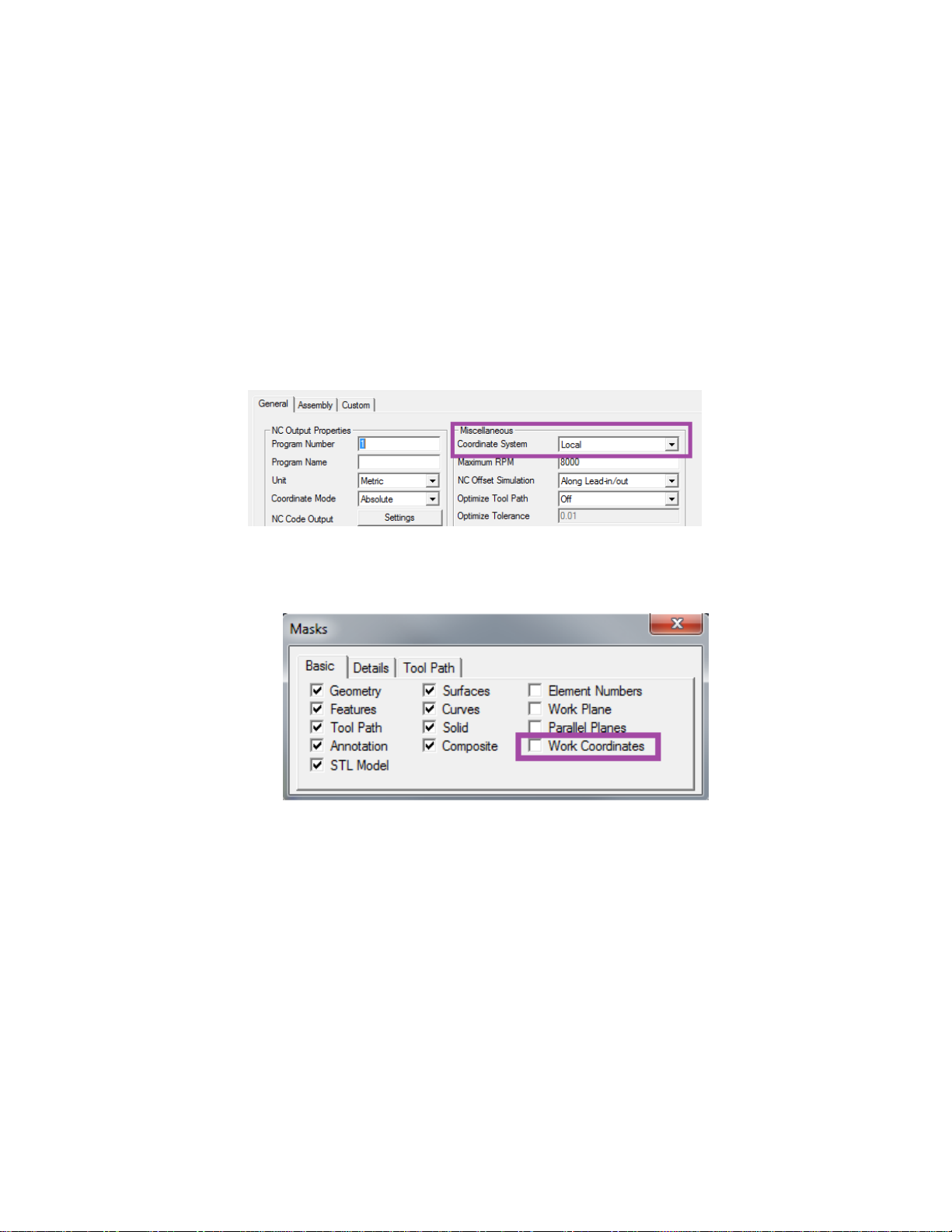

Program Datums on the machine can be defined as Work Coordinates in Esprit. Esprit

supports both Local and World Coordinate Systems. To set the Coordinate System in the

milling environment, go to Common Machining> Machine Setup> Coordinate Systems

and select between Local and World.

For most applications this will be set to Local.

To view your Work Coordinates in Esprit check the Work Coordinate box in in the

Masks box.

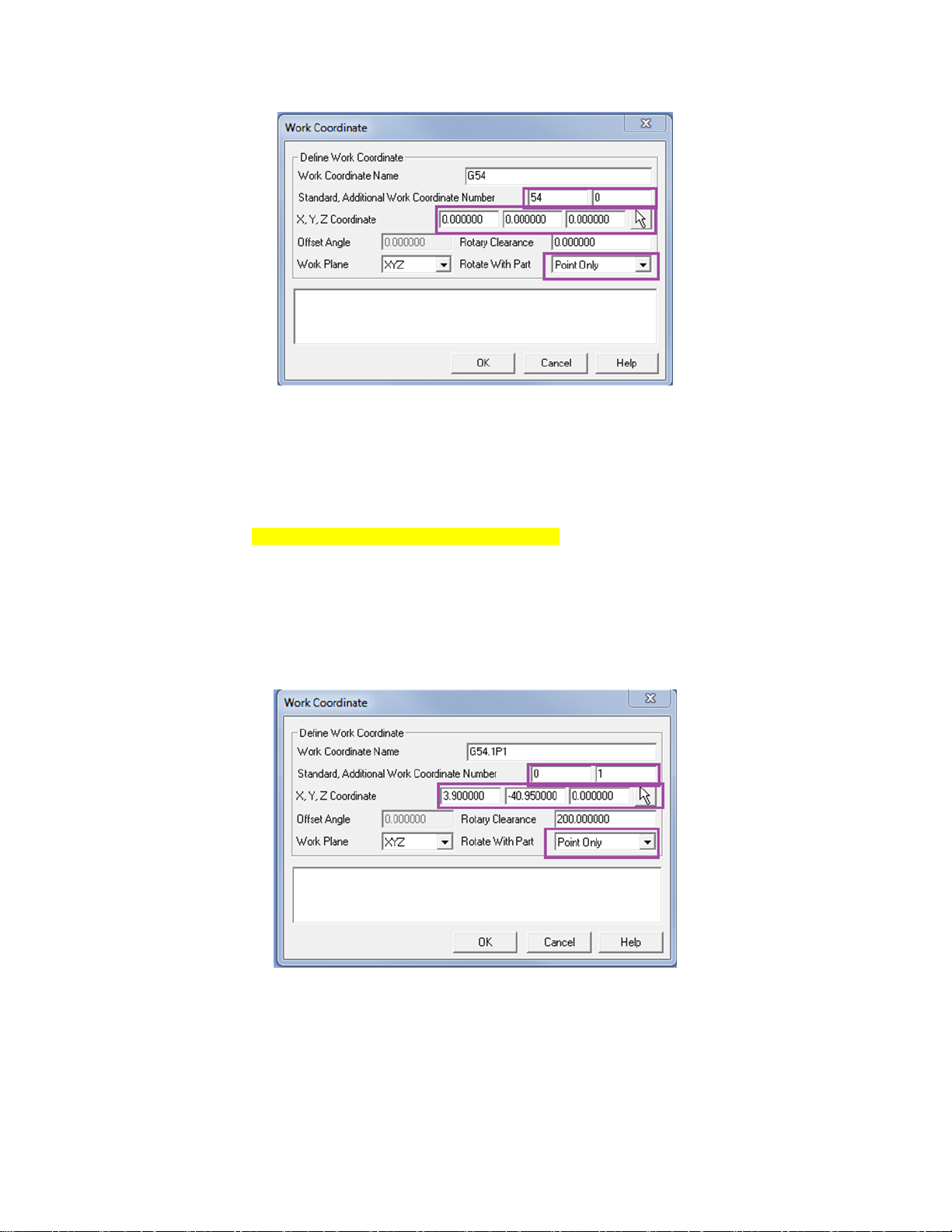

2.1. Standard Work Coordinate System G54 to G59

To define a Standard Work Coordinate set the Work Coordinate page as:

Standard is the Work Coordinate Number and Additional Work Coordinate Number is set

to 0. XYZ is the location of the Work Coordinate in the file relative to the Work Plane.

Rotate with Part needs to be set to Point Only.

M06

T7

G90 G94 G54 G17 G00 X109.5 Y100.0

G43 Z-3.0 H17 S7767 M03

M08

2.2. Extended Work Coordinate System G54.1 P1-300

To define an Extended Work Coordinate set the Work Coordinate page as:

Standard is set to 0 and Additional Work Coordinate Number is set to the P value. XYZ

is the location of the Work Coordinate in the file relative to the Work Plane. Rotate with

Part needs to be set to Point Only.

M06

G90 G94 G54.1 P1 G17 G00 X-2.5 Y-6.5383

G43 Z10.0 H1002 S11650 M03

M08

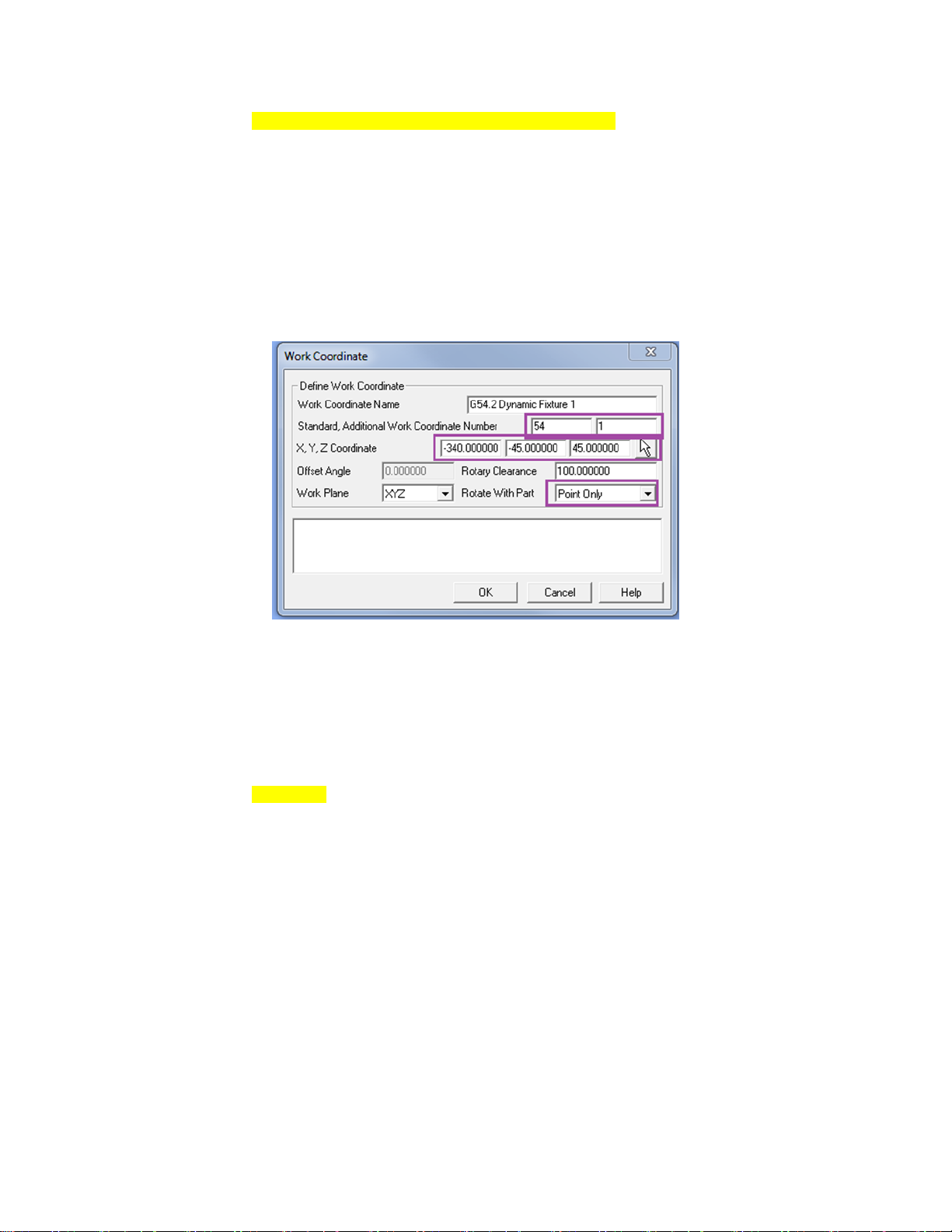

2.3. Dynamic Fixture Offset Work Coordinate System

G54.2 P

To define a Dynamic Fixture Offset Coordinate System, set the Work Coordinate page

as:

:

(SETTING FOR FIXTURE OFFSET G54.2)

G90 G10 L21 P1 X* Y* Z* A0 ( X-340.0 Y-45.0 Z45.0 )

:

:

M06

T2

G90 G54

G54.2 P1

M11

G00 A180.0

M10

G90 G94 G17 G00 X28.6 Y-46.4047

G43 Z92.0 H66 S1500 M03

M08

Note that the command line for the Dynamic Fixture Offset will be output near the

beginning of the NC file.

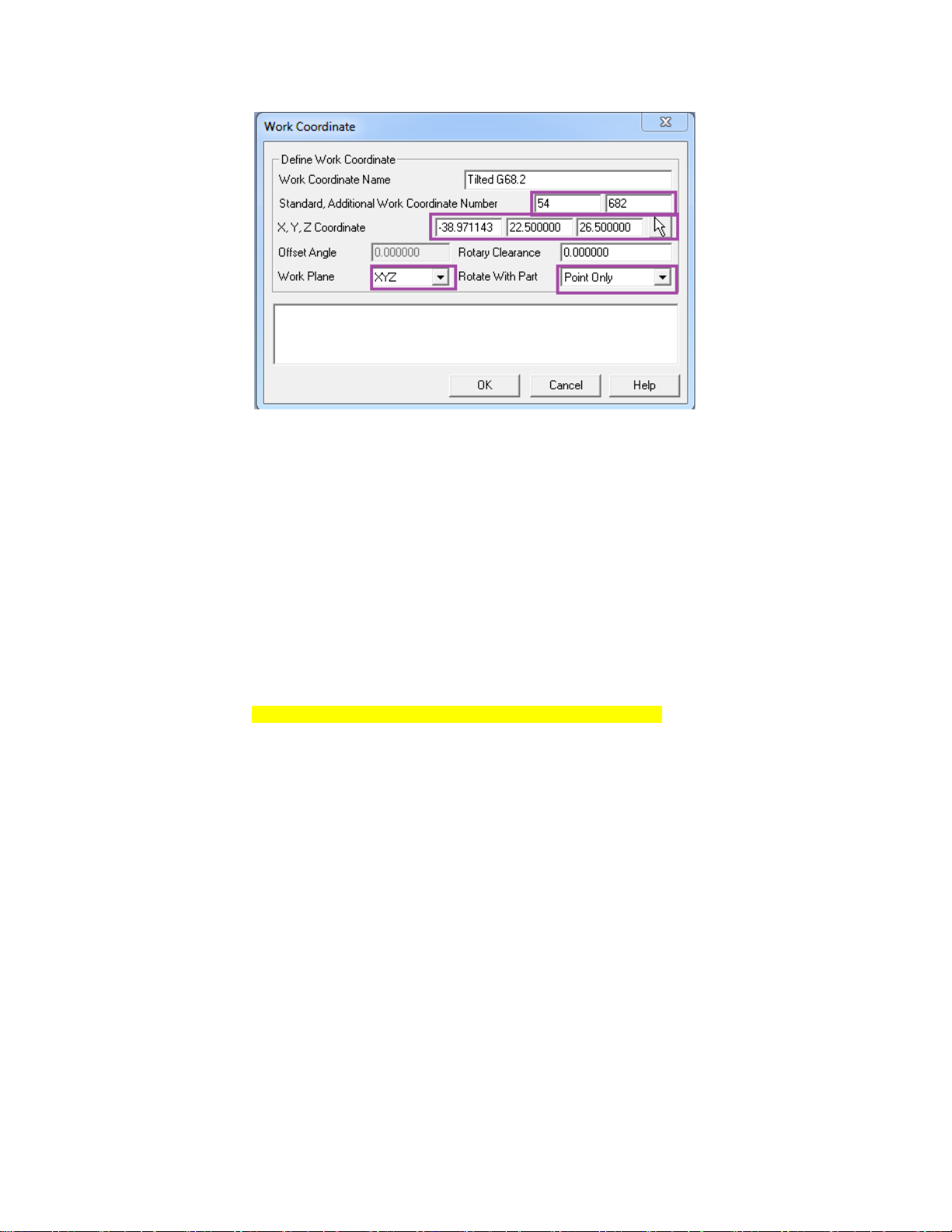

2.4 Tilted Plane Work Coordinate System G68.2

To define a Tilted Plane Work Coordinate System, set the Work Coordinate page as

follows. This example shows how to create the G68.2 can be defined in Esprit relative to

P0. In this case we define the Work Coordinate page as:

Standard can be set to an existing Work Coordinate and Additional Work Coordinate

Number is set to 682. XYZ is the location of the Work Coordinate in the file relative to

the current Work Plane which is XYZ. The XYZ Coordinate values in this scenario are

most commonly entered using the button on the far right, and digitizing the point in

Esprit where the new Work Coordinate will be located. The Work Plane is set to XYZ.

Rotate with Part needs to be set to Point Only.

:

M06

M69

M11

G00 B-90.0 C150.0

M68

M10

G49

G68.2 X-38.9711 Y22.5 Z26.5 I-60. J90. K-90.

G53.1

G17 G94 X0.0 Y38.9711

G43 Z24.5 H29 S3001 M03

M08

Note: This option is not available on the NV.

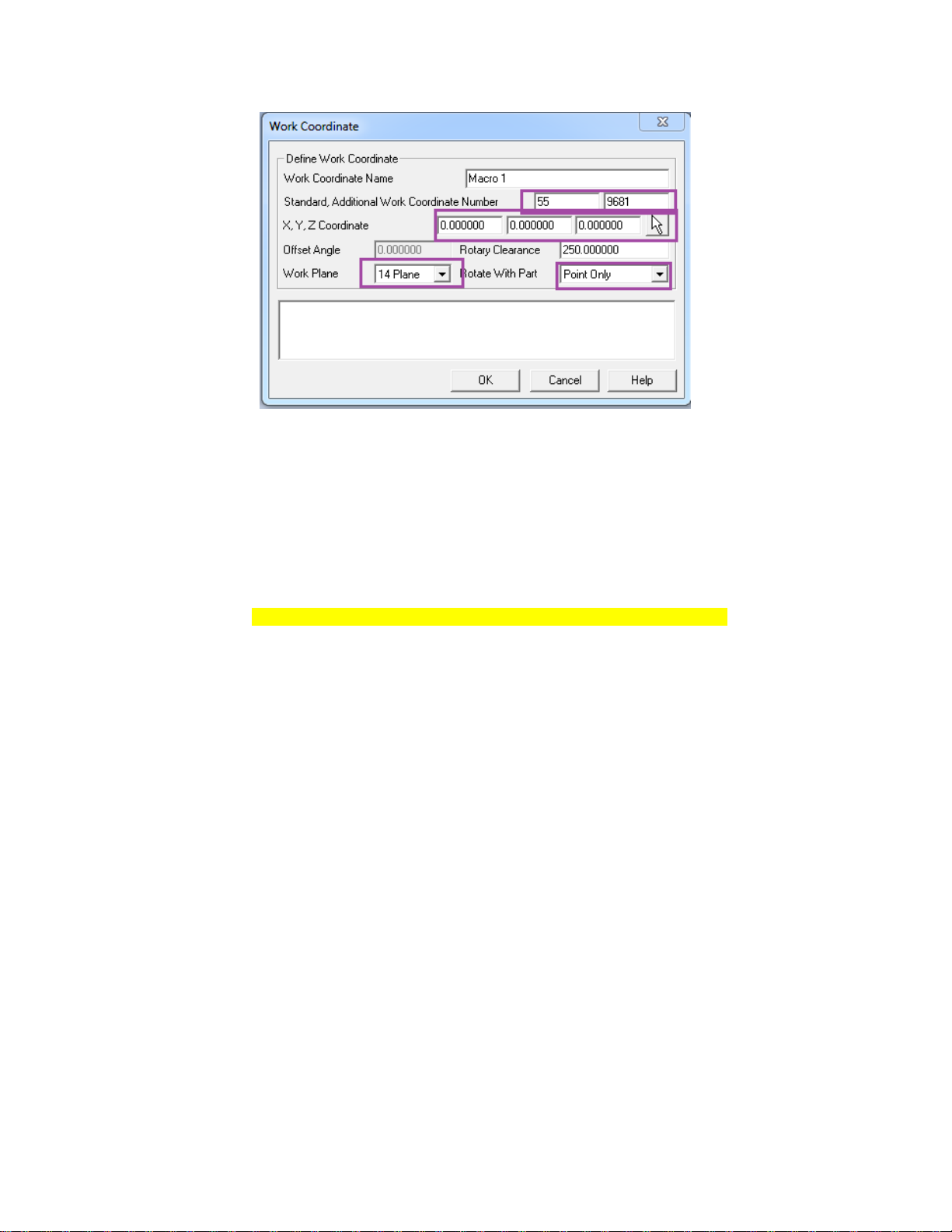

2.5 Macro Work Coordinate System G65 P9681

This item is available only on the NVX machine as an option and may not be installed.

Please contact Mori Seiki to check on its configuration and availability.

To define a Macro Work Coordinate System, set the Work Coordinate page as:

Standard is typically set to 54, but it can be set to an existing Work Coordinate.

Additional Work Coordinate Number is set to 9681. XYZ is the location of the Work

Coordinate in the file relative to the current Work Plane. The current Work Plane can be

any Work Plane in Esprit. In this example the Work Plane is set to an existing plane ’14

Plane’. Rotate with Part needs to be set to Point Only.

:

M06

G55

G65 P9681 X50.0 Y10.0 Z138.0 B60.0 C180.0 M55. Q59.

G59

M69

M11

G00 B60.0 C180.0

M68

M10

G17 G94 X-14.1421 Y8.5

G43 Z2.0 H69 S2000 M03

M08

3. Simultaneous 5 Axis Machining Settings

Creating 5x axis operations have specific Work Coordinate settings for the NVX and NV

machines.

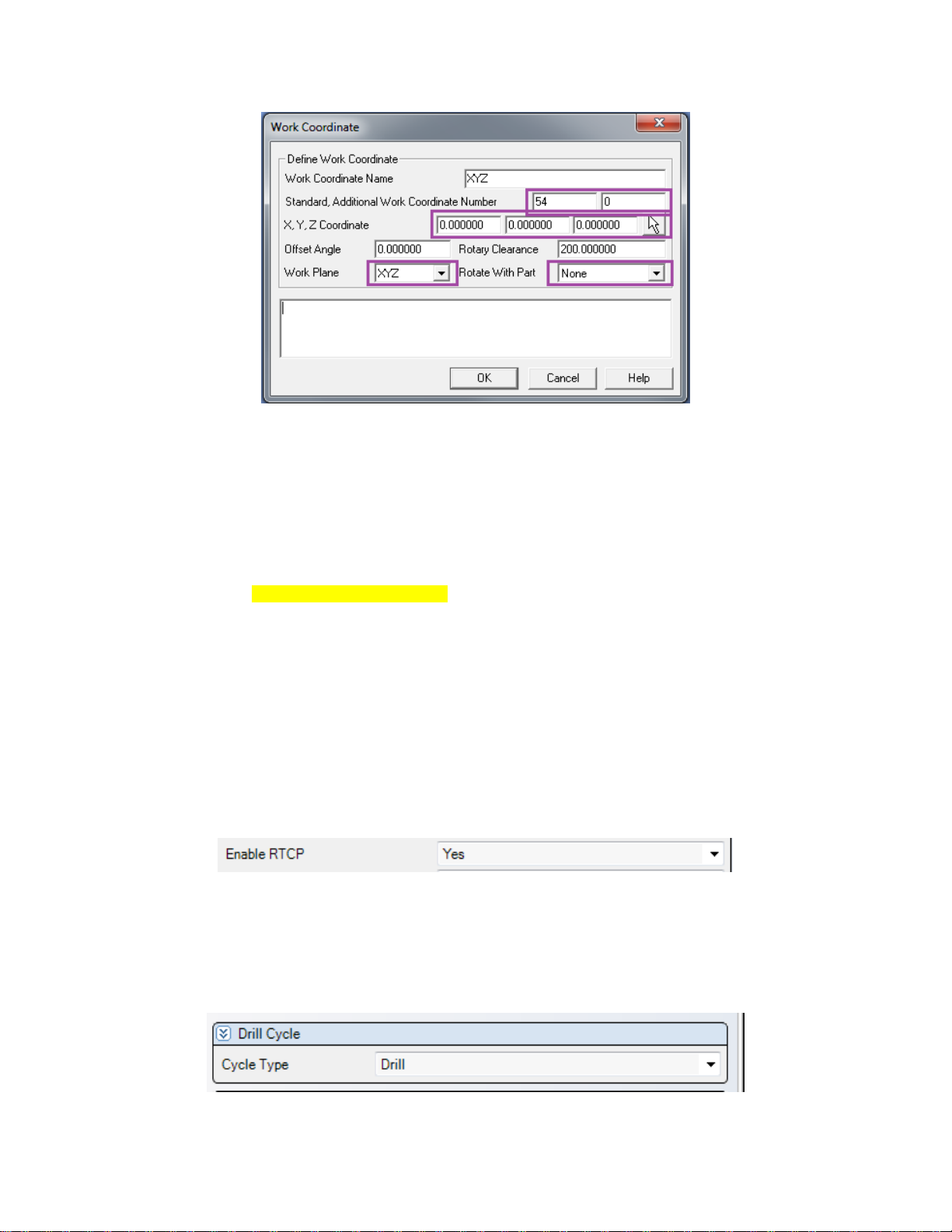

3.1 Work Coordinate Setting

To define a Work Coordinate System for 5x milling operations, set the Work

Coordinate page as:

Standard is the Work Coordinate Number, typically 54 and Additional Work Coordinate

Number is set to 0. The Work Plane is set to XYZ. Rotate with Part needs to be set to

None.

M06

M11

M69

G00 G54 G17 X0.0 Y0.0

G90 B0.0 C0.0

G49

G05 P10000

G43.4 H122 S329 M03

G00 X0.0 Y0.0 Z0.0 B0.0 C0.0

M08

3.2 RTCP

For the NVX and NV, we recommend setting RTCP ON for 5 axis operations with

DDRT2, and setting RTCP OFF for 5 axis operations with DDRT1. RTCP can be

enabled on the operation page

4. Drill Cycles

Drilling, Boring and Tapping cycles on the NVX can be set using the Drill operation page.

Selecting Cycle Type on the Drill operation page determines the output in the NC file.

Loading...

Loading...