esprit cam NTX User Manual

NT(X) Series

i

Table of Contents

1. Introduction .............................................................................................................. 1

2. Setting up the Esprit Environment ............................................................................ 1

2.1. Required Add-ins ............................................................................................... 1

2.1.1. How to Load an Add-in in ESPRIT .......................................................................... 1

2.2. Mori Seiki ESPRIT for Mapps Addin .................................................................. 4

2.3. Stock Automation ............................................................................................... 5

2.4. AutoSubStock (optional) .................................................................................... 7

2.5. Turning Work Coordinates Addin ....................................................................... 8

2.5.1. Setting Up the Turning WC addin ............................................................................ 8

2.6. AutoPark Addin (required on NT1000 machines) ............................................. 12

3. Machine Setup ....................................................................................................... 14

3.1. Introduction ...................................................................................................... 14

3.2. Set the Program Name, Program Number ....................................................... 14

3.3. Define the Turning Stock .................................................................................. 15

3.4. Tool Path Optimization with NURBS ................................................................ 17

3.5. Selecting Post Processors and Outputting NC Code ....................................... 18

3.6. Machine Parameters ........................................................................................ 20

3.6.1. Introduction ............................................................................................................. 20

3.6.2. Output of Program End (M02), Sub-Program End (M99) or Program End and

Rewind (M30) ....................................................................................................................... 20

3.6.3. TCP Type ................................................................................................................ 21

3.6.4. Set position of optional stop code (M01) in the NC code. ...................................... 21

3.6.5. Station on Turret 2 for Transfer .............................................................................. 21

3.6.6. Tail Stock Type ....................................................................................................... 22

3.6.7. Block Skip Method ................................................................................................. 22

3.6.8. C-Axis Rollover ...................................................................................................... 22

4. Work Coordinates .................................................................................................. 24

5. Tools (T-function) ................................................................................................... 26

5.1. T-function Specifications .................................................................................. 26

5.1.1. Upper Head (B-Axis Head): ................................................................................... 28

5.1.2. Lower Turret: .......................................................................................................... 29

5.2. Tool Life Management ..................................................................................... 30

ii

5.3. Tool Nose Direction (G43 H_ T_) ..................................................................... 32

5.4. Second home position ...................................................................................... 33

5.5. G361/362 Tool Change Command Setting ...................................................... 36

5.6. Tool Change position ....................................................................................... 38

6. Spindle Direction, Speed, and Feedrate ................................................................ 39

6.1. Turning Spindle Direction and Milling Tool Spindle Direction ........................... 39

6.2. Spindle Speed output for CSS Unit .................................................................. 41

6.3. Feedrate for 4-axis Milling Operations ............................................................. 42

6.4. Feedrate option for rapid moves in 5 axis operations ....................................... 43

6.5. Turning on AI Contour Control ......................................................................... 43

7. 5-axis Simultaneous Milling Options ...................................................................... 45

7.1. Introduction ...................................................................................................... 45

7.2. Definitions ........................................................................................................ 45

7.2.1. Rotate With Part ...................................................................................................... 45

7.2.2. Fixed ....................................................................................................................... 46

7.3. Operation Types ............................................................................................... 46

7.3.1. RTCP Type 1 WKP=0 (G43.4) ............................................................................... 46

7.3.2. RTCP Type 1 WKP=1 (G43.4) ............................................................................... 46

7.3.3. RTCP Type 2 WKP=0 (G43.5) ............................................................................... 47

7.4. Additional Information ...................................................................................... 48

8. Simultaneous Turning Operations: Turning on the same spindle with two turrets .. 49

8.1. Balance Roughing Cycle .................................................................................. 49

8.2. Other Turning Cycles ....................................................................................... 51

9. Park Operation ....................................................................................................... 53

9.1. Introduction ...................................................................................................... 53

9.2. How to park a tool ............................................................................................ 53

9.3. Stop Code Options ........................................................................................... 56

9.4. Setting the B axis angle ................................................................................... 57

9.5. Park head/ turret to its minimum travel position (G53) ..................................... 58

9.6. Park lower turret prior to a transfer (Z configurations only) .............................. 60

9.7. Setting up the park operation with the AutoPark addin .................................... 61

10. How to Program a Part Transfer ......................................................................... 62

10.1. Introduction ................................................................................................... 62

10.2. SP1-CutOff-BarFeed-First ............................................................................ 64

iii

10.3. SP1-CutOff-BarFeed-Last ............................................................................. 66

10.4. SP1 To SP2- BarFeed-Cutoff ....................................................................... 68

10.5. SP1 To SP2- BarPull-Cutoff .......................................................................... 70

10.6. SP1 To SP2-Cutoff-BarFeed ........................................................................ 72

10.7. SP1 To SP2-Release .................................................................................... 74

10.8. SP2 To SP1-Release .................................................................................... 76

10.9. Operation Tabs in the Workpiece Transfer Utility ......................................... 78

10.9.1. Park...................................................................................................................... 78

10.9.2. Part Eject ............................................................................................................. 79

10.9.3. Bar Feed .............................................................................................................. 80

10.9.4. Pick Up ................................................................................................................ 81

10.9.5. Bar Pull ................................................................................................................ 82

10.9.6. Cutoff .................................................................................................................. 83

10.10. Custom Settings for Part Transfer Cycles.................................................. 84

10.10.1. Workpiece Pushing Check (G38) ........................................................................ 85

10.10.2. C axis angle for pick operation ........................................................................... 86

10.10.3. Bar Feed positions relative to G53 ...................................................................... 87

10.10.4. Workpiece Ejector (NT-S and NT-SZ Only) ...................................................... 88

10.10.5. Work Coordinate for Pickup Operation .............................................................. 89

10.10.6. Smart Loader Shutter (M37) (NT1000 only) ...................................................... 90

11. Working with Long Parts: Pickup\Barpull then Simultaneous Machining ............ 91

12. Stock Repositioning ............................................................................................ 92

13. How to Output Coolant Codes ................................................................ ............ 95

13.1. Introduction ................................................................................................... 95

13.2. Setting First Coolant Code ............................................................................ 95

13.3. Setting the second coolant code (optional) ................................................... 97

13.4. Setting the High Pressure Coolant Pressure options .................................... 97

13.4.1. Upper Head Option ............................................................................................. 97

13.4.2. Lower Turret Options .......................................................................................... 97

14. Multiple Repetitive (Canned) Cycles ................................................................. 100

14.1. Introduction ................................................................................................. 100

14.2. Roughing Cycle........................................................................................... 102

14.2.1. Introduction ....................................................................................................... 102

14.2.2. O.D./I.D. Roughing ........................................................................................... 105

iv

14.2.3. Face Roughing................................................................................................... 106

14.3. Grooving Cycle ........................................................................................... 107

14.3.1. Introduction ....................................................................................................... 107

14.3.2. Face Grooving ................................................................................................... 110

14.3.3. O.D./I.D. Grooving ........................................................................................... 111

14.4. Threading Cycle .......................................................................................... 112

14.4.1. Introduction ....................................................................................................... 112

14.4.2. Threading with Canned Cycle Set to Single Path ............................................. 114

14.4.3. Threading with Canned Cycle Set to OFF ........................................................ 116

14.4.4. Threading with Canned Cycle Set to Multiple Path .......................................... 118

15. B axis Turing Cycle ........................................................................................... 120

16. Hole Machining Canned Cycles ........................................................................ 122

16.1. Introduction ................................................................................................. 122

16.2. Deep Hole Drilling Cycle (G74) ................................................................... 126

16.3. Face and Side High-Speed Deep Hole Drilling Cycle (G83.5/G87.5) ......... 127

16.4. Face and Side Deep Hole Drilling Cycle (G83.6/G87.6) ............................. 129

16.5. Face and Side Spot Drilling Cycle (G83/G87) ............................................. 131

16.6. Face and Side Tapping Cycle (G84/G88) ................................................... 132

16.7. Tapping at Center of Spindle (G32) ............................................................ 133

16.8. Synchronized Tapping (M329) .................................................................... 134

16.8.1. Limitations of Synchronized Tapping ............................................................... 134

16.8.2. Face and Side Synchronized Tapping (M329 G84/G88) .................................. 134

16.8.3. Face and Side (High-Speed) Deep Hole Synchronized Tapping (M329 G84/G88)

136

16.8.4. Spindle Synchronized Tapping (M329 G84) (Option) ..................................... 137

16.8.5. Face and Side Boring Cycle (G85/G89) ........................................................... 139

16.8.6. Boring in Turning Mode ................................................................................... 140

16.9. Spindle/Rotary Tool Spindle Simultaneous Operation Mode ...................... 141

17. 3D Coordinate Conversion (G68.1) .................................................................. 144

18. 4-Axis Wrap Milling Cycles with Interpolation ................................................... 144

18.1. Introduction ................................................................................................. 144

18.2. Cylindrical Interpolation ............................................................................... 144

18.3. Polar Interpolation ....................................................................................... 146

19. Tailstock ........................................................................................................... 148

19.1. Live Center on Lower Turret ....................................................................... 148

v

19.1.1. Defining Tailstock in Machine Setup................................................................ 148

19.1.2. Creating Tailstock Operation ............................................................................ 149

19.2. Second Live Center on Lower Turret .......................................................... 150

19.3. Independent Tail Stock ............................................................................... 152

19.3.1. Defining Tailstock in Machine Setup................................................................ 152

19.3.2. Creating Tailstock Operation ............................................................................ 153

19.4. Live Center on Sub Spindle ........................................................................ 154

20. Steady Rest ...................................................................................................... 154

20.1. Lower Turret Steady Rest ........................................................................... 154

20.1.1. Defining Steady Rest in Machine Setup ........................................................... 154

20.1.2. Defining Steady Rest in Machine Setup Utility (Mori Seiki Add-in) ............... 156

20.1.3. Creating Steady Rest Operation ........................................................................ 157

20.2. Independent Steady Rest ........................................................................... 159

20.2.1. Defining Steady Rest in Machine Setup ........................................................... 159

20.2.2. Defining Steady Rest in Machine Setup Utility (Mori Seiki Add-in) ............... 160

20.2.3. Creating Steady Rest Operation ........................................................................ 161

20.2.4. G478 Steady Rest/Sub Spindle Synchronize Command (NT-S 6000 only) ..... 163

21. Special considerations when Programming an NT1000 ................................... 164

21.1. Introduction ................................................................................................. 164

21.2. Mori Seki Macro Executer update required to work with ESPRIT 2012 and

newer post ............................................................................................................... 164

21.3. Setting the Sub Spindle work offset value in the machine control ............... 166

21.4. Motion Axis setup on ESPRIT for sub spindle operations on upper head ... 166

21.5. Setting the Work Support/Sub Spindle angle (BW Axis) ............................. 167

21.6. Conditions need to allow the Moving of the BW axis .................................. 169

21.7. Conditions need to allow the Moving of the B axis ...................................... 169

21.8. Setting A-axis Position with the AutoPark Addin ......................................... 170

21.9. Parking the Lower Turret ............................................................................ 173

21.10. Parking the A and BW axis Prior to Tool change ..................................... 175

21.11. Parking the B axis head Prior to BW Angle Change ................................ 177

21.12. Parking the BW axis Prior to part transfer................................................ 178

21.13. Maximize clearance when on the face of the main spindle with the B axis

head: 179

21.14. Part Release from Sub Spindle ............................................................... 180

21.15. Location of part release within the ESPRIT file: ....................................... 182

vi

21.16. Turret synchronization requirements for programming NT1000-WZ and

NT1000-SZ .............................................................................................................. 184

21.16.1. Parking the lower turret before a BW axis angle change made by an upper turret

operation: 184

21.16.2. Machining on the Main Spindle with the B axis head while machining on sub

spindle with lower turret: .................................................................................................... 184

21.16.3. Machining on the sub spindle with the B axis head while machining on the main

spindle with the lower turret: .............................................................................................. 185

21.16.4. Changing BW axis angle with B axis head operation while machining with lower

turret on the main spindle ................................................................................................... 185

21.16.5. Changing A axis position between two lower turret operations in a row: ........ 186

21.16.6. Machining with one head\ turret while other head\turret is waiting: ................ 186

21.16.7. Part release on sub spindle ................................................................................ 187

21.16.8. Part Transfer ...................................................................................................... 187

21.16.9. When in Long Part Machining mode and changing from Turning to MillTurn

operation on the same head\turret ....................................................................................... 188

22. Custom Settings Index ..................................................................................... 189

22.1. Operations Page ......................................................................................... 189

22.2. Tools Page .................................................................................................. 190

vii

1. Introduction

This is for ESPRIT 2012 or newer post processors and requires ESPRIT 2012 R3 or newer

(Build B19.0.3.1325 or above.

Please refer to NT programming manual for detailed information on the related G and M-codes.

2. Setting up the Esprit Environment

2.1. Required Add-ins

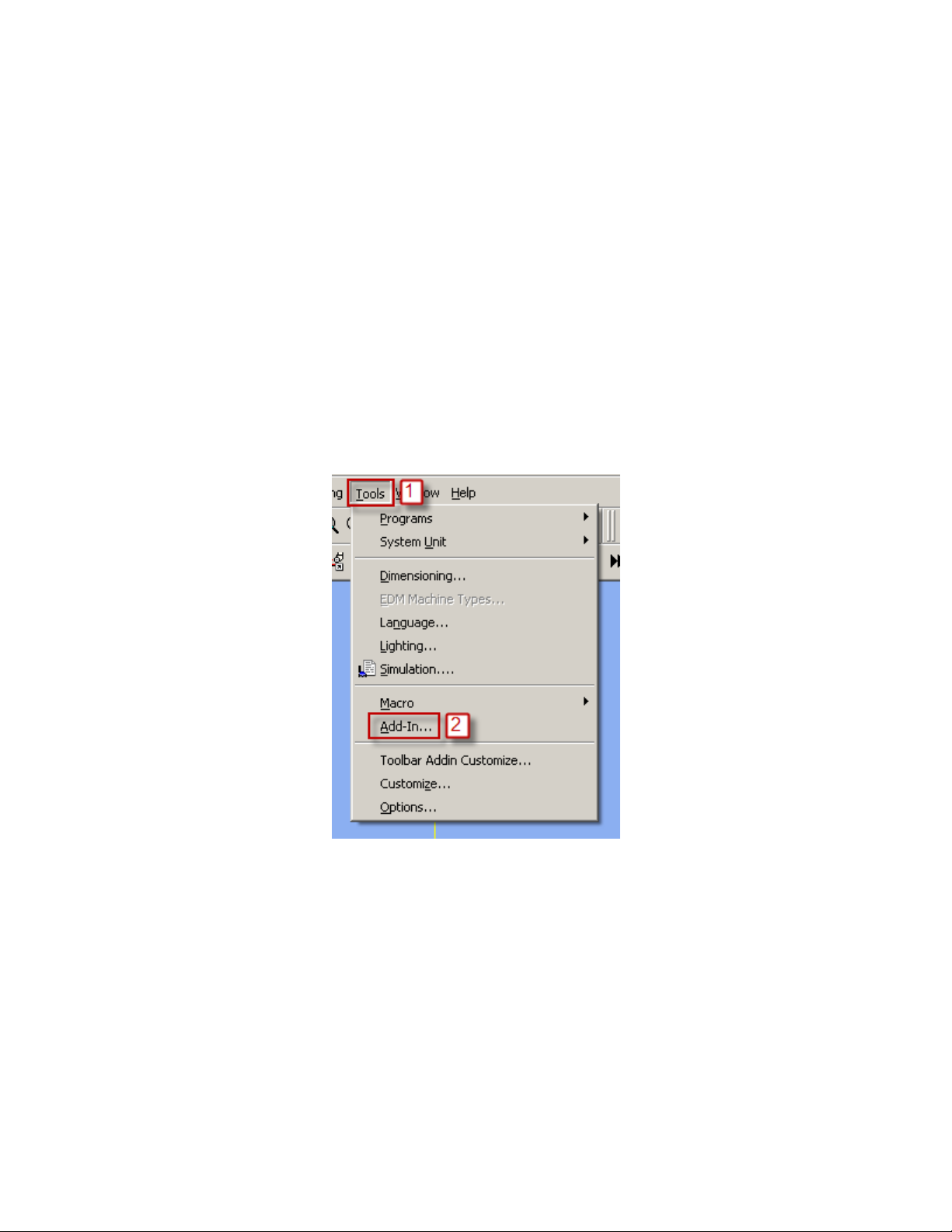

2.1.1. How to Load an Add-in in ESPRIT

To load an add-in in ESPRIT, from the Tools menu, select Add-In...:

1

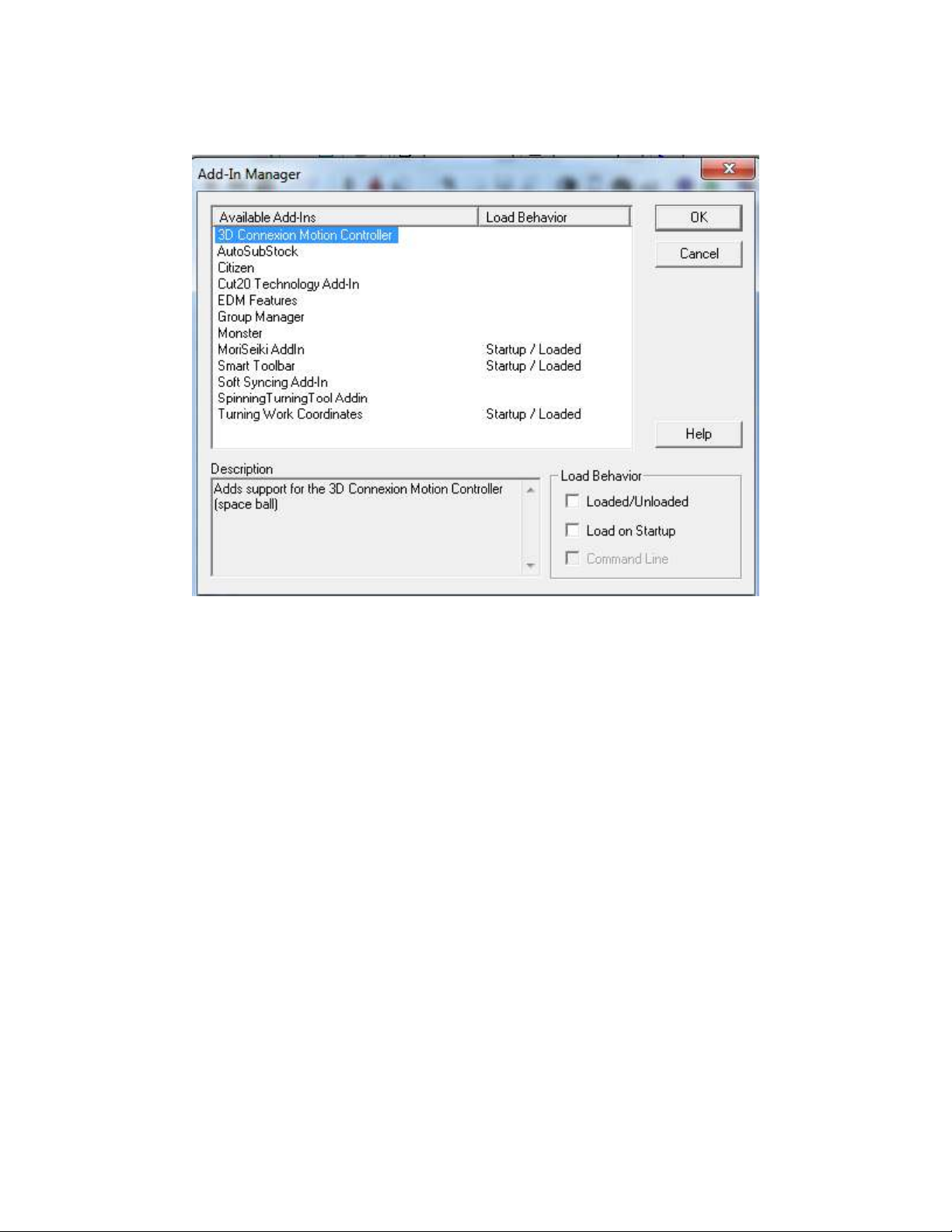

You will then see the add-in window:

2

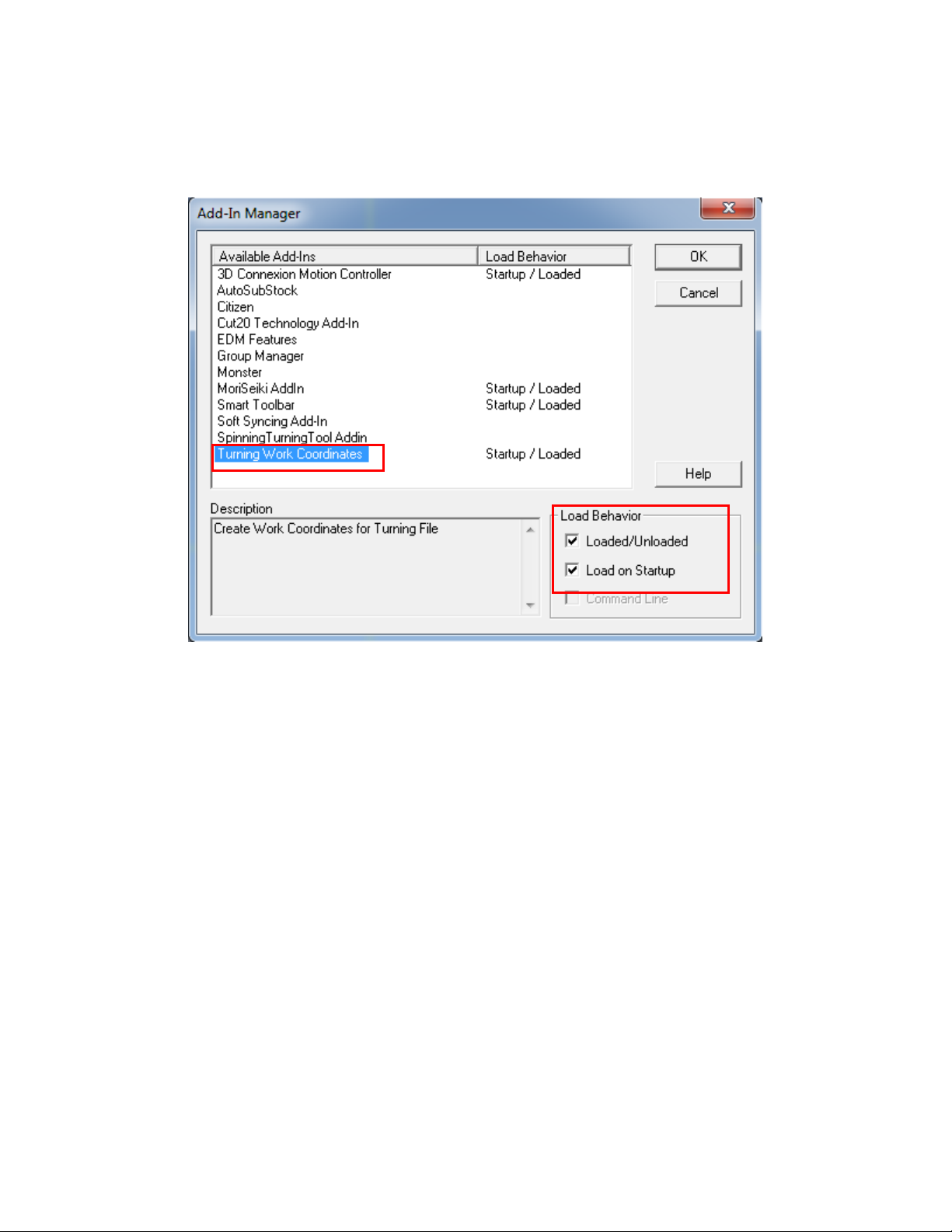

To load an add-in, highlight it in the Available Add-Ins list and check in Load Behavior

the box Loaded/Unloaded.

Check box Load on Startup so the addin will automatically load each time you start

ESPRIT

For the Mori Seiki NT series, you will need to load the following add-ins:

Turning Work Coordinates

Optional Addins that can also be loaded if needed:

Spinning Turning Tool Addin

AutoSubStock

3

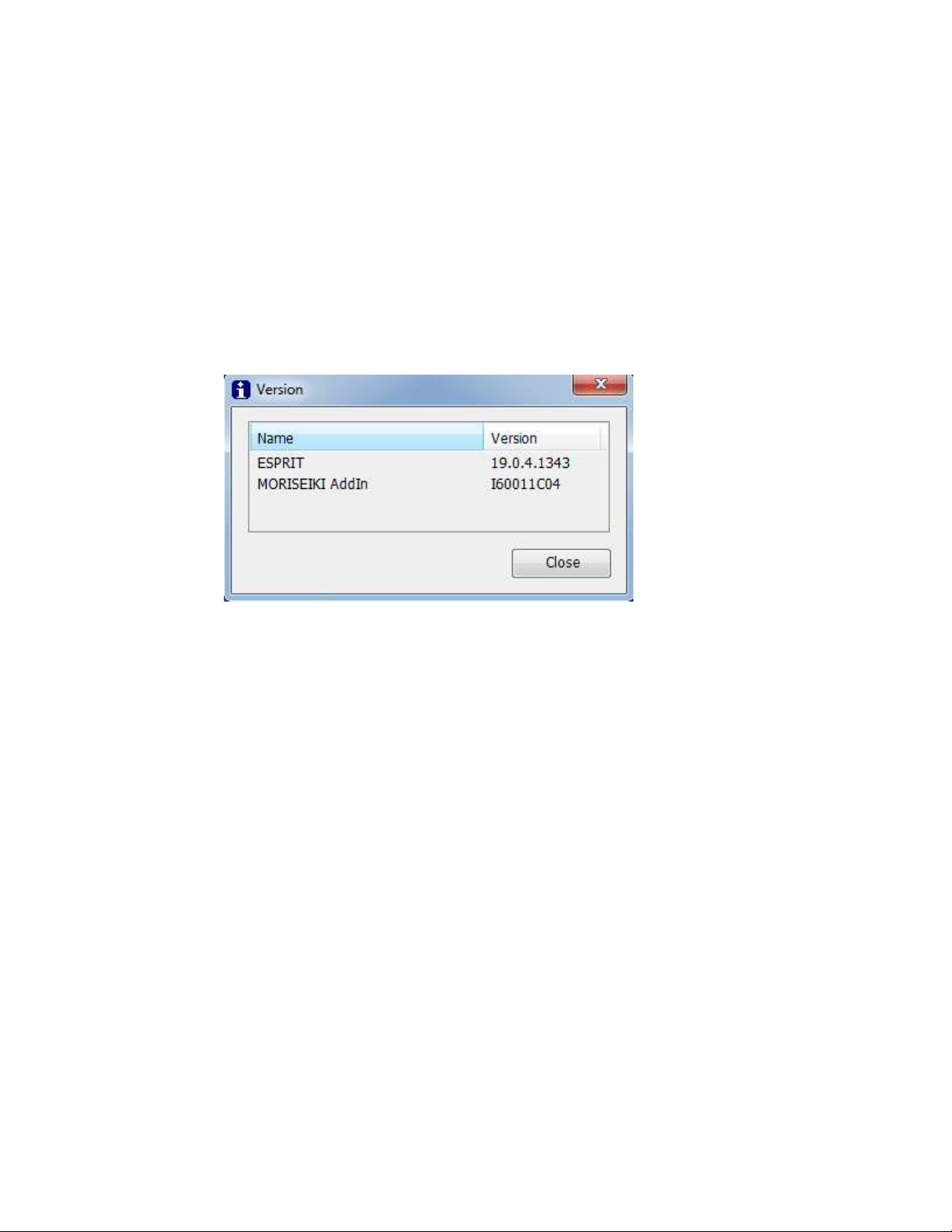

2.2. Mori Seiki ESPRIT for Mapps Addin

Installation of the Mori Seiki ESPRIT for MAPPS Addin is required. The Mori Seiki addin has a

number of components that are required for the programming of the Mori Seiki NT machines.

The Mori Seiki ESPRIT for MAPPS Addin is installed with the Mori Seiki Global installer.

The Mori Seki AutoPark addin is integrated with the ESPRIT Utilities.

ESPRIT for MAPPS addin version I60011C04 or newer is required

4

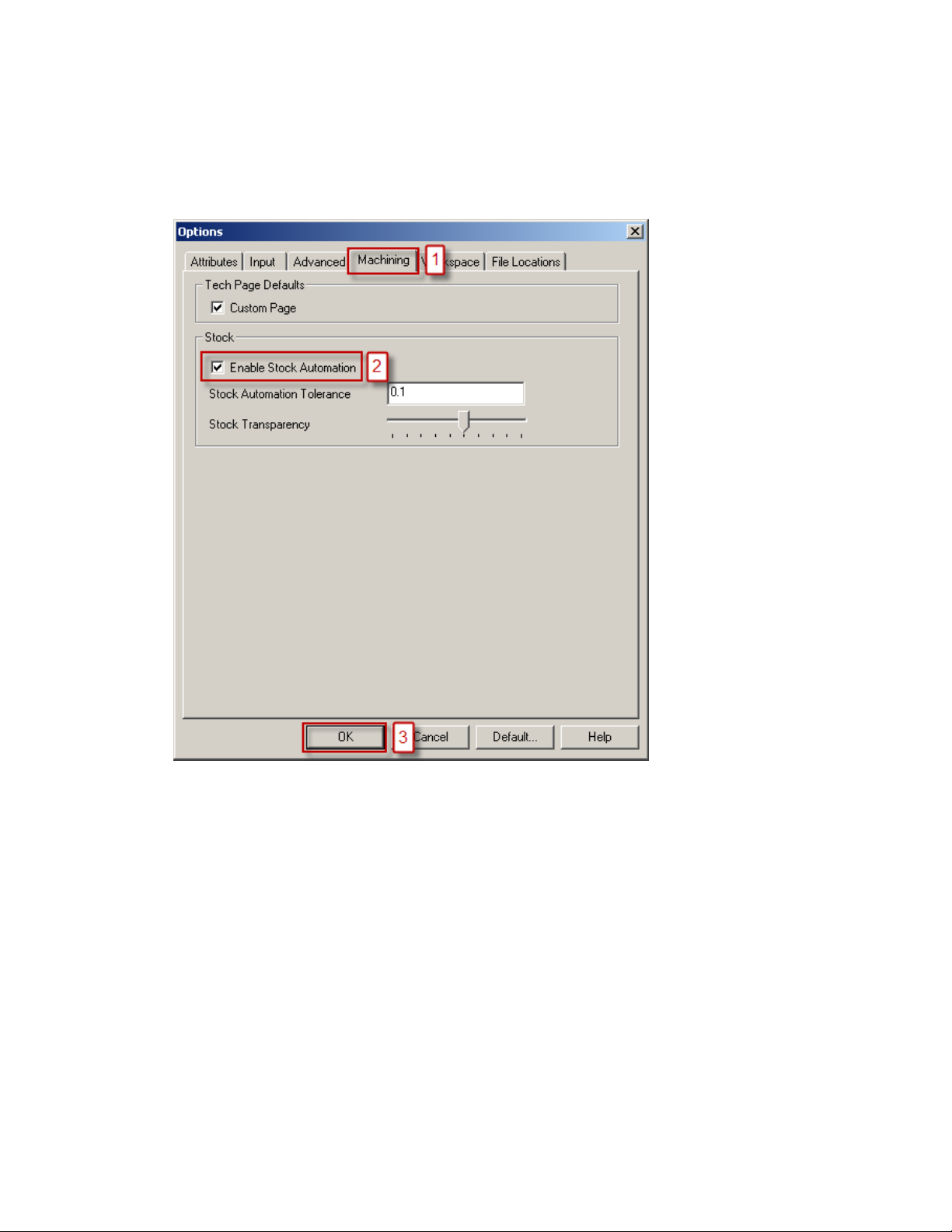

2.3. Stock Automation

In ESPRIT, from the Tools menu, select Options...

5

On the Machining tab, if you check Enable Stock Automation, The AutoSubStock add-in should

not be used since the Stock Automation will compute the state and shape of your stock present in

both the spindle 1 and spindle 2:

Please refer to the ESPRIT help file for additional information on stock automation.

6

SubStock

2.4. AutoSubStock (optional)

Important note: Note: If the Stock Automation function (above) is used, do not use the

AutoSubStock Addin.

The AutoSubStock add-in needs to be turned on prior to opening a file. This add-in will allow

you to correctly simulate the sub spindle work. It will also allow the simulation of production

work, when cutting on the main and the sub spindles at the same time.

Once you are done programming a part, simply play the entire simulation and once complete

click on Auto Sub Stock. This will save the sub stock in the sub spindle and stop the simulation.

If you restart the simulation, you will be able to see the cut on the main and sub spindles side all

at the same time.

7

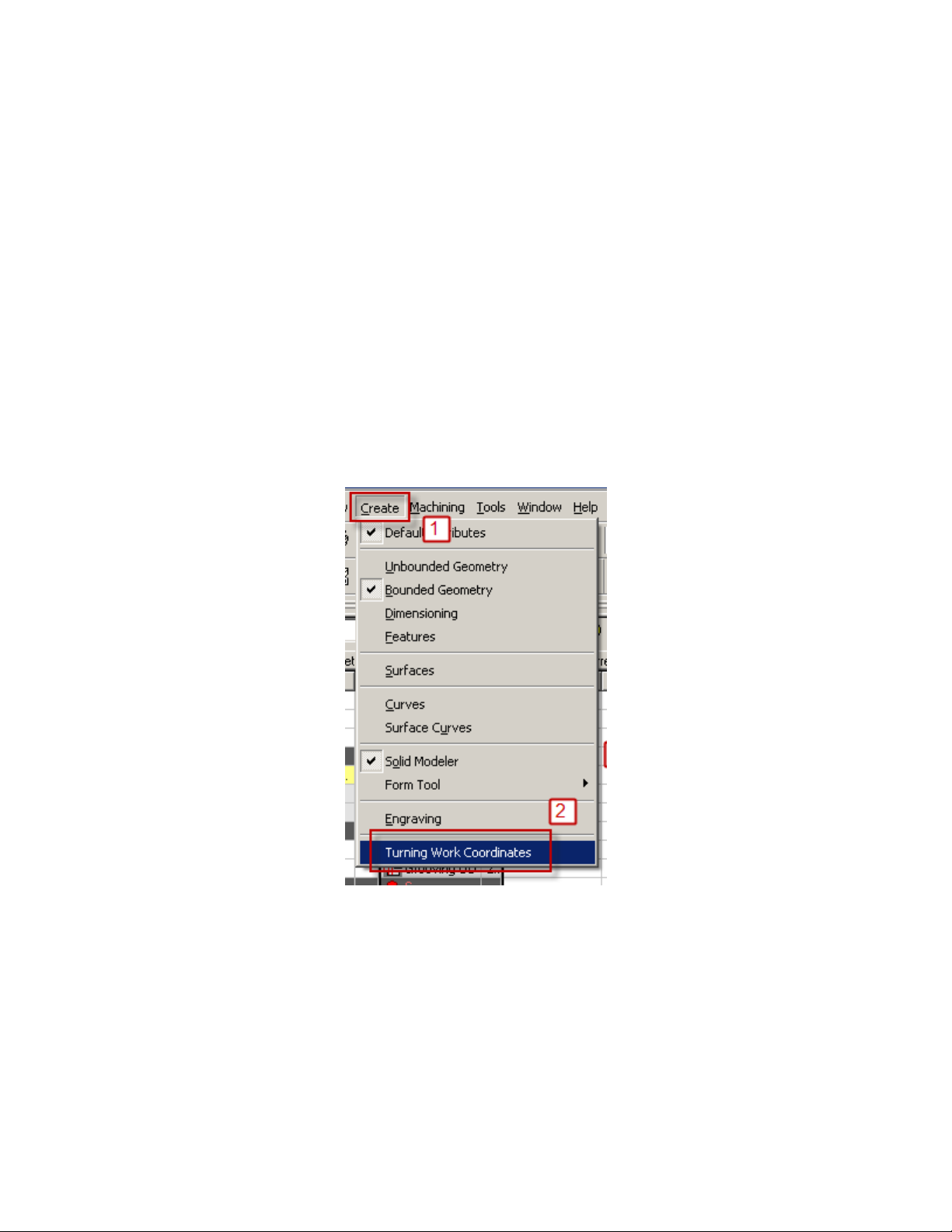

2.5. Turning Work Coordinates Addin

The Turning Work Coordinate add-in will sort your operations in the appropriate work

coordinates and also offset the NC code for the sub spindle operations. It is necessary to run this

add-in in order to generate correct NC code.

When the Addin is run the operations that have the Main Spindle selected will go under the

Work Coordinate (WC) created for the Main Spindle and the operations that have the Sub

Spindle. If an operation(s) are machined with the B axis at an angle other than -90, 0, +90 will be

placed in a “Baxis” version of the WC for the spindle the “tilted” operation is working on.

2.5.1. Setting Up the Turning WC addin

When first staring a new file in Esprit from the Create menu, select Turning Work

Coordinates.

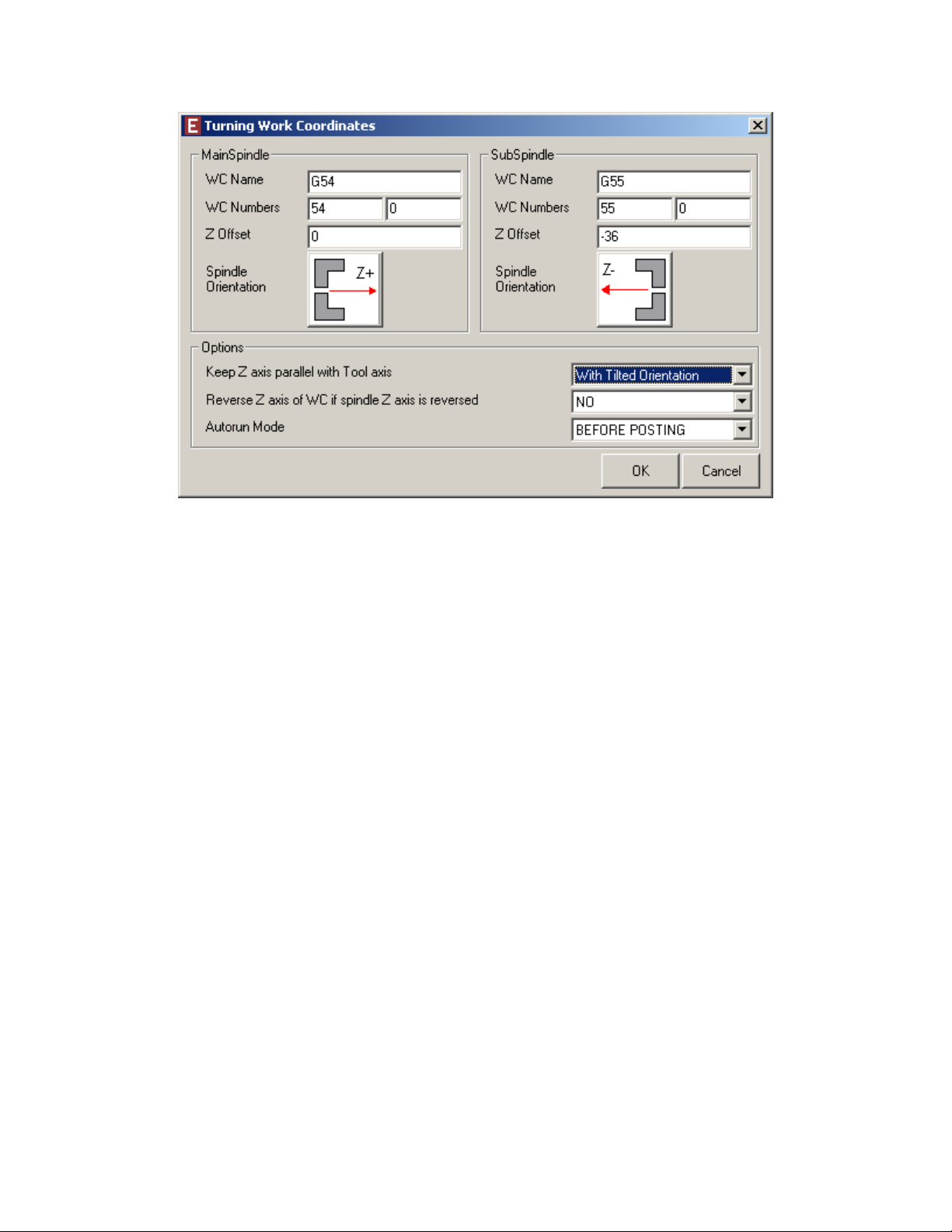

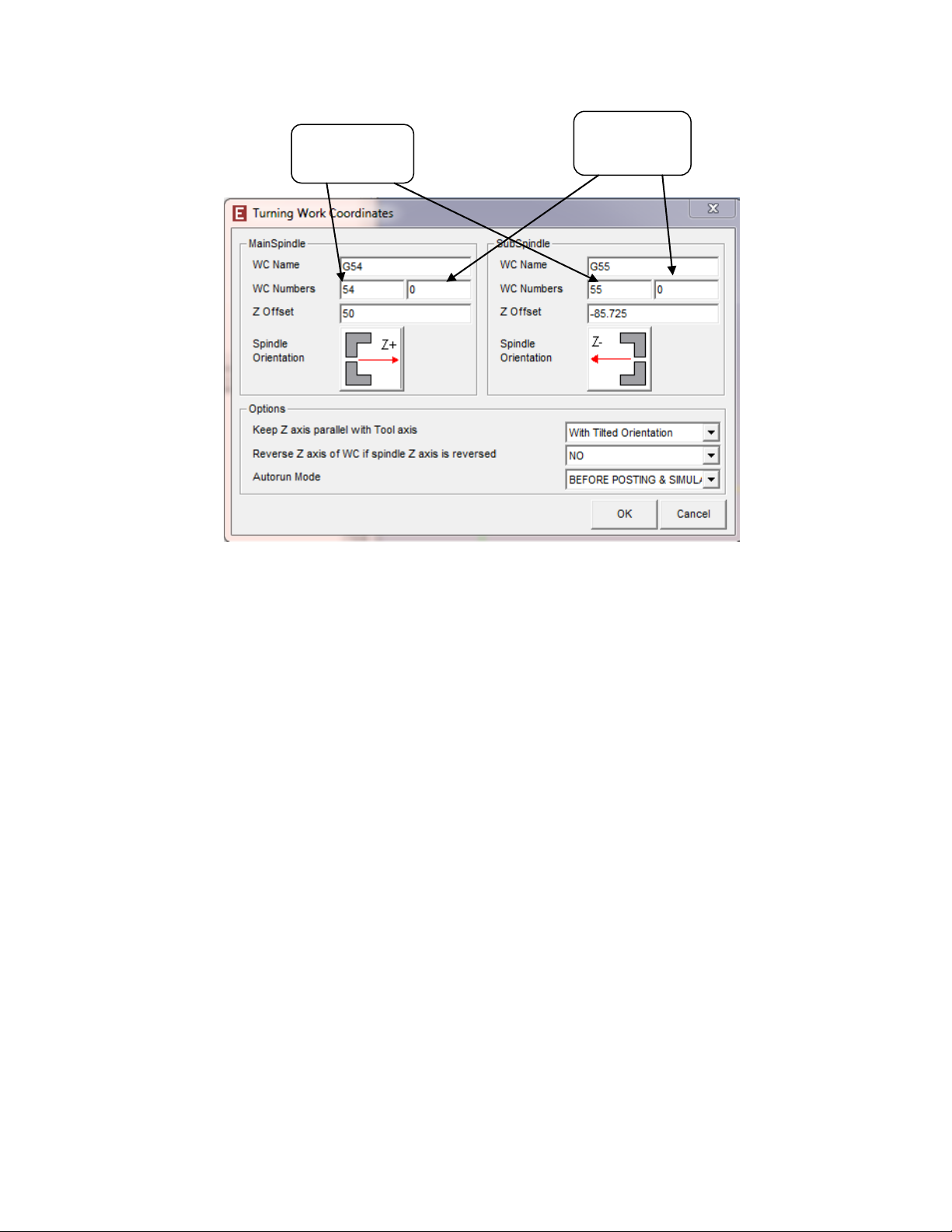

You will then see the Turning Work Coordinates dialog:

8

The Turning WC addin will look at your Machine Setup file and determine how the dialog

box needs to be setup for your machine. The Spindle names and orientation information in

the dialog box are taken directly coming from the Machine Setup.

WC Name: Corresponds to the Work Coordinate name. Please note that the name is just

informative and will not affect the NC code. This name will appear in the feature list inside

of Esprit.

WC Numbers: Both fields are used by the post. The Machine control has two sets of

offsets that can be used. The standard work coordinates (G54-G59) and the extended work

coordinates (G54.1 Pxx)

9

Standard

WC Field

Additional

WC Field

o The Standard WC number is used to output G54-G59. Enter 54 to have G54 in

NC code. 55 to have G55 in NC code, etc. If a machine is equipped with 2

spindles a value must be set for both spindles. When using the machines Standard

Work Coordinates (G54-G59) a zero (0) must be entered into the Additional

offset field.

Note: The NT1000 post has G59 is reserved for use on the Sub spindle when it is

tilted. If programming an NT1000 do not enter 59 into a WC in Esprit) .

o The Additional WC number is used to output extended work coordinate in the NC

code (G54.1 Pxx). For example if a 1 is entered into the Additional WC filed a

G54.1 P1 will be output in the NC code. When outputting the extended work

coordinates (G54.1 Pxx) a value of zero (0) must be entered into the Standard WC

field.

Z Offset: Used to setup the location of the work coordinates in Esprit. This is most

commonly only used for the sub spindle.

o Main Spindle: Typically set to zero. This means the program zero for main

spindle is P0 (World Zero) in Esprit.

o Sub Spindle: The sub spindle value is typically set to the negative value of the

finish part length. The value is pre-loaded from the Part Stock Length field of the

Machine Setup (on the General tab). For example if the finish part length is

100mm you would enter -100 in the Sub Spindle Z offset Field. The work

coordinate will be offset by minus this amount from P0.

10

o The Z offsets MUST have the correct values in them to have correct Z axis values

in your NC code.

Spindle Orientation: This information is coming from the Machine Setup and is just

informative.

11

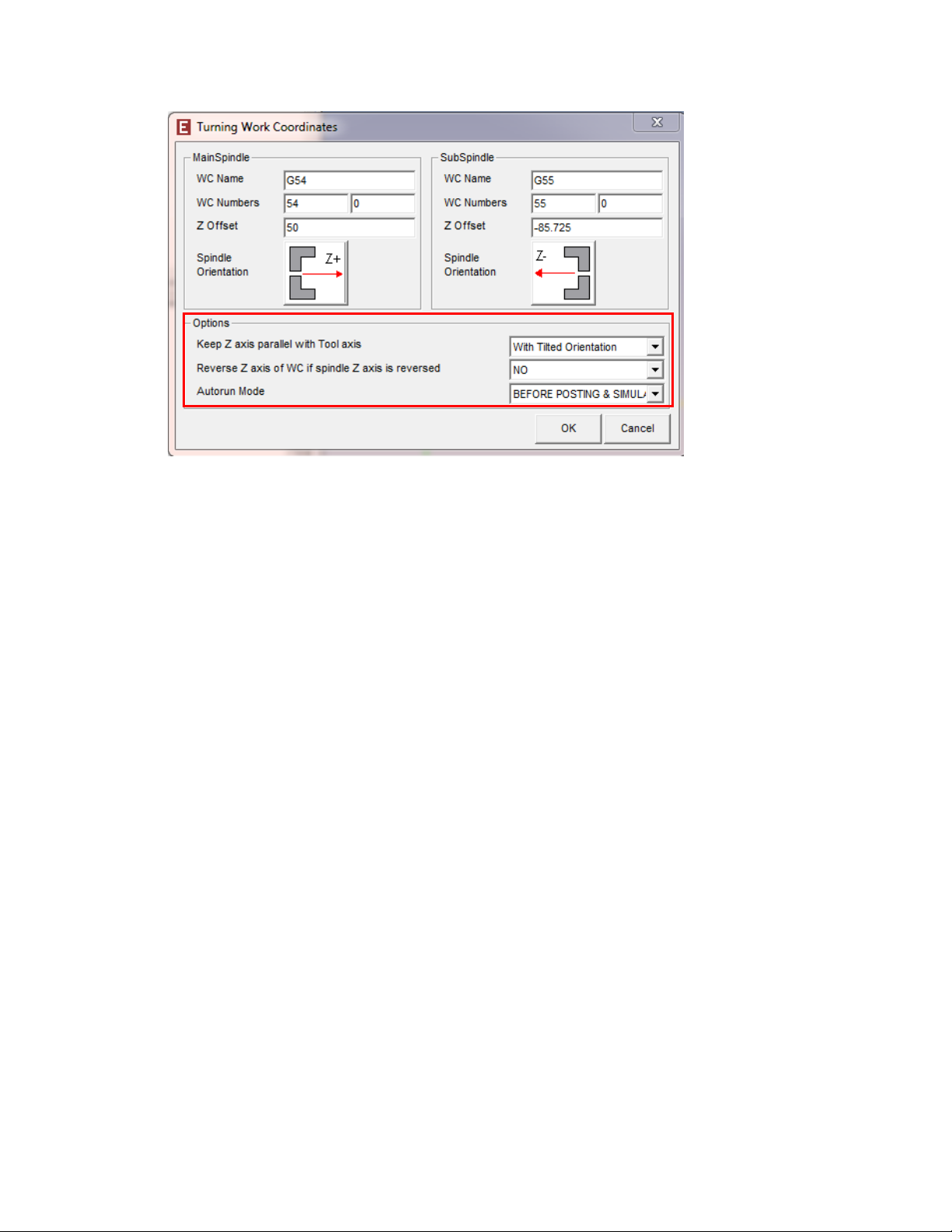

Options Section:

Keep Z axis parallel with Tool axis: This MUST be set to “With Tilted Orientation”

Reverse Z axis of WC if spindle Z axis is reversed: MUST be set to NO

Auto Run Mode: it is best to have the “Before Posting and simulation” Option selected.

This will cause the addin to run every time you simulate and post NC code and ensure

that the operations fall under the correct WC, this ensuring your NC code is correct.

2.6. AutoPark Addin (required on NT1000 machines)

The ESPRIT AutoPark addin was designed to help users park the turrets to the extreme travel

limits without having known the exact location of the travel limits in the machine coordinate

system. The NT machines are setup to use the Auto Park addin to positions the Head\Turret to

the left most position in the travel envelop of the NT machines.

In addition the AutoPark addin is used to position the A axis (Sub Spindle) in the NT1000

machines to ensure correct NT code and simulation.

The AutoPark Addin is only for use with ESPRIT 2012 or newer and the ESPRIT 2012 or newer

Mori Seki addin.

In addition the AutoPark addin will only function correctly if you have the latest Machine Setups

created for the ESPRIT 2012 or newer packages. ESPRIT files created prior to ESPRIT 2012

will need the Machine Setup pages updated to use the AutoPark addin.

12

For information as to how to use the addin please refer to the Setting up the park operation with

the AutoPark addin and Setting A-axis Position with the AutoPark Addin sections of this

manual.

13

1

2 3 4

5

3. Machine Setup

3.1. Introduction

Some important settings regarding the NC output are set in the Machine Setup.

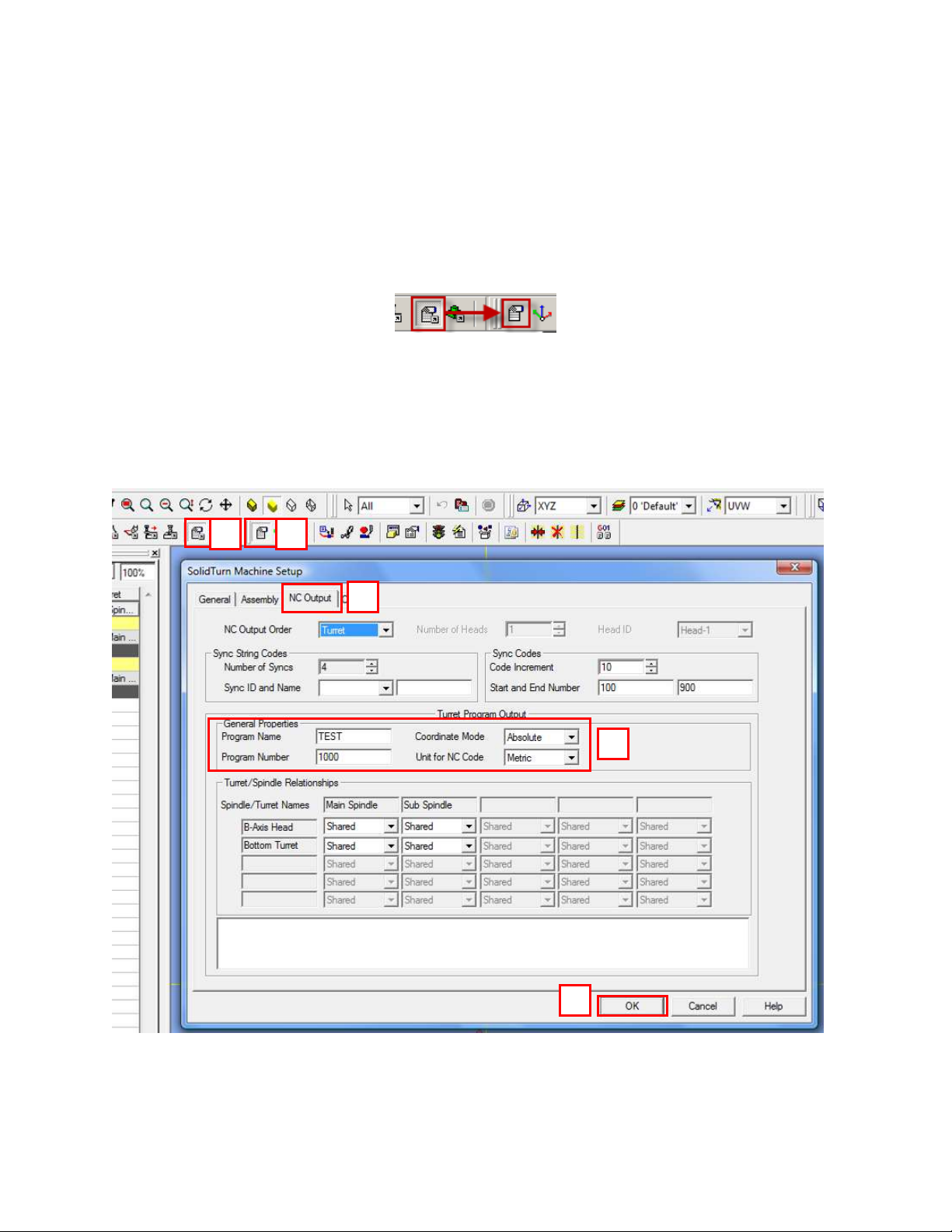

To open the Machine Setup, click on Common Machining and then on Setup:

3.2. Set the Program Name, Program Number

To set the program name and number output at the beginning of your NC code on each channel,

you will need to go to the NC Output tab of the Machine Setup. Under General Properties of the

Turret Program Output, enter the name of your program, its number. You can also specify here

the unit of your NC code and the coordinate mode.

14

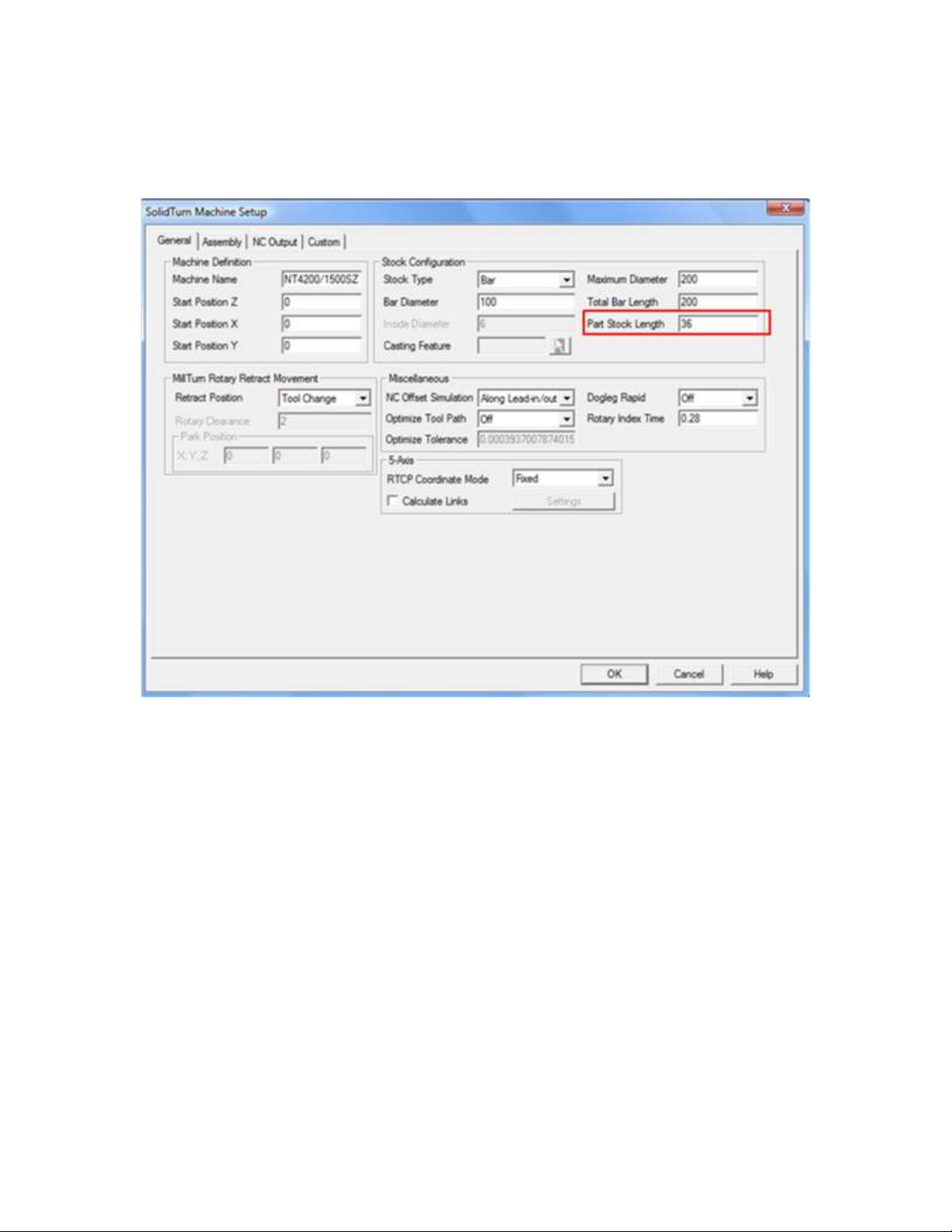

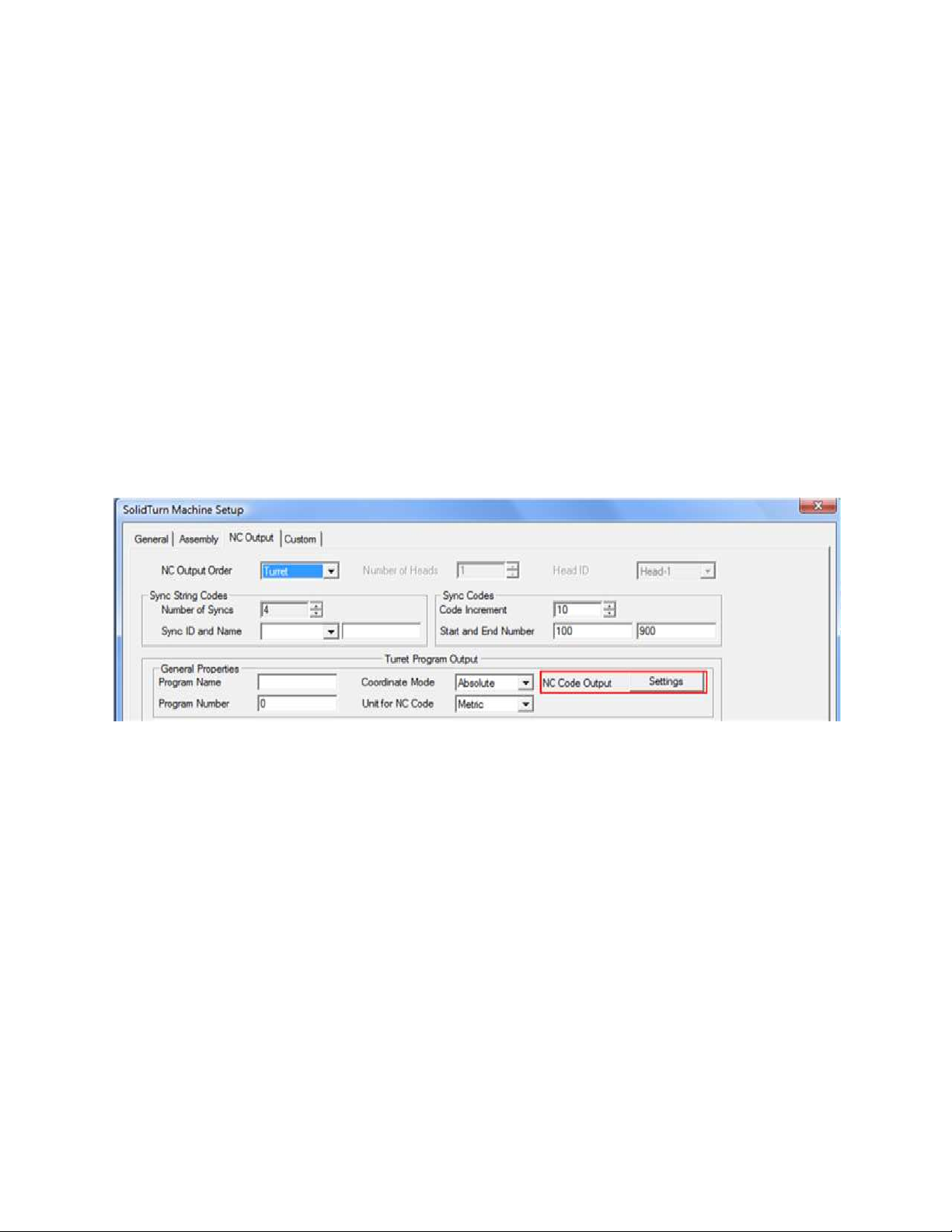

3.3. Define the Turning Stock

On the General tab of the Machine Setup, you can define your turning stock. For turning

operations, if you are using the Stock Type Automation, your NC output will be linked to the

defined turning stock.

Use Start Position Z to position the stock along the Z axis. It will be used, for example, to define

the front face facing amount.

Use Stock Type to define the shape of your stock: Bar, Tube (Inside Diameter will then be

available) or Casting (Casting Feature will then be available for selection).

Use Bar Diameter to specify the diameter of your stock.

Use Total Bar Length to define the total length of your stock.

Finally use Part Stock Length to define the length of your finish part. This will be used by the

Turning Work Coordinates add-in.

Note: ESPRIT supports a number of different stock configurations. Please consult the ESPRIT

Help file for detailed information.

15

In order to use the stock configuration from the machine setup dialog box you must have the

Simulate Turning Stock field (Found in the Simulation Parameter dialog box) checked (as shown

below):

16

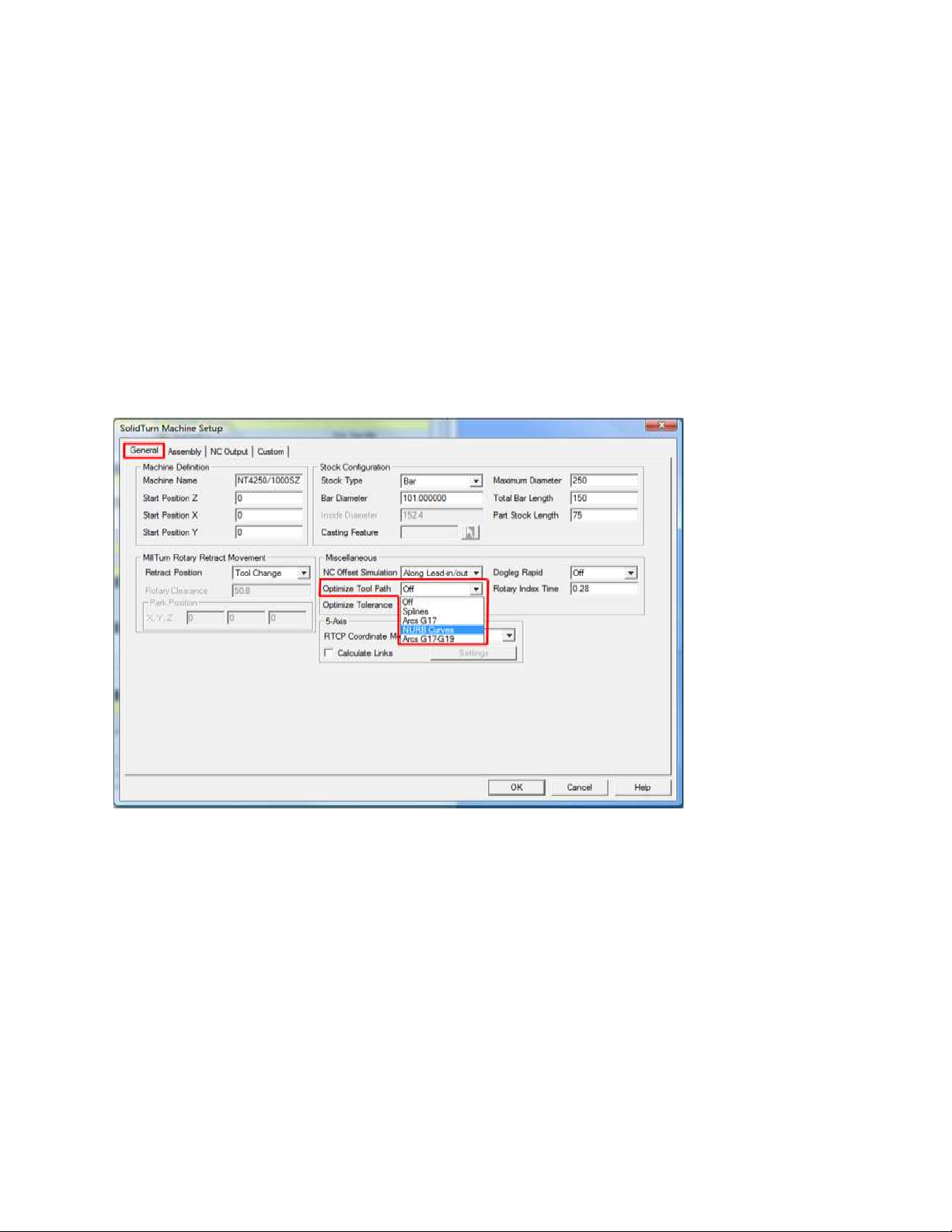

3.4. Tool Path Optimization with NURBS

With the Mori Seiki NT series machines, it is possible to translate non-uniform rational B-splines

(NURBS) used in modeling sculptured or curved surfaces directly in NC units. This is especially

helpful when programming complex three dimensional molds and tool dies.

To turn on NURBS Optimization in ESPRIT, navigate to the Machine Setup page and the

General tab. Under “Miscellaneous” there is a pull down labeled “Optimize Tool Path” open this

and scroll down to “NURBS Curves” to select NURBS optimization. Click OK to complete this

function.

Machine Setup General Tab

17

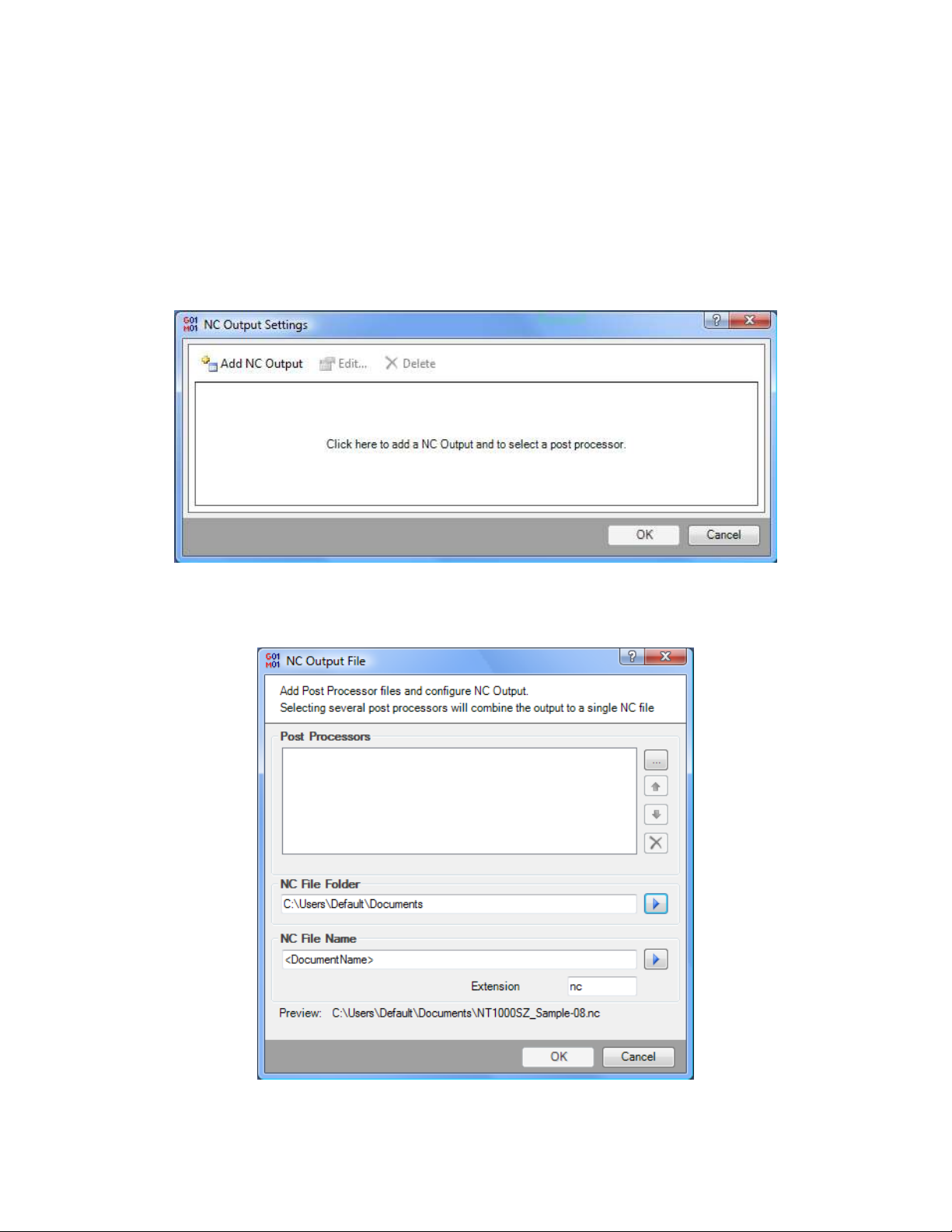

3.5. Selecting Post Processors and Outputting NC Code

Starting in ESPRIT 2011, there is now a new tool to output NC code from any ESPRIT file.

Now, the user simply needs to select NC Code from the Common Machining toolbar. The first

time that NC code is posted, ESPRIT will prompt the user to select the file location of the post

processor(s) to be used. The user will see the following window pop up upon first selecting NC

Code:

By selecting the “Add NC Output” button, the user is able to select the appropriate file location

for their post processor as well as determine the file location of the resultant NC code as well as

the name of the NC code file and file extension type:

18

For multi-turret machines such as the NT-SZ, NT1000WZ and NT1000SZ, the user should select

each turrets post processor separately and give each file a unique NC File Name. Once the user

has selected one post processor, they are able to select Add NC Output again and create a new

NC Output file for the other post processor, again with a unique NC File Name.

Once the user selects all necessary post processors and selects OK from the NC Output Settings

window, NC code will be generated and appear in the users selected NC code editor.

The next time the user chooses NC Code from the Common Machining toolbar, the NC code will

automatically be generated, without having to interface with the NC Output Settings window

again.

Note: If the user receives new post processors or would like to make any changes to the file

location or file name, they are able to do this by navigating to the Machine Setup in the Common

Machining toolbar. On the “NC Output” tab, there is a section on the right hand side called NC

Output Settings that will bring the user back into the NC Output Settings window and allow them

to make the necessary changes.

19

3.6. Machine Parameters

3.6.1. Introduction

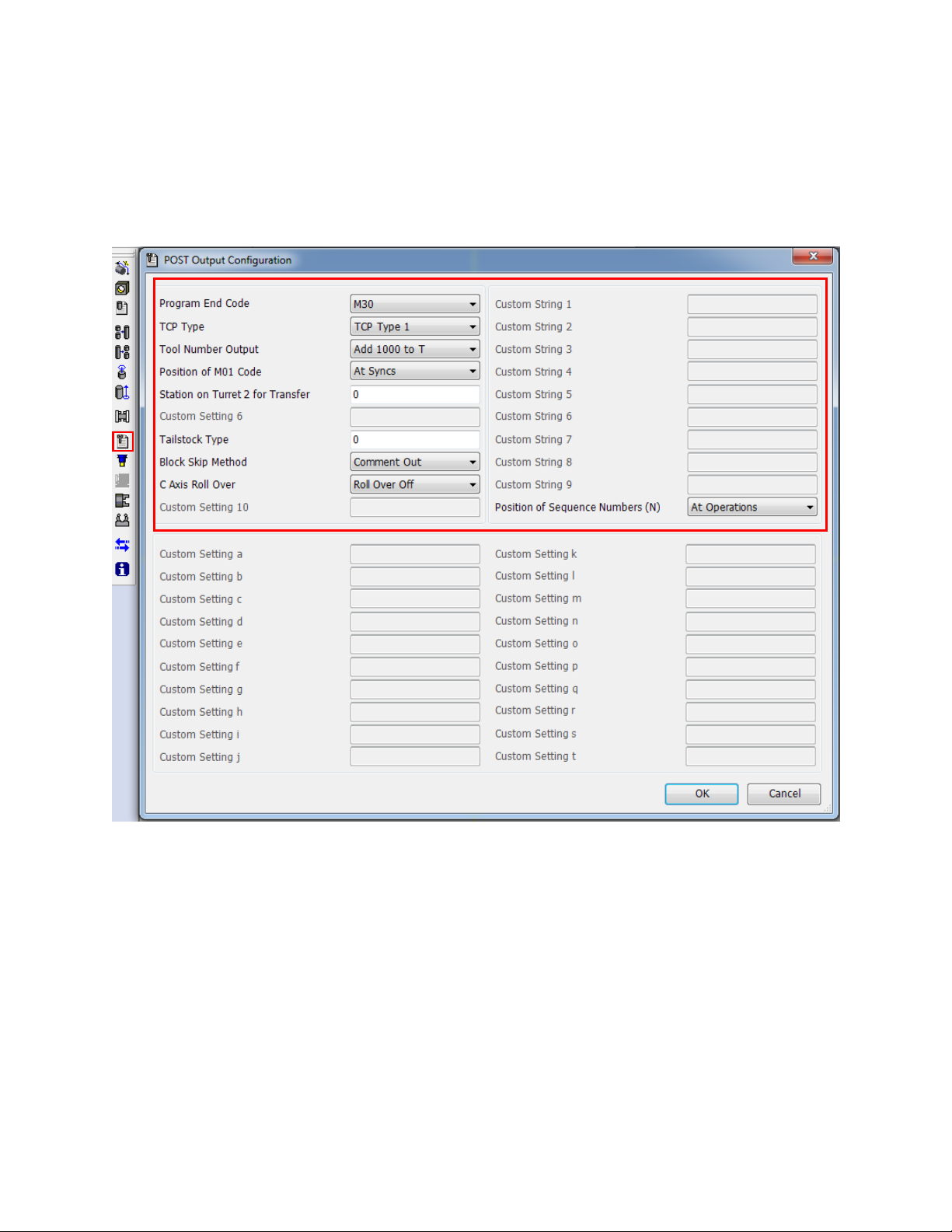

Machine parameters can either be set on the Machine Parameters tab of the Machine Setup

Utility (part of the MoriSeik AddIn).

3.6.2. Output of Program End (M02), Sub-Program End (M99) or

Program End and Rewind (M30)

On the POST Output Configuration, set Program End Code to M02 to output M02, set it to

M30 to output M30 or set it to M99 to output M99 at the end of the NC code of each turret.

Please note that M30 is the default.

20

3.6.3. TCP Type

This setting is to choose between G43.4 and G43.5 modes when machining in 5 axis

simultaneous mode. Type 1 is G43.4 and Type 2 is G43.5. Please see section 5-axis

Simultaneous Milling Options for more information on these options.

3.6.4. Set position of optional stop code (M01) in the NC code.

Upper head only machines (turrets (NT-S, NT1000-S, NT1000-W) have 2 options for outputting

the optional stop code (M01).

At Operations (at the end of every operation)

At Tool Cancel (at the end of a tool or at the end of an operation where the B axis angle,

spindle changes, or anything else that causes the post to output tool cancel section of NC

code)

By default, optional stop codes are output at the end of every operation.

Machines equipped with a lower turret (NT-SZ, NT1000-SZ, NT1000-WZ) have an a 3 options

for outputting the optional stop code:

At Syncs (at every sync in the ESPRIT file’s operation list)

At Operations (at the end of every operation as well as at every sync)

At Tool Cancel (at the end of a tool or at the end of an operation where the B axis angle,

spindle changes, or anything else that causes the post to output tool cancel section of NC

code, as well as every sync)

By default, optional stop codes will be output on each head after sync codes in the NC code

on a lower turret machine this way, optional stop can be turned on while running the NC

code on both heads at the same time (production mode).

The “At Operations” and “At Tool Cancel” can only run with the optional stop mode on

when running the machine at one head at a time (NC code proofing mode).

3.6.5. Station on Turret 2 for Transfer

If this value is not zero, this station 1 will be used as empty station during part transfer and part

release on release operations in the lower turret (NT-S and NT-SZ). If the tool station for is left

zero the turret will be left at the current station when the turret is parked by the transfer section in

the post.

By default this value is 0

21

Note: The lower turret can be parked to the lower turret park location with the park operation

before the transfer is programed. If this is done, the post will not move the turret or change the

station of the turret even if this setting is not zero.

For additional information see the Park Cycles section of this manual.

3.6.6. Tail Stock Type

This option is used to determine an “independent” tail stock is in the sub spindle of the machine

used as a live center or a standard tails stock mounted on the machine.

If a value of 0 is entered in the Tail Stock Type setting, the post will assume the machine is using

an independent tail stock.

If a value of 1 is entered the post will assume the center is in the sub spindle of the machine.

By default this setting is 0

For additional information see the Tailstock section of this manual.

3.6.7. Block Skip Method

When using spindle priority on turning cycles on lower turret type machines (see part Other

Turning Cycles section for additional information), you can use choose which symbol will be

output to skip the turning spindle control (spindle start and spindle stop as well as the spindle

speeds) on the slave turret.

Comment Out will put the spindle commands inside of a comment as follows “( G97 S2139

M04 )” in the slave turrets program

Block Skip will output a block skip “/” before the spindle commands in the slave turrets program

Block Skip 2 will output a block skip “/2” before the spindle commands in the slave turrets

program

By default Comment out is used.

3.6.8. C-Axis Rollover

For the Mori Seiki NT-SZ machine, it is sometimes necessary to limit the C-axis rotation angle

to between -360 and 360 degrees.

Roll Over Off will turn off roll over in the post.

Roll Over On will turn on C-axis roll over in the post.

By default Roll Over Off is used.

22

The Roll over function will need to match the mode of the machines control:.

On machine control, if <Roll over for C-axis> is invalid

(NC Parameter 1008 bit 0 = 0):

min. C-axis value is -99999.999°

max. C-axis value is +99999.999°

In ESPRIT use Roll Over Off

On machine control if <Roll over for C-axis> is valid

(NC Parameter 1008 bit 0 = 1):

min. C-axis value is -359.999°

max. C-axis value is 359.999°

In ESPRIT use Roll Over On

When C-axis roll over is on, C-axis will be indexed between -360° and 360°:

C-axis will be indexed with C values.

SolidMillTurn 4-axis wrap and rotary operations with interpolation off cannot be

programmed.

23

Loading...

Loading...