Page 1

Home > SPR1100 Handbook

1553-FGC 101 1400 Uen A

Ericsson SPR1100

Stream Processor

HANDBOOK

SPR11/CHASSIS/1AC, SPR11/CHASSIS/2AC, SPR11/CHASSIS/1DC,

SPR11/CHASSIS/2DC and Options

Software Version 6.0.11 (and later)

© Ericsson AB 2011. All rights reserved

Page 2

Home > SPR1100 Handbook > Preliminary Information

Preliminary Information

Scope of This Information

This topic defines who should use this information, and what equipment and options are

covered.

About This Information

Tabulates the history of this information. Lists the templates and style sheets used to create

the file.

Trademarks

List the trademarks and registered trademarks associated with the equipment.

Warning, Cautions and Notes

Defines the use and format of Warnings, Cautions and Notes throughout this information.

Contact Information

Gives contact information for Ericsson Customer Services, and Technical Training.

Compliance Statements

Compliance statements relating to EN55022/AS/NZS 3548 and FCC.

© Ericsson AB 2011. All rights reserved

Page 3

Home > SPR1100 Handbook > Preliminary Information > Scope of This Information

Scope of This Information

Who Should Use this Handbook

This guide is written for operators and users of the Ericsson SPR1100 and describes its

functions and operation. It will assist in the installation and day-to-day care and operation of

the unit. Maintenance information that requires covers to be removed is not included.

WARNING!

Do not remove the covers of this equipment. Hazardous voltages are present within this

equipment and may be exposed if the covers are removed. Only suitably trained and

experienced service engineers are permitted to service this equipment.

CAUTION!

Unauthorised maintenance or the use of non-approved replacements may affect the

equipment specification and invalidate any warranties.

Equipment Covered by this Handbook

Equipment Models

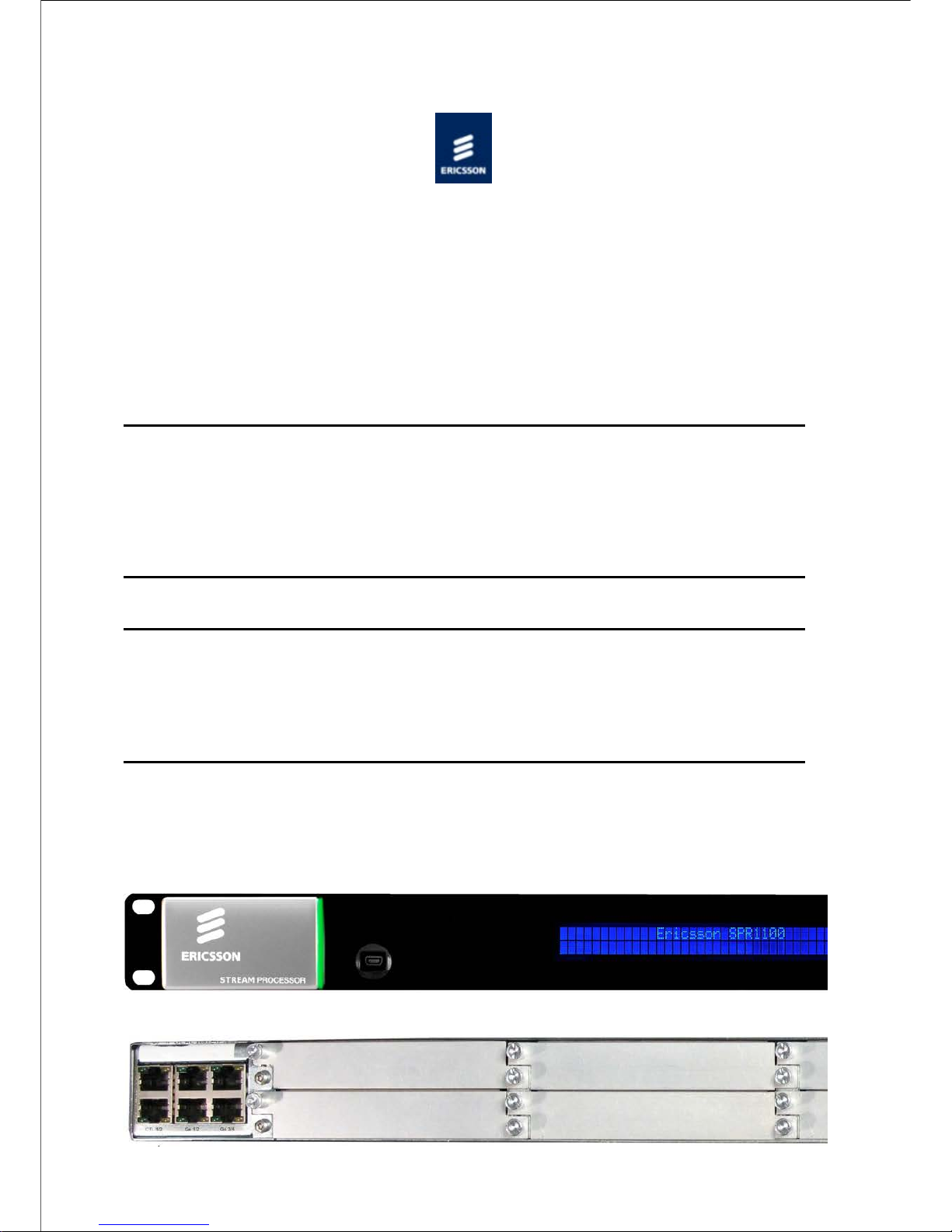

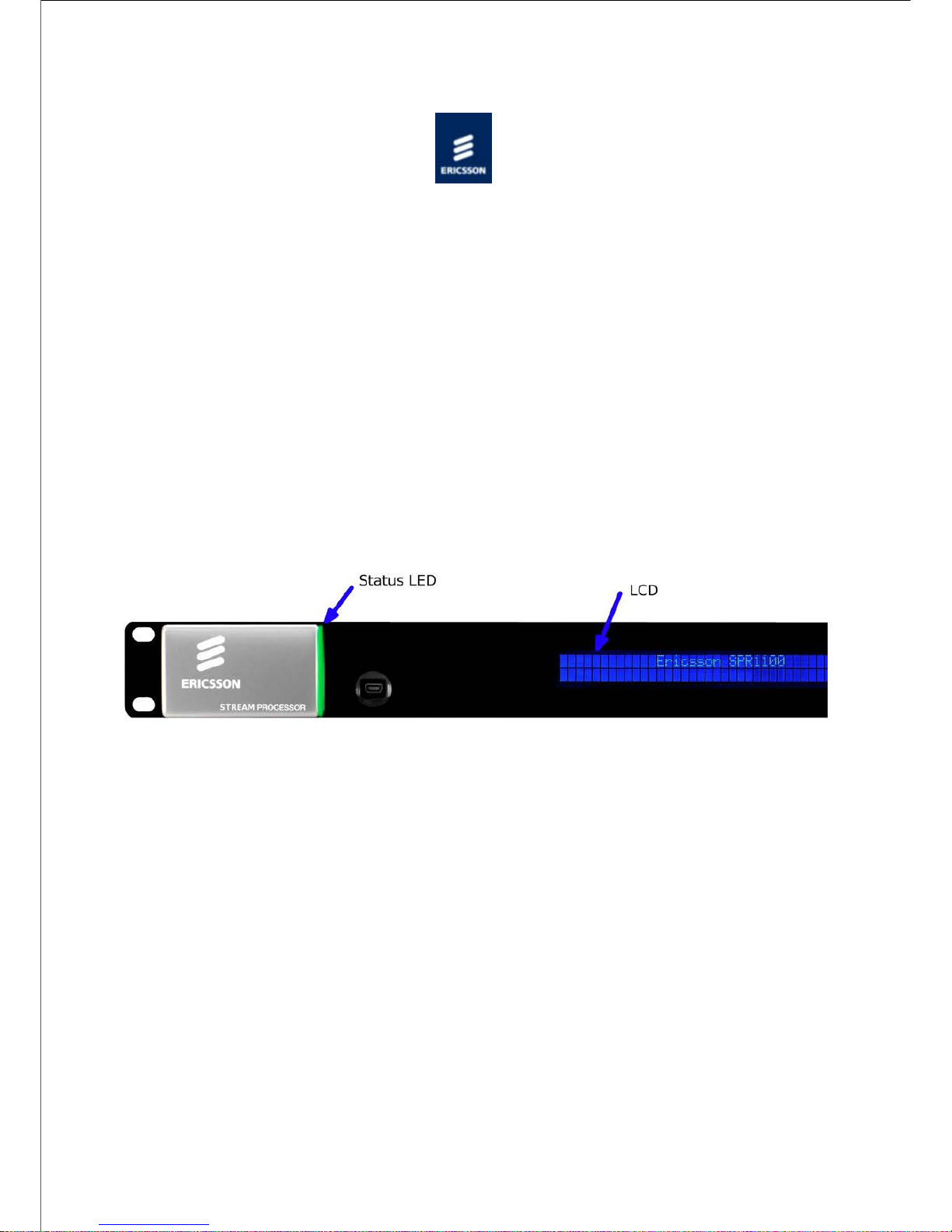

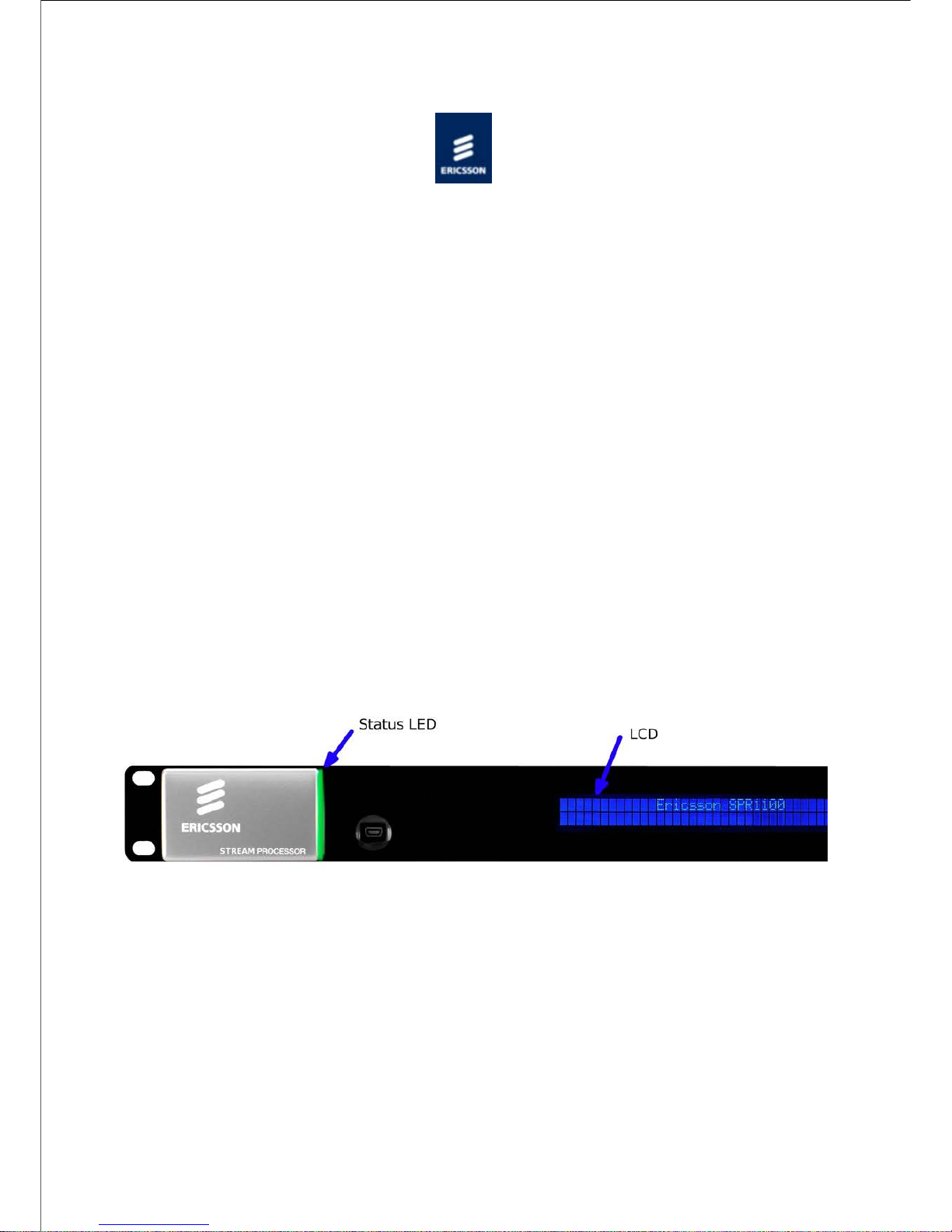

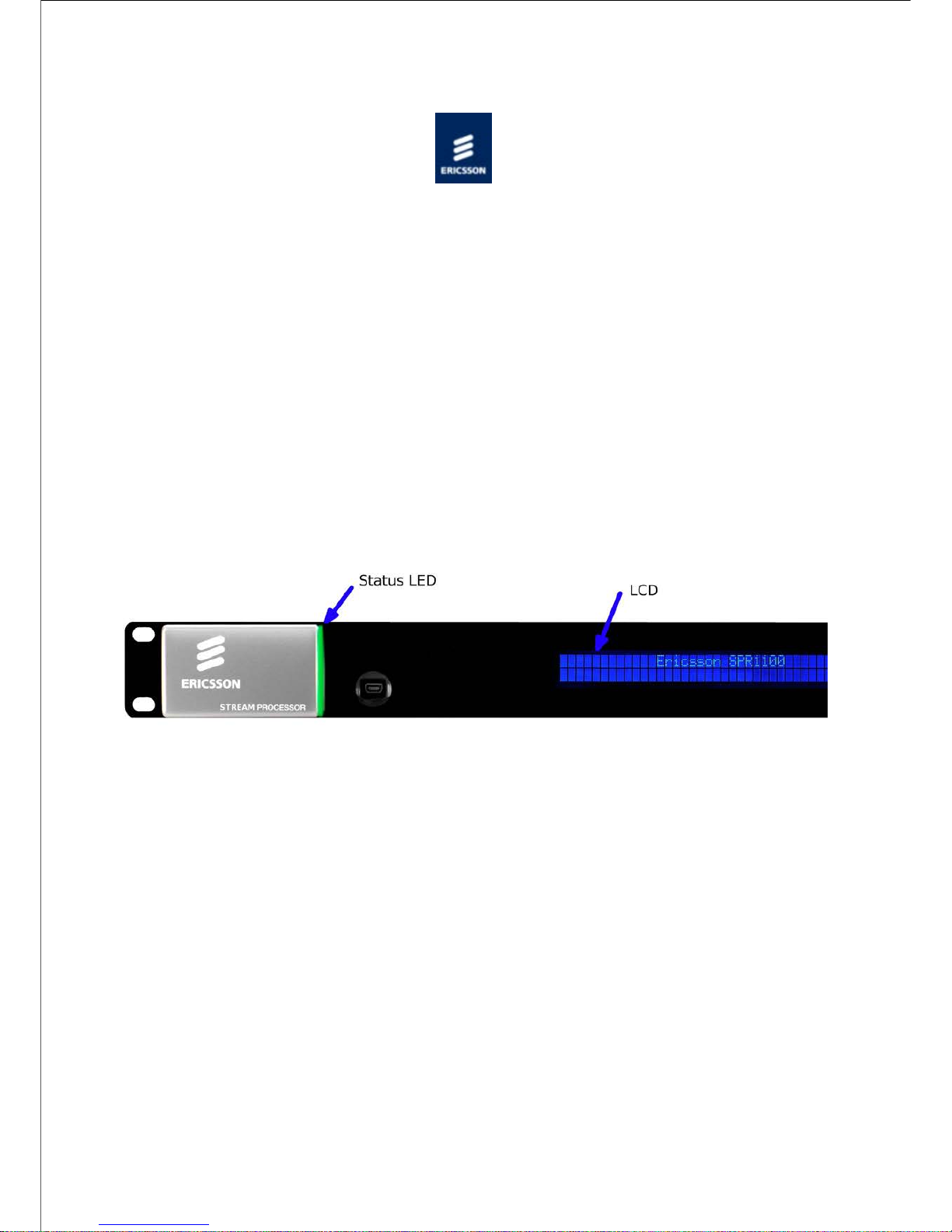

Front View of the Ericsson SPR1100.

Page 4

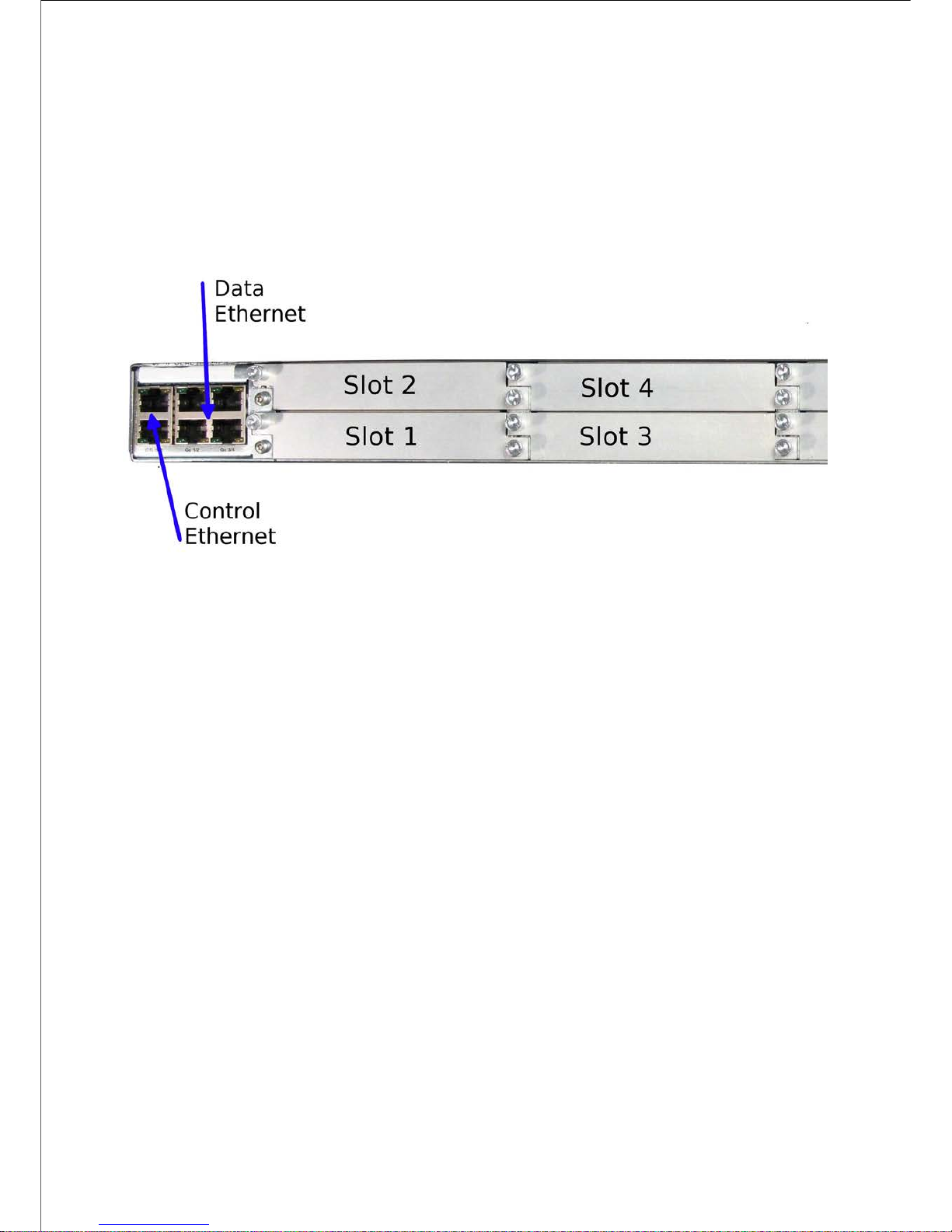

Rear View of the Ericsson SPR1100, single AC PSU variant.

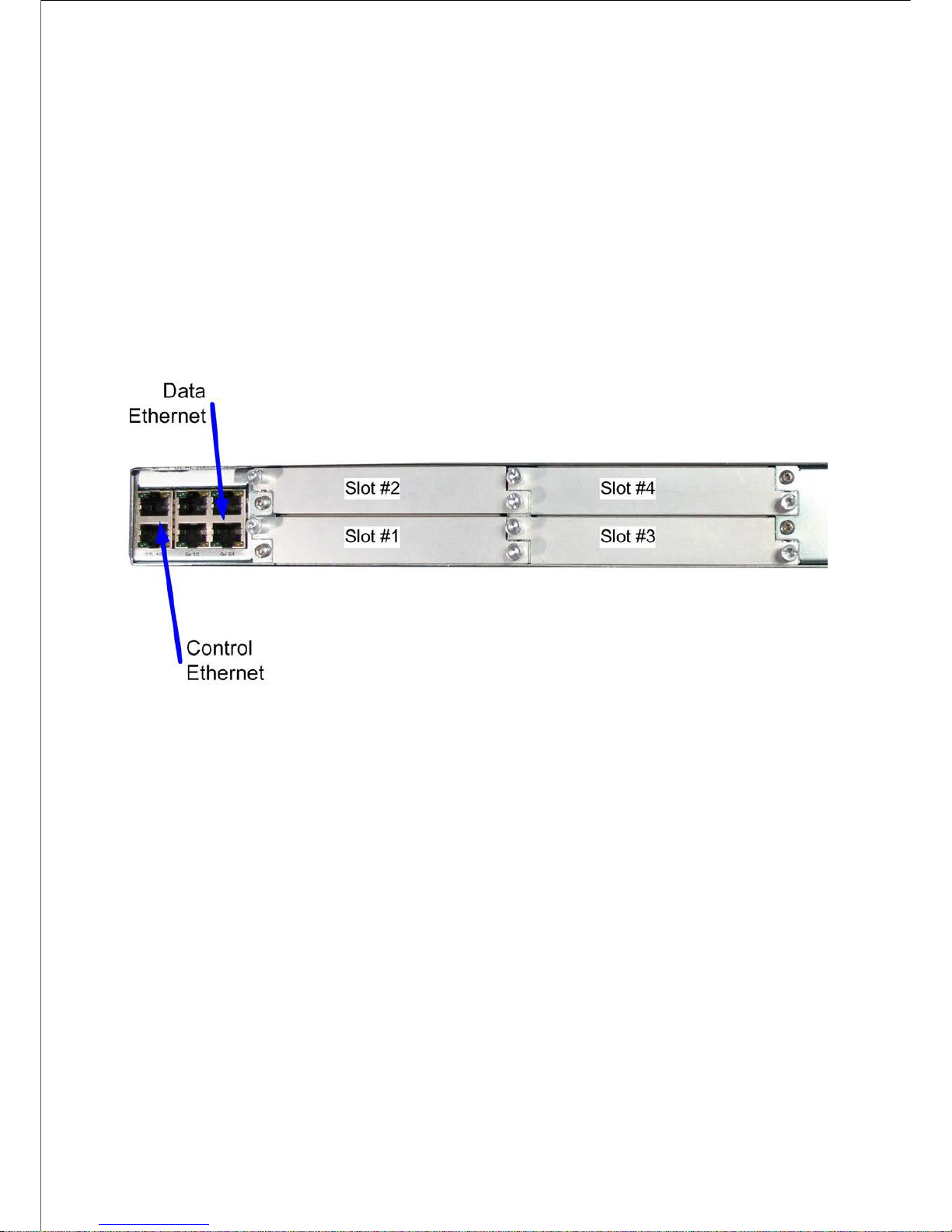

Rear View of the Ericsson SPR1100, dual AC PSU variant

Rear View of the Ericsson SPR1100, single DC PSU variant.

Rear View of the Ericsson SPR1100, dual DC PSU variant.

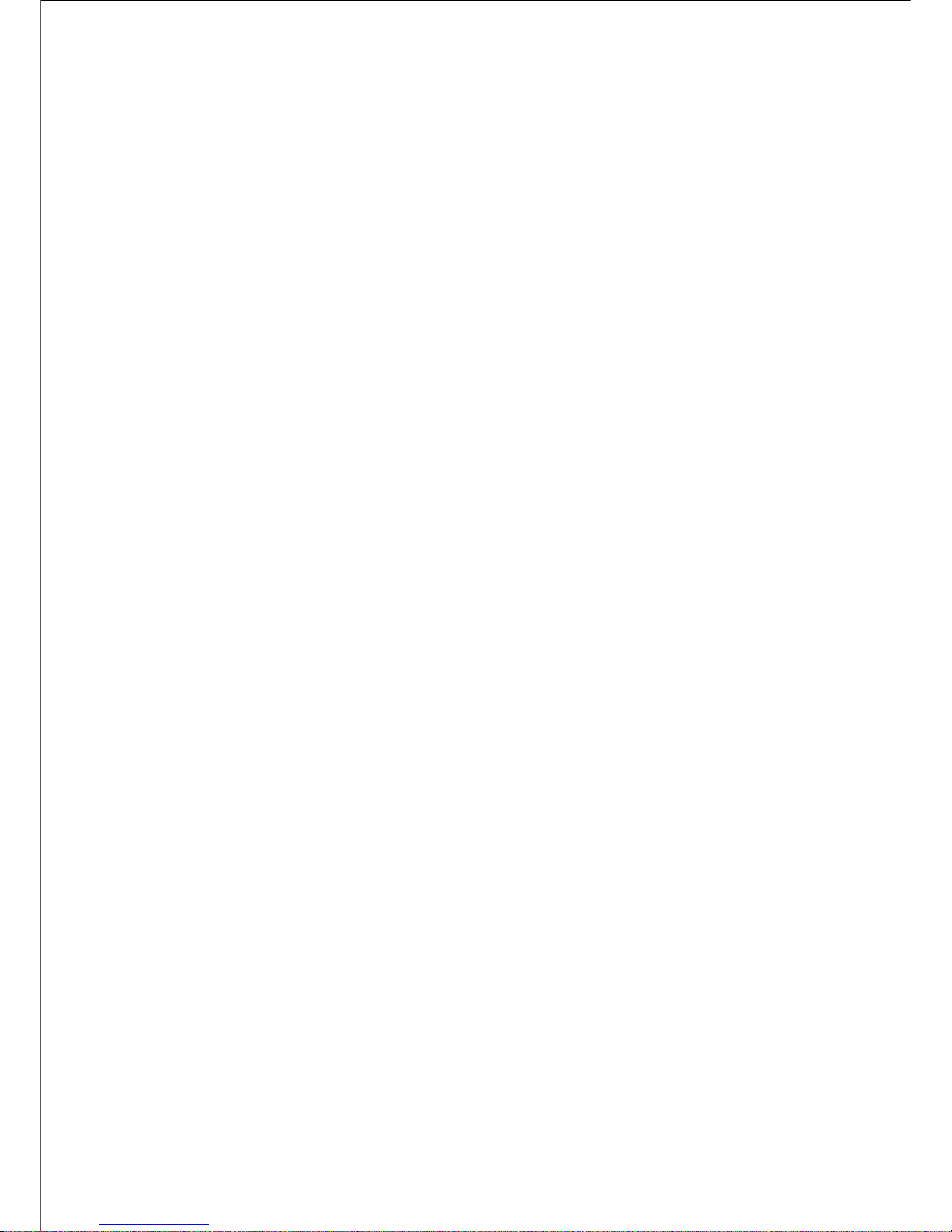

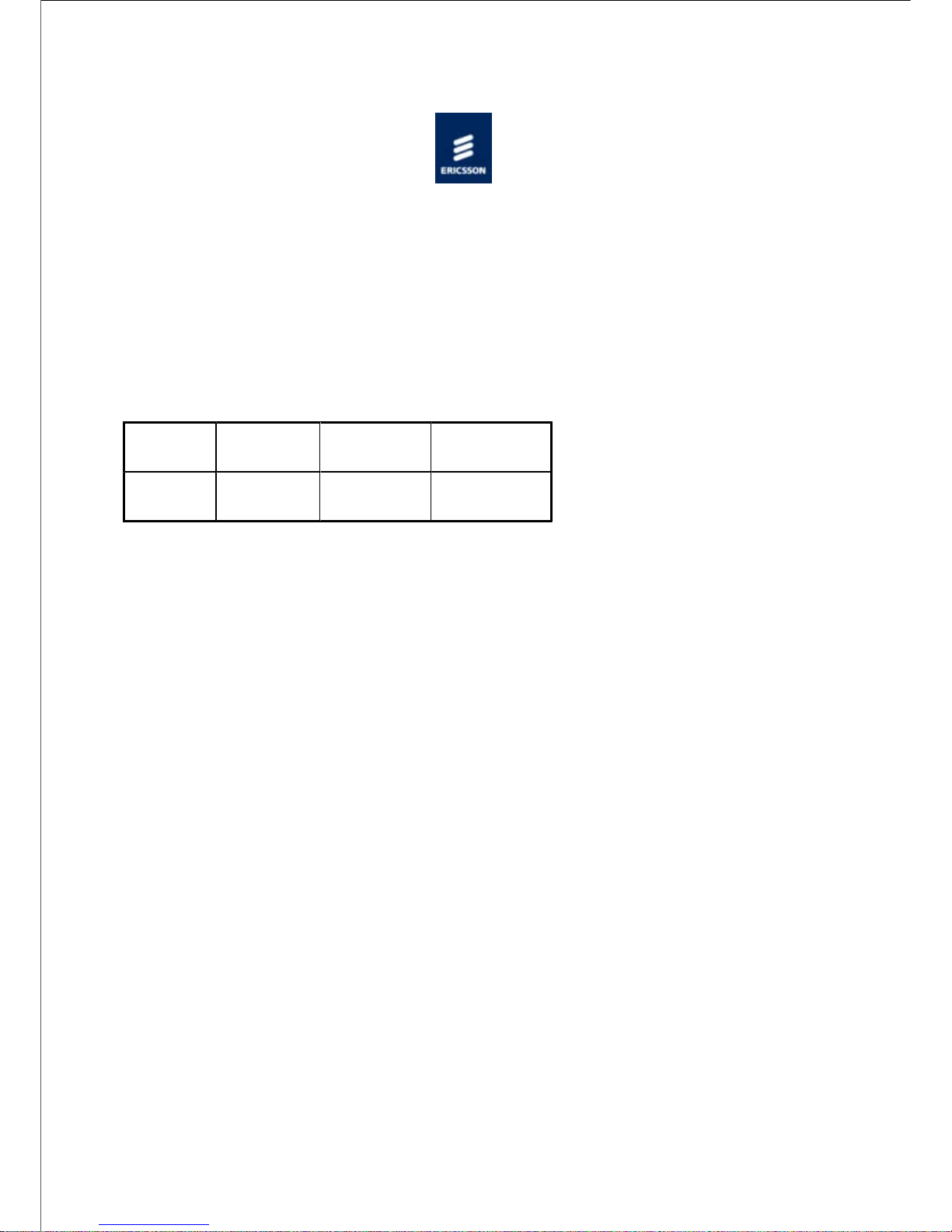

Product Codes

This information covers products with the marketing codes shown in the following table

Marketing Code

Description

Summary of Features

SPR11/CHASSIS/1AC

Ericsson SPR1100

Chassis with single

AC input

See Introduction>Base

Chassis>Base Unit (AC)

SPR11/CHASSIS/2AC

Ericsson SPR1100

Chassis with dual AC

input

See Introduction>Base

Chassis>Base Unit (Dual AC)

SPR11/CHASSIS/1DC

Ericsson SPR1100

Chassis with single

DC input

See Introduction>Base

Chassis>Base Unit (DC)

SPR11/CHASSIS/2DC

Ericsson SPR1100

Chassis with dual DC

input

See Introduction>Base

Chassis>Base Unit (Dual DC)

SPR/HWO/MPM1

MPM1 HD/SD

Transcoder Module

See Introduction>Transcoder

Cards>MPM1 Transcoder

Firmware/Software Versions

This information covers the functionality of the firmware/software versions which are

Page 5

contained within the Software Release Version 6.x.x .

This handbook continues to be relevant to subsequent build versions where the functionality

of the equipment has not changed. Where the build standard changes the functionality, a

new issue of this handbook will be provided.

© Ericsson AB 2011. All rights reserved

Page 6

Home > SPR1100 Handbook > Preliminary Information > About this Information

About this Information

Revisions

Any revision of this information will be by a complete reissue.

Issues are listed below:

Issue

Date

Build

Version

Comments

A

September

2011

6.0.11

Initial

release.

© Ericsson AB 2011. All rights reserved

Page 7

Home > SPR1100 Handbook > Preliminary Information > Trademarks

Trademarks

General

All best endeavours have been made to acknowledge registered trademarks and

trademarks. Any notified omissions will be rectified in the next issue. Some trademarks may

be registered in some countries but not in others.

Registered trademarks and trademarks used are acknowledged below and marked with their

respective symbols. However, they are not marked further within the text.

Copyright

© Ericsson AB 2011. All rights reserved. No part of this document may be reproduced in any

form without the written permission of the copyright owner.

Disclaimer

The contents of this document are subject to revision without notice due to continued

progress in methodology, design and manufacturing. Ericsson AB shall have no liability for

any error or damage of any kind resulting from the use of this document.

Registered Trademarks

Dolby® is a registered trademark of Dolby Laboratories Licensing Corporation.

DTS® is a registered trademark of Digital Theater Systems, Inc

Ethernet® is a registered trademark of Xerox Corporation.

Trademarks

Ethafoam™ is a trademark of The Dow Chemical Company.

Pozidriv™ is a trademark of European Industrial Services.

Reflex™ is a trademark of Ericsson AB.

Stratocell™ is a trademark of the Sealed Air Corporation.

© Ericsson AB 2011. All rights reserved

Page 8

Home > SPR1100 Handbook > Preliminary Information > Warnings, Cautions and Notes

Warnings, Cautions and Notes

Heed Warnings

All warnings on the product and in the operating instructions should be adhered to. The

manufacturer can not be held responsible for injuries or damage where warnings and

cautions have been ignored or taken lightly.

Read Instructions

All the safety and operating instructions should be read before this product is operated.

Follow Instructions

All operating and use instructions should be followed.

Retain Instructions

The safety and operating instructions should be retained for future reference.

WARNING!

Warnings give information which, if strictly observed, will prevent personal injury or death,

or damage to personal property or the environment. They are boxed for emphasis, as in this

example, and are placed immediately preceding the point at which the reader requires

them.

CAUTION!

Cautions give information which, if strictly followed, will prevent damage to equipment or

other goods. They are boxed for emphasis, as in this example, and are placed immediately

preceding the point at which the reader requires them.

Page 9

NOTE:

Notes provide supplementary information. They are highlighted for emphasis,

as in this example, and are placed immediately after the relevant text.

© Ericsson AB 2011. All rights reserved

Page 10

Home > SPR1100 Handbook > Preliminary Information > Contact Information

Contact Information

Ericsson Customer Services

Support Services

Our primary objective is to provide first class customer care that is tailored to your specific

business and operational requirements. All levels are supported by one or more service

performance reviews to ensure the perfect partnership between Ericsson and your business.

Warranty

All Ericsson Products and Systems are designed and built to the highest standards and are

covered under a comprehensive 12 month warranty.

Levels of Continuing Ericsson Service Support

For stand-alone equipment, then Ericsson's BASIC Essential support is the value for

money choice for you.

BASIC provides you with year-by-year Service long after the warranty has expired.

For systems support you can choose either Gold Business Critical support or Silver

Business Advantage. These packages are designed to save you costs and protect your

income through enlisting the help of our support specialists.

Call Ericsson Sales for more details.

Where to Find Us

Page 11

Customer Services

Europe, Middle

East and Africa

Tel:

+44 (0) 23 8048 4455

Fax:

+44 (0) 23 8048 4467

Email:

tvsupportemea@ericsson.com

Americas

Tel:

+888 671 1268

US and Canada

Tel:

+678 812 6255

International

Fax:

+678 812 6262

Email:

tvsupportamericas@ericsson.com

Compression

Email:

tvsupport@ericsson.com

Software

Support Centre

China

Tel:

+86 10 8476 8676

Beijing

Fax:

+86 10 8476 7741

Beijing

Tel:

+852 2590 2388

Hong Kong

Fax:

+852 2590 9550

Hong Kong

Email:

tvsupportapac@ericsson.com

Australia and

New Zealand

Tel:

+612 (0) 9111 4027

Fax:

+612 (0) 9111 4949

Email:

tvsupportanz@ericsson.com

Internet

Address

www.ericsson.com

Technical Training

Training Courses

Ericsson provides a wide range of training courses on the operation and maintenance of our

products and on their supporting technologies. We can provide both regularly scheduled

courses and training tailored to individual needs. Courses can be run either at your premises

or at one of our dedicated training facilities.

Where to Find Us

For further information on the Ericsson training programme please contact us:

Page 12

International

Tel:

+44 (0) 23 8048 4229

Fax:

+44 (0) 23 8048 4161

Email:

tvglobaltraining@ericsson.com

Return of Equipment

Contact your regional Ericsson office who will issue directions on how and where to return a

unit for service/repair/upgrade.

© Ericsson AB 2011. All rights reserved

Page 13

Home > SPR1100 Handbook > Preliminary Information > Compliance Statements

EN55022 and CISPR22

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the Handbook, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at ones own

expense.

FCC Code of Federal Regulations (CFR) Title 47 – Telecommunications, Part 15: radio

frequency devices, subpart B – Unintentional Radiators.

© Ericsson AB 2011. All rights reserved

Page 14

Home > SPR1100 Handbook > Read This First

Read This First!

Personnel

Ensure the personnel designated to fit the unit have the appropriate skills and knowledge. If

in any doubt, contact Customer Services (see Contact Information).

Installation

Installation of the product should follow these instructions, and should only use installation

accessories recommended by the manufacturers. When rack mounted, this equipment must

have shelf supports as well as being fixed at the front panel.

Mechanical Support

Do not use this product as a support for any other equipment.

Web Browser access

This product is designed to support control through Web browser access. The only

supported browser is Microsoft IE8 (earlier versions of IE are not supported)

© Ericsson AB 2011. All rights reserved

Page 15

Home > SPR1100 Handbook > Introduction

Introduction

The Unit is a flexible platform consisting of a base unit or chassis into which between one

and six Media Processing Modules (MPMs) can be plugged. The base unit provides an

Ethernet control interface, and Ethernet data interfaces, it also provides transport stream

processing functionality. Other functionality such as video / audio transcoding, or other

input or output interfaces are provided by the media processing modules.

License Keys

License Keys control the availability of some of the features accessible from the unit and are

issued to a specific chassis, not a module, and are held within the chassis.

Base Chassis

This section introduces the chassis and describes the functions associated with the host

controller.

Media Processing Module (MPM)

The following media processing module is available:

MPM1 HD/SD Transcoder

This provides high quality MPEG-2 and H.264 Video transcoding, and multi-standard

audio transcoding.

© Ericsson AB 2011. All rights reserved

Page 16

Home > SPR1100 Handbook > Introduction > License Keys

License Keys

Overview

License Keys control the availability of some features and are issued to a specific base unit

not a media processing module, even if the functionality being enabled is provided by a

module.

Features

License Keys consist of a feature, and the number of instances of this feature that are

allowed within the chassis.

License Keys are allocated on a ‘first configured first served’ basis within the chassis. If an

attempt is made to enable a feature, but the required license key is not available then the

feature is not enabled, and a log message is generated.

When a function that has a license associated with it is disabled, the license key is released

within 1 second, and therefore available to be re-allocated .

Verifying which licenses are present in the Unit

Access to the transcoder web pages is necessary to verify the licenses that are enabled on

the unit.

Navigate to Configure > Licenses. This page displays the marketing code, number of

each license and a description of the feature enabled by the license.

Ordering Additional Licenses.

N.B. License keys are unit-specific. They cannot be loaded onto a different unit.

When ordering additional licenses for existing units the following information is needed:

Unique Chip ID of the unit is required to generate the key.

This is retrieved by navigating to the following web page :

Configure > System > Base Unit > Advanced

The Chip ID value is displayed just beneath the diagram of the transcoder.

1.

The TOTAL FINAL number of ALL types of license required (including licenses already2.

Page 17

enabled on the unit) needs to be provided.

2.

The above information is used to generate a new license key file, which then needs to be

loaded onto the appropriate unit.

Entering License Keys

The keys are saved in an XML file (newlicensedetail.xml) ready to be entered onto the unit

via the web page

Browse to: Configure > Licenses

In the license box enter the license filename and select upload.

NOTE:

The front panel CANNOT be used to enter license keys!

© Ericsson AB 2011. All rights reserved

Page 18

Home > SPR1100 Handbook > Introduction > Base Chassis

Base Chassis

Overview

The base chassis provides the control interfaces, the data Ethernet ports, data routing

between the Ethernet ports, control software running on the base chassis, and the modules

slots. It also provides the ability to generate MPEG-2 transport streams from elementary

streams received from the modules.

The following is a summary of the features of the base chassis:

19" 1 ‘RU’ rack mount chassis.

Front panel LCD and keypad for limited control and status reporting.

Tri-colour LED to indicate chassis health.

Dual redundant Ethernet control ports.

Two pairs of dual redundant Ethernet ports for data input and output.

Single or dual AC power supply variants.

Single or dual DC power supply variants.

6 module slots (single AC or DC PSU chassis) or 4 module slots (dual AC or DC PSU

chassis)

Modules are ‘hot swappable’

Ericsson SPR1100 Front Panel

Ericsson SPR1100 Rear Panel - Single AC Chassis

Page 19

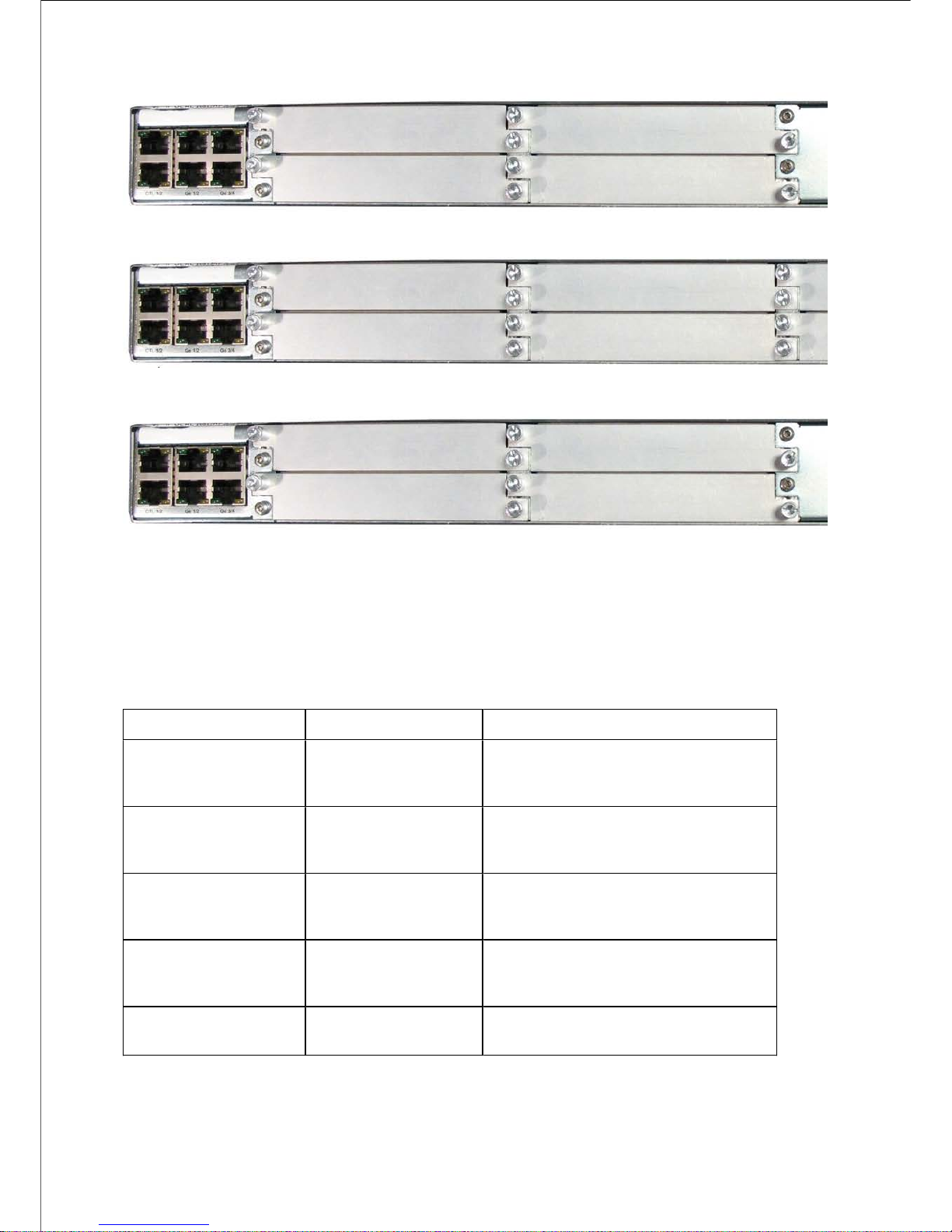

Ericsson SPR1100 Rear Panel - Dual AC Chassis

Ericsson SPR1100 Rear Panel - Single DC Chassis

Ericsson SPR1100 Rear Panel - Dual DC Chassis

NOTE:

Refer to Installing the Equipment > External Interfaces > Base Chassis for

more details of the items at the rear and front panels.

SPR11/CHASSIS/1AC 1U Base Chassis (AC)

Describes the single AC power supply base chassis.

SPR11/CHASSIS/2AC 1U Base Chassis (Dual AC)

Describes the dual AC power supply base chassis.

SPR11/CHASSIS/1DC 1U Base Chassis (AC)

Describes the single DC power supply base chassis.

SPR11/CHASSIS/2DC 1U Base Chassis (Dual AC)

Describes the dual DC power supply base chassis.

© Ericsson AB 2011. All rights reserved

Page 20

Home > SPR1100 Handbook > Introduction > Base Chassis > Base Chassis (AC)

SPR11/CHASSIS/1AC 1U Base Chassis (AC)

Overview

The Ericsson SPR1100 consists of a base chassis, a single AC mains input and up to six

modules. The base chassis is a 1 ‘RU’ 19" rack mount chassis that provides the control

interfaces, and two pairs of dual redundant Ethernet ports for data input and output.

The modules provide the video, audio and data processing functionality and can be ‘Hot

Swapped’ i.e. inserted or removed whilst the chassis is powered.

Single AC PSU Base Chassis

Front Panel

SPR11/CHASSIS/1AC Front Panel Items

LCD

Control and status information is displayed on a 2 line by 40 character display.

Buttons

Six buttons are provided for navigating through the front panel menus.

Status LED

The status LED is green when there are no active alarms or warnings and red if there is a

critical alarm.

The status LED is amber if there is an active warning, minor or major alarm.

USB Connector

Page 21

This is not for customer use.

Rear Panel

The modules, control Ethernet ports, data Ethernet ports, and the AC power input are all

accessible at the rear of the base chassis.

SPR11/CHASSIS/1AC Rear Panel Items [Single AC Chassis]

Page 22

Page 23

Ethernet Port Numbering

© Ericsson AB 2011. All rights reserved

Page 24

Home > SPR1100 Handbook > Introduction > Base Chassis > Base Chassis (Dual AC)

SPR11/CHASSIS/2AC 1U Base Chassis (Dual AC)

Overview

The Ericsson SPR1100 consists of a base chassis, dual AC inputs and up to four modules.

The base chassis is a 1 ‘RU’ 19" rack mount chassis that provides the control interfaces, and

two pairs of dual redundant Ethernet ports for data input and output.

The modules provide the video, audio and data processing functionality and can be ‘Hot

Swapped’, i.e. inserted or removed whilst the chassis is powered.

Why Have Two Mains Connectors

Many broadcasting sites have two power supply chains, either from the master switchboard

or, for major sites, from different points on the supply grid. As the most common cause of

system failure is loss of power, feeding the chassis from the separate chains ensures

reliability of supply and, therefore, continuity of service.

Dual AC PSU Base Chassis

Front Panel

SPR11/CHASSIS/2AC Front Panel Items

LCD

Control and status information is displayed on a 2 line by 40 character display.

Buttons

Six buttons are provided for navigating through the front panel menus.

Status LED

Page 25

The status LED is green when there are no active alarms or warnings and red if there is a

critical alarm.

The status LED is amber if there is an active warning, minor or major alarm.

USB Connector

This is not for customer use.

Rear Panel

The modules, control Ethernet ports, data Ethernet ports, and the AC power input are all

accessible at the rear of the base chassis.

SPR11/CHASSIS/2AC Rear Panel Items [Dual AC Chassis]

Page 26

Page 27

Ethernet Port Numbering

© Ericsson AB 2011. All rights reserved

Page 28

Home > SPR1100 Handbook > Introduction > Base Chassis > Base Chassis (DC)

SPR11/CHASSIS/1DC 1U Base Chassis (DC)

Overview

The Ericsson SPR1100 consists of a base chassis, a single DC power input and up to six

modules. The base chassis is a 1 ‘RU’ 19" rack mount chassis that provides the control

interfaces, and two pairs of dual redundant Ethernet ports for data input and output.

The modules provide the video, audio and data processing functionality and can be ‘Hot

Swapped’ i.e. inserted or removed whilst the chassis is powered.

Single DC PSU Base Chassis

Front Panel

SPR11/CHASSIS/1DC Front Panel Items

LCD

Control and status information is displayed on a 2 line by 40 character display.

Buttons

Six buttons are provided for navigating through the front panel menus.

Status LED

The status LED is green when there are no active alarms or warnings and red if there is a

critical alarm.

The status LED is amber if there is an active warning, minor or major alarm.

USB Connector

Page 29

This is not for customer use.

Rear Panel

The modules, control Ethernet ports, data Ethernet ports, and the DC power input are all

accessible at the rear of the base chassis.

SPR11/CHASSIS/1DC Rear Panel DC Power Socket

SPR11/CHASSIS/1DC DC Power Connector (end view)

SPR11/CHASSIS/1DC DC Power Connector (side view)

Page 30

Page 31

Ethernet Port Numbering

© Ericsson AB 2011. All rights reserved

Page 32

Home > SPR1100 Handbook > Introduction > Base Chassis > Base Chassis (Dual DC)

SPR11/CHASSIS/2DC 1U Base Chassis (Dual DC)

Overview

The Ericsson SPR1100 consists of a base chassis, two DC power inputs and up to four

modules. The base chassis is a 1 ‘RU’ 19" rack mount chassis that provides the control

interfaces, and two pairs of dual redundant Ethernet ports for data input and output.

The modules provide the video, audio and data processing functionality and can be ‘Hot

Swapped’ i.e. inserted or removed whilst the chassis is powered.

Dual DC PSU Base Chassis

Front Panel

SPR11/CHASSIS/2DC Front Panel Items

LCD

Control and status information is displayed on a 2 line by 40 character display.

Buttons

Six buttons are provided for navigating through the front panel menus.

Status LED

The status LED is green when there are no active alarms or warnings and red if there is a

critical alarm.

The status LED is amber if there is an active warning, minor or major alarm.

USB Connector

Page 33

This is not for customer use.

Rear Panel

The modules, control Ethernet ports, data Ethernet ports, and the DC power inputs are all

accessible at the rear of the base chassis.

SPR11/CHASSIS/2DC Rear Panel DC Power Socket

SPR11/CHASSIS/2DC DC Power Connector (end view)

SPR11/CHASSIS/2DC DC Power Connector (side view)

Page 34

Page 35

Ethernet Port Numbering

© Ericsson AB 2011. All rights reserved

Page 36

Home > SPR1100 Handbook > Introduction > Transcoder Cards

Transcoder Modules

The following transcoder module is supported in this release:

MPM1 HD/SD Transcoder (SPR/HWO/MPM1)

This card can transcode up to 12 standard definition or up to 4 high definition video inputs

using MPEG-2 or H.264 encoding, and can compress up to 24 audio streams, depending on

audio encoding mode.

© Ericsson AB 2011. All rights reserved

Page 37

Home > SPR1100 Handbook > Introduction > Transcoder Cards > MPM1 Transcoder Card

Media Processing Module (MPM1)

The MPM1 Transcoder Card has a unique processing engine that extracts the maximum

efficiency possible from the MPEG2 and H.264 specifications.

Summary of Features

Video Transcoding

Describes the Video processing functionality available in the MPM1.

Audio Transcoding

Describes the Audio Inputs and Coding Modes provided by the MPM1.

Data Processing

Describes the data extraction and processing capabilities of the MPM1

© Ericsson AB 2011. All rights reserved

Page 38

Summary of Features

Overview

The media processing module is a single slot solution which can transcode multiple MPEG-2

and/or H.264 video streams, at both SD and HD resolutions. Audio passthrough and

transcode functionality is also supported.

The total maximum number of transcodes per module is related to the resolution.

At SD resolution, each MPM1 can perform 12 simultaneous transcodes.

Each transcode involving a HD-resolution stream on input and/or output reduces the

number of possible SD transcodes by 3

Maximum number of SD-to-SD transcodes

Maximum number of HD transcodes

1209

1

62330

4

Video Formats

Profiles Supported

MPEG-4 AVC (H.264) Main Profile @ Level 3 to Level 4.1 (0.500 to 12.5 Mbps)

MPEG-4 AVC (H.264) High Profile @ Level 4.0 to Level 4.1 (1.000 to 20.0 Mbps)

MPEG-2 MP@ML Video (1.000 to 15.0 Mbps)

MPEG-2 MP@HL Video (2.000 to 30.0 Mbps)

SD Resolutions Supported

720 x 576 @ 25Hz

704 x 576 @ 25Hz

640 x 576 @ 25Hz

544 x 576 @ 25Hz

528 x 576 @ 25Hz

Page 39

480 x 576 @ 25Hz

352 x 576 @ 25Hz

720 x 480 @ 29.97Hz

704 x 480 @ 29.97Hz

640 x 480 @ 29.97Hz

544 x 480 @ 29.97Hz

528 x 480 @ 29.97Hz

480 x 480 @ 29.97Hz

352 x 480 @ 29.97Hz

HD Resolutions Supported

1280 x 720 @ 50Hz

960 x 720 @ 50Hz

1920 x 1080 @ 25Hz

1440 x 1080 @ 25Hz

1280 x 1080 @ 25Hz

1280 x 720 @ 59.94Hz

960 x 720 @ 59.94Hz

1920 x 1080 @ 29.97Hz

1440 x 1080 @ 29.97Hz

1280 x 1080 @ 29.97Hz

1920 x 1080 @ 23.976Hz

Video PIP Formats

MSTV

128 x 96 @ 25Hz

128 x 96 @ 29.97Hz

96 x 96 @ 25Hz

96 x 96 @ 29.97Hz

non-MSTV

192 x 192 @ 25Hz

192 x 192 @ 29.97Hz

144 x 144 @ 25Hz

144 x 144 @ 29.97Hz

Audio Formats

Supported audio decoding and encoding modes:

Page 40

- MPEG-1 Layer II (32 kbps to 384 kbps)

- MPEG-2 Layer II (32 kbps to 384 kbps)

- Dolby Digital 2.0, 5.1 (56 kbps to 640 kbps)

- MPEG-4 AAC/AAC-LC/HE-AAC (16-256kbps)

Audio Transcoding

The MPM supports transcoding between any of the supported formats.

The maximum number of simultaneous transcodes per card is summarised in the Audio

Transcoding page

VBI Passthrough

In addition to Audio and Video Transcoding, data may be passed through from Input to

Output. Typically, this can include :

Generic VANC carriage (SMPTE 2038)

VBI in PID

Teletext

DVB Subtitles

AFD

SCTE 35 Splicepoint Pass-Through

The MPM supports SCTE 35 pass-through. SCTE 35 may be added to any output stream by

dragging the component to the appropriate stream in the Services Configuration page. The

video will have the appropriate splice-points re-inserted at the right points on transcode.

© Ericsson AB 2011. All rights reserved

Page 41

Home > SPR1100 Handbook > Introduction > Transcoder Cards > MPM1 Transcoder Card > MPM1 Video

Transcoding

MPM1 Video Transcoding

Inputs and Outputs

The MPM1 Transcoder has no external inputs or outputs. All data is passed into and out of

the module via the internal connectors.

Overview

The MPM1 can transcode up to twelve SD-to-SD streams or up to four transcodes with HD

streams on input and/or output, or a combination of both. Each high-definition stream

reduces the maximum number of standard-definition streams by three

Video Compression Functionality

The supported formats and bit rates are summarised in the Coded Elementary Stream page

Any supported video format can be transcoded to any other supported video format, with

the following exceptions:

720p outputs can only be transcoded from 720p inputs

1080PsF outputs can only be transcoded from 1080PsF inputs

720p inputs cannot be transcoded into 1080i outputs

Any supported PIP format can be generated from any supported input video format

Loss of Video Input

On loss of video input, the MPM1 can be configured to select one of the default test patterns

or a freeze frame as the output.

© Ericsson AB 2011. All rights reserved

Page 42

Home > SPR1100 Handbook > Introduction > Transcoder Cards > MPM1 Transcoder Card > Audio Transcoding

MPM1 Audio Transcoding

Overview

Audio data comes to the MPM by way of the internal data connections, in just the same way

as the video.

The maximum number of simultaneous audio transcodes that can be performed on a MPM is

summarised below. It is possible to mix different audio transcodes on a module, in which

case the maximum number of transcodes must be scaled accordingly.

Outputs

Inputs

MPEG-

1L2

Dolby

Digital 2.0

Dolby

Digital 5.1

AAC/HE-

AAC 2.0

AAC/HE-

AAC 5.1

MPEG-1L2

2412n/a24n/a

Dolby Digital

2.0/5.1

18126126

AAC/HE-AAC

2.0/5.1

12126126

For example, per module, it is possible to transcode

24xMPEG L2

to

MPEG L2

or 12x

AACtoMPEG L2

or 18x

MPEG L2

to

MPEG L2

and3x

AACtoMPEG L2

Audio Pass-Through

Audio streams can be passed through directly from the input without re-encoding (passthrough mode). No audio licenses are required for this mode.

© Ericsson AB 2011. All rights reserved

Page 43

Home > SPR1100 Handbook > Introduction > Transcoder Cards > MPM1 Transcoder Card > Data Processing

Data Processing

Data Component Pass-Through

Data of any type can be passed through from the Input Transport Stream to the Output

Transport Stream.

NOTE:

Closed-Caption Data is handled slightly differently from other data types, and

will be automatically transcoded as necessary.

© Ericsson AB 2011. All rights reserved

Page 44

Home > SPR1100 Handbook > Installing the Equipment

Installing the Equipment

This chapter provides a guide to the suitability of an installation and gives detailed

procedures for the preparation and installation of the equipment. Also details the external

connectors and provides important safety information.

Preliminary Checks

Gives general information relating to Mechanical Inspection of the unit and how to move it

safely.

Site Requirements

Describes the requirements for powering the unit and the need for lightning protection (if

required).

Mounting in a Rack

Gives information associated with fixing the unit into a rack and the care and positioning of

cables.

External Interfaces

Describes the connectors relating to the base chassis.

© Ericsson AB 2011. All rights reserved

Page 45

Home > SPR1100 Handbook > Installing the Equipment > Preliminary Checks

Preliminary Checks

Mechanical Inspection

When taking delivery of an Encoder, check the equipment items delivered against the

enclosed delivery note. Inspect the equipment for damage-in-transit. If in doubt, please

contact Customer Services.

WARNING!

Removing the covers of this equipment may invalidate any warranties, cause a safety

hazard or/and affect the EMC performance. Check with Customer Services.

Moving the Equipment Safely

Do not place this product on an unstable cart, stand, bracket, or table. The product may fall,

causing serious injury and serious damage to the product. Use only with a cart, stand,

bracket or table recommended by Ericsson.

An appliance and cart combination should be moved with care. Quick stops, excessive force,

and uneven surfaces may cause the appliance and cart combination to overturn.

Do not move or carry the equipment whilst it is still connected to the supply or other leads,

is live or is in operation.

See, also:

The Handling and Lifting section in Read This First!

Appendices > Handling Option Cards > Handling Option Cards

© Ericsson AB 2011. All rights reserved

Page 46

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements

Site Requirements

This chapter provides a guide to the suitability of an installation and gives detailed

procedures for the preparation and installation of the equipment. Also details the external

connectors and provides important safety information.

AC Power Supply

Gives information relating to the AC power inlet and associated components.

DC Power Supply

Gives information relating to the DC power inlet and associated components.

Power Consumption

Details the power consumption of the base chassis and each transcoder module.

Protective and Technical Earths

Describes the requirements for earthing the unit.

Lightning Protection

This topic discusses the requirement of lightning protection (when appropriate).

© Ericsson AB 2011. All rights reserved

Page 47

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements > AC Power Supply

AC Power Supply

Variants

This Handbook covers two Base Chassis; a single AC PSU version, and a dual AC PSU

version.

Dual AC Power

[Single AC PSU]

[Dual AC PSU]

AC Power Receptacles

Specification

The equipment operates from an wide-ranging mains power supply (100-240 V AC 50/60 Hz

nominal) and is designed for use in ambient air temperature in the range 0°C to +50°C.

There are no links etc. to be altered for operation from different supply voltages. The full

Technical Specification is given in Technical Specification > Chassis [Host] > Power Supplies.

WARNING!

The following points regarding power connection must be adhered to ensure safe operation

of the equipment.

The equipment should only be operated from the type of power source indicated on the

marking label. If you are not sure of the type to your business, consult your appliance

dealer or local power company. Do not overload wall outlets and extension cords as this

can result in a risk of fire or electric shock.

1.

Page 48

The equipment is not fitted with an AC Power On/Off switch. Ensure the supply socket

outlet is installed or located near the equipment so that it is accessible.

2.

Remove both sources of mains power to the dual PSU version before removing covers or

moving the equipment.

3.

Supply Cord

A two-metre mains supply cord is supplied with this product. It is fitted with a moulded plug

suitable for the USA, UK or mainland Europe as advised at the time of ordering.

Wire Colours

The wires in the supplied cord are coloured as follows:

UK (BS 1363)

EUROPE (CEE

7/7)

USA (NEMA 515P)

Earth

Green and

yellow

Green and

yellow

Green

Neutral

Blue

Blue

White

Live

Brown

Brown

Black

Connecting the Equipment to the AC Power Supply

As there is no mains power switch fitted to this chassis, ensure the local AC power supply is

switched OFF before connecting the supply cord.

Connect the mains lead to the equipment and then to the local supply.

© Ericsson AB 2011. All rights reserved

Page 49

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements > DC Power Supply

DC Power Supply

Variants

This Handbook covers two types of DC Base Chassis; a single DC PSU version, and a dual

DC PSU version.

DC Power Connector

Specification

The equipment operates from a -48V DC power supply and is designed for use in ambient

air temperature in the range 0°C to +50°C. There are no links etc. to be altered for

operation from different supply voltages. The full Technical Specification is given in Technical

Specification > Chassis [Host] > Power Supplies.

WARNING!

The following points regarding power connection must be adhered to ensure safe operation

of the equipment.

This equipment is Class 1 and must have a protective earth.1.

The equipment should only be operated from the type of power source indicated on the

marking label. If you are not sure of the type to your business, consult your appliance

dealer or local power company. Do not overload wall outlets and extension cords as this

can result in a risk of fire or electric shock.

2.

The equipment is not fitted with an DC Power On/Off switch. Ensure the supply socket3.

Page 50

outlet is installed or located near the equipment so that it is accessible.

3.

Remove both sources of power to the dual PSU version before removing covers or moving

the equipment.

4.

Wire Colours

The wires in the supplied cord are coloured as follows:

Earth

Green and yellow

-48V

Blue

0V

Brown

Connecting the Equipment to the DC Power Supply

NOTE:

This equipment is not intended for direct connection to centralised DC power

systems in the USA or Canada.

This equipment does not have an input fuse. For protection of the DC wiring, a circuit

breaker of maximum 16A is recommended.

For wiring DC power, a minimum wire size of 1.0mm2 (17AWG) is recommended. This may

need to be increased for longer cable runs.

As there is no power switch fitted to this chassis, ensure the local DC power supply is

switched OFF before connecting the supply cord.

Connect the power lead to the equipment and then to the local supply.

© Ericsson AB 2011. All rights reserved

Page 51

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements > Power Consumption

Power Consumption

Rated current 4.0 – 2.0 A

Power consumption: 350W (Actual power consumption is dependant on the hardware

options selected, see Table of Typical Power Consumption).

Typical Power Consumption

Item

Description

Power

SPR11/CHASSIS/1AC

1U Base Chassis (AC)

70 W

SPR11/CHASSIS/2AC

1U Base Chassis (Dual

AC)

80 W

SPR/HWO/MPM1

MPM1 HD/SD

Transcoders (6 cards)

250 W

See also Technical Specification>Chassis>Power Supplies, Technical Specification>*

Transcoder>Power Supplies.

© Ericsson AB 2011. All rights reserved

Page 52

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements > Protective and Technical Earths

Protective and Technical Earths

Protective Earth

WARNING!

This unit must be correctly earthed as described below.

This unit must be correctly earthed through the moulded plug supplied. If the local mains

supply does not have an earth conductor do not connect the unit. Contact Customer

Services for advice.

1.

Before connecting the unit to the supply, check the supply requirements.2.

Technical Earth

The terminal marked at the rear panel is a Technical Earth. Its use is recommended. This is

NOT a protective earth for electric shock protection.

Technical Earth

The Technical Earth provides a suitable connection between the equipment and the

Page 53

installation to give a low impedance path at normal operating frequencies.

The terminal is provided to:

Ensure all equipment chassis fixed within a rack are at the same technical earth potential.1.

Eliminate the migration of stray charges when connecting between equipment.2.

To do this, connect a wire between the Technical Earth terminal and a suitable point on the

rack.

CAUTION!

It is strongly recommended that the earth terminal at the rear panel of the equipment is

connected to a site Technical Earth before any external connections are made and the

equipment is powered. This limits the migration of stray charges.

© Ericsson AB 2011. All rights reserved

Page 54

Home > SPR1100 Handbook > Installing the Equipment > Site Requirements > Lightning Protection

Lightning Protection

WARNING!

If the equipment has been subject to a lightening strike or power surge, which has stopped

it working, disconnect the power immediately, do not re-apply power until it has been

checked for safety. If in doubt, contact Customer Services.

Where appropriate, ensure this product has an adequate level of lightning protection.

Alternatively, during a lightning storm or when it is left unattended and unused for long

periods of time, unplug it from the supply outlet and disconnect the output equipment. This

prevents damage to the product due to lightning and power line surges.

© Ericsson AB 2011. All rights reserved

Page 55

Home > SPR1100 Handbook > Installing the Equipment > Mounting in a Rack

Mounting in a Rack

Gives information associated with fixing the unit into a rack and the care and positioning of

cables.

Installing the Equipment

Read This First: Read the information contained in this topic before beginning to install the

equipment.

Care in Positioning

This topic describes what needs to be considered before fixing the unit into a rack.

Fixing

Provides information related to the fixing of the unit in a rack.

Cable Types/Installing Cables

Tabulates the recommended cables required to maintain EMC compliance. Also describes the

care required when installing the cables.

© Ericsson AB 2011. All rights reserved

Page 56

Home > SPR1100 Handbook > Installing the Equipment > Mounting in a Rack > Installing the Equipment

Handling and Lifting

Handling the Equipment

The equipment must be handled and installed carefully and thoughtfully to prevent safety

hazards and damage.

Lifting

In some circumstances the unit might be awkward to lift. In which case, do not attempt to

lift or move it without proper assistance or equipment. If in doubt, seek assistance.

Electrostatic Handling

WARNING!

Static electricity can damage electronic components. To avoid damage, keep option cards in

their static-protective package until you are ready yo install them.

Refer to Options Cards for information relating to the handling of Option Modules.

Installing the Equipment

Read the comments in Read This First before starting work.

© Ericsson AB 2011. All rights reserved

Page 57

Home > SPR1100 Handbook > Installing the Equipment > Mounting in a Rack > Care in Positioning

Care in Positioning

Positioning the Unit

CAUTION!

The following points must be taken in to consideration when positioning the unit.

The fans contained within this unit are not fitted with a dust/insect filter. Pay attention to

the environment in which it is to be used.

1.

Do not install units so that the air intake of one aligns with the outlet on another. Provide

baffles and adequate spacing.

2.

The equipment should never be placed near or over a radiator or other source of heat. It

should not be placed in a built-in installation such as a rack unless proper ventilation is

provided and the instructions have been adhered to.

Allow at least 40 mm free air-space at each side of the equipment to ensure adequate

cooling.

Racks containing stacked equipment may need to be forced air-cooled to reduce the

ambient temperature within the rack.

Protection from Moisture

Do not install this equipment in areas of high humidity or where there is a danger of water

ingress.

Cooling

Side openings in the unit, as well as side-mounted cooling fans, are provided for ventilation.

They ensure reliable operation of the product and protect it from overheating.

Page 58

Airflow Through the Unit

WARNING!

The ventilation openings must not be blocked or covered.

© Ericsson AB 2011. All rights reserved

Page 59

Home > SPR1100 Handbook > Installing the Equipment > Mounting in a Rack > Fixing

Fixing

Overview

The equipment is designed for fixed use only and has been shipped with fixing brackets

suitable for a standard 19-inch rack. When installed in a rack, it should be secured using the

fixing brackets. In addition, support shelves must be used to reduce the weight on the

brackets. Ensure it is firmly and safely located and it has an adequate flow of free-air.

Fixing the Unit

Slide the unit onto the chassis supports and affix to the rack by means of an M6 x 18 mm

panhead screw in each corner.

A freestanding unit should be installed on a secure horizontal surface where it is unlikely to

be knocked or its connectors and leads disturbed.

© Ericsson AB 2011. All rights reserved

Page 60

Home > SPR1100 Handbook > Installing the Equipment > Mounting in a Rack > Cable Types/Installing Cables

Cable Types/Installing Cables

Cable Types

The signal cable types (or similar) described in the following table are those recommended

by Ericsson in order to maintain product EMC compliance.

Signal Type

Connector

Cable

Ethernet (Control)

RJ-45

Alcatel Data Cable FTP 7 x 0.16

Ethernet (Data)

RJ-45 Cat 5e

Belden Datatwist (S-FTP)

Installing Cables – Safely

Power supply cables should be routed so that they are not likely to be walked on or pinched

by items placed upon or against them. Pay particular attention to cables at plugs,

convenience receptacles, and the point where they exit from the appliance.

Do not run AC power cables in the same duct as signal leads.

Do not move or install equipment whilst it is still attached to the mains supply.

Ensure safety and ESD precautions are observed whilst inter-connecting equipment.

© Ericsson AB 2011. All rights reserved

Page 61

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces

External Interfaces

Describes the connectors and visual indicators associated with each component of the

equipment.

Base Chassis

Identifies and describes each connector and indicator associated with the Chassis.

© Ericsson AB 2011. All rights reserved

Page 62

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis

Chassis/Host

General

Identifies the position of the connectors and indicators at the front and rear panels and what

combinations of external interfaces are supported.

Control Ethernet

Identifies the Ethernet Control ports located at the rear panel of the chassis and tabulates

the connectors' pinout. Describes the operation of each port, and the Status and Activity

indicators.

Data Ethernet

Identifies the Ethernet Data ports located at the rear panel of the chassis and tabulates the

connectors' pinout. Describes the operation of each port, and the Status and Activity

indicators.

AC Input Connector

Shows the rear panel AC connector and provides fusing information.

DC Input Connector

Shows the rear panel DC connector.

USB Connector

Provides information associated with the USB connector located at the front panel.

© Ericsson AB 2011. All rights reserved

Page 63

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > General

General

1 ‘RU’ Base Chassis Single PSU Rear Panel

WARNING!

It is strongly recommended that the terminal marked at the rear panel of the equipment is

connected to a site Technical Earth before any external connections are made and the

equipment is powered. This limits the migration of stray charges.

Location of the Ethernet and Single AC Connectors at the Rear Panel

All signal connections are made via the rear panel.

NOTE:

Single AC PSU version shown.

Front Panel

Identifying Items Located at the Front Panel

The front panel provides a 2 line by 40 character display, 6 buttons, and a red/amber/green

Page 64

tri-colour status LED.

Items on the Front Panel

LCD

Control and status information is displayed on a 2 line by 40 character display.

Buttons

Six buttons are provided for navigating through the front panel menus. See Front Panel

Controls and Pushbuttons for more details.

Status LED

An LED located at the front panel gives an indication of the status of the unit.

LED

State

Unit Status

Off

Unit not powered

Green

No active warnings or alarms

Amber

Active warning/s, minor or major

alarm/s

Red

Active critical alarm/s

USB Connector

This is not for customer use. Please refer to USB connector .

1 ‘RU’ Base Chassis Dual PSU Rear Panel

This chassis is the same as the 1 ‘RU’ Base Chassis but with the dual PSU.

Data Ethernet

Page 65

Control Ethernet

AC Input

Location of the Ethernet and Dual AC Connectors at the Rear Panel (Blanking Plates Fitted)

A technical specification for the connections is given in Technical Specification > Base

Chassis .

© Ericsson AB 2011. All rights reserved

Page 66

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > Control Ethernet

Control Ethernet

Overview

The Ethernet control ports are used to connect the equipment to a PC for access with a web

browser.

Page 67

Ethernet Ctrl Port Numbering

Both connectors share the same IP address, Ctrl1 is the Primary control port, and is by

default the active control port. Control Port Ctrl2 should be considered as the secondary

control network as it will not respond to the Control Port IP Address unless control has been

passed to it either as a result of a redundancy switch, or via a user command. The active

control port switches when Ctrl1 has no link (e.g. carrier), and Ctrl2 has the link.

Refer to:

Operation and Control >Basic Functions > Ethernet: Control for Control Port Parameters.

NOTE:

This equipment can be controlled using a single control

connection.

Page 68

Item

Specification

Connector type

RJ-45 (100/1000 Base T)

Connector designation

Ctl 1/2

Pin outs

(Unused pins are not connected)

Pin 1 - Tx Out(+)

Pin 2 - TX Out (-)

Pin 3 - Rx In (+)

Pin 6 - RX Out (-)

Status and Activity Indication

Each Ethernet Control Port has a rear panel mounted status LEDs associated with it to

indicate link status, activity and speed as follows:

Left (Green) LED

Port

Status

Link

Speed

LED Status

Active

Port

No Link

Off

- - - - - - - - - - - -

- - - - - -

100 Mbps

Flash Off

x 2

- - -

-

1000

Mbps

Flash Off

x 3

- - - -

- -

Spare

Port

No Link

Off

- - - - - - - - - - - -

- - - - - -

100 Mbps

Flash On

x 2

- - - - - - - -

- - - - - -

1000

Mbps

Flash On

x 3

- - - - - - -

- - - - -

The Right LED flash sequence period is 1 s, with the short flash duration being 100 ms.

Page 69

Right (Yellow) LED

Link

Activity

LED Status

No Link

Off

- - - - - - - - - - - - - - - - -

-

Link

On

Activity

Flash

- - - - - -

-

© Ericsson AB 2011. All rights reserved

Page 70

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > Data Ethernet

Data Ethernet

Overview

The unit has four Ethernet ports - two for data input, and two for data output and will

respond to ARPs, pings and other low-level Ethernet traffic. The ports are accessible via RJ45 connectors on the rear panel of the chassis. These are labeled Ge 1, Ge 2, Ge 3 and Ge

4.

Ge 1 and Ge 2 are used for data input, while Ge 3 and Ge 4 are data output.

Data Port Numbering

Page 71

Item

Specification

Connector type

RJ-45 (100/1000 Base T)

Connector designation

Ge 1 /2 Ge 3 /4

Pin outs

(Unused pins are not connected)

Pin 1 - Tx Out(+)

Pin 2 - TX Out (-)

Pin 3 - Rx In (+)

Pin 6 - RX Out (-)

Status and Activity Indication

Each Ethernet Data Port has a rear panel mounted status LED associated with it to indicate

link status, activity and speed as follows:

Left (Green) LED

Link Speed

LED Status

No Link

Off

- - - - - - - - - - - - - - -

- - 100 Mbps

Flash Off x 2

- - - -

1000 Mbps

Flash Off x 3

- - - - - -

The left LED flash sequence period is 1 s, with the short flash duration being 100 ms.

Right (Yellow) LED

Link Activity

LED Status

No Link

Off

- - - - - - - - - - - - - -

- - - Link

On

Activity

Flash

- - - - -

Refer to:

Operation and Control > Ethernet Data for Control Port Parameters.

Page 72

Appendices > Technical Specification > Chassis (Host) > Data Ethernet Specification for the

electrical characteristics.

© Ericsson AB 2011. All rights reserved

Page 73

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > AC Input

Connector

Power Requirements

AC Connector

The AC input connector is as follows:

Item

Description/Specification

Connector

Mains input filter with CEE 22/IEC320

plug

Fusing

Fuse in live conductor in mains input

filter

Fuse type

Time delay (T) 1500 A High breaking

capacity (HBC)

AC Power

AC Power Inlets

AC Input

Refer to:

Technical Specification > Base Chassis > Power Supply

Installing the Equipment > Site Requirements > AC Power Supply

Installing the Equipment > External Interfaces > Base Chassis > AC Input

Connector

Page 74

© Ericsson AB 2011. All rights reserved

Page 75

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > DC Input

Connector

Power Requirements

DC Connector

The DC input connector is as follows:

Item

Description/Specification

Connector

AMP Universal MATE-N-LOK 1-480700-0

Molex MLX 50-84-1030

Fusing

Not fused.

DC Power Inlets

DC Input

Refer to:

Technical Specification > Base Chassis > Power Supply

Installing the Equipment > Site Requirements > DC Power Supply

© Ericsson AB 2011. All rights reserved

Page 76

Home > SPR1100 Handbook > Installing the Equipment > External Interfaces > Base Chassis > USB Connector

USB Connector

The USB connector on the front panel of the unit is not for customer use.

USB Connector

This connector is only used for Test/Maintenance purposes.

© Ericsson AB 2011. All rights reserved

Page 77

Home > SPR1100 Handbook > Getting Started

Getting Started

Before any communication can be made with the unit the Control IP address needs to be

configured. The topics in this section will guide you through the process.

Setting the IP address

Describes how to set the required IP Address from the Front Panel.

IP address Ranges

This topic shows a table of allocated IP addresses adhering to the RFC3330 range of

restrictions .

Manual configuration via the web pages

The unit has been designed to be configured and controlled by way of a web interface.

© Ericsson AB 2011. All rights reserved

Page 78

Home > SPR1100 Handbook > Getting Started > Setting the IP Address

Setting the Required IP Address from the Front Panel

Power on the unit

Wait for initialisation to complete (approximately 1.5 minutes, depending on the

number of options fitted in the chassis).

Press the Right arrow pushbutton until the IP address is displayed, press edit and

then use the up/down/right/left arrow pushbuttons to set the required IP address

- Right/left pushbuttons will move the cursor between characters

- Up/down pushbuttons will increase/decrease the number selected by the cursor

Press save to store the new IP address.

Continue and set the subnet mask and gateway address in the same way using the

down pushbutton to reach each parameter.

NOTE:

IP Address range 192.168.10.x (subnet 255.255.255.0) is used for internal

unit communications, so should not be used for external communications.

Refer to Operation and Control > Front Panel for more details describing Front Panel

features.

NOTE:

A pushbutton is illuminated when there is functionality available. If a

pushbutton is not illuminated, pressing it will have no effect.

© Ericsson AB 2011. All rights reserved

Page 79

Home > SPR1100 Handbook > Getting Started > IP Address Ranges

IP Address Restrictions

IP Addresses on the unit must adhere to RFC3330 range of restrictions as listed in the

following table of allocated IP addresses.

Address Block

Present Use

Reference

0.0.0.0/8

"This" Network

[RFC1700, p4]

10.0.0.0/8

Private-Use Networks

[RFC1918]

14.0.0.0/8

Public-Data Networks

[RFC1700, p181]

24.0.0.0/8

Cable Television Networks

---

39.0.0.0/8

Reserved but subject to

allocation

[RFC1797]

127.0.0.0/8

Loopback

[RFC1700, p5]

128.0.0.0/16

Reserved but subject to

allocation

---

169.254.0.0/16

Link Local

---

172.16.0.0/12

Private-Use Networks

[RFC1918]

191.255.0.0/16

Reserved but subject to

allocation

---

192.0.0.0/24

Reserved but subject to

allocation

---

192.0.2.0/24

Test-Net

---

192.88.99.0/24

6to4 Relay Anycast

[RFC3068]

192.168.0.0/16

Private-Use Networks

[RFC1918]

198.18.0.0/15

Network Interconnect Device

Benchmark Testing

[RFC2544]

223.255.255.0/24

Reserved but subject to

allocation

---

224.0.0.0/4

Multicast

[RFC3171]

240.0.0.0/4

Reserved for Future Use

[RFC1700, p4]

Page 80

NOTE:

The control network and data networks should not conflict. It is suggested

that the ranges for these networks are in the Private-Use Networks as listed in

the summary Table.

IP Address range 192.168.10.x (subnet 255.255.255.0) is used for internal

unit communications, so should not be used for external communications.

© Ericsson AB 2011. All rights reserved

Page 81

Manual Configuration via the Web Pages

The Ericsson SPR1100 has been designed to be configured and controlled by its own web

interface, which is described here.

The main Transcode Configuration page can be found by the following navigation :

Configure > Services

1) Configure Input Streams

The left-hand panel of the Transcode page defines the input Transport Streams to be

processed by the unit.

Page 82

Transport Streams are grouped by Physical Interface. Each Transport Stream is defined by

its IP address and port number. Multiple services can reside within each transport stream,

with multiple components within each service.

The tree of input streams is navigated by expanding and contracting items using the and

buttons alongside. All entries within an item can be expanded by right-clicking on that

item and selecting Expand All .

Selecting an item (by clicking on it) causes the relevant properties for that item to be

displayed in the "Properties" panel. Properties that cannot be edited will be "greyed out".

Transport streams may be added to a Data Interface by right-clicking on the interface entry

and selecting Add transport stream .

2) Configure Output Streams

The second panel from the left defines the output Transport Streams that will be produced

Page 83

by the unit.

Transport Streams are again grouped by Physical Interface. Each transport Stream has an

IP address and port number, and can contain multiple services, with multiple components in

each service.

Transport Streams may be added in several ways:

Right-clicking the Output Interface and selecting Add transport stream .

Dragging streams or services from the Inputs panel and dropping them onto an

appropriate place in the heirarchy of the Outputs panel.

NOTE:

Each input service may be used in up to two independent (and different)

transcode operations. This is achieved by dragging the same input service to

multiple output multicasts. Each transcode will require a separate license.

Output services can be duplicated up to four times, so that the same transcode operation

can be included in up to four output Transport Streams. This is achieved by right-clicking on

Page 84

the output service and selecting "Duplicate Selected on output".

3) Configure the Transcode Operations

Each item in the Outputs panel can be configured at its position in the heirarchy. This allows

the operator to configure all dependent items together; for example, selecting a transport

stream would allow all services within that transport stream to be configured together.

Individual components can also be altered if a common configuration is not desired.

Page 85

For each item selected, a number of panes will appear in the Properties panel. These

include:

Transport Stream

Service

Video Component

Video PIP Component

Audio Component

Not all of these will be available for every component.

Each pane of the configuration may have several sets of parameters that may be

configured. These are arranged in a tabbed interface within the pane.

Page 86

4) Warnings, Errors and History

At the bottom of the Services Configuration page is an "Information" panel. This can show

Warnings, Errors, or Change History according to the tab selection on the left hand side

5) Allocation Status

With the very dense transcode configurations possible with the Ericsson SPR1100, it is all

too easy to lose track of exactly how much of the unit's resource has been used.

To assist the operator in managing the total allocation usage, the Services Configuration

page has an Allocation pane to show the amount of resource allocated or available with the

configuration currently set up on the page.

If more detail is required, the panel has a "Details" tab which will show the

allocated/available breakdown for each transcode type.

6) Apply Configuration

Page 87

All configuration changes initially only occur in the User Interface. The Ericsson SPR1100

does not change its behaviour until the operator presses the "Apply All" button.

Once the configuration is applied, the unit is updated with the new configuration.

NOTE:

Changing the configuration may cause output glitching. This is kept to a

minimum; transcoder units which do not need reconfiguration will not be

interrupted. Additionally, changing the output bit rate will not cause a glitch.

© Ericsson AB 2011. All rights reserved

Page 88

Home > SPR1100 Handbook > Transport Stream Output

Transport Stream Output

Output

Gives information relating to the Transport Stream from the unit.

Transport Stream

Gives information relating to the components of the transport stream.

© Ericsson AB 2011. All rights reserved

Page 89

Home > SPR1100 Handbook > Transport Stream Output > Output

Transport Stream Output Overview

Gives the extent of MPEG-2 compliancy and an overview of the Transport Streams.

Describes the TS IP Output Parameters, and states the Transport Stream and Output Data

rates.

IP Port

Gives an overview of the IP Encapsulator functional block.

Pro-MPEG FEC

Gives a brief explanation of Pro-MPEG FEC

© Ericsson AB 2011. All rights reserved

Page 90

Home > SPR1100 Handbook > Transport Stream Output > Output > Transport Stream Output Overview

Transport Stream Output Overview

MPEG-2 Compliancy

The encapsulated transport stream packets (video, audio, VBI/ANC data and PCR - 188

bytes), are fully compliant MPEG-2 transport streams (all relevant fields completed,

continuity counters, PTS/DTS, adaptation fields etc.).

Transport Streams

The system can form up to 128 output transport streams, with each stream mirrored on the

two physical output interfaces.

Transport Streams are encapsulated in either a UDP or a UDP and RTP packet and can have

added Pro-MPEG FEC packets before being transmitted out of the assigned Data Ethernet

port(s).

ProMPEG FEC

ProMPEG FEC (Forward Error Correction) as per SMPTE 2022 1/2 can be added to the

MPEG-2 Transport Stream to improve the reliability over IP networks if the relevant license

(SPR/SWO/PROFEC) has been purchased. One license instance is required per Transport

Stream.

NOTE:

The ProMPEG FEC functionality is not yet available on this product. Please

contact Customer Services for more details.

TS IP Output Parameters

The user can configure the following parameters for a transport stream to be IP

encapsulated and output.

Page 91

Parameter

Value

Description

TS packets per

UDP packet

1 to 7 [Default

7]

Defines the number of transport

stream packets encapsulated in

a UDP packet

TS Mode

CBR

Constant bit rate output

Output Enable

Off [Default]

IP Output is disabled

On

IP Output is enabled if the IP

destination can be resolved

Dest. IP Address

aaa.bbb.ccc.ddd

The destination IP address

Source IP Port

0 to 65335

[default =

5500]

Source IP Port number

Dest. IP Port

0 to 65335

[default =

5500]

Destination IP Port number

Type Of Service

0 to 255

[Default = 4]

ToS value for inclusion in the IP

header

Time To Live

0 to 240

[ Default = 15]

TTL value for inclusion in the IP

header

Encapsulation

Type

UDP [Default]

UDP encapsulation of TS

packets

RTP

UDP/RTP encapsulation of RTP

Packets

RTP/FEC

Column

UDP/RTP encapsulation of RTP

Packets with added onedimensional FEC

RTP/FEC

Column and

Row

UDP/RTP encapsulation of RTP

Packets with added twodimensional FEC

Output Data Rate

The system is designed to support a maximum output data rate of 216 Mbps per transport

stream, up to a total of 900 Mbps (nominally 1 Gbps) per chassis.

The bit rate of each output transport stream can be individually controlled with a resolution

of 1 kps.

© Ericsson AB 2011. All rights reserved

Page 92

Home > SPR1100 Handbook > Transport Stream Output > Output > IP Port

IP Port

Overview

The IP Encapsulator within the Host Card encapsulates transport stream packets in either a

UDP or a UDP and RTP packet before transmitting them out of the assigned Data Ethernet

port(s).

Technical Specification

Refer to Technical Specification > IP Output Transport Stream for the technical specification.

© Ericsson AB 2011. All rights reserved

Page 93

Home > SPR1100 Handbook > Transport Stream Output > Output > ProMPEG FEC

ProMPEG FEC

NOTE:

This feature is not yet available.

FEC Parameters

FEC is set up on a per-transport stream basis. The following description applies to the

graphical user interface.

If the user has the appropriate license installed to use FEC then these are the parameters

which can be set (with itemised lists of available values where appropriate):

Parameter

Values

Description

IP

Encapsulation

UDP

UDP encapsulation of TS packets

RTP

RTP encapsulation of TS packets

RTP/FEC Column

UDP/RTP encapsulation of RTP Packets

with added one-dimensional FEC

RTP/FEC Column

and Row

UDP/RTP encapsulation of RTP Packets

with added two-dimensional FEC

Number of

Rows

4 - 20

An integer between 4 and 20. See FEC

constraints section for allowable

ranges.

Number of

Columns

1 - 20

An integer between 1 and 20. See FEC

constraints section for allowable

ranges.

Alignment

Block Aligned

Non Block Aligned

Constraints on FEC Parameters

To promote interoperability and simplify implementation, limits are specified for values of

the L (number of columns) and D (number of rows) parameters. ProMPEG FEC requires

equipment manufacturers to support all combinations of values of L and D within these

limits. The specified limits are:

Columns Only: (L*D <= 100) and (1 <= L <= 20) and (4 <= D <= 20)

Rows and Columns: (L*D <= 100) and (4 <= L <= 20) and (4 <= D <= 20)

Background

Page 94

Forward Error Correction or FEC, enables packets lost during transmission over IP networks

to be recovered by adding extra information to the transmitted data. The particular type of

FEC used on the unit is that specified by SMPTE 2022 1/2.

The key features of ProMPEG FEC are:

• Open standard FEC scheme.

• Increased robustness of transmission.

• Increases network reach through FEC on high loss links.

• Highly configurable depending on bandwidth vs. robustness.

• FEC transmitted separately to media stream.

• Independent of video compression standard (MPEG-2, MPEG-4).

ProMPEG FEC can help to solve the problems caused by missing packets. It is an open

standard for protection of contribution broadcast real-time transmissions over IP networks

by facilitating real-time lost packet recovery at the receive units. It permits flexible

configurations for optimisation requirements. The scheme uses an RTP layer which adds

timing information for sequence correction. FEC packets are transmitted in separate IP

packets. It uses a matrix of media packets to calculate the FEC packets. The matrix size

defined by columns (L) and rows (D). FEC packets are calculated along columns and rows

using the XOR function. FEC can be 1D (Column Only) or 2D (Column and Row). Media and

FEC packets are transmitted on separate IP streams with the Column FEC stream offset

from media stream and has a UDP port number which is the media port number +2. The

Row FEC stream is offset from Media stream and has UDP port number which is the media

port number +4. This arrangement means that non-enabled FEC receivers can simply ignore

FEC streams and decode the media packets. The FEC data stream is off-set from the media

stream to protect against burst error loss and jitter. At the receiver, lost packets recovered

using the FEC data packets. The Column FEC protects against burst errors and the Row FEC

protects against random errors. ProMPEG FEC recovers lost packets using column and

(optionally) row FEC packets using the XOR function on the remaining packets. Depending

on the distribution and severity of the pack loss not all errors are recoverable.

The overhead which results from ProMPEG FEC transmitting extra packets depends on

whether column or column and row FEC is selected and how many columns and rows there

are. (Note that L = number of columns, D = number of rows.)

Column FEC: 1D FEC Overhead = (L+(D*L))/(D*L) = 1/D + 1

Worst case, 4 rows = 25%

Best case, 20 rows = 5%

Column and Row FEC: 2D FEC Overhead = (D+L+(D*L))/(D*L)

Worst case, 4 x 4 = 50%

Best case, 10 x 10 = 20%

FEC offers two methods of block alignment (also referred to as FEC linearisation) for use

when generating FEC packets: Non Block Aligned and Block Aligned. Both are guaranteed of

being able to correct L errors, sometimes more. The Block Aligned method can however

correct 2L+2 errors; this never happens with Non-Block Aligned.

Non-Block Aligned can in theory have a lower latency at the decoder if it can be guaranteed

that the mode of operation will never change.

Page 95

Block Aligned linearisation is dealt with in Annex B of the ProMPEG Code of Practice. In

Block Aligned column FEC packets are sent every D’th frame and the L Column FEC packets

are played out every D slots. They are therefore evenly spread over the D*L matrix period.

Non Block Aligned linearisation is dealt with in Annex A of the ProMPEG Code of Practice. In

Non Block Aligned the matrix is ‘skewed’ for the column calculation. The L column FEC

packets are played out at the end of every column plus a constant. For ‘square’ matrices

(diamonds) where L=D then these column packets will emerge at regular intervals. For

‘rectangular’ diamonds they will not. In the case of a 4 column by 20 row matrix the 4 FEC

packets will emerge within 16 slots, followed by a gap of 64 slots before the next 4. It

therefore produces a less linear spread of packets.

Receivers which do not have FEC capability can simply ignore the FEC packets and just

make use of the media packets.

© Ericsson AB 2011. All rights reserved

Page 96

Home > SPR1100 Handbook > Transport Stream Output > Transport Stream

Transport Stream

Gives information relating to the components of the transport stream.

Services

This topic gives an overview of how the Service Information is formed and the Service

Information Tables (MPEG-2 SI) available from the MPMs. General information about

repetition rates for SI packets is also given.

Coded Elementary Stream

Supported Profiles and the Output Bit Rate are given. Describes the use of PCR

Placeholders.

Audio Output

Gives information on Transcoding and associated delay and lip sync.

Describes the use of PCR Placeholders in audio packets.

Transport Packets

General information on packetised elementary stream (PES) Packets. Also some specific

information relating to video Streams. Talks about PIDs used in Transport Packet Headers.

VBI Data on a Separate PID

States the conditions for VBI on a separate PID.

PID Assignment

Describes the assignment of PID values.

© Ericsson AB 2011. All rights reserved

Page 97

Home > SPR1100 Handbook > Transport Stream Output > Transport Stream > Services

Services

Overview

The system is capable of forming up to 72 services divided between the output transport

streams.

Each service can contain a maximum of 18 elementary streams, consisting of a maximum of

8 data components, 8 audio components, one main video and one PIP video component.

An elementary stream can be included in up to four services. Only one main video

elementary stream can be assigned to a service, and the audio delay will be matched to the

video. A PIP Video stream may also be added. Only one PCR can be associated with a

service.

Service Information Tables

The SI tables that the system generates for each individual output transport stream can be

selected. The following table shows the available levels.

SI Level

Description

Off

Elementary streams only

On (PAT/PMT Only)

PAT/PMT are generated

On (PAT/PMT/SDT/CAT)

The listed tables are generated. The CAT will

be empty as Conditional Access is not

supported in this release.

Some users may not require ETR 290 compliance, so it is possible to set the PMT repetition

rate to either 100 ms (default) or 500 ms.