Page 1

SmartEdge 600 Router Hardware Guide

Release 6.3

INSTALLATION

27/153 30-CRA 119 1170/1 Uen A

Page 2

Copyright

© Ericsson AB 2010. All rights reserved. No part of this document may be

reproduced in any form without the written permission of the copyright owner.

Disclaimer

The contents of this document are subject to revision without notice due to

continued progress in methodology, design and manufacturing. Ericsson shall

have no liability for any error or damage of any kind resulting from the use

of this document.

Trademark List

SmartEdge

NetOp

is a registered trademark of Telefonaktiebolaget LM

Ericsson.

is a trademark of Telefonaktiebolaget LM Ericsson.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 3

Contents

Contents

1 Site Preparation 1

1.1 Agency Compliance Information 1

1.2 Electrical Specifications 1

1.3 Electrical Power Connections 4

1.4 Environmental Requirements 4

1.5 Physical Specifications 5

1.6 Select the Rack 7

1.7 Select the Installation Method 8

1.8 Equipment and Personal Safety Warnings 9

1.9 DC Power Source Warnings 10

1.10 Access During Initial Startup and Reload Operations 11

1.11 Access During Normal Operations 11

1.12 Management Access Options 11

1.13 Gathering Cables and Tools 12

1.14 Management Access Cables 13

1.15 External Timing Cables 15

1.16 Line Card Cable Specifications 16

1.17 Transceiver-Based SONET/SDH Line Card Cables 17

1.18 10/100 Ethernet and Fast Ethernet–Gigabit Ethernet

Cables 18

2 Installing the Hardware 21

2.1 Install the Chassis Mounting Brackets 22

2.2 Install the Chassis 23

2.3 Install the Cable Management Brackets 23

2.4 Connect Power and Ground Cables 24

2.5 Optional AC Power Shelf 27

2.6 Card Slots 32

2.7 Install Cards 33

2.8 Connections for Management Access 40

2.9 Connections for External Timing Cables 41

2.10 Connections for Line Card Cables 42

2.11 Connect and Route Cables 43

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 4

SmartEdge 600 Router Hardware Guide

2.12 Power On and Off the System 46

3 Hardware Control and Troubleshooting 49

3.1 Hardware Status 49

3.2 CLI Commands for Hardware Control 50

3.3 CLI Commands for Hardware Troubleshooting 52

3.4 Values for CLI Input Arguments 52

3.5 Output Fields for the show chassis Command 53

3.6 Output Fields for the show disk Command 55

3.7 Output Fields for the show hardware Command 56

3.8 Output Fields for the show port Command 63

3.9 Output Fields for the show port transceiver Command 69

3.10 Troubleshoot with System and Card LEDs 72

3.11 Troubleshoot with System Power and Alarm LEDs 72

3.12 Troubleshoot with Card Status LEDs 81

3.13 Troubleshoot with On-Demand Diagnostics 81

3.14 Obtaining Assistance 87

4 Servicing Hardware 89

4.1 Adding a Second Controller Card 91

4.2 Replacing a Controller Card 91

4.3 Replacing a Transceiver 94

4.4 Cleaning Optical Connectors 97

4.5 Replacing the Fan Tray 98

4.6 Replacing the Air Filter 99

4.7 Remove and Replace an AC Power Module 100

5 System Overview 103

5.1 Specification Summary 103

5.2 Line Card Interfaces 103

5.3 Packet Mesh Architecture 104

5.4 Redundancy 104

5.5 Alarms 104

5.6 System Status 104

5.7 SmartEdge 600 Chassis 105

6 Card Descriptions 107

6.1 Controller Cards 108

6.2 8-Port ATM OC-3c/STM-1c Card 114

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 5

SmartEdge 600 Router Hardware Guide

6.3 4-Port ATM OC-3c/STM-1c Card 117

6.4 1-Port Enhanced ATM OC-12c/STM-4c Card 119

6.5 8-Port POS OC-3c/STM-1c Card 122

6.6 4-Port POS OC-12c/STM-4c Card 124

6.7 4-Port POS OC-48c/STM-16c Card 127

6.8 1-Port OC-192c/STM-64c Card 129

6.9 12-Port 10/100 Ethernet Card 131

6.10 60-Port Fast Ethernet Card 132

6.11 4-Port Gigabit Ethernet Card 135

6.12 4-Port Advanced Gigabit Ethernet Card 137

6.13 4-Port Gigabit Ethernet 3 Card 139

6.14 10-Port Gigabit Ethernet 1020 Card 141

6.15 20-Port Gigabit Ethernet 1020 Card 143

6.16 5-Port Gigabit Ethernet Card 146

6.17 20-Port Gigabit Ethernet Card 149

6.18 1-Port 10 Gigabit Ethernet Card 153

6.19 4-Port 10 Gigabit Ethernet Card 155

7 Advanced Services Engine 159

7.1 LEDs 160

7.2 Provisioning and Configuring the ASE Card 161

7.3 ASE Operational Commands 161

7.4 Operating Status 162

8 SmartEdge Storage Engine 163

8.1 Hard Disk Drive Description 163

8.2 Specifications and LEDs 163

8.3 Provision and Configure the SSE Card 166

8.4 SSE Operational Commands 166

8.5 Operating Status 168

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 6

SmartEdge 600 Router Hardware Guide

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 7

1 Site Preparation

Site Preparation

Select the installation site for the SmartEdge

®

600 router, considering

maintenance, electrical, and ventilation requirements. In addition, consider

current and future cabling requirements.

1.1 Agency Compliance Information

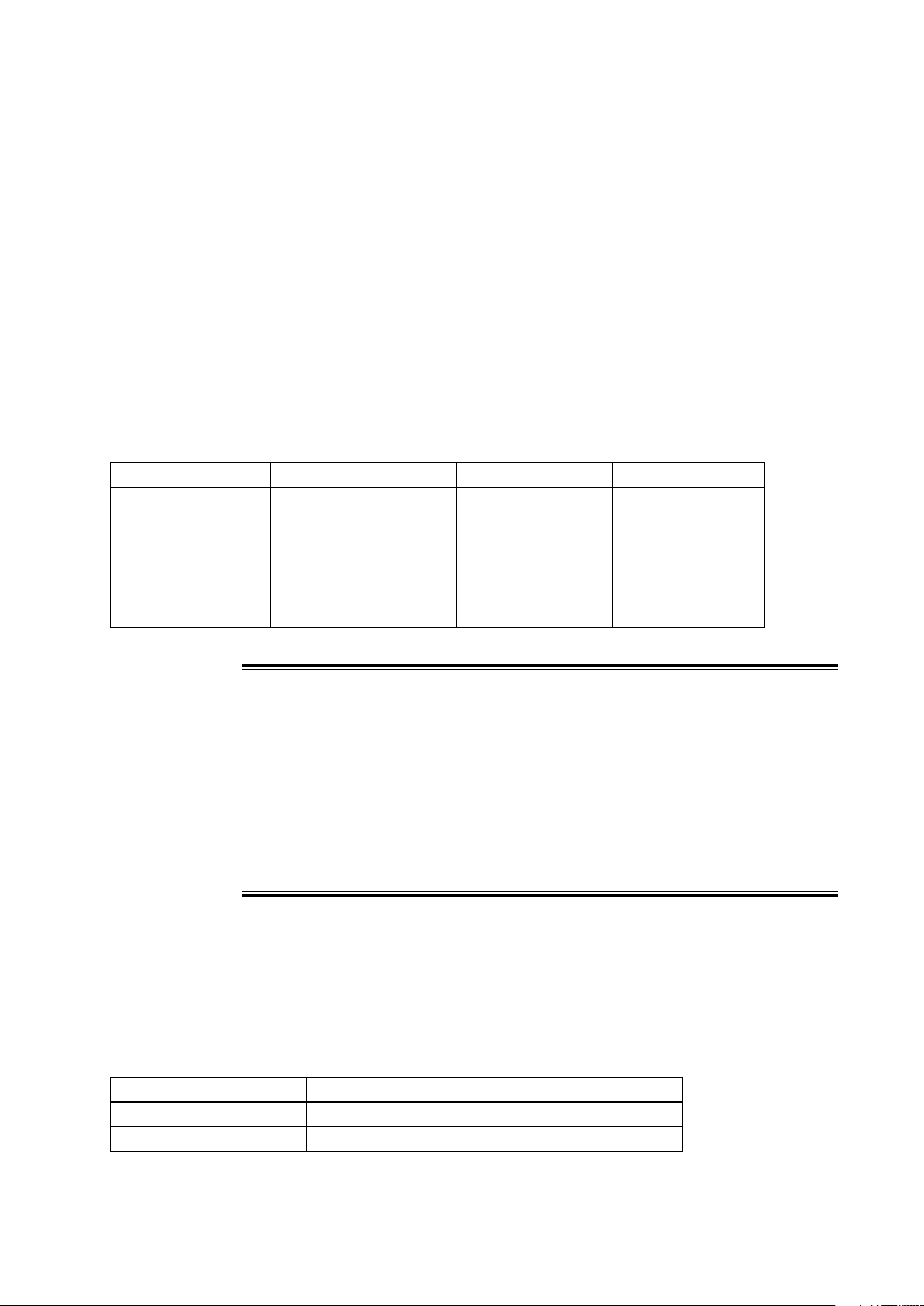

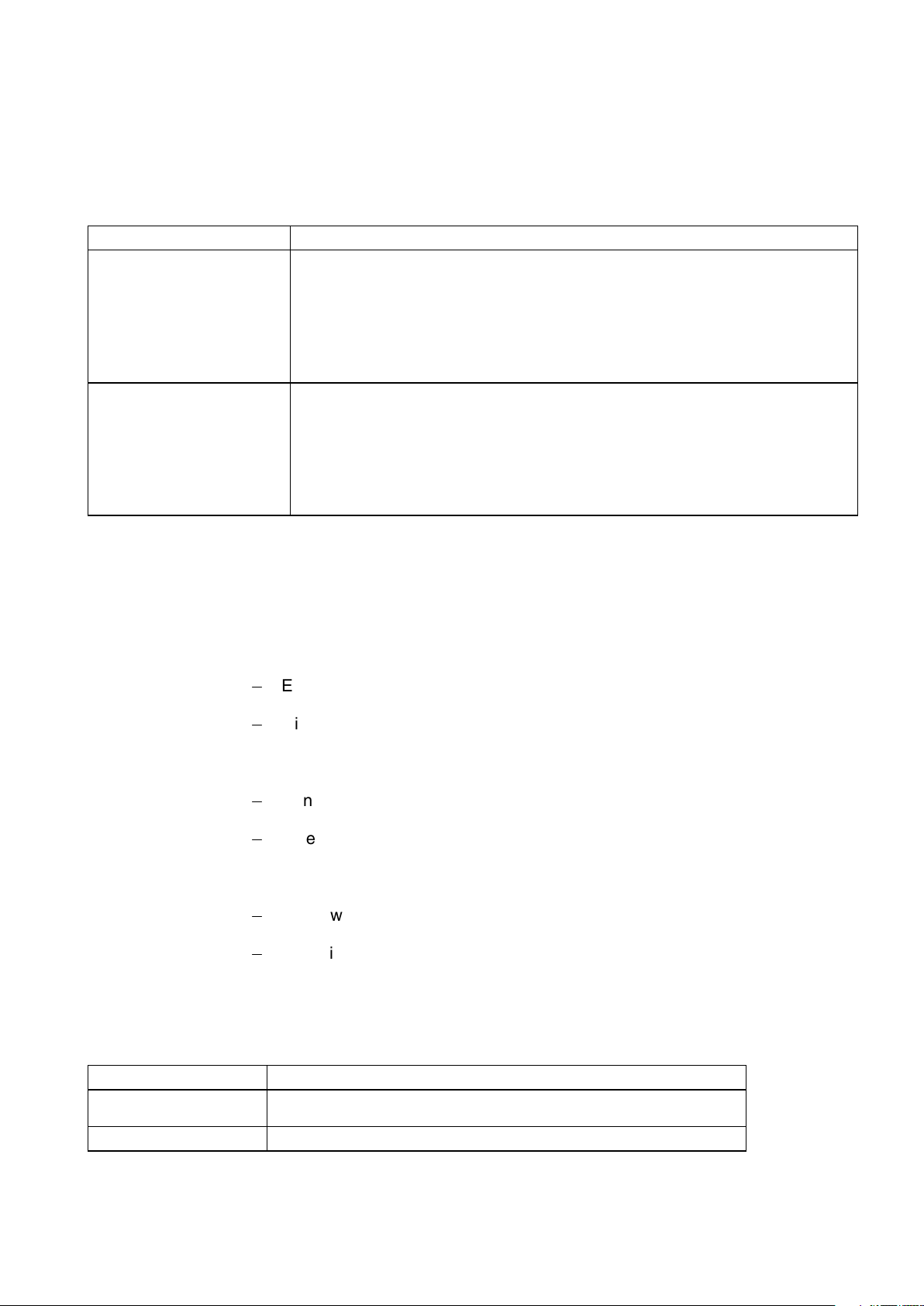

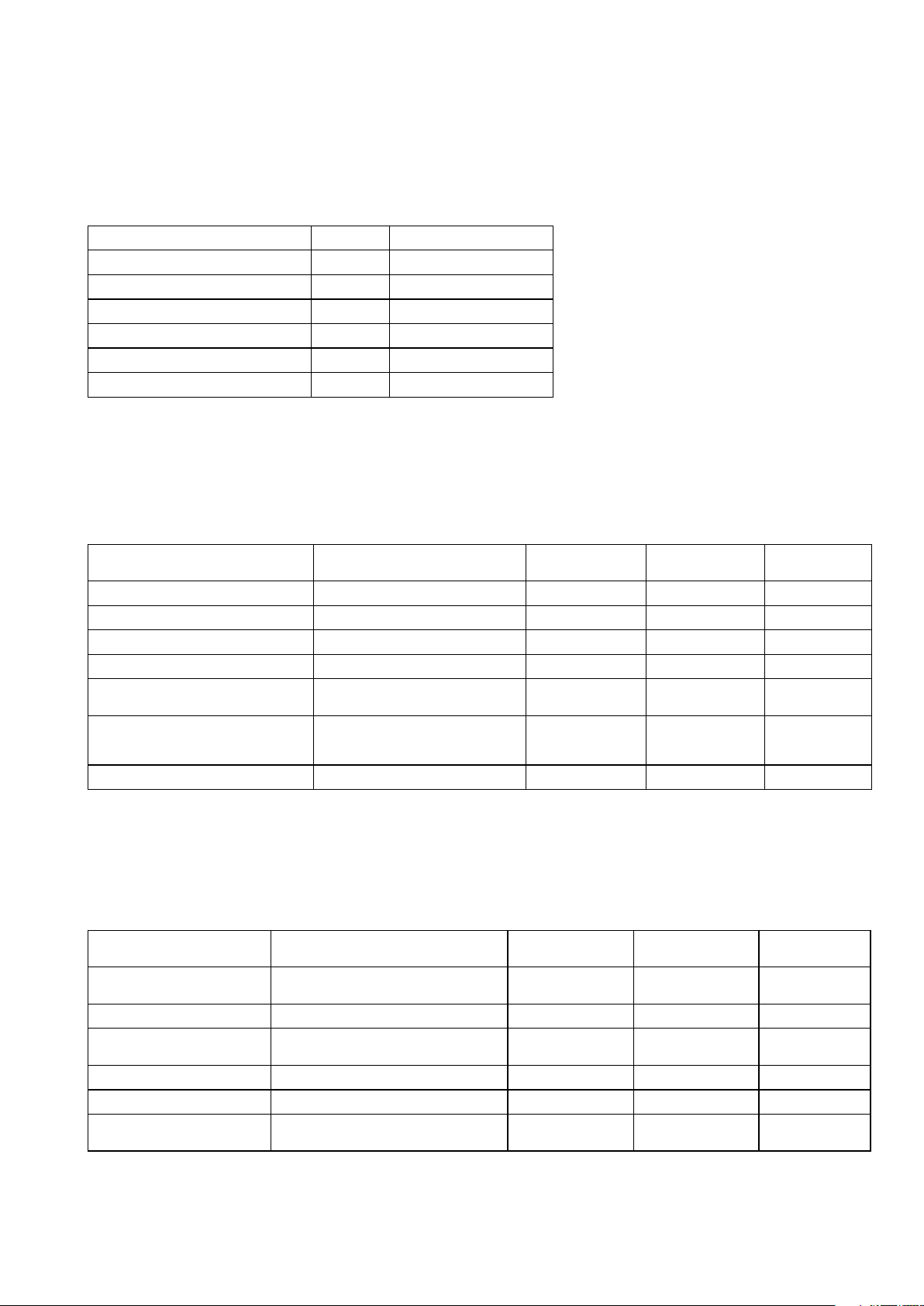

Table 1 Agency Compliance Standards

Product Safety Emissions Immunity NEBS Level 3

UL 60950

CSA 22.2 No. 60950

IEC60950

EN60950

AS/NZS 60950

FCC part 15, Class A

ETSI EN300 386

CISPR 22 Class A

VCCI Class A

EN55022, Class A

AS/NZA 3548 Class A

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-4-5

EN61000-4-6

ETSI EN300 386

GR-63-CORE

GR-1089-CORE

Caution!

Risk of equipment damage. The intrabuilding ports of the line cards are suitable

for connection to intrabuilding or unexposed wiring or cabling only. These ports

must not be metallically connected to interfaces that connect to the outside

plant (OSP) or its wiring. These interfaces are designed for use in intrabuilding

interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE, Issue

4) and require isolation from the exposed OSP cabling. The addition of primary

protectors is not sufficient protection to connect these interfaces metallically to

OSP wiring.

Note: The SmartEdge 600 router is suitable for installation in Network

Telecommunications Facilities and as part of the Common Bonding

Network (CBN).

1.2 Electrical Specifications

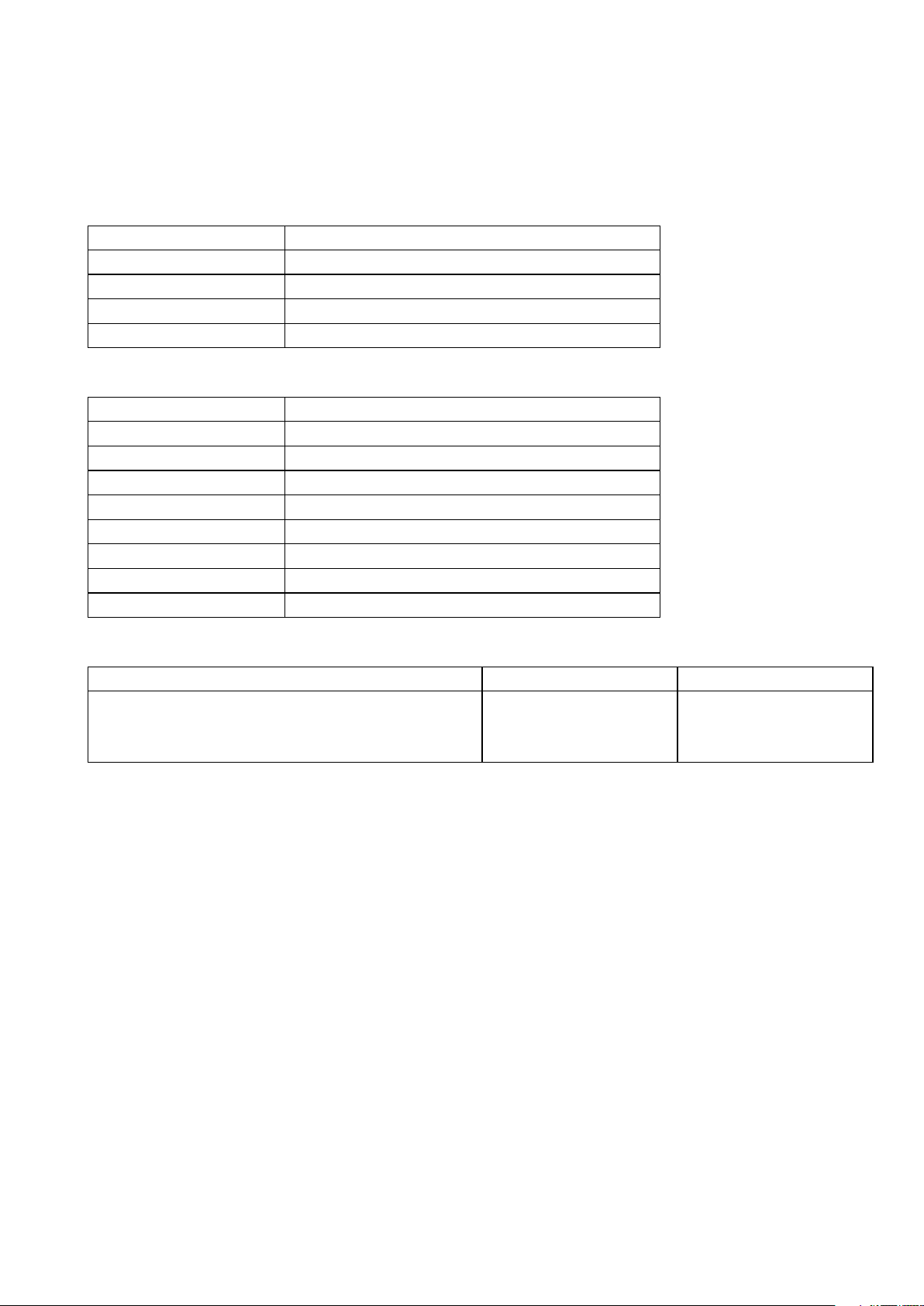

Table 2 DC Electrical Specifications

Requirement Value

Input voltage, nominal –48.0 VDC

Input voltage range –40.0 VDC to –57.5 VDC

127/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 8

SmartEdge 600 Router Hardware Guide

Table 2 DC Electrical Specifications

Requirement Value

Total input power, maximum 2736 VA

Input current rating per feed 57 ADC@–48 VDC

Source DC power requirement Sufficient to supply the rated input current Local codes apply

Number of input feeds Two: One from battery plant A and one from battery plant B

Table 3 AC (Optional) Electrical Specifications

Requirement Value

Input voltage, nominal 200 to 240 VAC

Input voltage range 175 VAC to 275 VAC

Input power, maximum 3120 VA

Input current rating 15.6A maximum @ 200 to 240 VAC

Input line frequency, nominal 50 to 60 Hz

Input line frequency, range 47 to 63 Hz

Source AC power requirement 20A, IEC-320

Number of input feeds Two independent branch circuits

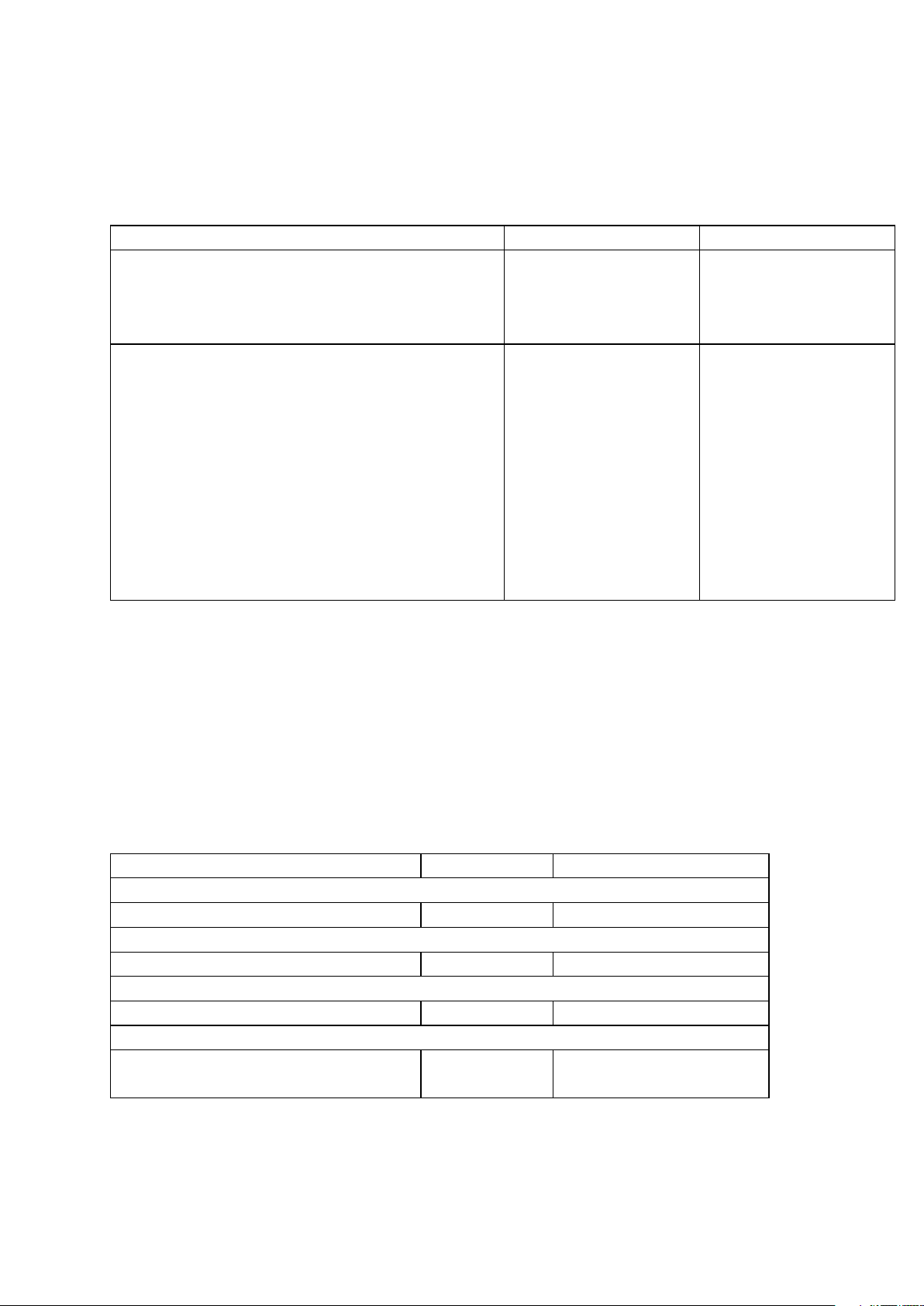

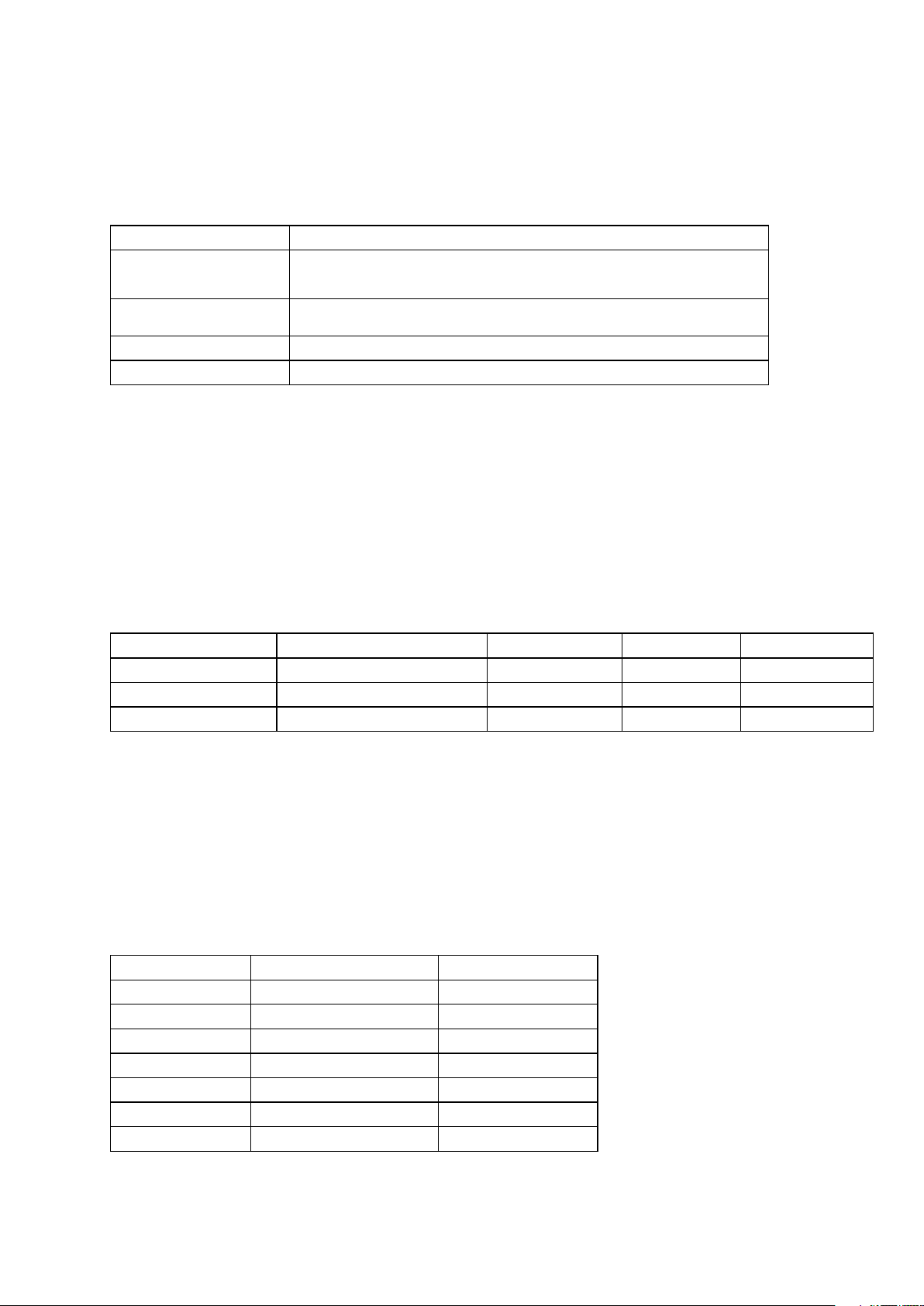

Table 4 Operating and Inrush Current for Line Cards at –48 VDC

Component Operating Current Inrush Current

ATM OC-3c/STM-1c (8-port)

ATM OC-3c/STM-1c (4-port)

Enhanced ATM OC-12c/STM-4c IR (1-port)

2.98

1.88

1.80

0.55

4.96

4.98

(1)

2 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 9

Site Preparation

Table 4 Operating and Inrush Current for Line Cards at –48 VDC

Component Operating Current Inrush Current

POS OC-3c/STM-1c (8-port, any SFP version)

POS OC-12c/STM-4c (4-port, any SFP version)

POS OC-48c/STM-16c (4-port, any SFP version)

OC-192c/STM-64c (1-port, any XFP version)

10/100 Ethernet (12-port)

Fast Ethernet–Gigabit Ethernet (60-port FE, 2-port GE)

Gigabit Ethernet (4-port, first versions)

Advanced Gigabit Ethernet (4-port, second versions)

Gigabit Ethernet 3 (4-port)

Gigabit Ethernet 1020 (10-port)

Gigabit Ethernet 1020 (20-port)

Gigabit Ethernet (5-port)

Gigabit Ethernet (20-port)

10 Gigabit Ethernet (1-port)

10 Gigabit Ethernet (4-port)

(2)

(3)

2.10

2.16

3.25

2.72

1.44

2.80

1.56

1.56

2.24

2.95

3.70

2.30

6.25

2.72

6.25

1.10

1.10

1.10

10.52 (max duration is 28 ms)

4.20

0.62 (max duration is 28 ms)

4.04

4.04

4.00 (max duration is 20 µs)

14.20 (max duration is 20 µs)

12.40 (max duration is 20 µs)

1.34 (max duration is 20 µs)

1.50

10.52 (max duration is 20 µs)

1.00

(1) Inrush current occurs during power on or during the installation of a component in a powered-on chassis. Unless

noted, maximum duration is 4 ms.

(2) The 20-port GE1020 card requires two adjacent slots.

(3) Because the TX SFP is larger than a standard SFP, you cannot insert two TX SFPs side by side on the 20-port

GE line card.

(1)

Note: The conventions of "traffic card" and "line card" have been used

interchangeably in various SmartEdge documentation.

Inrush current occurs during power on or during the installation of a component

in a powered-on chassis. Unless noted, maximum duration is 4 ms.

Table 5 Operating and Inrush Current for Chassis Components at –48 VDC

Component Operating Current Inrush Current

Controllers

XCRP4 (active or standby)

ASE

Advanced Services Engine

SSE

SmartEdge Storage Engine

Chassis

Fan tray (nominal speed)

Fan tray (high speed)

2.21

2.68

2.8

2.20

5.40

0.52 for 25 ms

1.20 for 120 ms

0.86 for 48 ms

6.60 for 3 ms

6.60 for 3 ms

327/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 10

SmartEdge 600 Router Hardware Guide

1.3 Electrical Power Connections

The SmartEdge 600 chassis power architecture has connectors for a single

power zone.

Primary sources are designated as A sources; backup sources are B sources.

For a fully redundant power configuration, both sources must be connected.

Each power connection must be able to supply a minimum of 75 amperes. DC

power connections require copper wire of a size suitable for the installation in

accordance with the National Electrical Code (in the United States) or applicable

local jurisdiction (outside the United States) installation requirements. An

external fuse panel, either a stand-alone unit or incorporated in a DC power

supply system, or a circuit breaker panel is required for power-on and power-off

control. A DC-powered system uses –48 VDC power and is powered from a

fuse panel, which can be damaged by overloaded circuits.

Caution!

Risk of equipment damage. Ensure that the fuses in the external fuse panel

are suitably rated for the installation in accordance with the National Electrical

Code (in the United States) or applicable local jurisdiction (outside the United

States) installation requirements.

1.3.1 AC Power Option

You can supply power to the SmartEdge 600 by means of an optional AC

Power Shelf (BMK 907 058/1). It requires a 200-240VAC power source. It has

two power modules (BMK 905 76/1) and a split power bus for redundancy.

Each power module is capable of delivering 2725 Watts.

The AC Power Shelf has a status port for use in monitoring warnings and errors.

1.4 Environmental Requirements

The installation area for the SmartEdge 600 hardware must allow the following

clearances:

• A minimum of 6.0 inches (15.2 cm) at the back of the chassis (for cable

routing)

• A minimum of 20.0 inches (50.8 cm) at the front of the chassis (for

maintenance)

4

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 11

Site Preparation

Caution!

Risk of equipment damage. The SmartEdge 600 router can be damaged by

lack of proper cooling and ventilation. To reduce the risk, never install the

chassis in an unventilated area, and always ensure that cooling equipment

sufficient to maintain a temperature of less than 104

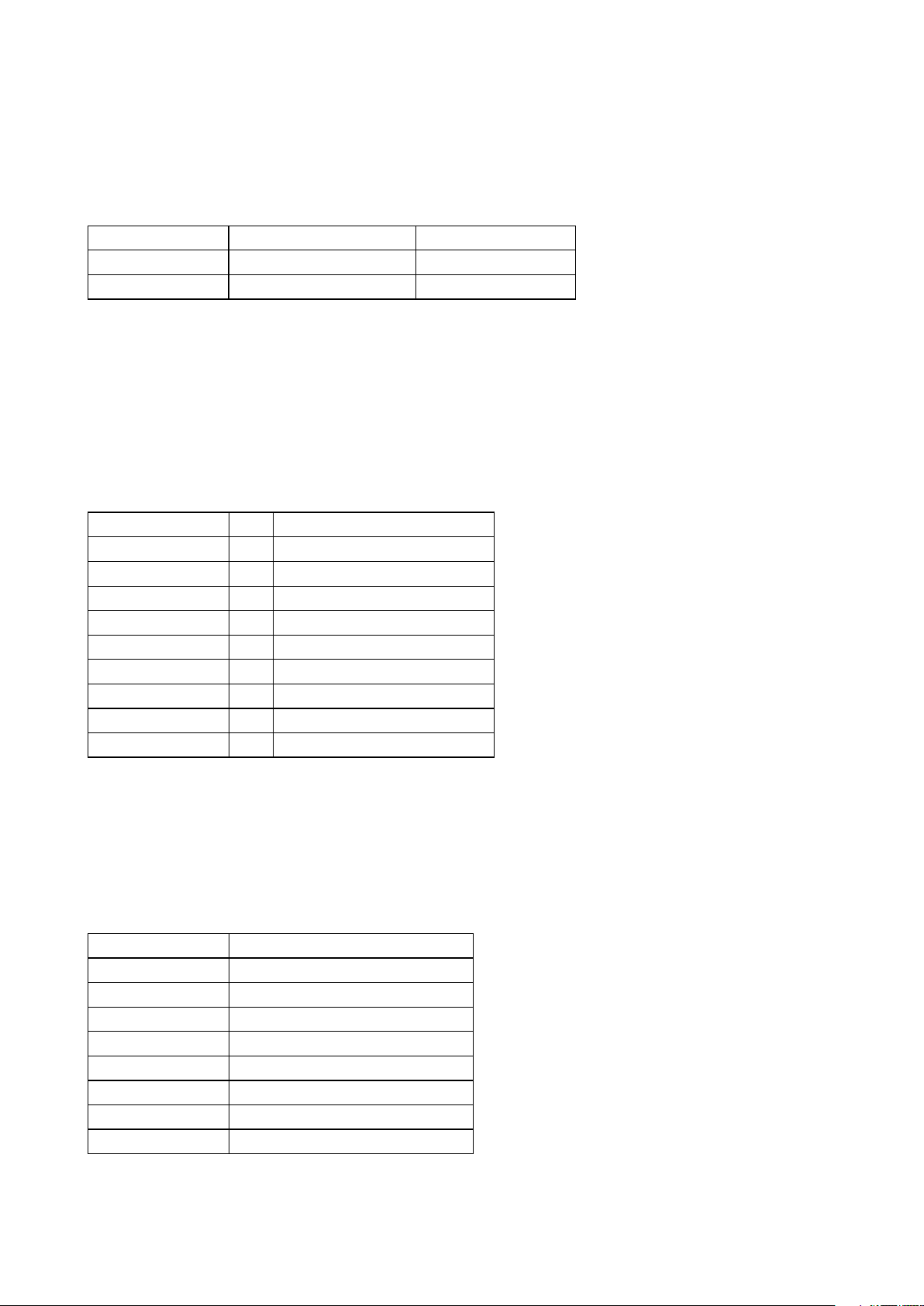

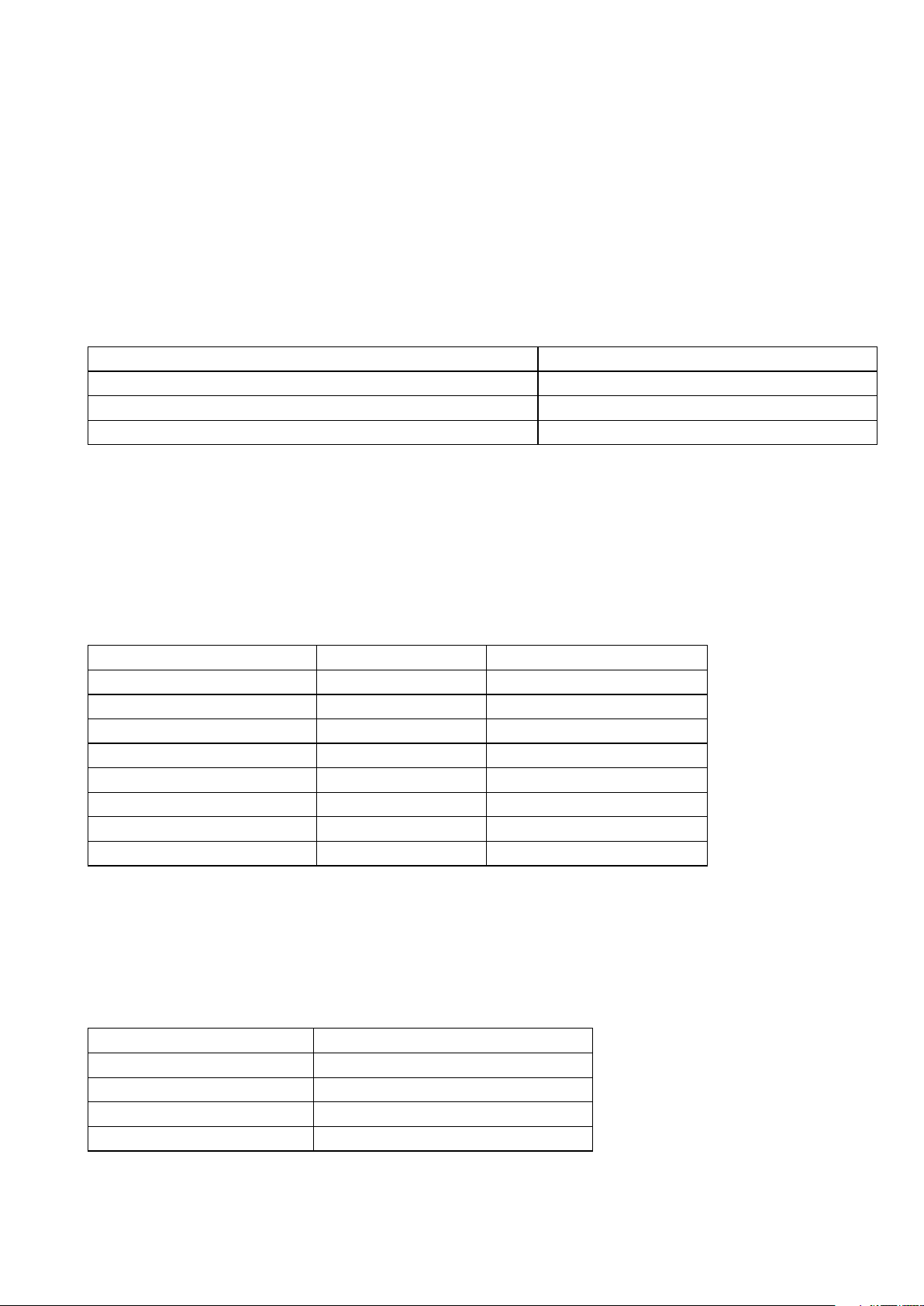

Table 6 Environmental Requirements

Specification Value

Cooling Forced air (fan cooled)

Operating temperature, nominal

Operating temperature, short term

Storage temperature

Operating relative humidity 5 to 95% RH (noncondensing)

Storage relative humidity 5 to 95% RH (noncondensing)

Operating altitude 0 to 10,000 ft (3,048m)

Earthquake Telcordia 63-CORE Zone 4-compliant

Thermal dissipation, maximum 2,736 watts (9,336 BTU/hour)

(1)

to 104

41

23

to 131F (–5

-38

to 150

(1) Short term refers to a period of time not more than 96 consecutive hours and a total of not more than 15 days in

one year (360 hours in any given year, but no more than 15 occurrences during that year).

F(5

to 40C)

to 55

F (–40to 70

C)

C)

F (40C) is available.

1.5 Physical Specifications

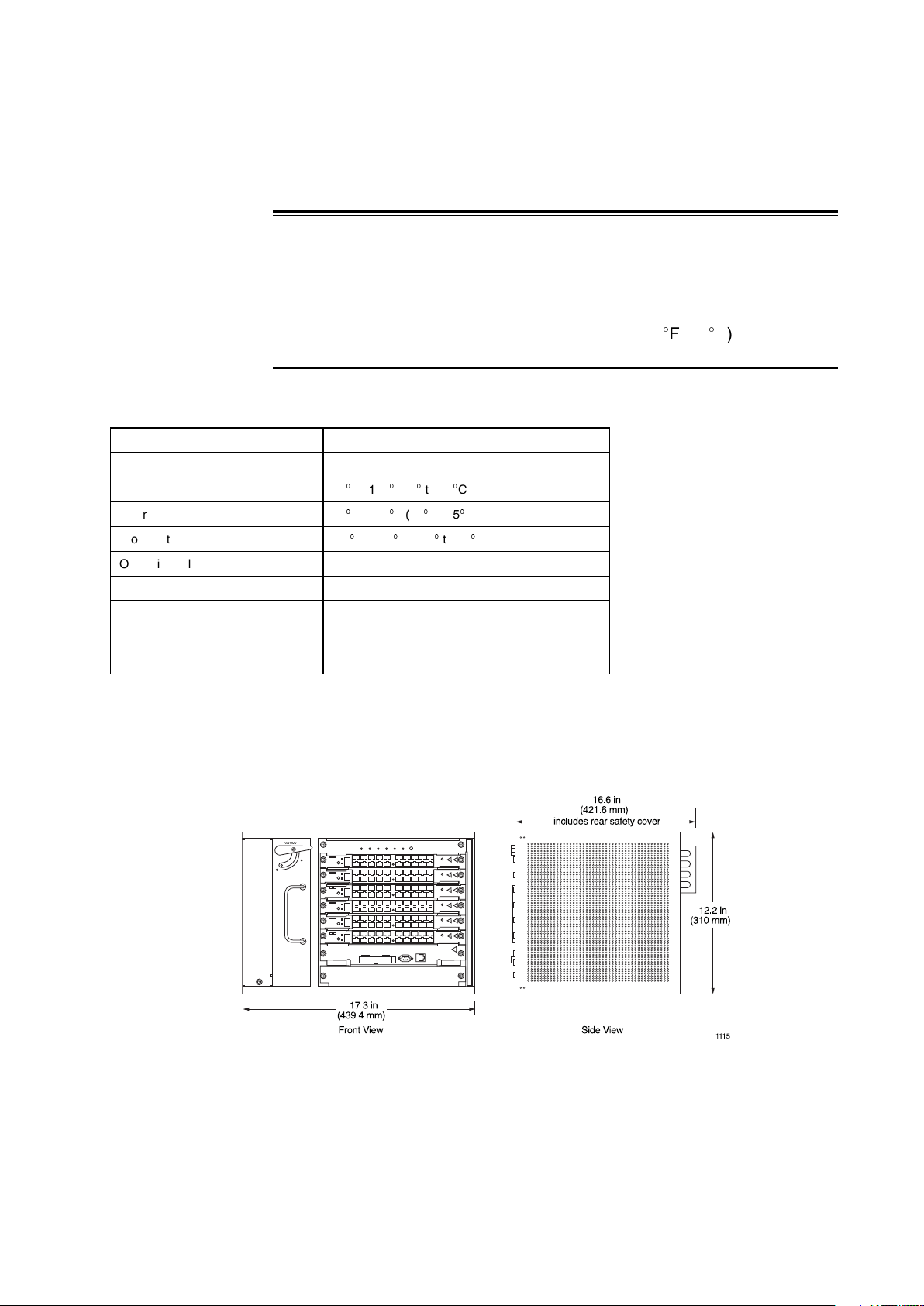

Figure 1 SmartEdge 600 Chassis Dimensions

Chassis depth dimension includes the front cable tray and the power safety

cover.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

5

Page 12

SmartEdge 600 Router Hardware Guide

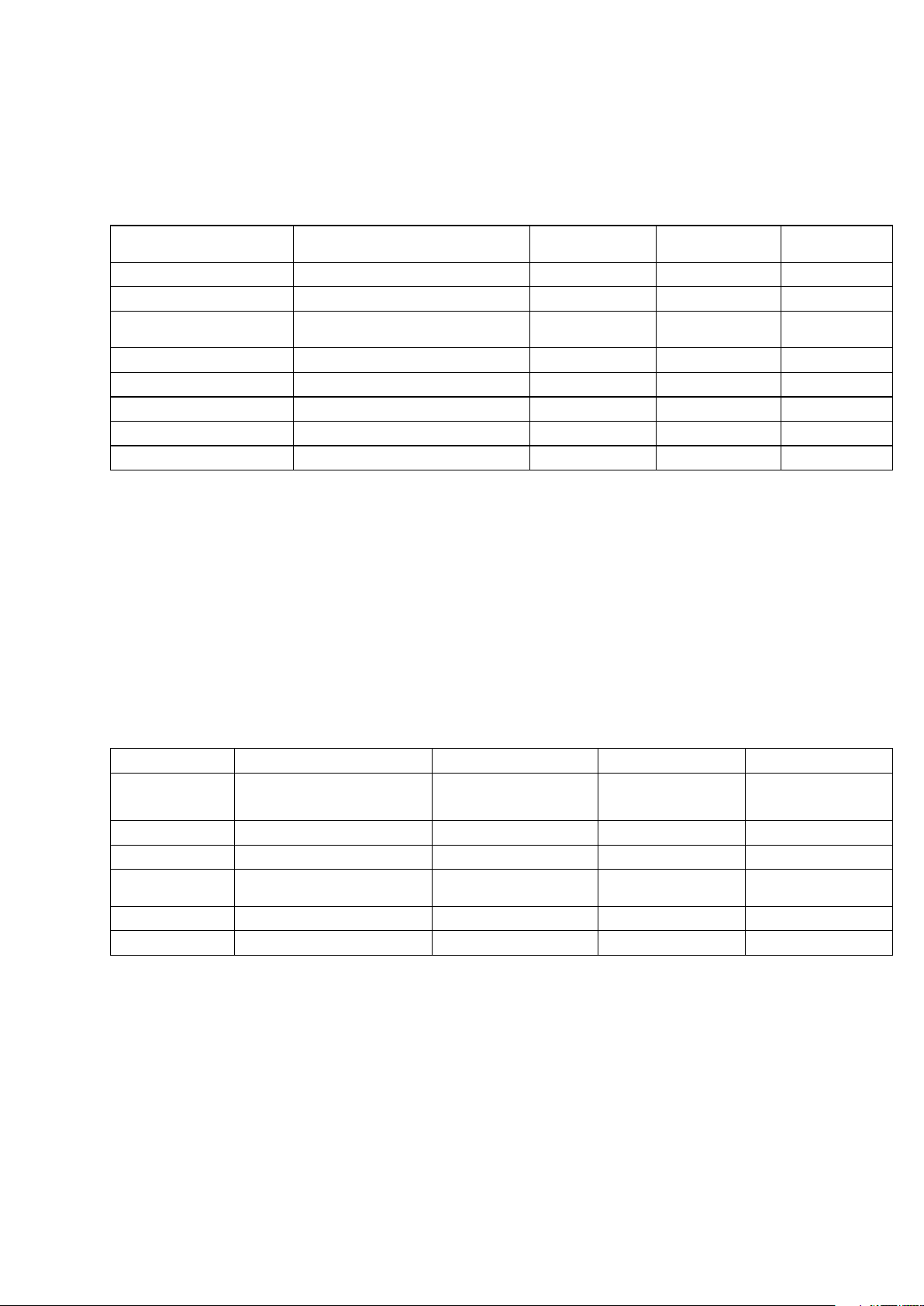

Table 7 SmartEdge 600 Chassis Physical Specifications

Mechanical Specification Value

SmartEdge 600 chassis

dimensions

Chassis weight 48.7 lb (22.1 kg) all card slots empty, ready for installation

Chassis mounting 19- or 23-inch rack

Total slots

Line card slots

Common equipment slots

Card dimensions 9.75 inches (247.7 mm) height

12.2 inches (310.0 mm) height

17.3 inches (439.4 mm) width

16.6 inches (421.6 mm) depth

94 lb (42.6 kg) with all slots filled

8

6

2

12.73 inches (323.3 mm) depth

(1)

(1) Includes rear safety cover.

Table 8 SmartEdge 600 Connections

Card Connections Connector Type

ATM OC-12c/STM-4c IR (1-port)

ATM OC-3c/STM-1c (4-port)

ATM OC-3c/STM-1c (8-port)

10/100 Ethernet (12-port)

Fast Ethernet–Gigabit Ethernet (60-port FE, 2-port GE)

Gigabit Ethernet (4-port, first and second versions)

Gigabit Ethernet 3 (4-port)

Gigabit Ethernet 1020 (10-port)

Gigabit Ethernet 1020 (20-port)

Gigabit Ethernet (5-port)

Gigabit Ethernet (20-port)

10 Gigabit Ethernet (1-port)

10 Gigabit Ethernet (4-port)

OC-192c/STM-64c (any XFP version)

OC-48c/STM-16c (4-port, any SFP version)

(1)

LC, front chassis access

LC, front chassis access

LC, front chassis access

RJ-45, front chassis access

MRJ21 (FE ports), RJ-45 (GE ports), front chassis

(2)

access

SC or RJ-45, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

LC, front chassis access

(3)

6 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 13

Site Preparation

Table 8 SmartEdge 600 Connections

Card Connections Connector Type

Management workstation (LAN)

Craft console (RS-232)

External Timing, Primary and Secondary (DS-1 or E1)

Modem, SL7 and SL8 (RS-232)

(4)

Alarm

Status/Ctl

Power and chassis ground

Advanced Services Engine RJ-45, front chassis access

(1) The 20-port GE1020 card requires two adjacent slots.

(2) The front panel has five MRJ21 connectors, each supporting 12 FE ports; a breakout cable, which uses RJ-45

connectors for the individual ports, is available from Ericsson.

(3) Connector type is determined by the gigabit interface converter (GBIC) version installed in the port.

(4) The SmartEdge OS does not support this connection.

(4)

(4)

RJ-45, front chassis access

DB-9, front chassis access

DB-9, rear chassis access

DB-25, rear chassis access

DB-25, rear chassis access

DB-37, rear chassis access

1/4-20 threaded holes on 0.625-inch (1.59 cm) centers,

rear chassis access

1.6 Select the Rack

You can mount the SmartEdge 600 chassis in a standard 19- or 23-inch rack.

Brackets for the 23-inch rack are not shipped with the chassis but are available

in the bracket spares kit (NTM 101 1517/1).

Risk of equipment damage. Never install the chassis in a rack that has not

been stabilized by being bolted to the floor and to the ceiling and always select

a mounting position that is suitable to the type of rack in which the chassis

is being installed.

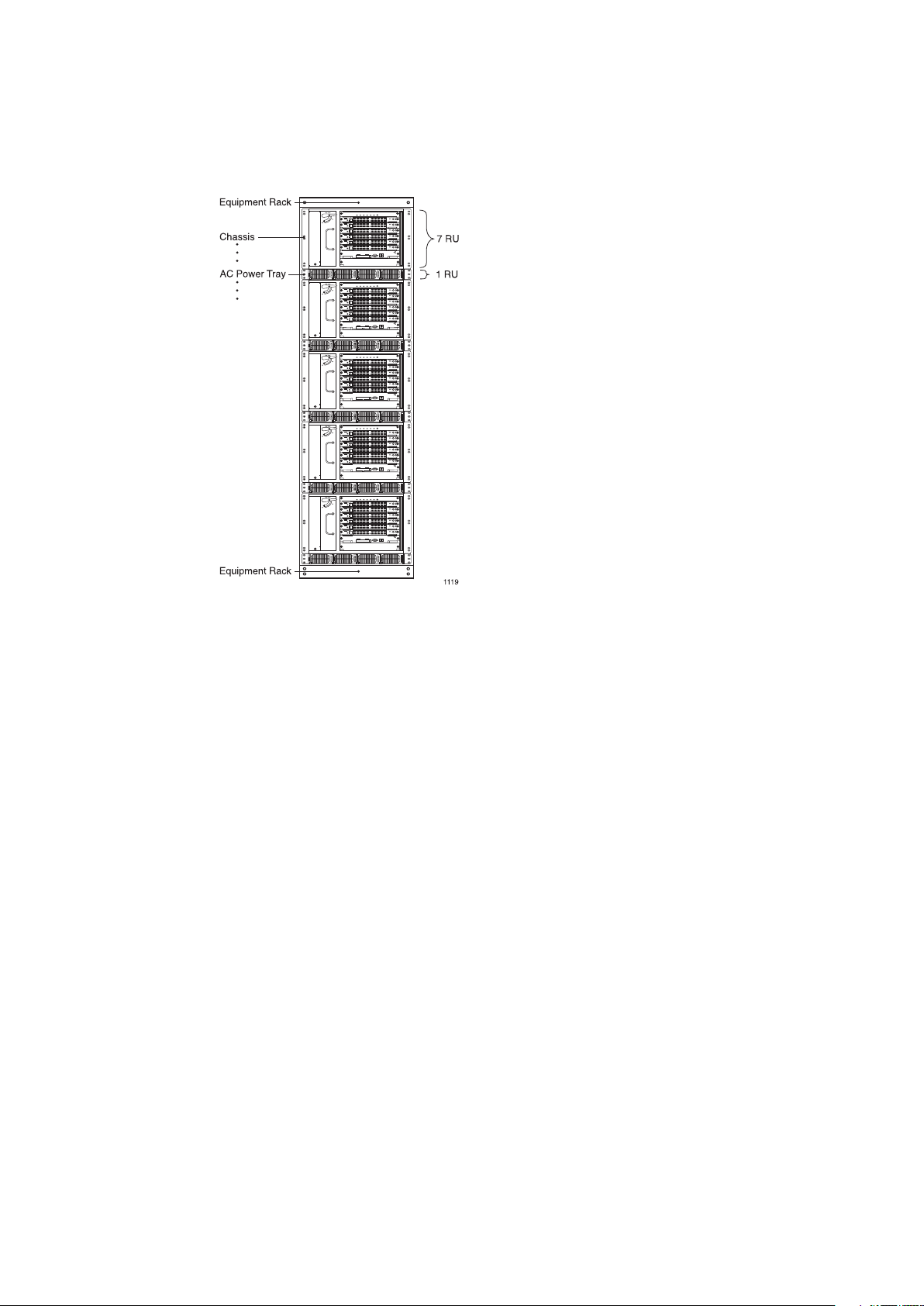

The SmartEdge 600 chassis requires 7 RUs—1.75 inches (4.50 cm). The

optional AC shelf at the bottom of the rack requires 1 RU; a stand-alone

external fuse panel requires 1 RU.

Note: Ericsson does not supply fuse panels.

Caution!

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

7

Page 14

SmartEdge 600 Router Hardware Guide

Figure 2 SmartEdge 600 Chassis in 42-RU Rack

Regardless of rack width and height, the SmartEdge 600 chassis can be

mounted only in the flush position.

1.7 Select the Installation Method

The SmartEdge 600 chassis is heavy, as much as 48.7 lb (22.1 kg) when

all slots have cards installed, and somewhat unwieldy. When planning the

installation, consideration must be given to how the chassis can best be

installed at the site you have chosen.

Two possible installation scenarios are to:

• Install the chassis as shipped.

Two people can perform the installation without additional aid if the chassis

is empty with no removable components installed. The effective weight of

the chassis without removable components is 48.7 lb (22.1 kg).

• Install the chassis with all components already installed.

Use a power lifting device to position the chassis in the rack if you intend to

install the fan tray, cable tray, and controller and line cards before installing

the system in a rack.

8

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 15

1.8 Equipment and Personal Safety Warnings

Warning!

Risk of electrical shock. Always remove the fuses in the fuse panel for all power

sources to the chassis before connecting the power cables to the chassis. After

the power cables are connected to the chassis and the fuse panel, the system

is fully powered on; there is no power switch.

Warning!

Site Preparation

Risk of electrical shock. This equipment must be connected to a protective

ground in accordance with the instructions provided in this guide. Improper

grounding can result in an electrical shock.

Warning!

Risk of electrical shock. Only qualified personnel are allowed to service the

system. There are mechanical and electrical shock hazards present throughout

the system if one or more of the cards is removed.

Caution!

Risk of severe damage to your eyes. Do not stare into the connector or directly

view the laser beam emerging from the connector. Keep the connectors

covered until you are ready to connect the fiber-optic cables. All versions of

the optical cards are Class 1 products, which use lasers to convert electrical

signals to optical signals that can damage your eyes.

927/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 16

SmartEdge 600 Router Hardware Guide

Warning!

Risk of personal injury. Disconnect the telecommunications network cables

before removing the card to which they are connected. This equipment does

not provide safety isolation between any port that is connected to a digital

network termination point and any other port to which terminal equipment may

be connected.

1.9 DC Power Source Warnings

Warning!

Risk of electrical shock. A readily accessible disconnection device, such as a

fuse in a fuse panel, must be provided in the fixed wiring for each DC power

source. It must be suitable for the rated voltage and current specified. Because

a system is fully powered on after all power connections are made, it can cause

shock if a power cable is disconnected from the chassis.

Warning!

Risk of electrical shock. Disconnect all telecommunications network lines

before disconnecting the unit from the ground point. Safe operation of this

equipment requires connection to a ground point.

Warning!

Risk of electrical shock. DC power sources can cause severe injury. The DC

power sources must be installed only in restricted access areas (dedicated

equipment rooms, equipment closets, or the like) in accordance with Articles

110-17, 110-26, and 110-27 of the National Electric Code, ANSI/NFPA 70.

Connect the chassis to a –48 VDC source that is reliably connected to earth.

10 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 17

Site Preparation

1.10 Access During Initial Startup and Reload Operations

During the initial startup, only the operable console port is the one labeled

ENET MGMT on the XCRP4 Controller card. During a reload operation, the

management port is disabled until the initial stage of the reload is complete; all

messages displayed during the reload are sent to the console port.

You access the SmartEdge 600 router with a terminal connected to the console

port, either directly or through a terminal server.

For information about configuring cards, ports, and circuits, see configuration

documents located at h

ttps://ebusiness.ericsson.net.

1.11 Access During Normal Operations

After you have configured the management port, you can use one or more of

the following options to provide management access:

• A local management workstation, using a connection to the Ethernet

management port on a controller card

• A remote management workstation, using a routed or bridged connection

to the Ethernet management port on a controller card

• A local console terminal with a direct connection to the Craft port on a

controller card

• A remote console terminal with a connection to the Craft port on a controller

card, using a terminal server or a modem

For redundancy, we recommend using two different methods (for example,

a remote workstation and a remote console terminal with a connection to

a terminal server). Further, if the configuration of the SmartEdge 600 router

includes redundant controller cards, you should use the same means of access

to connect each controller card, so that consistent management access, despite

a failure, is guaranteed.

1.12 Management Access Options

Table 9 Options for Management Access

Option Equipment Requirements

Ethernet port connection to a local

management workstation

Ethernet port connection to a

remote management workstation

A PC or workstation with support for SSH and Telnet. Shielded Ethernet crossover cable.

A PC or workstation with support for SSH and Telnet. Shielded Ethernet straight cable (shipped

with the system). Router or bridge.

1127/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 18

SmartEdge 600 Router Hardware Guide

Table 9 Options for Management Access

Option Equipment Requirements

Craft 2 port connection to a local

console terminal

Craft 2 port connection to a

remote console terminal

Local terminal—choose one of the following options:

• ASCII/VT100 console terminal or equivalent that runs at 9600 bits per second, 8 data bits, no

parity, 1 stop bit.

• PC or workstation in the same configuration as the ASCII/VT100 terminal.

Terminal server.

Craft console cable (shipped with the system).

Local terminal—choose one of the following options:

• ASCII/VT100 console terminal or equivalent that runs at 9600 bits per second, 8 data bits, no

parity, 1 stop bit.

• PC or workstation in the same configuration as the ASCII/VT100 terminal.

A modem that runs at 56 kbps (maximum), 8 data bits, no parity, 1 stop bit, or terminal server.

Modem or terminal server cable.

1.13 Gathering Cables and Tools

You need cables for the following connections:

• Line card cables:

0

Ethernet cards

0

Gigabit Ethernet cards

• Operations cables:

0

Console terminal and management workstation (RS-232, LAN)

0

External timing (one or two, optional)

• Power cables:

0

DC power (four or eight)

0

Chassis ground (two)

If you intend to build your own cables, see Management Access Cables for

cable and connector specifications.

Table 10 Tools Needed for SmartEdge 600 Hardware Installation

Tool Purpose

Heavy-duty cart Transport chassis and system equipment from the receiving area to the installation

Power lifter Optional (depending on installation scenario). Position the chassis in the rack.

site.

12 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 19

Site Preparation

Table 10 Tools Needed for SmartEdge 600 Hardware Installation

Tool Purpose

#1 Phillips screwdriver Remove and install the fan tray and cable tray; remove and install the cards. The

#2 or #3 Phillips screwdriver

7/16-inch torque wrench Connect the chassis ground cables.

Cable crimping tool

(2)

(1) Depending on the screws that you use to install the chassis in a rack, a #3 Phillips screwdriver might be more

appropriate than the #2 screwdriver.

(2) The OUR840 manufactured by Burndy Tooling (recommended) or equivalent.

(3) When barrel lugs are not provided, other options are available to secure the conductors.

screwdriver needs a 0.1875-inch barrel that is 5 to 6 inches long to install and

remove the cable tray.

(1)

Attach the mounting brackets to the chassis and air ramp. Install the chassis and air

ramp in the rack.

Secure barrel or open lugs to the DC power and chassis ground cables.

(3)

1.14 Management Access Cables

A management access cable connects a console terminal, management

workstation, or modem to a port on a controller card or the chassis.

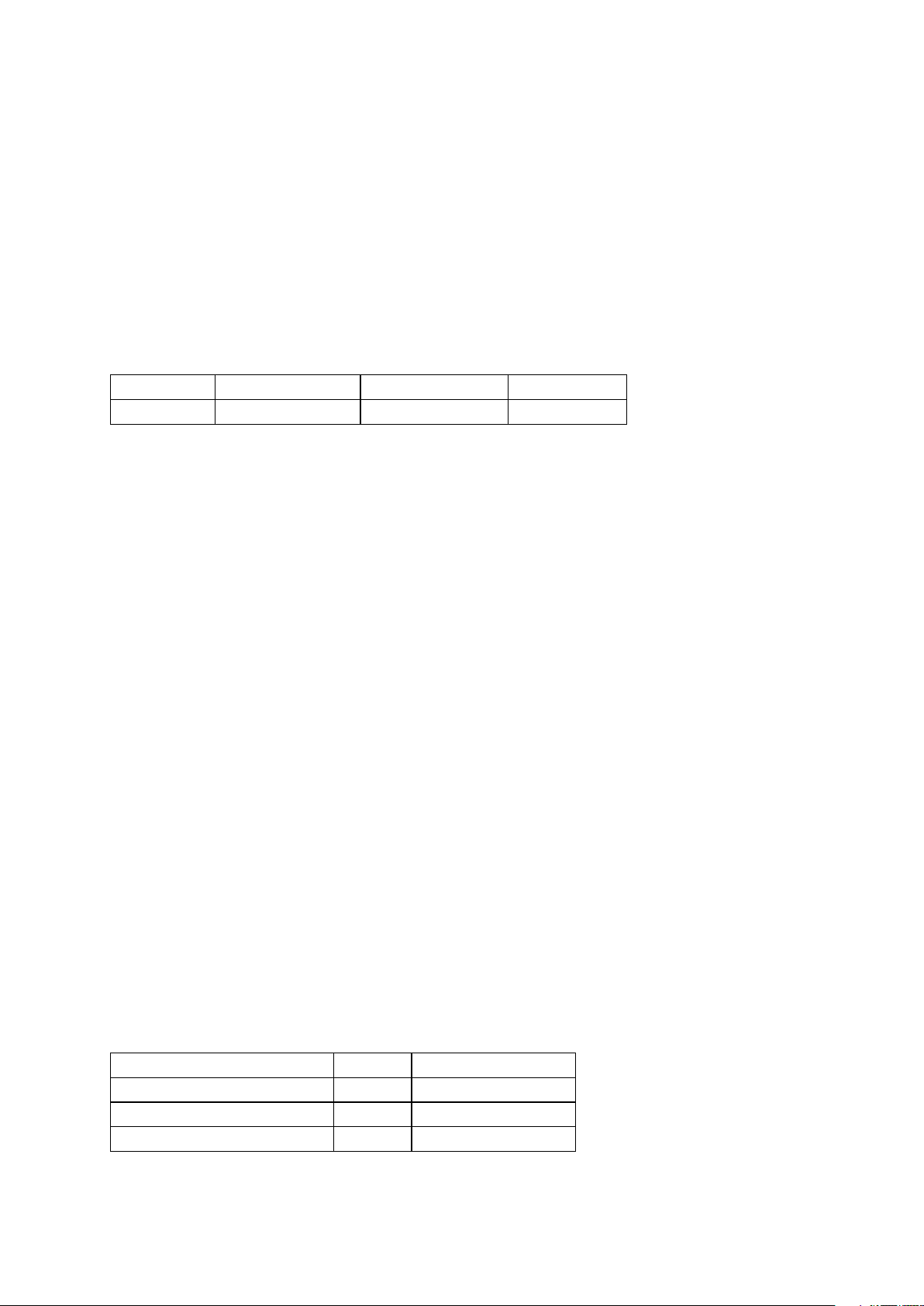

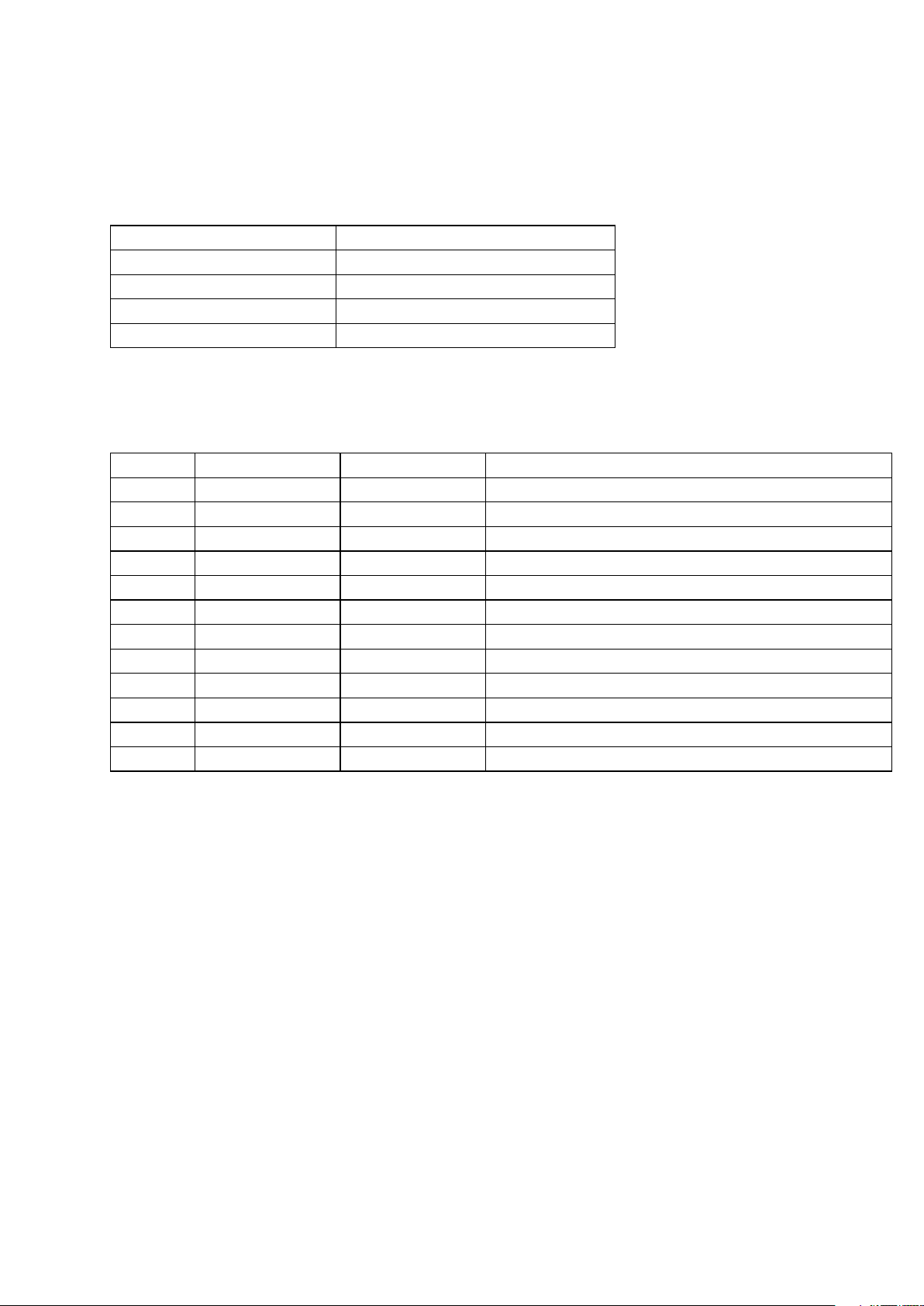

Table 11 Cable Specifications for Management Access Cables

Name Description System Connectors Cable Connector Maximum Length

Craft console cable RS-232 DB-9 female DB-9 male 35.0ft - 10.7m

Ethernet crossover cable Category 5 shielded twisted-pair RJ-45 female RJ-45 male 328.1ft - 100.0m

Ethernet straight cable Category 5 shielded twisted-pair RJ-45 female RJ-45 male 328.1ft - 100.0

(1) The maximum cable length for RS-232 cables is for any baud rate.

1.14.1 Craft Console Cable

This cable connects a local Craft console to the Craft 2 port on a controller

card. The cable is constructed as a straight-through connection between a

DB-9 male connector at the system end and a DB-9 female connector at the

computer terminal end.

Table 12 Craft Console Cable Pin Assignments

Signal Name

DCD (input) Received Line Signal Detector Not used

TXD (output) Transmitted Data SmartEdge 600 output

RXD (input) Received Data SmartEdge 600 input

DSR (input) DCE Ready Not used

–

DTR (output) DTE Ready Not used

CTS (input) Clear to Send Not used

(1)

Signal Function Notes

Signal Ground

–

(1)

1327/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 20

SmartEdge 600 Router Hardware Guide

Table 12 Craft Console Cable Pin Assignments

Signal Name

RTS (output) Request to Send Not used

RI (input) Ring Indicator Not used

(1) The direction, input or output, is with respect to the controller card: input describes data flowing into the controller

card; output describes data being transmitted by the controller card.

(1)

Signal Function Notes

1.14.2 Ethernet Crossover Cable

This shielded cable connects the Ethernet port on a PC to the Ethernet port

on a controller card. Both ends of the cable are terminated in standard RJ-45

eight-pin modular plugs.

Table 13 Ethernet Crossover Cable Pin Assignments

Other End

Signal Name Pin Notes

–

Tx (+)

Tx (–)

Rx (+)

––

––

Rx (–)

––

––

3

6

1

2

–

–

No connection

No connection

–

No connection

No connection

1.14.3 Ethernet Straight Cable

This shielded cable connects the Ethernet port on a controller card to a LAN

hub. Both ends of the cable are terminated in standard RJ-45 eight-pin modular

plugs.

Table 14 Ethernet Straight Cable Pin Assignments

Signal Name Notes

Tx (+)

Tx (–)

Rx (+)

–

–

Rx (–)

–

–

–

–

–

No connection

No connection

–

No connection

No connection

14 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 21

1.15 External Timing Cables

An external timing cable provides a connection from an external synchronization

source, such as a building integrated timing supply (BITS) or synchronization

supply unit (SSU), to the SmartEdge 600 router. Using two cables you can

connect the SmartEdge 600 router to primary and secondary inputs on the

external equipment.

Table 15 Cable Specification for External Timing Cable

Interface Description Chassis Connectors

External Timing Shielded twisted-pair DB-9 female DB-9 male

(1) The chassis connectors are on the rear of the chassis.

A cable consists of two individually shielded, twisted-wire pairs: one pair for the

synchronization input and another pair for the synchronization output.

(1)

Cable Connector

Site Preparation

Note: The XCRP4 Controller card can receive timing data only.

The nominal impedance of the DS-1 wire pairs is 100 ohms; that of the E1

wire pairs is 120 ohms.

One end of the cable is terminated with a DB-9 male connector; the other

end of the cable is left unterminated for attachment to the wire wrap posts

of the external equipment. Both of the DB-9 connectors (PRIMARY and

SECONDARY) on the rear panel of the SmartEdge 600 router have identical

pin assignments.

Note: An adapter, available as an option, provides wire wrap pins to allow you

to attach a cable without a connector.

To bring a signal from external equipment into the SmartEdge 600 router:

• For the DS-1 interface (BITS)—Connect the DS-1 output of the external

equipment to pins 2 and 6 of the DB-9 connector on the rear panel of the

router. The polarity of the signal does not matter. The router accepts a

standard BITS source transmitting a framed-all-ones pattern at the DS-1

rate of 1.544 Mbps.

• For the E1 interface (SSU)—Connect the E1 output of the external

equipment to pins 2 and 6 of the SSU DB-9 connector on the rear panel

of the router. The polarity of the signal does not matter. The router

accepts a standard synchronization source transmitting an HDB3-encoded,

framed-all-ones pattern at the E1 rate of 2.048 Mbps.

Table 16 External Timing Cable Pin Assignments

Signal Name

Shield Bare Wire Frame ground connection

External equipment input (+) White Twisted pair with pin 6

––

(1)

Color Notes

No connection

1527/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 22

SmartEdge 600 Router Hardware Guide

Table 16 External Timing Cable Pin Assignments

Signal Name

External equipment output (+) White Twisted pair with pin 9

Shield Bare Wire Frame ground connection

External equipment input (–) Blue Twisted pair with pin 2

––

––

External equipment output (–) Orange Twisted pair with pin 4

(1) The direction, input or output, is with respect to the controller card: input describes data flowing into the controller

card; output describes data being transmitted by the controller card.

(1)

Color Notes

No connection

No connection

1.16 Line Card Cable Specifications

Table 17 Cable Specifications for Line Cards

Card Type Description Card End Cable End

ATM OC-12c/STM-4c Single-mode fiber LC female LC male 9.3mi - 15.0km

ATM OC-3c/STM-1c SR-0 Multimode fiber LC female LC male 1.2mi - 2.0km

ATM OC-3c/STM-1c IR-1 Single-mode fiber LC female LC male 9.3mi - 15.0km

Advanced Services Engine Category 5 shielded twisted-pair RJ-45 female RJ-45 male 328.1ft - 100.0m

10/100 Ethernet Category 5 shielded twisted-pair

FE–GE: 10/100 ports Category 5 UTP braid shielded

FE–GE: 100/1000 ports Category 5 shielded twisted-pair RJ-45 female RJ-45 male 328.1ft - 100.0m

Ethernet straight or crossover

#24 AWG solid jacket, with copper

braid, tin shielded for each port

(1)

RJ-45 female RJ-45 male 328.1ft - 100.0m

MRJ21 female RJ-45 modular

plug, shielded,

male

(1) See cable options for a 10/100 Ethernet line card table to determine which cable, straight or crossover, is suitable;

the cable must be grounded at both ends.

Maximum

Distance

328.1ft - 100.0m

1.16.1 Transceiver-Based Gigabit Ethernet Line Card Cables

Table 18 Cable Specifications for Transceiver-Based Gigabit Ethernet Line Cards

Transceiver Description Card End

SX GBIC transceiver Multimode fiber 62.5/125 µm SC female SC male 1,804.4ft -

Multimode fiber 50/125 µm SC female SC male 656.2ft - 200.0m

TX transceiver 4-pair, Category 5 shielded

twisted-pair

LX GBIC transceiver Single-mode fiber 9/125 µm SC female SC male 6.2mi - 10.0km

LX70 GBIC transceiver Single-mode fiber 9/125 µm SC female SC male 43.5mi - 70.0km

SX SFP transceiver Multimode fiber 62.5/125 µm LC female LC male 1,640.4ft -

(2)

RJ-45 RJ-45 328.1ft - 100.0m

(1)

Cable End

Maximum

Distance

550.0m

500.0m

16 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 23

Site Preparation

Table 18 Cable Specifications for Transceiver-Based Gigabit Ethernet Line Cards

Transceiver Description Card End

Multimode fiber 50/125 µm LC female LC male 656.2ft - 200.0m

LX SFP transceiver Single-mode fiber 9/125 µm LC female LC male 6.2mi - 10.0km

ZX SFP transceiver Single-mode fiber 9/125 µm LC female LC male 49.7mi -

SR/SW XFP transceiver Multimode fiber 50/125 µm LC female LC male 984.4ft - 300.0m

LR/LW XFP transceiver Single-mode fiber 9/125 µm LC female LC male 6.2mi - 10.0km

ER XFP transceiver Single-mode fiber 9/125 µm LC female LC male 24.9mi - 40.0km

ZR XFP transceiver

DWDM transceiver

(4) (5)

(6)

Single-mode fiber 9/125 µm LC female LC male 49.7mi - 80.0km

Single-mode fiber 9/125 µm LC female LC male 49.7mi - 80.0km

(1)

Cable End

(1) The SC connectors on the card are type SC/PC; cable and card connectors must match.

(2) To comply with GR-1089 intrabuilding lightning surge requirements, intrabuilding wiring must be shielded, and the

shield for the wiring must be grounded at both ends.

(3) When the port level lossless flow control is enabled, the distance reach is limited to 43.5 mi (70.0 km).

(4) The ZR XFP transceiver is a multi-rate device and can be used in the 10GE line card and the SONET/SDH

OC-192c/STM-64c LR line card.

(5) Use part number XFP-OC192-LR2 when ordering the XFP transceivers with 10GE ZR functionality.

(6) DWDM XFP transceivers support only ITU channels 35, 36, 37, 53, and 54; see ITU DWDM Transmit Frequencies

and Wavelengths table in Chapter 6 for the frequency and wavelength of each ITU channel; specified in ITU G.694.1.

Maximum

Distance

(3)

80.0km

1.17 Transceiver-Based SONET/SDH Line Card Cables

Table 19 Cable Specifications for the SONET/SDH Line Cards

Transceiver Type Description Card Connector

SR / MM Multimode fiber 62.5/125 µm LC female LC male 1,640.4 ft - 500.0 m

SR / SM

IR / SM

IR-2 / SM (with XFP

transceiver)

LR-1 / SM Single-mode fiber 9/125 µm LC female LC male 24.9 mi - 40.0 km

LR-2 / SM Single-mode fiber 9/125 µm LC female LC male 49.7 mi - 80.0 km

(3)

(3)

Single-mode fiber 9/125 µm LC, FC, or SC female LC, FC, or SC male 1.2 mi - 2.0 km

Single-mode fiber 9/125 µm LC female LC male 9.3 mi - 15.0 km

Single-mode fiber 9/125 µm LC female LC male 24.9 mi - 40.0 km

(1) The SC connectors on the card are type SC/PC; cable and card connectors must match.

(2) For SFP-OC12-MM transceiver, the maximum distance is 500 meters.

(3) Use part number SFP-OC3-SM-IR when ordering the SFP transceivers with POS OC-3 SR-1 or POS OC-3

IR-1 functionality.

(1)

Cable Connector Maximum Distance

1.2 mi - 2.0 km

(2)

1727/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 24

SmartEdge 600 Router Hardware Guide

1.18 10/100 Ethernet and Fast Ethernet–Gigabit Ethernet

Cables

The choice of an Ethernet straight or crossover cable for a port on the 10/100

Ethernet card depends on the equipment to which it is being connected.

Table 20 Cable Options for a 10/100 Ethernet Line Card

Configuration Cable Type

Port is connected to a router. Straight

Port is connected to a switch. Crossover

Port is connected to a 10/100 Ethernet port in another SmartEdge router. Crossover

Note: The 10/100 Ethernet line card wiring is cross-connected like a switch or

hub; this condition is denoted with the label “X” by each port.

1.18.1 10/100 Ethernet Crossover Cable Pin Assignments

Both ends of this shielded and grounded cable are terminated in standard

RJ-45 eight-pin modular plugs.

Table 21 10/100 Ethernet Crossover Cable Pin Assignments

Signal Name Pin Notes

Rx (+)

Rx (–)

Tx (+)

––

––

Tx (–)

––

––

3

6

1

2

–

–

–

Termination network

Termination network

–

Termination network

Termination network

1.18.2 10/100 Ethernet Straight Cable Pin Assignments

Both ends of this shielded and grounded cable are terminated in standard

RJ-45 eight-pin modular plugs.

Table 22 10/100 Ethernet Straight Cable Pin Assignments

Signal Name Notes

Rx (+)

Rx (–)

Tx (+)

–

–

–

–

Termination network

18 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 25

Table 22 10/100 Ethernet Straight Cable Pin Assignments

Signal Name Notes

–

Tx (–)

–

–

Termination network

–

Termination network

Termination network

1.18.3 Fast Ethernet Breakout Cable Pin Assignments

Table 23 Fast Ethernet Breakout Cable Pin Assignments

Port MRJ21 Pins RJ-45 Pins Colors

1 121314 1236

2 341516 1236

3 25263728 1236

4 27283940 1236

5

6 781920 1236

7

8 31324344 1236

9 9 10 21 22 1 2 3 6

10 11 12 23 24 1 2 3 6

11 33 34 45 46 1 2 3 6

12 35 36 47 48 1 2 3 6

561718 1236

29 30 41 42 1 2 3 6

White/Blue Blue/White White/Orange Orange/White

White/Green Green/White White/Brown Brown/White

White/Gray Gray/White Red/Blue Blue/Red

Red/Orange Orange/Red Red/Green Green/Red

Red/Brown Brown/Red Red/Gray Gray/Red

Black/Blue Blue/Black Black/Orange Orange/Black

Black/Green Green/Black Black/Brown Brown/Black

Black/Gray Gray/Black Yellow/Blue Blue/Yellow

Yellow/Orange Orange/Yellow Yellow/Green Green/Yellow

Yellow/Brown Brown/Yellow Yellow/Gray Gray/Yellow

Violet/Blue2 Blue/Violet Violet/Orange Orange/Violet

Violet/Green2 Green/Violet Violet/Brown Brown/Violet

Site Preparation

1927/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 26

SmartEdge 600 Router Hardware Guide

20 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 27

2 Installing the Hardware

Installing the Hardware

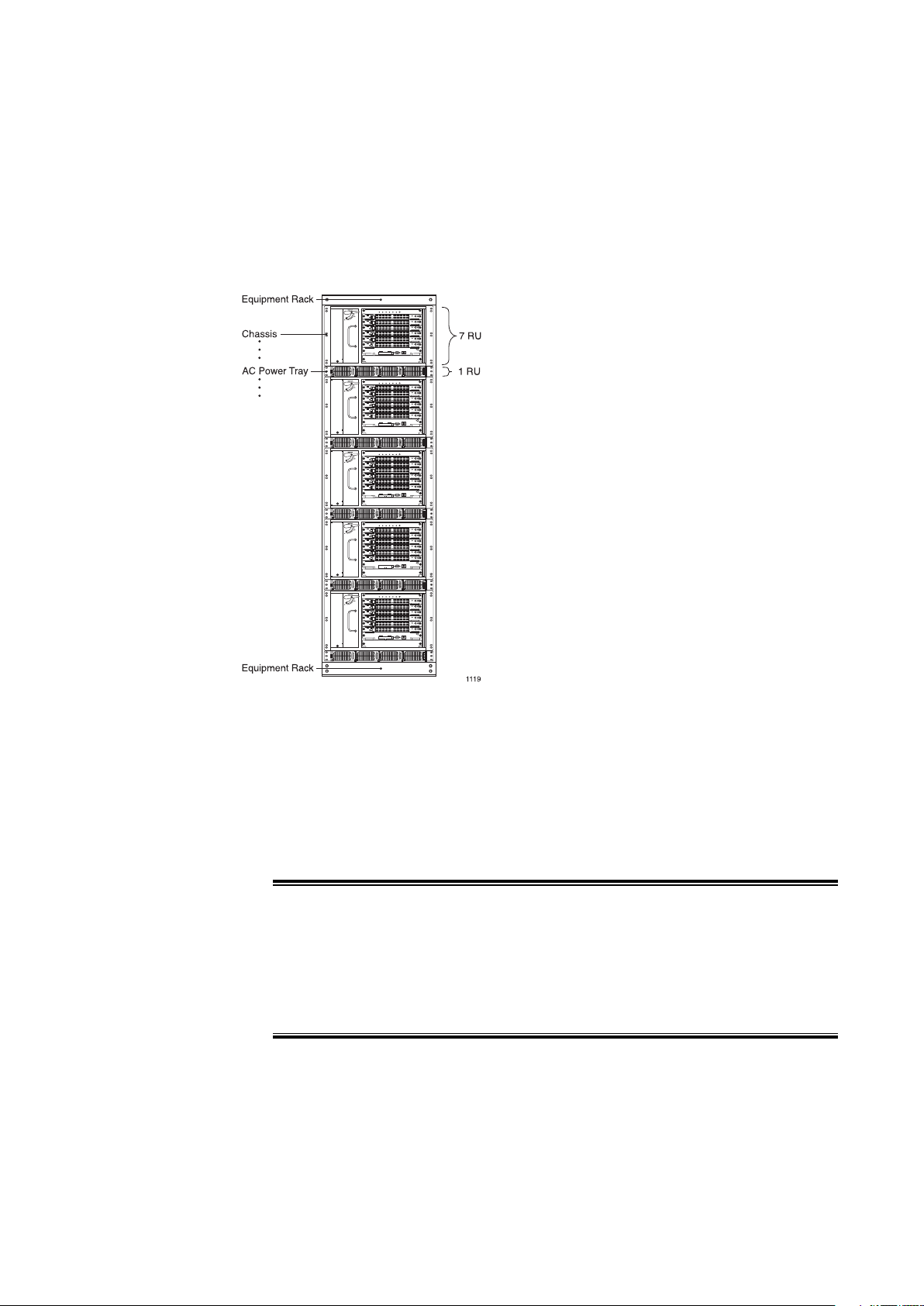

Figure 3 Fully Loaded 42 RU Rack Configuration

Decide where in the rack to position the chassis based on component stackup:

• The chassis requires seven rack units (RUs). An RU is 1.75 inches (4.5 cm).

• The optional AC power shelf requires one RU. It must be installed

immediately below the chassis.

• A standalone external fuse panel requires one RU.

Caution!

Risk of equipment damage. Never install the chassis in a rack that has not

been stabilized by being bolted to the floor and to the ceiling and always

select a mounting position that is suitable to the type of rack in which the

chassis is being installed.

2127/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 28

SmartEdge 600 Router Hardware Guide

2.1 Install the Chassis Mounting Brackets

FAN TRAY

114 9

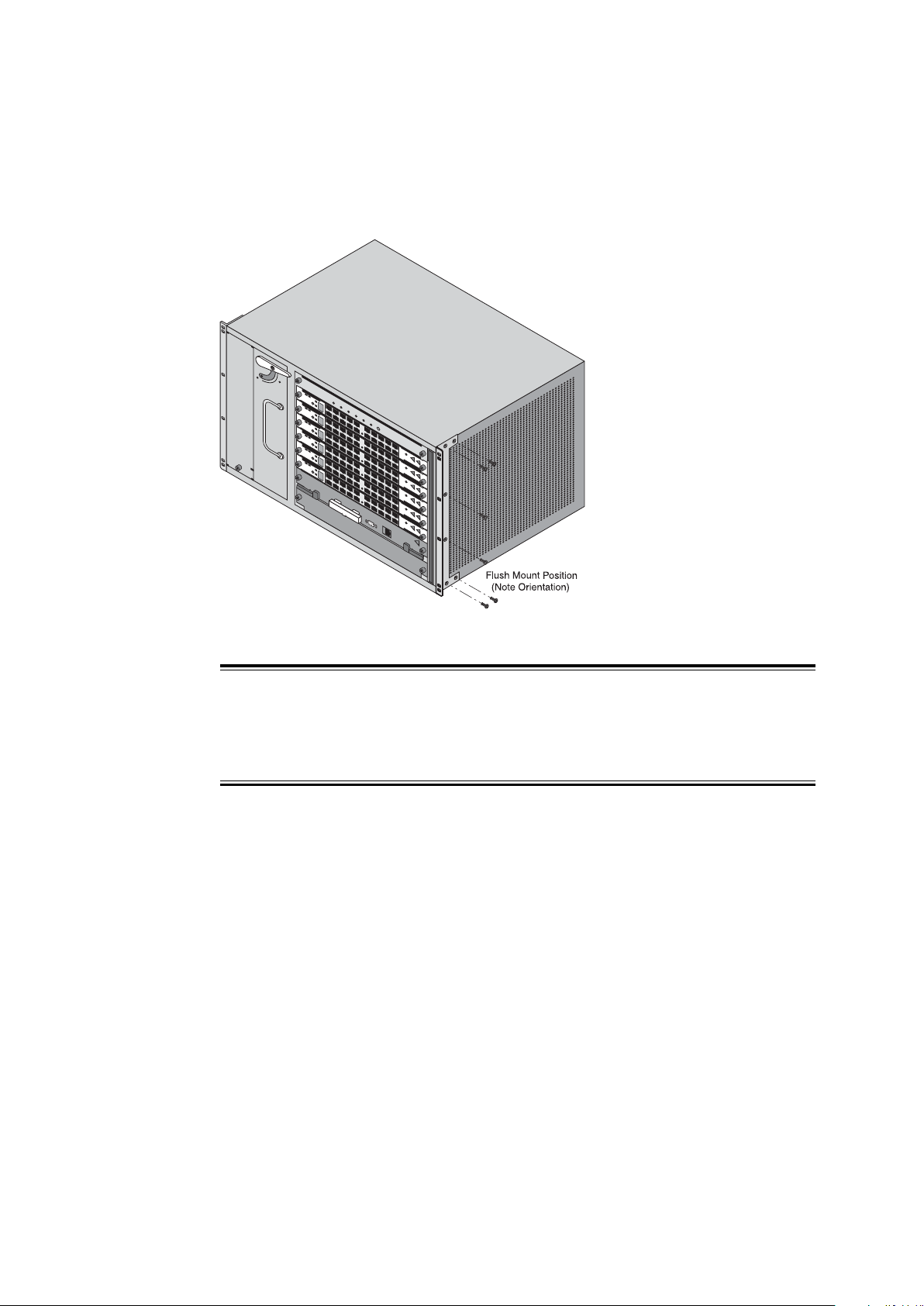

Figure 4 Installing Chassis Brackets for Flush Mount Position

Caution!

Risk of equipment damage. Always use the number and type of screws

specified in the instructions.

To install brackets:

1. Position a mounting bracket against one side of the chassis, lining up the

screw holes in the bracket with the screw holes in the side of the chassis.

2. Using a Phillips screwdriver, attach the bracket to the chassis with the

screws provided with the mounting bracket; tighten to a maximum torque of

15.0 inch-lbs (1.7 Newton-meters).

3. Repeat steps 1 and 2 to attach the second bracket to the other side of

the chassis.

22

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 29

2.2 Install the Chassis

Risk of personal injury. Do not lift or move the chassis without the aid of another

trained person A fully loaded chassis can weigh as much as 94 lb (42.6 kg) and

can cause injury if one person attempts to lift or move it. Always follow the

procedures at this installation site for safely lifting heavy objects.

Install the chassis in the rack:

1. With another installation engineer, lift the chassis to the position selected

in the rack.

Installing the Hardware

Warning!

2. Line up the screw holes in the mounting brackets with the screw holes

in the rack.

3. With one engineer holding the chassis in place, use the Phillips screwdriver

to secure the shelf to the rack using fasteners of the type compatible with

the rack. Tighten the fasteners to the vendor recommended torque level.

2.3 Install the Cable Management Brackets

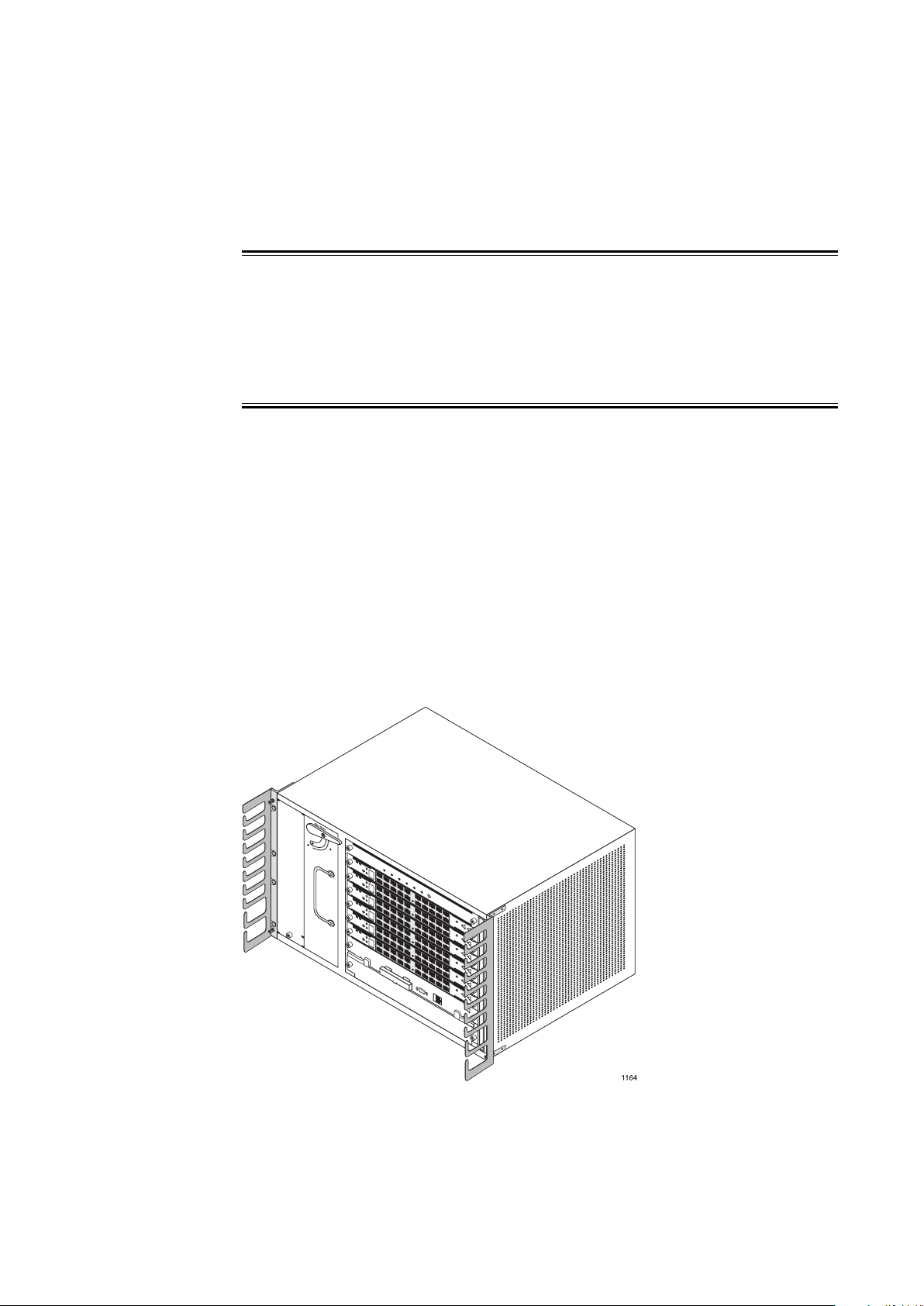

Figure 5 Installing the Cable Management Brackets

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

23

Page 30

SmartEdge 600 Router Hardware Guide

To install the left-side bracket, align it with the screw holes at the left side of

the rack and secure it to the rack with the two captive fasteners; tighten to a

maximum torque of 8.0 inch-lbs (0.9 Newton-meters).

For additional cable management, you can install another cable management

bracket at the right side of the chassis.

Note: When you install a ride-side cable management bracket, the air filter

access will be limited only to removal from the rear of the chassis.

2.4 Connect Power and Ground Cables

The chassis ground terminal is located at the bottom-right corner of the back

panel. The ground cables must be of a size suitable for the installation, and

must be installed in accordance with the National Electrical Code (in the

United States), or the applicable local jurisdiction (outside the United States)

installation requirements.

Connect a chassis ground cable:

1. Using a crimping tool, attach a two-hole lug to one end of the ground cable.

2. Secure the connection with a pair of lug nuts; tighten to a maximum torque

of 15.0 inch-lbs (1.7 Newton-meters).

3. Connect the other end of the cable to an appropriate ground point.

2.4.1 Connect DC Power Sources

The SmartEdge 600 chassis has two terminal blocks on the rear of the chassis

labeled BATTERY A and BATTERY B for A-side and B-side DC power cables,

which provides full power redundancy. Each terminal block has a pair of 1/4-20

studs.

The A- and B-side power cables connect to separate A-side and B-side

connectors on the external fuse panel or circuit breaker panel.

The terminal studs are labeled RETURN and -48V. Each power cable must

be of a size suitable for the installation and installed in accordance with the

National Electrical Code (in the United States) or applicable local jurisdiction

(outside the United States) installation requirements.

The following DC power source warnings and cautions apply when connecting

DC power sources:

24

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 31

Installing the Hardware

Warning!

Risk of electrical shock. The DC power sources must be installed only in

restricted access areas (dedicated equipment rooms, equipment closets, or the

like) in accordance with Articles 110-17, 110-26, and 110-27 of the National

Electric Code, ANSI/NFPA 70. Connect the chassis to a –48 VDC source that

is reliably connected to earth.

Warning!

Risk of electrical shock. A readily accessible disconnect device, such as a fuse

in a fuse panel, must be provided in the fixed wiring for each DC power source.

It must be suitable for the rated voltage and current specified. The system is

fully powered on after all power connections are made, it can cause shock if a

power cable is disconnected from the chassis.

Warning!

Risk of electrical shock. Disconnect all telecommunications network lines

before disconnecting the unit from the ground point. Safe operation of this

equipment requires connection to a ground point.

Warning!

Risk of electrical shock. This equipment uses –48 VDC power, which can

cause shock if inadequate power sources are connected to it. Verify that the

power sources for the system and DC power cables meet the specifications

provided in Chapter 1.

2527/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 32

SmartEdge 600 Router Hardware Guide

Risk of electrical shock. Always remove the fuses for both the A-side and

B-side power sources in the fuse panel before connecting the power cables to

the chassis. After the power cables are connected to the chassis and the fuse

panel, the system is fully powered on; there is no power switch.

Risk of electrical shock. This equipment must be connected to a protective

ground in accordance with the instructions provided in this guide. Improper

grounding can result in an electrical shock.

Warning!

Warning!

Caution!

Risk of equipment damage. A DC-powered system uses –48 VDC power, is

powered from a fuse panel, and can be damaged by overloaded circuits. To

reduce the risk, ensure that the fuses in the external fuse panel are suitably

rated for the installation in accordance with the National Electrical Code (in

the United States) or applicable local jurisdiction (outside the United States)

installation requirements.

Caution!

Risk of equipment damage. You can permanently damage the chassis if you

attempt to apply DC power to it and the DC power plugs are not installed in the

connectors on the rear of the chassis. To reduce the risk, ensure that the plugs

are installed as described in the following procedure.

26 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 33

2.4.1.1 Connect Power Cables

Figure 6 DC Power Connections

Installing the Hardware

Connect the power cables:

1. Using a crimping tool, attach a two-hole lug to one end of each power cable.

2. For the BATTERY A connection, secure the connection of the red cable to

RETURN with a pair of lug nuts and the black cable to -48V; tighten to a

maximum torque of 15.0 inch-lbs (1.7 Newton-meters).

3. For the BATTERY B connection, secure the connection of the red cable to

RETURN with a pair of lug nuts and the black cable to -48V; tighten to a

maximum torque of 15.0 inch-lbs (1.7 Newton-meters).

4. Use the provided metal loops in the chassis to dress the cables with tie

wraps.

5.

Note: The dressing of the DC jumper cables must allow for servicing the

push-through air filter and the fan tray from the rear of the chassis.

6. Install the safety cover.

2.5 Optional AC Power Shelf

The optional AC power shelf provides slots for two AC power modules, which

allows a SmartEdge 600 router to be installed at a site for which DC power

sources are not available. AC power shelf connects to the SmartEdge 600

chassis with two pairs of DC jumper cables using connectors on the rear of the

AC power shelf.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

27

Page 34

SmartEdge 600 Router Hardware Guide

Warning!

Risk of personal injury. Do not attempt to access any component inside the AC

power shelf; there are no user-serviceable components inside it.

Table 24 Order Numbers

BMG907058/1 Four-slot, one rack unit (RU) AC power shelf

BMK90576/1 2725 Watt AC power module unit with AC power cord

NTM1011728/1 Spare cable kit—Includes one interconnect data cable, one set of DC jumper

cables, and two AC power cords with North American plugs.

Risk of electrical shock. Do not disconnect the power cables to the chassis

until you have first deenergized the DC power supplies, and then removed the

fuses for both the A- and B-side power sources in the fuse panel. With the

power cables connected to the chassis and the fuse panel, the system is fully

powered on, and you can incur electrical shock when you remove the cables

from the chassis connectors.

2.5.1 Install the AC Power Shelf

Warning!

28

Figure 7 Positioning an AC Power Shelf

Install the AC power shelf:

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 35

1. Position the shelf directly below the chassis so the screw holes in the

shelf mounting brackets align with the screw holes in the rack just below

the chassis.

2. On a 19" wide rack, use the Phillips screwdriver to secure the shelf to the

rack using the fasteners of the type compatible with the rack. Tighten the

fasteners to the vendor recommended torque level.

2.5.1.1 Install the Ground Bracket

Installing the Hardware

Figure 8 Ground Bracket

Install the ground bracket between the shelf and the chassis:

1. On the chassis, remove the chassis ground lug at the lower-center rear of

the chassis.

2. Stack the ground bracket under the chassis ground lug and reattach it

using the existing hardware; tighten to a maximum torque of 15.0 inch-lbs

(1.7 Newton-meters).

3. On the AC power shelf, use the Phillips screwdriver to secure the bracket

to the available mounting position using the hardware provided.

2.5.1.2 Install AC Power Modules

Figure 9 AC Power Modules

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

29

Page 36

SmartEdge 600 Router Hardware Guide

Install AC power modules in the shelf:

1. Open the front ejector (fan cover) of the power module by squeezing the

latch spring and pulling open the ejector.

2. Insert a module into one of the two center slots (2 and 3) in the shelf.

Note: AC power modules operate only from the two center slots of the

3. Push the module in until the right side of the ejector engages the receptacle

slot in the shelf wall.

4. Push closed the ejector lever until the module spring latch locks on the

ejector to seat the module.

5. Insert the second module into the other center slot and repeat steps 3 and 4.

AC power shelf.

2.5.1.3 Connect the AC Power Shelf to the Chassis

Figure 10 AC Power Connections

Warning!

30

Do not connect the AC power cords to the building outlets until you have

completed the installation. If you connect the other end of the AC power cord to

a building outlet, you power on the system; there is no ON/OFF switch on the

AC power shelf.

Connect the shelf to the chassis:

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 37

Installing the Hardware

1. Unpack the two 6AWG red and two black DC jumper cables.

2. Flip open the touch-safe lug landing cover on the left-side terminal block.

3. Attach the short pair of red and black DC jumper cables to the left-side

terminals—red cable to the top terminal (+) and black cable to the bottom

one (-).

4. Secure each connection with a pair of 1/4-20 lug nuts; tighten to a maximum

torque of 62.0 inch-lbs (7 Newton-meters).

5. Snap the cover shut.

6. Attach the remaining ends to the bottom (BATTERY B) terminal block of

the chassis—red cable to the top terminal (RETURN) and black to bottom

one (-48V).

7. Secure the connections with pairs of lock washers and lug nuts; tighten to a

maximum torque of 62.0 inch-lbs (7 Newton-meters).

8. Use the provided metal loops on the chassis to dress the cables with tie

wraps.

Note: Dress the DC jumper cables so the push-through air filter and fan

tray can be serviced from the rear of the chassis.

9. Repeat this procedure for the right-side self connections using the long

pair of DC jumper cables.

10. Install the safety cover.

11. Connect the control cable from J1 (right-side flat connector) on the shelf to

the chassis connector labeled AC STATUS/CTL.

12. Insert the AC power cords for each power module into connectors 2 and 3

on the shelf.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

31

Page 38

SmartEdge 600 Router Hardware Guide

13. Power on the chassis by connecting the AC power cords to separate 220

VAC building outlets, each of which must be for a circuit rated at 20A with a

20A circuit breaker.

Note: The AC power cords ship with North American plugs installed. If

14. Check the status LEDs located on the alarm card at the front of the chassis

and the AC input power and DC output power LEDs on the front of each

installed power module.

you are connecting to another type of service, simply remove the

plugs and replace them with the appropriate plugs.

If you encounter problems installing the AC power shelf, contact your local

technical support representative.

2.6 Card Slots

Figure 11 SmartEdge 600 Card Slots

Table 25 Slot Assignments for SmartEdge 600 Cards

Card Slots Available

Controller

ATM OC-12c/STM-4c

ATM OC-3c/STM-1c (any version)

10/100 Ethernet

Fast Ethernet–Gigabit Ethernet

20-port Gigabit Ethernet 1020

Transceiver-based Gigabit Ethernet (any other version)

OC-192c/STM-64c (any XFP version)

(1)

7, 8

1to6

1to6

1to5

1to6

1to6

32 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 39

Table 25 Slot Assignments for SmartEdge 600 Cards

Card Slots Available

Advanced Services Engine

SmartEdge Storage Engine

(1) The 20-port GE 1020 requires two adjacent slots.

1to6

1to6

2.7 Install Cards

Installing the Hardware

Figure 12 Installing Cards

Warning!

Risk of personal injury. Only qualified personnel must install and service the

system and its components. To avoid injury, do not attempt to access any

component inside the chassis.

3327/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 40

SmartEdge 600 Router Hardware Guide

Risk of electrostatic discharge (ESD) damage. Always use an ESD wrist or

ankle strap when handling the card. Do not attach the wrist strap to a painted

surface. Avoid touching the card, components, or any connector pins.

Risk of severe damage to your eyes. All versions of the optical cards are Class

1 products, which use lasers to convert electrical signals to optical signals that

can damage your eyes. To reduce the risk when handling these optical cards,

keep the connectors covered until you are ready to connect the fiber-optic

cables. When you remove a cover, do not stare into the connector or directly

view the laser beam emerging from the connector.

Caution!

Caution!

Install cards:

1. Put on an ESD wrist strap, and attach it to an appropriate grounded surface.

Do not attach the wrist strap to a painted surface; an ESD convenience jack

is located on the front of the fan and alarm unit.

2. Select the slot for the card.

3. Remove the card from its antistatic bag. Save the bag for later use.

4. Align the card with the card guides at the right and left sides of the slot.

Caution!

Risk of equipment damage. If you feel any resistance, or hear the card

touching the components on the card installed in the adjacent slot at the

left, do not force the card into the slot. Ensure that the card is perpendicular

to the slot. If you feel any resistance, slightly lift the bottom edge of the

front panel until it can slide easily into the slot.

34

5. Position the ejector levers away from the front panel and then carefully slide

the card into the slot. The ejector levers rotate as the latching mechanisms

engage the walls of the slot and the connectors on the card are inserted

into the connectors on the backplane.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 41

6. Push on the ejector levers until they are parallel with the front panel; this

action fully seats the connectors with the backplane.

7. Secure the card in the chassis by tightening the screw at the top and

bottom of the front panel. Use a Phillips screwdriver to tighten each screw

to a maximum torque of 5.0 inch-lbs (0.6 Newton-meters).

8. Repeat steps 2 to 7 for each card to be installed.

2.7.1 Install Blank Cards

Risk of equipment damage. High temperature can damage router cards. Insert

a blank card in each empty slot.

Installing the Hardware

Caution!

When all cards have been installed, insert a blank card into every empty slot,

and tighten the captive screws at the top and bottom of the front panel.

2.7.2 Install Transceivers

Risk of severe damage to your eyes. Do not stare into the connector or directly

view the laser beam emerging from the connector. All versions of the optical

cards are Class 1 products, which use lasers to convert electrical signals to

optical signals that can damage your eyes. Keep the connectors covered until

you are ready to connect the fiber-optic cables.

Install Transceivers

Caution!

Figure 13 Installing a GBIC Transceiver

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

35

Page 42

SmartEdge 600 Router Hardware Guide

Figure 14 Installing an SFP Transceiver

Figure 15 Installing an XFP Transceiver

Gigabit Ethernet ports require a gigabit interface converter (GBIC), a small

form-factor pluggable (SFP), or a 10-Gbps SFP (XFP) transceiver in each port;

the port on an OC-192c/STM-64c card also requires an XFP transceiver.

Table 26 Transceiver Types for Line Cards

Line Card Transceiver

Gigabit Ethernet (4-port) GBIC SX, LX, LX70, TX

Advanced Gigabit Ethernet (4-port) GBIC SX, LX, LX70, TX

ATM OC-3c/STM-1c (4-port) GBIC IR

Enhanced ATM OC-12c/STM-4c (1-port) GBIC IR

ATM OC-3c/STM-1c (8-port) SFP SR-0, IR-1

POS OC-3c/STM-1c (8-port) SFP SR-0, SR-1, IR-1

POS OC-12c/STM-4c (4-port) SFP SR-1, IR-1

POS OC-48c/STM-16c (4-port) SFP SR-1, IR-1, LR-2

Gigabit Ethernet 3 (4-port) SFP SX, LX, TX, ZX, CWDMnnnn, DWDMnn

Gigabit Ethernet 1020 (10-port) SFP SX, LX, TX, ZX, CWDMnnnn, DWDMnn

(1)

Supported Versions

36 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 43

Installing the Hardware

Table 26 Transceiver Types for Line Cards

Line Card Transceiver

Gigabit Ethernet 1020 (20-port)

Gigabit Ethernet (5-port) SFP SX, LX, TX, ZX, CWDMnnnn, DWDMnn

Gigabit Ethernet (20-port)

10 Gigabit Ethernet (1-port) XFP SR, LR, ER, ZR, DWDMnn

10 Gigabit Ethernet (4-port) XFP SR, LR, ER, ZR, DWDMnn

SONET/SDH OC-192c/STM-64c (1-port) XFP SR-1, IR-2, LR-2

(1) If the transceiver has not been qualified for use in the line card, the system displays a warning message.

(2) The 20-port GE 1020 card requires two adjacent slots.

(3) Because the TX SFP is larger than a standard SFP, you cannot insert two TX SFPs side by side on the 20-port GE

traffric card.

(2)

(3)

SFP SX, LX, TX, ZX, CWDMnnnn, DWDMnn

SFP SX, LX, TX, ZX, CWDMnnnn, DWDMnn

(1)

Supported Versions

Stop!

Risk of data loss. Install only the transceivers approved by Ericsson. You can

corrupt the system if you attempt to install transceivers have not been tested

with SmartEdge line cards. To reduce the risk, .

To install a transceiver of any type:

1. Put on an antistatic wrist strap and attach it to an appropriate grounded

surface. Do not attach the wrist strap to a painted surface; an ESD

convenience jack is located on the front of the fan tray.

Stop!

Risk of ESD damage. Always use an ESD wrist or ankle strap when

handling any transceiver. Avoid touching its connector pins.

2. Ensure that the latching mechanism is closed.

3. With the transceiver connectors aligned with the RX and TX labels on the

front panel of the line card (as shown in Figure 14 or Figure 15), slide the

transceiver into the opening for the port until the rear connector is seated

and the locking mechanism snaps into place.

The labels for the TX and RX connectors vary by vendor. An arrow, which

can be incised on the case, usually indicates the traffic direction.

4. Remove the dust cover if you are installing an optical transceiver.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

37

Page 44

SmartEdge 600 Router Hardware Guide

GBIC transceivers are supported only on ports the first and second versions

of the Gigabit Ethernet line cards. SFP transceivers are supported only on

ports on GE3 and GE1020 line cards. XFP transceivers are supported only

on ports on 10GE line cards.

Note: Transceivers are are hot-swappable; you can replace any transceiver

without removing the Gigabit Ethernet card. However, you must shut

down the port before performing the replacement procedure.

Risk of data loss. You can corrupt the system if you attempt to install

transceivers (GBICs, SFP, or XFPs) that are not approved by Ericsson because

these items have not been tested with the SmartEdge router. To reduce the

risk, install only the transceivers approved by Ericsson.

Stop!

To remove a transceiver of any type:

1. Shut down all activities on the port with the transceiver you want to replace.

See related documentation at https://ebusiness.ericsson.net.

2. Put on an antistatic wrist strap and attach it to an appropriate grounded

surface. Do not attach the wrist strap to a painted surface; an ESD

convenience jack is located on the front of the fan tray.

Stop!

Risk of damage to fiber-optic cables. Never stop on a cable; never twist it

when connecting it to or disconnecting it from a line card.

3. Label and disconnect any cables attached to the transceiver you want to

replace.

Stop!

38

Risk of ESD damage. Transceivers contain electrostatic-sensitive devices.

To reduce the risk of ESD damage, always use an ESD wrist or ankle trap

when handling any transceiver. Avoid touching its connector pins.

4. Release the latching mechanism:

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 45

Installing the Hardware

a If the transceiver has a wire handle, unlatch it, and rotate it 90

b If the transceiver has latching tabs, squeeze and hold the tabs.

5. Withdraw the transceiver from its port and insert a dust cover over the

optical connectors.

2.7.3 Install CF Cards

Figure 16 Installing an External Storage Device

to 180

.

Each controller card has an external slot on the front panel in which you can

install an optional Type I or Type II external storage device.

If you install an external storage device in the active controller card, the standby

controller card, if installed, must also have an external storage device installed;

however, the device types need not match. The XCRP4 controller card

supports Type I devices only.

To install an external storage device:

1. If you are installing the device in an XCRP4 controller card, open the door

that covers the CF Type 1 slot until it “snaps” open.

2. Hold the device so that its pin-hole side faces the slot in the controller

front panel.

3. Horizontally align the device as close to the bottom edge of the slot as

possible and perpendicular to it.

4. Slowly insert the device in the slot. If the device does not engage the

connectors with approximately 0.5 inches (1.27 cm) of the device outside

the slot, do not continue. Remove the device and repeat this step. Do not

force the device into its slot. Check for one of the following conditions:

Misaligned—Check the position and alignment as described in Step 3.

Upside down—Remove the device and rotate it 180

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

and try again.

39

Page 46

SmartEdge 600 Router Hardware Guide

Damaged—Remove the device and discard it. Do not use it in any other

equipment.

Damaged slot connectors—Replace the controller card.

5. If you are installing the device in a controller card, close the door.

2.8 Connections for Management Access

Connecting a console terminal or management workstation to the SmartEdge

600 router is often a two-stage process. Initially the console terminal is

connected to the Craft port (also referred to as the console port) to configure

the Ethernet port (also referred to as the management port).

Configuring the management port and modifying the configuration of the console

port is described in relevant documents at https://ebusiness.ericsson.net.

2.8.1 Management Workstation

Figure 17 Connections for a Management Workstation

A management workstation is connected to the SmartEdge 600 router using

the Ethernet port on the front of a controller card. This type of connection

provides access to the SmartEdge OS command-line interface (CLI) after you

have configured the port.

Two types of connections are supported:

40

• Local connection using a shielded Ethernet crossover cable

• Remote connection using a shielded Ethernet straight cable

Neither type of connection is suitable during a reload operation, because the

Ethernet port is disabled until the reload is complete.

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 47

2.8.2 Local or Remote Console Terminal

Installing the Hardware

Figure 18 Connections for a Local or Remote Console

A local or remote console terminal is connected to the SmartEdge 600 router

using the Craft port on the front of a controller card. This type of connection

provides access to the operating system CLI, either directly or through a

terminal server.

A null modem is needed when connecting this cable to a modem; it is not

needed when connecting it to a PC or terminal server.

This port is always available; all system messages are directed to this port

during a power on or reload operation.

Note: When you first power on the system, the active controller card is in slot

6. Thereafter, the slot changes whenever a switchover occurs.

2.9 Connections for External Timing Cables

Figure 19 Connections for External Timing Cables

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

41

Page 48

SmartEdge 600 Router Hardware Guide

An external timing cable provides a connection from an external synchronization

source, such as a building integrated timing supply (BITS) or synchronization

supply unit (SSU), to your system. Each cable consists of two individually

shielded, twisted wire pairs: one pair for the synchronization input and another

pair for the synchronization output.

The controller cards can receive timing data only.

Two connections are possible: one from a primary source and one from a

secondary source. Either connection can provide timing for the entire chassis

(input), regardless of the configuration of the controller cards.

An adapter, available as an option, provides wire wrap pins to allow you to

attach a cable without a connector.

Note: The operating system does not support the status and control port.

2.10 Connections for Line Card Cables

All line card cables are connected to the front panels of the cards.

Table 27 Port Data for Line Cards

Line Card Type and Card Description Physical Ports

Enhanced ATM OC-12c/STM-4c IR (1-port)

ATM OC-3c/STM-1c (4-port)

ATM OC-3c/STM-1c (8-port)

10/100 Ethernet (12-port)

Fast Ethernet–Gigabit Ethernet (60-port FE, 2-port GE)

Gigabit Ethernet (4-port)

Advanced Gigabit Ethernet (4-port)

Gigabit Ethernet 3 (4-port)

Gigabit Ethernet 1020 (10-port)

Gigabit Ethernet 1020 (20-port)

Gigabit Ethernet (5-port)

Gigabit Ethernet (20-port)

10 Gigabit Ethernet (1-port)

10 Gigabit Ethernet (4-port)

OC-192c/STM-64c (1-port)

OC-48c/STM-16c (4-port)

(1)

(1) The 20-port GE1020 card requires two adjacent slots.

1

4

8

12

60, 2

4

4

4

10

20

5

20

1

4

1

4

Low-Density

Version

No

Yes

No

No

No

Yes

Yes

No

No

No

No

No

No

No

No

No

Low-Density

Port Numbers

–

1, 3

–

–

-

1, 3

1, 3

–

–

–

–

–

–

–

–

–

42 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 49

2.11 Connect and Route Cables

Installing the Hardware

Figure 20 Cable Routing

Cable connections are made with standard cables.

Caution!

Risk of severe damage to your eyes. All versions of the optical cards are Class

1 products, which use lasers to convert electrical signals to optical signals that

can damage your eyes. Keep the connectors covered until you are ready to

connect the fiber-optic cables. When you remove a cover, do not stare into the

connector or directly view the laser beam emerging from the connector.

Caution!

Risk of damage to fiber-optic cables. These cables are fragile and are easily

damaged when bent. Never step on a cable. Never twist it when connecting it

to or disconnecting it from a line card.

4327/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 50

SmartEdge 600 Router Hardware Guide

Connect and route the cables:

1. Put on an antistatic wrist strap, and attach it to an appropriate grounded

surface. Do not attach the wrist strap to a painted surface; an ESD

convenience jack is located in the lower right corner of the air intake panel

on the front of the chassis.

2. Connect and route the management access cables, depending on the

type of management access you have selected. To connect and route

the cables:

a Thread the system ends of the cables through the lowest opening in

the cable management bracket at the right side of the card slot.

b Insert each cable in the appropriate connector on the card.

c Tie-wrap the cables from each controller card to form a bundle, and

then tie each bundle to the rack.

3. Starting with the line card installed in slot 6, connect and route the line

card cables:

a Thread the system ends of the cables through an opening in the cable

management bracket at the right side of the card slot. Select an

opening that provides space for all cables to be connected to this card.

b Insert each cable in the appropriate connector on the card.

c Tie-wrap the cables to form a bundle, and then tie each bundle to the

rack.

4. Connect and route the breakout cables for the FE–GE line cards:

a Thread the MRJ21 connector end of a breakout cable through the cable

management bracket at the right side of the card slot.

b Attach the breakout cable to the right-most connector to be cabled on

an FE–GE line card. Position the connector so that the incised label

“KEY” on the connector is on the bottom side of the connector as you

face the chassis; see Figure 21.

Caution!

Risk of equipment damage. The cable connector is keyed to ensure

that you insert it with the correct orientation into the front panel

connector. However, it is possible to force an incorrectly positioned

cable connector into the connector on the front panel. To reduce the

risk of overriding the key, ensure that the incised “KEY” label is on the

left side of the connector.

44 27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

Page 51

Installing the Hardware

c Tighten the captive screws without letting the front panel support the

weight of the cable.

Caution!

Risk of equipment damage. A breakout cable for the 60 10/100 ports

on the FE–GE line cards is made of AWG #24 wire and includes

individual cables for 12 ports; when connected to the FE–GE front

panel, the cable weight can cause the front panel to be separated from

the FE–GE printed circuit board. To reduce the risk, never allow the

front panel to support the weight of the cable; support the cable and

immediately route it before you connect another cable.

d Tie-wrap the breakout cable to the rack so that it supports the weight

of the cable.

e Continue to connect and route the breakout cables for the other MRJ21

connectors on the card.

f Connect and route the cables for the GE ports on the FE–GE card as

described in Step 3

Caution!

Risk of equipment damage. You can damage the GE port cables if

you thread them through the same opening in the cable management

bracket that contains the breakout cables. To reduce the risk, use a

different opening in the cable management bracket for the GE port

cables.

Figure 21 Connecting an FE–GE Breakout Cable

27/153 30-CRA 119 1170/1 Uen A | 2010-04-09

45

Page 52

SmartEdge 600 Router Hardware Guide

2.12 Power On and Off the System

Caution!

Risk of equipment damage. Ensure that the fuses in the external fuse panel

are suitably rated for the installation in accordance with the National Electrical

Code (in the United States) or applicable local jurisdiction (outside the United

States) installation requirements.

Power on a SmartEdge 600 router by inserting the fuses in the external fuse

panel. The power LEDs on the front of the chassis light, depending on the

power connections you have made, to signify that power is being supplied.

Figure 22 SmartEdge 600 Status LEDs

Table 28 SmartEdge 600 Status LEDs

Label Activity Color Description

A, B On Green The –48 VDC power source (primary or backup) is present:

• A—Primary source

• B—Backup source

Off None The –48 VDC power source

FAN On Red A failure condition exists in the fan tray.

Off None The fan tray is fully