Page 1

Ericsson GSM System

RBS 2308 and RBS 2309

User’s Guide

EN/LZT 720 0027 R8A

Page 2

Page 3

RBS 2308 and RBS 2309 User’s Guide

Page 4

Copyright

© Ericsson AB 2006 – All Rights Reserved

Disclaimer

No part of this document may be reproduced in any form without the written

permission of the copyright owner.

The contents of this document are subject to revision without notice due to

continued progress in methodology, design and manufacturing. Ericsson shall

have no liability for any error or damage of any kind resulting from the use

of this document.

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 5

RBS 2308 and RBS 2309 User’s Guide

Contents

1 Introduction 1

1.1 Product Overview 2

1.2 Target Groups 3

1.3 Installation and Integration Process Overview 5

1.4 Radio Site Implementation Process 5

1.5 RBS Library Overview 8

1.6 Release History 8

2 Personal Health and Safety Information 11

2.1 Introduction 11

2.2 Hazard Symbols and Admonitions 12

2.3 General Safety Precautions 13

2.4 Electric Shock Hazards 14

2.5 Energy Hazards 15

2.6 Fire Hazard 16

2.7 Heat Hazards 17

2.8 Mechanical Hazards 18

2.9 Radio Frequency Exposure Hazards 19

2.10 Laser Hazards 20

2.11 Chemical Hazards 21

2.12 Other Hazards 23

3 System Safety Information 27

3.1 Introduction 27

3.2 Admonitions and Safety Symbols 28

3.3 Batteries 29

3.4 Electrical Installation 30

3.5 Electrostatic Discharge 31

3.6 Equipment Handling 32

3.7 Ground Connection 33

3.8 Lightning Protection 33

4 Tools and Instruments 35

4.1 Tools for Installation of RBS 2308 and RBS 2309 35

EN/LZ

T 720 0027 Uen R8A 2006-06-27

Page 6

RBS 2308 and RBS 2309 User’s Guide

4.2 Equipment for Antenna System Test

s

36

4.3 Equipment for Site Installation Tests 37

4.4 Equipment for PSTU Startup 37

4.5 Equipment for RBS Site Integration 38

4.6 Equipment for Maintenance 38

4.7 Kit Specifications 40

5 Installation of RBS 41

5.1 Introduction 41

5.2 Preconditions 41

5.3 Torque Settings 42

5.4 Installation Procedure 43

5.5 Installing Mixed Micro Configurations 85

6 Antenna System Tests 87

6.1 Checking the Installation 89

6.2 Calibrating the Antenna Tester 90

6.3 Performing DTF Tests 93

6.4 Naming a DTF Measurement 96

6.5 Calculating the Feeder Attenuation 97

6.6 Calculating the Feeder Delay 99

6.7 Performing SWR Test 101

6.8 Naming an SWR Measurement 103

6.9 Performing Concluding Routines 104

6.10 SWR – Return Loss Conversion Table 107

7 Site Installation Tests 109

7.1 Preconditions 109

7.2 Inspecting Cable Connections 110

7.3 Verifying AC Mains and DC Power Supply 111

7.4 Switching on the RBS 112

7.5 Testing Fan Unit 113

7.6 Setting IDB Parameters 114

7.7 Reading Fault Status 140

7.8 Testing External Alarms 142

7.9 Performing Concluding Routines 143

8 PSTU Startup 149

8.1 Preconditions 149

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 7

RBS 2308 and RBS 2309 User’s Guide

8.2 Work Process for PSTU Startup 150

8.3 Procedure 151

9 RBS Site Integration 161

9.1 Testing Transmission 162

9.2 Bringing the RBS into Service 164

9.3 Making Test Calls on the Air Interface 165

9.4 Performing Concluding Routines 169

10 Maintenance 175

10.1 Introduction 175

10.2 Preconditions 175

10.3 Fault Localization Using OMT 176

10.4 Troubleshooting Using the RBS Indicators 193

10.5 HW Replacement 207

10.6 Returning Hardware 255

11 Reconfiguring the RBS for IP Transmission 261

11.1 Introduction 261

11.2 Preconditions 261

11.3 Reconfiguration Procedure 261

12 Glossary 271

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 8

RBS 2308 and RBS 2309 User’s Guide

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 9

RBS 2308 and RBS 2309 User’s Guide

1 Introduction

This User’s Guide consists of the chapters listed below. Each chapter is briefly

summarized.

Introduction

This chapter.

Personal Health and Safety Information

Contains personal health and safety information that applies when working

with Ericsson system products.

System Safety Information

Contains system safety information that applies when working with Ericsson

system products.

Tools and Instruments

Contains lists of all recommended tools and instruments.

Installation of RBS

Describes activities for:

• Installation of the mounting base

• Connection of cables

• Connection of external antenna

• Mounting the radio c abinet on the mounting base

Antenna System Tests

Describes the site specific antenna tests that should be performed on site.

Site Installation Tests

Describes the site specific tests that should be performed on-site.

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 10

RBS 2308 and RBS 2309 User’s Guide

PSTU Startup

Describes how to pu

t the Packet-Switched Termination Unit (PSTU) into

operation.

RBS Site Integrat

ion

Describes how to i

ntegrate an RBS site into a network.

Maintenance

Describes first l

ine maintenance. This means that swap repair is carried out

on site and that o

nly replaceable units are handled.

Reconfiguring t

he RBS for IP Transmission

Describes how to

configure the RBS for IP-based transmission.

Glossary

Contains abbrev

iations and acronyms used in the text.

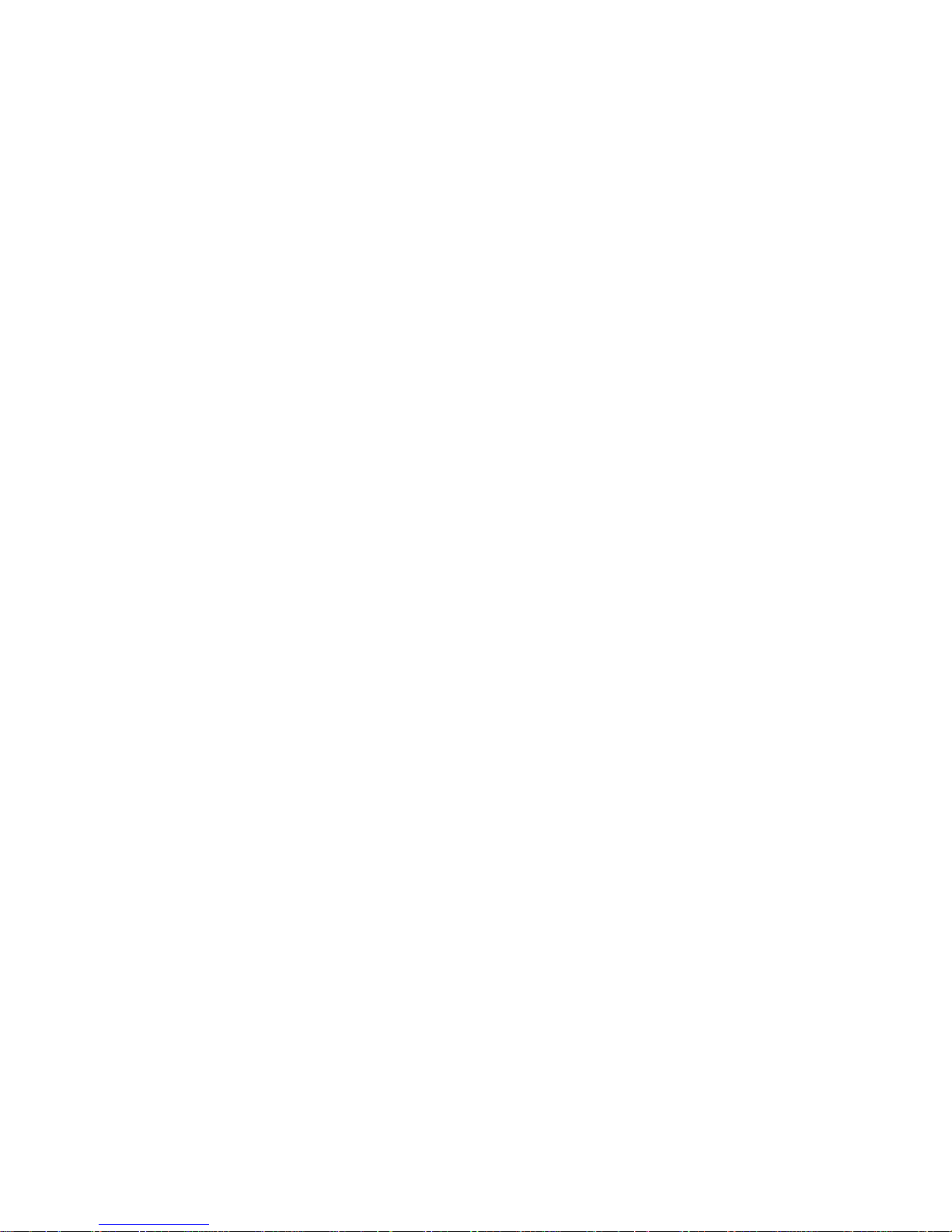

1.1 Product Overview

The RBS is a GSM EDGE micro base station for both indoor and outdoor micro

cell applications. It is a small yet complete station, with transceivers, switching

functions and transmission. The RBS 2308 supports both PCM and IP-based

transmission.

The RBS can be mounted on a mast/pole as easily as it can be fitted to a wall.

2

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 11

RBS 2308 and RBS 2309 User’s Guide

P015678B

MCB

Sunshield

TIM/PSTU

Flash Card

Sunshield

Screws

IXU (Master RBS)

MBU

Fan

RXBP

Fan Cover

RRU

Integral Sector Antenna

Integral Omni Antenna

Figure 1 RBS Ove

rview

IXU

Interface and Switching Unit

MBU Mounting Base Unit

MCB

Multicasting Box

PSTU Packet-Switched Termination Unit (available only for

RBS 2308)

RRU Remote Radio Unit

RXBP RX Bandpass Filter

TIM

Transmission Interface Module

External

optional battery backup is possible, as well as the option of having

integrat

ed antennas within the base station.

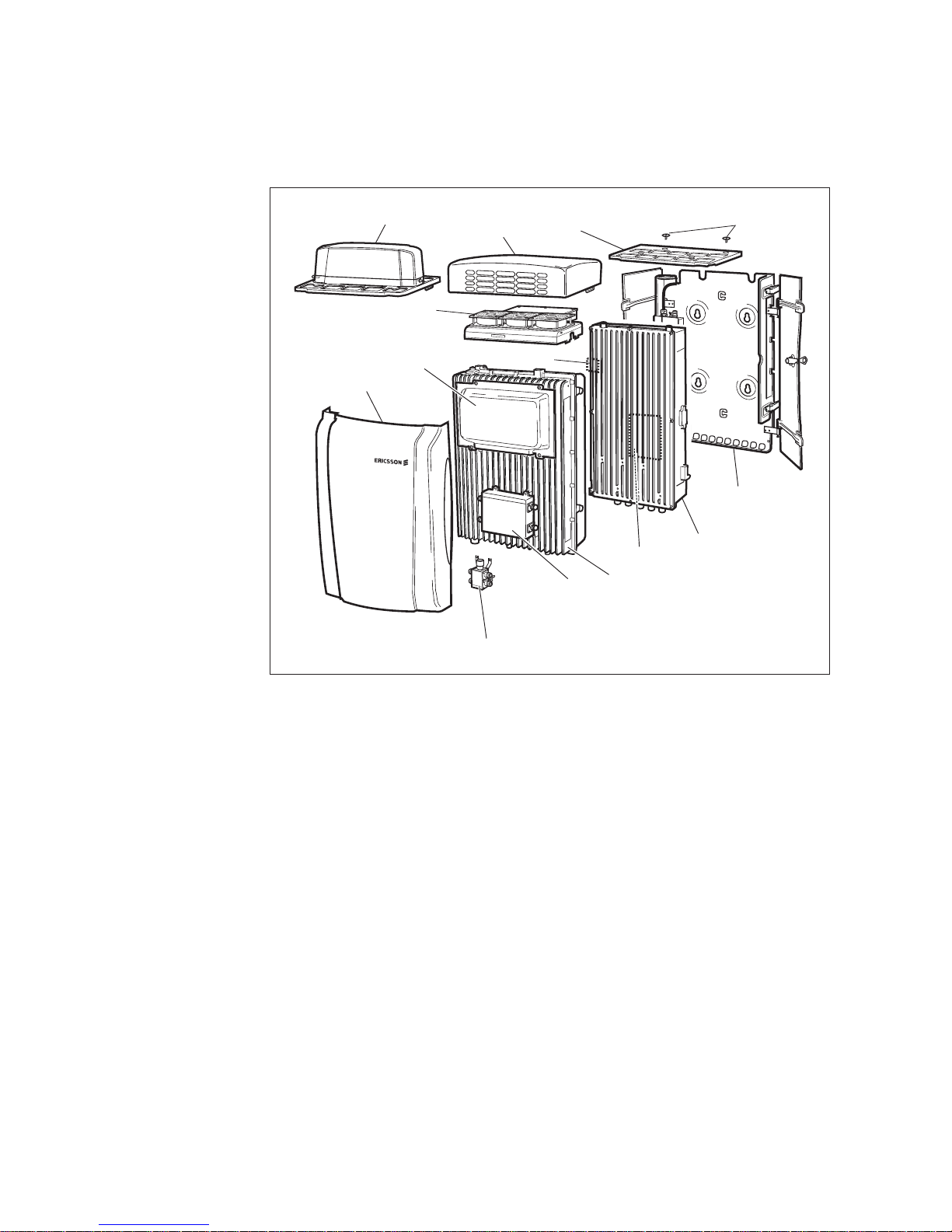

1.2 Target Groups

This section describes the target group for this manual, which is all personnel

involved in activities relating to the installation and integration of an RBS site.

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 12

RBS 2308 and RBS 2309 User’s Guide

TEMS

O

N

/O

FF

Y

E

S

N

O

1

2

3

4

5

6

7

8

9

*

0

#

CL

R

Cabinet Installation

Antenna System Tests

Site Installation Tests

RBS Site Integration

Fault Handling

OMT

Installation

Test and Integration

P008221B

Chapters Introduction, Safety Instructions and Tools and Instruments

used by all groups

Figure 2 Chapters Related to Specific Target Groups

During the whole Radio Site Implementation (RSI) process and the product’s life

cycle, the target groups require documents in addition to the above mentioned

manuals to complete the work.

Qualifications for Installation Personnel

Ericsson recommends that installation personnel possess the following skills:

• Technical college or equivalent education with an emphasis on electrical

engineering

• Familiarity with the equipment used during the installation process

• Knowledge of antenna systems

• Appropriate training and medical certificate for working at heights

• Good understanding of technical English

Qualifications for Test and Integration Personnel

Ericsson recommends that testing and integration personnel possess the

following skills:

4

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 13

RBS 2308 and RBS 2309 User’s Guide

• Basic Ericsson RBS 2000 Operation and Maintenance knowledge.

Personnel should be familiar with the tools and instruments recommended

in the chapters Antenna System Tests, Site Installation Tests, and RBS

Site Integration.

• Basic GSM knowledge

• Basic RBS 2000 knowledge

• Good understanding of technical English

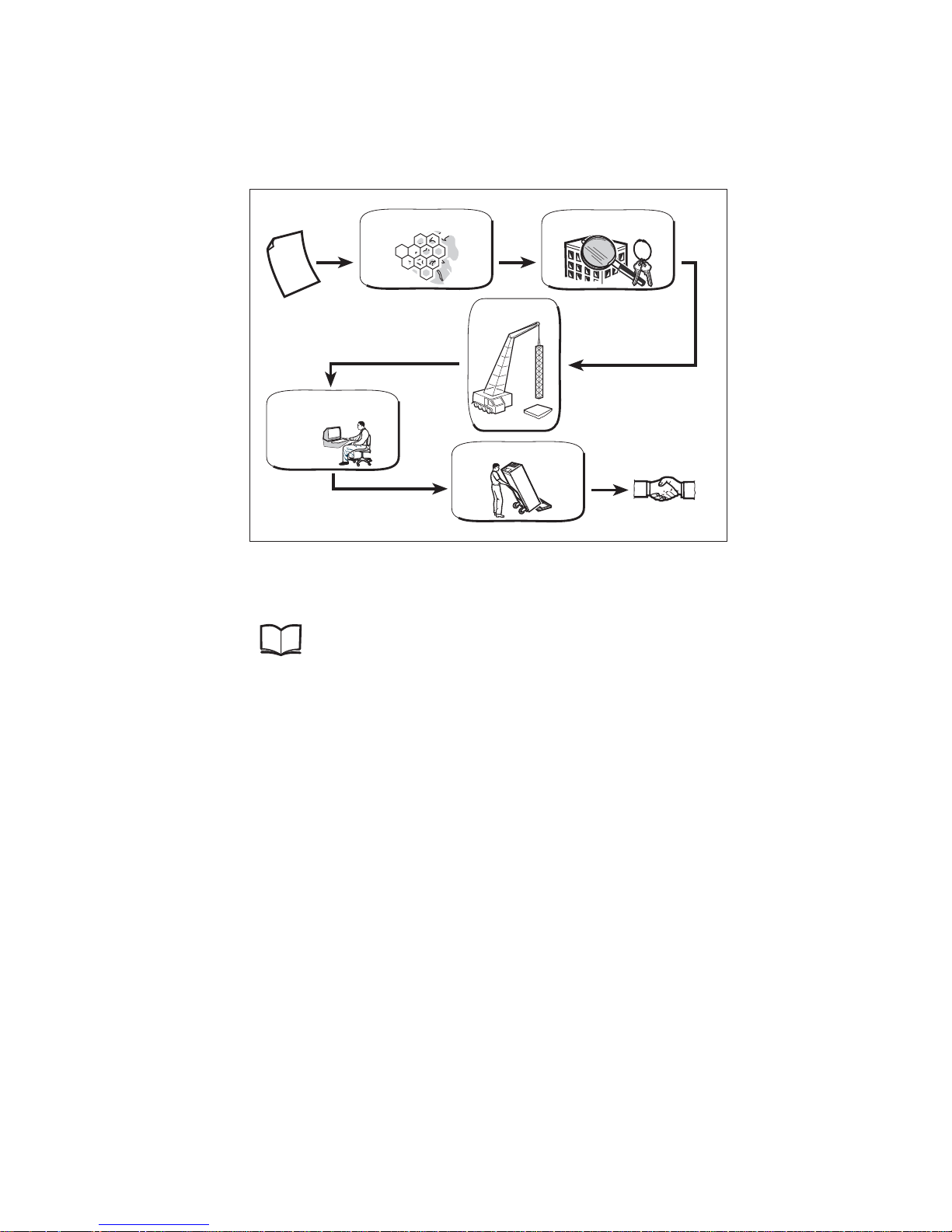

1.3 Installation and Integration Process Overview

This section describes the overall Installation and Integration process. This

process covers the work that follows the Installation Engineering process:

testing the antenna system, installing the cabinet, performing site installation

tests, and integrating the site into the network. A process overview is shown

below.

P016157A

Antenna System Tests

Site Installation Tests

RBS Site Integration

Cabinet Installation

Installation Engineering

Figure 3 Installation and Integration Process

1.4 Radio Site Implementation P rocess

This section describes the overall Radio Site Implementation process, of which

the Installation and Integration process is a part. The Radio Site Implementation

process covers the work from the initial stages of receiving an order, planning

and designing the entire network, to installing the RBS sites and integrating

them into the network.

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 14

RBS 2308 and RBS 2309 User’s Guide

Site Acquisition

Network Design

Acceptance (of site)

Contract is signed

P007657B

Radio Site

Installation Engineering

Civil Works

Installation & Integration

Figure 4 The Radio Site Implementation Process

For further information about the planning process, see:

Site Engineering Instruction

LZN 901 0602

Network Planning Process

The Network Planning process consists of the following activities:

• Dimensioning of network

• Dimensioning of equipment for radio, transmission, switching, operation

and maintenance

• Defining and ordering market adaptation products, for example programs

for national signalling towards the public telephone network

• Measurement of radio frequency and interference

• Producing digital maps and data

Site Acquisition

The Site Acquisition process is performed in close cooperation with the Civil

Works process and, to some extent, with the Engineering process.

The Site Acquisition process consists of the following activities:

6

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 15

RBS 2308 and RBS 2309 User’s Guide

• Searching for sites and obtaining a site appraisal

• Outlining the site design and evaluating the cost

• Negotiating and signing leasing contracts

• Handling permits and arranging a handover to the Engineering personnel

Civil Works

The Civil Works process is performed in close cooperation with the Site

Acquisition process and the Engineering process.

The Civil Works process consists of the following activities:

• Preparing a d etailed civil works design of the site

• Updating the costs for the site construction

• Arranging the site construction

• Performing a site inspection and handing over an as-built document to

the Engineering personnel

Engineering

The Engineering process begins when the Site Acquisition and Civil Works

processes are complete.

The Engineering process consists of the following activities:

• Measuring and collecting information about sites

• Designing the antenna and radio configuration, and producing cable

drawings

• Making drawings showing the positions of the antenna and RBS equipment

• Defining areas of responsibility between the purchaser and the contractor

• Producing site-specific information in the Site Installation Documentation.

For more information about the results from the site engineering process, see:

Site Engineering Instruction

LZN 901 0602

Installation and Integration

The work involved in this process is performed by installation personnel, and

test and integration personnel.

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 16

RBS 2308 and RBS 2309 User’s Guide

Installation pers

onnel are responsible for the following activities:

• Installing the antenna system

• Installing the RBS

• Earthing the RBS

• Connecting a power supply to the RBS

• Connecting the antenna system to the RBS

• Installing cable ladders and cable ducts

• Installing battery backup

• Installing transmission cables

The test and integration personnel are responsible for the following activities:

• Performing the tests specified i n the contract and integrating the site

• Commissioning of the PSTU

• Troubleshooting if tests indicate a fault

• Recording the test results in the Site Installation Documentation, which is

returned to the engineering personnel

1.5 RBS Library Overview

For information on the RBS library and other manuals related to the RBS, see:

RBS 2000 Library Overview

LZN 302 73

1.6 Release History

In addition to editorial changes, such as correction of typographical and layout

errors, this manual has been revised as follows:

1.6.1 R7B to R8A

General

• Information about the PSTU and IP-based transmission has been added

8

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 17

RBS 2308 and RBS 2309 User’s Guide

• Information about less-temperature-sensitive units with no heater has

been added

Chapter Site Installation Tests

• Section Setting IDB Parameters has been updated with new work process

Chapter PSTU Startup

• This is a new chapter

Chapter Maintenance

• A new section, Returning Hardware, has been added

Chapter Reconfiguring the RBS for IP Transmission

• This is a new chapter

1.6.2 R7A to R7B

Chapter Glossary

• New abbreviations added

1.6.3 R6A to R7A

Chapter Site Installation Tests

• Section Setting IDB Parameters updated with parameter descriptions

Chapter Maintenance

• Section Fault Localization Using OMT updated

1.6.4 R5A to R6A

The appendices EBB-01 Maintenance and Installation Instructions and EBB-06

Maintenance and Installation Instructions have been removed from the manual.

Chapter Installation of RBS

• Note about IDB added in section Replacing the Flash Card (If Applicable)

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 18

RBS 2308 and RBS 2309 User’s Guide

Chapter Site Insta

llation Tests

• Note about IDB adde

d in section Installing IDB

• Notes added to info

rm site personnel about indicators double-flashing

during function c

hanges

Chapter RBS Site I

ntegration

• Notes added to inf

orm site personnel about indicators double-flashing

during function

changes

Chapter Mainten

ance

• Notes added to in

form site personnel about indicators double-flashing

during function

changes

• New section, Dou

ble-Flash Indication of Function Changes, added

• Note about IDB ad

ded in section Flash Card Replacement

10

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 19

RBS 2308 and RBS 2309 User’s Guide

2 Personal Health and Safety Information

2.1 Introduction

This document presents the personal health and safety information that applies

when working with Ericsson system products. The instructions included are

mandatory to ensure personal safety while working with Ericsson system

products.

Note: Reduce the risk of accidents by studying all the information carefully

before starting work. If questions arise regarding health and safety

information, contact the supervisor or the local Ericsson company for

clarification.

For information on product safety for Ericsson system products, see:

System Safety Information,

Ericsson System Products

124 46–2886

Local Regulations

Local regulations, first and foremost national regulations, override the

information in this document. Where applicable local regulations are not

available, the information herein prevails.

Product Exclusion Indication

The information in this document covers personal health and safety aspects

of all Ericsson system products. As all the information does not apply to a

specific product, the readers must familiarize themselves with the potential

hazards indicated on the product they are working with to understand which

document parts apply to their product.

2.1.1 Target Group

The target group for this health and safety information is personnel who work

with Ericsson products. All personnel who work with engineering, installation,

test, and operation and maintenance of Ericsson products must familiarize

themselves with this information.

2.1.2 Educational Requirements

The safety instructions in the relevant manuals or documents require that

persons performing work on Ericsson products have the necessary education,

1

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 20

RBS 2308 and RBS 2309 User’s Guide

training and compe

tence required to perform work correctly. For certain work,

additional or spec

ial training may be required, for example authorization for

Authorized Servic

e Providers (ASP). ASP is an Ericsson certification procedure.

A good understanding of technical English is required, or of the language that

the information is presented in, to ensure that these and other instructions

can be understood and complied with.

2.2 Hazard Symbols and Admonitions

This section presents the types of admonitions and hazard symbols used in

all

Ericsson documentation. There are three levels of personal health and s

afety

admonitions that indicate risk to persons: danger, warning and caution

. Hazard

symbols are used to indicate these and to present various other hazards.

The admonition levels for personal health and safety are presented in order

of severity, with danger being the highest level, warning the intermediary

and caution the lowest. When admonitions are encountered anywhere in a

document, the information included should be read and any instructions should

be followed.

2.2.1 Personal Health and Safety Admonitions

Personal health and safety admonitions are used to indicate hazardous

activities and are normally preceded by the common hazard symbol shown in

the figure below, or in specific cases by specialized symbols, see Section 2.2.2

Special Hazard Symbols on page 13.

P002643A

Figure 5 Safety Hazard Symbol

The hazard symbol is common for all three admonition levels. The three

admonition levels are defined below:

Danger! Indicates that there is an imminent hazard that is likely

to result in death or serious injury.

Note: Danger can be accompanied by other symbols

depending on the country of operation.

Warning! Indicates that there is a potential hazard that could

result in death or injury.

Caution!

Indicates a hazard that could result in minor or moderate

injury.

12

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 21

RBS 2308 and RBS 2309 User’s Guide

2.2.2 Special Hazard Symbols

This section presents special hazard symbols used to indicate the risk of

chemical, electric shock, fire, heat, laser and Radio Frequency (RF) exposure

hazards:

P010387A

Figure 6 Chemical Hazard Symbol

P002645A

Figure 7 Electrical Hazard Symbol

P010385A

Figure 8 Fire Hazard Symbol

P010274A

Figure 9 Heat Hazard Symbol

P010341A

Figure 10 Laser Hazard Symbol

P002644A

Figure 11 RF E xposure Hazard Symbol

2.3 General Safety Precautions

This section presents general safety precautions to ensure that persons are not

injured when working with equipment.

• Items of jewelry, for example rings, watches and necklaces should be

removed as they can catch on moving parts, or when lifting equipment.

• Pay attention to the hazard labels and other information labels on products.

1

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 22

RBS 2308 and RBS 2309 User’s Guide

• Never remove or cov

er hazard symbols as this can endanger persons

working with the pr

oduct.

• Only use the tools described, in the manner indicated, in instructions.

2.4 Electric Shock Hazards

This section provides information and instructions relating to equipment

operating on voltage that entails an electric shock hazard.

Note: This information only applies to products marked with the electric shock

hazard symbol.

The term Electric Shock Hazard is defined below:

Electric Shock

Hazard

Hazard at voltage equal to or above 42.4 V peak or

60 V DC.

Danger!

Electric shock risk. Avoid both direct and indirect contact with parts connected

to mains power as this is likely to be fatal. Switch off the mains power before

starting work.

Danger!

Improper electrical installation may cause fire or electric shock that is likely to

be fatal. Only a qualified and authorized electrician is permitted to install or

modify electrical installations.

Note: Only qualified electricians are allowed to work directly with equipment

that presents an electric shock hazard.

Note: AC mains installation must be c arried out according to local regulations.

2.4.1 Safety Precautions for Working with Electrical Equipment

The following precautions must be observed when working with electrical

equipment:

• The AC mains is switched off.

14

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 23

RBS 2308 and RBS 2309 User’s Guide

• Equipment exposed to moisture is protected with a tent or other equipment.

• Power cables are installed according to instructions.

• Installed cables are always clearly marked with labels.

• All personnel are familiar with and understand the warning signs on

equipment.

• Only tested electrical tools are used.

• Holes are never drilled in equipment, or walls, without ensuring that there

are no concealed cables.

2.5 Energy Hazards

This section provides information on how to avoid energy hazards.

The term energy hazard is defined below:

Energy Hazard

Hazard at a stored energy level of 20 J or an available

continuous power level of 240 VA.

2.5.1 Batteries

This section provides instructions and information on the proper handling

of batteries.

Note: Where Ericsson is not the supplier of battery equipment, see the

manufacturer’s information on battery safety.

Caution!

Improper handling of batteries can result in the batteries short-circuiting, which

can result in serious injury due to high energy levels. Exercise the necessary

care when working with batteries.

1

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 24

RBS 2308 and RBS 2309 User’s Guide

Lithium Batteries

Warning!

Switching poles when replacing lithium batteries can result in an explosion

that can lead to injury. Always ensure that lithium batteries are connected

to the right poles.

2.5.2 Capacitors and Uninterruptible Power Systems

This section provides information on how to avoid energy hazards in Capacitors

and Uninterruptible Power Systems (UPS).

Warning!

High energy leve

ls are present in this unit. Improper handling of the unit can

lead to short cir

cuiting that can result in serious injury. Exercise care when

working with th

is unit.

Note: Some capacitors and UPSs have energy levels above 240 VA. If this is

the case this is indicated on the product with a voltage hazard.

2.5.3 Safety Precautions for Avoiding Energy Hazards

The following precautions must be observed w hen working with batteries and

other units that present an energy hazard:

• All metallic objects worn, such as wrist watches, rings, bracelets, and so

on are removed.

• Disconnect the charger power supply until the work is complete.

• Only use insulated tools.

2.6 Fire Hazard

This section provides instructions and information on safety precautions for

preventing fire.

16

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 25

RBS 2308 and RBS 2309 User’s Guide

Warning!

In the event of a fire, evacuate t

he building or equipment site and raise the fire

alarm at the closest alarm point

, or call the emergency number. Do not re-enter

a burning building under any ci

rcumstances.

Warning!

Heater in operation. Do not b

lock the heater vents or place combustible

materials close to the unit,

as this can cause a fire that can endanger life.

2.6.1 Fire Precautions

Note: When working with the installation or maintenance of equipment that

involves interfering with the fire sectioning of a building, this should be

carried out as quickly as possible.

Fire can spread to neighboring rooms. When working on equipment cable

ducts, channels and access holes might have to be opened, thereby interfering

with the fire sectioning of the building. The instructions below have to be

followed when work has been completed to restore the building’s fire sectioning:

1. Close the cable ducts and fire doors (if applicable) as soon as possible.

2. Seal cable ducts according to the regulations for the building.

3. Minimize the amount of inflammable material.

4. Remove empty packaging material from the equipment site.

5. Check that there is a functioning powder or carbon dioxide fire extinguisher

for electric apparatus at the equipment site.

2.7 Heat Hazards

This section describes how to avoid injury from hot surfaces or hot air in

equipment.

1

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 26

RBS 2308 and RBS 2309 User’s Guide

Caution!

Parts inside this equipment attain high temperatures during normal operation,

which can cause burns to the skin if touched without heat protective clothing.

Always use heat protective clothing when working with equipment containing hot

surfaces, or switch the equipment off and allow it to cool before starting work.

Caution!

A heater, producin

g hot air, is in use in this equipment. Direct contact with hot

air can lead to bur

ns. When the heater is in operation, avoid close contact

with the heater ai

r evacuation vent.

2.8 Mechanical Hazards

This section provides information on mechanical hazards in equipment

containing sharp edges or rotating blades.

Caution!

Sharp metal edges may exist that can cause cuts to the skin or clothing. Wear

protective gloves when handling this equipment.

Caution!

Rotating fan blad

es can cause injury to body parts that come into contact with

the blades. Blad

es in fan units continue to rotate for a period of time, even after

the fan has been s

witched off. Wait until fans have stopped rotating completely

before startin

g work on or near fans.

18 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 27

RBS 2308 and RBS 2309 User’s Guide

2.9 Radio Frequency Exposure Hazards

This section provides instructio

ns and information on potential hazards related

to radio frequency (RF) electro

magnetic field (EMF) exposure from fixed radio

transmitters (as opposed to mo

bile phones).

2.9.1 General RF Safety Information

Caution!

Excessive RF exposure can result in potentially adverse health effects. If it is

suspected that RF exposure limits may be exceeded, ensure that transmitting

antennas are switched off, or reduce output power whilst working with, or

near, antennas.

Note: RF exposure limits are specified by national and international health

authorities in standards, regulations or guidelines. The limits include

wide safety margins to protect from potentially harmful tissue heating.

2.9.2 RF Safety for Installation and Maintenance Personnel

It is important that all personnel working with the installation and maintenance

of transmitting equipment and antennas have basic knowledge regarding RF

safety. They must have been informed or trained to be observant of potential

risks of RF exposure exceeding specified safety limits, and be aware of

precautionary measures necessary for differing situations.

Caution!

Do not stand or work in front of an operational antenna, unless it has been

verified or documented that RF exposure levels are within specified safety limits.

Caution!

Always be aware of other RF transmission antennas located close to the

antenna you will be working with. If the RF exposure level is unknown, contact

the equipment operator or ensure that measurements are done to verify that

levels are below specified safety limits before starting work.

1

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 28

RBS 2308 and RBS 2309 User’s Guide

Caution!

Broken or disconne

cted RF cables can lead to exposure levels reaching, or

exceeding, specif

ied safety limits. Repair or reconnect cables before starting

work.

Note: Working outside of the main transmission direction of ordinarily

configured antennas is in most situations possible, since the RF

exposure does not normally reach specified safety limits in these

directions.

2.10 Laser Hazards

This section provides information on working with products that have devices

that communicate through optical fibres using laser.

Note: This information only applies to products marked with the laser hazard

symbol, stating the class of laser in use.

2.10.1 Class 1 Laser

This section provides information on working with equipment containing Class

1 laser.

Products containing a Class 1 laser, according to IEC/EN 60825, are safe

to use and therefore have no requirements for cautions or warnings during

operation or maintenance procedures.

2.10.2 Class 3 Laser

This section provides information on working with equipment containing Class

3 laser.

Danger!

Never look directly into the end of a fiber optic cable, or other laser source.

Equipment that transmits laser light can cause permanent eye damage. Switch

off the laser before starting work on laser equipment.

20 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 29

RBS 2308 and RBS 2309 User’s Guide

Safety Precautions for Working with Class 3 Laser

The following precautions must be observed when working with products

containing a Class 3 laser hazard symbol:

• Never look into the light emitting end of a functioning optical fibre.

• Switch off units producing the laser signal before disconnecting an optical

fibre.

2.11 Chemical Hazards

This section provides information on chemical hazards that can be present

in products.

2.11.1 Beryllium Oxide Hazard

This section provides information on Beryllium Oxide (BeO). BeO is a restricted

substance that is contained in certain components in some Ericsson products.

If a product contains BeO, this is clearly marked on the unit containing BeO.

The BeO hazard symbol is shown in the figure below.

P010382A

Figure 12 BeO Hazard Symbol

Note: This information only applies to products marked with the BeO symbol.

Danger!

This product contains Beryllium Oxide (BeO), which can cause injury to skin

or mucous membranes severe enough to endanger life or cause permanent

injury. BeO dust is created by chafing, filing, or breakage and is extremely

dangerous if inhaled, even for only a few seconds. Particles penetrating the

skin through wounds or abrasions are liable to cause chronic ulcerations. Do

not handle components containing BeO without protection.

Symptoms of BeO Poisoning

Symptoms of BeO poisoning are respiratory distress, cyanosis (grey-blue

discoloration of the skin and mucous membranes), or both. These symptoms

may develop within a week, or after a period of several years.

2

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 30

RBS 2308 and RBS 2309 User’s Guide

Safety Precaution

s for Working with Components Containing BeO

The following prec

autions must be observed when working with components

containing BeO:

• Do not carry loose components in pockets, bags, or containers, or tamper

with them in any way that could cause breakage or disintegration.

• Do not apply excessive heat during soldering.

• Do not break open components for inspection.

• Store components in their original packaging and do not mix them with

other components.

• Ensure that components do not become mechanically damaged.

• Use care when replacing defective components.

• Do not blow on exposed surfaces due to the danger of BeO dust.

• In case of accident, or if you feel unwell, seek medical advice immediately

and show the label where possible.

2.11.2 Battery Acid Hazard

This section provides information on chemical hazards related to lead-acid

batteries.

Caution!

Excessive heat can cause battery casing to soften and warp, potentially allowing

acid to escape. In contact with the skin, acid can cause injury, and if breathed

in, can affect the airways. Use protective equipment when replacing batteries.

Caution!

Batteries can leak electrolyte if improperly handled. Electrolyte in contact

with skin or eyes can cause injury. In the event of electrolyte injuries, rinse

the affected area with water and seek medical attention immediately. Use

protective equipment when replacing batteries.

22 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 31

RBS 2308 and RBS 2309 User’s Guide

Safety Precautions for Working with Lead-acid Batteries

The following precautions must be observed when working with lead-acid

batteries:

• Eye wash facilities, and protective gloves or aprons are available.

2.11.3 Gas Explosion Hazard

Open-cell lead acid batteries can give off gases that in the event of a fire

can cause an explosion that is likely to be fatal. All battery areas must be

adequately ventilated and protected from fire.

Danger!

Do not use open-cell lead acid batteries. Open-cell lead acid batteries give off

hazardous gases that, if ignited, can cause an explosion that is likely to be fatal.

2.12 Other Hazards

This section includes safety instructions and rules for the following hazards:

• Handling Heavy Goods

• Working at Height

2.12.1 Handling Heavy Goods

This section provides instructions and rules for handling heavy goods.

Note: Follow local regulations for safety clothing and safety equipment for

hoisting and moving goods.

Falling Objects

Warning!

Risk for falling objects, work at height in progress. Falling objects can cause

serious injury or even be fatal. Always wear a helmet and avoid standing in

the danger area.

2

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 32

RBS 2308 and RBS 2309 User’s Guide

Overloading

Warning!

Overloading, or other wrong use of lifting devices, can cause serious injury to

anyone hit by falling equipment. Do not create an angle exceeding 90° between

lifting straps as this increases the strain on them and can cause them to snap.

Caution!

The equipment is heavy. Lifting the equipment without the aid of a lifting device

can cause injury.

Unsecured Equipm

ent

Caution!

Tip risk! Unsecur

ed equipment can tip over if not secured properly, causing

injury to person

nel. Secure products with a high center of gravity as soon as

possible to avoi

d accidents.

2.12.2 Working at Height

This section provides information about working at height.

For information on climbing instructions for working at height, see:

Safe Climbing LZY 213 715/02

Safety Precautions for Working at Height

The following precautions must be observed when working at height:

• Personnel have the appropriate training and medical certificate.

24

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 33

RBS 2308 and RBS 2309 User’s Guide

• A full-body safety harness and safety helmet are available.

• Adequate protective clothing, essential in cold and wet weather, is available.

• All lifting devices are tested and approved, and ready for use.

• All personnel in the area are wearing helmets.

2

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 34

RBS 2308 and RBS 2309 User’s Guide

26

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 35

RBS 2308 and RBS 2309 User’s Guide

3 System Safety Information

3.1 Introduction

This document presents the system used for presenting system safety

information for Ericsson products. The instructions included are mandatory to

ensure product safety while working with Ericsson products.

Local regulations must be taken into consideration. The system safety

information in this document is in addition to local regulations.

Note: Reduce the risk of accidents by studying all the instructions carefully

before starting work. If questions arise regarding the safety instructions,

contact the supervisor or the local Ericsson company for clarification.

For information o n personal health and safety for Ericsson system products,

see:

Personal Health and Safety

Information, Ericsson System

Products

124 46–2885

Local Regulations

Local regulations, first and foremost national regulations, override the

information in this document. Where applicable local regulations are not

available, the information herein prevails.

Product Exclusion Indication

The information in this document covers system safety information for all

Ericsson system products. As all the information does not apply to a specific

product, the readers must familiarize themselves with the potential hazards

indicated on the product they are working with to understand which document

parts apply to their product.

3.1.1 Target Group

The target group for this system safety information is personnel who work

with Ericsson products. All personnel who work with engineering, installation,

test, and operation and maintenance of Ericsson products must familiarize

themselves with this information.

2

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 36

RBS 2308 and RBS 2309 User’s Guide

3.1.2 Educational Requi

rements

The product safety

instructions in the relevant manuals or documents require

that persons perfo

rming work on Ericsson products have the necessary

education, train

ing and competence required to perform work correctly. For

certain work, add

itional or special training may be required, for example

authorization fo

r Authorized Service Providers (ASP). ASP is an Ericsson

certification p

rocedure.

A good understanding of technical English is required, or of the language

that the information is presented in, to ensure that these instructions can be

understood and complied with.

3.2 Admonitions and Safety Symbols

This section presents the types of admonitions and safety symbols used in all

documents for Ericsson system products. There are two types of system safety

admonitions that indicate risk to products: Do! and Stop!. When admonitions

are encountered anywhere in a document, the information included should be

read and any instructions should be followed.

The figures below show the symbols used to i ndicate product safety

admonitions:

Figure 13 Do Safety Symbol

Figure 14 Stop Safety Symbol

The terms Do! and Stop! are defined below:

Do!

Indicates an action that must be performed to prevent

equipment damage, software corruption, data loss or

service interruption.

Stop!

Indicates that action must be avoided to protect

equipment, software, data or service.

The term “Note” is used to present important information that might otherwise

be overlooked.

3.2.1 Special Hazard Symbols

This section presents special hazard symbols used to indicate the risk of

Electrostatic Discharge (ESD):

28

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 37

RBS 2308 and RBS 2309 User’s Guide

P002646A

Figure 15 Electrostatic Discharge Hazard Symbol

3.3 Batteries

This section provides information on damage that can be caused to products

containing batteries that are damaged.

3.3.1 Overheated Batteries

Caution!

Do! Check batteries for signs of overheating. The casing surrounding

overheated batteries can be soft and warped. Replace damaged batteries

according to instructions.

If it is suspected that batteries are overheated, check the following:

• The internal temperature of the equipment is below +60°C (140°F).

• Batteries have not leaked.

Corrective Actions

1. Replace overheated batteries.

2. Treat leakages from batteries as described in Section 3.3.2 Treating

Hazardous Waste from Leaks on page 29.

3.3.2 Treating Hazardous Waste from Leaks

Caution!

Do! Check batteries for acid leakage. Acid can corrode the product. Replace

leaking batteries according to instructions.

2

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 38

RBS 2308 and RBS 2309 User’s Guide

In case of spillage

of hazardous substances, there should always be sufficient

absorbers or neutr

alizing materials available on site. There is a danger of

spillage occurrin

g when installing, removing, replacing or servicing batteries.

The absorbers and

neutralizing materials must be suitable for the hazardous

substances invol

ved. Typical neutralizing agents are shown inTable 1 on

page 30.

Table 1 Typical Neutralizers

Typical Neutralizers

Chemical Compound

Baking soda (bicarbonate) NaHCO

3

Sal soda Na2CO3IOH2O

Soda ash Na2CO

3

Note: Absorbers and neutralizing products will vary, depending on the c ountry

and battery manufacturer. Consult the battery manufacturer for specific

details of absorbers and neutralizing materials.

3.4 Electrical Installation

This section provides information on ensuring that AC and DC powered

products are not damaged due to improper installation.

Caution!

Stop! Do not install or modify AC or DC powered equipment unless you are a

qualified and authorized electrician. Improper installation work can seriously

damage the equipment.

3.4.1 Safety Precautions for Working with Elec trical Installations

The following precautions must be observed when working with electrical

installations:

1. Ensure that approved circuit breakers or fuses are installed.

2. Ensure that the cables used have a sufficient cross-sectional area in

accordance with product requirements and local laws and regulations.

3. Ensure that conductors are connected according to the connection diagram.

4. Label the cables correctly.

5. Check the installation work upon completion.

30

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 39

RBS 2308 and RBS 2309 User’s Guide

3.5 Electrostatic Discharge

This section provides informatio

n and instructions on Electrostatic Discharge

(ESD) product safety. ESD is def

ined below.

ESD

A static electric charge accum

ulates when a body rubs

against clothes, slides again

st a chair, when shoes rub

against a floor, or when ordin

ary plastics are handled,

and so on. The electrostatic c

harge can remain for a

considerable length of tim

e and is discharged when the

body comes into contact wit

h conductive material.

An ESD wrist strap must be us

ed when working with ESD sensitive components,

even in equipment rooms fi

tted with ESD protective floor covering. Although

ESD floor covering reduce

s the risk of ESD, if the wrong type of shoes are

used, or if the person is a

lready charged when they enter the room, the floor

covering in itself does

not protect from this, and therefore an ESD wrist s trap

must be used.

01_0250A

Figure 16 ESD wrist strap

The ESD wrist strap contains a resistor with resistance greater than 1 M in the

cable to protect the operator. The resistance value is low enough to discharge

the electrostatic voltage. The ESD wrist strap must be connected to ground.

Instructions for ESD Wrist Strap Use

1. Place the ESD wrist strap around your wrist and insert the connector at the

other end to the ground (earth) terminal on the equipment.

2. Always use the wrist strap when and where its use is required.

Note: Test the ESD wrist strap regularly.

3

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 40

RBS 2308 and RBS 2309 User’s Guide

3.5.1 Handling Printed B

oard Assemblies and IC Components

Note: Treating all

components as if they are ESD sensitive, whether they

have IC components

or not, reduces the risk for ESD and significantly

reduces the opera

ting time between failure.

Caution!

Stop! This product contains components sensitive to ESD. Use an approved

ESD wrist strap, connected to the product grounding point, to avoid damaging

these components.

Caution!

Do! Always use an approved ESD wrist strap when working with sensitive

equipment. Damage to components mounted on printed board assemblies can

occur if an ESD wrist strap is not used.

3.5.2 Storing and Trans

porting Printed Board Assemblies and IC

Components

When storing or t

ransporting printed board assemblies or IC components,

ensure one of the

following:

• The item is store

d or transported in its original packaging, or in other

anti-ESD mater

ial.

• The item is stor

ed or transported in a conductive material, or a special IC

carrier that ei

ther short-circuits or insulates all leads of the components.

3.6 Equipment Handling

This section provides information on how to avoid damage to products when

handling them.

32

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 41

RBS 2308 and RBS 2309 User’s Guide

Caution!

Do!

Tip risk! This equipment has a high center of gravity without all units installed.

Secure the equipment before opening the door.

Caution!

Stop! Never lift a unit by the cables as this can damage the equipment.

3.7 Ground Connection

This section provides information on product grounding (earthing) safety.

Note: The terms “grounding” and “earthing” are synonyms.

Caution!

Do! Products not connected to ground risk being damaged by overvoltage or

overcurrent. Always connect products to ground according to instructions.

3.8 Lightning Protection

This section provides infor

mation on protecting products from damage due to

lightning where a lightning

protection system is available.

Caution!

Do! Connect products to the

lightning protection system to protect the

equipment from transient s

urges.

3

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 42

RBS 2308 and RBS 2309 User’s Guide

34

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 43

RBS 2308 and RBS 2309 User’s Guide

4 Tools and Instruments

This section contains lists of all tools and instruments recommended for the

complete installation of the RBS 2308 and RBS 2309.

4.1 Tools for Installation of RBS 2308 and RBS 2309

Table 2 Basic Tools for Installation

Description

Specification

Adjustable spanner 10"

–

Drilling mach in e

–

Knife

(1)

–

Measuring tape

(1)

6m

Pen

–

Screwdrivers

(1)

Torx: T20 and T30

Screwdrivers

3 mm and 5.5 mm

Side cutting pliers

(1)

–

Snip nos e pliers

–

Socket set

(1)

10–19mm

Spirit le ve l

(1)

–

Torquewrench 5–25Nm

U wrenches

(1)

13 mm, 16 mm, 17 mm, 20 mm and 22 mm

Wire stripper

(1)

0.2–6mm

2

(1) Included in Personal Tool Set, Product Number LTT 601 135/1.

Table 3 Special Tools for Installation

Description

Specification

Product Number

Crimping tool set for grounding

LTT 601 86

Torque wrench

for N connector LSS 103 25/1

Torque wrench

for TNC connector

LTT 601 93

U-key, 32 mm

(1)

for 7/16 connecto r LSB 107 12/5

(1) Requires torque set 20–100 Nm, product number LTT 601 141/1.

4.1.1 Documentation

The following documents are required for the installation procedure:

3

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 44

RBS 2308 and RBS 2309 User’s Guide

• Completed and appr

oved record prepared during site preparation

• Site Installation Documentation (prepared by the Installation Engineering

department)

Standard Site Material Installation

Instructions

EN/LZT 720 0014

4.2 Equipment for Antenna System Tests

Table 4 Test Equipment for Antenna System Tests

Description

Specification

Product Number

Antenna tester set

Anritsu Site Master S331D LPK 102 101/10

Antenna tester

accessories

Accessories to the Anritsu Site

Master for micro RBSs

(1)

LPK 102 107/1

(1) Requires antenna tester set, product number L P K 102 101/10.

The Anritsu Site Master S331D is recommended for the Antenna System Tests,

but the following Site Master models can still be used if available: S251A/B and

S331A/B/C for GSM 800/900/1800/1900 antenna systems.

4.2.1 Documentation

The following documents are required for the antenna system tests:

• Site Installation Documentation

• A test record

For more detailed information on the Anritsu Site Master, see:

Anritsu Site Master User’s Guide (included in Antenna Tester

Set)

Note: Instructions for Site Master models S251A/B and S331A/B/C for GSM

800/900/1800/1900 antenna systems are not included in this document.

When using any of these models ensure that all necessary accessories

are included. See:

Standard Tools and Equipment

Catalogue

LZT 720 0013

36

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 45

RBS 2308 and RBS 2309 User’s Guide

4.3 Equipment for Site Installation Tests

Table 5 Test Equipment for Site Installation Tests

Description

Specification

Product Number

Fluke79III Multimeter

LPK 102 024/3

Torx T20

(1)

Torx screwdriver

–

(1) Included in Personal Tool Set, product number LTT 601 135/1.

There are different versions of the OMT depending on the BTS software

installed in the RBS. See table below.

Table 6 OMT Kits

Product

Name

Description Product No.

BSS SW

Compatibility

NTM 201 2289/3 Up to BSS R9.1

NTM 201 2289/4 Up to BSS R10

NTM 201 2289/5 Up to BSS R11

OMT Kit • Cable

• CD comprising OMT

SW and manual

NTM 201 2289/6 Up to BSS R12 and

BSS 06A

(1)

(1) BSS 06A is the successor to BSS R12

4.3.1 Documentation

The following documents are required for the site installation tests:

• A completed test record from antenna system tests

• A test record for site installation tests

OMT User’s Manual (included in

OMT Kit )

EN/LZN 720 0001

4.4 Equipment for PSTU Startup

Table 7 Basic Tools for PSTU Startup

Description

Specification

PC equipped with a VT100 terminal

emulator program and a standard

RS-232 serial port

–

Standard RS-232 serial cable. (The

standard OMT cable included in the

OMT kit can also be used.)

–

3

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 46

RBS 2308 and RBS 2309 User’s Guide

4.4.1 Documentation

The following docu

ments are required for the PSTU startup:

PSTU Command Description 1/190 82-LZA 701 0001

PSTU Alarm OPIs

4.5 Equipment for RBS Site Integration

Table 8 Test Equipment for RBS Site Integration

Description

Specification

Product Number

Loop forward/

backward board

Transmission test board

LPY 107 757/1

TEMS Kit GSM 800/1900

FAB 801 2524

TEMS Kit GSM 900/1800/1900

FAB 801 2523

4.5.1 Documentation

The following document is required for the RBS site integration:

TEMS Investigation GSM Manual

(included in TEMS Kit)

LZT 108 2684

4.6 Equipment for Maintenance

Table 9 Basic Tools for Maintenance

Description

Specification

Adjustable spanner 10"

–

Knife

(1)

–

Screwdrivers

(1)

Torx: T20 and T30

Screwdrivers

3 mm and 5.5 mm

Side cutting pliers

(1)

–

Snip nose pliers

–

Socket set

(1)

–

Torque wr ench

(1)

5–25Nm

38 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 47

RBS 2308 and RBS 2309 User’s Guide

Description

Specification

U wrenches

(1)

13 mm, 16 mm and 17 mm, 20 mm and 22 mm

Wire stripper

(1)

0.2–6mm

2

(1) Included in Persona l Tool Kit, product numbe r LTT 601 135/1.

Table 10 Special Tools for Maintenance

Description

Specification

Product Number

Fluke 79 III Multimeter

LPK 102 024/3

Torque wrench

for N connectors LSS 103 25/1

Torque wrench

for TNC connectors

LTT 601 93

There are different versions of the OMT depending on the BTS software

installed in the RBS. See table below.

Table 11 OMT Kits

Product

Name

Description Product No.

BSS SW

Compatibility

NTM 201 2289/3 Up to BSS R9.1

NTM 201 2289/4 Up to BSS R10

NTM 201 2289/5 Up to BSS R11

OMT Kit • Cable

• CD comprising OMT

SW and manual

NTM 201 2289/6 Up to BSS R12 and

BSS 06A

(1)

(1) BSS 06A is the successor to BSS R12

Table 12 Basic Tools for PSTU Maintenance in the RBS 2308

Description

Specification

PC equipped with a V

T100 terminal

emulator program

and a standard

RS-232 serial po

rt

–

Standard RS-232 serial cable. (The

standard OMT cable included in the

OMT kit can also be used.)

–

4.6.1 Documentation

The following documents are required for the maintenance work:

OMT User’s Manual (included in

OMT Kit)

EN/LZN 720 0001

3

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 48

RBS 2308 and RBS 2309 User’s Guide

RBS 2308, RBS 2309, and RBS 2109

Hardware Reference Manual

EN/LZT 720 0058

The following documents are required for maintenance of the PSTU in the

RBS 2308:

PSTU Command Description 1/190 82-LZA 701 0001

PSTU Alarm OPIs

4.7 Kit Specifica

tions

For a specific

ation of all required kits, see:

Standard Tools and Equipment

Catalogue

EN/LZT 720 0013

40

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 49

RBS 2308 and RBS 2309 User’s Guide

5 Installation of RBS

5.1 Introduction

This document describes how to install the RBS 2308 and RBS 2309.

Target Group

The target group for this instruction is personnel involved in the installation of

an RBS.

5.2 Preconditions

This section provides preconditions that must be met before starting the

installation work.

Note: Specific preconditions exist for wall and pole mounting.

Documentation

This section presents additional documents required for the installation

procedure.

Ensure that the following documents are available:

• Completed and approved record prepared during site preparation

• Site Installation Documentation (prepared by the Installation Engineering

department)

Standard Site Material Installation

Instructions

EN/LZT 720 0014

General Preconditions

Before starting site work, ensure the following:

• Site access permission received

• Ordered RBS, equipment, specified tools and other necessary facilities

have been delivered

• Site power is available

• Site Grounding Point is available

4

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 50

RBS 2308 and RBS 2309 User’s Guide

Note: The terms ear

thing and grounding are synonymous.

• Transmission line from the BSC is available

• During outdoor installation, protection for the RBS is available in case of

bad weather

Note: After installation, if the surrounding temperature changes between hot

and cold, then to avoid humidity damage the RBS must not be left

without power for more than 48 hours.

To switch on the RBS, see Chapter Site Installation Tests:

If any of the above preconditions cannot be complied with, then contact the site

supervisor or person responsible for the activity that has been missed.

Additional Preconditions for Wall-Mounted RBS

Before installing the RBS on a wall, ensure that the following preconditions

are met:

• The type of fasteners are suitable for the kind of wall material on which

the RBS is to be mounted

• The contact surfaces on the Mounting Base Unit (MBU) are supported by

the wall. If not, then a wall bracket is required

If any of the above preconditions cannot be complied with, then contact the site

supervisor or person responsible for activity that has been missed.

Additional Preconditions fo r Pole-Mounted RBS

Before installing the RBS on a pole, ensure that the following preconditions

are met:

• The pole must have the required diameter 60 – 114 mm

• A wall bracket is available

• A mast fixture set is available

If any of the above preconditions cannot be complied with, then contact the site

supervisor or person responsible for activity that has been missed.

5.3 Torque Settings

This section presents the recommended torque values to be used when

installing the RBS.

The tools needed for the installation are found in Chapter Tools and Instruments.

42

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 51

RBS 2308 and RBS 2309 User’s Guide

Table 13 Recommended Torque, Screws and Nuts

TorqueDimension

Ncm Nm

lbf-in lbf-ft

Notes

M3 110 ± 7

–

9.7 ± 0.6

––

M3 80 ± 7

–

7.1 ± 0.6

–

Reduced

torque for

plastic covers

M4 260 ± 15

–

23.1 ± 1.3

––

M4 170 ± 15

–

15.1 ± 1.3

–

Reduced

torque for

captive screws

M6

–

8.8 ± 0.5

–

6.5 ± 0.4

–

M8

–

21 ± 1.3

–

15.5 ± 1.0

–

M10

–

41 ± 2.5

–

30.2 ± 1.8

–

Table 14 Recommended Torque, Connectors

Torque

Connector

Ncm Nm

lbf-in lbf-ft

Notes

TNC

–

1.7 ± 0.15

–

1.3 ± 0.11

–

N

–

2.7 ± 0.20

–

2.0 ± 0.15

–

5.4 Installation Procedure

This section describes the installation procedure for the RBS.

4

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 52

RBS 2308 and RBS 2309 User’s Guide

Fig

ure 17 The RBS Installation Process

44

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 53

RBS 2308 and RBS 2309 User’s Guide

5.4.1 Unpacking RBS

Unpack the RBS on-site. To avoid damage, the RBS should not be unpacked

elsewhere and then transported to site.

Caution!

Stop! This product contains co

mponents sensitive to ESD. Use an approved

ESD wrist strap, connected to t

he product grounding point, to avoid damaging

these components.

In order to avoid damage to components due to electrostatic discharges during

unpacking, personnel must not come in contact with the connectors of the RBS.

Ensure that the correct material has been delivered. If the material is damaged,

complain immediately to the supervisor or the transport company.

5.4.2 Installing the Wall Bracket

Note: This section is only applicable for walls with very rough surfaces or

when the RBS is to be mounted on a pole.

This section describes how to install the wall bracket.

The wall bracket is for use as a complement to the mounting interface of the

Mounting Base Unit (MBU). Typical applications are rough surfaces and other

conditions where the mounting interface for the MBU is not flat. The plate must

also be used if the RBS is to be installed on a pole. See applicable section

below.

4

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 54

RBS 2308 and RBS 2309 User’s Guide

5.4.2.1 Installing the Wal

l Bracket on a Wall (Alternative)

1.

Place the drilling template in the position where the RBS is to be

located.

2. Use a spirit level to check that the drilling template is horizontal.

3.

Mark the position of the holes to

be drilled.

Note: The wall bracket must not

be used as a drilling template,

to avoid damaging the rust

protection surface.

P010150B

D

R

IL

L

T

E

M

P

L

A

T

E

F

O

R

W

A

L

L

B

R

A

C

K

E

T

R

e

c

o

m

e

n

d

e

d

h

o

le

s

UP

A

lte

rn

a

te

h

o

le

s

4.

Remove the template and drill the holes for the fasteners.

5.

Install the wall bracket and

secure it in position with all the

screws provided.

UP

P010151A

6.

Loosen the four nuts, on which the MBU is to be hung, until only a few

threads remain exposed.

5.4.2.2 Installing the Wall Bracket on a Pole (Alternative)

1. Choose the appropriate holes. See Figure below.

46

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 55

RBS 2308 and RBS 2309 User’s Guide

P010152A

B

A

A

B

UP

AB

Figure 18 Installatio

n Alternatives

A

Holes used for vertical poles

B

Holes used for horizontal poles

2. Ensure that the wa

shers are mounted correctly and attach the two clamps

with the screws an

d washers. See Figure below.

Note: Ensure that

the recess is attached in the correct direction.

P010171A

Recess

UP

Figure 19 Fastening Clamps to the Wall Bracket

3. Position the wall bracket on the pole and mount the clamps, tightening

the screws alternately to avoid bending them. Ensure that the washers

are mounted correctly.

4

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 56

RBS 2308 and RBS 2309 User’s Guide

P010170B

Recess

Figure 20 Installing the Wall Bracket on the Pole

5.4.3 Installing the MBU

This section describes how to install the Mounting Base Unit (MBU) on a wall or

wall bracket.

5.4.3.1 Installing the MBU on a Wall

1.

Place the drilling template in the position where the RBS is to be

situated.

2. Use a spirit level to check that the drilling template is horizontal.

3.

Mark the position of the

applicable holes to be drilled.

Note: To avoid damaging the

rust protection surface, the MBU

must not be used as a drilling

template.

P010234B

D

R

IL

L

T

E

M

P

L

A

T

E

F

O

R

W

A

L

L

B

R

A

C

K

E

T

R

e

c

o

m

e

n

d

e

d

h

o

l

e

s

UP

A

lte

r

n

a

t

e

h

o

le

s

4.

Remove the template and drill holes for the fasteners most suitable

for the wall material.

5.

Insert the fasteners and tighten them, remembering to leave enough

threads protruding to hang the M BU on.

48

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 57

RBS 2308 and RBS 2309 User’s Guide

6. Hang the MBU on the bolts,

applying just enough downward

pressure to ensure that the

screws fit in the keyholes.

P010120A

7.

Tighten the four bolts.

8.

Connect site earthing to the

MBU.

Note: In configurations with

more than one RRU and a 2-wire

DC Supply, an extra earthing

cable must be connected

between the RBSs.

P010190B

8 - 9 mm

4

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 58

RBS 2308 and RBS 2309 User’s Guide

5.4.3.2 Installing the MBU

on a Wall Bracket

1.

Install the MBU on the four

screws situated on the wall

bracket. Ensure that the

fastening screws are properly

fitted in the key holes.

P010180A

2. Use a spirit level to check that the MBU is positioned vertically.

3.

If the MBU is not in a vertical

position the then inclination can

be corrected by adjusting the

four distance nuts on the wall

bracket. To do this, the MBU

must be removed. Leave the

locking nuts on the fastening

screws.

Note: Do not loosen the inner

nuts. The inner nuts secure

the fastening screws to the wall

bracket.

Distance Nut

Inner Nut

Locking Nut

Fastening screws

P010179A

50 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 59

RBS 2308 and RBS 2309 User’s Guide

4. When the wall bracket is correctly adjusted, put back the MBU and

tighten the four locking nuts.

5.

Connect site earthing to the

MBU.

Note: In configurations with

more than one RRU and a 2-wire

DC Supply, an extra earthing

cable must be connected

between the RBSs.

P010190B

8 - 9 mm

5.4.4 Connecting Power

This section describes how to connect the power cable(s) to the RBS. The

section includes instructions for both AC and DC cables.

Danger!

Electric shock risk. Avoid both direct and indirect contact with parts connected

to mains power as this is likely to be fatal. Switch off the mains power before

starting work.

Danger!

Improper electrical installation may cause fire or electric shock that is likely to

be fatal. Only a qualified and authorized electrician is permitted to install or

modify electrical installations.

Note: Protective Earth must be connected to the earth terminal when

connecting power supply.

5

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 60

RBS 2308 and RBS 2309 User’s Guide

The Protective Ear

th terminal is located in the MBU, indicated by the earth

symbol, see the Fig

ure below.

Figure 21 Protective Earth

Note: Protective Earth connection is essential.

1.

Remove the MBU lid f rom the

MBU.

P010371A

AC

1

DC

1

RRU

1

0

0

0

2.

Cut the cable to the appropriate l ength.

3. Remove the cable insulation and

strip the conductors.

P010308A

52 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 61

RBS 2308 and RBS 2309 User’s Guide

4. Mount all cable inlet parts.

P010309A

5.

Route the AC mains cable into

the left inlet and the DC supply

cable into the right inlet. Then

tighten the cable glands.

P010310A

5.4.4.1 Connecting AC Mains

This section describes how to connect AC mains cable (if applicable).

1.

Ensure that the site power is turned off.

2.

Connect the AC cable to the

dedicated terminals.

P010119A

AC

1

DC

1

RRU

1

0

0

0

5

3

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 62

RBS 2308 and RBS 2309 User’s Guide

3. Ensure that the protective earth

is properly connected.

P010181A

LL

L = Line

PE = Protective Earth

PE

4.

If DC is not to be connected, put back the MBU cover onto the MBU.

5.4.4.2 Connecting DC Supply

This section describes how to connect the DC supply cable (if applicable).

1.

Ensure that the site power is turned off.

2.

Connect the DC cable to the

dedicated terminals. If 2-wire is

used, set the ground selector to

2-W.

P010511B

PE = Protective Earth

PE

48 V

48 V_RTN

2-W

54 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 63

RBS 2308 and RBS 2309 User’s Guide

3.

If 3-wire is used, set the ground

selector to 3-W.

P010510B

3-W

48 V

48 V_RTN

PE = Protective Earth

PE

4. Ensure that the prote

ctive earth is properly connected.

5.

Put back the MBU cover.

5.4.5 Replacing the Flas

h Card (If Applicable)

This section descr

ibes how to replace the existing flash card in the IXU. This is

done only if a flash

card, preloaded with site-specific data, is provided.

Note: Using the OM

T, always reload the software and install the appropriate

IDB after moving a

used flash card to another cabinet. This ensures

consistent soft

ware and correct configuration.

For information

about preloading the flash card, see Chapter Maintenance.

5

5

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 64

RBS 2308 and RBS 2309 User’s Guide

1. Remove the cover. Remove the

existing flash card by pulling up

the adjacent black plastic lever

and then pushing it down to eject

the card.

P010366A

2.

Insert the new flash c ard, push

it in, and reset the release lever

(ensuring that the card is in

position).

P010157A

Flash

Card

3. Put back the cover.

5.4.6 Installing the IXU

This section describes how to install the Interface and Switching Unit (IXU)

on the MBU.

Note: This section is valid only for the master RBS. IXU is not used in

extension RBSs.

56

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 65

RBS 2308 and RBS 2309 User’s Guide

1. Hook the IXU onto the MBU, and

secure it with the two screws

under the MBU.

P010365B

2.

Connect the IXU AC/DC cable.

P010174B

3. Loosen the eight screws on the IXU and open the cover.

5

7

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 66

RBS 2308 and RBS 2309 User’s Guide

4.

Connect the Y link cable to the

applicable connection port on

the IXU, see Table below.

P010155B

Y link Y link Y link

1-4 5-8 9-12

Y link Y link Y link

1-4 5-8 9-12

Note: Blanking plugs must be inserted in the unused cable inlets.

Table 15 Y link Connection Port

RBS Connection Port

RRU 1 Y link 1 – 4

RRU 2 Y link 5 – 8

RRU 3 Y link 9 – 12

Connectin

g the RBS 2302 to a New Master Cabinet in a Mixed Micro

Configura

tion

This secti

on describes how to connect RBS 2302 cabinet cables (TXL and

PCM) to th

e new master cabinet (RBS 2308 or RBS 2309) in a mixed micro

configur

ation. See also Section 5.5 Installing Mixed Micro Configurations on

page 85.

58

EN/LZT 720 0027 Uen R8A 2006-06-27

Page 67

RBS 2308 and RBS 2309 User’s Guide

1. Remove the TXL cover on the

new master cabinet IXU.

2.

Connect the TXL bus cable from the RBS 2302 cabinet to the new

master cabinet.

3.

Connect the PCM cable from the RBS 2302 cabinet to the new master

cabinet, according to Connecting PCM Coaxial 75 Ω or Connecting

PCM Coaxial 100/120 Ω.

Continue the RBS 2308 and RBS 2309 installation according to Section 5.4

Installation Procedure on page 43.

5

9

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 68

RBS 2308 and RBS 2309 User’s Guide

Connecting Extern

al Cables

This section descr

ibes how to connect different external equipment, for example

MINI LINK™ or trans

mission, see Figure below.

Note: To simplify

the cable connections, the connection frame on the IXU

can be removed.

EXT.ALARM 1-4

-48V

LINK

PORT A PORT C PORT B PORT D

P010211A

Figure 22 Connection Ports on the IXU

1.

Remove the connection frame

from the IXU.

P010126A

2. Remove the cable gland parts

and remove the sealing insert.

Route the cable through the

cable gland parts and strip the

cable insulation. Cut the cable

screen according to the figure.

P010463B

10 mm

60 EN/LZT 720 0027 Uen R8A 2006-06-27

Page 69

RBS 2308 and RBS 2309 User’s Guide

3.

Strip the conductors and fold

back the cable screen over the

inner part of the cable gland.

P010464B

10 mm

4. Insert the cable into the most

suitable inlet and tighten the

cable gland.

P010512A

5.

Strip the conductors and loosen

the termination blocks. Fasten

the conductors by inserting a

screwdriver in the upper slot.

Max 3.5 mm

P010229A

6

1

EN

/LZT 720 0027 Uen R8A 2006-06-27

Page 70

RBS 2308 and RBS 2309 User’s Guide

6.

If applicable, connect the

external alarm cables. See also

Figure 22 on page 60.

P010209A

EXT. Alarm. 1

EXT. ALARM.1. RTN

EXT. Alarm. 2

EXT. ALARM.2. RTN

EXT. Alarm. 3

EXT. ALARM.3. RTN

EXT. Alarm. 4

EXT. ALARM.4. RTN

EXT.ALARMS

7.

If applicable, connect the 48 V

LINK cable. SeealsoFigure22

on page 60.

P010514A

- 48 V

LINK

48 V

48 V_RTN

8.