Ericsson MASTR II 4EF4A1, MASTR II 4EF4A2, MASTR II 4EF4A3 Maintenance Manual

Mobile Communications

MASTR® II

POWER AMPLIFIER

MODELS 4EF4A1,2,3

Maintenance Manual

LBI-4938C

Printed in U.S.A.

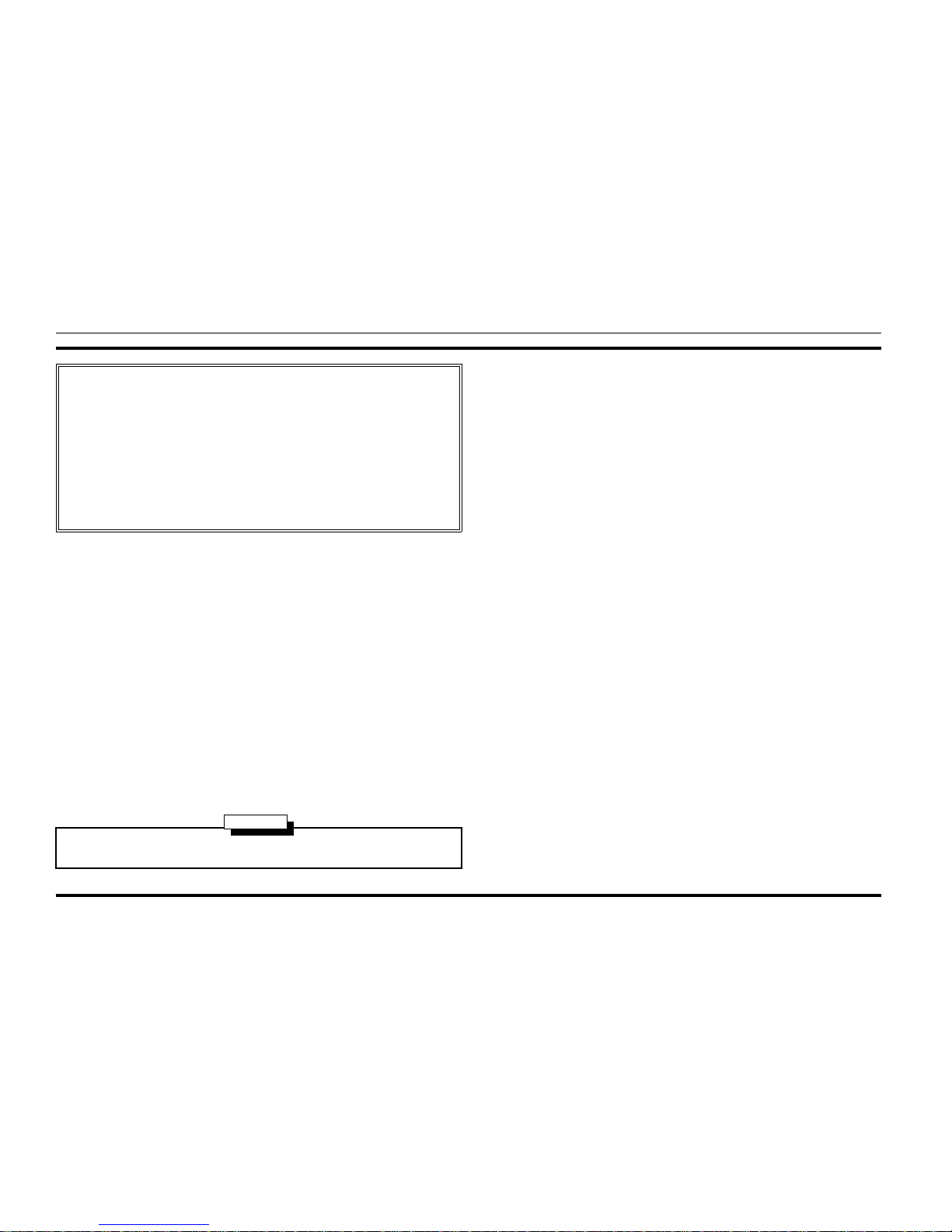

DESCRIPTION

General Electric Power Amplifier Models 4EF4A1, 2

and 3 operate in the 25-54 megahertz band. They are used

with an external driver and power supply to provide a power

output between 150 and 300 watts. The amplifier employs a

4CX250B as a power amplifier tube, with forced-air cooling

providedby a blower mounted on the power supply. Standard

RETMA rack-mounting dimensions are used. The tuning

controls most frequently used are located on the front of the

unit.

All the power connections, except the high voltage connection, are made with a 6-pin plug from the front of the

unit. High voltage is brought to the plate at the rear of the

plate compartment.

Antenna relay keying voltage connections are made behind the output Power Indicator, using screw connections.

The RF drive connection is made by an RG-58/U cable

plugged into the driver from the front of the unit.

CIRCUIT A NALYSIS

Excitation of the Power Amplifier at P482 is fed to coupling loop L482 and coupled to coil L484, which, with

C481, forms the grid tank of the amplifier. By adjusting the

PA GRID control (C481), the grid tank may be tuned to the

operating frequency. Coil L481 isolates RF from the power

cable.

In order to obtain optimum tube life the filament voltage

on the Power Amplifier tube V481 is set at the factory for 6

Volts with R4 on the High Power Power Supply. The filament voltage can be set for a higher value but with a corresponding decrease in tube life. C482, C483, and C484 are

RF by-pass capacitors and R481 is used as a screen RF decoupling resistor. Built into the tube socket, XV481, is a

ring-type capacitor which is used as a screen grid by-pass.

All input voltage connections to the Power Amplifier , except the B-plus voltage connection, are made at P481 on the

front side of the panel. The 2000-volt B-plus lead is connected at terminal P0-2 located in the rear on the plate cavity

cover. C485 provides bypassing for the B-plus and L485 is

an RF choke. The plate tank is composed of C488 and

L494. The plate tank is tuned to the operating frequency by

adjusting the PA PLA TE control C488.

Adjusting the PA COUPLING control varies the coupling from the plate to the output by controlling the amount

of magnetic flux linking the plate coupling loop to the outputloop. The filter consists of L490, L491, L492, L493,

C492, C493, L494 and C495.

Antenna coupling is adjusted by the PA ANTEN NA control C489. The signal is fed from the filter to J481. The signal from J481 is connected to the antenna through P1 and P2

on the Reflectometer and through the contacts on the antenna relay K482.

POWER REFLECTOMETER

The Power Reflectometer gives a relative voltage which

indicates forward and reflected RF power output.

The Reflectometer samples the magnetic field caused by

current in the transmission line and the electrical field from

the voltage on the line. on a properly matched line, these

two voltages are equal and cancel each other when reading

REFLECTED power ("0" reflected power). When the probe

is rotated 180, these two voltages add to indicate FORWARD power.

When the load is not matched, these two voltages become unequal and provide a ratio of incident (f or w a rd) to reflected power. Any s ignificant change in this ratio (if other

than 1:1) after initial installation and check out, should be

cause for examination of the antenna and feed line. Actual

V.S.W.R. as measured on a calibrated bridge, should remain

below 1.5:1 at all times.

ANTENNA RELAY

K482, the antenna relay, switches the antenna from the

receiver to the transmitter when the transmitter is keyed.

MAINTENANCE

PREVENTIVE MAINTENANCE

To obtain optimum performance from the equipment, a

program of regular preventive maintenance should be followed. This preventive maintenance should include the following:

1. A check of the operating frequency as required by

the Federal Communications Co mm ission.

2. A check of the PA PLATE current, Power A mp l ifie r

GRID current and PA PLATE voltage meter readings.

3. A check of the PA PLATE tuning and reflected

power (if any) and realignment if improper operation is indicated.

Copyright © 1978, General Electric Company

TABLE OF CONTENTS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CIRCUIT ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power Reflectometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Antenna Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power Amplifier Tube Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ALIGNMENT PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OUTLINE DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SCHEM AT IC DIAGRAM (Models 4EF4A1 & 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SCHEMATIC DIAGRAM (Model 4EF4A3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPECIFICATIONS

*

MODEL NUMBER 4EF4A1,2,3

USED WITH Driver Type KT-56-A and Power Supply 19D402530G1, G2 to

provide a 150-300 Watt (K T- 39-A) Transmitter

FREQUENCY RANGE 4EF4A1: 25-30 MHz

4EF4A2: 30-42 MHz

4EF4A3: 42-50 MHz

POWER INPUT 117 VAC, 50/60 Hz

Standby: 2 amps

Transmit: 9 amps (maximum)

POWER OUTPUT 150 to 300 Watts

TUBE COMPLEMENT (1) 4CX250B or 7203/4CX250B

AM HUM AND NOISE LEVEL Down 34 dB

MAXIMUM FREQUENCY SPREAD:

(2 or more channels) Full Specifications 1 dBDegradation

25-30 MHz 0.12 MHz 0.24 MHz

30-36 MHz 0.12 MHz 0.24 MHz

36-42 MHz 0.16 MHz 0.32 MHz

42-50 MHz 0.18 MHz 0.36 MHz

DUTY CYCLE Continuous --Blower recommended for cabinet ventilation under

conditions of high ambient temperatures or conti nuous d uty

operation.

AMBIENT TEMPER ATURE RANGE -30°C to +60°C (-22°F to +144°F)

DIMENSIONS (HxWxD) 7" x 19" x 11"

WEIGHT 18 pounds

* These specifications are inte nd ed p rimarily for the use of the serviceman . Refer to the appropriate Specificat i on S he et for the

complete specifications.

No one should be permitted to handle any portion of the equipment that is supplied with high voltage; or to connect any external apparatus to the units while the units are supplied with power. KEEP AWAY FROM LIVE CIRCUITS!

WARNING

LBI-4938 LBI-4938

1

4. A check for loose nuts, screw s, cables and parts.

5. An inspection of the high- and low- voltage connections.

POWER AMPLIFIER TUBE

REPLACEMENT

To remove the P o w er A mplifier tube, proceed as follows:

1. Remove the high-voltage lead from P0-2, located

on the rear of the Power Amplifier.

2. Loosen the winged screws holding the rear cover

plate to the assembly.

3. Slide off the rear cover plate.

4. Insert the prongs of the tube extractor (included

with the station equipment) between the cooling

fins of the PA tube plate.

5. Pull the tube straight out from the socket.

To reinsert the Power Amplifier tube, proceed as follows:

1. Insert the prongs of the tube extractor between the

cooling fins of the PA tube plat e.

2. Push the PA tube all the way into the socket while

observing the key on the tube and socket. The tube

extractor may be left on the tube cooling fins.

3. Replace the rear cover plate of the Power Amplifier.

4. Tighten the winged screws on the rear cover plate.

5. Replace the high-voltage lead to P0-2 on the rear of

the Power Amplifier.

BLOWER

The blower motor bearings are to be lubricated every

2000 hours of operation. A small oil can for this purpose is

mounted on the power supply chassis, at the right of the

blower motor. Use the oil recommended in the Parts List.

(See Parts List on back of Schematic Diagram.)

MULTI-FREQUENCY OPERATION

1. Tune the PA on the LF ( lo w est fr eq uency).

2. Select the HF (highest frequency ) a nd re-peak the grid

tuning.

3. Select LF and adjust the PA plate tuning CW (clockwise) to let the plate current rise 5 - 10 mA.

4. Then re-adjust the screen control for rated plate current level.

5. Select HF to compare the plate currents.

6. If there is greater than 10 mA difference then repeat

the step at the lowest frequency (LF) by adjusting the

plate tuning control CW for another 5 - 10 mA increase.

7. Re-set the screen control for rated plate current and

compare the highest frequency current again.

8. Continue this process until there is less than 10 mA

difference at the two freq ue nc ie s.

ALIGNMENT PROCEDURE

This Alignment Procedure is provided for completely realigning and loading Power Amplifier Models 4EF4A1, 2, 3

(using KT-56-A as a Driver Unit) in a KT-39-A transmitter.

Before tuning the Power Amplifier, the Driver (KT-56-A,

C) must be aligned according to the Driver ALIGNMENT

PROCEDURE.

1. Connect the antenna or some other suitable 50-ohm

load to the top jack on the Power Amplifier antenna

relay.

2. Turn the PLATE switch OFF on the PA Power Supply.

3. Tune the SCREEN adjust on the PA Power Supply

fully counterclockwise.

4. Place the power switches located on the Power Panel

and Driver Power Supply to the ON position. Turn

the PA Power Supply Control switch to the ON position. Allow 15-minutes for warmup.

5. Connect a microphone to the MIKE jack (J1215) on

the back of the station control shelf mother bo ar d.

6. Loosen the locking ring on the PA COUPLING control and push the control in and turn fully counterclockwise. Rotate the meter switch on the POWER

PANEL to TX Driver and meter switch on Receiver/Exciter door to position 10.

7. Key the driver and adjust the Power Control potentiometer on the driver PA for approximately 2 amperes

of driver PA collector current (0.6 V on 3 V scale of

tune-up meter) Rotate meter switch on power panel to

PA GRID. Tune the PA GRID for maximum voltage

on the tuning meter and then readjust the power control potentiometer for the following voltage on that

meter:

4EF4A1-2 0.75 VDC

4EF4A3 2.0 VDC Min. (2.5 VDC Msx:)

8. Turn the PLATE switch on the PA Power Supply to

the ON position.

9. While keying the Driver, adjust the PA Plate control

for a minimum reading at the PA PLATE current meter. Do not exceed 275 mA of plate current. Retune

the GRID per STEP 7.

10. Rotate the meter switch on the Power Panel t o Forward/Reverse position. Rotate the Reflectometer to

the Forward position.

11. While keying the Driver, adjust the PA FILTER control for maximum meter reading.

12. While keying the Driver adjust the SCREEN control

for 250 mA on the plate curren t met er.

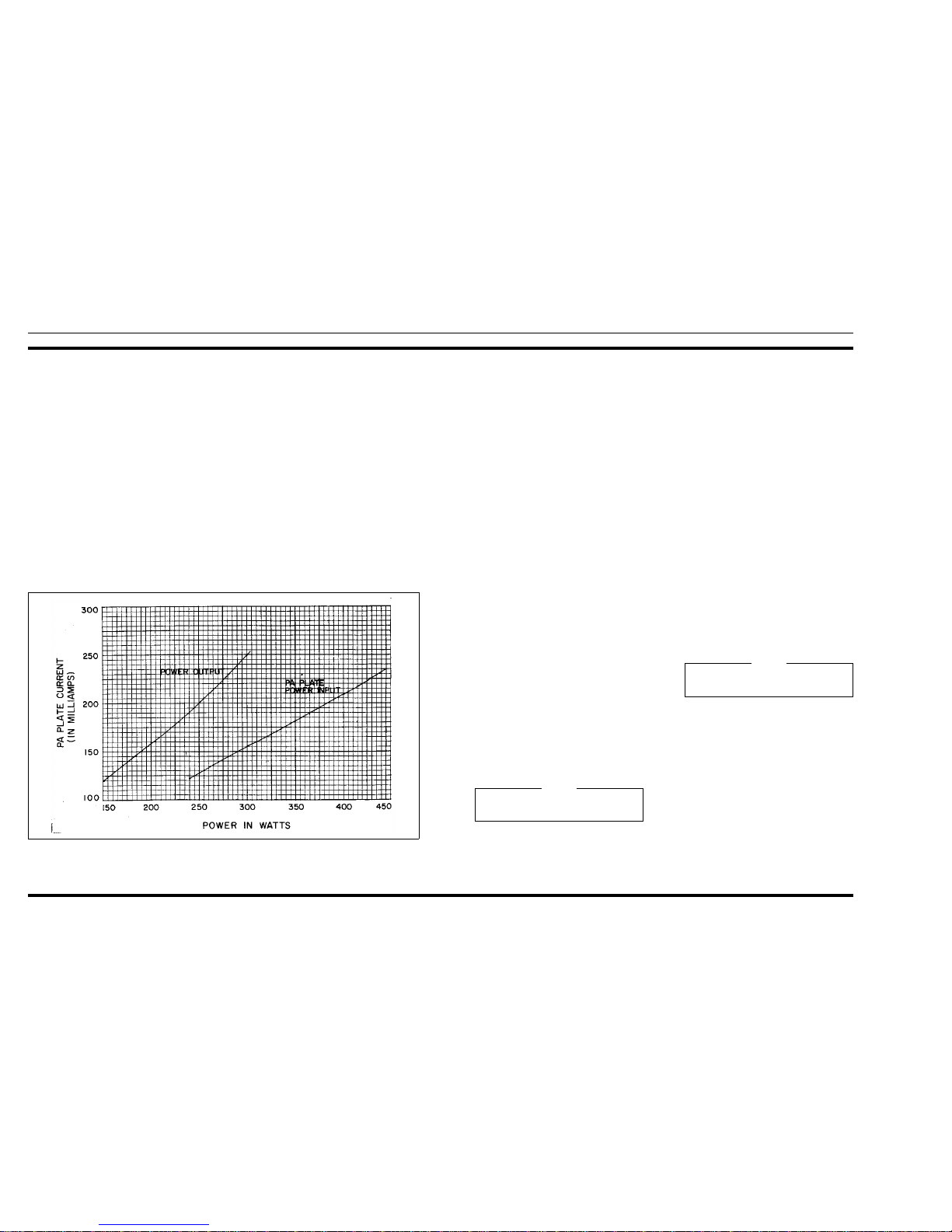

Figure 1 - Power and PA Plate Current Levels

Make sure the PLATE switch on the PA POWER

SUPPLY is in the OFF position.

NOTE

The current readings on the meter includes approximately 25 mA of scree n curren t.

NOTE

ALIGNMENT PROCEDURE

25-50 MHz, 300-WATT

MASTR II POWER AMPLIFIER

MODELS 4EF4A1, 2 & 3

LBI-4938 LBI-4938

2

Loading...

Loading...