Page 1

LBI-39128

Installation & Operation

EDACS

Power Monitor Unit

ericssonzericssonz

Page 2

LBI-39128 CONTENTS

TABLE OF CONTENTS

INTRODUCTION....................................................................................................................................... 6

DESCRIPTION........................................................................................................................................... 6

APPLICATION NOTES............................................................................................................................. 7

VAX SITE CONTROLLER COMPUTER.......................................................................................... 7

APPLICATION SOFTWARE PROMS............................................................................................... 7

PERSONALITY PROMS .................................................................................................................... 7

INSTALLATION........................................................................................................................................ 8

SITE CONTROLLER HARDWARE................................................................................................... 8

SITE CONTROLLER SOFTWARE.................................................................................................... 8

Application Software PROMs....................................................................................................... 9

Personality PROMs....................................................................................................................... 9

PMU HARDWARE ............................................................................................................................. 9

A. Addition from No PMU............................................................................................................ 9

B. Upgrade from Old PMU........................................................................................................... 12

C. Adaptation from Old PMU ....................................................................................................... 13

INITIAL POWER-UP.......................................................................................................................... 14

PMU PROGRAMMING...................................................................................................................... 15

Terminal Setup.............................................................................................................................. 15

Software Initialization ................................................................................................................... 15

Time/Date/Password...................................................................................................................... 17

Antenna Mapping.......................................................................................................................... 18

POWER SENSOR CALIBRATION.................................................................................................... 19

Unidirectional Power Sensors ....................................................................................................... 19

Bi-directional Power Sensors ........................................................................................................ 20

FINAL CHECK.................................................................................................................................... 21

(Continued)

Page

NOTICE

NOTICE

This Manual covers Ericsson and General Electric products manufactured and sold by Ericsson Inc.

This Manual covers Ericsson and General Electric products manufactured and sold by Ericsson Inc.

NOTICE

NOTICE

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier. Any

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier. Any

repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

manufacturer could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

NOTICE!

NOTICE!

The software contained in this device is copyrighted by Ericsson Inc. Unpublished rights are reserved under the copyright

The software contained in this device is copyrighted by Ericsson Inc. Unpublished rights are reserved under the copyright

laws of the United States.

laws of the United States.

This manual is published by

This manual is published by

inaccuracies of current information, or improvements to programs and/or equipment, may be made by

inaccuracies of current information, or improvements to programs and/or equipment, may be made by

changes will be incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any means,

changes will be incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of

electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of

Copyright March 1995, Ericsson Inc.

Ericsson Inc.

Ericsson Inc.

, without any warranty. Improvements and changes to this manual necessitated by typographical errors,

, without any warranty. Improvements and changes to this manual necessitated by typographical errors,

Ericsson Inc.

Ericsson Inc.

, at any time and without notice. Such

, at any time and without notice. Such

Ericsson Inc.

Ericsson Inc.

2

Page 3

CONTENTS LBI-39128

TABLE OF CONTENTS (Cont.)

Page

OPERATION.............................................................................................................................................. 22

STARTUP............................................................................................................................................ 22

Polling Recovery........................................................................................................................... 22

EDACS Configuration Setup ........................................................................................................ 22

Polling Failure............................................................................................................................... 22

MONITOR........................................................................................................................................... 22

Power Sensor Monitoring.............................................................................................................. 22

Power Measurements .................................................................................................................... 23

SWR Calculations......................................................................................................................... 23

ALARMS............................................................................................................................................. 23

Alarm Reporting............................................................................................................................ 24

Excessive Alarms.......................................................................................................................... 24

PARAMETERS ................................................................................................................................... 25

Channel PMU Enable.................................................................................................................... 25

Site PMU Enable........................................................................................................................... 25

PMU Model .................................................................................................................................. 25

Transmitter Lower Alarm Limit.................................................................................................... 27

Transmitter Upper Alarm Limit .................................................................................................... 27

Antenna Lower Alarm Limit......................................................................................................... 27

Antenna Upper Alarm Limit ......................................................................................................... 27

SWR Upper Alarm Limit.............................................................................................................. 28

Antenna Mapping.......................................................................................................................... 28

ALARM LIMIT RE-CONFIGURATION ........................................................................................... 28

Alarm Limits As Installed............................................................................................................. 28

Transmitter Power Alarm Limits................................................................................................... 28

Antenna Power Alarm Limits........................................................................................................ 28

Antenna SWR Alarm Limit........................................................................................................... 29

MAINTENANCE........................................................................................................................................ 30

POWER SENSOR CALIBRATION.................................................................................................... 30

TIME AND DATE ADJUSTMENT.................................................................................................... 30

DIAGNOSTIC SCREENS................................................................................................................... 30

Alarm History Report Screen........................................................................................................ 30

Channel Monitor Screen................................................................................................................ 30

SOFTWARE UPDATES ..................................................................................................................... 32

ERASE ALL PROGRAMMING ......................................................................................................... 32

ALARM DELAY ADJUSTMENT...................................................................................................... 33

TROUBLESHOOTING....................................................................................................................... 34

GLOSSARY................................................................................................................................................ 36

PMU INTERCONNECT DIAGRAM - EDACS REPEATER CABINET ................................................. 37

PMU INTERCONNECT DIAGRAM - SITE CONTROLLER CABINET (Upgrade) .............................. 38

3

Page 4

LBI-39128 FIGURES AND TABLES

LIST OF FIGURES AND TABLES

Figure 1 - Location of PMU Components.................................................................................................... 6

Figure 2 - Card Layout for PDP Upgraded to VAX .................................................................................... 7

Figure 3 - Location of Fastener Screws on Computer.................................................................................. 8

Figure 4 - Location of PROM Card in Computer ........................................................................................ 8

Figure 5 - Location of PROM Card in Older Computer.............................................................................. 8

Figure 6 - Location of PROMs on PROM Card .......................................................................................... 8

Figure 7 - Application Software PROM Label ............................................................................................ 9

Figure 8 - Personality PROM Label ............................................................................................................ 9

Figure 9 - Antenna Power Sensor Connections............................................................................................ 11

Figure 10 - Connections for Addition from No PMU.................................................................................. 12

Figure 11 - Connections for Upgrade from Old PMU................................................................................. 13

Figure 12 - Connections for Adaptation from Old PMU ............................................................................. 14

Figure 13 - DB-25 Terminal Connections ................................................................................................... 15

Figure 14 - DB-9 Terminal Connections ..................................................................................................... 15

Figure 15 - Operation Select Menu (Main Menu) ....................................................................................... 16

Figure 16 - Setup Selection Menu ............................................................................................................... 16

Figure 17 - Site Data #1 Screen................................................................................................................... 17

Figure 18 - Analog Input Channel Screen.................................................................................................... 18

Figure 19 - Analog Input Channel Screen Showing Antenna Channel Parameter ....................................... 19

Figure 20 - Unidirectional Power Sensor Calibration Screw....................................................................... 19

Figure 21 - Bi-directional Power Sensor Calibration Screws ...................................................................... 20

Figure 22 - Analog Pseudo Channel Screen ................................................................................................ 29

Figure 23 - Report Selection Menu.............................................................................................................. 31

Figure 24 - Alarm History Report Screen.................................................................................................... 31

Figure 25 - Channel Monitor Screen............................................................................................................ 31

Figure 26 - Location of PMU Software....................................................................................................... 32

Figure 27 - Location of DIP Switches ......................................................................................................... 33

Page

Table 1 - Selection of Installation Procedure............................................................................................... 9

Table 2 - Parts for Addition from No PMU................................................................................................. 10

Table 3 - Parts for Upgrade from Old PMU................................................................................................ 12

Table 4 - Parts for Adaptation from Old PMU............................................................................................ 13

Table 5 - Terminal Communications Protocol............................................................................................. 15

Table 6 - Power Sensor Voltage-to-Power Conversion Table..................................................................... 21

Table 7 - PMU Option Parameters .............................................................................................................. 26

Table 8 - SWR Upper Limit ........................................................................................................................ 30

Table 9 - Channel Numbers for Channel Monitor Screen............................................................................ 32

Table 10 - Troubleshooting Symptoms........................................................................................................ 34

4

Page 5

PMU:

Mechanical:

Width ............................................................ 19 in. (482.6 mm)

Height............................................................3.5 in. (88.9 mm)

Depth............................................................. 6 in. (152.4 mm)

Weight........................................................... < 5 lb. (2.27 kg)

Environmental:

Temperature Range.......................................0° to 60° C (32° to 140° F)

Relative Humidity.........................................0 to 95%

Power Requirements:

External.........................................................12 Watts (max.) at 12 Vdc (nominal)

RAM Battery Life .........................................3 years

Power Sensors:

19C336861P2 - Unidirectional

Frequency Range........................................... 450 to 1000 MHz

Maximum Power...........................................1000 Watts

19C336861P3 - Bi-directional

Frequency Range........................................... 450 to 1000 MHz

Maximum Power...........................................1000 Watts

19C336861P4 - Bi-directional

Frequency Range........................................... 66 to 325 MHz

Maximum Power...........................................1000 Watts

SPECIFICATIONS LBI-39128

SPECIFICATIONS

Data Interfaces:

Site Controller Computer:

Baud Rate...................................................... 9600

Data Bits........................................................8

Parity Bit.......................................................None

Stop Bit.........................................................1

RS-232 CRT Terminal (or PC):

Baud Rate...................................................... 9600

Data Bits........................................................8

Parity Bit.......................................................None

Stop Bit.........................................................1

5

Page 6

LBI-39128 INTRODUCTION / DESCRIPTION

INTRODUCTION

This manual describes the installation and operation of

the Decibel Products DB8860-based PMU (Power Monitor

Unit) for non-simulcast EDACS (Enhanced Digital Access

Communications System) repeater sites that use a VAX

computer for the Site Controller. This manual covers only

those features of the Decibel Products DB8860 that are

required for this application.

The user must provide an RS232 CRT terminal (or PC

with terminal emulation software) for installation and

maintenance.

DESCRIPTION

The PMU (Power Monitor Unit) is used to quickly

identify damaged transmitters, transmit combiners, transmit

antennas, and connecting cables so that the equipment can

be quickly removed from service and repaired. The PMU is

a microprocessor-driven power monitoring and reporting

device that receives power measurements from the power

sensors, receives monitoring instructions from the Site

Controller computer, and reports alarm conditions back to

the Site Controller computer.

A unidirectional power sensor is placed at the output of

each transmitter to send forward power measurements to the

PMU. A bi-directional power sensor is placed at the output

of each transmitter combiner to send forward and reflected

power measurements to the PMU.

The Site Controller computer tells the PMU which

power sensors to monitor and when, by telling the PMU

when each transmitter is keyed and unkeyed.

The PMU reports an alarm for a specific transmitter

when the output power measurement for that transmitter

exceeds the upper or lower power limit. The Site Controller

computer then takes that transmitter out of service.

The PMU reports an alarm for a specific antenna

number when the input power measurement for that antenna

exceeds the upper or lower power limit, or the SWR

calculation exceeds the upper limit.

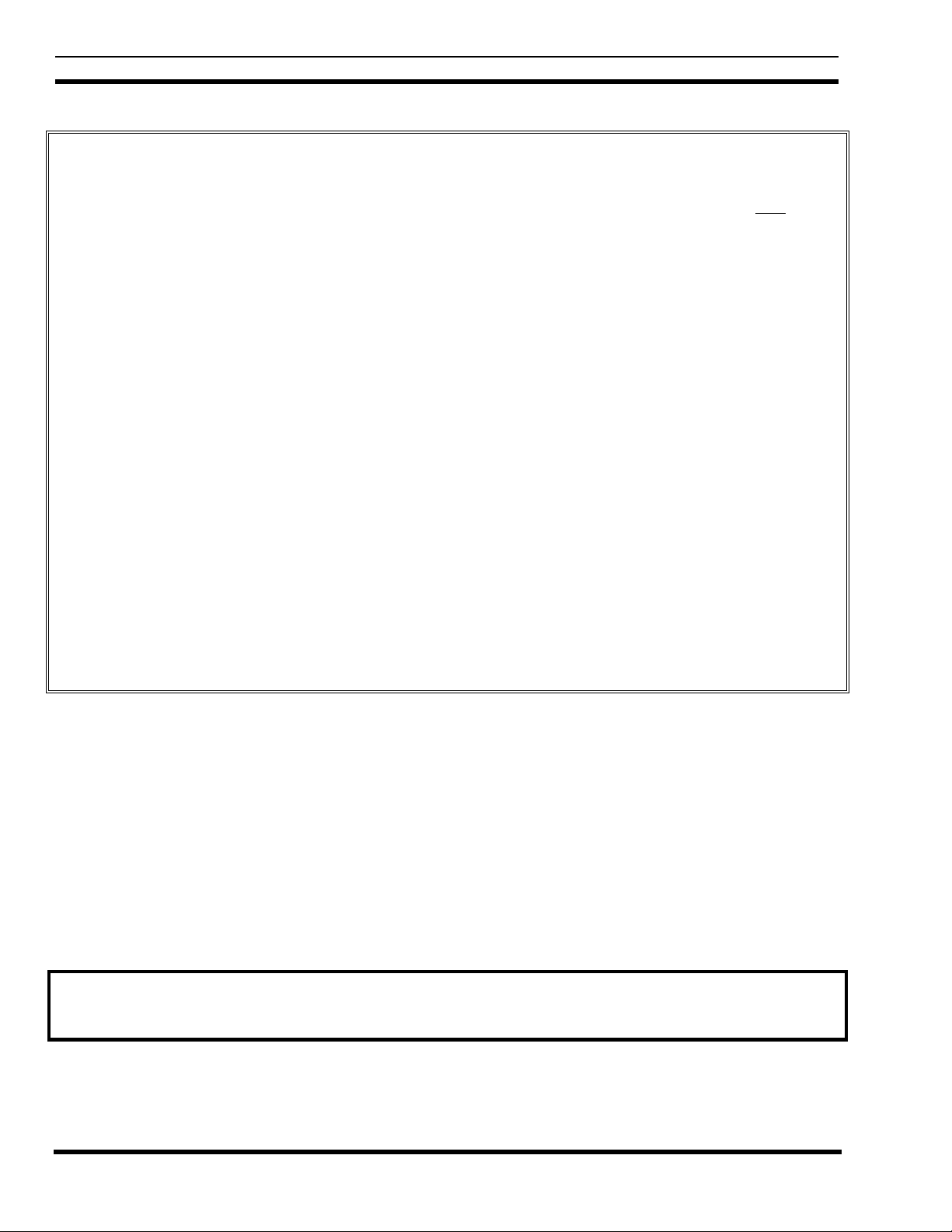

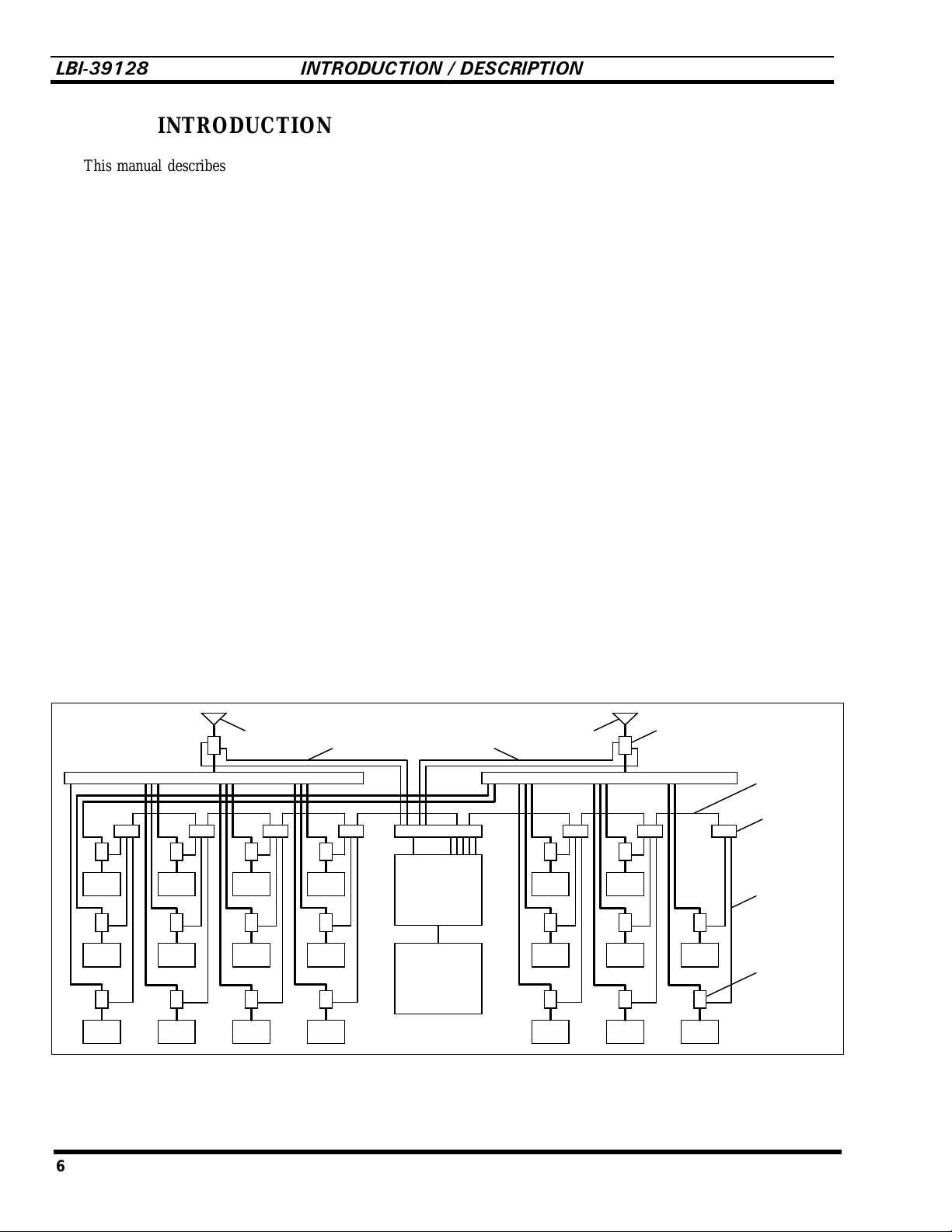

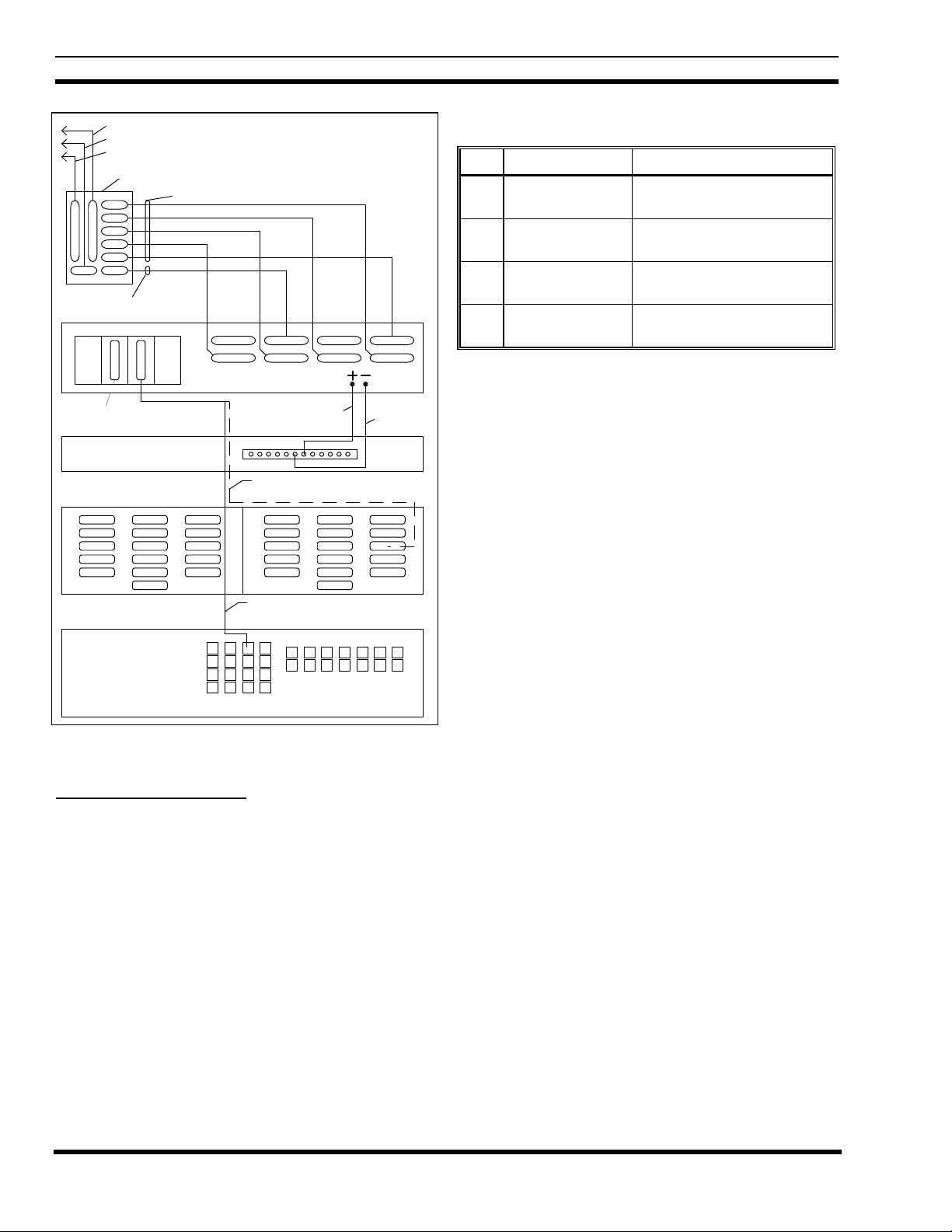

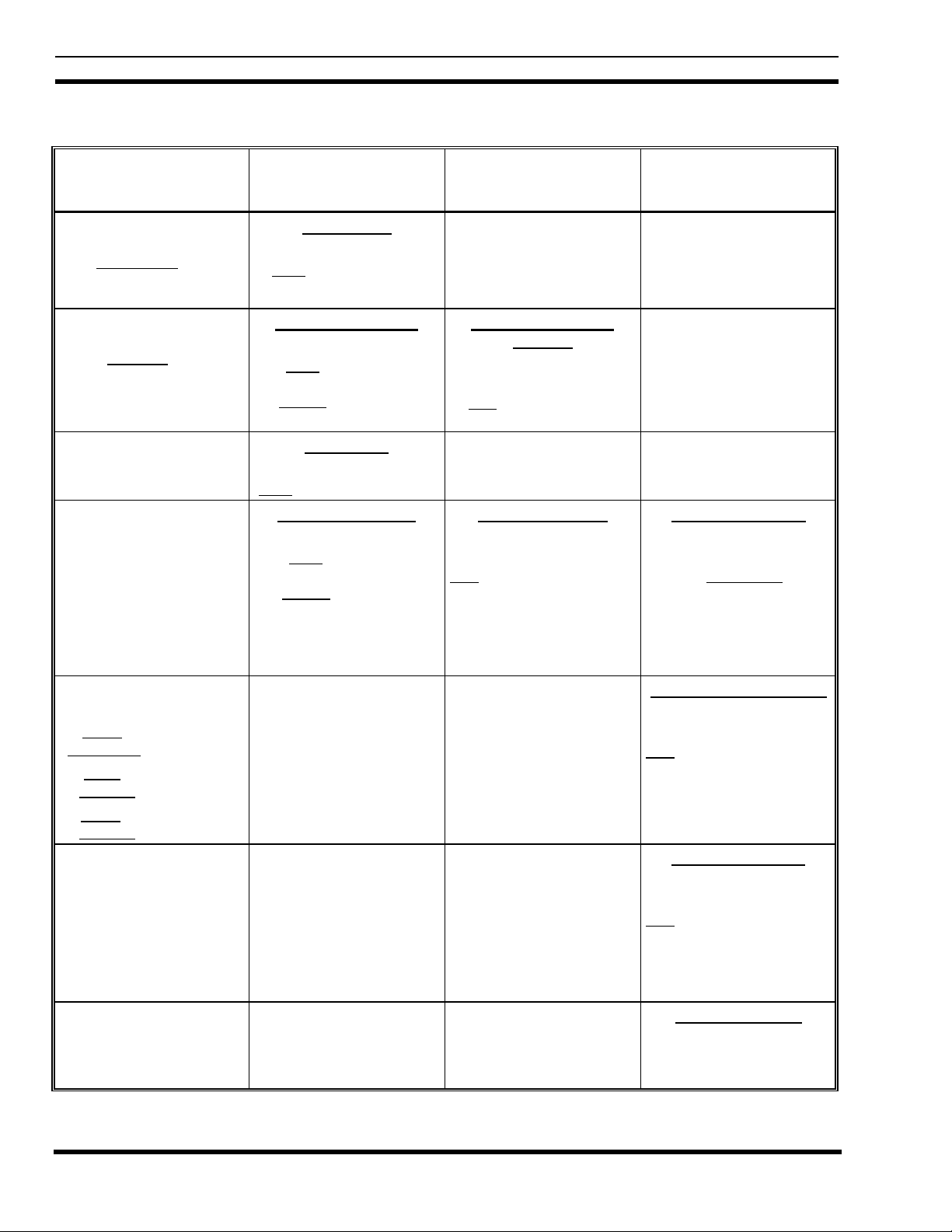

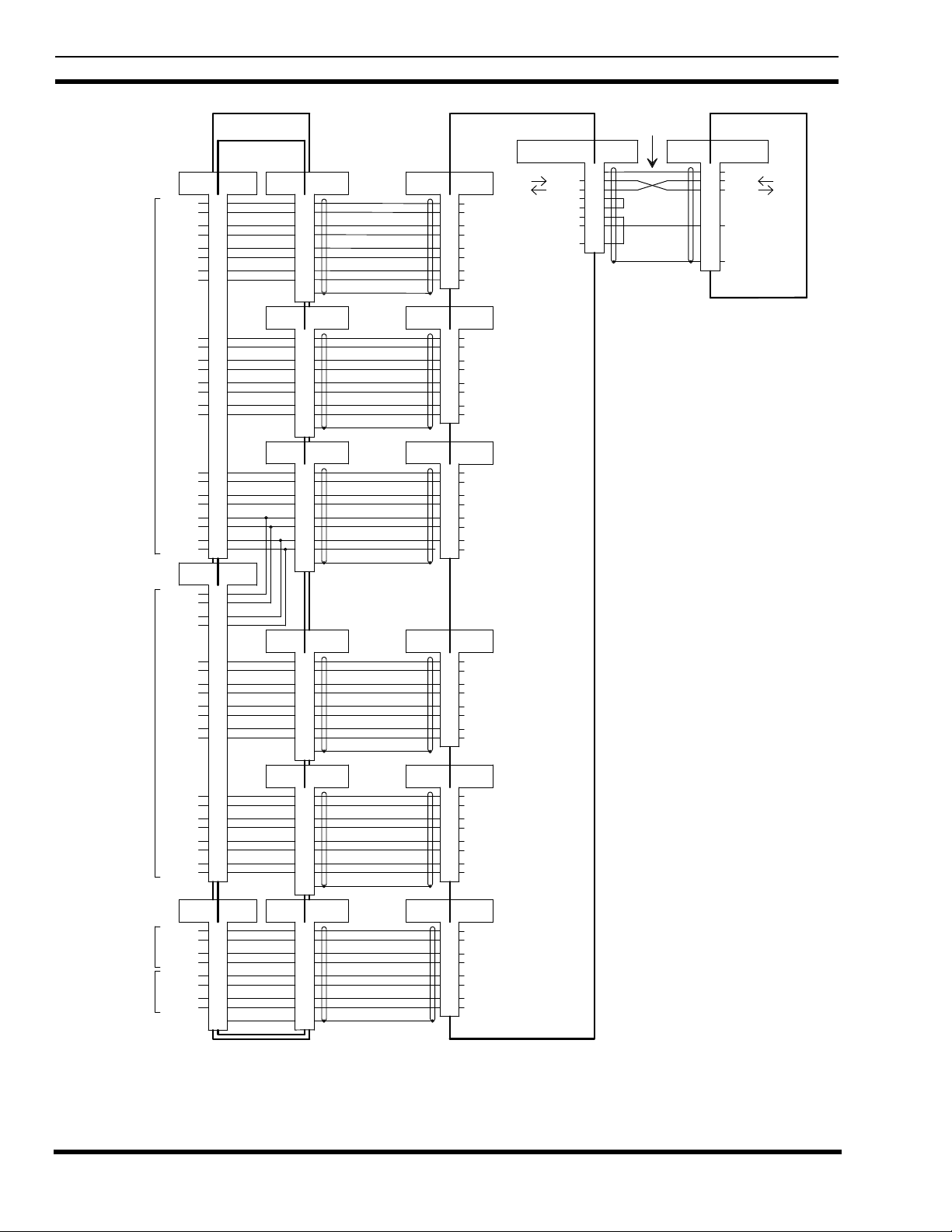

Figure 1 shows the locations of the PMU-related

components in a standard 20-channel EDACS installation

after the PMU option has been installed. Each standard

EDACS repeater cabinet includes the unidirectional power

sensors, power sensor cables, power sensor module, and

cabinet interconnect cable. The cable between the Site

Controller computer and the PMU, the cables between the

PMU and the Power Sensor interface module, and the Power

Sensor interface module all come with the PMU. The bidirectional (antenna) power sensor(s) are ordered separately.

If the PMU option is to be installed in an older EDACS

site, you may need some additional material to update or

adapt to the older equipment (see the Installation section in

this manual for details).

Xmtr

#12

Xmtr

#11

Xmtr

#10

Xmtr

#9

Xmtr

#8

Xmtr

#7

Antenna #1

Xmtr

#6

Xmtr

#5

Xmtr

#4

Antenna Power Sensor Cable

Interface Module

Xmtr

#3

Xmtr

#2

Xmtr

#1

Power

Monitor

Unit

Site

Controller

Computer

Antenna #2

Transmitter Combiner #2Transmitter Combiner #1

Xmtr

#15

Xmtr

#14

Xmtr

#13

Xmtr

#18

Xmtr

#17

Xmtr

#16

Bi-directional

Power

Sensor

Xmtr

#20

Xmtr

#19

Cabinet

Interconnect

Cable

Power Sensor

Interface

Module

Transmitter

Power Sensor

Cable

Unidirectional

Power

Sensor

Figure 1 - Location of PMU Components

6

Page 7

APPLICATION NOTES LBI-3912

8

APPLICATION NOTES

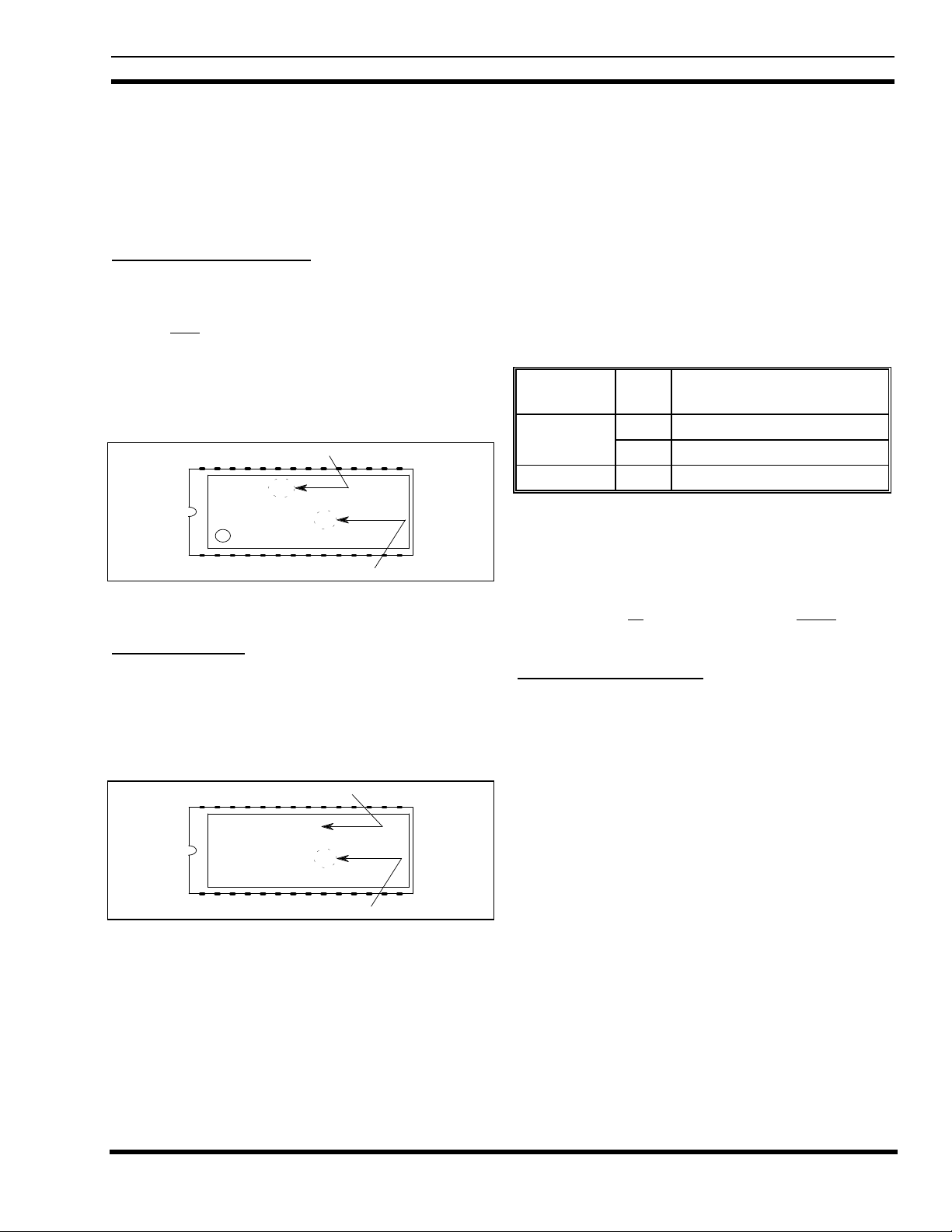

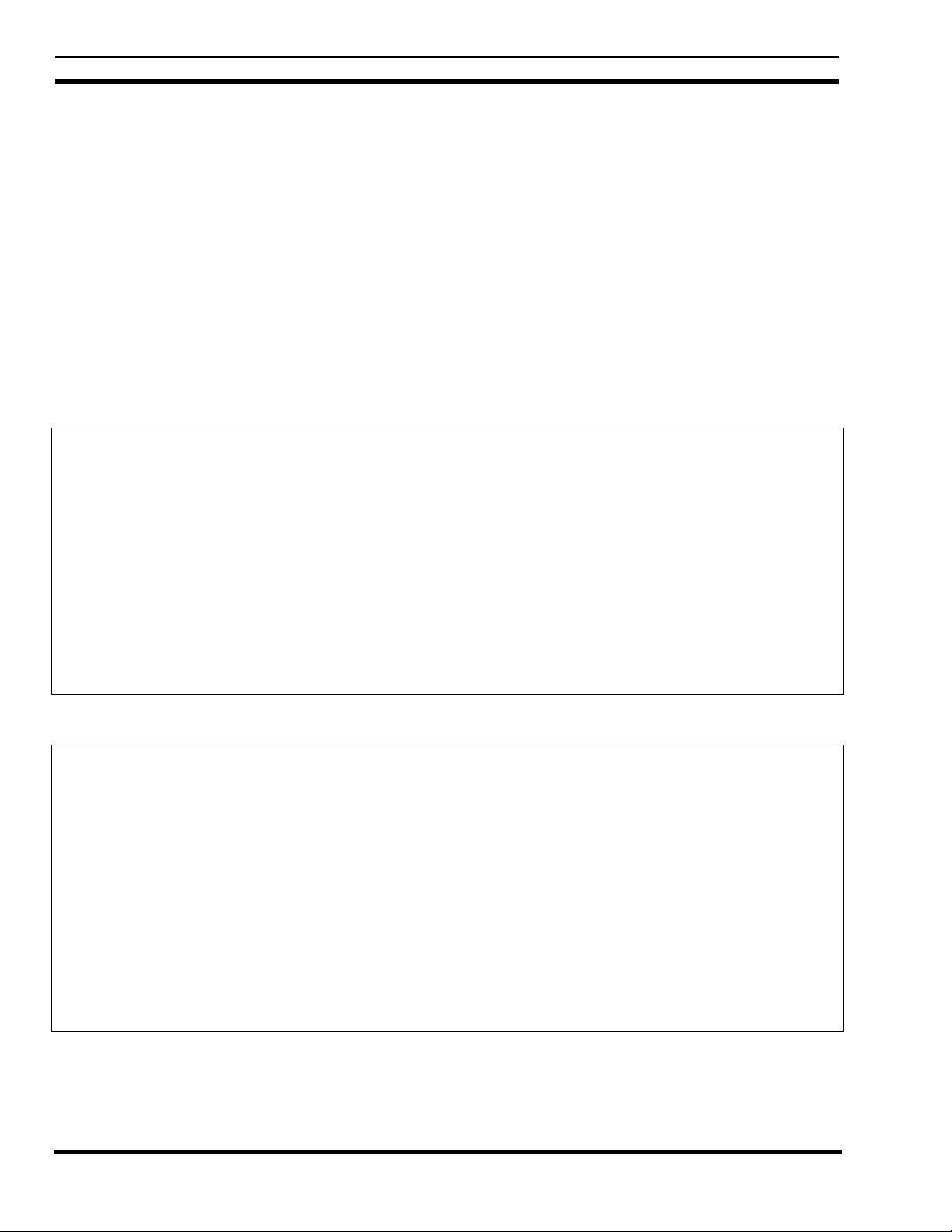

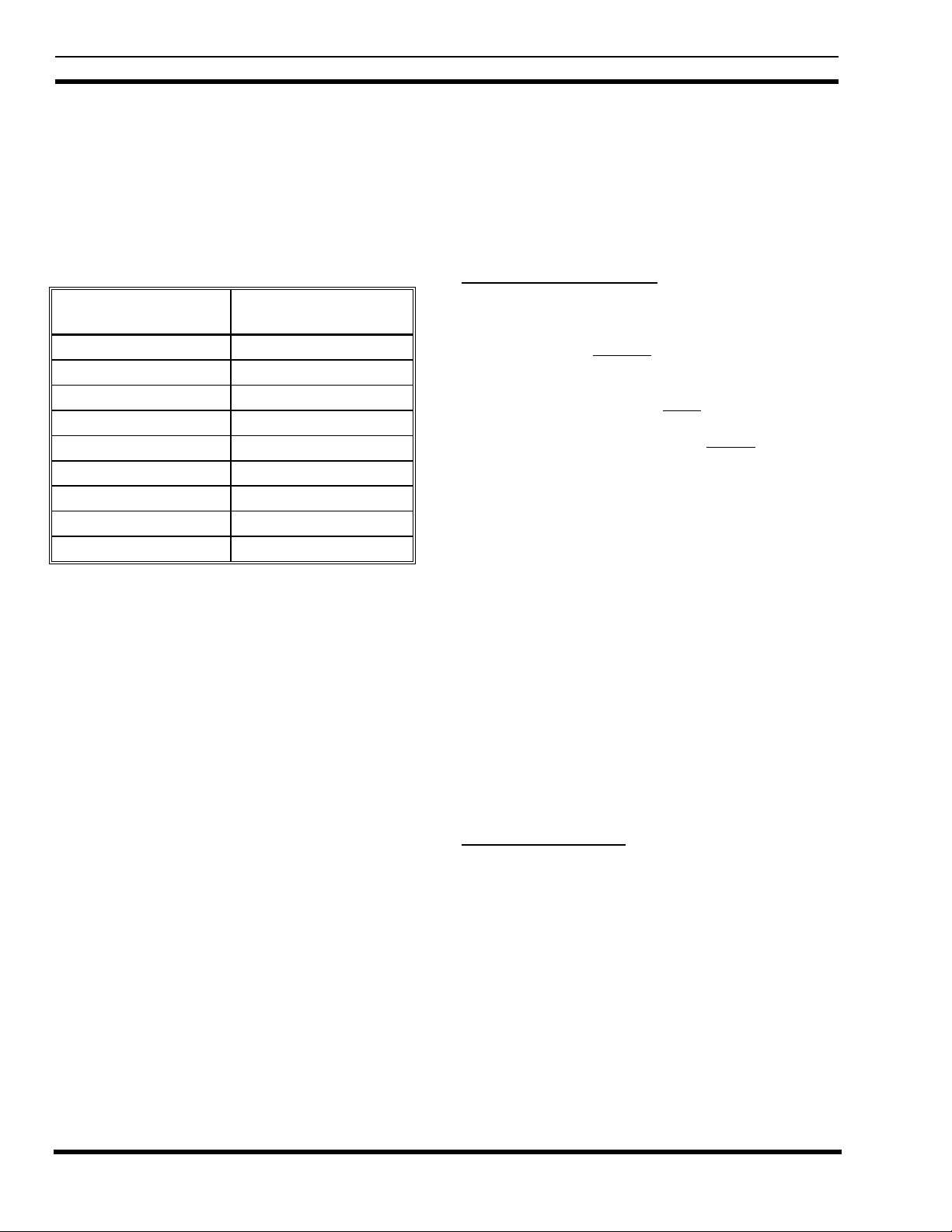

VAX SITE CONTROLLER COMPUTER

Make sure that the Site Controller computer, at the

location where this PMU is to be installed, is a VAX model

or a PDP model that has been upgraded to a VAX model. To

determine if a PDP model has been upgraded internally to a

VAX model, you must look inside the PDP system chassis

and see which cards are installed. PDP models that have

been upgraded to a VAX model will have their cards

arranged in the card cage as shown in Figure 2.

KA620-BA

MS630-BB

MRV11-D H3656-00

CQ1610#1

CQ1610#2

EMPTY

EMPTY

EMPTY

•

PMU Enable

(for each channel) if that channel number is to be

monitored by the PMU. This parameter is not

System Manager re-configurable and therefore all

equipped channels must be enabled. It is

recommended that all 20 channels be enabled

(equipped or not).

•

Power Monitor Unit

to “Off” (if you want the PMU option disabled) or

“On” (if you want the PMU option enabled). This

parameter is System Manager re-configurable, but

must be set to “On” if the site is being operated

without a System Manager. It is recommended that

this parameter be set to “On”, even if the site is

being operated with a System Manager.

•

PMU Model

8843” (PMU protocol set to 2400 Baud for Decibel

Products DB8843 based old PMU) or “New-8860”

(PMU protocol set to 9600 Baud for Decibel

Products DB8860 based new PMU). This

parameter is not System Manager re-configurable

and therefore must be set to “New-8860”.

- This parameter set (mask) defines

- This parameter can be set

- This parameter can be set to “Old-

Figure 2 - Card Layout for PDP Upgraded to VAX

APPLICATION SOFTWARE PROMS

The Site Controller computer’s Application Software

PROMs must be marked 344A3265Gx, where x = 6 or

higher. (Application Software PROMs with x = 5 or lower

will not work for the new PMU.) If new Application

Software PROMs are needed, they should be ordered when

ordering the new PMU.

PERSONALITY PROMS

The Site Controller computer’s Personality PROMs

must be replaced, even if the system currently has an old

PMU and a System Manager. New Personality PROMs

should be ordered when ordering the new PMU.

When ordering new Personality PROMs, you must give

the correct information for the following four PMU

parameters (don’t assume that the person taking the order

will know what you want, need, or the recommendations

given here):

•

PMU Power Levels

lower power level limit for all transmitters (one

limit is applied to all). This parameter is System

Manager re-configurable, but must be set to some

power level lower than rated power if the site is

being operated without a System Manager. It is

recommended that this parameter be set to 50% of

the rated power, even if the site is being operated

with a System Manager.

- This parameter defines the

NOTE

If this PMU option is being installed in the field,

these Personality PROMs must be changed, even

if the system currently has the old PMU option

and a System Manager.

7

Page 8

LBI-39128 INSTALLATION

INSTALLATION

SITE CONTROLLER HARDWARE

Verify that the Site Controller computer is a VAX

model, or a PDP model that has been upgraded to a VAX

model (see the VAX Site Controller heading in the

Applications Notes section). If you find that the Site

Controller computer is a PDP model, upgrade kits are

available through Ericsson Service P arts. Alternatively, the

PDP model may be replaced with the current 19A149302P9

VAX model.

SITE CONTROLLER SOFTWARE

The Site Controller computer contains a set of 14

Application Software PROMs and a set of two Personality

PROMs. Both sets are located on the PROM card. Access to

the PROM card in the latest VAX version of the Site

Controller computer is through the b ack using the following

procedure:

1. Turn off the Site Controller computer.

Access to the PROM card in previous VAX versions

and older PDP versions that were upgraded to a VAX

version is through the top using the following procedure:

1. Turn off the Site Controller computer.

2. Pull the Site Controller computer chassis all the

way forward on its slide-out track.

3. Pull up the top cover and the attached card cage.

4. Remove the PROM Card (see Figure 5) by pulling

on the two tabs fastened to the front edge of the

card. (This is a three-handed operation - observe

standard handling practices for static sensitive

components.)

PROM Card

Figure 5 - Location of PROM Card in Older Computer

2. Loosen the two fastener screws holding the back

panel to the chassis (see Figure 3).

28293031

15

Fastener

Screws

27 26 25 24

20212223

19 18 17 16

14 13 12 11 10 9

2345678

1

0 SM

Figure 3 - Location of Fastener Screws on Computer

3. Rotate the back panel down and out of the way (be

careful not to damage the ribbon cables).

PROM Card

Figure 4 - Location of PROM Card in Computer

4. Remove the PROM Card (see Figure 4) by pulling

on the two tabs fastened to the front edge of the

card. (Observe standard handling practices for

static sensitive components.)

Personality

PROMs

13 14

01-02

01 02

09 10

11 12

Application

0605

0807

Software

PROMs

01-14

0201

03 04

Figure 6 - Location of PROMs on PROM Card

8

Page 9

INSTALLATION LBI-39128

The location of the Application Software and

Personality PROMs on the PROM card is shown in Figure

6. When replacing PROMs, be sure to get each new PROM

in the correct location, and with the notched end as shown.

Be especially careful of location numbers 01 and 02 since

these numbers are used for both sets of PROMs.

Application Software PROMs

Check the revision number marked on the Application

Software PROMs. Each of the 14 Application Software

PROMs must be marked 344A3265Gx, where x = 6 or

higher. (Application Software with x = 5 or lower will not

work for the new PMU option.) Figure 7 shows where to

find the software revision number and the PROM location

number on a typical Application Software PROM label.

Replace all 14 Application Software PROMs if required.

Software Revision

344A3265G6

VAX SITE CTRLR

EDACS

1994 BY ERICSSON GE

C

01

PROM Location

Figure 7 - Application Software PROM Label

Personality PROMs

Replace the two Personality PROMs, even if a PMU

was previously installed with this Site Controller computer.

Figure 8 shows a typical Personality PROM label. (See the

Application Notes section if you need to order new

Personality PROMs.)

Serial Number

SER#: 12345678

SITE CONTROLLER

EDACS

PERSONALITY

01

PROM Location

Figure 8 - Personality PROM Label

PMU HARDWARE

There are three procedures for the installation of the

PMU hardware. The procedure you should use will depend

upon whether or not the Site Controller cabinet presently

contains EDACS Interface Panels and/or an old PMU. The

EDACS Interface Panels are located in the back of the

cabinet, near the top. Each panel consists of a 5 1/4 inch X

19 inch frame containing one or more interface modules

(boards with connectors). Use Table 1 to select the right

PMU hardware installation procedure for your system.

Table 1 - Selection of Installation Procedure

INTERFACE

PANEL

Yes No A. Addition from No PMU

No Yes C. Adaptation from Old PMU

The table and the procedures assume that the equipment

that presently exists in the Site Controller cabinet is one of

the previous standard configurations. Regardless of which

procedure is used, it is very important to know exactly what

equipment presently exists, review what has to be done, and

be sure you have all the parts you will need before

the installation.

A. Addition from No PMU

Use this procedure only if your Site Controller cabinet

has EDACS Interface panels, but doesn’t have a PMU.

This procedure consists of adding the PMU, Power

Monitor interface module, cables between the PMU and the

Power Monitor interface module, cable between the PMU

and the Site Controller computer, and DC power wires to the

PMU, all in the Site Controller cabinet. It also consists of

adding the antenna power sensor(s) in the RF Equipment

cabinet(s), and the antenna power sensor cables between the

antenna power sensor(s) in the RF Equipment cabinet(s) and

the Power Monitor interface module in the Site Controller

cabinet.

OLD

PMU

HARDWARE INSTALLATION

PROCEDURE

Yes B. Upgrade from Old PMU

you sta rt

9

Page 10

LBI-39128 INSTALLATION

Parts Required

Before you start this procedure, be sure you have all the

parts on hand. The parts for this procedure are shown in

Table 2.

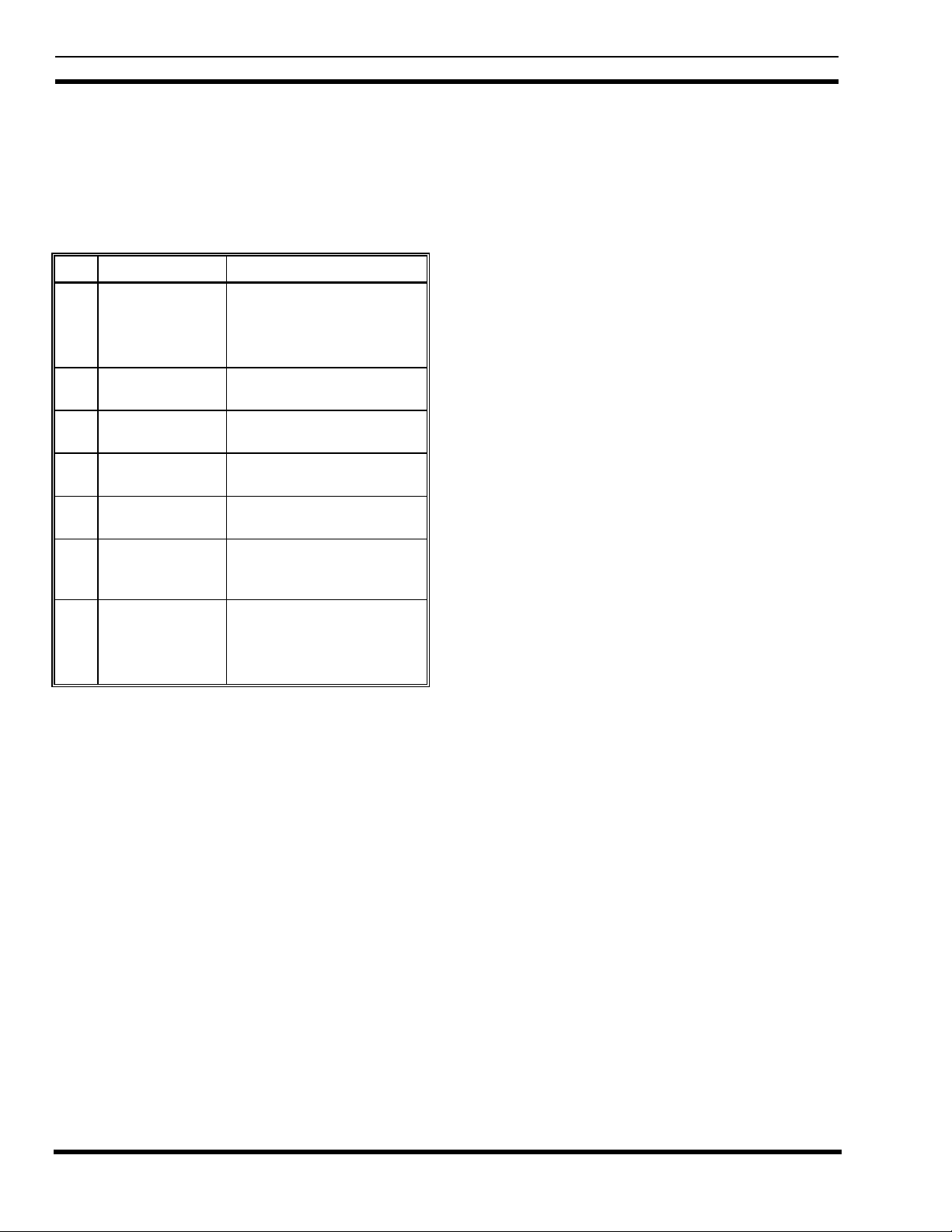

Table 2 - Parts for Addition from No PMU

QTY PART # DESCRIPTION

1 19D903880P100

or

19D903880P101

1 350A1380P1 Decibel Products DB8860-

1 188D6466P1 Cable - PMU to Power

5 188D6466P2 Cable - PMU to Power

1 19C852632G1 Power Sensor interface

1 19C852677P1 Cable - Power Sensor

1 or219C336861P3

or

19C336861P4

Procedure

The following steps involve equipment in the Site

Controller cabinet, except as noted:

Cable - DILOG Panel to

PMU

Cable - Site Controller

computer to PMU

based PMU Unit

Sensor interface module

Sensor interface module

module

interface module to Antenna

power sensor(s)

Antenna power sensor (450

- 1000 MHz)

Antenna power sensor (66 -

325 MHz)

the four thread forming screws provided with it. (You

will need a T15 Torx-head screwdriver.) If an old

Power Sensor interface module is mounted there,

replace it with the new 19C852632G1 interface module.

This interface module contains two 19C852379G1

Channel Termination Boards, each containing 12

shorting jumpers. The boa rd plugged into J1 is used to

short any unused power sensor circuit for Transmitter

channels #1 through #12. T he board plugged into J2 is

used to short any unused power sensor circuit for

Transmitter channels #11 through #20.

6. Remove the 19C852379G1 Channel Termination Board

from J1 on the Power Sensor interface module (installed

in step 5), and connect a 25-pair cabinet interconnect

cable in its place. Connect the other end of the 25-pair

cabinet interconnect cable to J14 or J15 on the Power

Sensor interface module in the EDACS Repeater

cabinet containing the transmitter for channel #1). If the

two cabinets are next to each other in the same row, use

a 5-ft 19D903880P120 cable. If the two cabinets are

across from each other in different rows, use a 15-ft

19D903880P121 cable.

7. Starting with the cabinet containing the transmitter for

channel #1, follow the daisy chain of 25-pair cabinet

interconnect cables connected to J14 and J15 on the

Power Sensor interface module in each EDACS

Repeater cabinet until an empty J14 or J15 connector is

found. Plug the 19C852379G1 Channel Termination

Board (removed in the previous step) into this empty

connector.

8. Remove the shorting jumper for each transmitter

channel # equipped with a power sensor (P#

corresponds to transmitter channel #).

1. Turn off the main 12V power supply for the cabinet.

2. Replace the 5 1/4 inch blank panel just above the

Downlink GETC (called Trunking Card in some older

installations) with the PMU. There will be a half rack

unit space (7/8 inch) both above and below the PMU.

3. Connect the #18 red wire from the terminal on the back

of the PMU labeled “+”, to TB10-7 on the back of the

Downlink GETC shelf.

4. Connect the #18 black wire from the terminal on the

back of the PMU labeled “–”, to TB10-6 on the back of

the Downlink GETC shelf.

5. Mount the new 19C852632G1 Power Sensor interface

module on the left-hand end of the upper EDACS

Interface Panel in the upper rear of the cabinet, using

10

Note that there is a shorting jumper for transmitter

channels #11 and #12 on each of the 19C852379G1

Channel Termination Boards. Therefore, if transmitter

channel #11 or #12 is equipped with a power sensor, a

jumper must be removed from each of the two channel

termination boards.

9. If the system does not have any additional EDACS

Repeater cabinets not included in the daisy chain in the

previous step, go to step 11.

If the system has additional EDACS Repeater cabinets

not included in the daisy chain in the previous step,

remove the 19C852379G1 Channel Termination Board

from J2 on the Power Sensor interface module (installed

in step 5), and connect a 25-pair cabinet interconnect

cable in its place. Connect the other end of the 25-pair

cabinet interconnect cable to J14 or J15 on the Power

Page 11

INSTALLATION LBI-39128

Sensor interface module in the EDACS Repeater

cabinet containing the transmitter for channel #11 or

#13). If the two cabinets are next to each other in the

same row, use a 5-ft 19D903880P120 cable. If the two

cabinets are across from each other in different rows,

use a 15-ft 19D903880P121 cable.

10. Starting with the cabinet containing the transmitter for

channel #11 or #13, follow the daisy chain of 25-pair

cabinet interconnect cables connected to J14 and J15 on

the Power Sensor interface module in each EDACS

Repeater cabinet until an empty J14 or J15 connector is

found. Plug the 19C852379G1 Channel Termination

Board (removed in the previous step) into this empty

connector.

11. Remove a shorting jumper in the 19C852379G1

Channel Termination Board for each transmitter

channel # equipped with a power sensor (P# plus 12

corresponds to transmitter channel #). Note that the P#

corresponds to a different transmitter channel # in this

case.

Note that there is a shorting jumper for transmitter

channels #11 and #12 on each of the 19C852379G1

Channel Termination Boards. Therefore, if transmitter

channel #11 or #12 is equipped with a power sensor, a

jumper must be removed from each of the two channel

termination boards.

12. Connect the five new 188D6466P2 cables from J3

through J7 on the Power Sensor interface module in the

upper EDACS Interface Panel, to Port 1 through Port 5

respectively on the back of the PMU.

13. Connect the new 188D6466P1 cable from J8 on the

Power Sensor interface module in the upper EDACS

Interface Panel, to PORT 7 on the back of the PMU.

If the Site Controller computer does not have modular

RJ11-8 connectors on its back panel, connect the new

19D903880P100 cable from the right-hand VDT

Interface on the back of the PMU to connector #13 on

the right-hand (B) DILOG panel (above the Site

Controller computer).

15. Install the 19C336861P3 or P4 antenna power sensor(s)

at the output of the transmitter combiner(s) in the RF

Equipment cabinet(s).

16. Install the 19C852677P1 antenna power sensor cable

from J9 on the Power Sensor interface module in the

Site Controller cabinet, to the antenna power sensor(s)

in the RF equipment cabinet(s) as shown in Figure 9. If

the system has only one antenna, tack solder a jumper

(tip to shield) on each of the unused phono plugs to

short the forward and reflected power sensor circuits for

antenna #2.

19C852632G1

J9

DB-9 (F)

1

6

2

7

3

8

4

9

High

Ground

High

Ground

High

Ground

High

Ground

POWER SENSOR

Antenna Power Sensor Cable

Antenna #1

Antenna #2

to Interface Module

Antenna Power Sensors

Forward

Reflected

Forward

Reflected

DB-9 ( M)

Figure 9 - Antenna Power Sensor Connections

17. Double check the installation using the interconnection

diagram shown in Figure 10.

14. If the Site Controller computer has modular RJ11-8

connectors on its back panel, connect the new

19D903880P101 cable from the right-hand VDT

Interface on the back of the PMU, to Port 29 on the

back of the Site Controller computer.

18. Set the power switch on the back of the PMU to the

“Off” position.

19. Turn on the main 12V power supply for the cabinet.

11

Page 12

LBI-39128 INSTALLATION

Daisy Chain Cable to Power Sensors for Transmitter Channels 11 - 20

Antenna Power Sensor Cable to Power Sensors for Antennas 1 & 2

Daisy Chain Cable to Power Sensors for Transmitter Channels 1 - 12

19C852632G1 POWER SENSOR INTERFACE MODULE

J3

J4

J1 J2

J5

J6

J7

J8J9

188D6466P1 Cable

VDT Interfaces

Programming

Terminal

Connection

DOWNLINK GETC

(TRUNKING CARD)

0511 0511AB

188D6466P2 Cables (5 Each)

PORT 8 PORT 6

POWER MONITOR UNIT

PORT 7 PORT 5

112

6

Use 19D903880P100 Cable If

Connecting to DILOG Panel

#18 Red

7

PORT 1PORT 4 PORT 2PORT 3

#18 Black

13B

Table 3 - Parts for Upgrade from Old PMU

QTY PART # DESCRIPTION

1 350A1380P1 Decibel Products DB8860-

based PMU Unit

1 188D6466P1 Cable - PMU to Power

Sensor interface module

5 188D6466P2 Cable - PMU to Power

Sensor interface module

1 19C852632G1 Power Sensor interface

module

Procedure

The following steps involve equipment in the Site

Controller cabinet only:

1. Turn off the main 12V power supply for the cabinet.

2. Mark “+” on the wire going to the screw terminal

marked “+” on the back of the old PMU. Then

disconnect this wire at the PMU end.

DILOG DILOG

Use 19D903880P101 Cable If

Connecting to Site Controller Computer

Port 29

SITE CONTROLLER

COMPUTER

Figure 10 - Connections for Addition from No PMU

B. Upgrade from Old PMU

Use this procedure only if your Site Controller cabinet

has EDACS Interface panels and an old PMU.

This procedure consists of upgrading the Site Controller

by replacing the old PMU, replacing the old Power Sensor

interface module, and replacing the cables between them.

Parts Required

Before you start this procedure, be sure you have all the

parts on hand. The parts for this procedure are shown in

Table 3.

3. Mark “–” on the wire going to the screw terminal

marked “–” on the back of the old PMU. Then

disconnect this wire at the PMU end.

4. Mark “RS-232” on the cable going to the DB-25

connector marked “RS-232” on the back of the old

PMU. Then disconnect this cable at the PMU end.

5. Disconnect any cables going to the connectors marked

“Antennas 1-4”, “Transmitters 1-9”, “Transmitters 1018”, and “Transmitters 19-20” on the back of the old

PMU. (There is no need to label these cables since they

will not be used with the new PMU.)

6. Replace the old PMU with the new PMU. There will be

a half rack unit space (7/8 inch) both above and below

the new PMU.

7. Connect the existing wire labeled “+” in step 2 to the

terminal labeled “+” on the back of the new PMU.

8. Connect the existing wire labeled “–” in step 3 to the

terminal labeled “–” on the back of the new PMU.

9. Connect the existing cable labeled “RS232” in step 4 to

the right-hand VDT interface on the back of the new

PMU (see Figure 7).

12

10. Find the Power Sensor interface module mounted in the

left end of the upper EDACS Interface Panel in the

upper rear of the cabinet. If a cable is connected to the

Page 13

INSTALLATION LBI-39128

Power Sensor interface module connector marked “J1”,

label the cable “J1” and disconnect it from the Power

Sensor interface module.

11. If a cable (or an existing 19C852379G1 Channel

Termination Board) is connected to the Power Sensor

interface module connector marked “J2”, label the cable

(or board) “J2” and disconnect it at the Power Sensor

interface module.

12. Find the cables (or group of cables) connected to the

Power Sensor interface module connectors marked “J6”

and “J7”, determine which cable (or group of cables)

goes to some point outside the cabinet, label this cable

(or group of cables) “J9” (the connector number on the

new Power Sensor interface module is different), and

disconnect this cable (or group of cables) at the Power

Sensor interface module.

13. Remove the old 19C852213G1 Power Sensor interface

module and all cables still connected to it (all cables

still connected to it should have been disconnected at

their other end in step #5).

14. Mount the new 19C852632G1 Power Sensor interface

module in the space vacated by the old module.

15. Connect the existing cables (or board) labeled “J1”,

“J2”, and “J9” in steps 10-12 to the connectors marked

“J1”, “J2”, and “J9” respectively on the new Power

Sensor interface module.

16. Connect the 5 new 188D6466P2 cables from J3 through

J7 on the new Power Sensor interface module to Port 1

through Port 5, respectively, on the back of the new

PMU.

17. Connect the new 188D6466P1 cable from J8 on the

new Power Sensor interface module to Port 7 on the

back of the new PMU (skip Port 6).

18. Double check the installation using the interconnection

diagram shown in Figure 11.

Daisy Chain Cable to Power Sensors for Transmitter Channels 11 - 20

Antenna Power Sensor Cable to Power Sensors for Antennas 1 & 2

Daisy Chain Cable to Power Sensors for Transmitter Channels 1 - 12

19C852632G1 POWER SENSOR INTERFACE MODULE

J3

J4

J1 J2

J5

J6

J7

J8J9

188D6466P1 Cable

VDT Interfaces

Programming

Terminal

Connection

DOWNLINK GETC

188D6466P2 Cables (5 Each)

PORT 8 PORT 6

POWER MONITOR UNIT

Existing Cable To Site Controller Computer

PORT 7 PORT 5

#18 Red

112

7

6

PORT 1PORT 4 PORT 2PORT 3

#18 Black

Figure 11 - Connections for Upgrade from Old PMU

This procedure consists of replacing the old PMU with

the new PMU, adding an adapter cable between the existing

transmitter power sensor cables and the new PMU, and

adding an adapter cable between the existing antenna power

sensor cable and the new PMU. The existing RS232 data

link to the Site Controller computer and the two DC power

wires can be re-connected directly to the new PMU. This

procedure upgrades the system to the extent that it adds the

new PMU, but uses adapter cables instead of upgrading to

the EDACS Interface Panel configuration.

Parts Required

Before you start this procedure, be sure you have all the

parts on hand. The parts for this procedure are shown in

Table 4.

Table 4 - Parts for Adaptation from Old PMU

19. Set the power switch on the back of the PMU to the

“Off” position.

20. Turn on the main 12V power supply for the cabinet.

C. Adaptation from Old PMU

Use this procedure only if your Site Controller cabinet

doesn’t have EDACS Interface panels, but does have an old

PMU.

QTY PART # DESCRIPTION

1 350A1380P1 Decibel Products DB8860-

based PMU Unit

1 188D6451P1 Adapter Cable - Transmitter

power sensor circuits

1 188D6496P1 Adapter Cable - Antenna

power sensor circuits

13

Page 14

LBI-39128 INSTALLATION

Procedure

The following steps involve equipment in the Site

Controller cabinet, except as noted:

1. Mark the cables and wires going to the old PMU as

follows:

• Mark “Antennas 1-4” on the cable going to the DB-

15 connector on the back of old PMU marked

“Antennas 1-4”.

• Mark “Transmitters 1-9” on the cable going to the

DB-37 connector on the back of the old PMU

marked “Transmitters 1-9”.

• Mark “Transmitters 10-18” on the cable going to

the DB-37 connector on the back of the old PMU

marked “Transmitters 10-18”.

• Mark “Transmitters 19-20” on the cable going to

the DB-25 connector on the back of the old PMU

marked “Transmitters 19-20”.

• Mark “RS-232” on the cable going to the DB-25

connector on the back of the old PMU marked

“RS-232”.

• Mark “+” on the wire going to the screw terminal

marked “+”.

• Mark “–” on the wire going to the screw terminal

marked “–”.

2. Turn off the main 12V power supply for the cabinet.

3. Disconnect the cables and wires from the old PMU.

4. Replace the old PMU with the new PMU. There will be

a half rack unit space (7/8 inch) both above and below

the PMU.

5. Connect the 188D6451P1 adapter cable as follows:

• Connect the two DB-37 connectors on the adapter

cable marked “P2” and “P3” to the existing cables

(disconnected from the old PMU) marked

“Transmitters 1-9” and “Transmitters 10-18”

respectively.

• Connect the five DB-25 connectors on the other

end of the adapter cable marked “P5”, “P6”, “P7”,

“P8”, and “P9” to Port 1 through Port 5

respectively on the back of the new PMU.

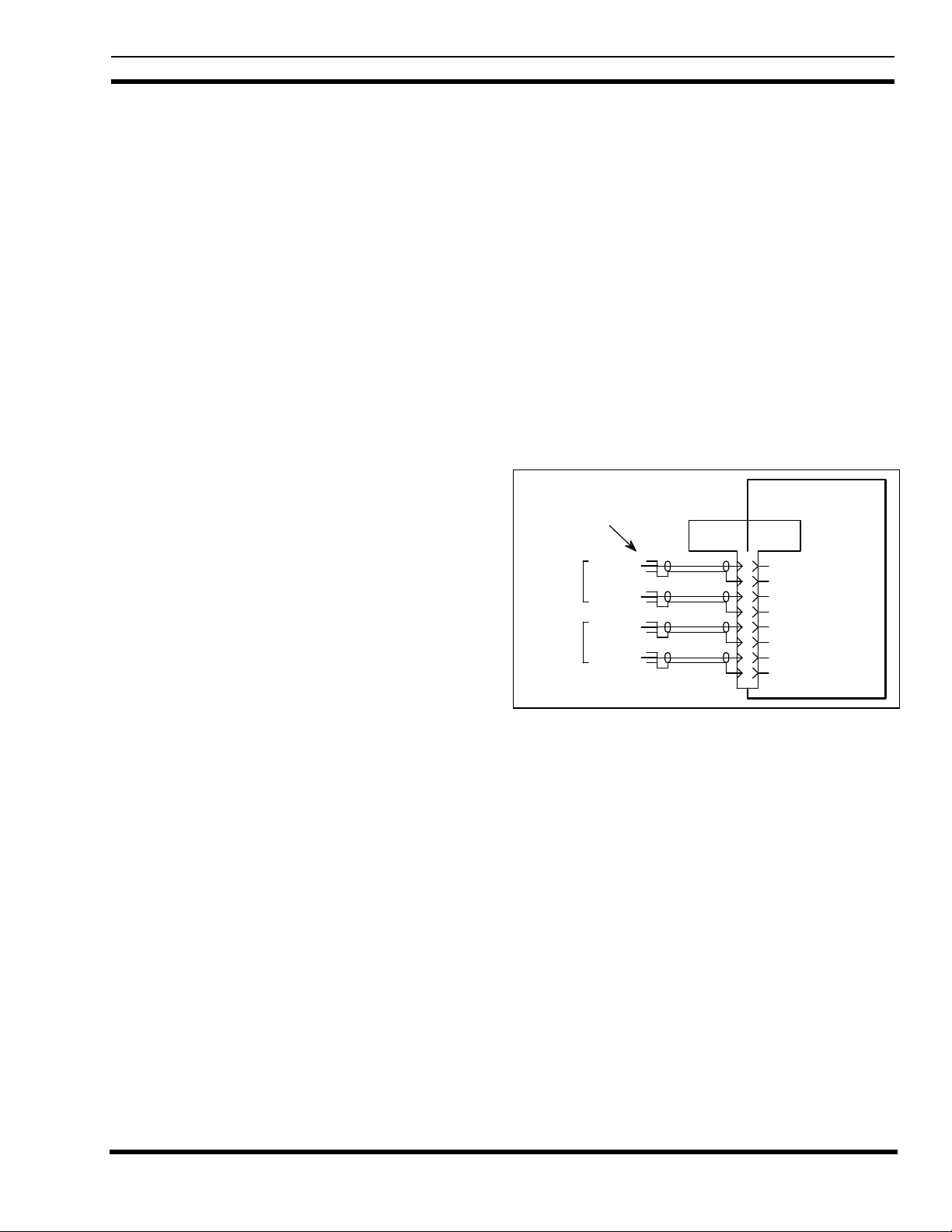

6. Connect the 188D6496P1 adapter cable as follows:

• Connect the DB-15 connector on the adapter cable

marked “P2” to the existing cable (disconnected

from the old PMU) marked “Antennas 1-4”.

• Connect the DB-25 connector on the adapter cable

marked “P3” to Port 7 on the back of the new

PMU.

7. Connect the existing cable (disconnected from the old

PMU) marked “RS-232” to the right VDT Interface

connector on the back of the new PMU.

8. Connect the existing wires (disconnected from the old

PMU) marked “+” and “–” to the screw terminals on the

back of the new PMU marked “+” and “–” respectively.

9. Double check the installation using the interconnection

diagram shown in Figure 12.

Transmitters 1-9

Transmitters 10-18

Transmitters 19-20

188D6451P1 Adapter Cable

188D6496P1 Adapter Cable

Antennas 1-4

VDT Interfaces

Programming

Terminal

Connection

P2

P3

P4

P2

POWER MONITOR UNIT

P3

PORT 7 PORT 5PORT 8 PORT 6

P5P6P7P8 P9

PORT 1PORT 4 PORT 2PORT 3

_

+

RS-232

Figure 12 - Connections for Adaptation from Old PMU

10. Set the power switch on the back of the PMU to the

“Off” position.

11. Turn on the main 12V power supply for the cabinet.

INITIAL POWER-UP

• Connect the single DB-25 connector on one end of

the adapter cable marked “P4” to the existing cable

(disconnected from the old PMU) marked

“Transmitters 19-20”.

14

After the PMU equipment has been mounted and

checked, you are ready for the initial power-up of the PMU.

1. Temporarily disconnect the data link cable to the Site

Controller computer from the right-hand VDT Interface

Page 15

INSTALLATION LBI-39128

on the back of the PMU (this cable will be re-connected

later in the installation).

2. Switch the On/Off switch on the back of the PMU to the

“On” position.

3. Verify that the “PWR” indicator on the front panel of

the PMU stays on continuously.

4. Verify that the three other indicators on the front panel

of the PMU are flashing in a repeating sequence. The

“MUX” indicator should flash once every 250

milliseconds; first by itself, next with the “DATA”

indicator, and then with the “ALARM” indicator.

PMU PROGRAMMING

The PMU’s operational program will use the factory

default values for its operational parameters unless reconfigured by the user. The user-configurable parameters

may be re-configured through the use of an RS232 CRT

terminal (or PC with terminal emulation software) connected

to the PMU.

CAUTION

(or PC COM Port)

11

Tx Data

Rx Data

33

4

CTS CTS

6

Ground

7

Null Modem Cable

Figure 13 - DB-25 Terminal Connections

(or PC COM Port)

11

Rx Data

Tx Data

33

4

DTR

Ground

6

7

RTS

8

CTS

Null Modem Cable

PMURS232 CRT Terminal

Left VDT Interface

DB-25 (F)DB-25 (M) DB-25 (M)DB-25 (F)

22

Tx Data

Rx Data

RTSRTS

4

55

6

DSRDSR

7

Ground

2020

DTRDTR

PMURS232 CRT Terminal

Left VDT Interface

DB-25 (F)DB-9 (M) DB-25 (M)DB-9 (F)

22

Tx Data

Rx Data

RTS

4

55

CTS

6

DSRDSR

7

Ground

209

DTR

Changing parameters not covered in this

manual may lead to unsatisfactory operation of

the PMU option.

Terminal Setup

The following initial steps are required to set up the

terminal and access the PMU.

1. Connect the RS232 CRT terminal to the left-hand VDT

Interface connector on the back of the PMU (see Figure

12). (DO NOT plug into the front of the PMU.) If the

RS232 CRT terminal has a male DB-25 port, connect

per Figure 13. If the terminal has a male DB-9 port,

connect per Figure 14.

CAUTION

DO NOT plug the RS232 CRT terminal in to t he

front panel of the PMU (damage to terminal

may result). This connnector is for another

device in another application.

Figure 14 - DB-9 Terminal Connections

2. Turn the terminal on and set the communications

protocol per Table 5.

Table 5 - Terminal Communications Protocol

PARAMETER VALUE

Baud Rate 9600 BPS

Data Bits 8

Parity None

Stop Bits 1

3. Press the Enter key one or more times until the

“Disconnected - Hit Any Key To Connect” prompt

appears on the terminal:

Software Initialization

Before you attempt to program any PMU parameters,

all parameters should be returned to the factory default

values. The following procedure is used to initialize the

PMU with its factory defaults:

15

Page 16

LBI-39128 INSTALLATION

4. Type 8860 and press the Enter key. The Operation

Select Menu should then appear on the terminal as

shown in Figure 15 (revision # and date may be

different). If the PMU does not respond to this entry,

the password may have been re-configured from its

factory default value. See the Erase All Programming

heading in the Maintenance section for the procedure to

return all parameters to the factory default values,

including returning the password to 8860.

5. With the Operational Select Menu shown on the

terminal, type 4 (for item #4 - Setup) and press the

Enter key. The Setup Selection Menu should then

appear on the terminal as shown in Figure 16.

SENTRY 8860 COPYRIGHT 1987-1994 DECIBEL PRODUCTS

PATENT 4,823,280

OPERATION SELECT MENU SENTRY PMU REV 8.6 12/07/94

1. DISCONNECT

2. REPORTS

3. MANUAL CONTROL

4. SETUP

5. HARDWARE STATUS

6. SOFTWARE STATUS

7. RESET ***WARNING - FOR EMERGENCY ONLY***

ENTER SELECTION:

6. With the Setup Selection Menu shown on the terminal,

type 10 (for item #10 - Erase All Programming) and

press the Enter key.

7. At the “Enter Y to Continue, Any Other Character to

Abort:” prompt (after the warning message), type Y and

press the Enter key.

8. At the “Enter Site Password” prompt, type 8860 and

press the Enter key.

9. At the “Enter Site ID” prompt, type 1234 and press the

Enter key. You will be given a 4-second countdown and

then a flashing “Sentry Initialized” message.

10. Finally the Setup Selection Menu should appear on the

terminal.

Figure 15 - Operation Select Menu (Main Menu)

SETUP SELECTION MENU

1. RETURN TO OPERATION SELECT MENU

2. SITE DATA #1

3. SITE DATA #2

4. ANALOG INPUT CHANNEL

5. DIGITAL INPUT CHANNEL

6. ANALOG PSEUDO CHANNEL

7. DIGITAL PSEUDO CHANNEL

8. RELAY OUTPUTS

9. INPUT CONVERSION TABLE

10. ERASE ALL PROGRAMMING

11. db TEST CONFIGURATION

12. db TOWER LIGHTS CONFIGURATION

ENTER SELECTION: _

Figure 16 - Setup Selection Menu

16

Page 17

INSTALLATION LBI-39128

Time/Date/Password

The following steps to set the time, date, and password

are optional and have no affect on the performance of the

PMU:

11. With the Setup Selection Menu shown on the terminal,

type 2 (for item #2 - Site Data #1) and press the Enter

key. The Site Data #1 screen should then appear o n the

terminal as shown in Figure 17.

12. With the Site Data #1 screen shown on the terminal,

type 1 (for item #1 - Time) and press the Enter key.

13. At the “Enter New Data:” prompt, type up to 4

numerical characters (do not type the colon, am, or pm)

and press the Enter key. Use the following samples as a

guide:

Type 1 or 01 to get 1:00 am.

Type 13 to get 1:00 pm.

Type 130 to get 1:30 am.

Type 1330 to get 1:30 pm.

SITE DATA #1

14. With the Site Data #1 screen shown on the terminal,

type 2 (for item #2 - Date) and press the Enter key.

15. At the “Enter New Data:” prompt, type 4 numerical

characters (do not type the / ) and press the Enter key.

The first 2 numbers are for the month; the second 2

numbers are for the day of the month. Use the following

samples as a guide:

Type 1 or 01 to get 1/00.

Type 12 or 120 to get 12/00.

Type 0120 to get 1/20.

Type 1201 to get 12/01.

16. With the Site Data #1 screen shown on the terminal,

type 3 (for item #3 - Year) and press the Enter key.

17. At the “Enter New Data:” prompt, type all 4 characters

for the year and press the Enter key.

18. With the Site Data #1 screen shown on the terminal,

type 6 (for item #6 - Password) and press the Enter key.

1. TIME = 0:01 am

2. DATE = 1/01

3. YEAR = 1994

4. SITE NAME = NOT PROGRAMMED

5. SITE ID = 1234

6. PASSWORD = 8860

7. REPORT TIME = 8. REPORT TIME =

9. REPORT TIME = 10. REPORT TIME =

11. PH #1 PRI=H 12. PH #1 ALT=

13. RETRY INTERVAL #1 (min)= 10

14. PH #2 PRI= 15. PH #2 ALT=

13. RETRY INTERVAL #2 (min)= 10

14. PH #3 PRI= 15. PH #3 ALT=

13. RETRY INTERVAL #3 (min)= 10

14. PH #4 PRI= 15. PH #4 ALT=

13. RETRY INTERVAL #4 (min)= 10

ENTER ITEM NUMBER TO CHANGE,

"H" FOR HELP MENU, "A" TO ABORT,

OR "E" TO END PROGRAMMING THIS CHANNEL:

Figure 17 - Site Data #1 Screen

17

Page 18

LBI-39128 INSTALLATION

19. At the “Enter New Data:” prompt, type up to 4

characters for the password and press the Enter key.

Check the password shown on the Site Data #1 screen

to be absolutely sure it is what you expected and want.

If not, return to step #8 and redo the password. If you

try to enter more than 4 characters, only the first 4 will

be used. After you are satisfied with the password, go

on to the next step.

20. Type E (to end programming this screen) and press the

Enter key. The Setup Selection Menu should then

appear on the terminal.

Antenna Mapping

Antenna Mapping tells the PMU which antenna is used

by each transmitter. The factory defaults have AI025

(antenna #1) mapped for transmitters #1 through #10 and

AI027 (antenna #2) mapped for transmitters #11 through

#20. If any transmitter is connected to an antenna other than

described by these default values, the Antenna Channel

parameter must be re-configured.

The following steps must be repeated for each

transmitter that is connected to a different antenna # than

described by the PMU’s factory defaults. Those transmitters

for which the PMU’s factory defaults are correct, may be

skipped. Transmitters may be configured in any order, but

starting with the lowest transmitter # and working your way

up will probably be the easiest way to keep track of which

ones have been done.

22. At the “Enter Channel Number” prompt, type the

channel number of the transmitter and press the Enter

key. The Analog Input Channel screen for that channel

should then appear on the terminal (see Figure 18). (If

item #10 - Channel Enable Method = 5, item #11 will

not be present.)

23. With the Analog Input Channel screen shown on the

terminal, type 1 (for item #1 - Channel Type) and press

the Enter key.

24. At the “Enter New Data” prompt, type 3 and press the

Enter key. The screen will be re-written to add item #11

(or #12) - Antenna Channel (see Figure 19).

25. Type 11 or 12 (whichever corresponds to the Antenna

Channel) and press the Enter key.

26. At the “Enter New Data” prompt, type AI025 for

antenna #1 or AI027 for antenna #2, and press the Enter

key. The screen will be re-written to show the new

value.

27. Type E (to End programming this channel) and press

the Enter key. The Setup Selection Menu should then

appear on the terminal.

This completes the configuration of the Antenna

Channel parameter for the selected transmitter. If this

parameter needs to be changed for another transmitter,

return to step 21. When this parameter is satisfactory for all

transmitters, go on to step 28.

21. With the Setup Selection Menu shown on the terminal,

type 4 (for item #4 - Analog Input Channel) and press

the Enter key.

ANALOG INPUT CHANNEL 1

1. CHANNEL TYPE (0-13) = 0

2. DESCRIPTION = TX01

3. UNIT ID = AI01

4. MEASUREMENT UNITS = Watts

5. ALARM DELAY (1/4 sec) = 3

6. LOWER ALARM LIMIT = 0.0

7. UPPER ALARM LIMIT = 125.0

8. ALARM REPORT TYPES (1,2,3,4) =

9. ALARM RELAY NUMBER = 0

10. CHANNEL ENABLE METHOD (0-5) = 0

11. CHANNEL ENABLE THRESHOLD = 0.0

ENTER ITEM NUMBER TO CHANGE,

"H" FOR HELP MENU, "A" TO ABORT,

OR "E" TO END PROGRAMMING THIS CHANNEL:

Figure 18 - Analog Input Channel Screen

18

Page 19

INSTALLATION LBI-39128

ANALOG INPUT CHANNEL 1

1. CHANNEL TYPE (0-13) = 3

2. DESCRIPTION = TX01

3. UNIT ID = AI01

4. MEASUREMENT UNITS = Watts

5. ALARM DELAY (1/4 sec) = 3

6. LOWER ALARM LIMIT = 0.0

7. UPPER ALARM LIMIT = 125.0

8. ALARM REPORT TYPES (1,2,3,4) =

9. ALARM RELAY NUMBER = 0

10. CHANNEL ENABLE METHOD (0-5) = 0

11. CHANNEL ENABLE THRESHOLD = 0.0

12. ANTENNA CHANNEL = AI025

ENTER ITEM NUMBER TO CHANGE,

"H" FOR HELP MENU, "A" TO ABORT,

OR "E" TO END PROGRAMMING THIS CHANNEL: _

Figure 19 - Analog Input Channel Screen Showing Antenna Channel Parameter

28. With the Setup Selection Menu shown on the terminal,

type 1 (for item #1 - Return To Operation Select Menu)

and press the Enter key.

29. The Operation Select Menu should then be shown on

the terminal. Type 1 (for item #1 - Disconnect) and

press the Enter key.

Calibration Screw

30. The “Disconnected - Hit Any Key To Connect” prompt

should then appear on the terminal.

POWER SENSOR CALIBRATION

The power sensor provides a DC voltage output

representing the power through it. This calibration method

uses an in-line wattmeter to read the power going through

the power sensor, a DC voltmeter to measure the DC voltage

out of the power sensor, and a conversion table to simulate

the PMU’s calculation of power from this DC voltage. This

DC voltage is then adjusted (using the 20-turn p otentio meter

mounted in the power sensor) until the power read from the

conversion table agrees with the power read on the power

meter.

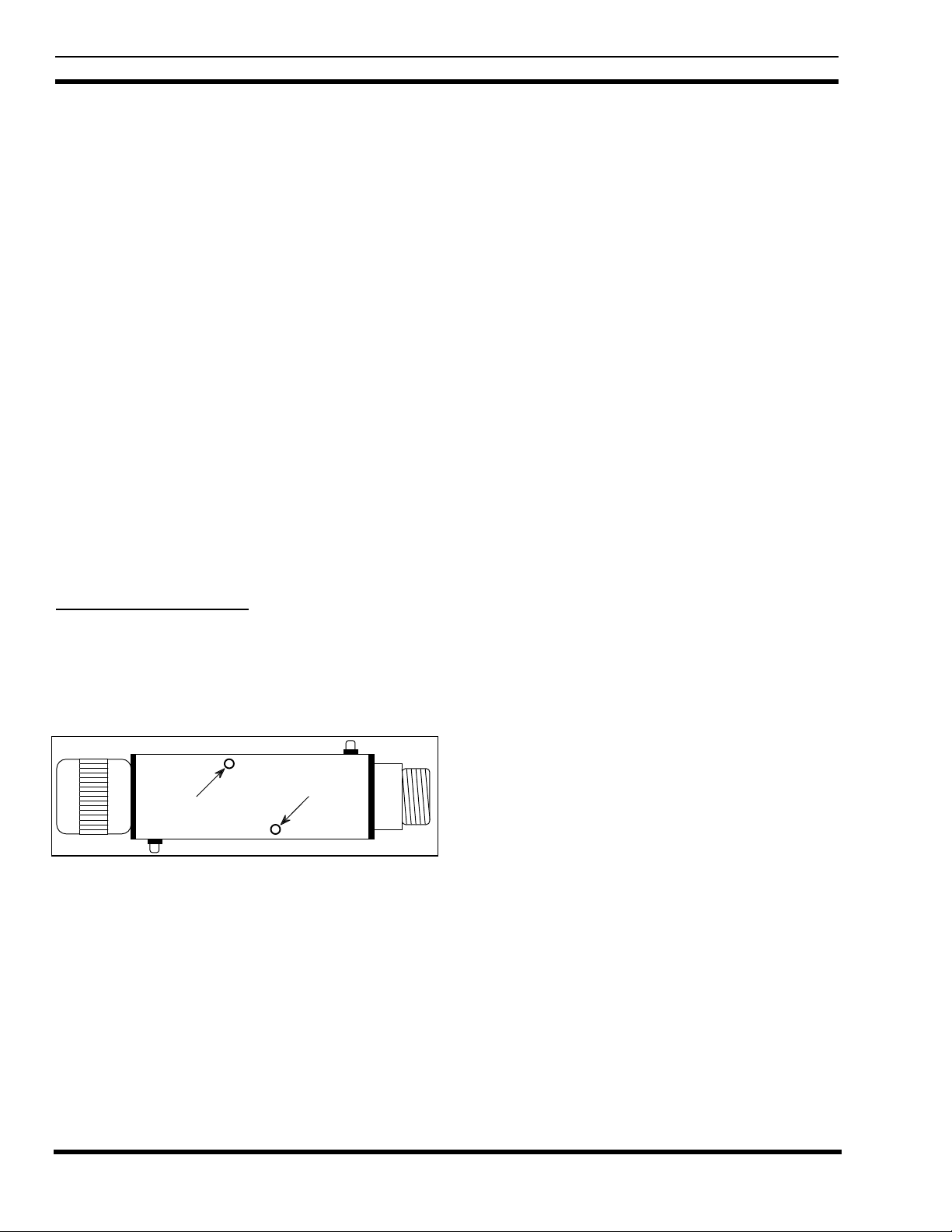

Unidirectional Power Sensors

Use the following procedure to calibrate the

unidirectional power sensors used at the output of each

transmitter. Start with the transmitter for channel #1. The

location of the calibration screw is shown in Figure 20.

Figure 20 - Unidirectional Power Sensor Calibration Screw

1. Turn off the 12V station power supply for the

transmitter.

2. Disconnect the coax (from the power sensor to the

combiner) at the power sensor end, and insert an in-line

wattmeter (make sure the wattmeter is rated high

enough to handle the power from the transmitter).

3. Disconnect the power sensor cable from the phono

connector on the power sensor, and attach the DC

voltmeter in its place (center pin is positive). (An

alternate method is to disconnect the power sensor cable

at the PMU - see interconnection diagram at end of

manual - and attach the DC voltmeter to the end of the

cable.)

4. Turn on the 12V station power supply for the

transmitter.

5. Manually key the transmitter using the switch marked

“REM KEY”, or press and hold the PTT switch on a

hand-held microphone plugged into the transmitter.

6. Measure the DC voltage on the meter, look up this

voltage in Table 6 (V in volts) to get the correspond ing

19

Page 20

LBI-39128 INSTALLATION

power (P in watts), and compare with the actual power

measurement on the power meter. Because the table

does not contain all values of V and P, you may need to

interpolate to get the values you need.

7. Turn the calibration screw (clockwise if the measured

power is lower than the power from the table) and

repeat steps 6 and 7 until the measured power is the

same as the power from the table.

8. Turn off the 12V station power supply for the

transmitter.

9. Disconnect the DC voltmeter from the phono connector

on the power sensor, and re-connect the power sensor

cable in its place.

10. Remove the wattmeter from between the power sensor

and the coax to the combiner, and re-connect the coax

to the power sensor.

11. Turn on the 12V station power supply for the

transmitter.

12. Repeat steps 1 through 11 for the next transmitter until

each transmitter has had its power sensor calibrated.

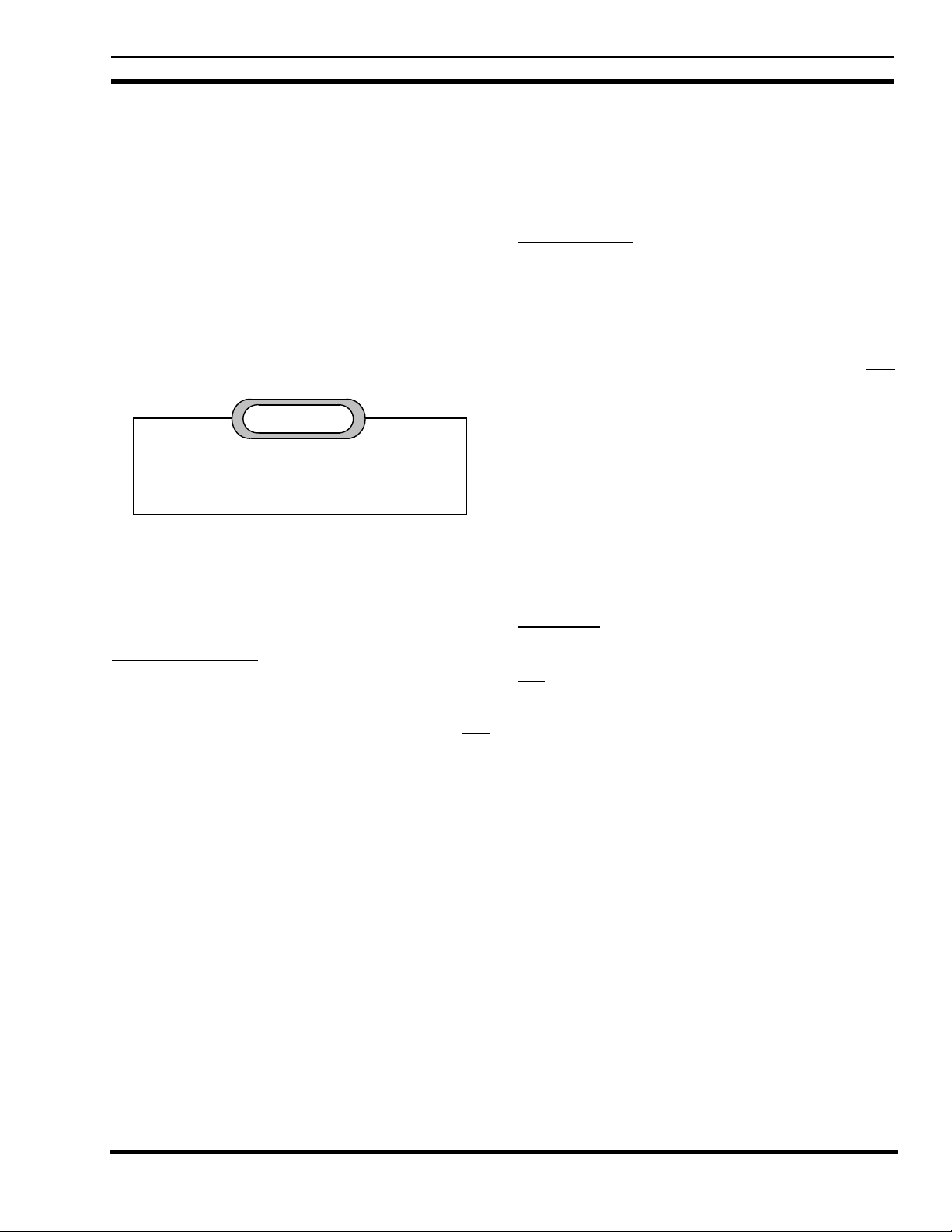

Bi-directional Power Sensors

Use the following procedure to calibrate the bi-

directional power sensors used at the output of each

combiner. Start with the combiner that feeds antenna #1.

The locations of the calibration screws are shown in Figure

21.

Reflected Power

Calibration Screw

Calibration Screw

Forward Power

Forward Power

Reflected Power

Figure 21 - Bi-directional Power Sensor Calibration Screws

1. Disconnect the coax (from the power sensor to the

antenna) at the power sensor end, and insert an in-line

wattmeter set to measure forward power (make sure the

wattmeter is rated high enough to handle the power

from all the transmitters feeding the combiner).

2. Disconnect the power sensor cable from the phono

connector for the forward power on the power sensor,

and attach the DC voltmeter in its place (center pin is

positive). (An alternate method is to disconnect the

power sensor cable at the PMU - see interconnection

diagram at end of manual - and attach the DC voltmeter

to the end of the cable.)

3. Manually key the transmitter using the switch marked

“REM KEY”, or press and hold the PTT switch on a

hand-held microphone plugged into the transmitter.

4. Measure the DC voltage on the meter, look up this

voltage in Table 6 (V in volts) to get the equivalent

power calculation (P in watts), and compare with the

actual power measurement on the power meter.

5. Turn the calibration screw (clockwise if the measured

power is lower than the power from the table) and

repeat steps 4 and 5 until the measured power is the

same as the power from the table.

6. Disconnect the DC voltmeter from the phono connector

on the power sensor, and re-connect the power sensor

cable in its place.

7. Set the in-line wattmeter to measure reflected power.

8. Disconnect the power sensor cable from the phono

connector for the forward power on the power sensor,

and attach the DC voltmeter in its place (center pin is

positive).

9. Manually key the transmitter using the switch marked

“REM KEY”, or press and hold the PTT switch on a

hand-held microphone plugged into the transmitter.

10. Measure the DC voltage on the meter, look up this

voltage in Table 6 (V in volts) to get the equivalent

power calculation (P in watts), and compare with the

actual power measurement on the power meter.

11. Turn the calibration screw (clockwise if the measured

power is lower than the power from the table) and

repeat steps 10 and 11 until the measured p ower is the

same as the power from the table.

12. Disconnect the DC voltmeter from the phono connector

on the power sensor, and re-connect the power sensor

cable in its place.

13. Remove the wattmeter from between the power sensor

and the coax to the combiner, and re-connect the coax

to the power sensor.

14. Repeat ste ps 1 through 13 for the other co mbiner (if two

transmit antennas are used).

20

Page 21

INSTALLATION LBI-39128

Table 6 - Power Sensor Voltage-to-Power Conversion Table

VP VP VP VP VP VP VP VP

0.00 0.0 0.62 25.5 1.25 80.6 1.87 164.4 2.50 276.7 3.13 417.2 3.76 585.9 4.38 782.7

0.01 0.6 0.64 26.8 1.27 82.8 1.89 167.5 2.52 280.6 3.15 422.0 3.77 591.6 4.40 789.3

0.03 1.0 0.66 28.1 1.28 85.0 1.91 170.6 2.54 284.6 3.17 426.9 3.79 597.4 4.42 795.9

0.05 1.4 0.68 29.5 1.30 87.2 1.93 173.7 2.56 288.6 3.19 431.8 3.81 603.1 4.44 802.5

0.07 1.8 0.70 30.8 1.32 89.5 1.95 176.9 2.58 292.7 3.22 436.7 3.83 608.9 4.46 809.2

0.09 2.2 0.72 32.2 1.34 91.8 1.97 180.1 2.60 296.8 3.23 441.7 3.85 614.8 4.48 815.9

0.11 2.7 0.74 33.6 1.36 94.1 1.99 183.3 2.62 300.9 3.25 446.7 3.87 620.6 4.50 822.7

0.13 3.2 0.76 35.1 1.38 96.5 2.01 186.5 2.64 305.0 3.27 451.7 3.89 626.5 4.52 829.4

0.15 3.7 0.77 36.6 1.40 98.8 2.03 189.8 2.66 309.2 3.28 456.7 3.91 632.4 4.54 836.2

0.17 4.3 0.79 38.1 1.42 101.3 2.05 193.1 2.68 313.3 3.30 461.8 3.93 638.4 4.56 843.0

0.19 4.9 0.81 39.6 1.44 103.7 2.07 196.4 2.70 317.5 3.32 466.9 3.95 644.4 4.58 849.9

0.21 5.5 0.83 41.2 1.46 106.2 2.09 199.8 2.72 321.8 3.34 472.0 3.97 650.4 4.60 856.8

0.23 6.1 0.85 42.8 1.48 108.7 2.11 203.2 2.74 326.1 3.36 477.2 3.99 656.4 4.62 863.7

0.25 6.8 0.87 44.4 1.50 111.2 2.13 206.6 2.75 330.4 3.38 482.3 4.01 662.4 4.64 870.6

0.27 7.5 0.89 46.0 1.52 113.7 2.15 210.0 2.77 334.7 3.40 487.5 4.03 668.5 4.66 877.6

0.28 8.3 0.91 47.7 1.54 116.3 2.17 213.5 2.79 339.0 3.42 492.8 4.05 674.6 4.68 884.5

0.30 9.1 0.93 49.4 1.56 118.9 2.19 217.0 2.81 343.4 3.44 498.0 4.07 680.8 4.70 891.5

0.32 9.9 0.95 51.2 1.58 121.5 2.21 220.5 2.83 347.8 3.46 503.3 4.09 686.9 4.72 898.6

0.34 10.7 0.97 52.9 1.60 124.2 2.23 224.1 2.85 352.2 3.48 508.6 4.11 693.1 4.74 905.7

0.36 11.6 0.99 54.7 1.62 126.9 2.25 227.6 2.87 356.7 3.50 514.0 4.13 699.3 4.76 912.7

0.38 12.5 1.01 56.5 1.64 129.6 2.27 231.2 2.89 361.2 3.52 519.3 4.15 705.6 4.77 919.9

0.40 13.4 1.03 58.4 1.66 132.4 2.28 234.9 2.91 365.7 3.54 524.7 4.17 711.9 4.79 927.0

0.42 14.4 1.05 60.3 1.68 135.1 2.30 238.5 2.93 370.3 3.56 530.2 4.19 718.2 4.81 934.2

0.44 15.3 1.07 62.2 1.70 137.9 2.32 242.2 2.95 374.8 3.58 535.6 4.21 724.5 4.83 941.4

0.46 16.4 1.09 64.1 1.72 140.8 2.34 245.9 2.97 379.4 3.60 541.1 4.23 730.8 4.85 948.6

0.48 17.4 1.11 66.1 1.74 143.6 2.36 249.7 2.99 384.0 3.62 546.6 4.25 737.2 4.87 955.9

0.50 18.5 1.13 68.0 1.76 146.5 2.38 253.5 3.01 388.7 3.64 552.1 4.27 743.6 4.89 963.2

0.52 19.6 1.15 70.1 1.77 149.4 2.40 257.3 3.02 393.4 3.66 557.7 4.28 750.1 4.91 970.5

0.54 20.7 1.17 72.1 1.79 152.4 2.42 261.1 3.05 398.1 3.68 563.3 4.30 756.5 4.93 977.8

0.56 21.9 1.19 74.2 1.81 155.3 2.44 264.9 3.07 402.8 3.70 568.9 4.32 763.0 4.95 985.2

0.58 23.1 1.21 76.3 1.83 158.3 2.46 268.8 3.09 407.6 3.72 574.5 4.34 769.5 4.97 992.6

0.60 24.3 1.23 78.4 1.85 161.3 2.48 272.7 3.11 412.4 3.74 580.2 4.36 776.1 4.99

FINAL CHECK

Before the installation is complete, the Site Controller

computer must be re-connected and the PMU option given a

final operational check.

1. Re-connect the data link cable from the Site Controller

computer to the right-hand VDT Interface connector on

the back of the PMU (cable was temporarily

disconnected for initial power-up and antenna

mapping).

2. Verify that the “PWR” indicator on the front panel of

the PMU stays on continuously.

3. Verify that the three other indicators on the front panel

of the PMU are flashing in a repeating sequence. The

“MUX” indicator should flash once every 250

milliseconds; first by itself, next with the “DATA”

indicator, and then with the “ALARM” indicator.

21

Page 22

LBI-39128 OPERATION

OPERATION

The PMU performs the following operations:

• Monitors the detector output voltages from the

transmitter and antenna power sensors under the

direction of the Site Controller computer.

• Converts the detector output voltages to power and

SWR levels.

• Compares the power and SWR levels to user-

configurable alarm threshold limits.

• Sets the power alarm status for each monitored

transmitter and antenna.

• Reports the power alarm status of each transmitter

and antenna to the Site Controller computer.

The Site Controller computer performs the following

operations:

• Tells the PMU which transmitter channels to

monitor.

• Tells the PMU when each transmitter starts and

stops transmitting.

Manager), it should start sending a poll message to the PMU

once each second (even if the PMU doesn’t reply or isn’t

connected).

As soon as the PMU is operating (power on), it should

start looking for messages from the Site Controller computer

(even if the Site Controller computer isn’t sending a poll

message or isn’t connected). As soon as it receives a poll

message, it should reply with a status message within one

second.

EDACS Configuration Setup

After receiving five consecutive status message

responses (each within one second) to five consecutive poll

messages, the Site Controller computer should send the

EDACS Configuration Setup information to the PMU. This

information consists of which transmitter channel numbers

are PMU enabled, and the low alarm limit for each

transmitter channel number.

After receiving the EDACS Configuration Setup

information, the PMU should be ready to monitor the

transmitter and antenna power sensors under the direction of

the Site Controller computer. The Site Controller computer

should continue to send a poll message to the PMU once

each second, and the PMU should continue to reply with a

status message within one second of each poll message.

• Uses the power alarm status to help determine

which transmitter channels are useable.

• Uses the power alarm status to control the ANT

PWR FAIL and CHN PWR FAIL indicators on the

Alarm and Control Unit (if present in the system).

• Uses the power alarm status to direct Test Calls by

the Test Unit (if present in the system).

• Reports the power alarm status to the System

Manager (if present in the system).

STARTUP

Directions from the Site Controller computer to the

PMU, and reports of power alarm status from the PMU to

the Site Controller computer, are sent over the serial data

link connecting the two.

Polling Recovery

As soon as the Site Controller computer is operating

(power on and initialization complete) and the parameter

that enables the PMU option is enabled (initialized from the

Personality PROMs or re-configured from the System

Polling Failure

If at any time the PMU fails to reply to a poll message

within one second, or the Site Controller computer is

initialized (by reset or power-up), the Site Controller

computer must again receive five consecutive replies and

send the EDACS Configuration Setup information before

the PMU is again ready to monitor the power sensors.

MONITOR

Power Sensor Monitoring

When the PMU is ready to monitor the power sensors,

the Site Controller computer sends a message to the PMU

each time a transmitter is keyed or unkeyed. The message

tells the PMU which transmitters are keyed (transmitting),

and which are not. From the EDACS Configuration Setup