Ericsson ALLEGRA EDACS Maintenance Manual

AE/LZB 119 1645 R1B

Printed in U.S.A.

Maintenance Manual

ALLEGRA - EDACS

®

800 MHz DUPLEX PORTABLE

ericssonz

Ericsson Inc.

Private Radio Systems

Mountain View Road

Lynchburg, Virginia 24502

1-800-528-7711 (Outside USA, 804-528-7711)

NOTICE!

This manual covers Ericsson and General Electric products manufactured and sold by Ericsson Inc.

NOTICE

Repairs to this equipment should be made only by an authorized service technician or in a facility designated by the supplier. Any

repairs, alterations or substitutions of recommended parts made by the user to this equipment not approved by the manufacturer

could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

NOTICE!

The software contained in this device is copyrighted by Ericsson Inc. Unpublished rights are reserved under the copyright

laws of the United States.

This manual is published by Ericsson Inc., without any warranty. Improvements and changes to this manual necessitated by typographical errors, inaccuracies of

current information, or improvements to programs and/or equipment, may be made by Ericsson Inc., at any time and without notice. Such changes will be

incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any means,. Electronic or mechanical,

including photocopying and recording, for any purpose, without the express written permission of Ericsson Inc.

Copyright May 1995, Ericsson Inc.

TABLE OF CONTENTS

Page

SPECIFICATIONS*.........................................................................................................................................................2

DESCRIPTION.................................................................................................................................................................2

RELATED MANUALS ................................................................................................................................2

OPTIONS AND ACCESSORIES ....................................................................................................................................2

PROGRAMMABLE FEATURES ...........................................................................................................................2

OTHER PROGRAMMABLE FEATURES............................................................................................................2

CONTROLS AND INDICATORS ...................................................................................................................................3

OPERATION..................................................... .. .. .. .. .................................... .. .. .. .................................... .. .. .. .. ..................3

CIRCUIT DESCRIPTION................................................................................................................................................3

LOGIC BOARD.......................................................................................................................................................3

Microprocessor..............................................................................................................................................3

Modem ASIC .................................................................................................................................................3

Flash Prom Circuitry.....................................................................................................................................3

I2 C Device Interface ....................................................................................................................................4

Bertram IC Interface......................................................................................................................................4

Synthesizer I nterface.......................................................... ...........................................................................4

ASP Interface.............................................. .................................................. .................................................4

Keyboard Interface........................................................................................................................................4

Battery Power Control Circuits.....................................................................................................................4

Receive Audio ........................... .......... .......... .......... .......... .......... .......... .......... .......... .......... .......... .......... ......4

Transmit Audio ..............................................................................................................................................5

TABLE OF CONTENTS - CONTINUED

Page

RF BOARD ..............................................................................................................................................................5

Power Distribution ........................................................................................................................................5

Transmitter:....................................................................................................................................................5

Tx-Synthesizer:..............................................................................................................................................5

Rx-Synthesizer:.............................................................................................................................................5

Receiver .........................................................................................................................................................6

SERVICE SECTION.........................................................................................................................................................6

CARE OF EQUIPMENT................................................................................................................. ........................6

SERVICE & TROUBLESHOOTING..............................................................................................................................6

LOGIC BOARD TEST PROCEDURE...................................................................................................................6

Test Fixtures: ................................................................................................................. ................................6

Reference Drawings......................................................................................................................................6

Visual Inspection: ..........................................................................................................................................6

POWER-UP:..................................................................................................................................................6

Flash Program Code:.....................................................................................................................................6

Initiate Test Mode: .........................................................................................................................................6

MEMORY TESTS: ...........................................................................................................................................................8

AUDIO TESTS: ................................................................................................................................................................8

DISPLAY TEST: ...............................................................................................................................................................8

KEYBOARD TEST:.........................................................................................................................................................8

ELECTROSTATIC DEVICES .........................................................................................................................................8

DISASSEMBLY AND REASSEMBLY...........................................................................................................................8

Disassembly ................................................................................. ..................................................................8

Reassembly .......................... ..........................................................................................................................8

BATTERY REMOV AL AND INSTALLATION......... ... ... .. .... .. .... .. .... .. .... .. .... .. ... ... .. .... .. .... .. .... .. .... .. .... .. ... ... .. .... .. .... .. .... .9

Standard Battery Removal and Insertion......................................................................................................9

High Capacity Battery Removal and Insertion.............................................................................................9

SMD COMPONENT REMOVAL AND REPLACEMENT...................................................................................9

PROGRAMMING THE RADIO......................................................................................................................................9

SERVICING THE BATTERY....................................................................................................................... .. .................9

PARTS LIST

LOGIC BOARD .......................................................................................................................................................15

RF BOARD ..............................................................................................................................................................16

MISCELLANEOUS PARTS....................................................................................................................................17

PRODUCTION CHANGES.............................................................................................................................................17

IC DATA DIAGRAMS

IC Data, Logic Board ....................................................................................................................................10

IC Data, RF Board.........................................................................................................................................14

ASSEMBLY DIAGRAMS

RADIO ASSEMBLY................................................................................................................................................17

LOGIC BOARD .......................................................................................................................................................18

RF BOARD ..............................................................................................................................................................21

SCHEMATIC DIAGRAMS

LOGIC BOARD .......................................................................................................................................................18

RF BOARD ..............................................................................................................................................................21

REVISION HISTORY

REVISION DATE REASON FOR CHANGE

R1A 5/96 Original issue.

R1B 1/96 Correct parts on Parts List and schematics. Revision Letter changes to RF Board.

AE/LZB 119 1645 R1B

1

DESCRIPTION

This manual contains essential information needed to main-

tain the Ericsson ALLEGRA EDACS

®

800 MHz Duplex Portable radio. Included in this manual is a brief description of the

radio, troubleshooting and alignment information, radio disassembly and reassembly procedures, battery replacement and

disposal procedures, and circuit descriptions.

The ALLEGRA Duplex Portable radio is synthesized, microprocessor based, high performance duplex portable FM radio. Operation in the 800 MHz frequency range this radio

provides reliable two-way radio communications in EDACS

environments. The ALLEGRA EDACS radio is available in two

models: Interconnect only or Interconnect/Dispatch. A wide

variety of options and accessories are available.

Duplex operation is provided in EDACS systems while

operation in the Telephone Interconnect mode. At all other

times, the radio operates in the half-duplex mode, i.e. when

placing group calls in the EDACS environments.

Advanced state- of- the -art technology is used in the design

and manufacture of this synthesized radio to provide the most

in flexibility, capability, and adaptability to various system

configurations. This flexibility allows the user to have the

operation of his radio customized or tailored (by programming)

to satisfy his needs by activating the desired features. The

ALLEGRA is small, compact, lightweight, yet ruggedly constructed to provide reliable service.

RELATED MANUALS

Operator’s Manual........................................ AE/LZT 123 1872

Installation, Vehicle Handsfree .................... AE/LZT 123 1874

User’s Guide, Vehicle Handsfree ................. AE/LZT 123 1873

EDACS II Programming Software...............................TQ3373

Programming Cable............................................RPM 113 1460

OPTIONS AND ACCESSORIES

DYCH5B Rapid Multi-Charger, 120 VAC (for high and

ultra high capacity batteries)

DYCH5D Rapid Travel Charger, 12 Vdc

DYCF1F Power Adapter, 1 2 VDC

DYMC5V Portable Handsfree (includes microphone

and earpiece

DYMN7A Vehicle Handsfree Installation Package

DYPA5Z High Capacity Battery

DYPA7A Ultra High Capacity Battery

PROGRAMMABLE FEATURES

The Allegra is PC programmable, allowing it to be customized or upgraded quickly and easily. All programmable functions are controlled by the microcomputer and are field programmable through a compatible DOS based PC. The microcomputer reads specific information from the EPROM. Refer

to the EDACS Software Programming manual for programming

details.

In addition to the 50 number memory, the ALLEGRA duplex

portable radio allows several time-out options to accommodate

user needs.

User programmable features include:

• 50 number memory

• Carrier Control Timer - A single value can be se-

lected that applies to all trunked operation.

• Voice Scan Lockout Timer - Provides a time limit

that disables group scanning following initiation of a

voice call.

• Special Call Time Out - Drops the radio out of spe-

cial call mode after a specified period of operator inactivity.

• Individual/Interconnect Call time-out - A time-out

that drops the radio out of an individual/interconnect

call after a specified period of time.

OTHER PROGRAMMABLE FEATURES

• Flex Keys - Any one of these three keys (A, B, or C)

can be programmed to function as the emergency

button.

• Automatic Login - Supported for EDACS Systems

• Wide Area Scan - Supports wide area roaming.

When scanning, there is a programmable time interval that determines when the radio starts scanning

the next site.

• Supervisory Mode - Allows the radio to handle all

normal supervisory functions.

• Programmable Audio/Display - This programmable

option handles display and audio during emergency

situations. The display can be programmed to hold

the display unchanged until PTT is pressed or the

emergency is cleared. The audio option similarly ,

SPECIFICATIONS*

SYSTEM

FCC Identification Number AXATR-331-A2

Frequency Range 800 MHz

Channel Spacing 25 kHz

Batteries Rechargeable Nickel-cadmium battery, 6.5 Volts

nominal; high capacity DYPA5Z or ultra high

capacity DYPA7A

Current Drain (maximum)

Receive 120 ma

Standby 105 ma

Transmit 750 ma (high power)

ENVIRONMENTAL

Temperature Range -25° C to +50° C (-13° F to -58° F)

Relative Humidity 0% at 40° C non-condensing

PHYSICAL

Dimensions

Radio 6”H x 2.75”W x 1.25”D

Weight

Radio (includes high capacity battery) 11.7 ounces

TRANSMITTER

Output Power - High 0.75 Watts

Low 0.4 Watts

Frequency Stability 1.5 PPM

FM Hum and Noise -37 dB

Audio Distortion Less than 5%

Deviation

HSD 3.25 kHz

LSD 1.00 kHz

DTMF 3.50 kHz

Limit 4.70 kHz

Microphone Sensitivity 317.5 V ol ts

RECEIVER

Sensitivity

12 dB SINAD (Simplex Radio)** -115 dBm

20 dB (Duplex Radio) -114 dBm

Squelch 9.5 dB SINAD

Audio Power Output 1.0 Volts rms

Audio Distortion Less than 5%

** Interconnect/Dispatch Models Only

* These specifications are intended primarily for use by the service technician during servicing. Refer to the appropriate

Specification Sheet for complete specifications.

AE/LZB 119 1645 R1B

2

causes the radio to remain muted until PTT is

pressed or the emergency is cleared.

• Priority System Scan - Allows the ALLEGRA Du-

plex Portable to search for a second operating system while locked onto the c control channel of the

selected system. The scan frequency is programmable.

• TX Disable Group - Prevents keying the radio on a

selected group (monitor operation only)/

• RX Disable Group - Prevents unmuting a radio on a

selected group.

• Control Channel Limits - Provides limited scanning

of a frequency set for a control channel.

CONTROLS AND INDICAT ORS

The 20 button keypad, and internal speaker and a liquid

crystal display (LCD) are located on the front of the radio.

Viewed from the front, a PTT (push-to-talk) button is located

on the left side adjacent to the display. (Interconnect/Dispatch

models only). The microphone is on the lower left and the

earpiece on the top center. The fold-up antenna is on the top

right side.

The keypad is used for manual number entry, access to a

telephone interconnect system and activation of various

EDACS features. The keypad is divided into a function portion

and a numeric portion as is found on a basic touch-tone telephone.

The display has an eight alphanumeric character line (upper

line) used to show the operational mode of the radio and has a

numeric character line (middle line) used to show talk time.

Eight status indicators, used to indicate various operating conditions, such as; function key pressed, transmitter on, service

available, radio in use, horn alert active, radio locked or transmit

muted, are located below the character lines within the display.

The Allegra Duplex radio also generates a unique set of alert

tones to indicate the operating status of the radio when used in

EDACS applications. The alert tones are defined in the operator’s manual.

Figure 1 identifies the location of all controls and status

indicators.

OPERATION

The radio is powered ON by pressing and holding the

O

button. All status indicators turn on momentarily and after 2

seconds a short beep will be heard and a message “---ON---”

will be displayed on the LCD. A self diagnostic test is performed

when the radio is first turned on if enabled through programming. In the Interconnect Only Model, the display will then

display “CC SCAN“ if looking for the contact channel or

“READY“ when the control channel has been found and a call

request can be placed. To turn the radio

OFF,

press and hold

the

O

button again. After 2 seconds a short beep will be heard

and a message “TURN OFF” will be displayed on the LCD.

When turned off, the radio retains the last user selections (unless

programmed for a particular power up option). Additionally, the

O

key is used to terminate interconnect and individual calls.

Refer to EN/LZT 123 1872 for detailed operating proce-

dures.

CIRCUIT DESCRIPTION

LOGIC BOARD

The logic board, through the use of a microprocessor,

controls the operation of the radio. The keyboard accepts user

inputs and forwards this information on to the microprocessor. The microprocessor executes the user selected functions

and then displays related user information on the LED to

facilitate operation.

Microprocessor

The control center for operations on the logic board is the

Intel 80C51GB microprocessor, D701. The microprocessor

is connected by a parallel bus to a 128K x 8 flash prom (D703)

for operational software, a 32K x 8 RAM (D707) for temporary data storage, and an Ericsson ASIC modem chip (D702).

It controls the Audio Signal Processor (ASP) (D601), a

DTMF generator, the LCD display, and the personality

EEPROMS by way of serial lines. The microprocessor has

five single bit I/O ports for controlling the synthesizer, keypad, and audio functions not provided in the ASP’s registers.

There is an A/D port on the microprocessor which is used to

make battery voltage and RSSI (Receive Signal Strength

Indicator) measurements and also as input lines for the keyboard. The microprocessor’s async serial port is used to

provide a path into the radio for personality programming,

flash programming and test. The async serial port is available

at the UDC connector of the radio at a 5 volt level. These

levels must be converted to RS232 levels by an external

device, such as a TQ3370, before being connected to a computer.

Modem ASIC

The modem ASIC, D702, executes a variety of housekeeping chores in addition to its data function. It also controls

the ALE Latch function of separating the lower address byte

from the microprocessor’s multiplexed data and address

lines. The demultiplexed lower address byte is used by the

ram and flash prom.

The power-up reset pulse from the LM2951 5V (N805)

regulator and level inverter N712/1 pin 3 comes into the

modem on RESIN (33). It is OR’ed with the output of an

internal watchdog timer circuit before being outputted on

RESOUT (43). This line is then inverted by N712-4 before

being used as the system reset line. The watchdog waits about

two seconds before resetting the system.

The system clock is generated from an 11.059 MHz

crystal (B701) by an oscillator circuit in the modem chip. The

buffered output of this oscillator (Clk1) provides the master

clock to the microprocessor and the ASP chip. The modem

chip also divides the 11.059 MHz frequency down to 614 kHz

at CLK2. This line is used to generate the floating voltage

required by the LCD display. It is also used as a clock for the

busy tone notch filter and the clock into the Bertram ASIC on

the RF board. Transistor V701 is used to add another capacitor to the crystal circuit to move its frequency slightly to avoid

micro spurs. V701 is controlled by open collector switch SW3

of the ASP IC.

The timing for the data modem part of the ASIC is also

derived from the chip’s oscillator. The modem consists of a

digital phase locked loop (PLL), receive data detector, an

eight bit shift register for transmit, and a sync word detector.

It will also generate an interrupt to the microprocessor. The

register bit that resets the watchdog is also located in one of

the data modem registers.

Device address decoding is accomplished by a simulated

74HC138 within the modem ASIC. Addresses A15, A14, and

A13 are brought into the ‘C,’ ‘B’, and ‘A’ inputs of the

“HC138” to divide the data space into 8K segments. The

lower two spaces, Q0 and Q1, are AND’ed with gate U710-3

and used to select the lowest 16K of the microprocessor

address space and the upper 16K of the 32K x 8 ram.. (Note

that A14 of the ram is pulled to 5V, forcing the chip to

selection the upper 16K. Q3 selects the data modem registers

of the modem chip. The 32K combined decode of Q4 through

Q7 is not used. The HC138 is enabled on its “G2B” input by

P5.6 of the microprocessor. This allows the microprocessor

to remove the ram and data modem from the address space

during flash prom programming.

Flash Prom Circuitry

The flash prom containing the radio’s operating software

(D703) is an Intel 28F001 128K x 8 byte memory. The block

feature of this device is not used. The VPP flash voltage

connects to both VPP (9) and PD (6). The 128K byte memory

is segmented into 64K banks by connecting P5.7 of the

microprocessor to A16. The micro’s PSEN enable is connected directly to the prom’s output enable for read operations. PSEN is AND’ed with the micro’s P5.6 flash write

enable line to form the prom’s chip select. In normal operation, the device is only selected when PSEN is low. During

flash programming, the prom is always selected.

Flash programming requires the use of software inside the

microprocessor. Normally, the VPP flash voltage is not connected to any source. For flash programming, it is connected

to a +12V supply at the UDC connector. This voltage is

divided down to provide a 5V level to the processor’s EA pin.

This sets the processor into a mode where the lower 16K of

the address space is internal to the microprocessor. This space

contains the software to address the flash prom, read and write

Figure 1. Allegra Controls and Indicators

AE/LZB 119 1645 R1B

3

a packaged protocol from the microprocessor’s serial port,

keep the watchdog occupied, and implement the prom manufacturer’s programming algorithm.

Normally, the radio is flashed through a TQ3370 interface

device. This TQ3370 contains circuitry to convert the battery

output of the radio to 12 volts. The radio should be power

cycled when being flashed so that the microprocessor is reset

with the VPP supply on. This will allow it to begin running

with EA high and to execute code from its internal memory.

Note, there is no solid mechanism for causing a reset when

VPP is applied. However, there is an implied mechanism in

that when one applies VPP , one changes the system’ s memory

map. This will probably crash the operating software. The

modem’s watchdog may then fire and the microprocessor

should come up with its internal program running.

For flashing, the prom is broken down into four 32K

banks. This is so the prom can “appear” to be in the upper

32K of the microprocessor’s data space. A16, controlled from

P5-7 of the microprocessor, handles half of this task just as it

does in normal operation. A15 is AND’ed with the P3.5 of the

microprocessor. In this way , it is poss ibl e to phys ical ly write

prom address 0000H while it appears to be at address 8000H

to the microprocessor. The write line into the flash is also

AND’ed with P5.6, the flash write enable line. This provides

some protection against inadvertent writes into the flash and

also keeps the write line off of the prom during normal

operation. The flash write enable line also removes the ram

and modem registers from the data space by disabling the

address decoder circuitry inside the modem ASIC.

I2C Device Interface

The microprocessor runs several sets of serial devices

through its data I/O lines. One set of lines forms an I

2

C bus.

This is a standard arrangement involving a bi-directional data

line and a microprocessor generated clock line. The data line

is called ‘DATA, K-R3 and is on P1.2 of the microprocessor.

Note it is multiplexed with row three of the keyboard and the

data lines of the synthesizers. The clock line is called IICCLK and is generated by P4.4 of the microprocessor. There

are three 24164 serial EEPROMS (D801-D803), a DTMF

generator D804, and the LCD display (N806) on the I

2

C

lines.

The serial EEPROMS are 2K x 8 devices. There is an

address field in the I

2

C data stream. The 24164 device is

easily paralleled with other I

2

C devices by setting its three

hard-wired upper address lines. Their flexibility is also useful

for working around the less adaptable DTMF generator and

LCD display. The EEPROMS are used to store personality

data.

The DTMF generator runs off of a color burst crystal

(B801). It can generate any of the sixteen tone combinations

under control of the microprocessor. It also has power saving

and spur reducing functions that cut off the oscillator. DTMF

tone out of the IC goes into the external microphone input of

the ASP ASIC.

The LCD display is another I

2

C device. It can be considered as a six pin connector on the board. One line is ground

and two are the I

2

C clock and data lines. The display also

requires a 5V supply and a high value resistor to ground for

its oscillator circuit. The VLCD line provides a variable

voltage for contrast. It is generated by rectifying the 614 kHz

clock to develop a floating voltage. It is then run through a

simple transistor regulator with a thermistor in the reference

setting voltage divider. The voltage at the pin varies from -0.5

to +0.5 volts, referenced to ground depending on temperature.

Low temperatures will generate negative voltages.

Bertram IC Interface

Another set of serial control lines is used to talk to the

Bertram chip on the RF board. Bertram requires four lines,

called CLOCK, LATCH, DFO, and DTO. The CLOCK line

is generated from the modem’s 614.4 kHz line. It is gated on

and off under control of ‘CLK-SEL, bit P4.6 of the microprocessor. The clock line is also capable of being read by the

SEP-CLK(P4.0) line of the microprocessor. The LATCH line

is generated by bit BERT-LE (P4.5) of the microprocessor.

Data from Bertram comes in on the SEP-DAT (P4.1) line of

the microprocessor. It is also AND’ed with the data to Bertram by an AND gate. This is because Bertram expects a

closed loop circular serial bus. Data to Bertram comes from

the DI-EW, K-R2 on P1.1 of the microprocessor. Note, it is

multiplexed with row two of the keyboard. The complex

timing of these lines is accomplished under software control

by the microprocessor.

Bertram is used to provide divider information to the

synthesizers and return lock status. The chip also generates a

TTL level CAS signal when the received signal strength is

above a threshold value. This is called RXCD at the J101 RF

board to logic board connector and RSSI or microprocessor

A/D bit ACH5 on the logic board.

Synthesizer Interface

Four microprocessor bit ports are used to load and control

the synthesizers on the RF board. They form a serial bus

consisting of a data, clock and latch line. They are DATA,

K-R3, CLK, K-R1, LTX, and LRX. The synthesizer data line

is DAT A, K-R3 from microprocessor port P1.2. It goes to both

synthesizers. The synthesizer clock line, CLK, K-R1 comes

from microprocessor port P1.0 and is also used for both

synthesizers. The latch lines are separate for each synthesizer.

The latch line for the receive side is LRX (P5.4). The latch

line for the transmit side is LTX (P5.3). The timing of these

signals is under control of the microprocessor’s software.

ASP Interface

The microprocessor receives and sends information to the

ASP ASIC over a three wire serial bus. The information consists

of a data, clock, and enable line. DATA, K-R3 (P1.2) is used

once more as the data line. CLK, K-R1 (P1.0) is used as the

clock and is also multiplexed with the synthesizer and keyboard.

The enable line is unique to the ASP. It comes from P4.7

(ASP-EN) on the microprocessor. The master clock for the ASP

is the buffered 11.059 MHz (ASP-CKIO) clock out of the

modem ASIC. The ASP is discussed in more detail in the audio

section.

Keyboard Interface

The Allegra radio uses a software scanned keyboard consisting of 20 keys in a five row by four column matrix. It is not an

actual keyboard. Instead, it consists of interweaved gold plated

runs of signal and ground on the logic board that get shorted

together by conductive pads on the front panel’s rubber keypad.

The keyboard is scanned by pulling down the row lines one at

a time and reading the column inputs. The rows are output on

the lower five bits of port 1 of the microprocessor. The columns

are read as digital inputs on the lower four bits of the microprocessor’s A/D port.

The first three row lines are multiplexed with other functions. Each row control pin (except for row 5) pulls the keyboard

row low through the associated diode. This prevents a user who

is using the keyboard from corrupting the multiplexed functions. There are also two keys that are direct inputs to the

microprocessor. The first is the PTT switch. It is connected to

microprocessor port P3.2. The second is ON/END. It is connected to microprocessor A/D port ACH4. This switch is also

connected to the radio’s power switch circuitry. The PTT and

ON/END switch also exit the radio through the UDC connector.

The radio’s LCD display and keypad are backlit by 12

LED’s. The display consists of six paralleled lines of two LED’s

in series. The bottom of these lines is pulled to ground by two

transistors to distribute the power dissipation. These transistors

are controlled by microprocessor port P5.5 through a PNP buffer

transistor.

Battery Power Control Circuits

Power is supplied by the battery and applied to the radio

through power FET (field effect transistor) V801. The FET is

controlled by P-HOLD (ASP switch SW4) or from the keyboard’s ON/END switch. When the radio is “off”, no power is

applied to the system, thus keeping P-HOLD open and V806

off. When ON/END is not pressed, it is open. This keeps PNP

transistor V803 off which in turn keeps NPN transistor V805

off. Transistor V805 actually controls the power FET’s gate.

Pressing the ON/END key brings the line low turning on V803.

V803 then turns on V805 which then turns on power FET V801.

The system will power up. This includes turning on the 5V

regulator and generating a reset pulse for the system.

When the radio is “on”, pressing the ON/END key long

enough will tell the radio to turn itself off. It does this by clearing

P-Hold, which then turns off V806. When the ON/END key is

released, V803 turns off which turns off V805. V805 will then

turn off power FET V804, cutting off power to the radio.

Three other circuits relate to the battery. First, the battery

voltage is divided by 2 and applied to the BATT-TEST input on

the microprocessor’s A/D (ACH7). Second, microprocessor

port BATT-LED (P3.4) is used to control the LED at the top of

the radio. It is used when the microprocessor detects low battery

voltage. Third, microprocessor port P5.2 (SWDIS) is used to

control the SWDC 5V at the UDC connector through a PNP

transistor.

Receive Audio

The 450 kHz IF is brought in from the RF board and applied

to the logic board. It is then fed into a phase lock loop discriminator (N603). The difference in frequency between the incoming signal and an internal VCO produces an error voltage that

corresponds to the transmitter’s modulation. The VCO is set to

900 kHz by R603 and C605. There is an internal divide by two

circuit within the IC. The audio output is then passed through

an emitter follower (V601) to the ASP ASIC at pin 50 of the

DISC for squelch and the A1-IN (pin 44) input for the data and

receive audio circuits.

The ASP chip includes two op amp bias supplies: One for

receive functions and one for transmit functions. The inputs for

the supplies originate internally from the chip for bypass capacitors. The input for the Rx bias voltage is pin 39 and the output

is pin 40. For the Tx bias, the input is on pin 64 and the output

is on pin 63. There is also a 1 uF bypass capacitor on the Rx

supply output and a 2.2 uF on the Tx output. The 3V bias

generator of the ASP is not used.

The ASP chip controls the squelch function. Discriminator

audio is received on DISC pin 50 as DISC. It is passed through

a high pass filter to remove voice frequency components and

The microprocessor is capable of reading the ON/END key

directly. It will heavily debounce the key to prevent accidental key presses. Then it will set P-HOLD which will turn on

V806, keeping V805 turned on. The radio will then remain

“on” after the ON/END key is released.

NOTE

AE/LZB 119 1645 R1B

4

then rectified. This voltage is compared with a voltage supplied

under software control, D/A. on the ASP’s. The output of this

comparator is passed to the microprocessor on the ASP CAS

(ACH.6) A/D input line. It is then used in conjunction with the

tracking data to determine if a signal is present. The response

time of the circuit is controlled by external capacitor C640 in

fast squelch mode with C641 being paralleled by ASP switch

SW2 (Pin 16) for the slow squelch function. An external resistor

network including thermistor R642 is used to track out temperature variations. The resistor network interfaces with pins 53-55

of the ASP’s “A” op amp. Squelch hysteresis is assumed to be

a software function.

Demodulated audio also enters the ASP chip RAFI (Pin 44).

It passes through a gain stage and then through a 300 to 3000

Hz bandpass filter before exiting the ASP as HP10 on Pin 45.

Software switches provide for bypassing the bandpass filter.

This is desirable when looking for high speed (9600 baud) data.

In this case, the output HP10, is applied to limiter comparator

NRI (Pin 31) against a 1 uF averaging capacitor at pin 32.

Something wrong in here. ASP switch SW5 (Pin 13) is used to

block the output of the busy tone filter when looking for high

speed data. The output of this comparator is called LOSC (Pin

21). It is buffered by transistor buffer V606 and applied to the

data input of the modem ASIC and the ASP-LDSC (P4.2) input

of the microprocessor.

The notched audio returns to the ASP on pin 28, VGAF. It

then goes into a switch array. This array decides which device

to connect to the speaker. The choices are the unnotched output

of the bandpass filter, the audio from the notch filter, an ASP

generated alert tone, or the output of the DTMF generator as a

side tone. Two external resistors allow adjustment of the alert

tone level. The DTMF input is on pin 29, DTMF.

The de-emphasis network is after the switch. It can also be

switched in and out. The volume control is after the de-emphasis

network. It allows 32 levels of volume under software control.

The digital volume control allows for separate levels for normal

operation and operation in a vehicular charger. The audio passes

through one more mute switch before leaving the ASP on pin

27, RXAF. From here, the audio goes to the expander portion

of a NE578D compander IC, D605. This IC attempts track out

large swings in the volume level to provide a constant level into

op amp N604, which is used as a driver for the earpiece audio.

The compandor function can be defeated by ASP switch SW0

(pin 18). Earpiece audio also goes out the UDC connector as

EXT-SPKR.

The audio input at RAFI (pin 44) can also be connected to

a 210 Hz low pass filter. This strips voice information off to

leave Channel Guard or low speed data information. This information exits the ASP on pin 37, CGO, and passed through

limiter comparator C3 with a 10 uF averaging capacitor, C660.

The data input is on pin 35. The averaging input is on pin 34.

The output of the comparator, LCGO (pin 22) is applied to

microprocessor pin ASP-LCG (P4.3). The low speed data decode or Channel Guard detection is accomplished in software.

The logic board contains a buzzer, H803, which is used to

provide an audible alerting signal. This is accomplished under

software control by toggling microprocessor port BUZZER

(P1.7) on and off at the desired frequency. The port pin, D70129, drives transistor V802 which, in turn, switches the 5v supply

on and off through a 10 ohm resistor.

Transmit Audio

Audio from the internal mic is received by the ASP ASIC on

pin 74, IMIC. Audio from the UDC connector is received by the

ASP ASIC on pin 75, TTON. Both mic inputs provide a bias

voltage from the ASP generated TX BIAS supply. The mic

inputs are then fed to a switch. A third input into this switch is

the DTMF encoder chip on the EMIC (73) pin. (There is a 20

dB pad between the DTMF IC and the ASP input.) After the

switch, the audio passes through a software selectable gain

stage. It then passes through the pre-emphasis filter and then a

300 Hz high pass circuit to keep voice from conflicting with

Channel Guard or low speed data. From there, the audio leaves

the ASP on pin 70, TONE and applied to the compressor side of

the NE578D compandor, D605. The compressor provides an

AGC function to hold the mic audio more constant. From the

compressor, the audio is returned to the ASP on pin 57, TIN. It

passes through a limiter circuit and summed with the data and

tone components of the Tx modulation at a common summation

junction.

High speed data from the modem ASIC is received by the

ASP on D601-80 as IDAT. It passes through a data filter before

being combined with the Tx audio at the common summing

junction. It is possible to bypass the data filter.

Channel Guard and low speed data are generated at digital

levels by the microprocessor on walsh bit outputs WB1 (P5.0)

and WB2 (P5.1). The walsh bits are combined in a resistor

network to act as a two bit D/A. For tone generation, a sine wave

is approximated in six steps to create a more easily filtered

signal. The combined walsh bits enter the ASP at pin 38, TOIN,

for Channel Guard and low speed data.

The DTIN input to the ASP, D601, connects directly to the

common summing junction through a switch. Its audio frequency tones are sufficiently filtered by the post limiter filter i n

the ASIC. The low frequency TIN is passed through the 210 Hz

low pass filter to filter out the waveform. This is required since

higher level harmonics tend to significantly degrade hum and

noise. Note, this is the same filter that is used on the receive

side. The filtered signal exits the ASP on pin 37, CGO. It then

goes to ASP D601-58, CGIN, and into C3, limiter comparator.

CGIN is connected directly to the common summing junction

by a switch.

A 3000 Hz low pass post limiter filter follows the common

summing junction. (This filter can be bypassed when sending

high speed data.) Following the filter is a 32 position deviation control. The output of this attenuator is passed through a

switch before exiting the ASP on pin 60, TXAU. It then passes

through a resistor network before going to the modulation

circuits on the RF board.

RF BOARD

Refer to schematic diagram 188D6251. Each sheet of the

drawing contains a major board function. These functions and

locations are listed below:

• Sheet 1 RF board control and block diagram.

• Sheet 2 Transmitter

• Sheet 3 Transmit synthesizer

• Sheet 4 Receiver synthesizer

• Sheet 5 Receiver

Power Distribution

DC power is supplied to the radio by a NiCd battery At

full charge the battery delivers 7.2 volts to the radio. If the

output voltage falls to is less than 5.3 volts, the Audio/logic

board turns the radio off.

DC voltage from the GEL Cell battery pack is applied to

the RF board through J103.1, 2 and fuse F101. Test points

TP168 and TP108 allow you to monitor the battery voltage

on either side of the fuse. Unregulated, unswitched voltage

only is applied to the transmitter power amplifiers U200,

Q200, and to the Audio/logic board through J101.8. Battery

voltage is connected to accessory connector X201 and to 5

volt regulator and switching circuitry consisting of V804,

MBT3904 and MBT3906. This switching circuitry generates

SWDC (switched 5 Vdc) which is returned to the RF board

on J101.1 as SWDC. SWDC is applied to Power Regulator

U161, Bertram RF Controller (U101-3) as VBAT and pin 1

as STARTUP, and to DC control Transistor Q131. Control

transistor Q131 supplies SWDC to 5 volt regulator D100. The

output of the regulator is distributed as VREG to the receiver,

TCXO, Bertram U101-5 (TP131) and pins 16 and 37 through

respective voltage dividers, and to MOSFETS Q511 and

Q531.

VRX is originated by U161 and applied to receiver synthesizer U400, RXVCO U410 and driver U430 and to pass

transistors Q161 and Q162. The pass transistors are controlled by the Bertram RF Controller and supply voltages VTX1

(TP162) and VTX2 (TP164) to the transmitter circuitry:

U200, U300, TXVCO U310, and MOSFET driver Q330.

C116 provides low frequency filtering while capacitors

C101 through C115 decouple any noise transients that may

be present on the control lines to the Bertram Radio Interface

Controller. TP109 allows the technician to monitor the POWDET line.

Transmitter:

The transmitter contains preamp Q200 and power amp

U200, with a broadband 815 MHz filter feeding the antenna

connection. The transmitter PA delivers 0.75 watts (0.4 watts

on low power) to the antenna.

Bertram Radio Interface Controller U101 receives instructions form the Audio/Logic board via serial data link,

J101.11, identified as “DFO”. Information is returned to the

Audio/Logic board through J101 -13 and is identified as

“DTO”. Both DFO and DTO are clocked by J101.12 (C1008).

Transmit on-off switching is controlled by Bertram Radio

Interface Controller using two switching circuits. Bertram

output, Dout4 (U101-20), controls voltage switching transistor Q161 (TP162). Q161 switches power on/off to transmitter

PA U200, transmit synthesizer U300, RF power sense D240,

RF amplifier Q200, and buffer Q330. TXON control from the

Bertram (DOUT1, U101-41) controls transmit on-off switch

Q201. Q201 switches amplifier Q200 on and off as required

by the current status of the radio.

Transmitter output power is regulated to its high or low

tracking data setting (see Audio/logic board) by sensing

(transformer W202/W203) and detecting (D240, C241) final

power (Bert op amp #1 pin 38, 39, and 40) relative to the DAC

setting (Bert output pin 35) obtained by Bertram from the

Audio/Logic board.

Tx-Synthesizer:

The channel frequency is set by loading transmit synthesizer chip U320 from the Audio/Logic board via J101.5 and

J101.6, “Syntcl” and “Syntdata”. The synthesizer chip sets

the channel center frequency through its fN pin U320-10 and

monitors/locks the frequency by “listening” to the VCO output via C312. Audio signals from the audio/logic (J101.7

“Mod”) varies the VCO (U310) frequency according to the

audio amplitude set on the Audio/Logic board. Transmit

synthesizer chip voltage is switched on-off in the same fashion as the transmitter power out, by Bertram ‘Dout3’, via

voltage switching transistor Q162. The switched voltage is

designated as VTX2. Q330 is used to buffer the VCO out, and

feeds the transmitter pre-amp. Power to buffer Q330 is

brought in from VTX1 under control of Bertram ‘Dout4’.

AE/LZB 119 1645 R1B

5

Rx-Synthesizer:

The receive channel frequency is set in the same manner

as the transmit channel frequency, except its components, the

Synthesizer chip (U420), the buffer (U430), and the VCO

(U410), get power from VRX. VRX is controlled from the

Audio/Logic board (J101.1 “SWDC”) through power control

chip U161.

Receiver

The antenna input feeds broadband filter FL501 which, in

turn, feeds input buffer/amp Q511. “The output of buffer/amp

Q511 is then filtered by FL521. The 1st IF frequency is

provided by mixer Q531. Q531 combines the Rx Synthesizer

output with the antenna signals to generate the 1st. IF frequency. The output of the 1st mixer is coupled to the input of

77.25 MHz SAW filter FL541 through a parallel resonant tank

consisting of L531, C538, and C539. The IF filter FL541

passes only the tuned channel frequency at 77.25 MHz. This

first IF is down converted to 450 kHz (into Bert) 2nd mixer

U501. The output of the mixer U501-14 is routed to pin 15 of

the Bertram Radio Controller and to the Audio/Logic board

through J101.15 (TP115).

SERVICE SECTION

The Service Section contains information designed to

assist you in the proper care and maintenance of your radio

and to insure optimum performance. Alignment of the radio

consists of performing the tracking procedures included in

this section. Various dis play indicators and tones provide the

current operating status of the radio.

CARE OF EQUIPMENT

1. Keep the exterior of the radio clean. Use a soft damp

cloth.

2. To ensure efficient power transfer from the battery

to the radio, wipe the contacts of the battery and

radio to remove dirt or grease; Use a soft dry cloth.

3. When the accessories connector is not in use, cover

the connector with the protective dust cap to prevent

he build up of dust or water particles.

SERVICE & TROUBLESHOOTING

Troubleshooting the radio in the field consists of board

substitution using boards taken from a radio that has been

proven to operate in accordance with manufacturers specifications. Service and tracking procedures are provided for

reference only. Successful completion of these procedures

assure the radio will perform in accordance with the manufacturers specifications.

LOGIC BOARD TEST PROCEDURE

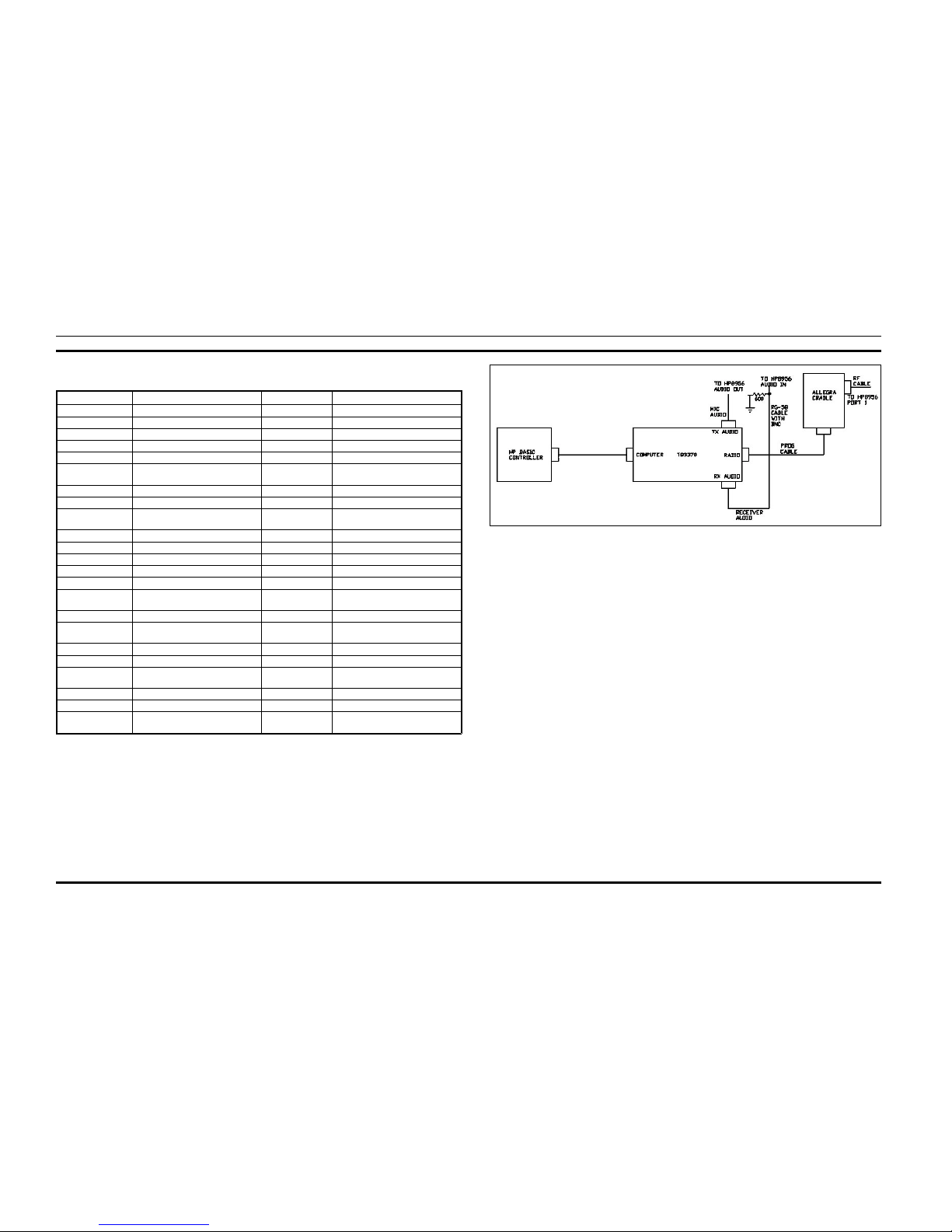

Test Fixtures:

The logic board is tested using a TQ3370 interface box

and interface cable to connect the logic board to a DOS based

computer. The cable between the TQ3370 box and the logic

board is shown in Table 1. The cable connects to X201 of the

logic board. The logic board is powered from a 7.0 volt supply

through the TQ3370 interface box.Figure 2 shows a test setup

diagram to test the logic board.

Reference Drawings

344A4736 .............................Flash Programming Specification

350A1225 ...........................................Personality Specification

CXC 112 874.................... Dispatch and Interconnect Software

CXC 112 873.................................Interconnect Only Software

Test mode software allows access to most radio functions.

It consists of binary commands with appropriate parameters.

The logic board responds to a command by executing the

requested action, returning any appropriate data: a completion

code of 01h if “successful” and 02h if “failed”, and a ““ to

indicate it is ready for the next command. Table 2 is a list of test

functions.

Visual Inspection:

Carefully inspect the solder connections to the pins on X101

(Connector to RF board), D6 01 (ASP Chip), D703 (Flash

Prom), and D707 (Ram). These are fine pitched parts. The use

of a microscope is recommended.

POWER-UP:

1. Verify DTR on the computer is in its positive voltage

state.

2. Verify the power supply is off.

3. Connect the Logic Board under test to the TQ3370

Interface Box.

4. Apply 7.5 volts to the TQ3370 Interface Box. Note,

there are two diode drops in the TQ3370 box between

the power supply and the logic board. The TQ3370 box

will use about 50 Ma of current. Current from the

supply must be under 150 Ma

Flash Program Code:

Flash the current version Allegra operating software into the

logic board with the current ‘FLASH.EXE program. Successfully flashing the radio verifies that most of the logic circuitry

is operating properly. The flash programming protocol for the

Allegra Portable is:

Interconnect w/Dispatch: CXC 112 874 (Identified by the

presence of a PTT switch on the side.)

Interconnect Only: CXC 112 873 (No PTT switch)

Initiate Test Mode:

1. Power cycle the radio.

2. Put a “break” condition on the serial port for about one

second. The logic board will respond with an ASCII

“>“ (3eh).

3. Send an ASCII “GE” (47h 45h) to the logic board. This

puts it in programming mode. The logic board will

show the software revision on the display and will

respond with six bytes (plus a “>“) per the personality

programming specification.

4. Send an ASCII “GF” (47h 46h) to the logic board. This

places the radio in test mode. The logic board will

respond with an ASCII “>“ (3eh).

Do not carry the radio by the antenna. Do not use

chemical cleaners, spray or petroleum based p roducts.

They may damage the radio housi ng .

CAUTION

Field repair is limited to removal and replacement of

the RF or Logic Board and case assembly parts such as

PTT switch, covers, antenna, keypad, etc. If more intense servicing is required, return the radio to your local

Ericsson Dealer for factory repairs.

NOTE

Radio Pin

Number

TQ3370 Pin Number Description

1 16 External Mic

2 Service - 1

3 Unmute

4 1, 2, 3, 4, 13 Ground

5 14 External Speaker

6 Service - 2

7 9, 25 Service - 3

8

9 12 Rxd (TQ3370 to

Logic Board)

10 11 Txd (Logic Board

to TQ3370)

11 17 ON/END

12 SW 5V

13 6, 8, 18, 20 Vbatt (Power To

Logic Board)

14 15 Ptt Switch

15 5 12V Flash Voltage

16 1, 2, 3, 4, 13 Ground

Table 1. Logic Board to TQ3370 Interface Cable

AE/LZB 119 1645 R1B

6

Test Mode Code Function Test Mode Code Function

(01) Select Channel (19) Enable/Disable The Busy Tone Filter

(02) Select Frequency (1A) Enable/Disable The Busy Tone Filter

(03) T oggle Transmitter On/Off (1B) Initialize The Asp To A Known State

(04) T oggle Receive Audio On/Off (1C) Generate Standard/Alternate Busy Tone

(06) Toggle High Speed Data On/Off (1E) Manipulate The Synth Bandwidth

(07) Toggle Low Speed Data On/Off (1F) Manipulate MDR/MDX Specific

Parameters

(08) Report Receiver Carrier Sense (20) Read Tracking Data

(09) Generate Alert T one (21) Write Tracking Data

(0A) Write External Ram (22) Set D/A And Read Output Bit Of

Squelch

(0B) Read External Ram (23) Set Tx Deviation

(0C) Report Software Checksum (24) Set Volume

(0D) Conduct Modem Loopback Test (25) Set Tx Output Power Value

(0E) Report K ey Press/Releases (26) Xram Test

(0F) Write 1 Audio ASIC Registers (27) Set Bertram Chip On/Off

(10) Write All Audio ASIC Registers (28) Write 1 Audio ASIC Registers With Bit

Mask

(11) Report Audio ASIC Registers (29) Test Of Rx And Tx Synthesizer Lock

(12) Do A Dacs Control Channel

Transmission

(2A) Test Of Personality EEPROM

(13) Return To Programming Mode (2B) Report Battery Sense A/D Value

(14) Generate DTMF Tone (2C) Receive Audio Motorboating Test

(15) Transmit Digital Data (2D) Toggle All LCD Segments And LED’s

On And Off

(16) Receive Digital Data (2E) Report Current Keypad Condition

(17) Detect A Tone (2F) Toggle Buzzer On/Off

(18) Generate/Decode Digital Channel

Guard

(30) Bertram Reference Voltage Trimming

Table 2. Test Mode Functions

Figure 2. Logic Board Test Setup Diagram

AE/LZB 119 1645 R1B

7

MEMORY TESTS:

1. Run the Xram test by sending a 26h command to the

logic board. If successful, the logic board will respond

with a 01 3e.

2. Program default tracking data with the 21h test command. The format is:

21h

addr

data

where the tracking data address is listed below in Table

3. The logic board will respond with a 01 3e if the

command was successful.

3. Verify the tracking data with the 20h test command.

The format is:

20h

addr

where addr is the same as the programming tracking

data test command 21h. The logic board will respond

with the requested tracking data value and a 01 3e.

4. Send a 13h test mode command to get back into

programming mode.

5. Program a default personality with the current PC

Programming program.

6. Send an ASCII “GF” (47h 46h) command to get the

radio back into the test mode.

AUDIO TESTS:

1. Test DTMF by sending the following sequence to the

logic board:

1b Initialize asp

04 01 Turn on the speaker

24 3f Set max volume

14 0e Generate 1477 Hz

2. Measure at least 1 Vrms at X201 Pin 1.

3. Measure 1477 Hz +/- 5 Hz at X201 Pin 1.

4. Measure distortion at X201 Pin 1. It should be less than

5%.

5. Disable DTMF generation

6. Test the alert tone by sending the following sequence

to the logic board:

09 01 Generate tone

7. Measure at least 1 Vrms at X201 Pin 1.

8. Measure less than 5% distortion at X201 Pin 1.

09 00 Disable alert tone generation

9. Test the buzzer by sending the following sequence to

the logic board:

2f 01 Enable buzzer

10. Verify the buzzer is sounding

2f 00 Disable buzzer

DISPLAY TEST:

1. Send a 2d 01 command to the logic board. All segments

in the display must turn on. All LED’s must turn on.

2. Send a 2d 00 command to the logic board. All segments

in the display must turn off. All LED’s must turn off.

KEYBOARD TEST:

The logic board takes one sample of the keypad and

reports a code out the serial port when it receives a 2eh

command. Test for each of the logic board’s keys. Note the

ON/END key can not be tested. It can not be read because

it is being held low by a ground in the TQ3370 box on X201

Pin 11. The return codes are listed below in Table 4.

ELECTROSTATIC DEVICES

DISASSEMBLY AND REASSEMBLY

The following procedures are intended to facilitate the disassembly and re-assembly of the radio. The complete set of

procedures are given since the antenna assembly requires complete disassembly. Refer to assembly diagram ROA 117 2224.

Tool Recommended: Disassembly Tool 19B802630,

1/4” Hex driver

Disassembly

1. Remove the antenna connector screw on the back of the

case, next to the antenna. NOTE: Some versions have a

rubber cover over this coaxial connector.

2. Remove the battery. Refer to procedures ”Inserting and

Removing the Battery”.

3. After removing the battery, remove the two screws (now

exposed) from the case assembly.

4. Using the antenna tool, (or carefully bend the case sides

outward) to release the plastic tabs, two in each side.

5. Tilt the case backwards and upward toward the antenna

end. Remove the coaxial collar.

6. Lift off the RF board assembly with the shield box.

7. Remove the antenna assembly.

8. Lift out the audio logic board.

9. Lift off the PTT button.

Reassembly

1. Check the placement of the buzzer and microphone. Be

sure the buzzer gasket is properly seated over the edge of

the board.

2. Be sure the LCD is placed against alignment edges on

the lightguide.

3. Guide the audio/logic board into the case. If the buzzer

and/or microphone keep the board from seating, realign

and retry.

4. Place the RF board onto the frame.

5. Place the antenna assembly into the frame making sure

that the coaxial connector protrudes through the RF

board.

6. Place the coaxial collar onto the RF board assembly.

7. Carefully seat the RF assembly onto the audio/logic

CMOS Integrated Circuit devices used in

this equipment can be destroyed by static

discharges. Before soldering one of these

devices, the service per son shou ld disc har ge

himself by touching the case of a benc h t est

instrument that is equipped with a 3-prong power cord

connected to an outlet with a known good earth gr ound.

When soldering or desoldering a CMOS device, the soldering iron being used should also have a 3-prong p ower

cord connected to an outlet with a known good earth

ground. A battery operated soldering iron may be used in

place of a standard soldering iron.

CAUTION

00 High Power - Low Split 04 High Power - Mid Split 08 High Power -High Split

01 Low Power - Low Split 05 Low Power - Mid Split 09 Low Power - High Split

02 Voice Deviation - Low Split 06 Voice Deviation - Mid Split 0a Voice Deviation - High Split

03 Data Deviation - Low Split 07 Data Deviation - Mid Split 0b Data Deviation - High Split

0c Battery Correction Factor

18 Squelch Setting

Table 3.Tracking Data Address For Tes t Mod e Co mmands 20 & 21

KEY CODE KEY CODE KEY CODE KEY CODE

1 01 80 3E 2 01 40 3E 3 01 20 3E FCN 01 10 3E

4 02 80 3E 5 02 40 3E 6 02 20 3E CLR 02 10 3E

7 04 80 3E 8 04 40 3E 9 04 20 3E UP 04 10 3E

* 08 80 3E 0 08 40 3E # 08 20 3E DOWN 08 10 3E

SEND 10 80 3E ON/END ----------- RCL 10 20 3E STORE 10 10 3E

PTT 10 01 3E NO KEY 10 00 3E

Table 4. Keyboard Return Codes

h

AE/LZB 119 1645 R1B

8

Loading...

Loading...