Page 1

Trouble Shooting Guide, Advanced

Trouble Shooting Guide, Advanced

by Toko (toko@gsm-free.org)

4/00021-3/00021/16 C Approved according to 1776-3/FEA 209 544

Page 2

Trouble Shooting Guide, Advanced

Contents

1 Explanations........................................................................................................................3

2 Enter Test Program............................................................................................................7

3 Calibration IQ...................................................................................................................12

4 TxVCO...............................................................................................................................14

5 VCXO.................................................................................................................................19

6 Calibration RSSI...............................................................................................................23

7 Power Level Calibration...................................................................................................25

8 Intermediate Power Calibration......................................................................................30

9 Transient Spectrum (Spectrum due to Switching).........................................................31

10 Modulation Spectrum Switched Mode (Spectrum due to Modulation)......................36

11 EE-prom ............................................................................................................................45

12 ADC Calibration (Voltage Calibration)..........................................................................46

13 Current Calibration..........................................................................................................49

14 Network Problems ............................................................................................................53

15 Phase and Frequency Error.............................................................................................62

16 Output Power....................................................................................................................63

17 Burst Timing (Power Time Template)............................................................................67

18 Sensitivity (Rx Quality) ....................................................................................................69

19 Rx Level.............................................................................................................................74

20 Audio..................................................................................................................................76

21 Keyboard...........................................................................................................................83

22 Display................................................................................................................................85

23 Buzzer ................................................................................................................................89

24 Illumination.......................................................................................................................90

25 Top Indicator.....................................................................................................................92

26 SIM Problems (“Insert card”).........................................................................................94

27 Selftest................................................................................................................................97

28 ADC Values.......................................................................................................................99

29 Revision History..............................................................................................................102

4/00021-3/00021/16 C 2(102)

Page 3

1 Explanations

1.1 Conditions

All measurements described in this Trouble Shooting Guide – Advanced, are performed in

EFRA with test program in the phone. Some of the faults can occur in tests without test

program, e.g. Go/No Go -tests. In these cases you have to program the phone with test program

before starting to trouble shoot using this guide.

For trouble shooting with signal program, see 4/00021-2/FEA 209 544/16.

For component placing see1078-2/FEA 209 544/16.

In case of liquid damage no further action should be taken, handle the unit according to the local

company directives.

When measuring with the probe, remember to set the correct attenuation (ext. preamp. gain) on

the spectrum analyzer. To get the most appropriate value, set the gain according to Tx output on

a correct working card.

Trouble Shooting Guide, Advanced

1.2 Abbreviations

B: Crystal.

C: Capacitor.

D: Digital circuit.

F: Over voltage protection.

H: Buzzer, LED and pads for display.

J: Connector.

L: Coil.

N: Analogue circuit.

P: Test point.

R: Resistor.

S: Keyboard pads.

U: BALUN Component that converts a balanced signal to an unbalanced or the other way

around.

V: Transistor or diode.

X: Contact surface on the circuit board.

Z: Filter.

4/00021-3/00021/16 C 3(102)

Page 4

Trouble Shooting Guide, Advanced

AGND: Ground for analogue signal.

AFMS: Audio from mobile station.

ATMS: Audio to mobile station.

DCIO: DC voltage through the system connector for charging.

GND: Ground.

LED3K: Logical signal that activates the background illumination.

ONSWAn: Voltage from the On/Off key that starts the phone.

RTC: Real Time Clock. The clock that keeps track of time and date.

SIMCLK: Signal from the processor used for communication to SIM, clock signal.

SIMDAT: Signal from the processor used for communication to SIM, data signal.

SIMRST: Signal from the processor used for communication to SIM, r eset signal.

SIMVCC: Feed voltage for SIM.

VBATT: Battery voltage (4.8V)

VCORE: DC voltage for the processor and memory (2.5 V)

VDIG: DC voltage for the processor and memory (3.2 V)

VLCD: DC voltage for the display that controls the contrast.

VRAD: DC voltage for the radio part except the synthesiser. (3.75 V)

VRTC: DC voltage for the real time clock. (2.5 V)

VVCO: DC voltage for the synthesiser (3.75 V)

I2C: Communications standard for two-way communication using only 2 wires,

clock and data.

4/00021-3/00021/16 C 4(102)

Page 5

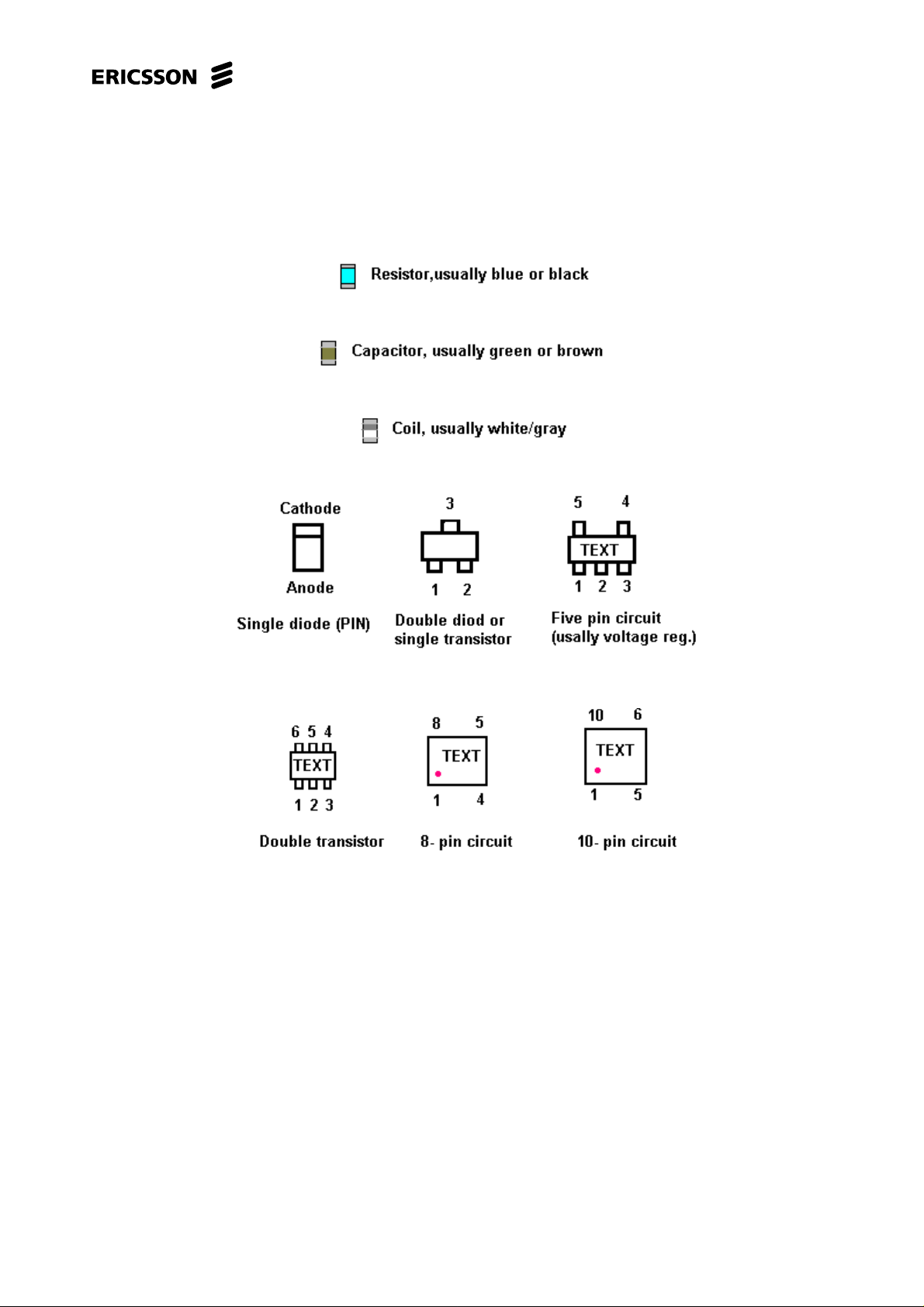

1.3 Pin placing

Trouble Shooting Guide, Advanced

4/00021-3/00021/16 C 5(102)

Page 6

Trouble Shooting Guide, Advanced

4/00021-3/00021/16 C 6(102)

Page 7

2 Enter Test Program

2.1 Introduction

To be able to use EFRA, the phone has to be programmed with test program. The programming

is also performed in EFRA.

If the phone cannot be programmed, proceed to section 2.3.

If the phone does not start in the radio calibration or trouble shooting part of EFRA, despite an

approved flash programming, proceed to section 2.2.

2.2 The phone does not start in the test program

Trouble Shooting Guide, Advanced

Attach a dummy battery and press the On/Off button. Check the display and the current

consumption.

If the phone starts (showing the revision of the test program in the display) and consumes 30 –

50 mA, the phone is usually without fault.

Check your equipment.

The following things are necessary for the phone to start in the test program:

Correct battery voltage (4.8 V).

Correct feed voltage to the trouble shooting box (15 V).

The current limitation must be set high enough on both outputs of the power amplifier (2A).

The phone must be started before clicking on the ”Startup” in EFRA.

The following signal must be found at the system connector of the phone: TTMS, TFMS,

VPPFLASH, GND and VDD.

Correct serial port of the trouble shooting box chosen.

”Mode”-switch should be in position ”Service”.

A Hardlock connected and installed.

If the fault really is electrical, open the phone and make a visual check of the board.

Make sure that there is not any liquid damage, burned or damaged pads at the system connector

or bad soldering of e.g. D600 or D610.

Power up the board and start it by using a pulse at the DCIO (or the On/Off button).

Check the amplitude of MCLK at C680 using the spectrum analyser (>3 dBm). We have been

using the following settings: CF – 13MHz, SPAN – 1 MHz, RBW – 10 kHz, VBW – 10 kHz

andSWEEP–30ms.

If MCLK is too low, the fault usually is due to L340, B301 or a s hort circuit in C343.

If the fault still remains, try to program the phone again.

If the phone consumes more then 200 mA, proceed to section 2.4.3.

If the phone consumes no current at all, when the button is pressed, open the phone and check

for liquid damage. Also make sure that the keyboard and the keyboard pads are okay and that

they are clean.

4/00021-3/00021/16 C 7(102)

Page 8

If there is a signal program in the phone, you have to program it with the test program.

2.3 The phone cannot be programmed

Makesurethat:

the battery screws are okay and tightened;

the system connector is not dirty or liquid damaged.

Attach a dummy battery. If the phone consumes current immediately, the fault is usually due to

a short circuit of VBATT, but first you must make sure that the isolation of the frame is not in

contact with the plus pole of the board.

Trouble Shooting Guide, Advanced

Start the phone with the On/Off button and check the current consumption.

If the phone consumes no current at all when the button is pressed, there is probably liquid

damage. Open the phone and check for liquid damage. Also make sure that the keyboard and the

keyboard pads are okay and that they are clean.

If the phone consumes more then 200 mA, proceed to section 2.4.3.

If the phone does not start, try to program it on board level.

If the phone does not start in the flash programmer, proceed to section 2.4.1.

If the phone can be programmed, but does not start afterwards or is troublesome in the flash

programmer, proceed to section 2.4.2.

If the phone starts after programming, the fault is probably solved, but to eliminate the

possibility of intermittent faults make sure that the soldering at D600, D610 or D630 are correct.

4/00021-3/00021/16 C 8(102)

Page 9

2.4 Measuring at a powered circuit board

2.4.1 Does not start in the flash programmer

Make sure that the pads of the system connector are not burned or in any way damaged.

Attach the board to the fixture. Power up the board by keeping DCIO high.

Measure the voltages VDIG (3.2 V) and VCORE (2.5 V).

If any of the voltages are too low, measure the resistance to ground (VDIG > 1 kohm, VCORE

> 25 kohms).

If the resistance is correct, replace the corresponding circuit (VDIG - N701, VCORE - N700).

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

increasing after removal. Do not forget to mount all the components that have been removed.

You should also replace the circuits on which you have lifted the pins. The short circuit is

usually due to D610, D600 or any of C600, C602-C611, C614, C800, C802-C807, C902, C906

for VDIG and D900 or any of C900, C901, C903-C905 for VCORE.

Trouble Shooting Guide, Advanced

If any of the voltages are too high, replace the corresponding circuit.

Measure the power reset at C710 (>3 V). If it is lower, the fault is probably due to C710 or

N550.

Measure the voltage VRAD/VVCO (3.8 V).

If the voltage is incorrect, measure the resistance between ground and N580:5 (50 kohms).

If the resistance is correct, replace N580.

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short-circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

raising after removal. Do not forget to mount all the components that have been removed. You

should also replace the circuits on which you have lifted the pins. The short circuit is usually

due to N550, or any of the 10nF-capacitors on VRAD/ VVCO.

Check the amplitude of the clock, using the oscilloscope, at B301:3 (>0.7 V t- t). You can also

use the spectrum analyser to check the amplitude (>1 dBm). We have been using the following

settings for the oscilloscope: CF – 13MHz, SPAN – 1 MHz, RBW – 10 kHz, VBW – 10 kHz

and SWEEP – 30 ms. A fault of the clock can be due to L340, B301 or a short circuit in C343,

D600, N300 or C300. Sometimes the fault is due to N202.

4/00021-3/00021/16 C 9(102)

Page 10

Trouble Shooting Guide, Advanced

Make sure that the soldering at D600, D610 or D630 are correct. If they are correct and all the

feed voltages and the clock are correct, the fault is usually due to D600. The fault can also be

due to D610 or D630.

Try to program the phone between each replacement.

2.4.2 Can be programmed, but does not start afterwards or is

troublesome in the flash programmer

Make sure that the pads of the system connector are not burned or in any way damaged.

Open the phone and check for liquid damage.

Attach the board to the fixture. Power up the board by keeping DCIO high.

Measure the voltages VDIG (3.2 V) and VCORE (2.5 V).

If any of the voltages are too low, measure the resistance to ground (VDIG > 1 kohm, VCORE

> 25 kohms).

If the resistance is correct, replace the corresponding circuit (VDIG - N701, VCORE - N700).

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

raising after removal. Do not forget to mount all the components that have been removed. You

should also replace the circuits on which you have lifted the pins. The short circuit is usually

due to D610, D600 or any of C600, C602-C611, C614, C800, C802-C807, C902, C906 for

VDIG and D900 or any of C900, C901, C903-C905 for VCORE.

If any of the voltages are too high, replace the corresponding circuit.

Measure the voltage VRAD/VVCO (3.8 V).

If the voltage is incorrect, measure the resistance between ground and N580:5 (50 kohms).

If the resistance is correct, replace N580.

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

raising after removal. Do not forget to mount all the components that have been removed. You

should also replace the circuits on which you have lifted the pins. The short circuit is usually

due to N550, or any of the 10nF-capacitors on VRAD/ VVCO.

Check the amplitude of the clock, using the oscilloscope, at B301:3 (>0.7 V t- t). You can also

use the spectrum analyser to check the amplitude (>1 dBm). We have been using the following

settings for the oscilloscope: CF – 13MHz, SPAN – 1 MHz, RBW – 10 kHz, VBW – 10 kHz

and SWEEP – 30 ms. A fault of the clock can be due to L340, B301 or a short circuit in C343,

D600, N300 or C300. Sometimes the fault is due to N202.

4/00021-3/00021/16 C 10(102)

Page 11

Make sure that the soldering at D600, D610 or D630 are correct. If they are correct and all the

feed voltages and the clock are correct, the fault is usually due to D600. The fault can also be

due to D610 or D630.

Try to program the phone between each replacement.

2.4.3 Consumes more then 200 mA

Open the phone and check for liquid damage.

Make sure that the pads of the system connector are not burned.

Attach the board to the fixture. Power up the board by keeping DCIO high.

Measure the voltages VDIG (3.2 V) and VCORE (2.5 V).

Trouble Shooting Guide, Advanced

If any of the voltages are too low, measure the resistance to ground (VDIG >1 kohm, VCORE

>25 kohms).

If the resistance is correct, replace the corresponding circuit (VDIG - N701, VCORE - N700).

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

raising after removal. Do not forget to mount all the components that have been removed. You

should also replace the circuits on which you have lifted the pins. The short circuit is usually

due to D610, D600 or any of C600, C602-C611, C614, C800, C802-C807, C902, C906 for

VDIG and D900 or any of C900, C901, C903-C905 for VCORE.

If any of the voltages are too high, replace the corresponding circuit.

Measure the voltage VRAD/VVCO (3.8 V).

If the voltage is incorrect, measure the resistance between ground and N580:5 (50 kohms).

If the resistance is correct, replace N580.

If the resistance is too low, use the schematics. Remove the components one by one (or lift the

pin/pins feeding the circuit), that is fed from the short circuited voltage, and measure the

resistance after each removal. You have found the faulty component when the resistance is

raising after removal. Do not forget to mount all the components that have been removed. You

should also replace the circuits on which you have lifted the pins. The short circuit is usually

due to N550, or any of the 10nF-capacitors on VRAD/ VVCO.

Check the amplitude of the clock, using the oscilloscope, at B301:3 (>0.7 V t- t). You can also

use the spectrum analyser to check the amplitude (>1 dBm). We have been using the following

settings for the oscilloscope: CF – 13MHz, SPAN – 1 MHz, RBW – 10 kHz, VBW – 10 kHz

and SWEEP – 30 ms. A fault of the clock can be due to L340, B301 or a short circuit in C343,

D600, N300 or C300. Sometimes the fault is due to N202.

Make sure that the soldering at D600, D610 or D630 are correct. If they are correct and all the

feed voltages and the clock are correct, the fault is usually due to D600. The fault can also be

due to D610 or D630.

Try to program the phone between each replacement.

4/00021-3/00021/16 C 11(102)

Page 12

3 Calibration IQ

3.1 What is calibration IQ

The IQ-filter consists of two parts. The first part is a passive lowpass-filter between the

waveform generator in D600 and N202 consisting of R642-R645, C106 and C108. The second

part is a software- controlled filter in N202 that is calibrated with a certain test signal from the

waveform generator.

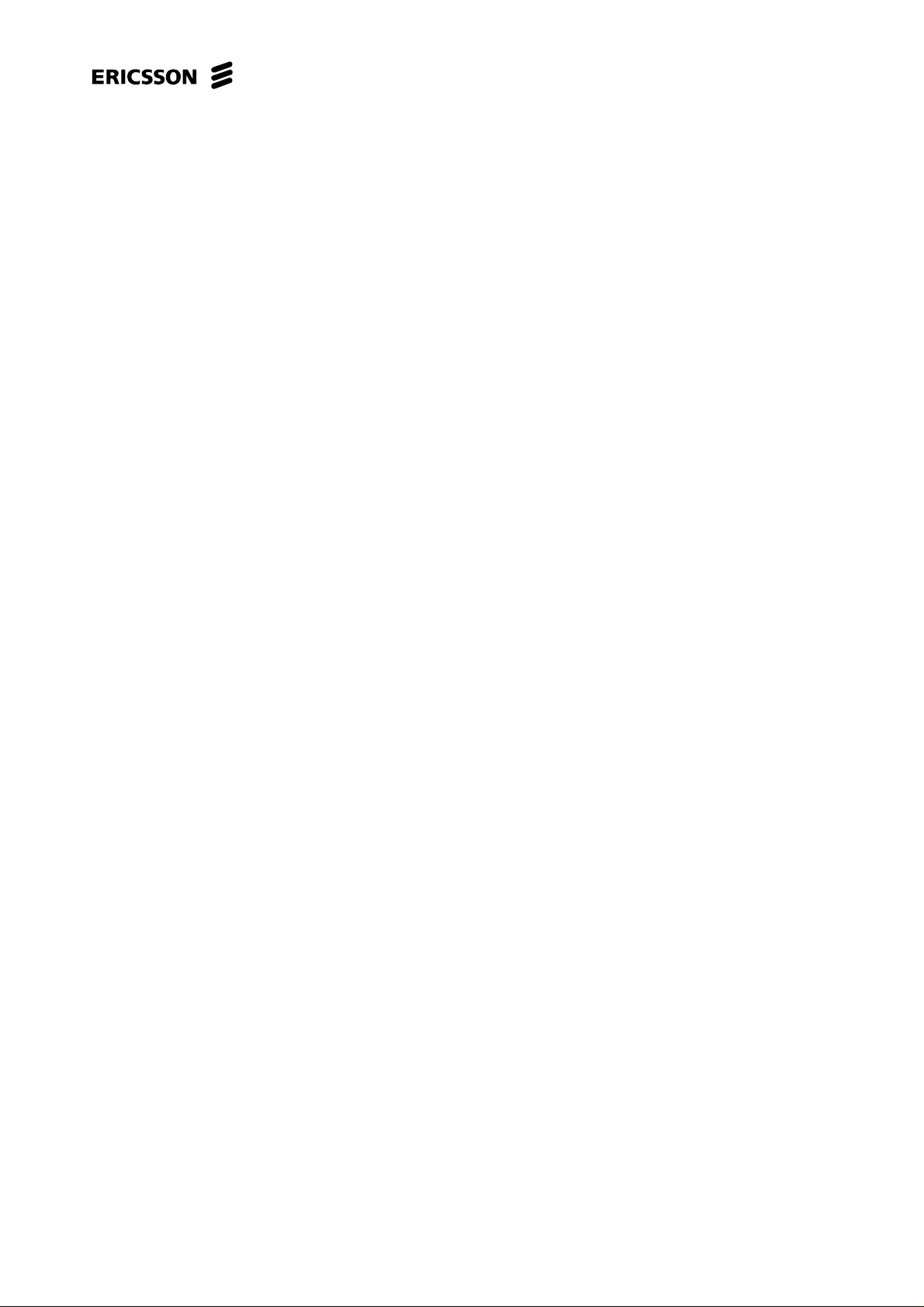

When calibrating, the transmitter is powered up in static mode with the test modulation. The

peak, that exists at CF-201 kHz related to the highest peak (CF+67 kHz), is measured, and the

LPBW/LPQ parameters in Homeros are tuned, until correct suppression (typ -21 dBm) is

obtained.

Trouble Shooting Guide, Advanced

Fig. 3.1

3.2 How to find the fault

Open the phone and check for liquid damage.

Attach the board in the fixture and start the test program.

NOTE! If the card i s of type 2, with the EKA power module, remember to attach the

negative bias voltage in the fixture.

Change the settings on the spectrum analyser to: SPAN: 1 MHz, RBW: 10 kHz, VBW:10 kHz,

SWEEP: 30 ms.

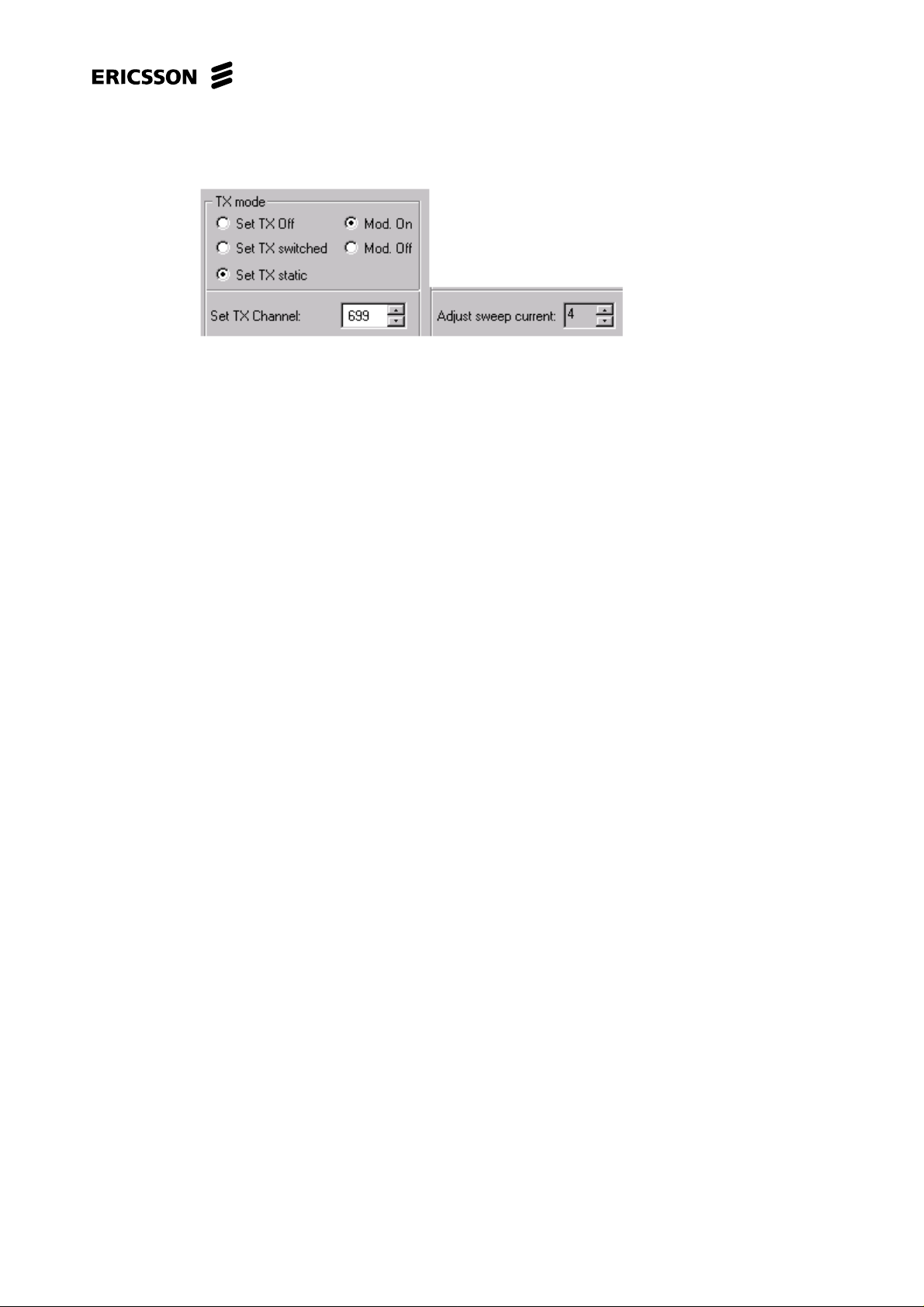

Start the transmitter in static mode with modulation on the middle channel (699) on the DCS

1800-band (Fig. 3.2). If the transmitter does not lock, decrease the sweep current.

4/00021-3/00021/16 C 12(102)

Page 13

Trouble Shooting Guide, Advanced

Fig. 3.2

Make sure that the spectrum looks like in Fig. 3.1.

If the spectrum does not look like the figure it is either one of the modulation signals (MODQN,

MODQP, MODIN, MODIP) that is missing from D600 or the lowpass-filter to the modulation

signals that is faulty (R642-R645, C106, C108).

Measure on the capacitors with an oscilloscope. The signals are sinus shaped with the frequency

67.7 kHz and the amplitude 3.0 V. Compare the signals with each other. The fault is probably

on the one modulation signal that differ from the others. If the modulation signals looks good

and are in the right phase (90 degrades turned compared to each other) then the fault could be

caused by N202.

4/00021-3/00021/16 C 13(102)

Page 14

4TxVCO

4.1 What is TxVCO – Calibration

In the GSM900-system a phone can communicate with the base station at 124 frequencies in

each direction (890.2 - 914.8 MHz for the transmitter and 935.2 - 959.8 MHz for the receiver).

In the GSM1800-system it is possible to communicate at 374 frequencies in each direction

(1710.2 – 1784.8 MHz for the transmitter and 1805.2 – 1879.8 MHz for the receiver).

The communication between the base station and the phone are done switched. The system

makes it possible to change frequency between each burst. For every new burst the transmitter

synth of the phone has to lock again at the frequency the base station expects, before activating

the transmitter.

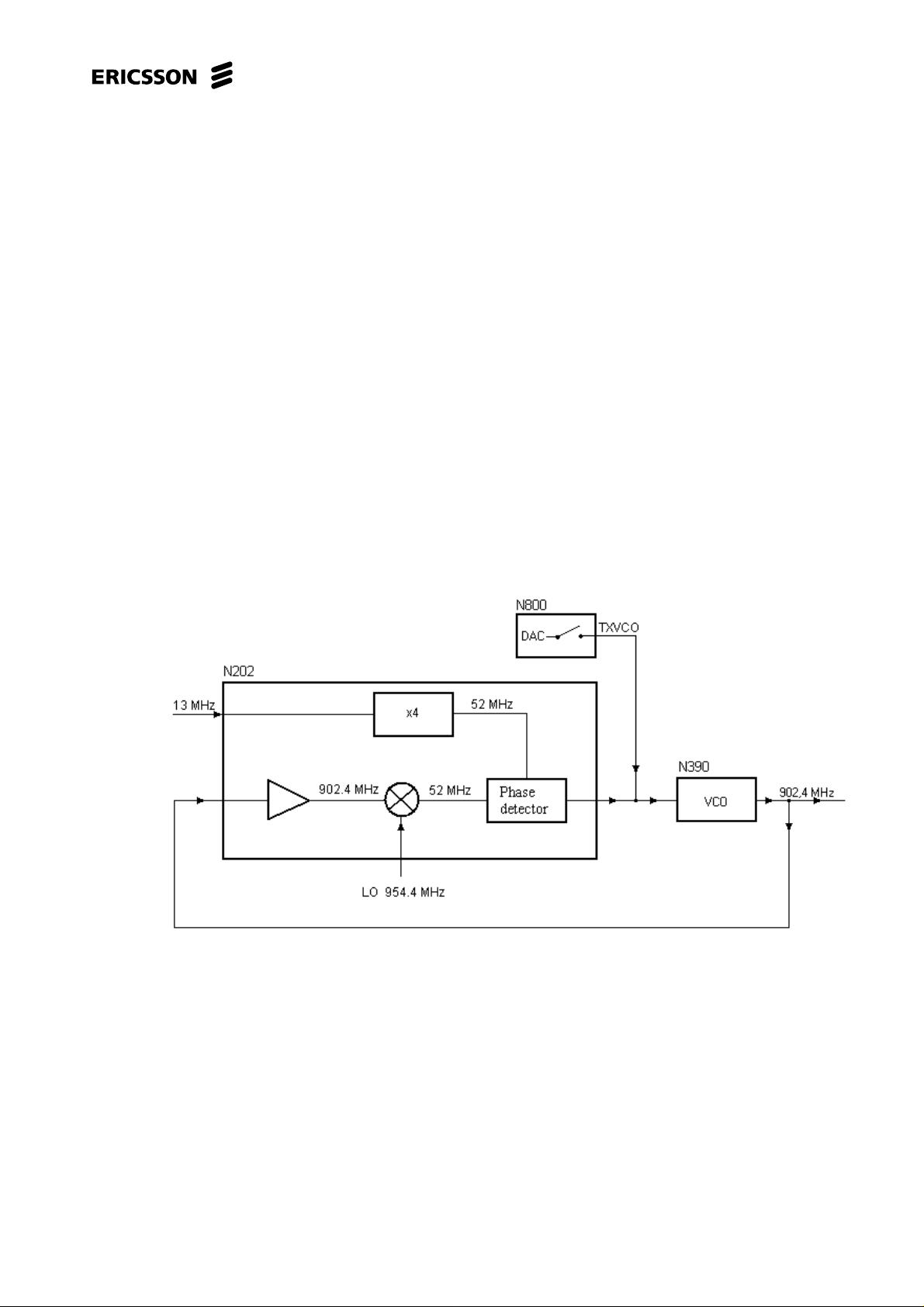

Fig 4.1 and Fig 4.2 shows two simplified diagrams over the lock-on of the Tx-synth. The

frequencies are for channel 62 (GSM900) and channel 699(GSM1800).

Trouble Shooting Guide, Advanced

GSM 900

Fig. 4.1

4/00021-3/00021/16 C 14(102)

Page 15

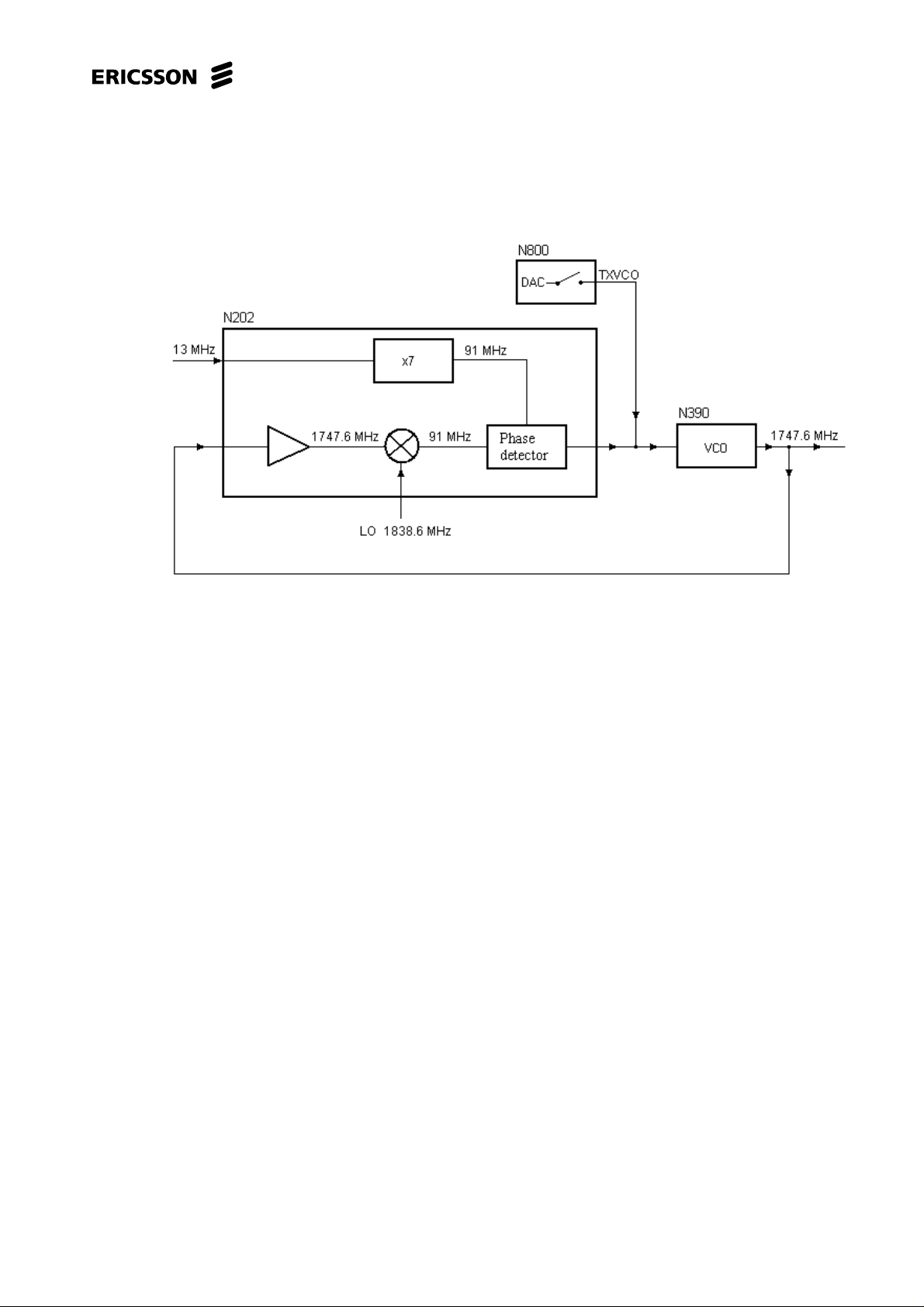

GSM 1800

Trouble Shooting Guide, Advanced

Fig. 4.2

The frequency of the transmitter has to lock during a predestinated time. To make the locking

time fast enough, the phone uses pre-learned TxVCO-values read from the EEPROM. The l ockon begins with the TxVCO-AC transforming a, for this particular channel, saved EEPROMvalue to a start value for the control voltage of the VCO (N390). The voltage is a little bit higher

than the expected value when the synth has locked on. By using the start value of the control

voltage the VCO generates a transmitter frequency that is only a little too high. The transmitter

frequency is fed back through a mixer to the Phase detector (both inside N202). The Phase

detector compares the mixed frequency (91 or 52 MHz) with an intern reference signal (7x13

=91 or 4x13 =52 MHz). The result of the phase comparison is a DC voltage that controls the

VCO. The TxVCO-DAC is disconnected and the Phase detector takes over the adjustment of the

control voltage to the VCO. When the transmitter synth has locked on (the Phase detector in

N202 has stabilized the control voltage and the frequency), the phone can begin to transmit.

The start value of the synth, the TxVCO value, has to be calibrated due to the differences of

tolerance in the components of the transmitter synth. The calibration i s performed in switched

mode, at two channels: for GSM900 high (channel 94 or 908,8 MHz) and low (channel 30 or

896 MHz) and for GSM1800 high (channel 826 or 1773.0 MHz) and low (channel 570 or

1721.8 MHz). The values for other channels you get by interpolation.

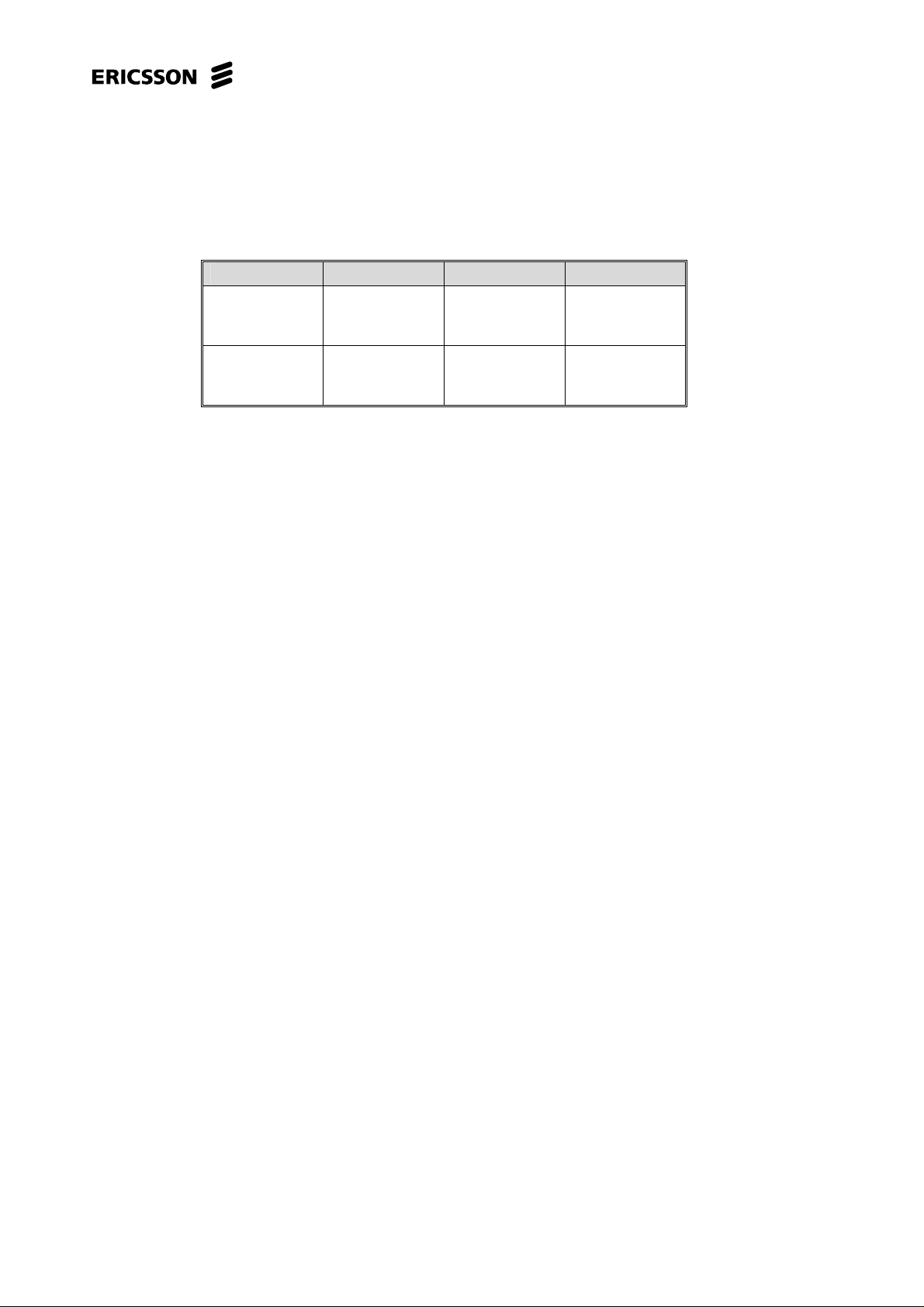

The tables below (Table 4.1 and 4.2) show the limits for the T xV CO – values.

4/00021-3/00021/16 C 15(102)

Page 16

GSM 900

TxVCO Min Max

Ch 30 56 A6 Hex

86 166 Dec

CH 94 6A BA Hex

106 186 Dec

Table 4.1

GSM 1800

TxVCO Min Max

Ch 570 37 87 Hex

55 135 Dec

CH 826 7E CE Hex

126 206 Dec

Table 4.2

Trouble Shooting Guide, Advanced

4.2 How to find the fault

Open the phone and check for liquid damage.

Power up the board and start the phone in the test program.

Measure the voltage at C853 and C854. Replace the corresponding capacitor if the voltage is

lower than approximately 1.1 V.

NOTE! If the card is of type 2 (roa 117 3258/2 or roa 117 3920/2), remember to attach the

negative bias voltage before changing to static mode.

GSM900:

Start the transmitter in static mode at channel 62 (902.4 MHz) and check the amplitude and the

frequency. If the frequency i s faulty, try to decrease the ”Adjust sweep current” until the

frequency of the transmitter has locked on. We have been using the following settings on the

spectrum analyser while measuring: CF- 902.4 MHz, SPAN- 200 MHz, RBW- 10 kHz, V BW10 kHz and Sweep- 30 ms.

If the transmitter locks, start the transmitter in switch mode at middle channel (62) with ”DAC 4

value” at FF. We have been using the following settings on the spectrum analyser while

measuring: CF- 902.4 MHz, SPAN- 0 MHz, RBW- 300 kHz, VBW- 100 kHz and Sweep- 0.8

ms.

Check if there is an output power (32 dBm) at the antenna plate using the spectrum analyser.

If the output power is correct, the phone is probably without fault. Try the phone in the test

again.

If there is no switched output power at all or if it i s too low, proceed to chapter 14 (”Network

problem”) section 14.3.1.

If the transmitter does not lock, start the transmitter in static mode again and change the settings

for the spectrum analyser to: 954.4 MHz, SPAN- 200 MHz, RBW- 10 kHz, VBW- 10 kHz and

Sweep- 30ms.

Check the frequency and the amplitude of the LO-signal at N331:1 (0dBm).

4/00021-3/00021/16 C 16(102)

Page 17

Trouble Shooting Guide, Advanced

If the amplitude and the frequency is correct, proceed to section 14.2.1.

If the frequency is correct, but the amplitude is too low, check the feed voltage at N331:7 (3.7

V).

If the voltage is correct, replace N331.

If the voltage is incorrect, check VVCO (3.8 V), SYNTON (3.8 V), BANDSEL and V337 with

the belonging components.

If the amplitude is correct, but the frequency is incorrect, the fault is usually due to N300. It can

also be due to N331 or D600.

If the signal is several MHz wide, replace C313.

(To make a more accurate frequency measuring, try to decrease SPAN to 1 MHz.)

GSM1800:

Start the transmitter in static mode at channel 699 (1747.4 MHz) and check the amplitude and

the frequency. If the frequency is faulty, try to decrease the ”Adj ust sweep current” until the

frequency of the transmitter has locked on. We have been using the following settings on the

spectrum analyser while measuring: CF- 1747.4 MHz, SPAN- 200 MHz, RBW- 10 kHz, V BW10 kHz and Sweep- 30 ms.

If the transmitter locks, start the transmitter in switch mode at middle channel (699) with ”DAC

4 value” at FF. We have been using the following settings on the spectrum analyser while

measuring: CF- 1747.4 MHz, SPAN- 0 MHz, RBW- 300 kHz, VBW- 100 kHz and Sweep- 0.8

ms.

Check if there is an output power (28-32 dBm) at the antenna plate using the spectrum analyser.

If the output power is correct, the phone is probably without fault. Try the phone in the test

again.

If there is no switched output power at all or if it i s too low, proceed to chapter 14 (”Network

problem”) section 14.3.1.

If the transmitter does not lock on, start the transmitter in static mode again and change the

settings for the spectrum analyser to: 1838.6 MHz, SPAN- 200 MHz, RBW- 10 kHz, VBW- 10

kHz and Sweep- 30ms.

Check the frequency and the amplitude of the LO-signal at N330:1 (0dBm).

If the amplitude and the frequency are correct, proceed to section 14.2.2.

If the frequency is correct, but the amplitude is too low, check the feed voltage at N330:7 (3.7

V).

If the voltage is correct, replace N330.

If the voltage is incorrect, check VVCO (3.8 V), SYNTON (3.8 V), BANDSEL and V338 with

the belonging components.

If the amplitude is correct, but the frequency is incorrect, the fault is usually due to N300. It can

also be due to N330 or D600.

If the signal is several MHz wide, replace C313.

(To make a more accurate frequency when measuring, try to decrease SPAN to 1 MHz.)

4/00021-3/00021/16 C 17(102)

Page 18

4.2.1 Tx–synth fault for GSM900

Power up the board and enter the test program.

Start the transmitter in static mode at channel 62.

Use the following settings for the spectrum analyser: CF- 902.4 MHz, SPAN- 200 MHz, RBW10 kHz, VBW- 10 kHz and Sweep- 30 ms.

Measure the amplitude and the frequency of the signals TXINA and TXINB at C370 and C371

( -13 dBm, the frequency should be 902.4 MHz when the synth has locked).Measure on both

sides of the capasitors to make sure that they are not broken.

If the TXIN-signal is too low, the fault is usually due to N390 (9 dBm at N390:6) or its feed

voltages. The fault can also be due to too large attenuation in N391, C370 or C371.

If the level of the TXIN-signal is correct, find out if the LO signal (954.4 MHz) is correct.

Measure at L331 (-7 dBm).

If the LO signal is correct the fault is probably due to N202, see chapter 18.5.

If it is low or missing, follow the signal back to the VCO (N331:1).

Trouble Shooting Guide, Advanced

If the signal is low or missing at the VCO, check that the feed voltage, VV CO on N331:7, is

correct (3.8 V). Also check the control voltage on N331:5 (2.0 V).

If the control voltage is incorrect, the fault is probably due to N300 or C300.

If the voltages are correct, N331 is probably broken.

4.2.2 Tx–synth fault for GSM1800

Power up the board and enter the test program.

Start the transmitter in static mode at channel 699.

Use the following settings for the spectrum analyser: CF- 1747.6 MHz, SPAN- 200 MHz,

RBW-10kHz,VBW-10kHzandSweep-30ms.

Measure the amplitude and the frequency of the signals TXINA and TXINB at C370 and C371

( -10 dBm, the frequency should be 1747.6 MHz when the synth has locked). Measure on both

sides of the capasitors to make sure that they are not broken.

If the TXIN-signal is too low, the fault is usually due to N390 (11dBm a t N390:6) or its feed

voltages. The fault can also be due to too large attenuation in N391, C370 or C371.

If the level of the TXIN-signal is correct, find out if the LO signal (1838.6 MHz) is correct.

Measure at N202:40,41.

If the LO signal is correct the fault is probably due to N202, see chapter 18.5.

If it is low or missing, follow the signal back to the VCO (N330:1).

If the signal is low or missing at the VCO, check that the feed voltage, VV CO on N330:7, is

correct (3.8 V). Also check the control voltage on N330:5 (2.0 V).

If the control voltage is incorrect, the fault is probably due to N300 or C300.

If the voltages are correct, N330 is probably broken.

All values are approximates, measure the exact values for your equipment using an approved

phone.

4/00021-3/00021/16 C 18(102)

Page 19

5VCXO

5.1 What is VCXO

The phone has got a reference crystal of 13 MHz, which signal is used for both the radio and the

logic.

The logic uses the clock signal MCLK as master clock and for the synchronisation of the digital

circuits of the logic.

The radio uses the 13 MHz signal as a reference signal for frequency regulation of both the

transmitter and the receiver.

The frequency fault of both the transmitter and the receiver must be inside the valid limits. The

phone has to have the possibility to control the frequency of the reference crystal to be able to

maintain the limits during different circumstances. This is possible since the reference crystal is

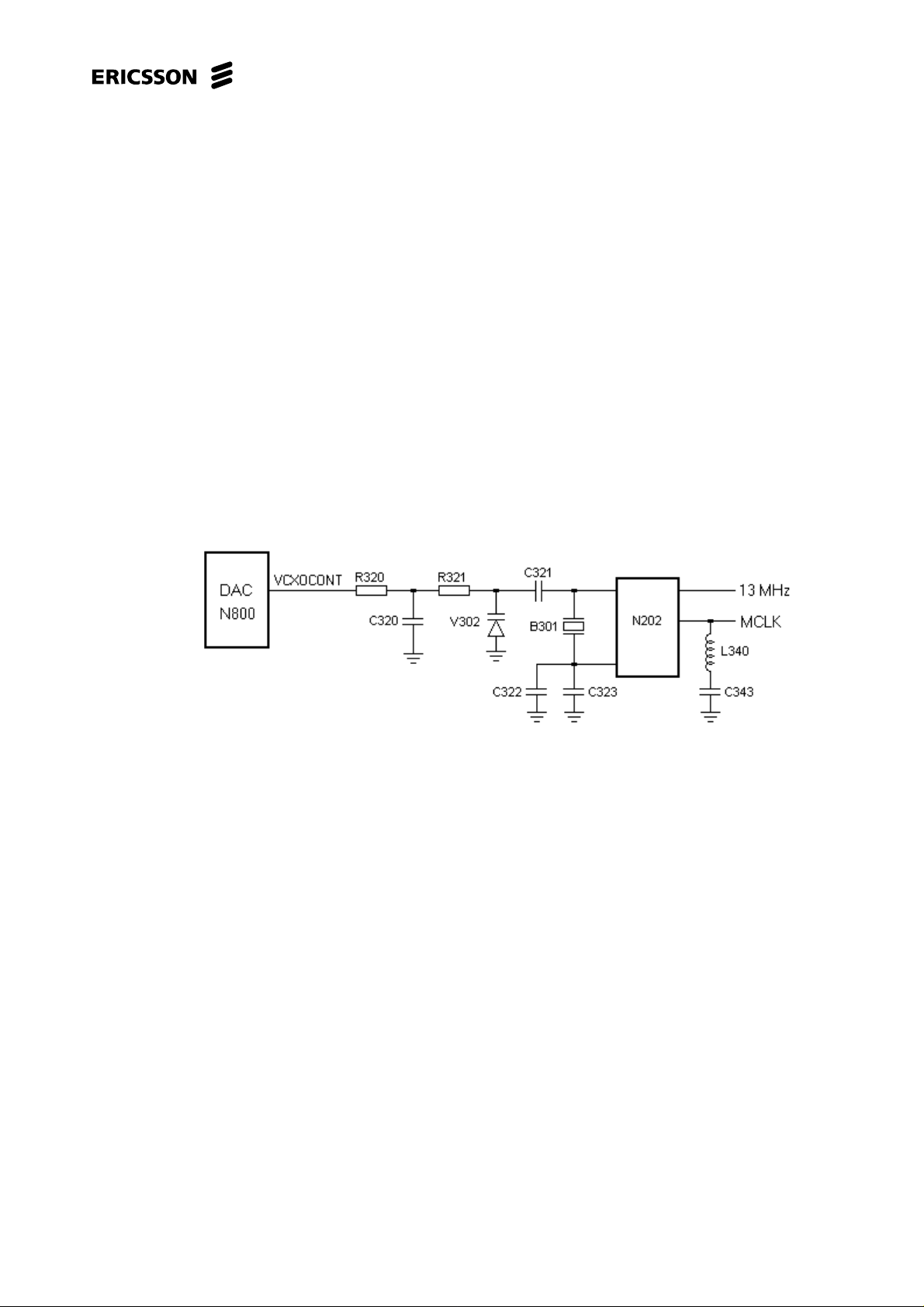

a Voltage Controlled Crystal Oscillator (VCXO). The schematic is shown in the figure below.

Trouble Shooting Guide, Advanced

Fig. 5.1

The crystal B301, the capacitors C321, C322, C323 and the varicap diode V302 are forming an

oscillating circuit. The active part of the oscillating circuit is in N202. By changing the DC

voltage of the varicap diode its capacitance changes, this changes the frequency of the

oscillating circuit. The control voltage VCXOCONT for the varicap diode comes from a DAC

in N800. The range of the DAC is between 0 and 3FF Hex, that is equivalent to a control

voltage between 0 and 3 V.

The frequency of the oscillating circuit is amplified in N202 and goes to the radio and the logic

through two outputs called 13MHz and MCLK.

5.2 VCXO measurements in the radio calibration in EFRA

There are three measurements and one calibration, concerning VCXO, in the radio calibration in

EFRA. The measurements are:

1. VCXO Control at DAC 00 Hex;

2. VCXO Control at DAC 3FF Hex;

3. VCXO Control Range.

4/00021-3/00021/16 C 19(102)

Page 20

Trouble Shooting Guide, Advanced

These three measurements control the adjustment range, in ppm, of the crystal. The

measurement is performed as follow:

The transmitter is started in static mode at any channel and the VCXO value 00 Hex.

The output frequency of the transmitter is measured.

The adjustment range in ppm for DAC 00 Hex is measured according to the formula below:

The adjustment range (in ppm) = (The measured frequency – the frequency of the channel) *

1000000 / the frequency of the channel

E.g. channel 699:

The frequency of the channel: 1747.6 MHz

The measured frequency: 1747.4 MHz

(1747.4 – 1747.6) * 1000000 / 1747.6 = - 114 ppm

The abbreviation ppm means ”parts per million”, i.e. 1 Hz divergence per MHz of the output

frequency of the transmitter. Meaning that a difference of one ppm at the middle channel of the

transmitter (1747.6 MHz) gives a frequency divergence of 1747.6 Hz.

The VCXO value changes to 3FF and the frequency of the transmitter is measured again. The

adjustment range is calculated in the same way, but the result should be positive.

The VCXO Control Range is calculated from the values from the two measurements above. You

check the adjustment range for the values between 00 and 3FF Hex.

The measuring of the adjustment range is important to verify that the reference frequency can be

controlled enough, up and down.

In Calibration VCXO, the 13 MHz crystal is being trimmed at channel 570. By sending the

DAC value 200 Hex and comparing the received frequency to the one for channel 570, an offset

is calculated. This offset is used in an algorithm to establish the value for the DAC for the

TCXO.

The calibrated VCXO value is somewhere in the middle of 00 and 3FF, Hex.

4/00021-3/00021/16 C 20(102)

Page 21

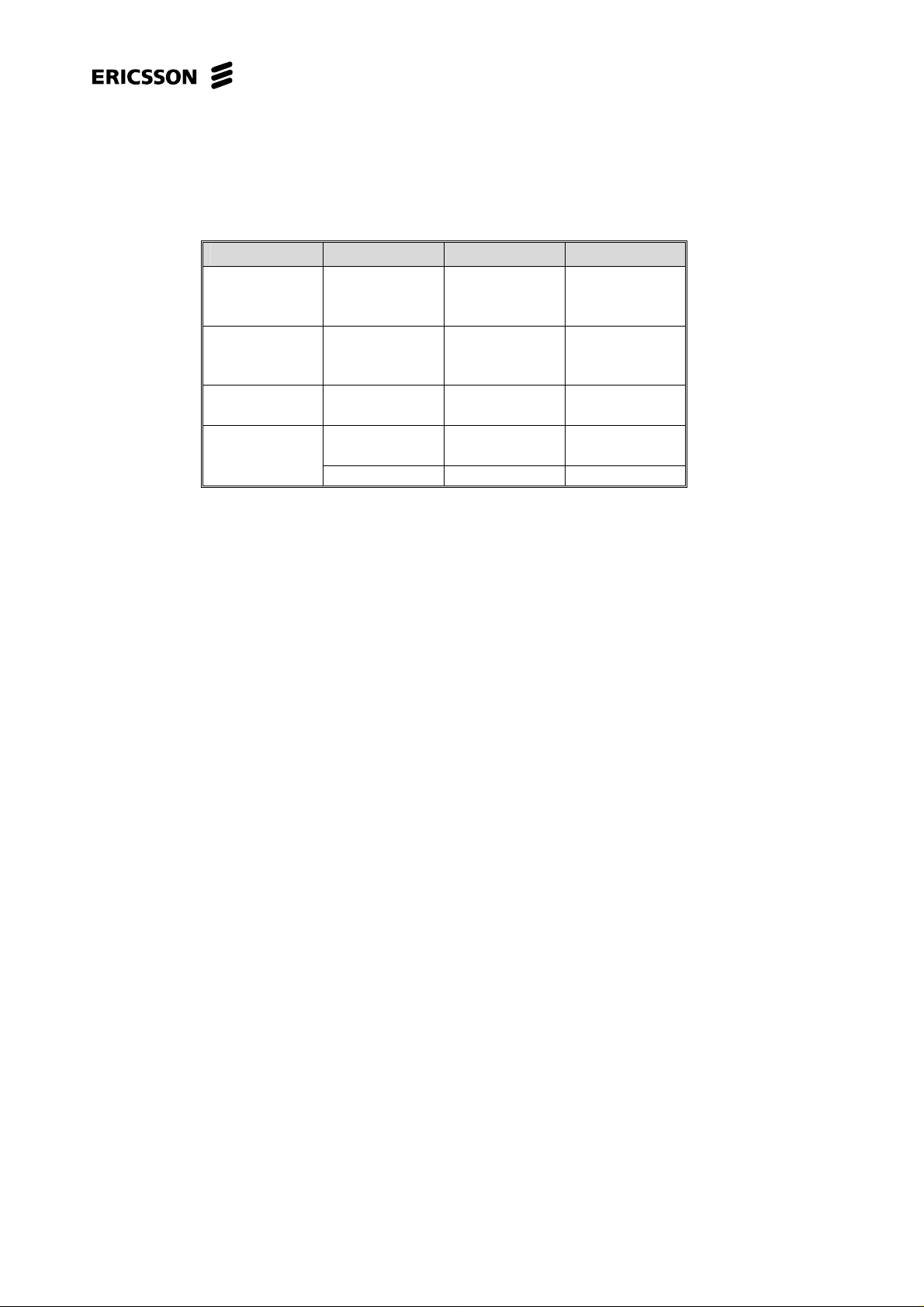

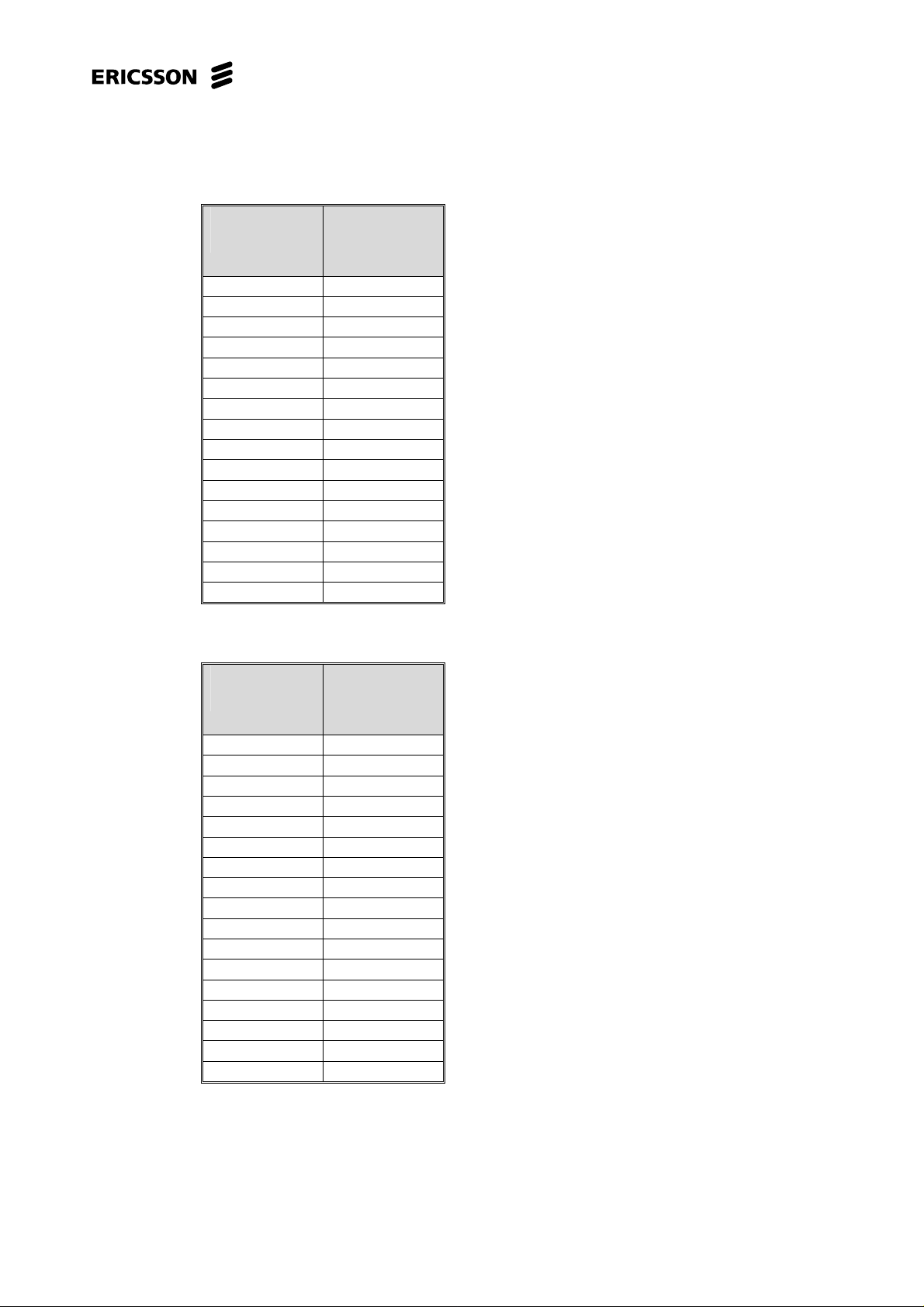

Table 5.1shows the limits for the VCXO measurements.

Parameter Min Max Unit

VCXO

Control at

DAC 00 Hex

VCXO

Control at

DAC 3FF Hex 13 67 ppm

VCXO

Control Range 40 80 ppm

Calibrated

VCXO 262 762 Dec

DAC 106 2FA Hex

-67 -13 ppm

Table 5.1

Trouble Shooting Guide, Advanced

5.3 How to find the fault

Open the phone and check for liquid damage.

Start the phone in the test program.

Start the transmitter in static mode at middle channel (699). Make sure that the transmitter locks.

Turn off t he modulation by selecting ”Mod off”.

Go to Misc /DAC Parameter.

Set TCXO to 00 Hex. Notice t hat the DAC value does not change until clicking at ”Close”.

Measure the DC voltage at C320 (0.3 V).

Set TCXO to 3FF Hex. Notice that the DAC value does not change until clicking at ”Close”.

Measure the DC voltage at C320 (2.9V).

If both voltages are correct, but any of the VCXO measurements are incorrect, the fault is

usually due to B301. Sometimes the fault is due to V302, C321, C322 or C323.

If both voltages are constantly too low, remove C320. Measure the voltages again.

If the voltages are correct now, the fault was a short circuit in the capacitor.

If the fault remains, it is usually due to N800,C853 or C854. (The voltage at C853 and C854

should be 1.1V)

If both voltages are equal, but not 0 V, the fault is almost always due to N800.

If both voltages are correct, but the V CXO calibration is incorrect, the fault i s usually due to

B301 or V302. Sometimes it is due to C321, C322 or C323.

VCXO faults can be due to N202, but that is not very common.

4/00021-3/00021/16 C 21(102)

Page 22

Trouble Shooting Guide, Advanced

You can verify that the fault is gone by measuring the output frequency of the transmitter with

VCXO-DAC at 00 and 3FF Hex and compare the result with table 5.2.

Parameter Min Max Unit

VCXO

Control at

DAC 00 Hex 1747.4829 1747.5773 MHz

VCXO

Control at

DAC 3FF Hex 1747.6227 1747.7171 MHz

Table 5.2 (Applies for channel 699)

4/00021-3/00021/16 C 22(102)

Page 23

6 Calibration RSSI

6.1 What is RSSI

In the mobile phone, the received RF-signal strength is measured and indicated by a f unction

called RSSI, Received Signal Strength Indicator.

During a call in progress the phone measures the current signal strength sequentially from a

number of base stations ordered by the switch when setting up t he call. The measurement starts

at the base station serving cell and continues with the RF-signals of up to 6 surrounding base

stations. The measurement cycle is continually repeated.

The logic part of the phone then calculates a number of values of the received RF-signals and

reports the amplitude of the RF-signals from the different base station to the switch through a

logical channel.

The signal strength report is used in an evaluation process for Location and Handover, i.e. when

the switch evaluates the speech quality, signal strength and traffic parameters to be outside the

limit values of the current physical channel and chooses to start a new channel for the

connection. A physical channel is the combination of a timeslot (TS) and a radio channel

(ARFCN). The physical channel (TS/ARFCN) can be allocated to the current base station or any

of the surrounding base stations at handover.

Trouble Shooting Guide, Advanced

For the speech quality and the MS to Base distance, it is important that the reported

measurements of the RF-signal are correct and calibrated towards known values. If the reported

values are too high it results in late handovers and bad readability due to the limits that are set

out of reach for the MS. The opposite, t oo low values, provokes the switch to make unnecessary

handovers, increased traffic load and perhaps dropped calls by forced release.

The received signal carries information both in phase as well as amplitude. The phase contains

the digital information (speech and signalling data) and is detected in a phase digitizer for

further processing in the main program. The amplitude of the received signal is measured in

N800, giving a value called RSSI.

RSSI is used for two measurement functions, electrical and numerical (mean value and

momentary value). The electrical value of the RSSI is used to report the signal strength to the

switch through the base station as current Rx-level. The numerical RSSI-value is calculated and

only used internally in the phone by the DSP.

The RSSI measuring procedure is to compare the strength of the measured signals and compare

them to a calibrated scale of reference levels and point out the one closest to the current RFlevel. There are two scales, one for GSM900 and one for GSM1800, both are calibrated

separately. To create these scales, the MS is calibrated with known RF-signal levels from –

110dBm to –40dBm, with a 5dBm increment at a frequency in the Mid ARFCN range (ARFCN

62 is usually used as a mid channel for GSM900 and ARFCN 699 for GSM1800). This

procedure is called RSSI calibration.

These 15 RF-signal levels are digitized by the RSSI function and temporarily saved in the RAM

memory by a test program. The test program then performs an interpolation and calculates the

rest of the (up to 256) reference value positions and loads them into a part of the MS program

memory, EEPROM.

4/00021-3/00021/16 C 23(102)

Page 24

Every RF-signal level, that is processed by the RSSI-function, can now be presented in digital

form by reading the nearest corresponding reference level from the EE-PROM, with a resolution

of 16 bits, and sending it as current Rx-level information to the base station.

These reference l evels are unique for every phone since the signal path through every receiver is

dependent on unique parameter values. As, for instance, component tolerances, mounting,

soldering and so on. Every change, for instance a repair, an adjustment, a component being

soldered, a component ageing and so on, brings the possible need of a new calibration.

6.2 How to find the fault

The fault can be due to either an incorrect measurement of the RSSI value or too large losses in

the signal path. If the RSSI calibration is incorrect for only one frequency band, GSM900 or

GSM1800, the fault is usually in the signal path, see chapter 18 (Sensitivity and Rx-quality) for

a hint on where to troubleshoot. To check the measurement of the RSSI value, only one of the

frequency bands is needed. We have used the GSM900 band.

Trouble Shooting Guide, Advanced

Set Rx-amplitude from GSM-test set to 947.4 MHz and -50 dBm. Use a modulated signal

(GMSK on).

Open the phone and check for liquid damage.

Attach the board to the fixture and start the test program.

Go to Radio/RSSI Measurement and make a RSSI measurement at channel 62.

If the RSSI value is about 0xC8, it is probably okay. But to be sure, measure at -100 dBm

(should be about 0x44).

If the RSSI value is 0x00 or 0xFF (for different signal strengths), the fault is usually due to

N800 or D600.

If the value is faulty, the problem is probably in N202, N800 or N300.

4/00021-3/00021/16 C 24(102)

Page 25

7 Power Level Calibration

7.1 Introduction

In the GSM 900 system, it is possible for a phone to transmit with 15 different power levels,

from 33 dBm (power level 5) to 5 dBm (power level 19). In the GSM1800 system, it is possible

for a phone to transmit with 16 different power levels, from 30 dBm (power level 0) to 0 dBm

(power level 15). It is best to transmit at as low output power as possible, but with maintained

transfer quality, in order to e.g. save current in the battery and restrict the disturbances. The base

station evaluates the transfer quality and informs the phone when to change the output power.

For the base station to be able to regulate the output power of the phone in a satisfying way, the

power levels of the phone have to be as the base station expect. This means that the power levels

of the phone have to be calibrated to be accurate enough.

Trouble Shooting Guide, Advanced

Fig 7.1 shows a very simplified schematic of the power regulation.

Fig. 7.1

The calibrated DAC values are stored in the EEPROM. When the base station orders the phone

to transmit at a certain power level, the DAC value for the current power level is taken from the

EEPROM and sent to the Power level-DAC in N800. The output voltage POWLEV of the DAC,

lets the power regulation of the radio know how large the power should be. N550 uses

POWLEV to create the control voltage VREG with Offset level and Full Power level.It

regulates the amplification of the power amplifier. The regulation is fed back by measuring the

current consumption of the power amplifier using R412. The signal is called VSENSE.

Table 7.1 (GSM900) and 7.2 (GSM1800) shows the allowed DAC values and the output power

goal of the calibration.

4/00021-3/00021/16 C 25(102)

Page 26

Trouble Shooting Guide, Advanced

Power

Level

Output

Power

(dBm)

5 32.5 ±0.3

6 30.5 ±0.3

7 29 ±0.5

8 27 ±0.5

9 25 ±0.5

10 23 ±0.5

11 21 ±0.7

12 19 ±0.7

13 17 ±0.7

14 15 ±0.5

15 13 ±0.5

16 11 ±0.5

17 9 ±0.5

18 7 ±0.5

19 5 ±0.5

Table 7.1 (GSM 900)

Power

Level

Output

Power

(dBm)

0 30 ±0.3

1 28 ±0.5

2 26 ±0.5

3 24 ±0.5

4 22 ±0.5

5 20 ±0.7

6 18 ±0.7

7 16 ±0.7

8 14 ±0.7

9 12 ±0.7

10 10 ±0.7

11 8 ±0.7

12 6 ±0.7

13 4 ±0.7

14 2 ±0.7

15 0 ±0.7

Table 7.2 (GSM1800)

4/00021-3/00021/16 C 26(102)

Page 27

The power calibration is a part of the radio calibration in EFRA. The calibration is performed in

15 steps, from the highest (5) to the lowest (19), for GSM900 and in 16 steps for GSM1800 (0-

15), one step for each power level. The computer controls the calibration by setting t he Power

level DAC for the phone at the current power level and checking the output power using a

spectrum analyser or a GSM test set. Default values are used as starting DAC values. The

computer changes the DAC value to attain the correct output power for the current power level.

The value is temporarily saved in the RAM of the phone. When the computer has attained the

right output power for each power level, the values for the power levels not in use are first

interpolated, then all DAC values are saved in the EEPROM. If the correct power is not

achieved or one of the DAC values is outside of the limits, then the calibration has failed and

nothing is written i n the EEPROM.

7.2 How to find the fault

If the power calibration failed or if the output power is several dBm too low, open the phone and

check for liquid damage.

Make sure that the antenna connector (W101) is okay.

Power up the board and start it in the test program.

Trouble Shooting Guide, Advanced

Measure the voltage at C833. If it is lower than approximately 1.5 V, replace the capacitor.

For GSM900:

Start the transmitter in switch mode at middle channel (62) and ”DAC 4 value” at FF. Check if

there is enough output power (30- 35 dBm) at the antenna plate using the spectrum analyser. We

have been using the following settings while measuring: CF- 902.4MHz, SPAN- 0 Hz, RBW300 kHz, VBW- 100 kHz and Sweep- 0.8 ms.

If the output power is correct, the fault can be due to the frame. The fault can also be due to a

change in the characteristics in some of the components, participating in the power regulation,

because of ageing. For some power levels this can make the output power or the DAC values

ending up outside the limits. In that case, the fault is usually due to N400 or N550. The fault can

also be due to N800, N390 or D600.

If the output power is too low, measure the control voltage POWLEV at N550:10 using an

oscilloscope. It should l ook like in Fig 7.2.

Fig. 7.2

4/00021-3/00021/16 C 27(102)

Page 28

Trouble Shooting Guide, Advanced

If the control voltage is too low, the fault is usually due to N800. It can also be due to D600.

If the control voltage is correct, measure VREG at N550:16 or N400:4 (type 2 PA 3.5 V, same

frequency), N400:7(Type 1 PA).

If VREG is too low, the fault is probably due to N550 or N400.

If VREG is correct, measure the signal Tx at N390:6 (10 dBm).

If the signal Tx is correct at N390:6, check the output power from N400:16 (Type 2 PA28

dBm), N400:4 (Type 1 PA 31 dBm).

If the output power is too low, replace N400.

If the output power is correct at N400 but low or missing at the antenna connector, the fault is

probably due to N203.

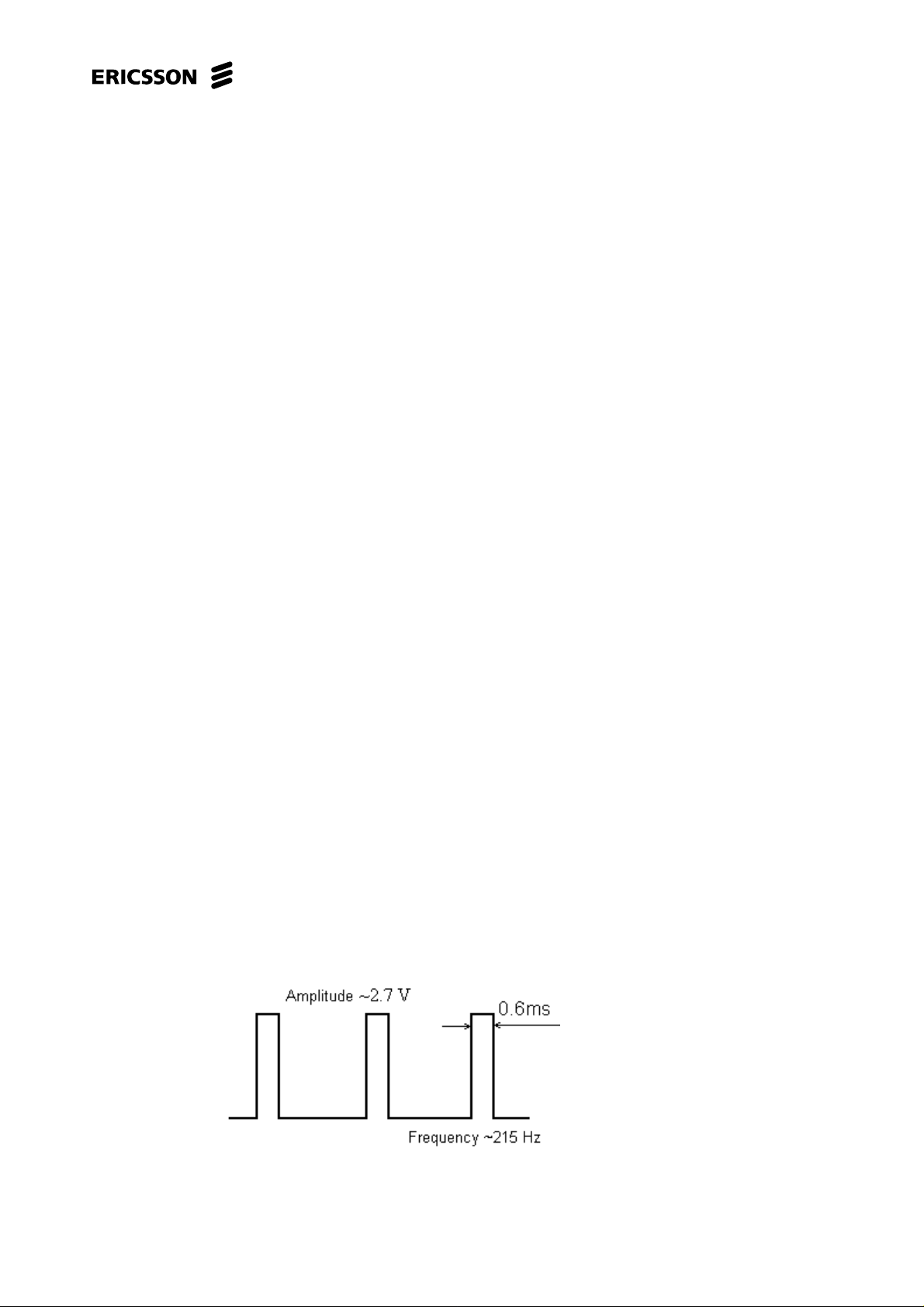

If the signal Tx is too low at N390:6, measure the feed voltage at N390:3 using an oscilloscope

(3.8 V, 215 Hz).

If the feed voltage is correct, the fault is usually due to N390 or N400.

If the feed voltage is incorrect, the fault is usually due to V350 or V351. Make sure that VRAD

is okay.

For GSM1800:

Start the transmitter in switch mode at middle channel (699) and ”DAC 4 value” at FF. Check if

there is enough output power (28- 32 dBm) at the antenna plate using the spectrum analyser. We

have been using the following settings while measuring: CF- 1747.6MHz, SPAN- 0 Hz, RBW300 kHz, VBW- 100 kHz and Sweep- 0.8 ms.

If the output power is correct, the fault can be due to the frame. The fault can also be due to a

change in the characteristics in some of the components, participating in the power regulation,

because of ageing. For some power levels this can make the output power or the DAC values

ending up outside the limits. In that case, the fault is usually due to N400 or N550. The fault can

also be due to N800, N390 or D600.

If the output power is too low, measure the control voltage POWLEV at N550:10 using an

oscilloscope. It should l ook like in Fig 7.2.

If the control voltage is too low, the fault is usually due to N800. It can also be due to D600.

If the control voltage is correct, measure VREG at N550:16 or N400:4 (type 2 PA 3.5 V, same

frequency), N400:7(Type 1 PA).

If VREG is too low, the fault is probably due to N550 or N400.

If VREG is correct, measure the signal Tx at N390:6 (13 dBm).

If the signal Tx is correct at N390:6, check the output power from N400:26(Type 2 PA31 dBm),

C408 (Type 1 PA 28 dBm).

If the output power is too low, replace N400.

If the output power is correct at N400 but low or missing at the antenna connector, the fault is

probably due to N203.

If the signal Tx is too low at N390:6, measure the feed voltage at N390:3 using an oscilloscope

(3.8 V, 215 Hz).

4/00021-3/00021/16 C 28(102)

Page 29

Trouble Shooting Guide, Advanced

If the feed voltage is correct, the fault is usually due to N390 or N400.

If the feed voltage is incorrect, the fault is usually due to V350 or V351. Make sure that VRAD

is okay.

All the mentioned signal strength levels are approximate, especially when measuring at the

signal before the power amplifier, since the output power of the power amplifier radiates back

to the probe. You have to consider this when comparing your values with a reference.

4/00021-3/00021/16 C 29(102)

Page 30

8 Intermediate Power Calibration

8.1 What is intermediate power

Intermediate Power is a calibration necessary to do to fulfil the demands of the GSMspecification for the up- and down-ramping of the power and to minimize the transient spectra.

The up- and down-ramping of the control voltage of the power amplifier does not change

momentarily from zero-to-max/max-to-zero. That would cause a large number of over tones due

to the switch. The up- and down-ramping of the control voltage are i nstead performed with two

help steps. The control voltage then passes through an exponential amplifier and a Bessel low

pass filter in N550 where the transient disturbance is reduced. This gives a control voltage

without the straight, vertical edges and the sharp corners that produces the over tones. The two

help steps in the up- and down-ramping of the power are called Intermediate Power level.

Trouble Shooting Guide, Advanced

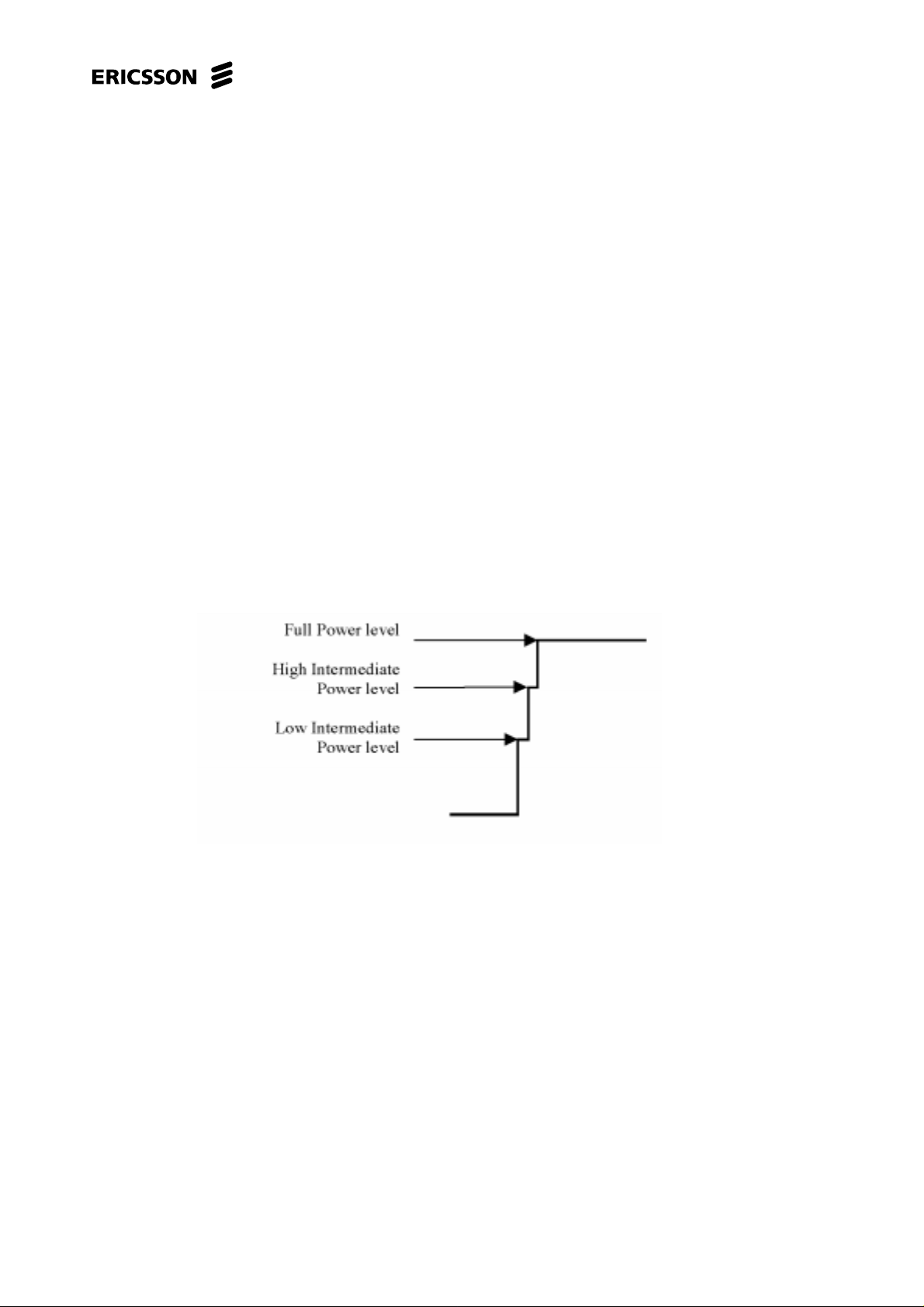

The figure below shows the up-ramping of the control voltage before it passes through the

exponential amplifier and the low pass filter, i.e. what the up-ramping steps looks like.

Fig. 8.1

The three power steps Low Intermediate Power level, High Intermediate Power level and Full

Power level are set by the power level DAC in N800 and are amplified and filtrated in N550.

Low and High Intermediate Power level uses default values to generate the voltage.

Fullpowerlevel(5–19forGSM900and0–15forGSM1800) is calibrated so that the Power

levels are correct according to the GSM – specification.

Intermediate Power level is calculated at the power calibration and is not shown in the test

protocol.

4/00021-3/00021/16 C 30(102)

Page 31

Trouble Shooting Guide, Advanced

9 Transient Spectrum (Spectrum due to Switching)

9.1 What is transient spectrum

In the GSM-system is all communication between the base station and the phone done switched,

in shape of bursts. The burst is a squared output power pulse with step up- and down-ramping.

Every time the voltage of the squared pulse changes rapidly there will be formed a number of

over tones. The over tones have got different frequencies and amplitudes. The amount of over

tones and what amplitude they have got depends on how steep the up- and down-ramping is, the

higher up- and down-ramping, the higher amplitude and frequency of the over tone. The over

tones form a spectrum that is called transient spectrum or ”Spectrum due to switching”.

To be able to get lower amplitudes for the over tones in the transient spectrum, the up- and

down-ramping does not change momentarily from zero-to-max/max-to-zero. Instead this is done

with two help steps, these two help steps are called Low and High Intermediate Power level.

The figure below shows what the control signal POWLEV from N800 (DAC 2) looks like. The

times in the figure are approximate measured at an approved phone at full Power level.

Fig. 9.1

The control voltage POWLEV then passes through an exponential amplifier and a Bessel low

pass filter in N550 where the transient disturbance is reduced. This gives a control voltage

without the straight, vertical edges and the sharp corners that produces the over tones. The

amplified and filtrated control voltage is called VREG and looks like the figure below.

4/00021-3/00021/16 C 31(102)

Page 32

Trouble Shooting Guide, Advanced

70 300 25 543 35 t (µs)

Fig. 9.2

The actual up- and down-ramping are much shorter then other parts of the control voltage.

Therefore it is only the up- and down-ramping in the figure that is timely proportional to each

other. The proportion for the amplitude is correct at Power level 5 (for GSM900) and Power

level 0 (for GSM1800).

The Zero Power level is a voltage level from the DAC that assures no output power at all. The

Offset level is the highest possible voltage before the power amplifier starts to transmit. The

Offset voltage compensates for the differences of voltage fault between different power

amplifiers and is produced in N550.

The tables below show the limits for maximum power levels at transient disturbances.

GSM 900

Parameter Min Normal Max Units

Fc +400 kHz - - -19 dBm

Fc -400 kHz - - -19 dBm

Table 9.1

GSM 1800

Parameter Min Normal Max Unit

Fc +400 kHz - - -22 dBm

Fc -400 kHz - - -22 dBm

Table 9.2

”Measure Transient Spectra” is a part of the radio calibration in EFRA. It is performed after the

power calibration and measures the power levels at the middle channel frequency (± 400 kHz)

of the t ransmitter. The power level must not be higher then –19 dBm for GSM900 and –22 dBm

for GSM1800.

4/00021-3/00021/16 C 32(102)

Page 33

Trouble Shooting Guide, Advanced

9.2 How to measure the transient spectrum

GSM900:

Power up the board and start it in the test program.

Start the transmitter in switched mode at channel 64 and power level 5.

(Before performing a transient spectrum measurement you have to make sure that the spectrum

analyser has got the correct amplitude compensation. To do this you use a phone with a known

output power and start the transmitter in static mode at power level 5. Then you compensate the

spectrum analyser until the correct output power is achieved. Convenient settings for this are:

CF – 902.8 MHz, SPAN – 0 MHz, RBW – 300 kHz, VBW – 100 kHz and SWEEP – 0.8ms.)

One method to measure the transient spectrum is to use the following settings at the spectrum

analyser: CF – 903.2 MHz, SPAN – 0 MHZ, RBW – 30 kHz, VBW – 100 kHz and SWEEP – 6

ms. You measure the highest level of the signal. The easiest way t o do it is to use ”single

sweep” to freeze the picture and ”peak search” to find the highest level. The spectrum should

look like the figure below.

Fig. 9.3

For the example in the picture we have measured the transient spectrum at channel 64 + 400

kHz. Do the same measurement at channel 64 - 400 kHz, by changing CF at the spectrum

analyser to 902,4 MHz. The power level must be inside the limits, i.e. lower then -19 dBm, for

both frequencies.

It is very difficult to make an exact transient spectrum measurement on a trouble-shooting site

since there are a lot of disturbances in the air. It can be a difference of a few dBm compared to

the measurement in EFRA.

4/00021-3/00021/16 C 33(102)

Page 34

GSM1800:

Same as for GSM900, but do not forget to change to GSM1800 and Power level 0 in the test

program, also change CF at the spectrum analyser. The Power level must be inside the limits,

i.e. lower than –22 dBm, for both frequencies.

9.3 How to find the fault

The fault is usually due to too low amplification in the power amplifier. When the amplification

in the power amplifier is lower then normal, but still high enough for the phone to pass the

power level calibration, the power amplifier is working at its maximum limit. This can result in

over tones in the shape of distortion.

The fault can also be due to a fault in the up- and down-ramping or one of the synths producing

over tones.

Trouble Shooting Guide, Advanced

You must start the phone in the test program and activate t he transmitter in static mode at full

Power level.

Check the control voltage VREG at N550:16 or N400:4 (type 2 PA 3.5 V, same frequency),

N400:7(Type 1 PA) using the oscilloscope. It should look like in the Fig. 9.4. Note t hat the

sweep time are different in the upper picture compared to lower pictures (the upper picture 0.2

ms/square and the lower pictures 10µs/square). We have been using a 10 times-probe, which

means that the amplitude are 10 times higher in the reality compared to what the picture is

showing (500 mV/square in stead of 50 mV).

4/00021-3/00021/16 C 34(102)

Page 35

Trouble Shooting Guide, Advanced

Fig. 9.4

If the up- and down-rampinglooks like the pictures above, the fault almost always is due to

distortion caused by the power amplifier. Replace N400 and do a new radio calibration. The few

times the fault are not due to N400 it is usually N390.

If the up- and down-rampingdoes not look like the pictures, the fault can be due to the

exponential amplifier, the low pass filter or the offset voltage. All three of the parts are

functions in N550.

If the offset voltage is too low, the fault is probably due to N550.

If the offset voltage is too high, the fault is probably due to C564. When C564 is faulty, it can be

difficult to calibrate the lowest power levels.

If the up- and down-ramping is steeper and/or there is a large curve in the middle of the

ramping, it is the low pass filter or the exponential amplifier that is faulty. The fault is due to

C561, C562 or N550.

If the up- and down-rampingis considerably shorter than in the pictures, the fault is due to

either C560 or N550. When C560 is faulty, it can be difficult to calibrate the lowest power

levels.

4/00021-3/00021/16 C 35(102)

Page 36

Trouble Shooting Guide, Advanced

10 Modulation Spectrum Switched Mode

(Spectrum due to Modulation)

10.1 Introduction

10.1.1 Description

In the GSM system the mobile phone (MS) transmitter ( Tx) output RF- signal is time-shared,

according to the principle of TDMA. This implies the transmitter to be STARTED exactly at a

controlled point of time to reach a specific RF-powerlevel within a very short and clearly

defined period of time < 28 µS. This RF-power levelshift, called upramp, must be as smooth

and linear as possible during t he transition low to high, in order to limit the spectral propagation.

The controlfunction for this levelshift is accordingly preprogrammed in three steps, each of

which is smoothed i n a digital function of a besselfilter.

When the transmitter is up at the decided RF-powerlevel, it is ready to send the message in a

digital burstformat. The message must be fully completed during a clearly defined period on the

timeaxis. Two different time interval exist. It is during this interval, the real significant message

is going to be sent. Some of the messages are system information only and some are digital

speech frames. But mostly both types in the same data packet. The method chosen for the

transmission via the transmitter carrier is decided to be GMSK digital modulation. Also during

this time interval, the spectral propagation must be limited within a specified bandwidth for the

system. Because of that limitation, there will be a compromise between readability / penetration

and the available frequency band. More about this in section 10.1.3.

After hopefully a completed message time-lapse, the transmitter shall be ST OPPED exactly at a

controlled point of time, to return to RF-off level again, within a very short and clearly defined

period of time <28µS. The transmitter RF-powerlevel downshift is called downramp and also

this must be as smooth and linear as possible during the transition from high to low, in order to

limit the spectral propagation. Same control functionality, as in the previous upramp, over three

steps and a besselfilter, is also utilized for the downramp.

The transmitter RF-powerlevel as a function of time can be seen in Fig 10.1.

4/00021-3/00021/16 C 36(102)

Page 37

(**)

+4

+1

-1

-6

-30

(***)

Trouble Shooting Guide, Advanced

dB

(*)

8µs 10µs 10µs 8µs

10 µs

(147 bits)

7056/13 (542.8) µs

10 µs

Fig. 10.1

Time mask for normal duration burst 147 bits 542.8 µS. There is also a shorter accessburst 87

bits 321.2 µS. (not present). Both have the same time period-length for the RF-levelshift.

According to the principle of TDMA and the burst nature of the signal, the output RF spectrum

results from two effects:

the RF-power levelshift at upramp and downramp. Designated: Spectrum due to Switching

transients.

the digital modulation process. Designated: Spectrum due to the Modulation and wide band

noise.

10.1.2 Consequences in spectrum and testing

In digital TDMA-systems as GSM 900 -1800 -1900 the transmitted RF-signal is repeated over

time, in a syncronuous timepattern. The active time intervals in the system, for the transmitter

and the receiver respectively, are called Timeslot (TS). In the system, the timeslots are allocated

on RF-carriers, in two frequency duplex at an Absolute Radio Frequency Channel Number

(ARFCN). This combination of time and frequency TS / ARFCN, is called a physical channel.

The system also has the ability to change the ARFCN each time the physical channel is opened,

in a programmable so called frequency hopping pattern controlled by the switch.

t

The MS consequently has the ability to syncronuous follow the physical channel,bothinthe

time-domain and in the frequency-domain. Accordingly the MS timing functions are facing

specific demands, on precisely switching the transmitter and receiver up and downand for the

stability and rapid changing of RF-channel in the frequencygenerator. Due to this rapid RFlevelshift, in both the time- and fre quency-domain, unwanted spectrum components are

generated and occupying some space in the total spectrumdistribution, in excess to the

modulation from the wanted signal.

4/00021-3/00021/16 C 37(102)

Page 38

Trouble Shooting Guide, Advanced

Thetwoeffectsof,theRF-powerlevelshiftupramp / downramp and the digital modulation

respectively, are specified separately in GSM 11.10 and 11.20. The measurement method used

to analyse separately those two effects is based on the "ringing effect" during the transients and

is a measurement in the time domain, at each point in frequency.

In order to get a reliable testresult, the two effects must be separated in two different

measurements, which is possible thanks to the fact, they are separated in the time domain. This

will also put demands on the i nstruments, to have the feature of synchronising to the physical

channel TS / ARFCN, both in normalmode and hoppingmode. And in addition to that also

timegating, to make it possible to activate the measurement, between a START point and a

STOP point, i n the RF-signals time domain. So called Gated Measurements.

The effect of the RF-power levelshift, designated Spectrum due to switching transients, will then

be possible to separate from the total spectrum by setting the timegate closed and deactivate the

instrument for the time interval where switching is present. Gate closed, will exclude

measurement results from the instrument video screen.

By adaptation of START and STOP points in the time domain for Gated Measurements in

spectrum, it will be possible to analyse also this effect of switching. But, that is a measurement

not included in the scope of this description.

10.1.3 The actual RF-spectrum

When the MS has a call in progress, the transceiver is switching between receive / transmit, to

follow the physical channel according to the principle of T DMA. In the frequency domain

around the carrier ARFCN, the transmitter produces a RF-spectrum with an amplitude and

bandwidth depending on the Tx RF-power and the two effects of switching and modulation, as

we have learned from the previous description. The spectrum is spread over a wide frequency

band, but is technically limited by the equipment design and must conform within the GSM

spectrum mask.

To verify that the MS really conform to the spec GSM 11.10 it is tested over the frequency

band, at integer multiples of the channelseparation 200 kHz, on both sides of the carrier ARFCN

specified in a Method of test 13.4 and a Procedure. This test is rather complicated and time

consuming and is mandatory for design and production to fulfill the requirements for type

approval. But for testing at normal maintenance and repair, it is permitted to reduce the testand

simplify for economical reasons, at a reasonable l evel.

With a Spectrum Analyser set to zero span, resolution bandwidth 30 kHz, peak hold and video

bandwidth 100 kHz, it is possible to catch a narrow sample of the spectrum, as a time waveform

due to a transmitted burst. By repeating that sample over the time- and frequency - domains for

a long raw of consecutive bursts it will be possible to measure the average of the spectrum

components selected, in a timegated measurement. The example of such a time waveform as

seen in a 30 kHz RBW offset from the carrier, is given in Fig 10.2.

4/00021-3/00021/16 C 38(102)

Page 39

Trouble Shooting Guide, Advanced

Fig. 10.2

Note that in this time waveform spectrum components from both the switching and the

modulation are visible. Looking at the timeaxis we know that the transmitter is started before

the useful burst at the upramp. The instrument is time gated and the START point is set to the

beginning of the burst (0%).

At that part of the waveform the spectrum is still affected by the upramp and a peak of

switching transients is visible. The beginning of the time waveform is therefor not good for

measuring the modulation spectrum.

In the middle of the burst there is a training sequence usually called midamble, with an equal

bitpattern in every normal burst. This part is not interesting for modulation measurements either.

The part of the waveform that follows after the midamble, called the "Averaging period" in the

picture, is the part decided to be measured as the Spectrum due to the Modulation and wide

band noise by definition in the GSM spec. This period is finished at 90%, before the end of the

burst. This is to avoid interference from switching transients at the downramp.Attheendofthe

time waveform again spectrum components from the switching is present, because the timegated

measurement has got a STOP point at the end of the downramp period.

By setting the START- and STOP points to the appropriate timing around the specified period,

the modulation spectrum generated by at least 40 of the bits 87 to 132 is measured. The

spectrum analyser averages over the gated period and over 50 bursts when the MS is

commanded to its maximum power or 200 bursts at the minimum power level.

This measurement is referred to the GSM specification 05.05 s 4.2 Output RF spectrum.

4/00021-3/00021/16 C 39(102)

Page 40

Trouble Shooting Guide, Advanced

10.1.4 Spectrum due to the modulation and wide band noise

The telephone is connected to a test equipment: Fixture, Computer with a testprogram,

Communication T ester or a Spectrum Analyser and a Powersource. T he Tx is started at high

power level PL 5 in switched mode on an ARFCN in the Mid ARFCN range. At the same time

the Rx is switched OFF.

A specific designed base band signal for testing is generated by the testprogram and injected to

the Tx- modulator. The signal, only used for testing has a digital pattern combined from a

Pseudo Random Bit Sequence (PRBS) and Training Sequence (TSC nr 0). These are combined

in a burst with the two datafields filled with PRBS and TSC 0 as the midamble. The signal

pattern is designed to give a modulation spectrum, good for testing, that optimally uses the

channel bandwidth.

A gated measurement is performed with the Spectrum Analyser set to capture the whole useful

part of the burst, i.e. from 0% to 100% in Fig 10.2. No matter of the interference from switching

transients. Assumed to be negligible.

Each carrier is measured at the time. Beginning with the ARFCN here called Fc. An average of

the modulation power content in the spectrum on Fc is taken from 3 repeated bursts. The result

will be used as a reference level.

Two more measurements will be done at the adjacent RF-channels + 400kHz and - 400kHz

apart from the Fc. But still the Fc as the active modulated carrier. Equally an average of the

modulation power content in the spectrum on the adjacent RF-channel is taken from 3 repeated

bursts on each of the two RF-channels at the time. The two results from Fc+400kHz and Fc–

400kHz are compared to the result from Fc as a reference RF–power level in dBm.

When compared to the reference, each of the two adjacent RF-channels gets a lower value,

calculated as a difference in dBc down from the Fc. The smallest difference is the valid

measurement result. (Easiest to achieve, but closest to the limit).

This is the measurement result of Spectrum due to the Modulation and wide band noise and will

be examined according to the requirements specification in the doc 1524 TEST DATA written

and approved by the Ericsson Testengineering and based on the GSM specification.

The requirement is that the absolute RF levels in dBm and the levels in dBc relative to Fc, from

all three results must not exceed the limit of a modulation spectrum mask decided in the GSM

spec. Any crossing of this limit is considered as a failure.

4/00021-3/00021/16 C 40(102)

Page 41

10.2 How to find the fault

The ”Modulation Spectrum Switched Mode” is sometimes called ”Spectrum due to modulation”

or ”Switched Modspectra” and is a measurement in the radio calibration in EFRA. The

measurement is done at middle channel with the highest calibrated power level in switched

mode, Power level 5 for GSM900 and Power level 0 for GSM1800.

An average value over a number of bursts at carrier wave frequency (902.4 MHz for GSM900

and 1747.6 MHz for GSM1800) is calculated at first.

Then a new average value over some other bursts is calculated, but at a frequency +400 kHz

from the carrier wave frequency.

One more average value is calculated, now at a frequency –400 kHz from the carrier wave

frequency.

The level (+400 kHz or –400 kHz) with the most faulty value is reported as the measured value

related to the carrier wave amplitude.

Trouble Shooting Guide, Advanced

The measurement ”Modulation Spectrum Switched Mode” is very difficult to perform at a

trouble shooting bench. Since you only measure at a part of the burst, between the up- and

down-ramping, it demands among other things a special trig. You calculate the average value by

measuring at a number of bursts at the chosen part. You can measure at correct number of

bursts, trig in the correct way (measure at correct part of the burst), calculate the average value

and finally relate the value to the output power using a computer (and the appropriate software).

But since you do not have access to computer controlled instrument when trouble shooting, you

have to use indirect measuring methods, for example checking the static spectra.

A ”Modulation Spectrum Switched Mode”- fault usually occurs together with a ”Transient

Spectra”-fault. Such a fault is usually due to a fault in the up- and down-ramping. If this is the

case, start trouble shooting according to chapter 9 (”Transient spectrum”).

The fault is usually due to too low amplification in the power amplifier. When the amplification

is lower then normal, but still high enough for the phone to pass the Power Level Calibration,

the power amplifier is working at its maximum limit. This can result in over tones in the shape

of distortion. The fault can also be due to noise at one of the feed voltages of the radio or an

appearance of unwanted frequencies (e.g. noise) in the output signal.

Open the phone and check for liquid damage.

Start the phone in the test program.

Start the transmitter of the phone in static mode, without modulation, at channel 62 for GSM900

or channel 699 for GSM1800.

NOTE! If the card is type 2, remember to use the negative bias voltage when changing to

static Tx mode.

Compare the spectrum with the one of a working phone. Make sure that the level of the noise is

not higher than for a working phone. Sometimes the level of the noise is low, but wide banded.

To be able to find the noise during such circumstances you have to check the spectrum at both 1

MHz and 10 MHz SPAN.

4/00021-3/00021/16 C 41(102)

Page 42

Trouble Shooting Guide, Advanced

The settings for the spectrum analyser are, for GSM900: CF- 902.4 MHz, RBW- 10 kHz, VBW10 kHz, Sweep- 30 ms and SPAN 1 MHz, respectively 10 MHz. For GSM1800: CF- 1747.6

MHz, RBW- 10 kHz, VBW- 10 kHz, Sweep- 30 ms and SPAN 1 MHz, respectively 10 MHz.

The spectra should look like the figures below.

1 MHz SPAN, no modulation

Fig. 10.3

10 MHz SPAN, no modulation

Fig. 10.4

4/00021-3/00021/16 C 42(102)

Page 43

10 MHz SPAN, no modulation

Wide banded noise

Trouble Shooting Guide, Advanced

Fig. 10.5

Turn the modulation on.

Compare the inter modulation products with the one of a working phone. They must not be too

high.

A normal spectrum with modulation should look like the figure below.

1 MHz SPAN, modulation set on

Correct spectrum

Fig. 10.6

If there is noise in the spectrum, the fault can be due to noise in one of the feed voltages,

VRAD, VVCO or maybe VDIG. Noise can be due to e.g. ageing filter capacitors (usually the

electrolytes) or deteriorated performance in the voltage regulators of the radio. If you have got a

really good oscilloscope, it is possible to measure the noise. Noise in the spectrum can also

come from the synths, either in the PLL-circuit N300, N202 or in one of the VCO’s.

4/00021-3/00021/16 C 43(102)

Page 44

Trouble Shooting Guide, Advanced

If the inter modulation products have not got the right level, proceed to chapter 3 (”Calibration

IQ”-fault).