INSTRUCTION SHEET

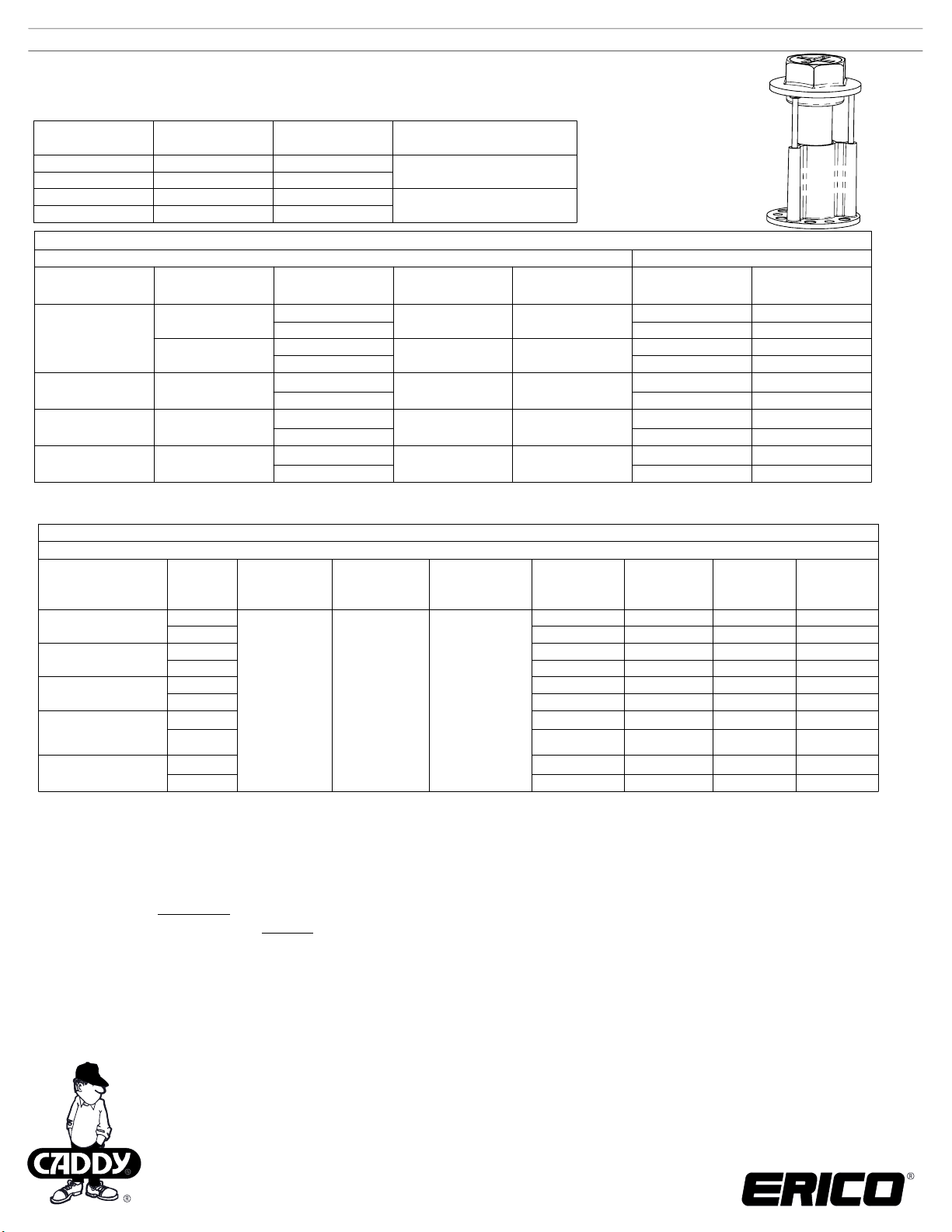

CADDY® ROD LOCK Plywood Pre-set Anchor

3/8 inch, 1/2 inch, M10 and M12

Part Number

CRLW37EG

CRLWM10EG

CRLW50EG

CRLWM12EG

Article Number

N/A

390019

N/A

390020

Rod Size

3/8"

M10

1/2"

M12

Max. FM® 1951 pipe size

4" or DN100

8" or DN200

Allowable Tension & Shear Loads for Threaded Rod*

Threaded rod itself

Steel Type

Standard Carbon

Steel Rod

High Strength

Carbon Steel Rod

Stainless Steel Rod

(SS304/ SS316)

Europe Steel Rod

ASTM®/ISO® Steel

designation

A307, Grade C

A36

A193, Grade B7

A193, Grade

B8/B8M, Class 1

ISO 898-1,

Class 4.6

Threaded rod size

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

M10

M12

Minimum Yield

strength

Minimum Tensile

strength

36.0 ksi

36.0 ksi

105.0 ksi 120.0 ksi

30.0 ksi 75.0 ksi

240 MPa 400 MPa

58.0 ksi

58.0 ksi

Allowable Tension

Load

Lbs [kN]

2,115 [9.5] 1,090 [4.9]

3,755 [16.9]

2,115 [9.5] 1,090 [4.9]

3,755 [16.9]

4,375 [19.7] 2,255 [10.1]

7,775 [35.0] 4,050 [18.2]

2,720 [12.1]

4,850 [21.6] 2,500 [11.1]

2,350 [10.5]

3,390 [15.1]

Allowable Shear

Load

Lbs [kN]

1,940 [8.7]

1,940 [8.7]

1,400 [6.2]

1,210 [5.4]

1,745 [7.8]

* Do not use a hot dip galvanized threaded rod.

* For in-door applications only.

Product Allowable Tension & Shear Loads with Normal-Weight Concrete (See Notes 1, 2, 3, 4 & 5)

Normal-Weight Concrete having 3,000 psi [20.7 Mpa] minimum compression strength

Threaded Rod Steel

Type

A307, Grade C

A36

A193, Grade B7

A193, Grade

B8/B8M, Class 1

(SS304/ SS316)

Europe ISO Class 4.6

Threaded

rod size

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

M10

M12

Minimum

Concrete slab

Thickness

Inch [mm]

3-1/4" [83mm]

Minimum Edge

Distance Inch

[mm]

Minimum

Spacing

Inch [mm]

6" [152mm] 8" [203mm]

Ultimate

Tension Load

Lbs [kN]

Ultimate

Shear Load

Lbs [kN]

4,220 [18.8] 3,270 [14.6]

4,820 [21.7] 5,820 [25.9]

4,220 [18.8] 3,270 [14.6]

4,820 [21.7] 5,820 [25.9]

4,220 [18.8] 5,330 [24.0]

4,820 [21.7] 7,400 [33.3]

4,220 [18.8] 4,210 [18.7]

4,820 [21.7] 7,400 [33.3]

4,220 [18.8] 3,630 [16.2]

4,820 [21.7] 5,235 [23.3]

Allowable

Tension Load

Lbs [kN]

Allowable

Shear Load

Lbs [kN]

1,407 [6.3] 1,090 [4.9]

1,605 [7.2]

1,940[8.7]

1,407 [6.3] 1,090 [4.9]

1,605 [7.2]

1,940[8.7]

1,407 [6.3] 1,775 [8.0]

1,605 [7.2]

2,465 [11.1]

1,407 [6.3] 1,405 [6.2]

1,605 [7.2]

2,465 [11.1]

1,407 [6.3] 1,210 [5.4]

1,605 [7.2] 1,745 [7.8]

Notes:

1. Allowable tension & shear load capacities are calculated using an applied safety factor of 3.0

2. Allowable working load must be the lesser of product allowable tension & shear loads showing above table.

3. NFPA® 13 design requirements are 5 times the weight of the water filled pipe plus 250 lbs.

4. MSS requires the safety factor of 3.5

5. Allowable loads for anchors to resist short term loads such as earthquake or wind may be increased by 33.33% for the duration of the

load where permitted by code.

WARNING:

ERICO products shall be installed and used only as indicated in ERICO product instruction sheets and training materials. Instruction sheets are available at

1.

www.erico.com

ERICO products must never be used for a purpose other than the purpose for which they were designed or in a manner that exceeds specified load ratings.

2.

All instructions must be

3.

Improper installation, misuse, misapplication or other failure to completely follow ERICO's instructions and warnings may cause product malfunction, property

4.

damage, serious bodily injury and death.

Products that are manufactured using spring steel components shall be used only in a non-corrosive indoor environment.

5.

All pipe supports, hangers, intermediate components and structural attachments must ONLY be used as described herein and are NEVER to be used for any

6.

other purpose.

NOTE: All load ratings are for static conditions and do not account for dynamic loading such as wind, water or seismic loads, unless otherwise noted.

The customer is responsible for:

a. Conformance to all governing codes.

b. The integrity of structures to which the products are attached, including their capability of safely accepting the loads imposed, as evaluated by a qualified

engineer.

c. Using appropriate industry standard hardware as noted above.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site must be observed.

Always use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

ASTM is a registered trademark of American Society for Testing and Materials

FM is a registered certification mark of FM Approvals LLC, LTD

ISO is a registered trademark of International Organization for Standardization

NFPA is a registered trademark of National Fire Protection Association, Inc.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

and from your ERICO customer service representative.

completely

followed to ensure proper and safe installation and performance.

TECHNICAL SUPPORT:

www.erico.com

CFS479_C

1 OF 2

© 2013, 2014 ERICO International

Corporation.

INSTRUCTION SHEET

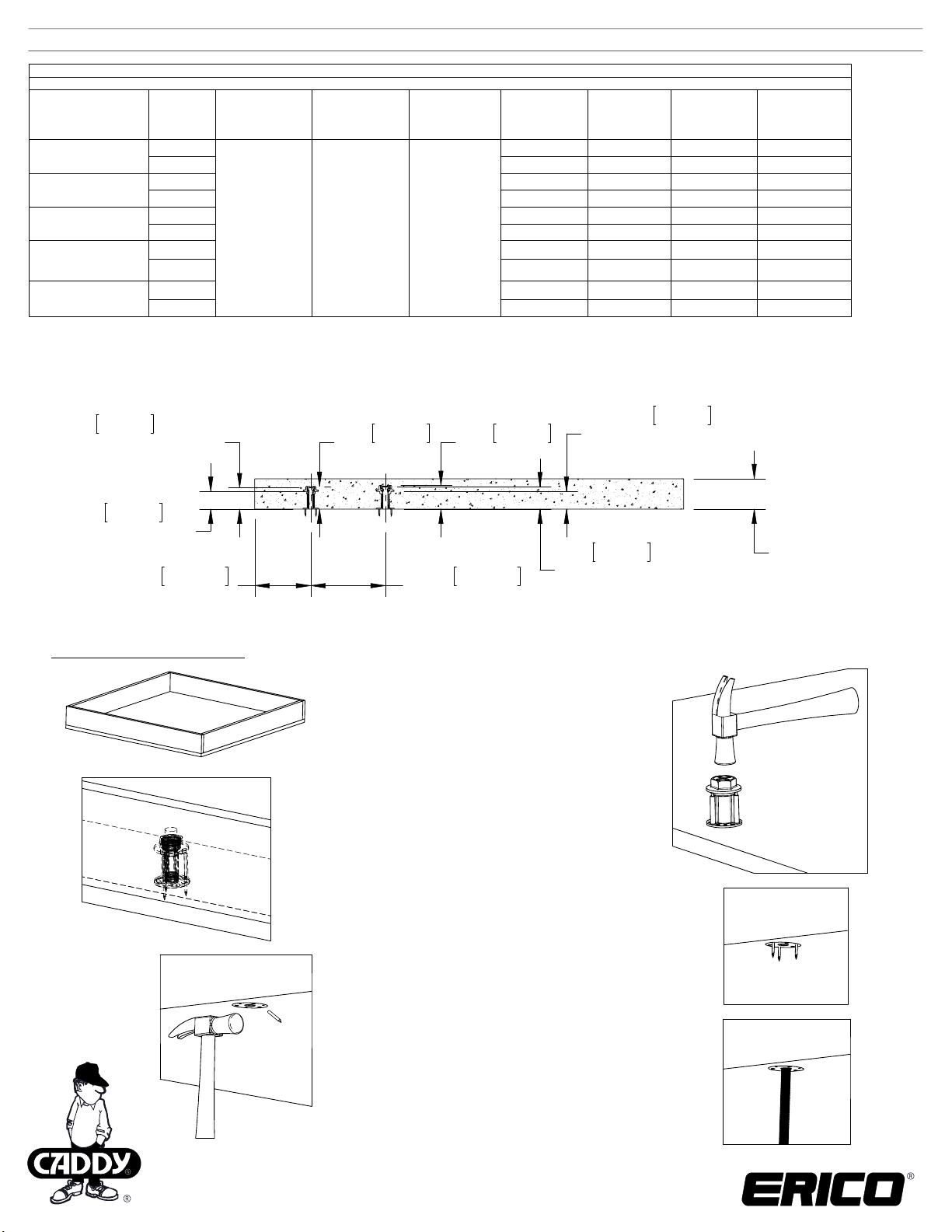

Product Allowable Tension & Shear Loads with Light-Weight Concrete (See Notes 1, 2, 3, 4 & 5)

Threaded Rod

Steel Type

A307, Grade C

A36

A193, Grade B7

B193, Grade

B8/B8M, Class 1

(SS304/ SS316)

Europe ISO

Class 4.6

Notes

:

1.

2.

3.

4.

5.

2.2in

55mm

Threaded

Allowable tension & shear load capacities are calculated using an applied safety factor of 3.0

Allowable working load must be the lesser of product allowable tension & shear loads showing above table.

NFPA® 13 design requirements are 5 times the weight of the water filled pipe plus 250 lbs.

MSS requires the safety factor of 3.5

Allowable loads for anchors to resist short term loads such as earthquake or wind may be increased by 33.33% for the duration

of the load where permitted by code.

required

threaded rod depth

for 3/8in & M10

Light-Weight Concrete having 3,000 psi [20.7 Mpa] minimum compression strength

rod size

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

3/8"

1/2"

M10

M12

Minimum

Concrete slab

Thickness

Inch [mm]

3 1/4" [ 83mm]

Minimum Edge

Distance

Inch [mm]

6" [152mm] 8" [203mm]

2.4in

61mm

Minimum

Spacing

Inch [mm]

3/8in & M10

Ultimate

Tension Load

Lbs [kN]

3,710 [16.5] 3,270 [14.6]

4,270 [19.2] 5,820 [25.9]

3,710 [16.5] 3,270 [14.6]

4,270 [19.2] 5,820 [25.9]

3,710 [16.5] 5,280 [23.8]

4,270 [19.2] 7,180 [32.3]

3,710 [16.5] 4,210 [18.7]

4,270 [19.2] 7,180 [32.3]

3,710 [16.5] 3,630 [16.2]

4,270 [19.2] 5,235 [23.3]

2.3in

63mm

1/2in & M12

Ultimate

Shear Load

depth for 1/2in & M12

Allowable

Lbs [kN]

1.9in

Tension Load

Lbs [kN]

1237 [5.5]

1,425 [6.4]

1,237 [5.5] 1,090 [4.9]

1,425 [6.4]

1,237 [5.5] 1,760 [7.9]

1,425 [6.4]

1,237 [5.5] 1,405 [6.2]

1,425 [6.4]

1,237 [5.5] 1,210 [5.4]

1,425 [6.4] 1,745 [7.8]

48mm

Concrete cone

Allowable

Shear Load

Lbs [kN]

1,090 [4.9]

1,940[8.7]

1,940[8.7]

2,395 [10.8]

2,395 [10.8]

1.9in

48mm

Concrete cone

depth for 3/8" & M10

6.0in

152mm

Edge to Center

Assembly Instructions

3-1/4in [83mm]Min.

Concrete Thickness

8.0in

203mm

Between Centers

2.3in

58mm

required

threaded rod depth

for 1/2in and M12

:

Step 1 - Construct the necessary wood form.

Step 2 - Assemble anchor to

wood form using a hammer.

Step 3 - Pour concrete into wood form.

Step 4 - After concrete is cured,

remove wood form.

Step 5 - Remove protruding nails

by shearing off with a hammer.

Step 6 -Push-in threaded rod.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

TECHNICAL SUPPORT:

www.erico.com

CFS479_C

2 OF 2

© 2013, 2014 ERICO International

Corporation.

Loading...

Loading...