Page 1

Refer to the mold tag for applicable instruction sheets. IPRSJ_C

CADWELD® Rail Joint Head Bonds

IPRSJ_C

WARNING: The area where the bond is to be

I. HOW TO READ THESE INSTRUCTIONS /

WHAT THE SYMBOLS MEAN

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and the explanations with them, deserve your careful

attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions

and warnings are not substitutes for proper accident

prevention measures.

SAFETY ALERT SYMBOL: Indicates warning or caution. It may

!

be used in conjunction with other symbols or pictographs.

WARNING: Failure to obey a safety warning may result in

!

property damage, serious personal injury or death, and the

serious personal injury or death of others. Always follow the

safety precautions to reduce these risks.

CAUTION: Failure to obey a safety caution may result in property

!

damage, personal injury, and injury to others. Always follow

the safety precautions to reduce the risk of fi re, other property

damage and personal injury.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

In the following instructions, cautions and warnings, there are

two types of consequences for failure to heed:

A. IMMEDIATE, that may result in personal injury or a failed

operation that may result in a less than optimum bond and that

will not give the physical and electrical performance expected.

!

applied must be sheltered suffi ciently if the weather is

inclement. This is to keep the rail surface, all equipment, and

materials dry until the weld is completed. Failure to do so may

result in an unsafe application with the risk of personal injury

and a less than optimum bond.

CAUTION: The work area must be well ventilated.

!

Workers should avoid breathing the smoke of the exothermic

reaction by positioning themselves upwind of the mold before

igniting the welding material. After ignition, it is advisable to

step back from the mold. Failure to observe this instruction

may result in lung irritation.

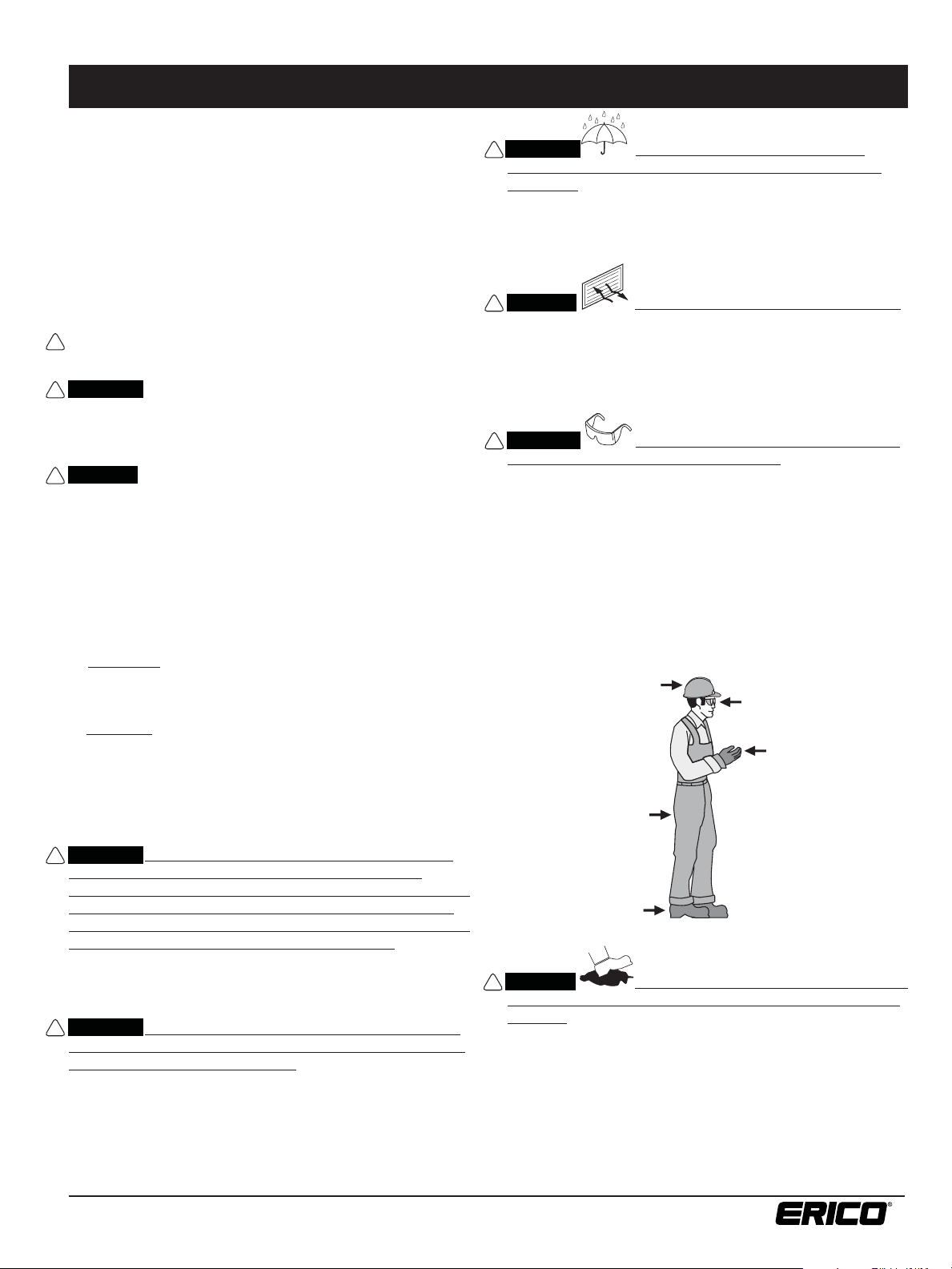

WARNING: The worker(s) performing the welding

!

must be properly dressed and equipped. Examples include

cotton or woolen garments (most synthetic fabrics melt rather

than char when exposed to fl ame, causing severe burns), safety

footwear with non-slip soles, head protection, leather gloves,

eye goggles and other clothing and equipment recommended

or required by the person’s employer, industry practice, or

applicable laws and regulations. The worker(s) must not be

under the infl uence of any alcohol, drugs or other chemicals

that would impair their judgment or performance of the job.

Failure to observe this may result in serious personal injury.

See Figure 1.

Safety Helmet

Safety Goggles

B. EVENTUAL, that may result in a later premature rail break,

causing a serious derailment accident with personal injuries

or death, and loss of property.

II. GENERAL RULES FOR SAFETY IN THE APPLICATION

OF EXOTHERMIC HEAD BONDS TO THE RAIL

WARNING: Do not attempt to make an exothermic bond

!

until you have thoroughly read and understand the

instructions that accompany all of the various components

of the system and have been properly trained in the use

of this product. Use only the system components designed

to be used together from a single manufacturer. Failure to

comply may result in unsatisfactory bonding as well as accidents

involving fi re, personal injury, and rail damage that may lead to

property damage, injury or death.

WARNING: Only the correct grinding equipment, welding

!

equipment, welding material, and bonds designed for the

specifi c application must be used. All items used must be

designed and supplied by the same manufacturer. All items must

be in good condition and not worn, altered or damaged. Failure

to do so may result in an unsafe application with the risk of

personal injury and/or a less than optimum bond.

Cuffed Leather

FIGURE

1

Jacket or Shirt

and Trousers

Safety Shoes

CAUTION: The worker(s) must be certain that they

!

can achieve good footing in the area where the weld will

be done. They should be able to step away from the weld

reaction, to be upwind of it. Failure to observe this may result

in personal injury.

Gloves

www.erico.com

1

Page 2

Refer to the mold tag for applicable instruction sheets. IPRSJ_C

CADWELD® Rail Joint Head Bonds

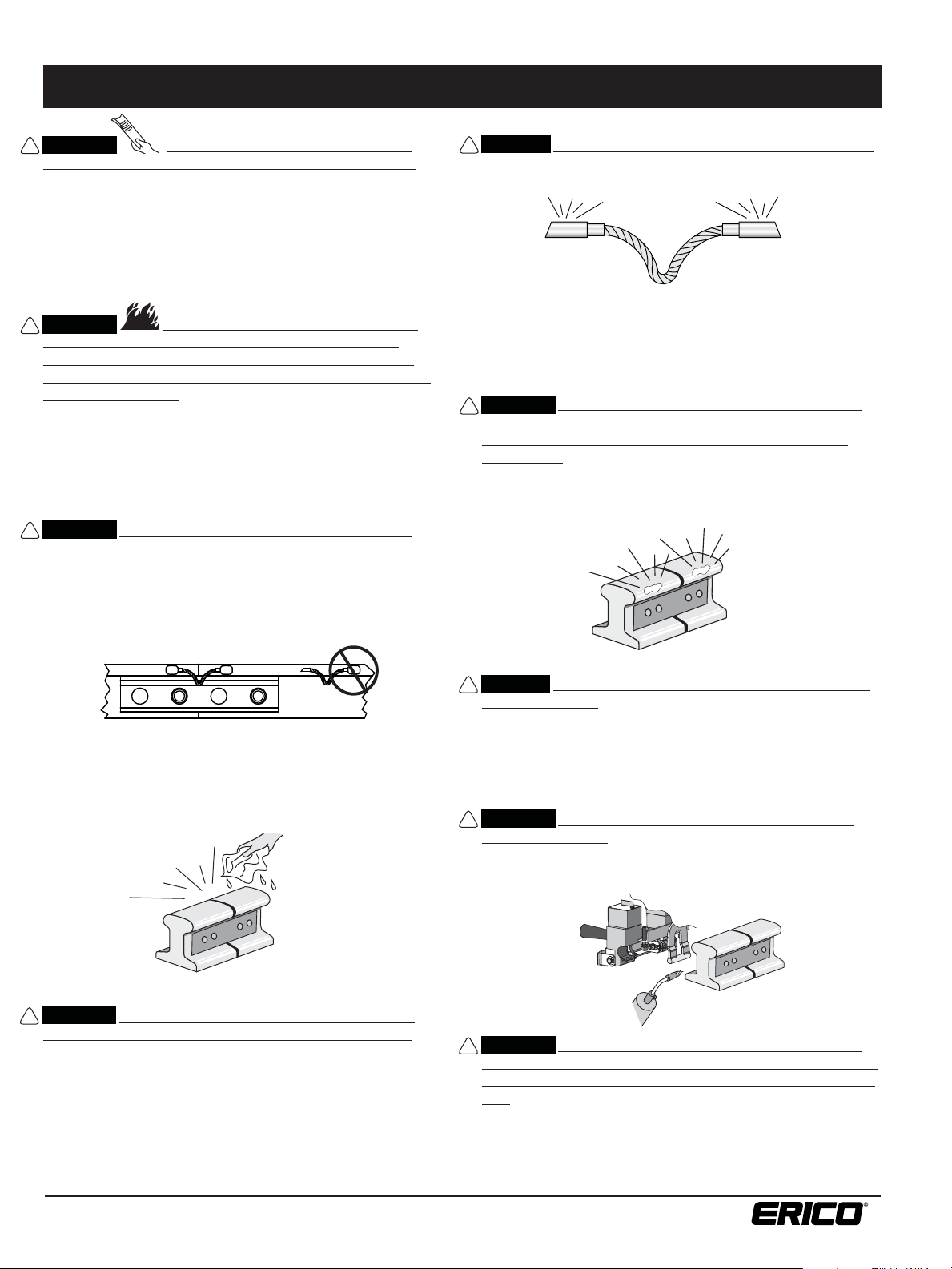

WARNING: Carefully following the instructions

!

for exothermic bonding is very important to achieving

a quality reliable bond. Failure to do so may cause hidden

potential problems, the least of which is a poor electrical

connection, and the most serious of which is an eventual

broken rail leading to property damage, injury or death to

the installer and others.

III. PREPARATION

WARNING: Protect against potential fi re hazards

!

local to the bonding area and remove all fl ammable

materials from the work area. Notify in advance other

workers in the immediate area that a welding procedure

is about to be done. Failure to do this increases the risk of

fi re with the possibility of property damage, personal injury

and death.

NOTE: In case of a fi re involving large quantities of exothermic

welding material, CO

a distance are required to reduce the spread of the fi re.

WARNING: The location of the bond is very important!

!

The intent of a rail head bond is to electrically join two rail

sections. Rail head bonds must be done only within the confi nes

of the joint/splice bar as near to the bar center as practical.

Failure to observe this may result in a rail break leading to

property damage, injury or death to others. See Figure 2.

2

or large quantities of water applied from

CAUTION: The bond terminals must have a bright surface.

!

Failure to comply with this may result in a less than optimal weld.

See Figure 4.

FIGURE

4

3.

Lightly grind the rail surface using an ERICO® approved grinding

wheel that is self-cleaning or a CADWELD

Cleaner. Grinding wheels with resin binders may leave a surface

fi lm that may contaminate the surface, interfering with the

achievement of an optimum bond and causing weld porosity.

WARNING: The area of the rail head to be bonded must

!

be lightly ground to a bright fi nish with no visible scratch

marks or gouges (normal uniform fi nishing marks are

acceptable). Failure to observe this may result in visible

scratches or gouges due to overly aggressive grinding that are

potential crack initiators and that may lead to rail breaks causing

derailment accidents with property damage, injury and death to

others. See Figure 5.

FIGURE

5

®

T-34 Rail Head

FIGURE

2

1. Clean the rail surface and bond terminals. Scrape off excess

dirt and grease, and wipe away any remaining residue using

a clean rag saturated with a railroad approved solvent.

See Figure 3. The rail must be dry prior to welding!

FIGURE

3

WARNING: The area of the rail where the bond will be

!

applied and the bond terminals must be clean and dry.

Failure to comply can cause poor bonding, excessive weld

porosity, and/or spewing molten welding material with the

potential for serious burns to the worker.

2. Use abrasive cloth or wire brush on the bond terminals if

needed to remove surface oxidation.

CAUTION: Grinding must not be done more than 4 hours

!

prior to bonding. If the time lapse is longer, suffi cient

contaminating rust may re-form requiring additional grinding.

Failure to observe this may result in a less than optimum bond.

4. Dry the mold and rail by heating them to about 250°F (120°C)

with a small propane torch.

WARNING: The rail and mold must both be warmed to

!

drive off moisture. Failure to observe this may result in weld

spatter with the potential for serious burn injury, and a less than

optimum bond with excessive porosity. See Figure 6.

FIGURE

6

WARNING: Rebonding over the application of an earlier

!

bond is only permissible in areas of minimal stress such as

the head of the rail within the confi nes of the joint/splice

bar! Remove the original bond by grinding down to a smooth

layer of parent rail steel.The new bond can then be made in the

same location as the previous bond.Failure to observe this may

result in a rail break leading to property damage, injury or death

to others.

www.erico.com

2

Page 3

Refer to the mold tag for applicable instruction sheets. IPRSJ_C

CADWELD® Rail Joint Head Bonds

IV. WELDING PROCEDURE

1. Place bond in welder with fl at surface against rail head and

end of terminal against bond clip. This correctly positions

bond in weld cavity. Be sure the bond clip is in good condition

and properly positions terminal under center of tap hole as

shown. See Figure 7.

Tap Hole

Bond

FIGURE

7

Bond Clip

Terminal

2. Position the welder with attached molds on the rail head.

The bottom edge of the mold should be aligned with the

lower edge of the rail head. Use the mold height adjusting

screws to properly align the mold. See Figure 8.

3. Close clamp to lock welder on rail. Clamp is adjustable for

rail sizes. Check that mold face fi ts against rail and bond

terminal is held against rail by clevis. See Figure 8.

Clamp Adjustment Screw

in excess of 4000°F, therefore great care must be exercised

to avoid spillage of the molten metal. Failure to observe this

warning may result in molten metal leakage onto the rail

with immediate risk of personal injury, and potentially serious

structural damage to the rail that could result in a rail break

leading to property damage, injury or death to others.

FIGURE

9

4. Insert one steel disk, dished (concave) side up, in the crucible

to cover the taphole. See Figure 10.

Mold Height Adjusting Screw

Graphite Cover

Starting Material

FIGURE

8

WARNING: Correctly positioning the mold against the rail

!

with the welder device is critical for safety and success in

making a bond. There must be no cracks between the lower

part of the mold that contains the weld cavity and the rail

surface; if a crack is present, the mold should be discarded and

a new one used. See Figure 9. (Molds can generally be used for

up to 50 welds.) The exothermic reaction reaches a temperature

Welding Material

Disk

Bond Clip

Splice Bar

FIGURE

10

CAUTION: The steel disc must be correctly installed into

!

the mold crucible. Failure to properly position it may result

in premature leakage into the mold area, resulting in an

unacceptable weld. See Figure 11.

FIGURE

11

5. Dump the contents of the welding material container into

the crucible, being careful not to upset the disk.

Starting Material

Welding Material

Disk

www.erico.com

3

Page 4

Refer to the mold tag for applicable instruction sheets. IPRSJ_C

CADWELD® Rail Joint Head Bonds

CAUTION: Install only the specifi ed welding material in

!

the mold crucible. Use only the welding material size that is

specifi ed on the mold. ERICO

is formulated specifi cally for use with rail steel; it is packaged in

a blue tube with a yellow cap. Dump all of the welding material

into the crucible, then carefully tap the tube on a hard surface

to loosen the starting material from the bottom of the tube and

distribute half on top of the welding material, close the mold

cover, and pour the remainder in the opening of the mold cover.

See Figures 10 and 12. Failure to comply may result in diffi culty

getting the reaction started and/or an unacceptable weld.

FIGURE

12

®

brand of welding material (F80)

Starting Material

Crucible Cover

Changing Molds (See Figure 13.)

A. Remove mold back frame Screw “A”.

B. Pull out worn mold.

C. Insert new mold, replace Screw “A”. Check bolt “B” to be

sure it is not too tight. Mold must be free to move within

frame against pressure spring.

Pull Out Worn Mold

FIGURE

13

Bolt “B”

Screw “A”

CAUTION: Avoid direct eye contact with the “fl ash” of

!

light from the ignition of the starting material.

6. Position yourself upwind of the molds, place the tip of the

fl int ignitor at the cover opening and ignite. Remove the

igniter quickly to prevent fouling. If igniting two molds in

sequence, ignite the downwind mold fi rst.

CAUTION: Allow 15 seconds for mold cooling after the

!

reaction. This will permit the molten metal to solidify.

7. Carefully open the mold cover and break up the slag in the

crucible using the blade of the mold cleaning tool.

8. Unlock clamp and remove welder by pulling the mold straight

back from the rail. Failure to observe this may result in mold

damage and its premature scrapping. Molds can generally be

re-used up to 50 times.

9. Dump the slag from the crucible and remove the slag from

the taphole using the curved end of the mold cleaner. Dump

slag in the ballast, not onto the ties.

10.

Check the molds for breakage or residual slag before

proceeding with the next weld.

Note: If you have any questions or require further instructions,

or would like training, contact ERICO at 1-800-447-7245.

Copyright ©2008, 2010, 2012, 2013 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

www.erico.com

4

IPRSJ_C R1121IS10WWEN PUR1013

Loading...

Loading...