Page 1

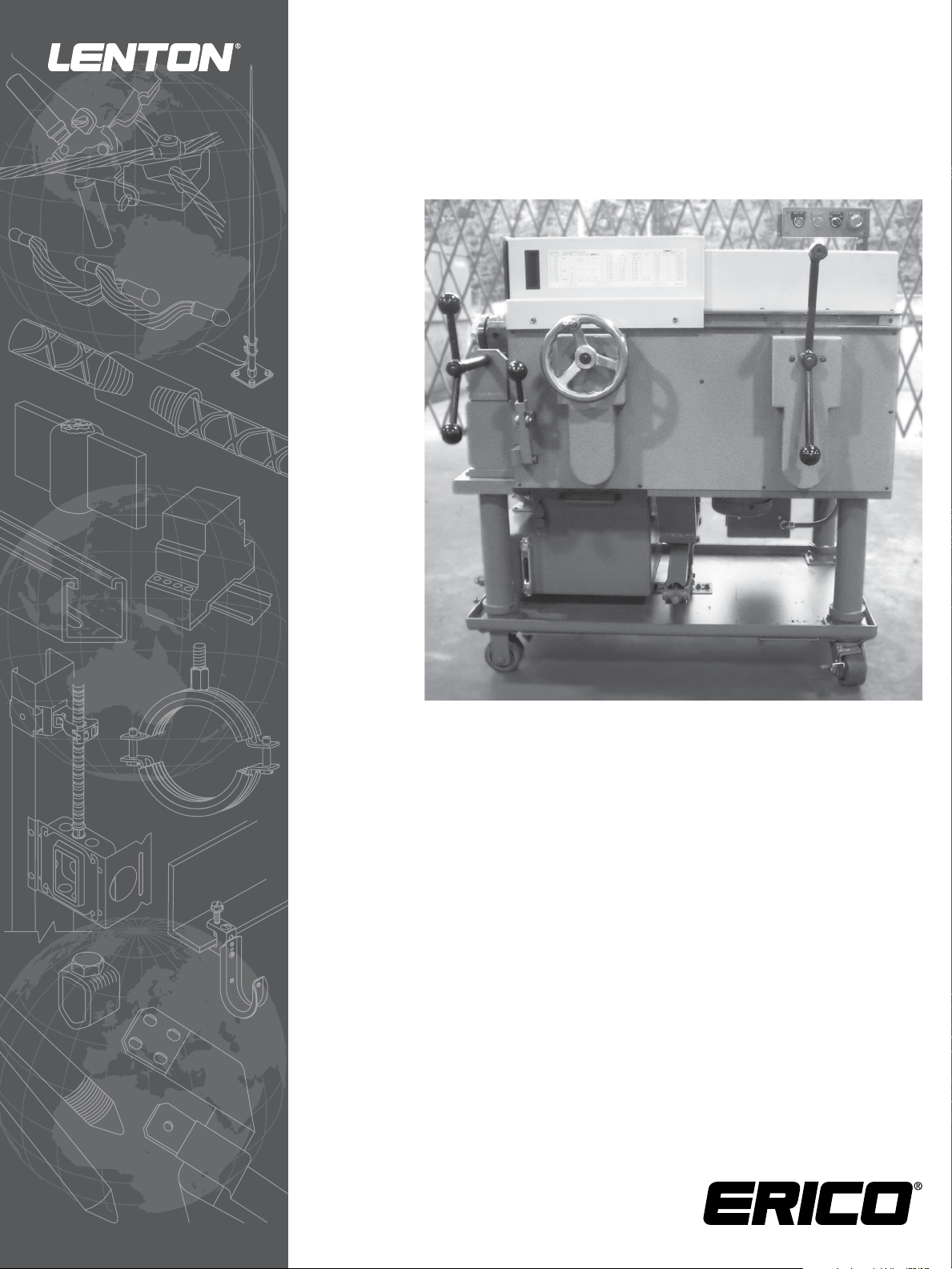

Mid-Range Bar Threader

Instruction Manual

Page 2

Table of Contents

Uncrating the Machine ....................................................... 3 – 4

Electrical ..................................................................................... 5

Center Rings ........................................................................ 6 – 7

Add Oil ....................................................................................... 8

Change Control Key .......................................................... 9 – 10

Change Chasers and Holders .......................................... 11 – 15

Change Control Block .................................................... 16 – 18

Threading Operation ...................................................... 19 – 20

Checking Threads and Bar End Engagement ...................... 21

Maintenance ........................................................................... 22

Troubleshooting ..................................................................... 23

Operator Reference Chart ..................................................... 23

WARNING

1. ERICO products shall be installed and used only as indicated in ERICO

product instruction sheets and training materials. Instruction sheets

are available at www.erico.com and from your ERICO customer

service representative.

2. ERICO products must never be used for a purpose other than the

purpose for which they were designed or in a manner that exceeds

specified load ratings.

3. All instructions must be completely followed to ensure proper and

safe installation and performance.

4. Improper installation, misuse, misapplication or other failure to

completely follow ERICO’s instructions and warnings may cause

product malfunction, property damage, serious bodily injury and death.

The customer is responsible for:

a. Conformance to all governing codes.

b. The integrity of structures to which the products are attached,

including their capability of safely accepting the loads imposed,

as evaluated by a qualified engineer.

c. Using appropriate industry standard hardware as noted above.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site

must be observed. Always use appropriate safety equipment such as

eye protection, hard hat, and gloves as appropriate to the application.

2

www.erico.com

Page 3

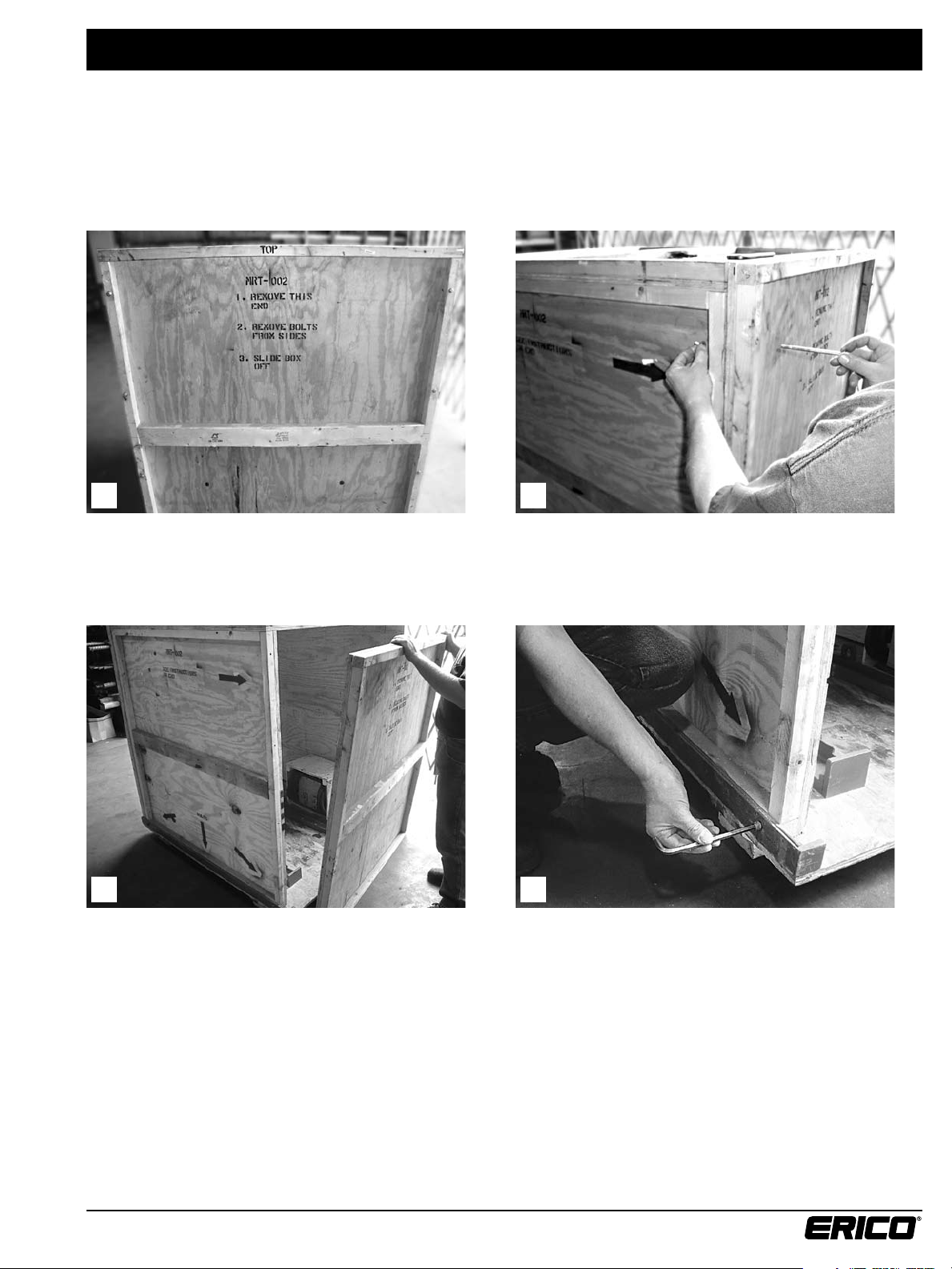

Uncrating the Machine

When uncrating the machine please follow these steps.

If you have any questions please call ERICO Inc. at 1 (800) 822-7975.

21

Locate the front door panel. Loosen the eight bolts and wing-nuts securing the door.

43

Remove the front door. Remove the three bolts from the bottom of each side.

www.erico.com

3

Page 4

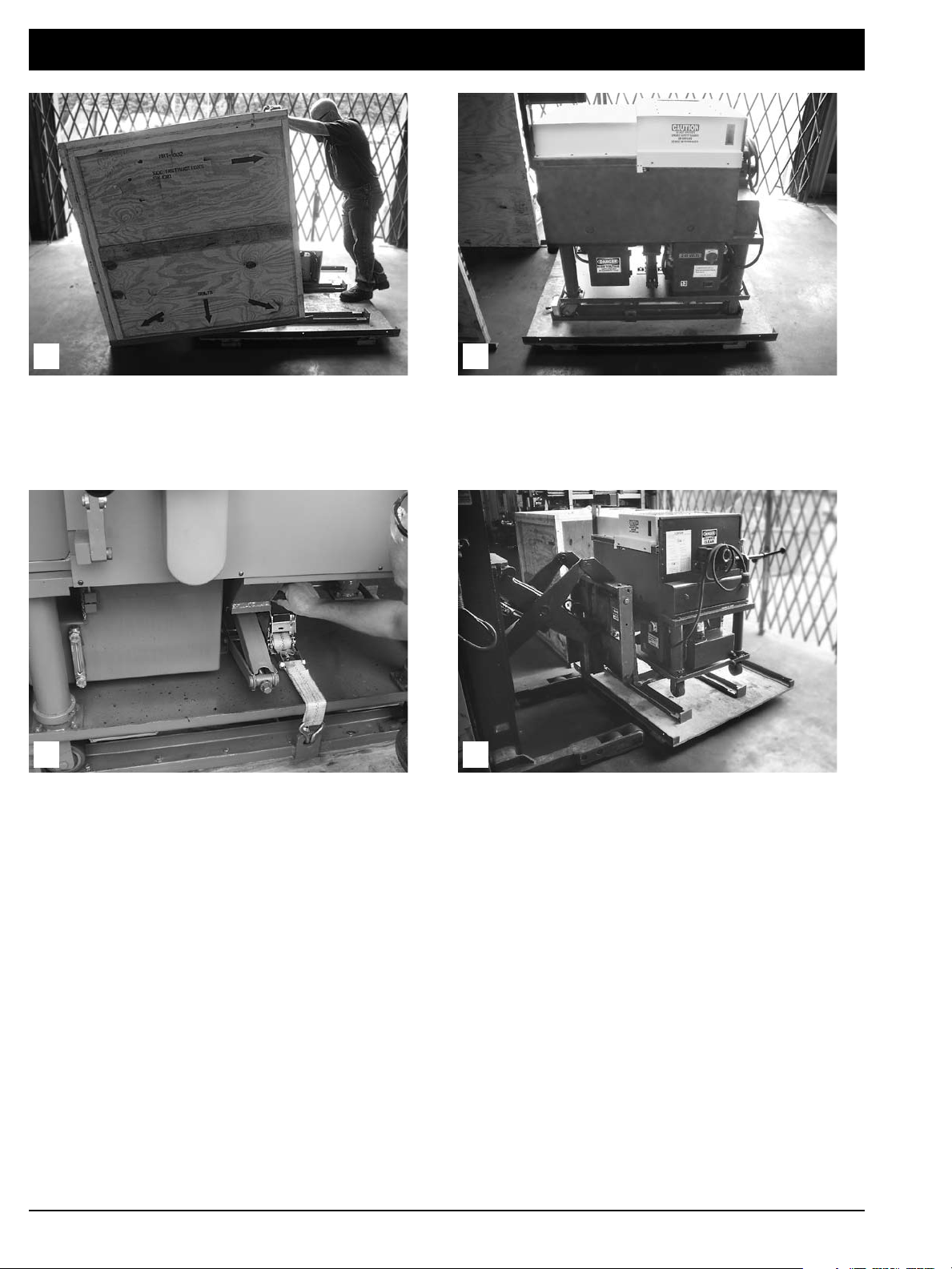

Uncrating the Machine

5

Slide the top off the base Machine on crate base

6

7 8

Remove the tie-down to lift machine from base The machine can now be lifted off the base

4

www.erico.com

Page 5

Electrical

21

The Mid-Range Bar Threader requires 220-240 volt,

3 phase power. A four-pronged locking plug as shown

is standard.

Power Panel

Inverter Box

Main Power

Disconnect Switch

View of Inverter Box and Power Panel. The Red Knob

located on the Power Panel is the main power

disconnect switch.

After connecting the power be sure the head of the bar

threader is rotating in the direction indicated by the red

arrow on the hood. If it is not rotating in the correct

direction, switch any two of the power leads in the plug.

Inverter

43

View of inside the Inverter Box. The Inverter controls the

high and low speed on the DC Motor.

5

View of inside the Power Panel.

www.erico.com

5

Page 6

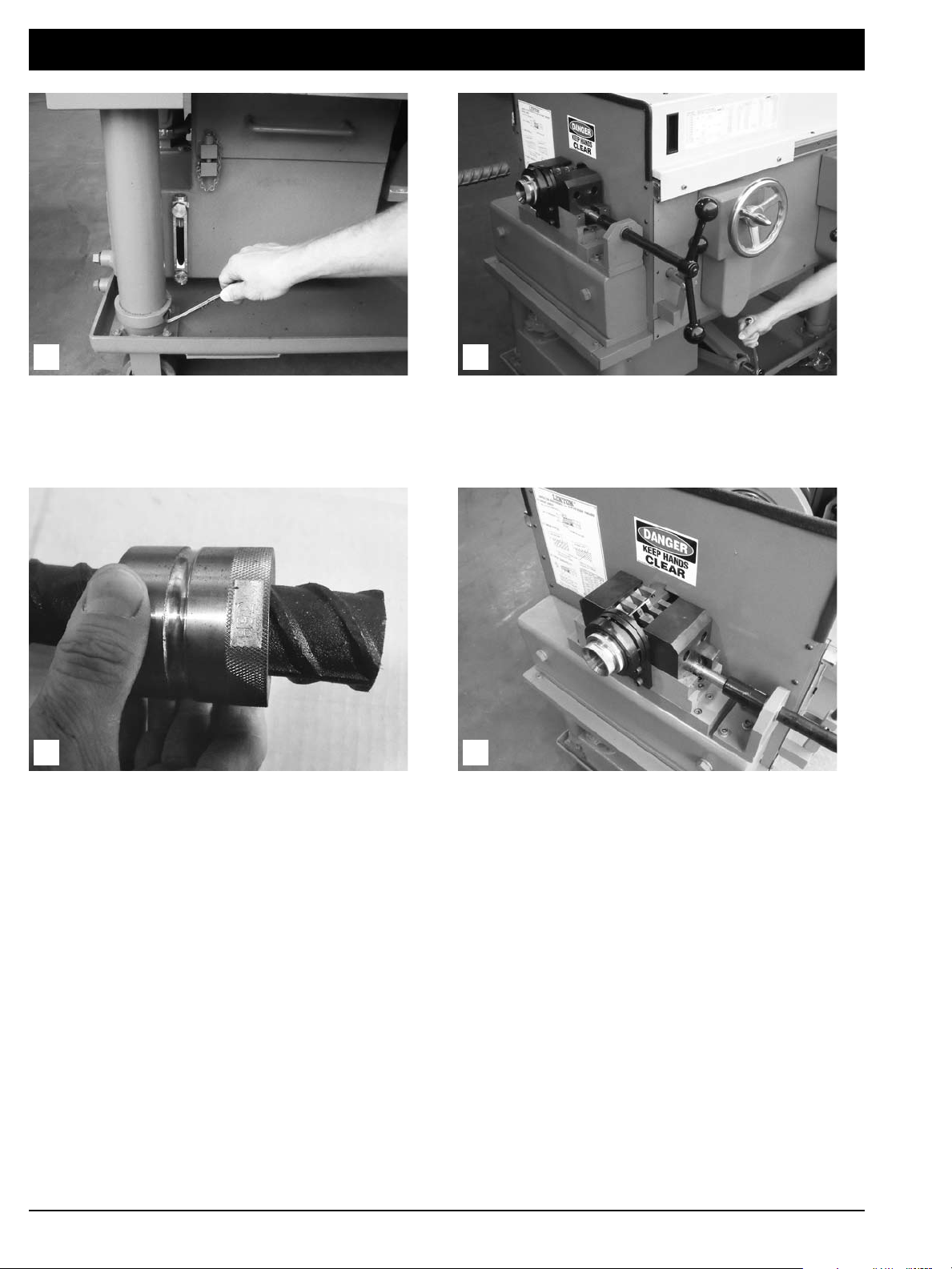

Center Rings

21

Before adjusting the table height, you must first loosen

each collar located at the bottom of each table leg.

To obtain the best centering of the rebar into the

threading machine, the best fitting set of center rings

should be used. We offer two or three different size sets

per bar. To make sure you are using the correct set, slide

one of the center rings per set over the bar ends to be

threaded to determine which one slides on easily with

the least amount of slop. Each center ring is stamped

with the bar size it is to be used with in millimeters.

Adjust the table height with a ½” square drive ratchet

using a ¾” standard drive socket.

43

The bar threader will come to you set up to run the largest

bar size you will be threading.

6

www.erico.com

Page 7

Center Rings

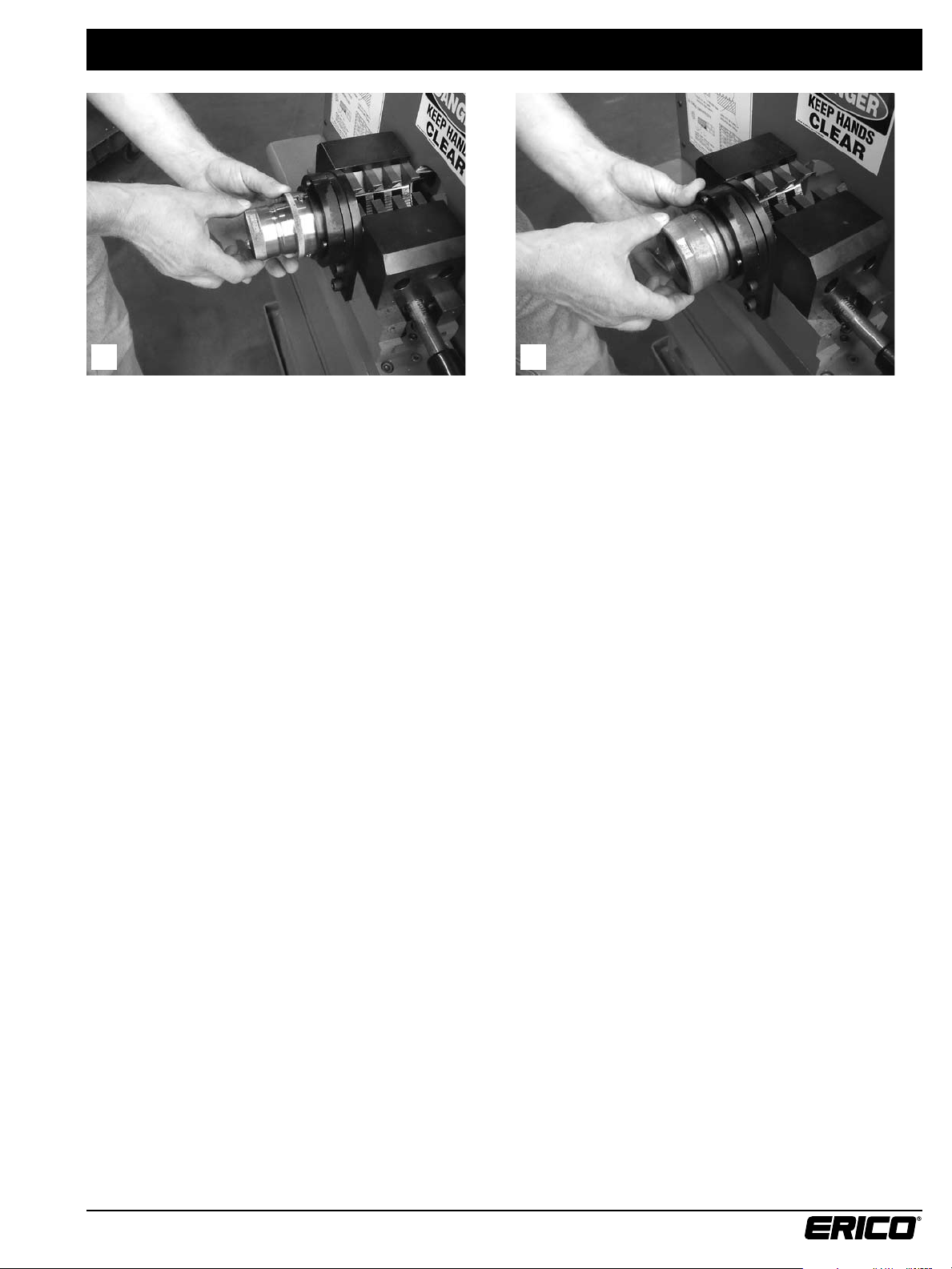

65

To change centers to a different bar size or to go with a

set that fits the bar better, push in the release ring and

pull out the existing center. Put in the new center and

lock it in place by letting loose of the release ring.

When threading a #14 or #18 bar, the adaptor ring must

be removed. This is done in the same way you remove the

center ring as in the previous step.

www.erico.com

7

Page 8

Add Oil

21

Prior to threading, the oil must be added. Pour the oil

onto the chip funnel and it will flow into the oil reservoir.

Only part # ELOIL should be used.

The reservoir is properly filled when the oil level is at the

top of the sight glass.

8

www.erico.com

Page 9

Change Control Key

1A 1B

Remove the cover plate bolts. Three bolts hold it in place.

32

Remove the holders from the head of the bar threader. To change the key, remove the screw, compression spring,

and the support rod from the head.

54

To remove the control block loosen the support rod

bushing and pull out the support rod and spring.

This will free the control block to fall down.

Loosen the front bearing and remove the rear bearing.

www.erico.com

9

Page 10

Change Control Key

76

Slide the key out. Each key is stamped on the front with

the metric bar size.

8 9

Before tightening the threaded bushing down make sure

that carriage is all the way back to the right.

Slide in the new key and replace and tighten both the

front and rear bearings.

While holding the feed handle back move your control ring

handle forward into step drum position number three.

10 11

When installing the new control block in the cutting square

replace the support rod, spring, and screw. The support rod

goes through the hole in the control block and engages in

a hole on the other side of the cutting square.

You should always tighten your threaded bushing down

until the spring is fully compressed then back off half of

a turn.

10

www.erico.com

Page 11

Change Chasers and Holders

1A 1B

Remove the face plate bolts. Three bolts hold it in place.

32

Remove the holders from the head of the bar threader. Loosen the set screw as shown above.

4A 4B

Slide the chaser out of the holder. Chasers and holders have matching numbers.

The number 1 chaser goes into the number 1 holder, etc.

www.erico.com

11

Page 12

Change Chasers and Holders

65

Before installing the chaser make sure the woodruff key

is tight. Press on both ends of the woodruff key with an

allen wrench, it should not move.

7

Take the hold down pin (ELMP203PIN) and place it through

the hole of the chaser as shown above.

To replace a woodruff key, set the key into the slot by

hand and drive into position using a hammer and punch.

8A

Insert the chaser pin into the top hole of the holder and

push down making sure that the woodruff slot aligns with

the woodruff key until the chaser sits completely flush on

the holder shelf.

8B

This is what a chaser looks like when it is installed correctly

onto the holder.

9

After the chaser is installed correctly on the holder, hold

the chaser in place while tightening down the set screw

against the hold down pin.

12

www.erico.com

Page 13

Change Chasers and Holders

10A 10B

Before replacing the holders make sure the cavity in the head and the holders are clear and free of chips.

Wipe all flat surfaces with a clean rag.

11A 11B

The number 1 holder with the slot in it to accept the

control block must be replaced first, followed by

holders 4, 2 and 3.

Step 1 – insert holder #1 as shown.

11C 11D

Step 2 – Slide holder #4 into position Step 3 – Slide holder #2 into position

www.erico.com

13

Page 14

Change Chasers and Holders

11E 12

Step 4 – Slide #3 holder into position.

13

After the holders have been installed in the cutting

square, check that the numbers on the face of the

holders match the corresponding numbers on the

face of the cutting square.

After sliding all of the holders into position, use your

thumbnail to make sure that the holders are recessed

inside the cutting square.

14

After installing the chaser holders, check to see that they

do not protrude outside of the cutting head. This would

prevent free holder movement during threading. If any

do protrude outside, remove them and reclean the head

and holder(s). Also look over the holder for any burrs that

might need taking down with a stone.

15A 15B

After the holders are installed into the head correctly, wipe off the face plate and fasten it to the head.

14

www.erico.com

Page 15

Change Chasers and Holders

16 17

Stone the flat surfaces in the cutting square. Stone the flat surfaces on the chaser holder.

18 19

Stone the cover plate.

After the holders are installed into the head correctly,

wipe off the face plate and align to the head.

20 21

Fasten face plate to the head.

Turn on the machine and move the body of the machine

back and forth to make sure the holders are opening and

closing properly. A “gushing” sound can be heard if they

are working properly.

www.erico.com

15

Page 16

Change Control Block

1A 1B

To change the control block, remove the face plate. Three bolts hold it in place.

Remove the chaser holders from the cutting square as

shown above.

Position the new control block as shown. Replace the

support rod, spring, and screw. The support rod goes

through the hole in the control block.

32

To remove the control block loosen the support rod screw

and pull out the support rod and spring. This will free the

control block to fall down.

54

Before replacing the holders make sure the cavity in the

head and the holders are clear and free of chips.

16

www.erico.com

Page 17

Change Control Block

76

Wipe the holders clean of any chips and contaminants. The number 1 holder with the slot in it to accept the control

block must be replaced first. Followed by holders 4, 2 and 3.

8

After the holders have been installed in the cutting square,

check that the numbers on the face of the holders match

the corresponding numbers on the cutting square face.

10

9

After sliding all holders into position, use your thumbnail

to make sure that the holders are recessed inside the

cutting square.

After installing the chaser holders, check to see that

they do not protrude outside of the cutting head.

This would prevent free holder movement during

threading. If any do protrude outside, remove them

and reclean the head and holder(s). Also look over

the holder for any burrs that might need taking

down with a stone.

www.erico.com

17

Page 18

Change Control Block

11B11A

After the holders are installed into the head correctly, wipe off the face plate and fasten it to the head.

12

Turn on the machine and move the body of the machine

back and forth to make sure the holders are opening and

closing properly. A “gushing” sound can be heard if they

are working properly.

18

www.erico.com

Page 19

Threading Operation

21

Prior to positioning the rebar in the machine, be sure that

the machine carriage is all the way back to the right.

Bar Stop

Position the Bar Stop so that it covers the hole in the

face plate. Butt the rebar up against it. This assures the

correct bar placement into the bar threader.

Also be sure that the step drum is in the correct

starting notch.

43

Once the bar is in position tighten the vise.

Make sure the vise is good and tight to prevent

bar rotation during threading.

Bar Stop

65

Move the Bar Stop away from the bar. To turn on the machine, the safety hood must be in

the forward position. Select the proper cutting speed

(Bar sizes #4 through #11 – High, #14, #18 – Low)

then press the motors start button.

www.erico.com

19

Page 20

Threading Operation

87

Make sure oil is flowing into the head of the bar threader.

If it is, then with the right hand handle move the body of

the bar threader forward. Apply pressure on the handle once

the cutters are in contact with the bar, for at least one half

turn of the handle. After this initial engagement the body

of the machine will move forward automatically.

9

Holding the machine carriage all the way back, move the

step drum to the next forward notch. Refer to reference

chart for # of passes.

Once the body of the machine stops moving forward it is

time to again move the machine carriage and the control

ring handle all the way back to the right.

10

After the last threading pass, move the machine carriage

and the control ring handle all the way back to the right.

11

Position the control ring in the same notch you used for the

first pass. The bar threader is now ready for the next bar.

20

www.erico.com

Page 21

Checking Threads and Bar End Engagement

21

The thread profile should be checked with a

brand new chaser.

3

If the diameter of the bar is off, the adjustment screw is used to

make up the difference. The adjustment screw is located at the

back of the machine. Turning it in, increases the bar end diameter,

turning it out, decreases the diameter.

To check the bar end diameter after threading slide the

bar end gauge over the bar and look to see if the end of

the bar falls within the step range of the gauge.

If the diameter of the bar is off, the proper adjustment can very

easily be made by measuring the amount of protrusion from or

recession into the gauge.

Example: If the bar is protruding beyond the gage by 1/8 inch you

would turn the adjustment screw in (clockwise) so that the machine

body would move forward 1/8 inch. If the bar was 1/8 inch too

short you would turn the screw out (counter-clockwise) moving

the body of the machine back 1/8 inch.

A scrap piece of bar should be used to set the bar end

gauge prior to making a production run.

www.erico.com

21

Page 22

Maintenance

21

First step is to remove the pin located on the chip drawer. Machine chips are caught in the screened drawer above the

oil reservoir. The drawer should be emptied as required during

the machining run and at the end of the day.

3

At the end of each day 15 minutes should be put aside to

drain the oil and clean out the oil reservoir.

The oil is drained by loosening and removing the drain plug

at the side of the oil reservoir. An oil pan and crescent wrench

is provided to accomplish this.

Let the oil sit in the oil pan overnight to allow the fine chips

to settle to the bottom. Next morning slowly pour the oil

back into the bar threader and clean out the oil pan.

22

www.erico.com

Page 23

Troubleshooting

1. If the LENTON bar threader will not start,

check the following:

a. Check that the machine is plugged in and the

power is on.

b. Machine hood must be in the forward position.

c. The correct electrical power must be used.

See “Electrical” section.

2. If the cutting oil is not flowing to the

cutting head, check the following:

a. Oil level – see “Add Oil” section.

b. Please make sure your chip drawer and reservoir

is empty of chips.

c. If you are having electrical problems please call

LENTON Service Group.

3. If the motor is stalling during threading,

check the following:

a. Improper machining step – see “Threading

Operation” section.

b. Proper voltage – see “Electrical” section.

c. Proper cutting speed.

d. Bar loose in the vise.

e. Chaser wear.

f. Bent bar ends.

4. If the chasers are wearing prematurely,

check the following:

a. Improper oil flow.

b. Harder than normal rebar.

5. If the bar threader will not engage the rebar,

check the following:

a. Is the bar stop moved out of the way.

b. Proper rotation of the cutting head –

see “Electrical” section.

c. Improper first pass machining step –

see “Threading Operation” section.

6. If the bar ends have stripped threads,

check the following:

a. Are the chaser holders in the correct position –

see “Change Chasers and Holders” section.

b. Are the woodruff keys tight in the slot –

see “Change Chasers and Holders” section.

c. Chaser wear.

7. If the chaser holders will not shift in the

cutting head, check the following:

a. Chips, dirt or other contaminants in the

cutting head.

b. Bent control rod.

c. Damaged control key.

d. Damaged control block.

e. Chaser holder(s) protruding beyond face

of cutting square.

Operator Reference Chart

Bar Size Number

Bar Size Metric

Chaser Holder Set

Bar End Gauge

Control Key

Control Block

Guide Rings Standard

Guide Rings Large

Guide Rings Extra Large

No. of Threading Steps

Operating Speed

Spring Size

* Note: Bar end gauges with suffix “HT” may be substituted.

www.erico.com

4 5 6 7 8 9 10 11 14 18

12 mm 16 mm 20 mm 22 mm 25 mm 28 mm 32 mm 36 mm 43 mm 57 mm

101D 101D 111D 111D 111D 111D 111D 111D 121D 131D

ELBEG12A ELBEG16A ELBEG20A ELBEG22A ELBEG25A* ELBEG28A* ELBEG32A* ELBEG36A* ELBEG43A* ELBEG57A*

ELK12 ELK16 ELK20 ELK22 ELK25 ELK28 ELK32 ELK36 ELK43 ELK57

E2 E2 E2 E2 E2 E2 E2 E2 A2 A2

12D 16B 20A 22A 25A 28A 32A 36A 43A 57A

12E 16C 20B 25A 25B 28B 32B 36B 43B 57B

N/A N/A N/A N/A N/A N/A N/A N/A 43C 57C

1 1 2 2 2 2 2 3 4 4

High High High High High High High High Low Low

Blue Blue Blue Blue Blue Blue Blue Blue Red Red

23

Page 24

www.erico.com

AUSTRALIA

Phone 1-800-263-508

Fax 1-800-423-091

BELGIUM

Phone 0800-757-48

Fax 0800-757-60

BRAZIL

Phone +55-11-3623-4333

Fax +55-11-3621-4066

CANADA

Phone +1-800-677-9089

Fax +1-800-677-8131

CHINA

Phone +86-21-3430-4878

Fax +86-21-5831-8177

DENMARK

Phone 808-89-372

Fax 808-89-373

FRANCE

Phone 0-800-901-793

Fax 0-800-902-024

GERMANY

Phone 0-800-189-0272

Fax 0-800-189-0274

HUNGARY

Phone 06-800-16538

Fax +39-0244-386-107

INDONESIA

Phone +62-21-575-0941

Fax +62-21-575-0942

ITALY

Phone 800-870-938

Fax 800-873-935

MEXICO

Phone +52-55-5260-5991

Fax +52-55-5260-3310

NORWAY

Phone 800-100-73

Fax 800-100-66

POLAND

Phone +48-71-349-04-60

Fax +48-71-349-04-61

SINGAPORE

Phone +65-6-268-3433

Fax +65-6-268-1389

SPAIN

Phone 900-993-154

Fax 900-807-333

SWITZERLAND

Phone 0800-55-86-97

Fax 0800-55-96-15

THAILAND

Phone +66-2-267-5776

Fax +66-2-636-6988

UNITED ARAB

EMIRATES

Phone +971-4-881-7250

Fax +971-4-881-7270

UNITED KINGDOM

Phone 0808-2344-670

Fax 0808-2344-676

CHILE

Phone +56-2-370-2908

Fax +56-2-369-5657

Copyright ©2010, 2011 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

HONG KONG

Phone +852-2764-8808

Fax +852-2764-4486

NETHERLANDS

Phone 0800-0200-135

Fax 0800-0200-136

SWEDEN

Phone 020-790-908

Fax 020-798-964

UNITED STATES

Phone 1-800-753-9221

Fax +1-440-248-0723

IP8235_A C282IS11WWEN 0.1M0711

Loading...

Loading...