Page 1

INSTRUCTION SHEET

LENTON® LOCK

B-Series

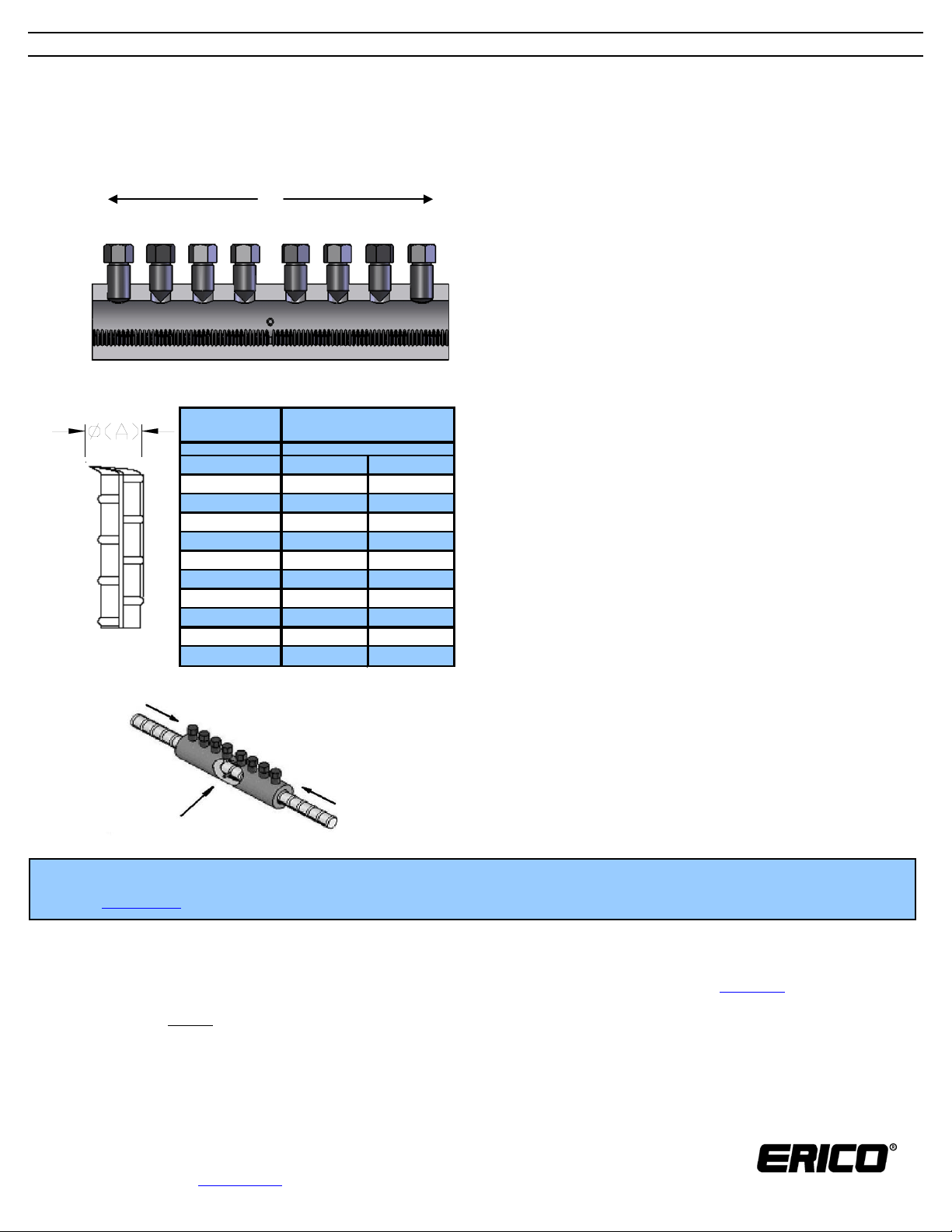

Figure 1

Rebar Size

Maximum Rebar Shear

Lip Diameter (A)

in mm

10 or 12 (#4)

0.57 14.5

14 or 16 (#5)

0.73 18.5

18 or 20 (#6)

0.93 23.5

22 (#7)

1.08 27.5

25 (#8)

1.16 29.4

28 or 30 (#9)

1.32 33.5

32 (#10)

1.48 37.5

34 or 36 (#11)

1.67 42.5

38 or 40

1.83 46.5

43 (#14)

2.07 52.5

57 (#18)

2.62 66.5

Figure 3 Solid contact between bar and stop pin as shown.

Step 3

is made with the center

must be flush against cent er stop pin.

Step 4 for coupler sizes 12(#4) – 36(#11):

For rebar sizes 40 through 57(#18), follow ‘

the next page.

For Caltrans Ultimate performance on sizes 32(#10) and 36(#11),

also follow ‘

To avoid bolts from vibrating loose, it is suggested that each bolt

be pre

prior to applying final bolt torque.

Tighten bol ts, beginning in the cent er of the couple r and working

to the outside (A to D). A standard wrench, impact wrench or nut

runner may be utilized to tighten the bolts.

Figure 1 Assembly cross section

Figure 2 Maximum shear lip

A B C D

D C B A

TIGHTEN

TIGHTEN

Step 1:

commencing splicing. Ensure the LENTO

sized properly for the bars being spliced and per project plans.

Product should arrive with bolts configured as s hown in Figure 1.

One round point bolt should be on each end for sizes 10 (#3)

through 40mm. Two round point bolts should

sizes 43 (#14) and 57 (#18).

Step 2:

slurry, rust, etc. which may affect product performance. Ensure

maximum rebar lip does not exceed limits set in Figure 2.

Excessive shear l

*When using an air impact wrench it is recommended to use a wrench with double the torque rating identified. Impact sockets should always be used when using an

Read all instructions and procedures before

N® LOCK coupler is

be on each end for

Ensure the rebar is free of any excessive dirt, concrete

ip interferes with rebar installation.

: Insert rebar into LENTON LOCK coupler until contact

stop pin as shown in Figure 3. Rebar

Alternate step 4’ on

Alternate step 4’ on the next page.

impact wrench. Additionally, check the air pressure and air flow requirements prior to installation. Refer to complete installation instructions provided with the product or

available at

www.erico.com prior to commencing installation.

-torqued (Approximately <50% is recommended torque)

WARNING

1. ERICO products shall be installed and used only as indicated in ERICO product instruction sheets and training materials. Instruction sheets are available at www.erico.com and from your ERICO customer

service representative.

2. ERICO products must never be used for a purpose other than the purpose for which they were designed or in a manner that exceeds specified load ratings.

3. All instructions must be completely followed to ensure proper and safe installation and performance.

4. Improper installation, misuse, misapplication or other failure to completely follow ERICO’s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death.

The customer is responsible for:

a. Conformance to all governing codes.

b. The integrity of structures to which the products are attached, including their capability of safely accepting the loads imposed, as evaluated by a qualified engineer.

c. Using appropriate industry standard hardware as noted above.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site must be observed. Always use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

www.erico.com ERICO International Corporation

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH and LENTON are registered trademarks of E RICO International Corporation

Page 2

INSTRUCTION SHEET

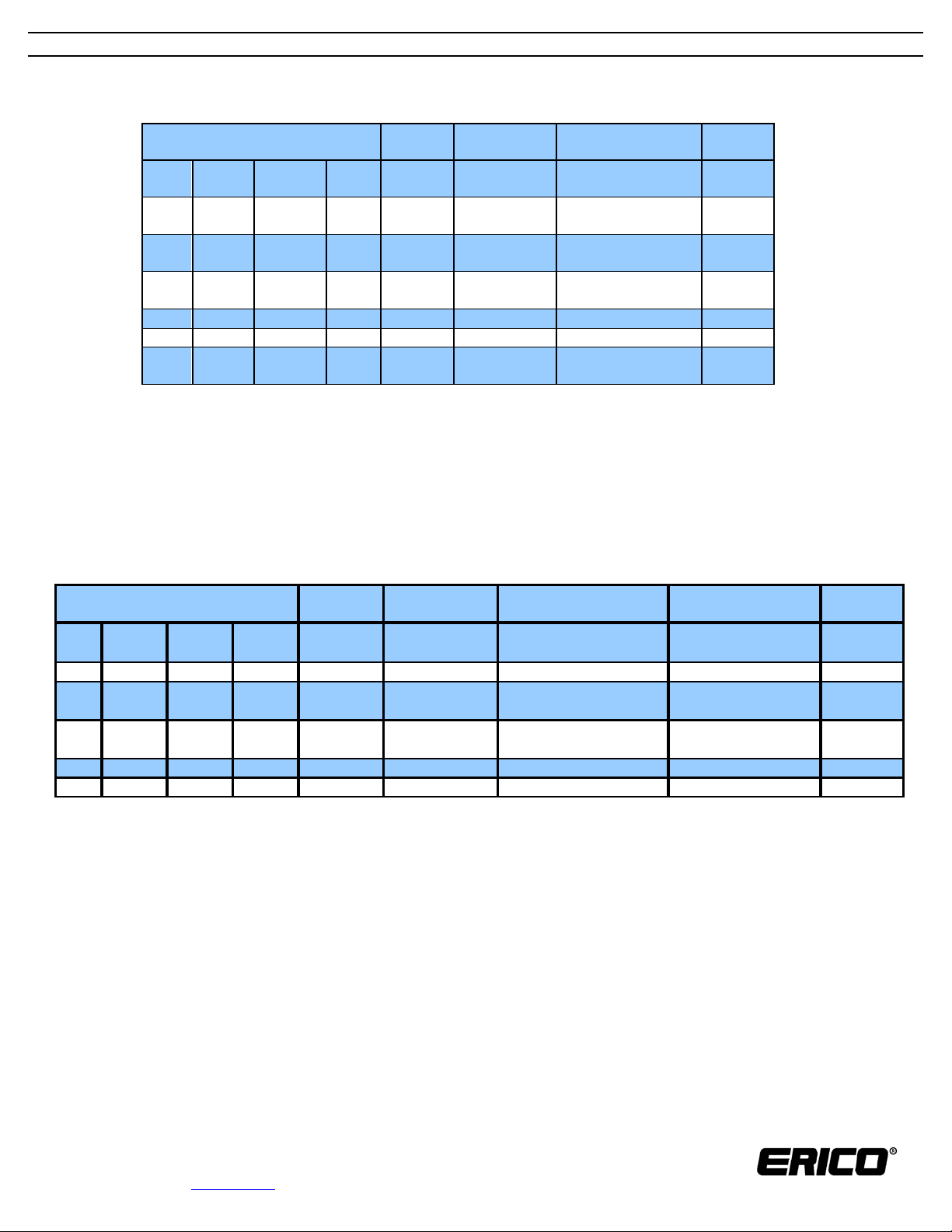

Rebar Designation Coupler Socket Size

Pre Torque

(all bolts if required)

Average Torque to

Shear Bolts

Number of

Bolts

In-lb Metric Canada

Soft

Metric

in mm ft-lb N-m ft-lb N-m

#10 32 - 32 LL32B1 13/16 21 400 545 500 680 8

- 34 - - LL36B1 13/16 21 400 545 550 750 10

#11 36 35 M 36 LL36B1 13/16 21 400 545 550 750 10

- 38 - - LL40B1 13/16 21 400 545 580 790 12

- 40 - - LL40B1 13/16 21 400 545 580 790 12

#14 43 45 M 43 LL43B1 1 25 675 915 960 1300 14

#18 57 55 M 57 LL57B1 1 25 675 915 960 1300 18

Alternate Step 4:

Alternate Step 4 is

Pre

and finish tightening the bol

bolt

tightening of the bo

If bolt head does not shear, the installer should verify the appropriate torque was met (see Table 2). If a minimum cover must

Repeat procedure for other end of the sleeve.

Shear Bolts

of Bolts

Metric

-

10 - 10

LL12B1

1/2

13

150

205

6

#4

12

10 M

13

LL12B1

1/2

13

150

205

6 - 14 - -

LL16B1

1/2

13

150

205

6

#5

16

15 M

16

LL16B1

1/2

13

150

205

6 - 18 - -

LL20B1

1/2

13

150

205

8

#6

20

20 M

19

LL20B1

1/2

13

150

205

8

#7

22

-

22

LL22B1

5/8

16

250

340

8

#8

25

25 M

25

LL25B1

5/8

16

350

475

8

#9

28

30 M

29

LL28B1

5/8

16

350

475

10

-

30

-

-

LL28B1

5/8

16

350

475

10

Table 1. Torque values for coupler sizes #4 (12mm) through #9 (30mm)

Pre-Torque is not required for these sizes

Rebar Designation Coupler Socket Size

In-lb Metric Canada

Soft

Average Torque to

in mm ft-lb N-m

Number

-torque the bolts beginning in the center of the coupler and working to the outside (A to D). See table 2. Then go back to bolt A

shears off when the proper torque is achieved. A standard wrench, impact wrench or nut runner may be utilized for the final

required for sizes 40 through 5 7(#18), and for Caltrans Ultimate requirements sizes 32(#10) and 36(#11).

ts, once again beginning in the center of the coupler a nd working to the outside (A to D). T he head of the

lts.

Table 2. Alternate Step 4: Two-step torque sequence for coupler sizes 32(#10) and larger

be maintained, the head can be cut off after the proper torque has been applied.

If during installation the bolt strips, as defined by a loss of resistance to the applied to rque, stop the installation immediately.

Remove the un-sheared damaged bolt. Contact ERICO for LENTON Technical Support

Transition Splices: LENTON LOCK is designed for use as a one -step transition/reducer splice on all types of rebar.

Contact ERICO for details.

Closure Pour Splices: Refer to instruction sheet PDF113 for details. Additional copies of instructions and application

information are available at www.erico.com

www.erico.com ERICO International Corporation

Loading...

Loading...